Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Avoid direct contact wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

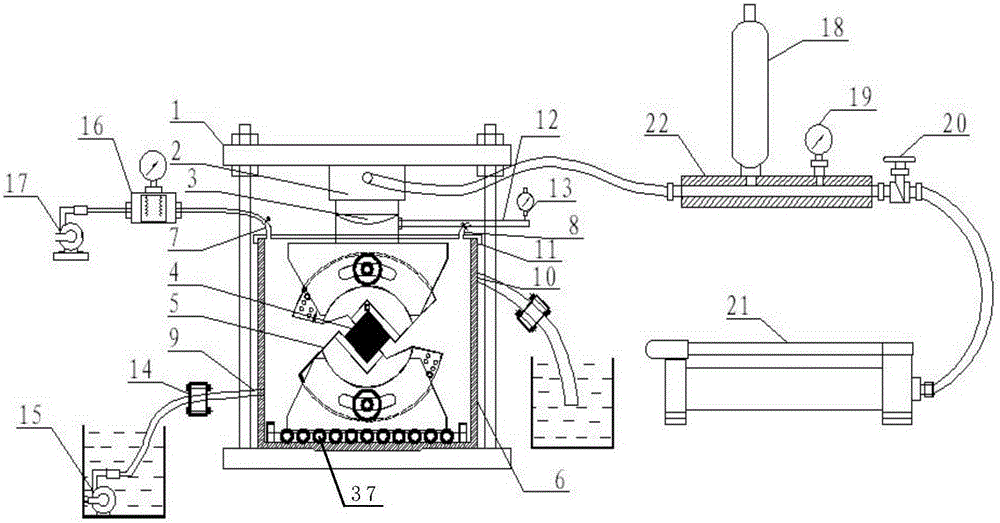

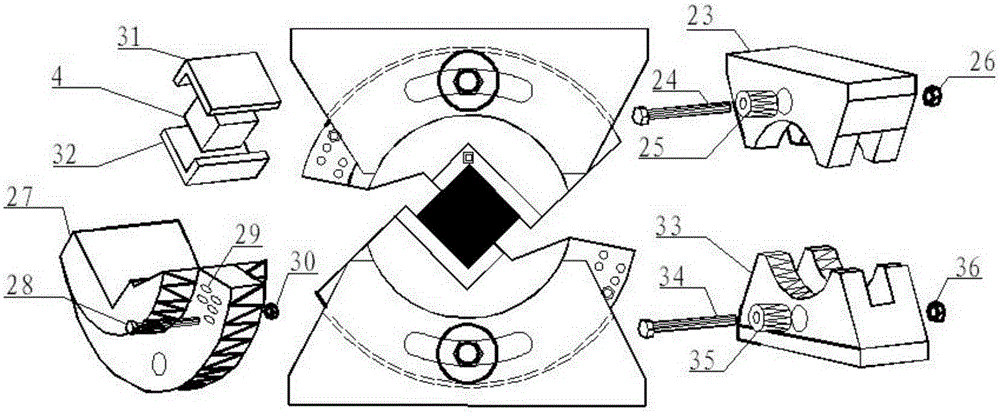

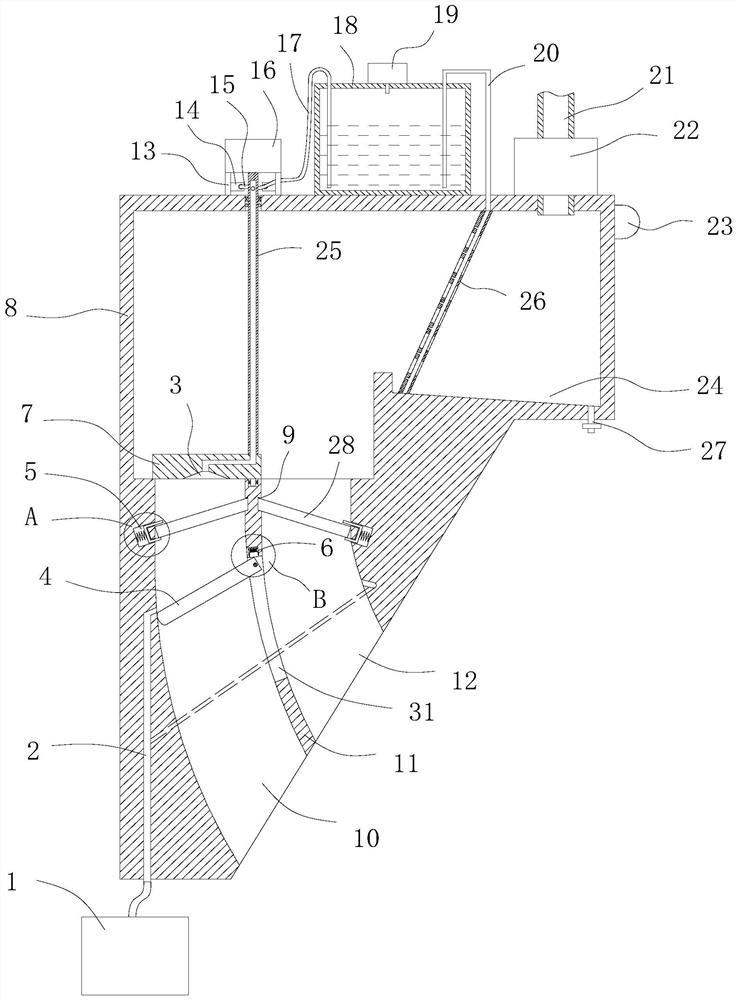

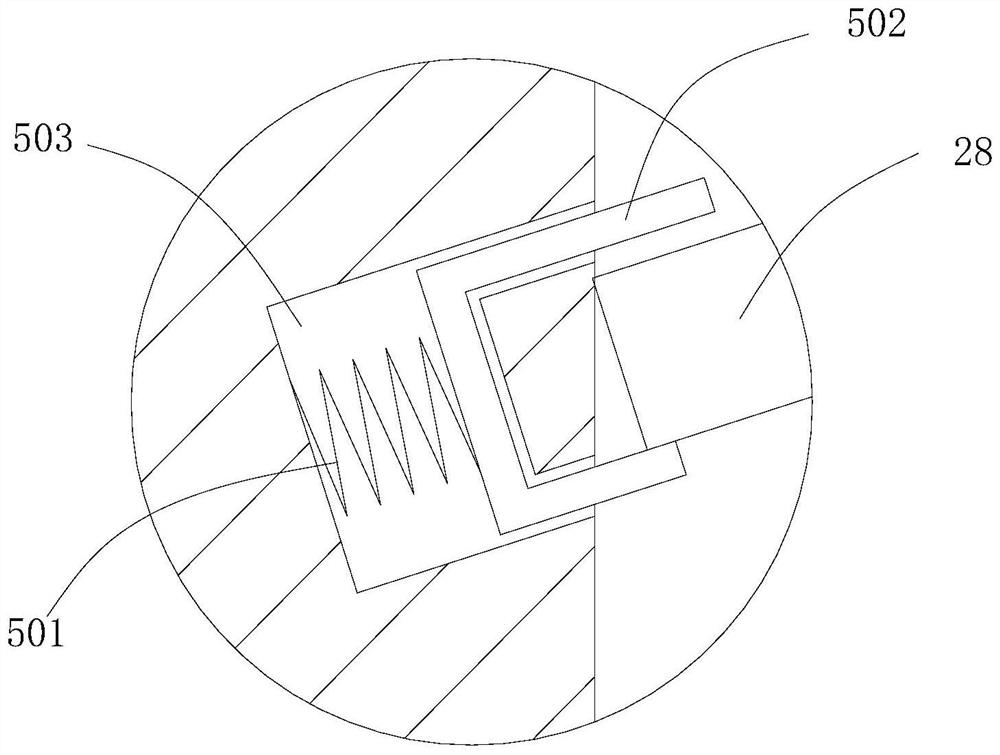

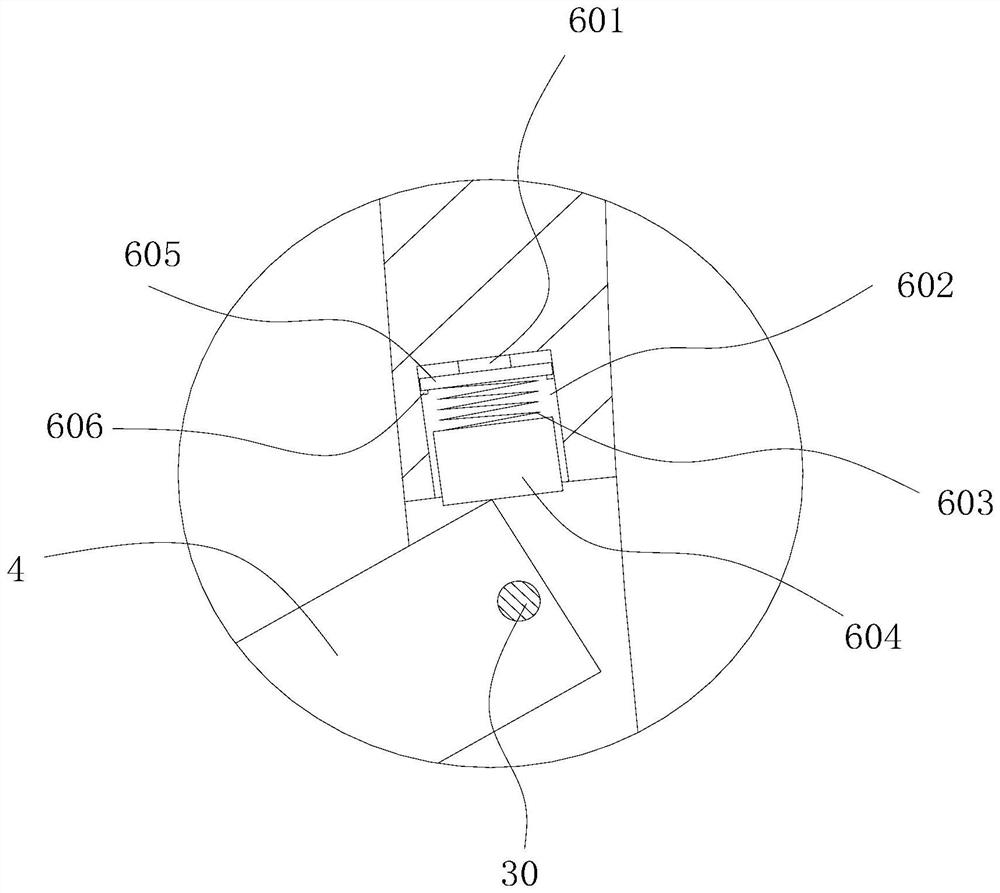

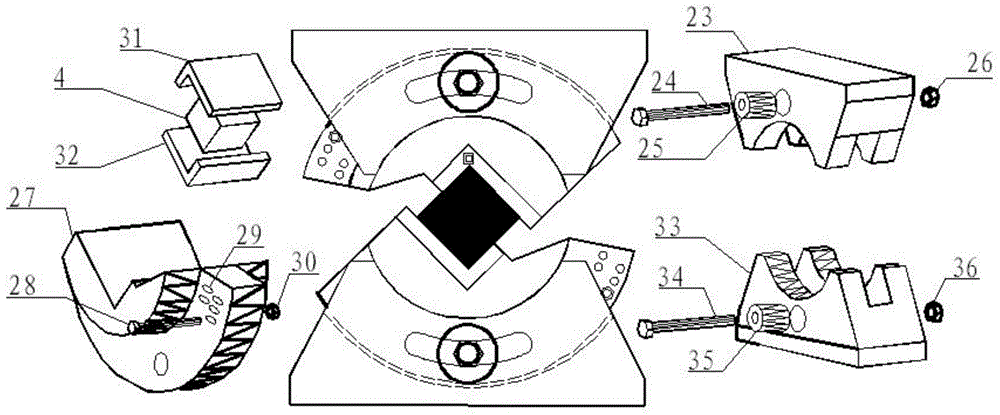

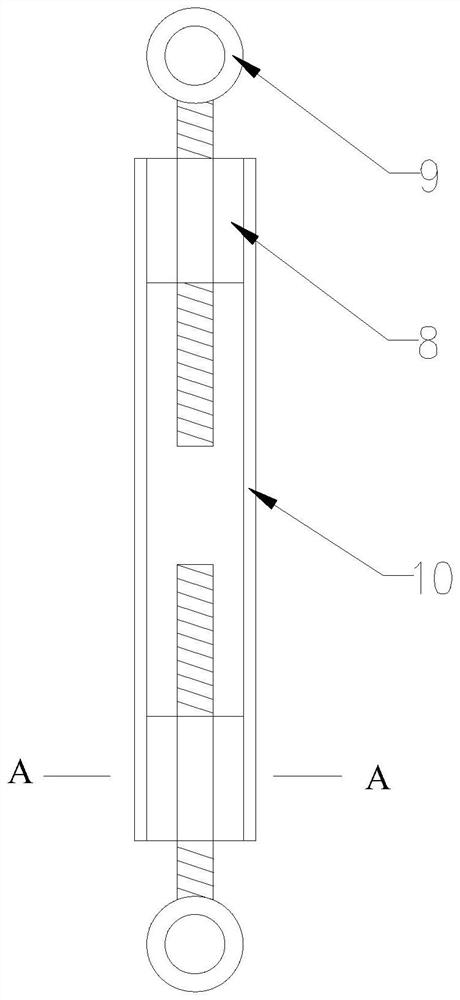

Compression-shear testing apparatus for rock in dry-wet cyclic process

ActiveCN105181483ASimple structureEasy to operateMaterial strength using steady shearing forcesCyclic processEngineering

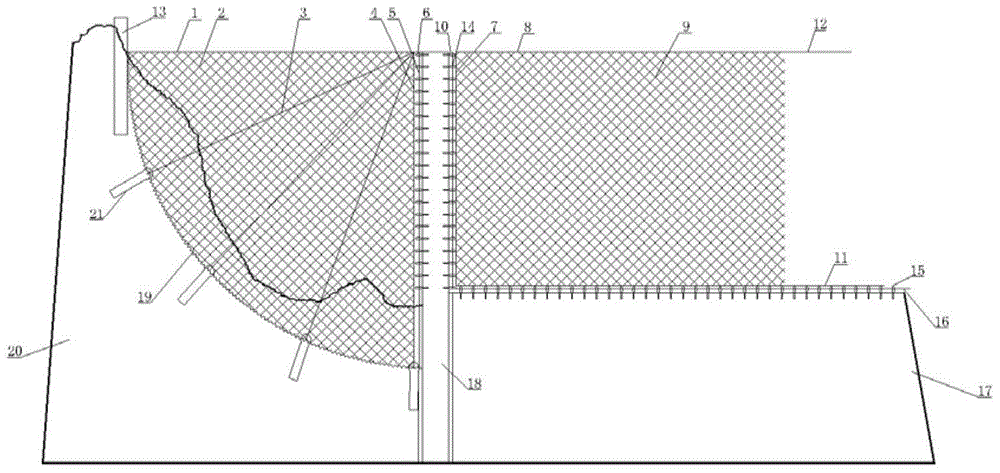

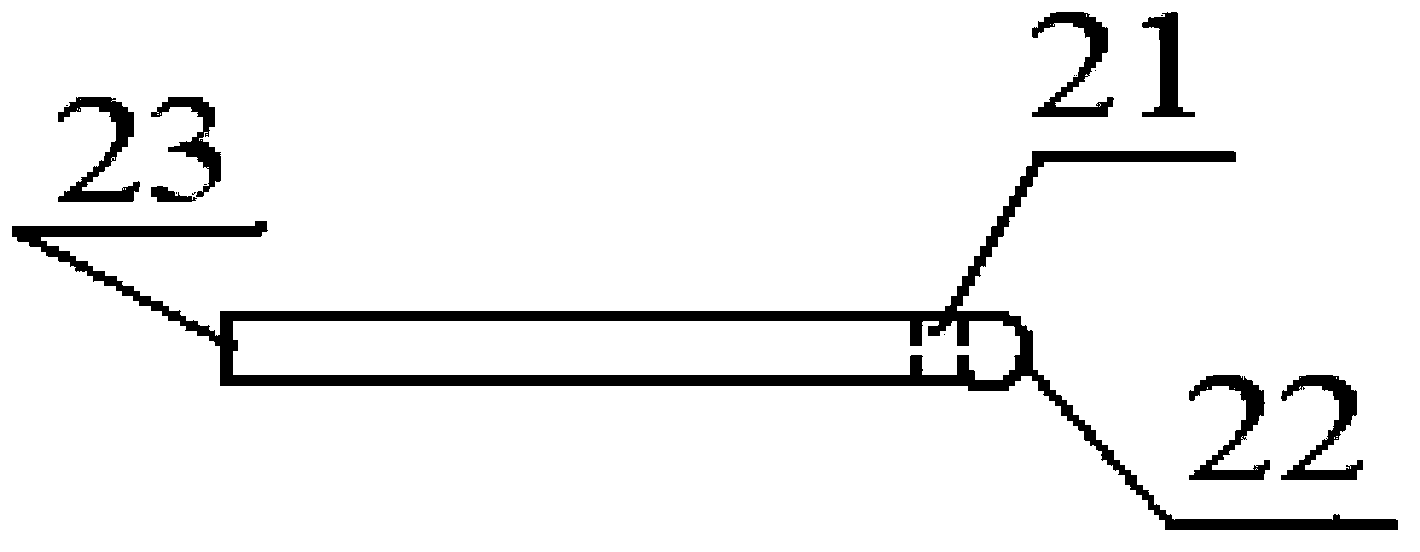

The invention belongs to the field of geotechnical engineering, and in particular relates to a compression-shear testing apparatus for a rock in a dry-wet cyclic process. The apparatus comprises an angle-variable compression-shear unit, and a compression machine for vertically applying load onto the angle-variable compression-shear unit; the apparatus also comprises a reservoir, water injection equipment for carrying out moisture saturation treatment on a rock sample in the angle-variable compression-shear unit, and heating equipment for carrying out hot-gas drying treatment on the rock sample in the angle-variable compression-shear unit. The angle-variable compression-shear unit is located in the reservoir, and the reservoir is communicated with the water injection equipment and the heating equipment. By adopting the compression-shear testing apparatus, the integration of rock sample dry-wet cyclic treatment and a shear test is realized, and the apparatus has the advantages of simple structure, convenient operation, low cost, wide application range and long service life; the rock samples in different states after different dry-wet cyclic times can be accurately simulated, shear test research is carried out on the rock samples, and moreover, failure load and displacement of the rock samples in the vertical direction in the shear test process can be recorded in real time.

Owner:ANHUI INST OF BUILDING RES & DESIGN

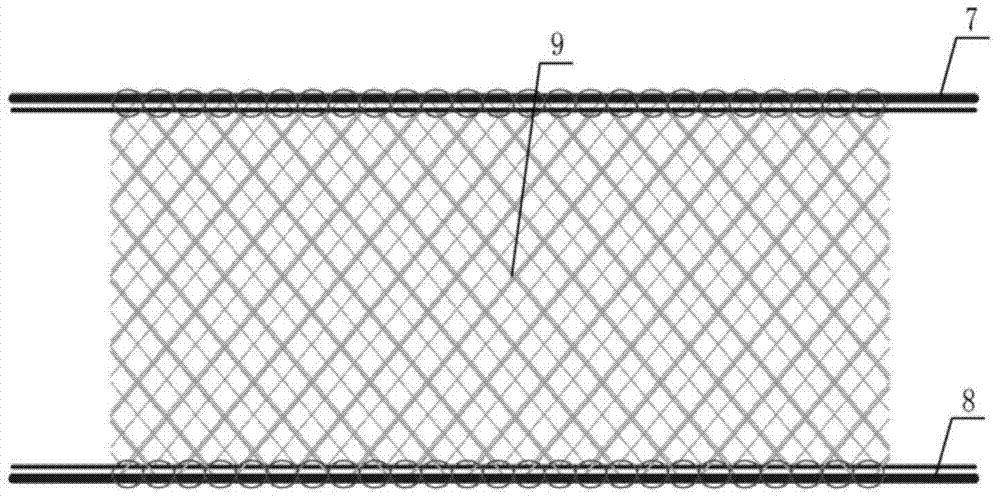

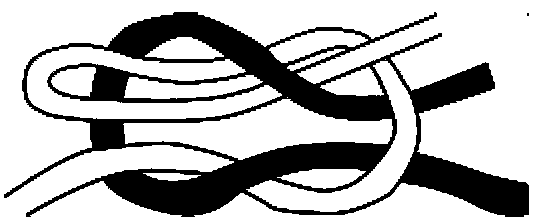

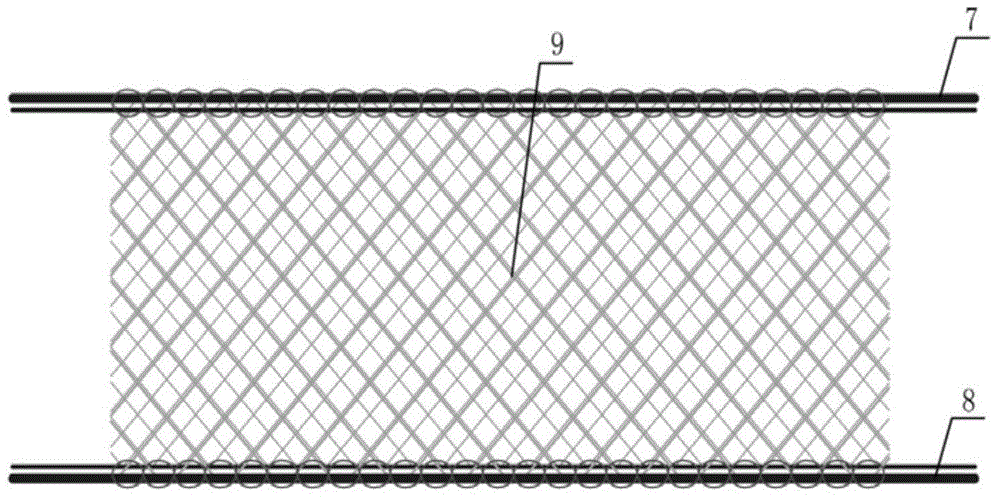

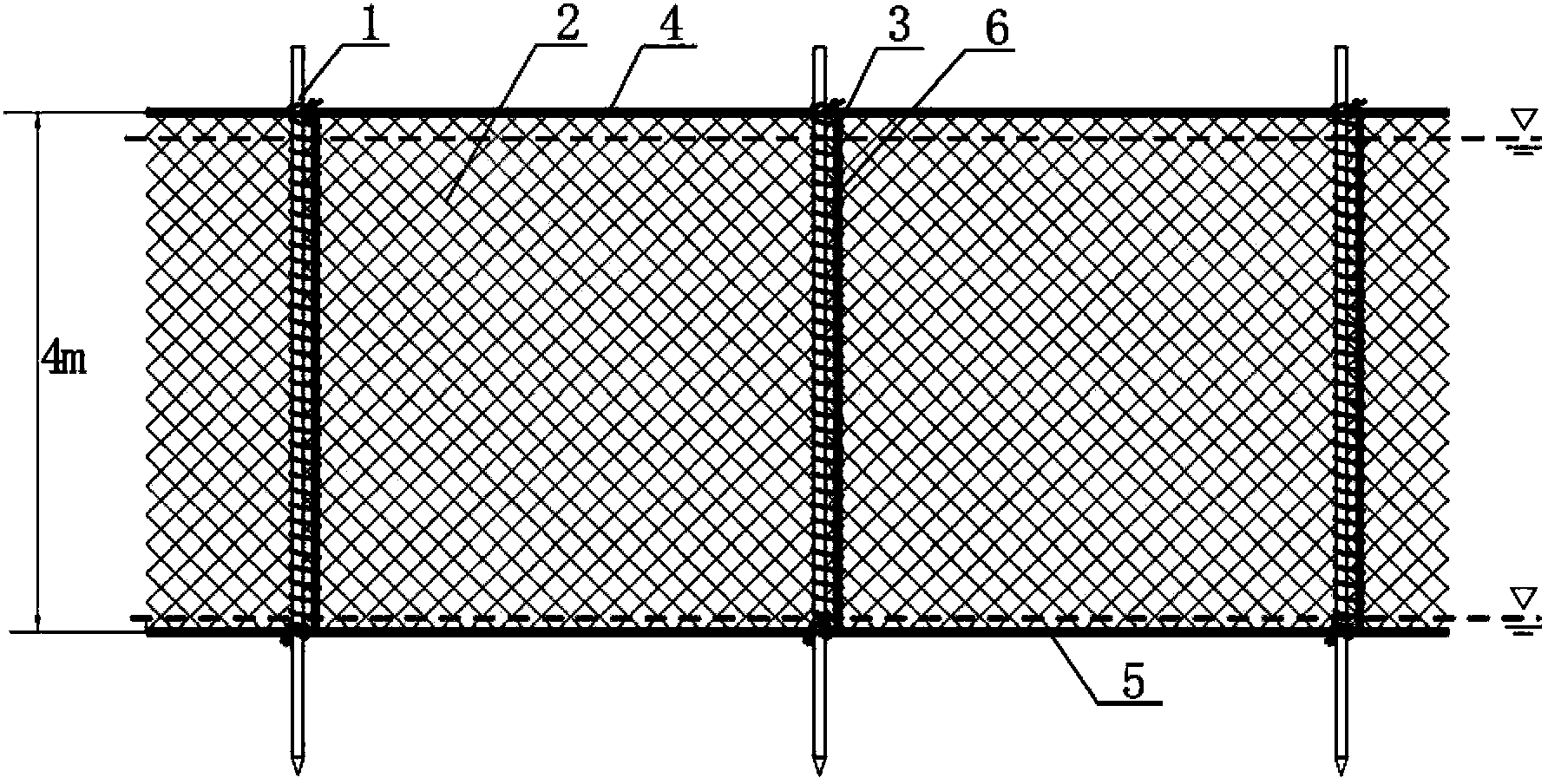

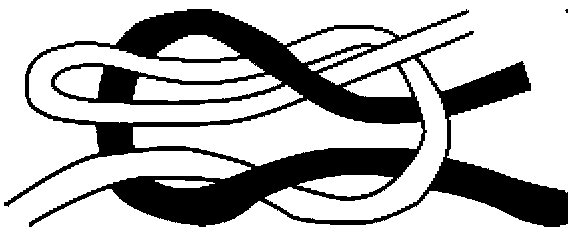

Marine ranching dike netting gear component assembly method

The invention discloses a marine ranching dike netting gear component assembly method, wherein a double-layer fiber net, a medium-soft connection net and a woven net are used. The marine ranching dike netting gear component assembly method is characterized in that an upper margin line of the woven net and a lower line of the double-layer fiber net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; next, a lower line of the medium-soft connection net and a connecting steel cable on the woven net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; then, an upper line of the medium-soft connection net and a connecting net line on the double-layer fiber net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; after an upper line of the double-layer fiber net, the upper line of the medium-soft connection net, the lower line of the medium-soft connection net, a lower margin line of the woven net and the double-layer fiber net are subjected to anti-dirt treatment, a large-mesh ultra-high molecular weight polyethylene warp knitting net is directly bound, connected and fixed to a marine ranching dike netting gear pile.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

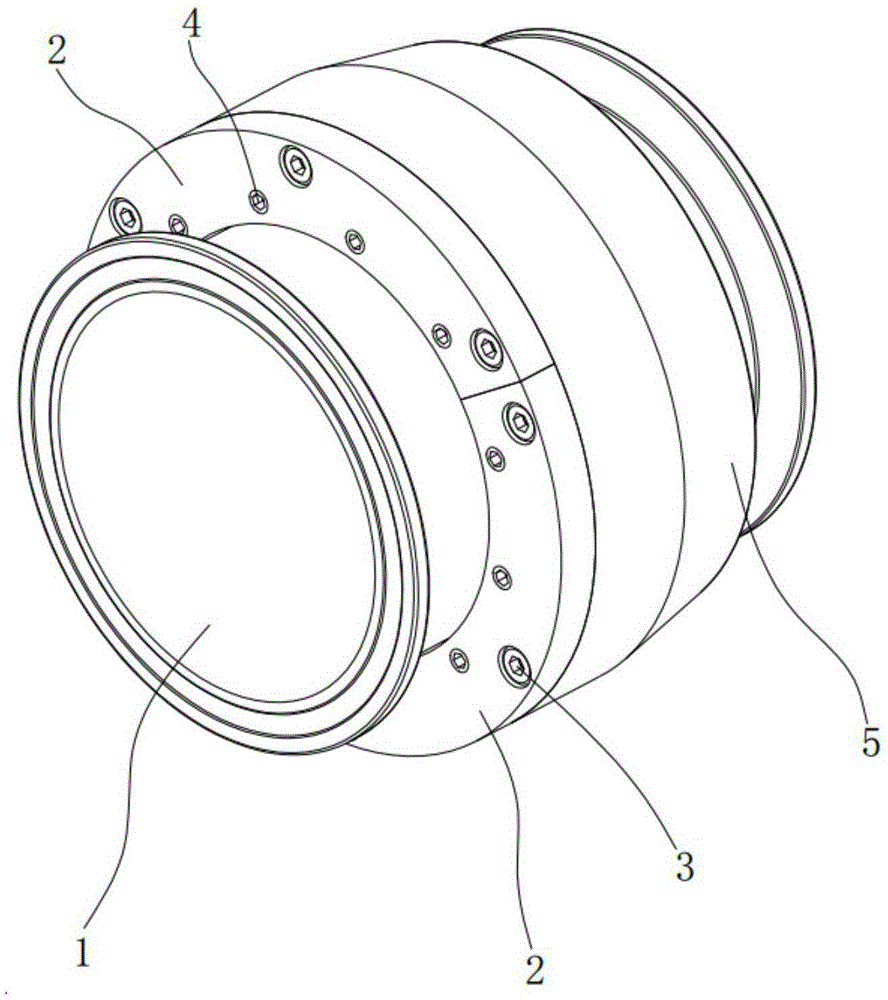

Hoop connector and connecting device with same

InactiveCN105276313AFirmly connectedEasy to assembleAdjustable jointsEngineeringElectrical and Electronics engineering

The invention discloses a hoop connector and a connecting device with the same. The hoop connector comprises a first sleeve and a second sleeve. The first sleeve comprises a first body, a first connecting ring and a second connecting ring. The second sleeve comprises a second body, a third connecting ring and a fourth connecting ring. A second annular groove is formed in the inner end face of the second connecting ring. A step hole is formed in the second sleeve. The second connecting ring stretches into the step hole. A wear-resisting ring is arranged between the outer end face of the second connecting ring and the step face of the step hole. The outer side of the first body is sleeved with end face fixing plates which are fixedly connected with the third connecting ring and connected with spring plunger screws, and the ends of the spring plunger screws are clamped in the second annular groove. By means of the hoop connector and the connecting device with the same, angle adjustment and assembling of pipelines in onsite pipeline connection are facilitated, and waste of manpower in the assembling process of equipment is greatly reduced.

Owner:KUNSHAN CHENGFENGDA IND EQUIP

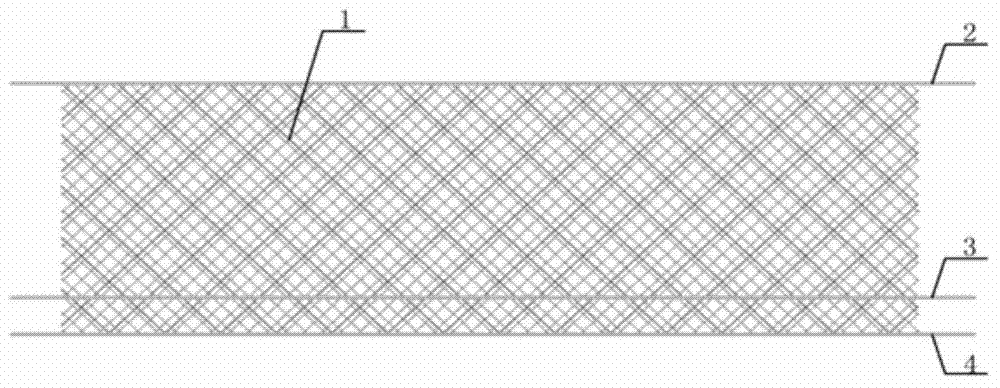

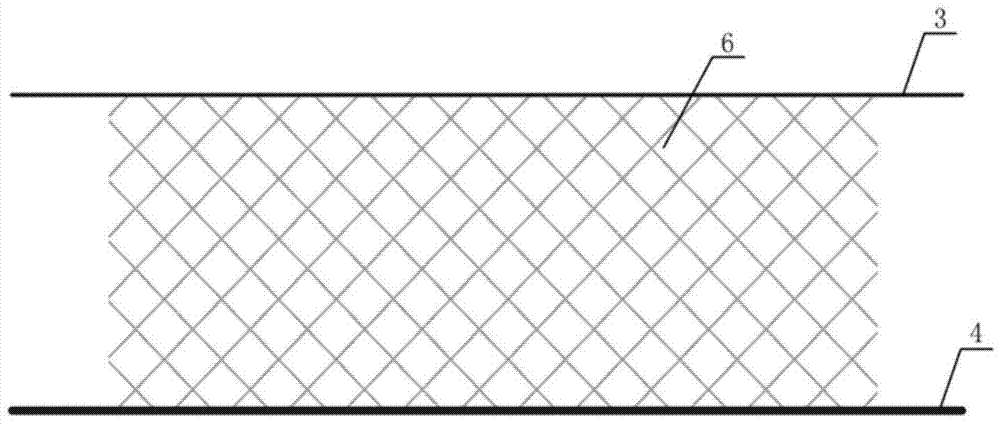

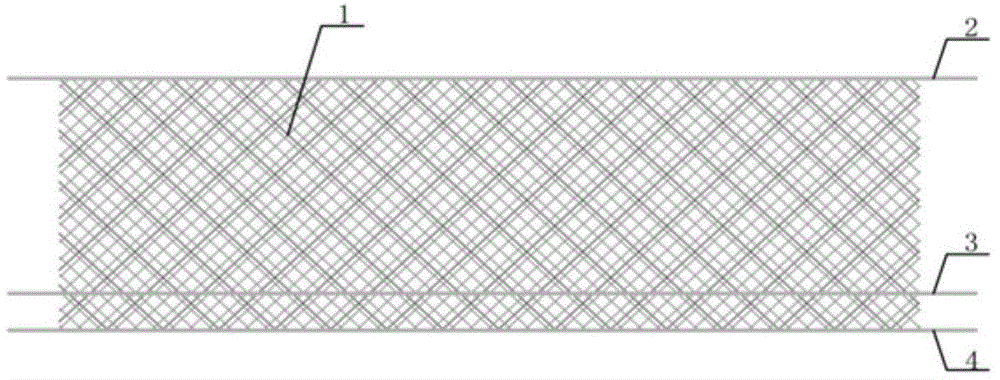

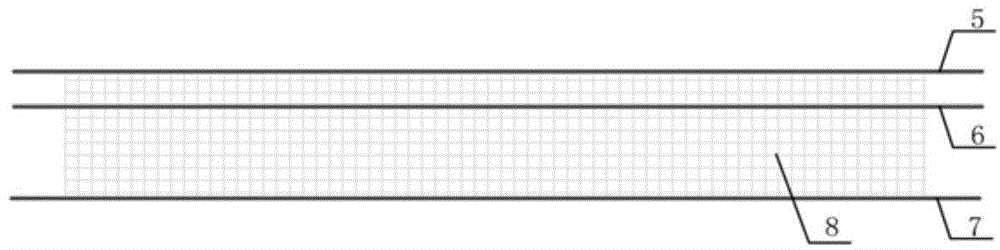

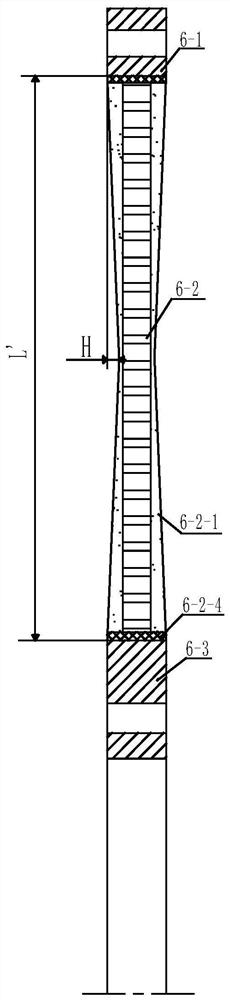

Processing method for large netting gear clothes of double-layer structure

ActiveCN103609496AIncreased service life and equipment levelsHigh strengthClimate change adaptationPisciculture and aquariaEngineeringUltra-high-molecular-weight polyethylene

A processing method for large netting gear clothes of a double-layer structure is characterized in that a small mesh ultra-high molecular weight polyethylene warp knitting net and a large mesh ultra-high molecular weight polyethylene warp knitting net are processed respectively; a head line is arranged on the upper edge in the length direction of the small mesh ultra-high molecular weight polyethylene warp knitting net which is 492m*11m and goes through anti-dirty treatment, and a foot line is arranged on the lower edge; a head line is arranged on the upper edge of the large mesh ultra-high molecular weight polyethylene warp knitting net which is 492m*11m and goes through anti-dirty treatment, and a foot line is arranged on the lower edge; the head line of the small mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment and the head line of the large mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment are bound into a head line of the large netting gear clothes of the double-layer structure; the foot line of the small mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment and the foot line of the large mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment are bound into a foot line of the large netting gear clothes of the double-layer structure.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

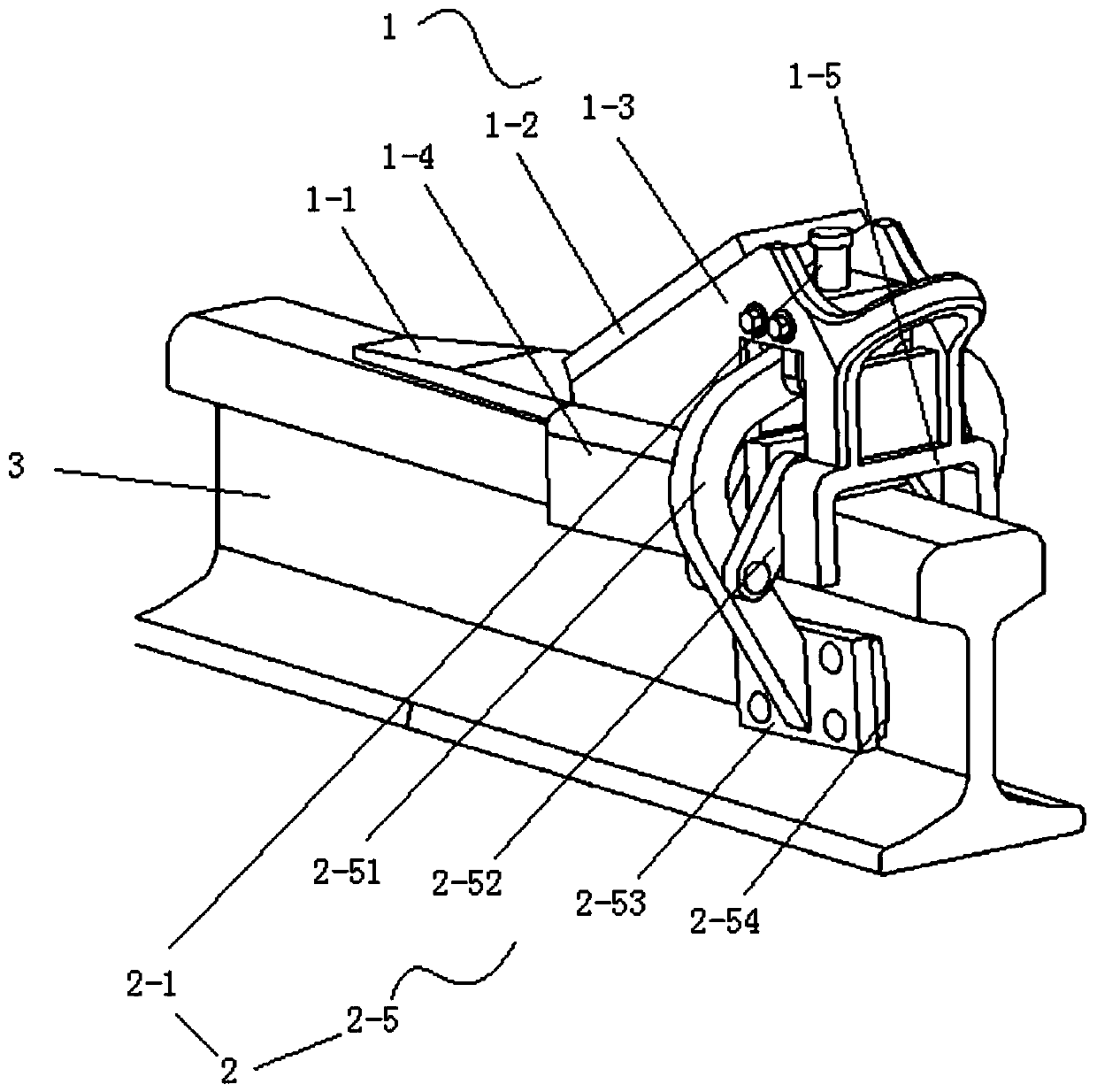

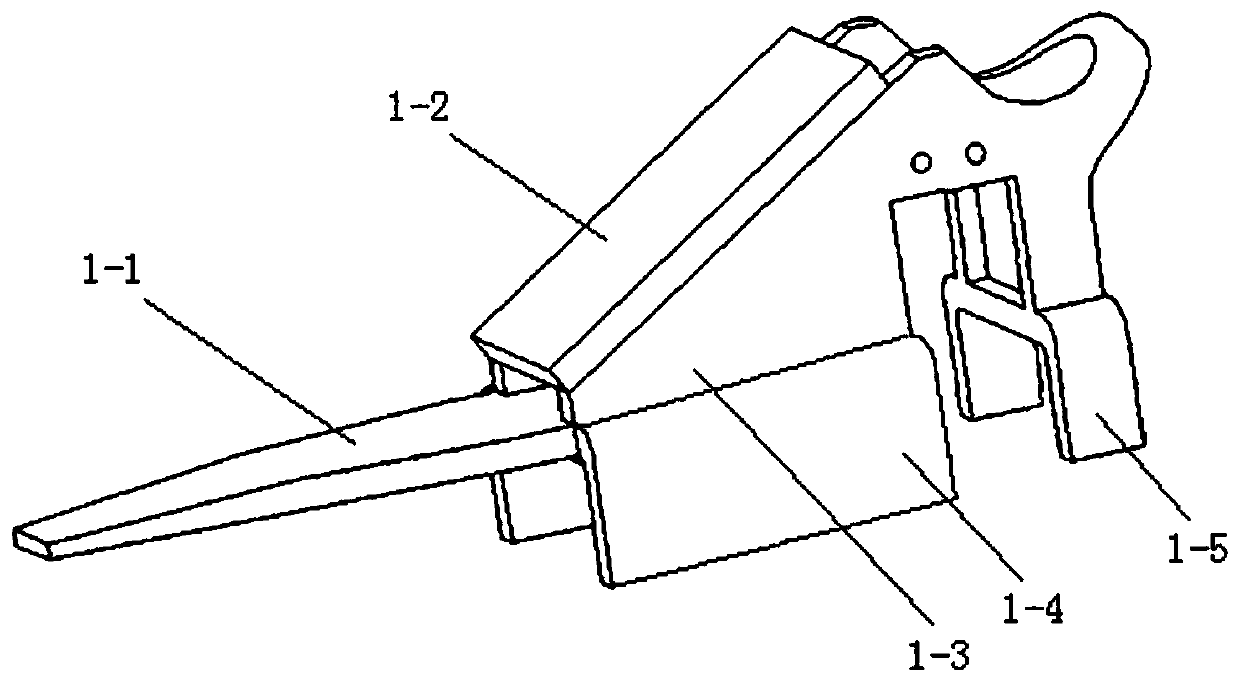

Linkage braking railway vehicle wheel stopper

PendingCN110901684AIncrease brake frictionReduce the difficulty of operationTrack-braking member co-operationControl theoryWork time

A linkage braking railway vehicle wheel stopper comprises a body and a linkage braking device, the linkage braking device is clamped in the body, the body is pressed to drive the linkage braking device to brake, the linkage braking device comprises a pressure bearing assembly, and the pressure bearing assembly is provided with a linkage assembly in a linkage mode. The pressure-bearing assembly ispressed to move longitudinally to drive the linkage assembly to move transversely. Through the arrangement of the structure, the stability and safety of the wheel stopper are improved, the operation difficulty is reduced, the installation and disinstallation process is simplified, and the working time is shortened.

Owner:CHANGAN UNIV

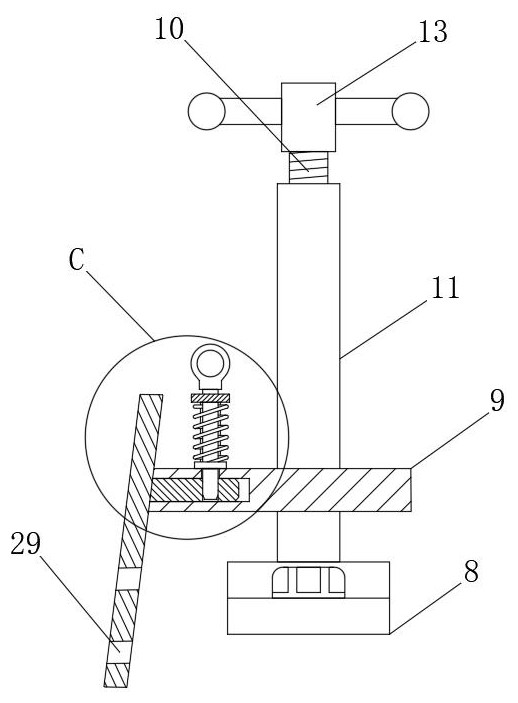

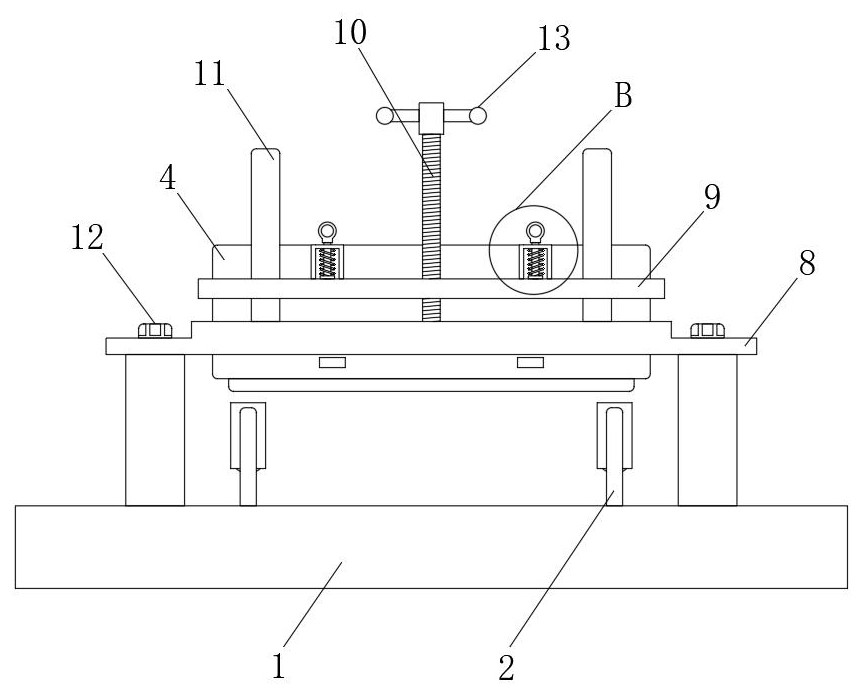

Adjustable rubber cutter

InactiveCN103963088AEasy to replaceAvoid direct contact wearMetal working apparatusEngineeringScrew thread

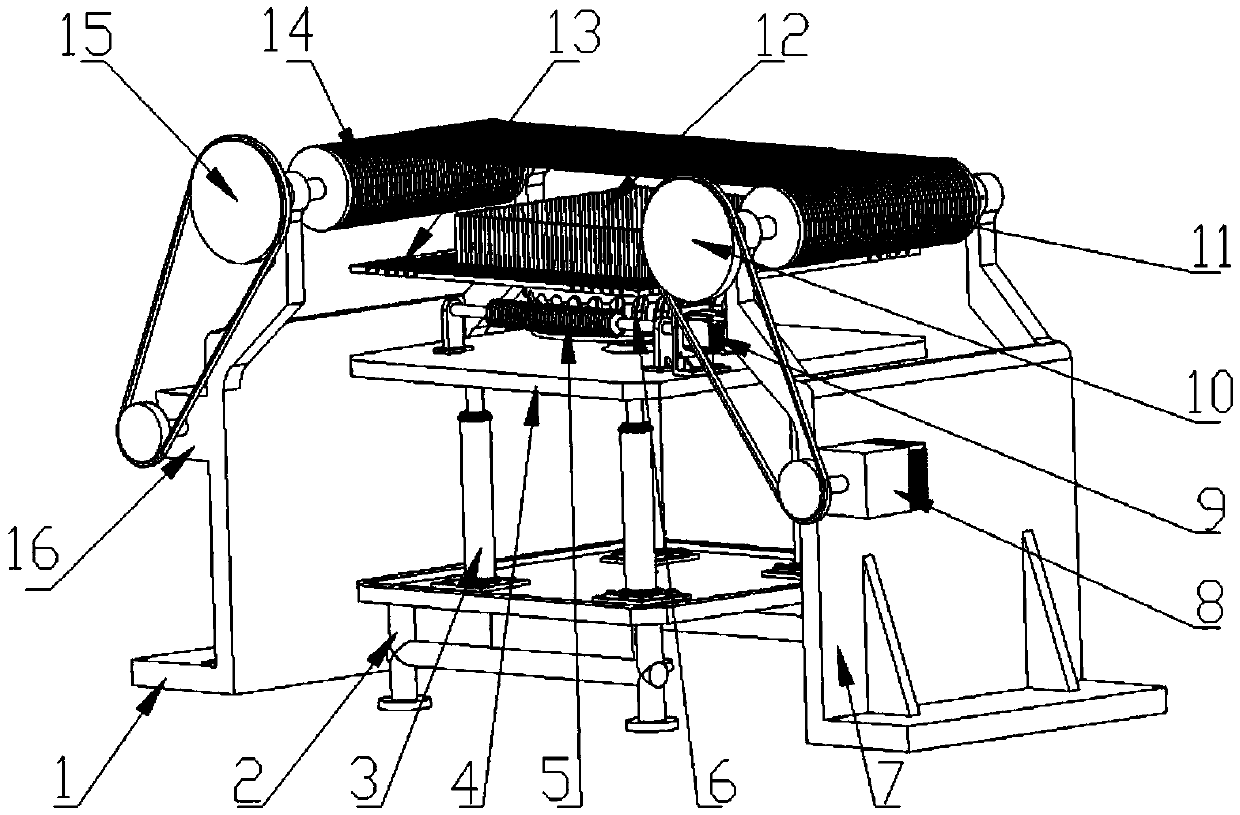

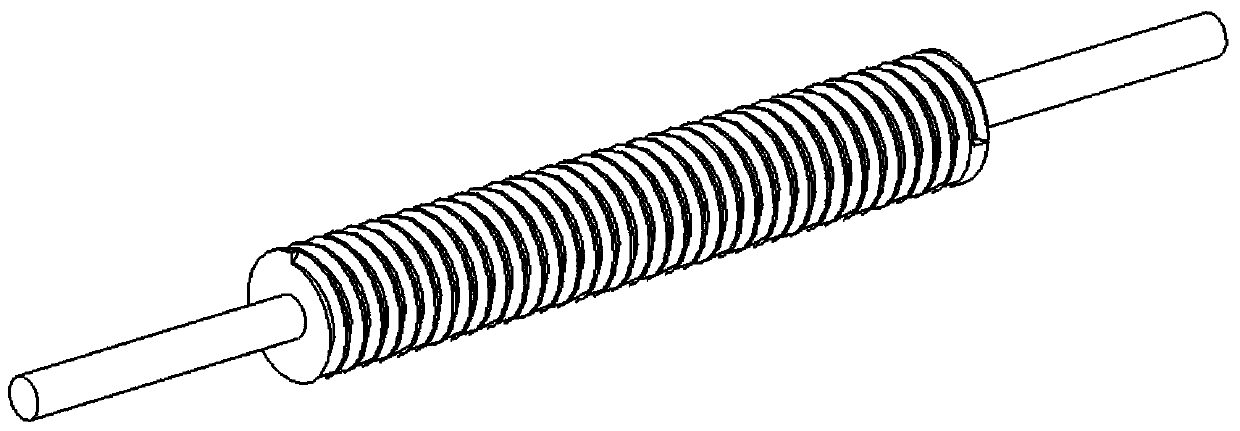

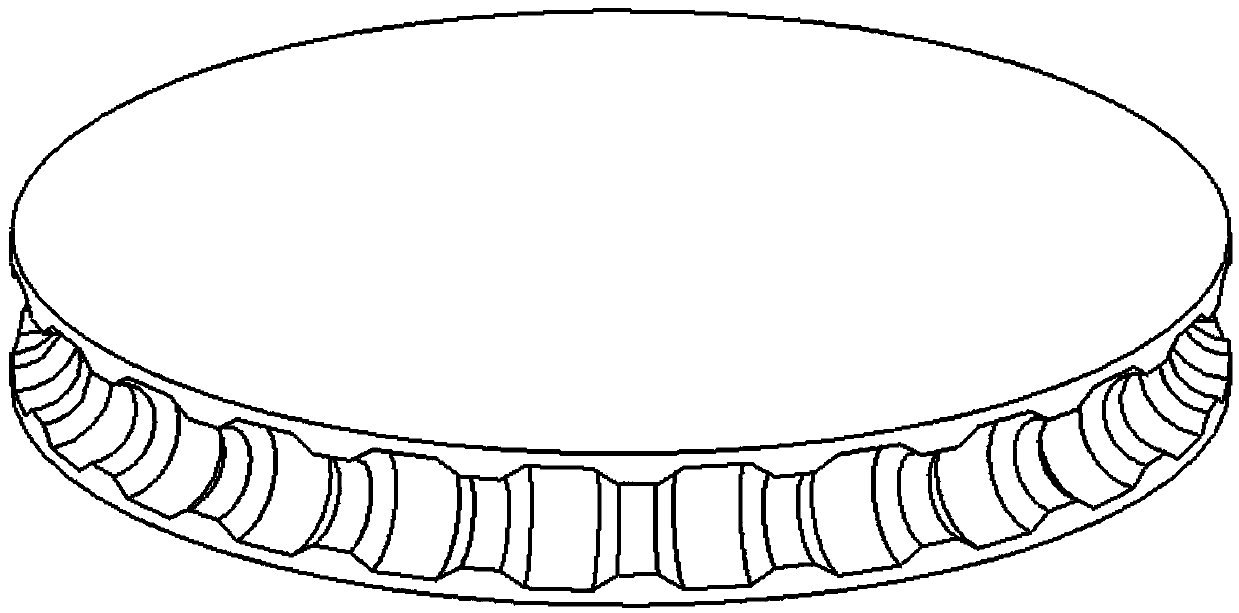

The invention relates to a device in the technical field of rubber cutting machines, in particular to an adjustable rubber cutter. The rubber cutter comprises a first support, a second support, a transmission device, a control device, a base, pressure rod devices, a workbench, worms, a worm gear, a rubber cutting mould and a mould adjusting base plate, the first support and the second support are arranged symmetrically, the transmission device and the control device are symmetrically arranged on the first support and the second support, and the base, the pressure rod devices, the workbench, the worms, the worm gear, the rubber cutting mould and the mould adjusting base plate are arranged between the first support and the second support. The lower ends of the pressure rod devices are arranged on the base, and the upper ends of the pressure rod devices are fixed to the lower surface of the workbench. The worms are connected through two connecting holes protruding out of the upper surface of the workbench. The worms and the worm gear are matched to be connected through threads. The upper surface of the worm gear is fixed to the lower surface of the mould adjusting base plate, and the worm gear and the workbench form a rotating pair through a bearing arranged in the center of the workbench. The lower end of the rubber cutting mould is clamped in a groove in the upper surface of the mould adjusting base plate.

Owner:SHANGHAI JIAO TONG UNIV

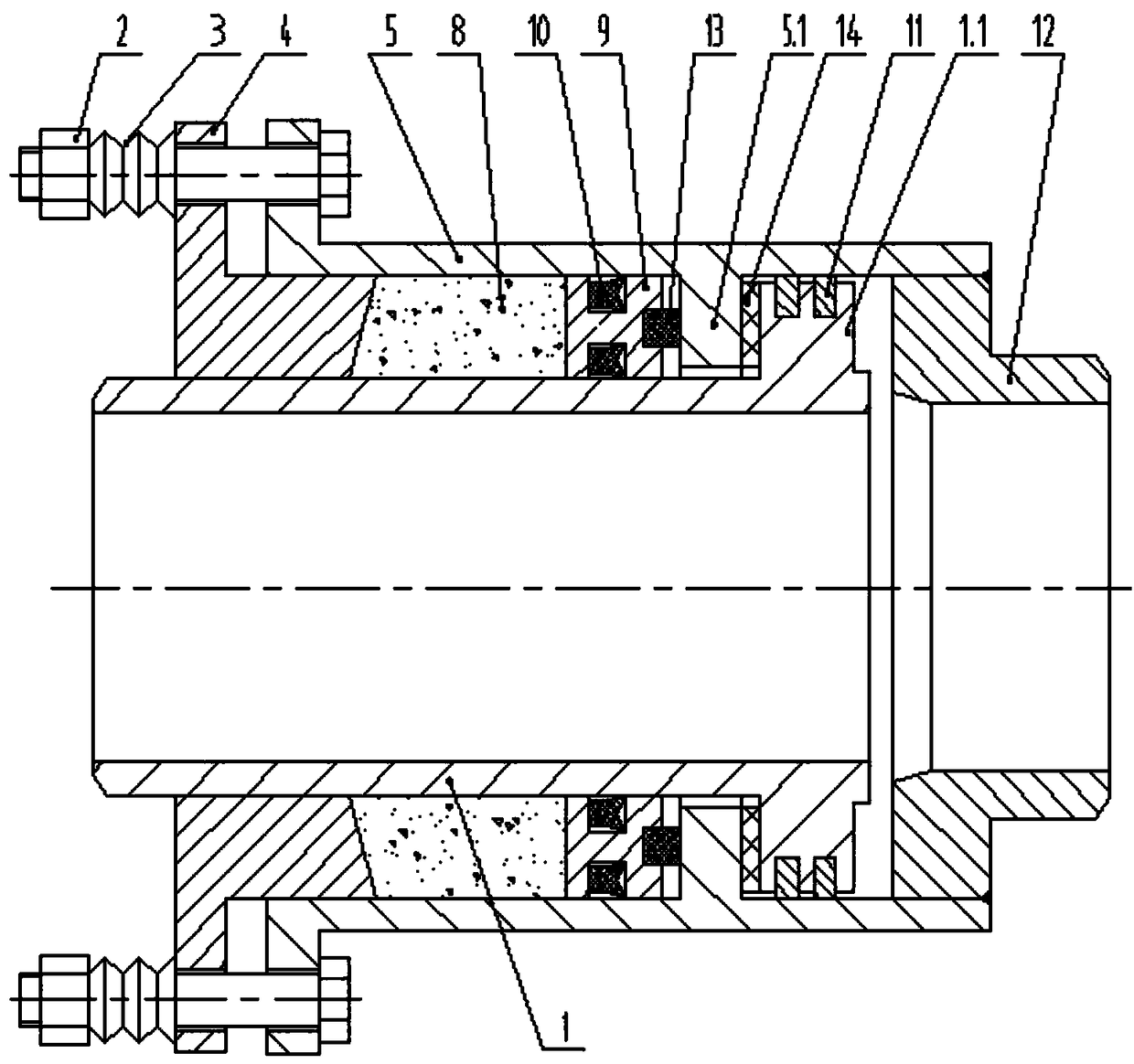

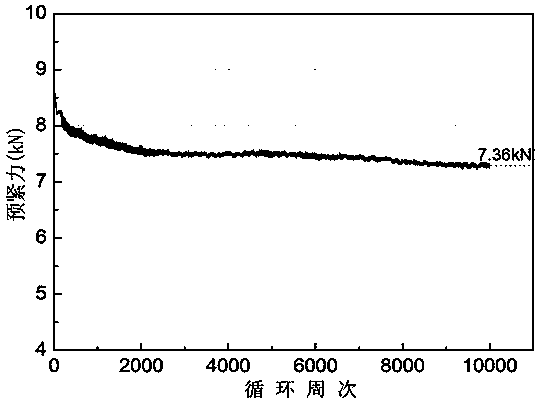

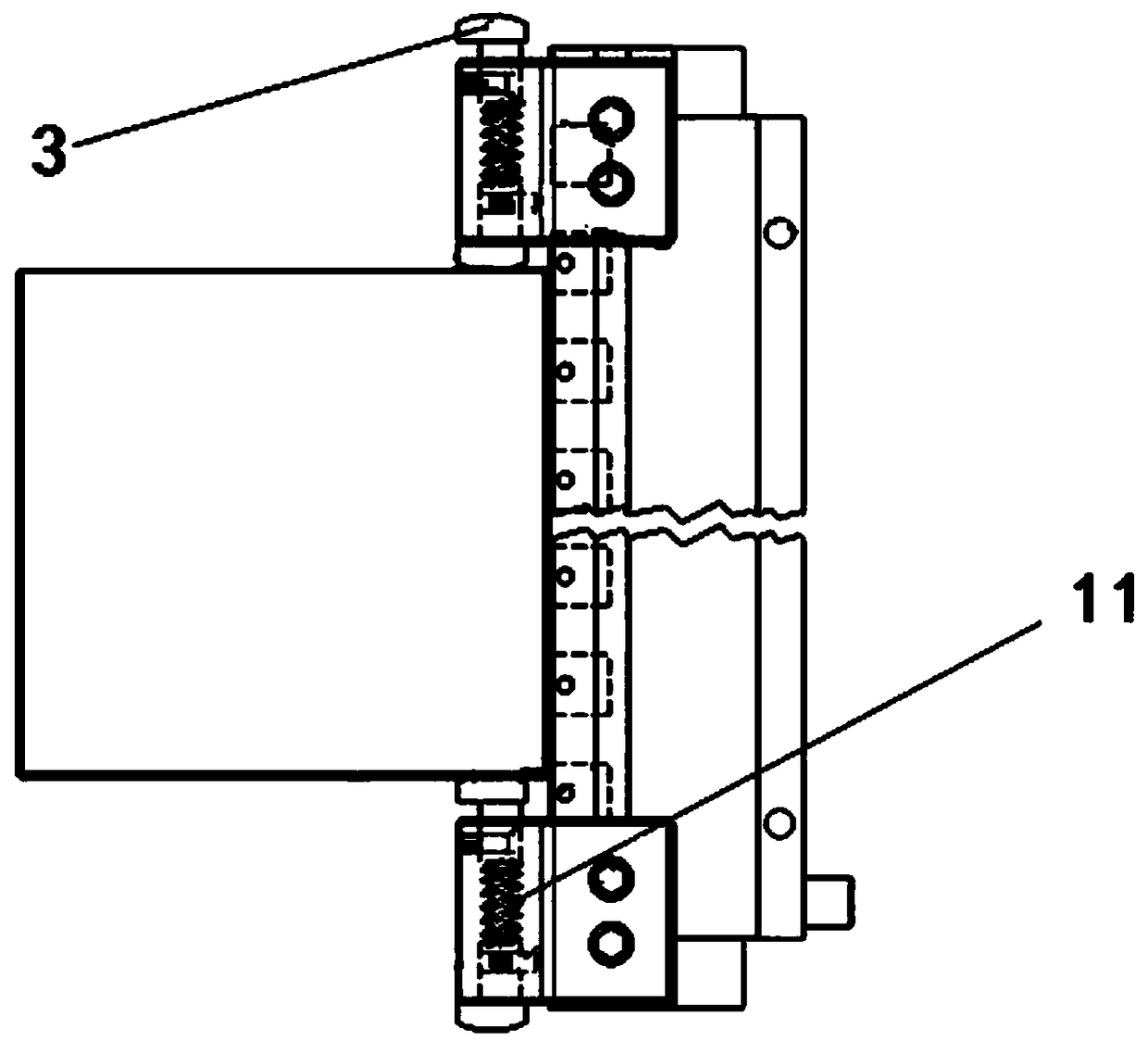

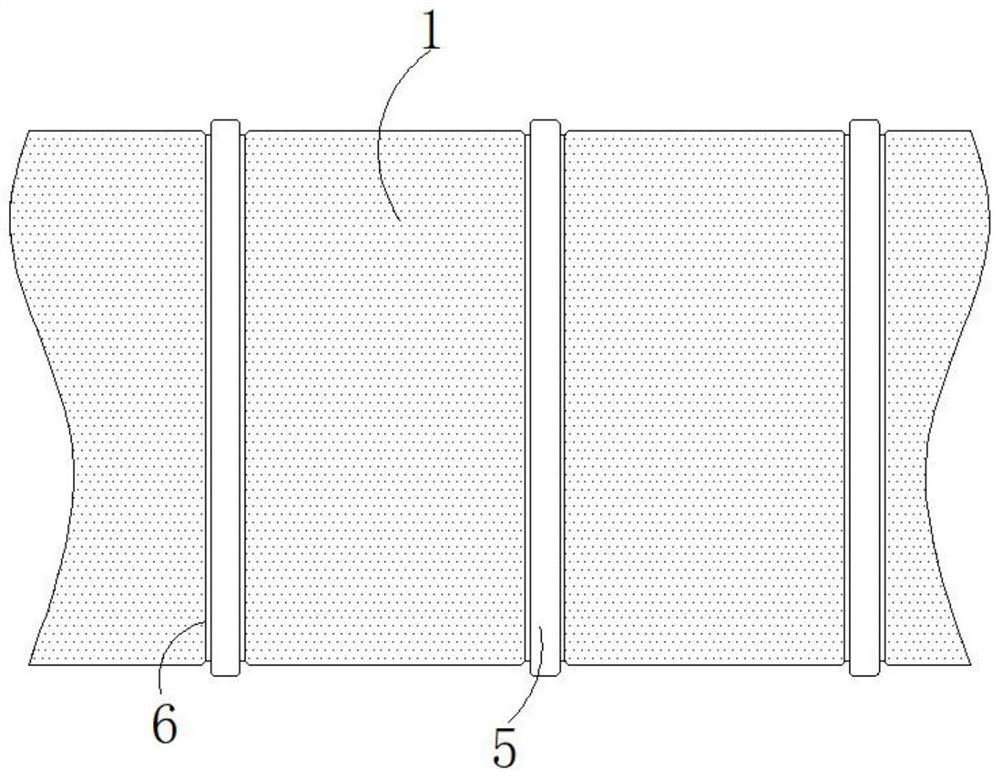

Vibration reduction device for diaphragm coupling and vibration reduction method of vibration reduction device

ActiveCN112324813AIncreased resonance bandwidthReduce damage rateYielding couplingNon-rotating vibration suppressionCouplingEngineering

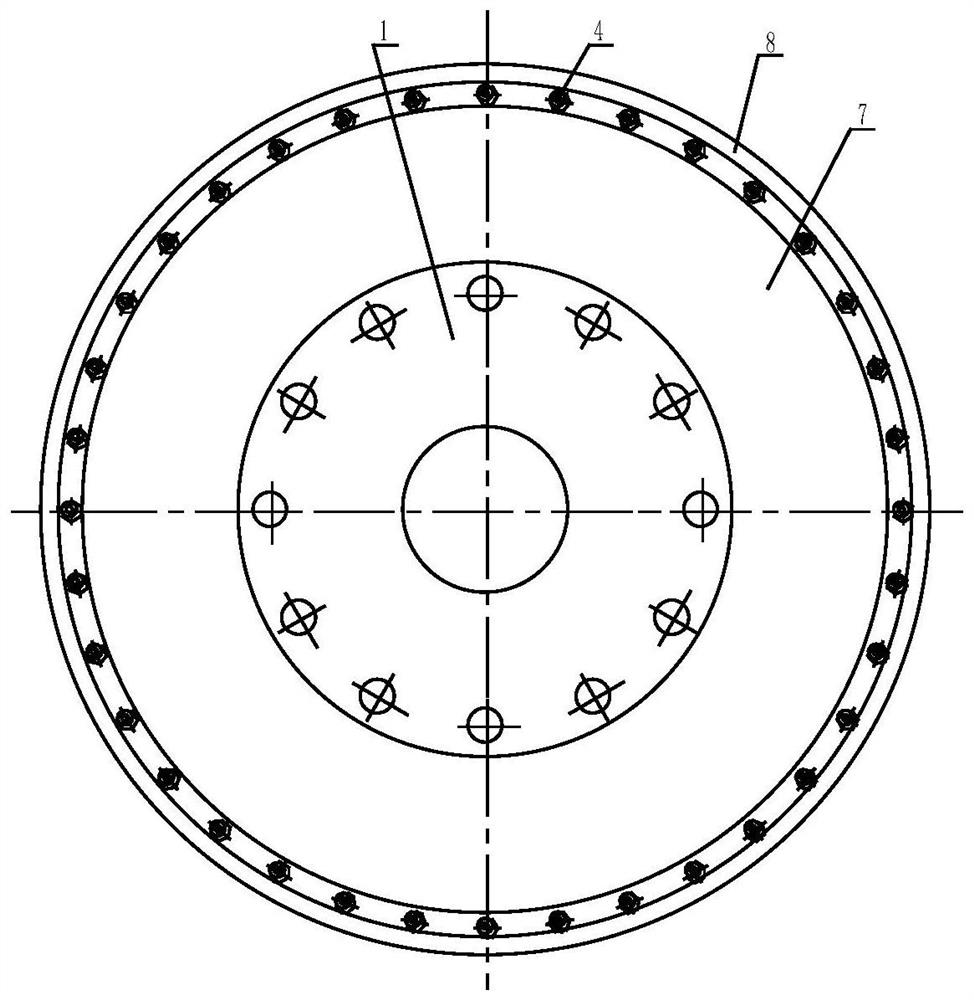

A vibration reduction device for a diaphragm coupling comprises an intermediate shaft, wherein the intermediate shaft is of a sleeve-shaped structure with two ends large in diameter and the middle small in diameter, the two ends are sequentially connected with an intermediate flange and an outer flange respectively, the intermediate flange and the intermediate shaft are connected through a plurality of bolts III, a plurality of dynamic vibration absorption components are evenly distributed in a large-diameter hole of the intermediate shaft in the circumferential direction, a plurality of diaphragm sets are arranged in the outer flange, the diaphragm sets are connected with the intermediate flange and the outer flange through a plurality of bolts I, each diaphragm set is formed by alternately arranging and installing a plurality of diaphragms and a plurality of vibration reduction elements in parallel, a flange I is mounted in an inner hole of each diaphragm set in a sleeved mode, eachflange I is step-shaped, a stop block is arranged at the inner side of each diaphragm set, and each flange I, the corresponding diaphragm set and the corresponding stop block are connected through a plurality of bolts II. Due to the arrangement of the diaphragm sets, the resonance bandwidth is effectively increased; the dynamic vibration absorption devices realize both axial vibration absorption and radial vibration absorption and can bear large loads, so that the vibration reduction effect is enhanced, the service life of the diaphragm coupling is greatly prolonged, and the requirements for power transmission and structural strength of the coupling are met.

Owner:JIANGSU UNIV OF SCI & TECH

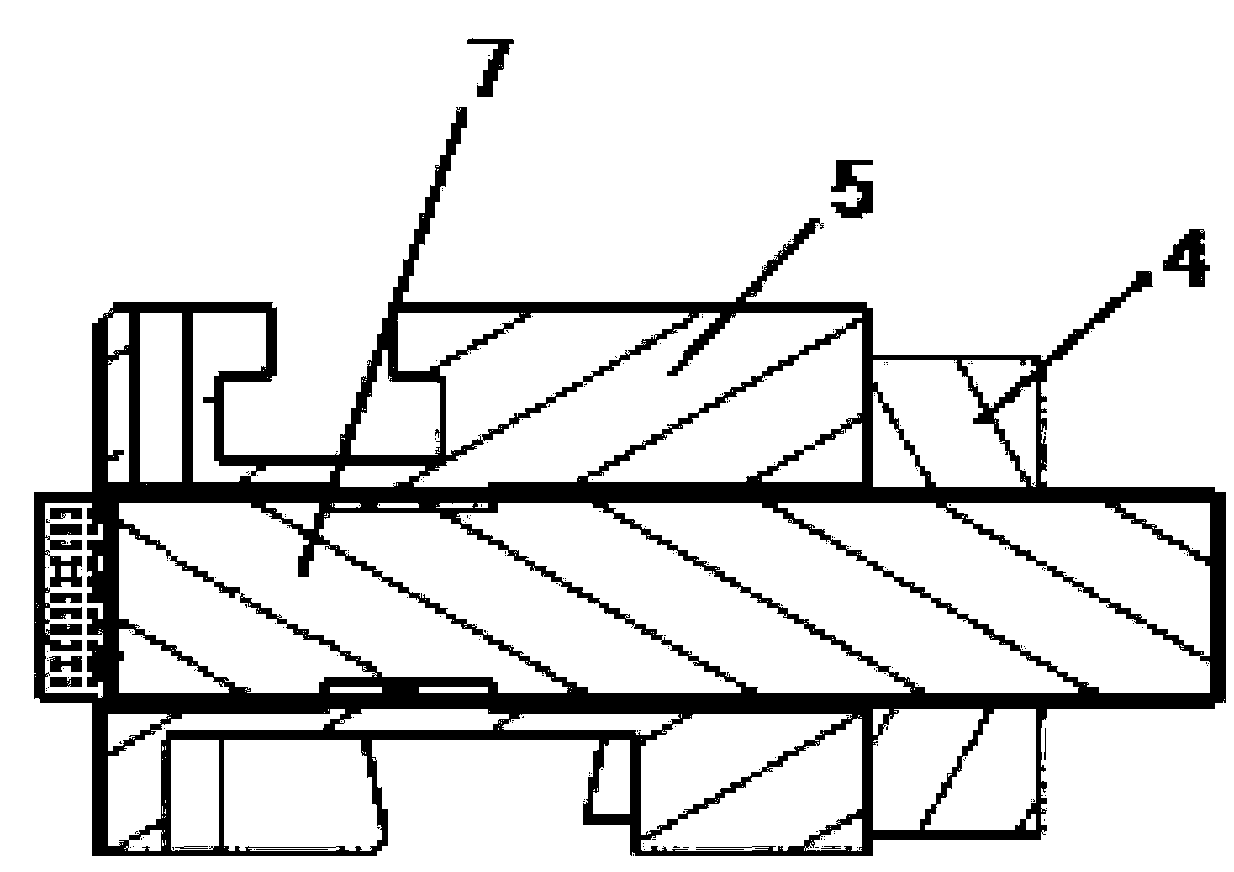

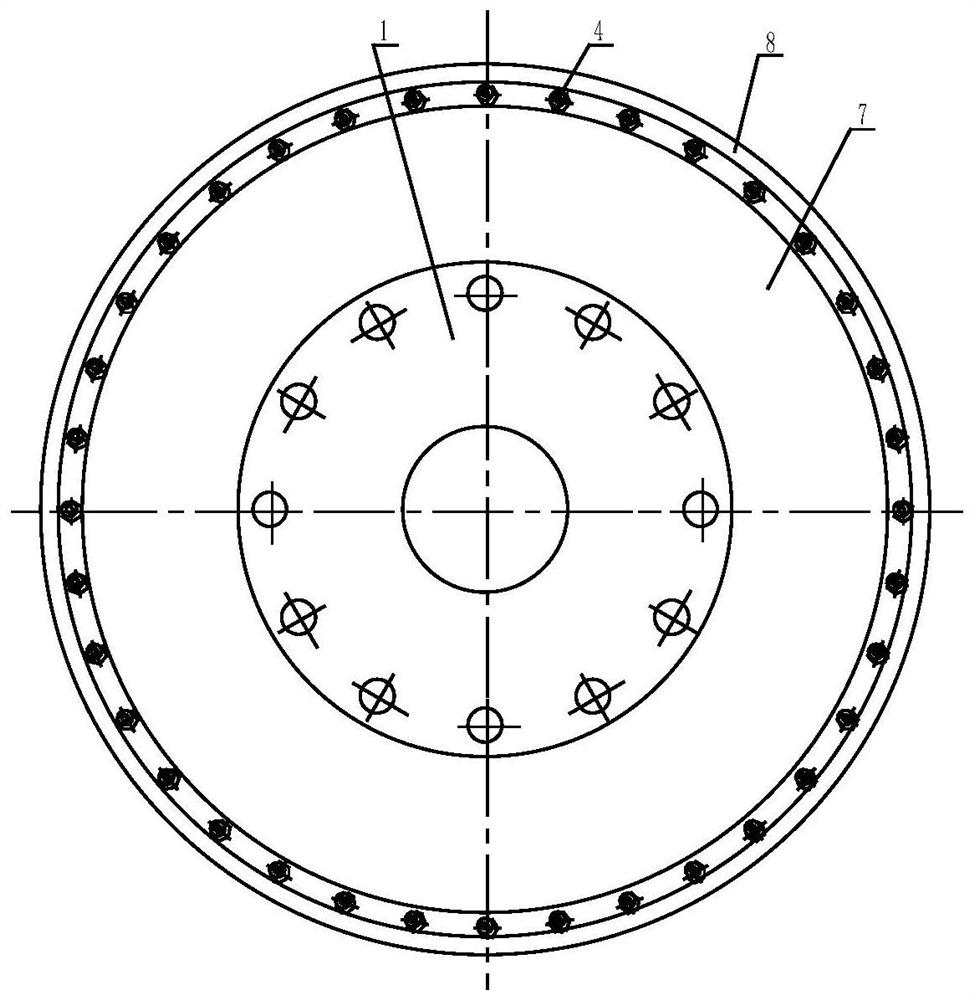

High temperature resistant and high pressure resistant rotary compensator

InactiveCN108071891AImprove high temperature resistanceEasy to assemblePipeline expansion-compensationWear resistantEngineering

The invention discloses a high temperature resistant and high pressure resistant rotary compensator, which comprises a rotary inner pipe, a bolt nut assembly, an outer sleeve pipe, a gland, a graphitepacking, a movable seal ring and a connecting pipe. More than two first ring grooves are formed in an outer wall of an outer convex shoulder of the right end of the rotary inner pipe; a high-temperature medium seal ring is arranged in each first ring groove, is a slip ring and is tightly matched with an inner hole of the outer sleeve pipe; and openings of the high-temperature medium seal rings ineach two adjacent first ring groove are staggered. The high temperature resistant and high pressure resistant rotary compensator has the further improvements that the movable seal ring is arranged between a left end face of an inner convex shoulder of the outer sleeve pipe in a packing seal cavity and the graphite packing; a seal structure is arranged between the movable seal ring and the inner hole of the outer sleeve pipe, the outer wall of the rotary inner pipe, and the left end face of the inner convex shoulder of the outer sleeve pipe; a wear-resistant ring is arranged between a right end face of the inner convex shoulder of the outer sleeve pipe and a left end face of the outer convex shoulder of the right end of the rotary inner pipe; an elastic self-sealing structure is arranged;and a surface, contacting the graphite packing, on the gland is a conical surface. The high temperature resistant and high pressure resistant rotary compensator provided by the invention is high temperature resistant, adopts multiple sealing structures, and is high pressure resistant.

Owner:江苏苏创管业科技有限公司

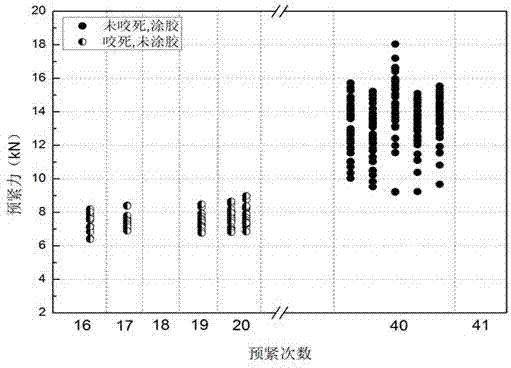

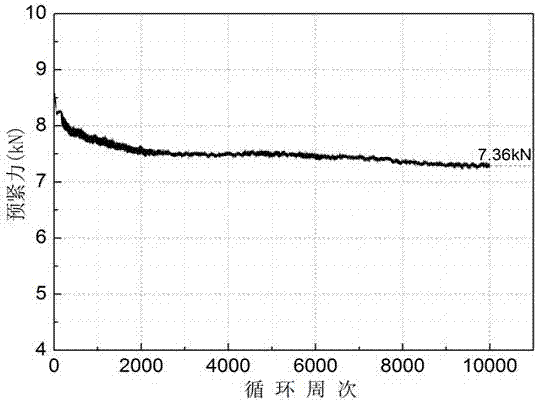

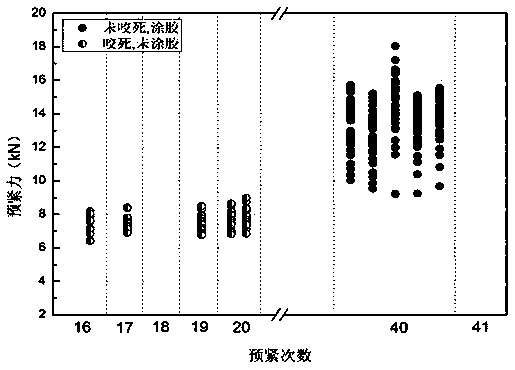

Anti-seizing and anti-loosening glue for stainless steel threaded connection and preparation method thereof

ActiveCN107325737AAvoid killingAvoid direct contact wearNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyMethacrylate

The invention discloses an anti-seizing and anti-loosening glue for stainless steel threaded connection and a preparation method thereof. The preparation method comprises the following steps: adding olefine esters into a reaction kettle, adding BPO dibenzoyl peroxide, stirring and dissolving, and then heating till the viscose of the product is increased, continuing heating for ageing and cooling to room temperature, thereby acquiring a white transparent olefine ester copolymer; adding acetone and stirring, thereby acquiring a PMM solution in concentration of 20%; taking the PMM solution, adding silicone grease and stirring, and then adding coupling reagent, cyanoacrylate and epoxy resin and uniformly stirring, thereby acquiring a PMMA bonding solution; mixing the PMMA bonding solution and an organic amine solvent at ratio, thereby acquiring the glue. An organic polymer silicate film is formed between the threads by the organic silicide contained in the glue, the direct contact and abrasion of the threads can be prevented and the anti-seizing purpose can be achieved. The mixture of methacrylate and acrylics contained in the glue has an excellent bonding characteristic and can prevent the bolt from loosening.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Anti-seizure and anti-loosening glue for stainless steel thread connection and preparation method thereof

ActiveCN107325737BAvoid killingAvoid direct contact wearNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyMethacrylate

The invention discloses an anti-seizing and anti-loosening glue for stainless steel threaded connection and a preparation method thereof. The preparation method comprises the following steps: adding olefine esters into a reaction kettle, adding BPO dibenzoyl peroxide, stirring and dissolving, and then heating till the viscose of the product is increased, continuing heating for ageing and cooling to room temperature, thereby acquiring a white transparent olefine ester copolymer; adding acetone and stirring, thereby acquiring a PMM solution in concentration of 20%; taking the PMM solution, adding silicone grease and stirring, and then adding coupling reagent, cyanoacrylate and epoxy resin and uniformly stirring, thereby acquiring a PMMA bonding solution; mixing the PMMA bonding solution and an organic amine solvent at ratio, thereby acquiring the glue. An organic polymer silicate film is formed between the threads by the organic silicide contained in the glue, the direct contact and abrasion of the threads can be prevented and the anti-seizing purpose can be achieved. The mixture of methacrylate and acrylics contained in the glue has an excellent bonding characteristic and can prevent the bolt from loosening.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Method for manufacturing low-carbon type jellyfish fence device

InactiveCN103461229BReduce raw material consumptionImprove overall performanceClimate change adaptationPisciculture and aquariaCopper wireEngineering

The invention provides a method for manufacturing a low-carbon type jellyfish fence device. The method adopts bamboo rods, a copper-alloy oblique and square net, high-strength polyethylene monofilaments, ultra-high molecular weight polyethylene net wires and a twelve-strand dacron rope, and is characterized in that high-strength polyethylene monofilament ropes are manufactured by using the high-strength polyethylene monofilaments; the exteriors of the bamboo rods are sheathed with plastic-coated waterproof canvas sleeves; the canvas-sheathed bamboo rods are installed on each side of a jellyfish pool; the high-strength polyethylene monofilament ropes are installed as perpendicular lacing lines in the length direction of the copper-alloy oblique and square net, and two net ends are connected in an equal mesh way by a copper wire with 1mm wire diameter; one high-strength polyethylene monofilament rope is installed on each of the upper edge and the lower edge of the copper-alloy oblique and square net as an upper lacing line and a lower lacing line; the copper-alloy oblique and square net is perpendicularly assembled on the peripheral canvas-sheathed bamboo rods in sequence, and the lower lacing line closely sticks to the bottoms of peripheral grooves; waste meshes are filled in the peripheral grooves and then sand is fully filled and tamped; the twelve-strand dacron rope is tied on the top end of each canvas-sheathed bamboo rod, and the other end of the twelve-strand dacron rope is tied with a wooden pole which is fixedly arranged in sandy soil on the bottom of the jellyfish pool.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Marine ranching dike netting gear component assembly method

The invention discloses a marine ranching dike netting gear component assembly method, wherein a double-layer fiber net, a medium-soft connection net and a woven net are used. The marine ranching dike netting gear component assembly method is characterized in that an upper margin line of the woven net and a lower line of the double-layer fiber net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; next, a lower line of the medium-soft connection net and a connecting steel cable on the woven net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; then, an upper line of the medium-soft connection net and a connecting net line on the double-layer fiber net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; after an upper line of the double-layer fiber net, the upper line of the medium-soft connection net, the lower line of the medium-soft connection net, a lower margin line of the woven net and the double-layer fiber net are subjected to anti-dirt treatment, a large-mesh ultra-high molecular weight polyethylene warp knitting net is directly bound, connected and fixed to a marine ranching dike netting gear pile.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Processing method for large netting gear clothes of double-layer structure

ActiveCN103609496BExtended service lifeImprove equipment levelClimate change adaptationPisciculture and aquariaEngineeringUltra-high-molecular-weight polyethylene

A processing method for large netting gear clothes of a double-layer structure is characterized in that a small mesh ultra-high molecular weight polyethylene warp knitting net and a large mesh ultra-high molecular weight polyethylene warp knitting net are processed respectively; a head line is arranged on the upper edge in the length direction of the small mesh ultra-high molecular weight polyethylene warp knitting net which is 492m*11m and goes through anti-dirty treatment, and a foot line is arranged on the lower edge; a head line is arranged on the upper edge of the large mesh ultra-high molecular weight polyethylene warp knitting net which is 492m*11m and goes through anti-dirty treatment, and a foot line is arranged on the lower edge; the head line of the small mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment and the head line of the large mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment are bound into a head line of the large netting gear clothes of the double-layer structure; the foot line of the small mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment and the foot line of the large mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment are bound into a foot line of the large netting gear clothes of the double-layer structure.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Novel efficient oil smoke purification device

PendingCN114811688AGuaranteed purification effectReduce labor intensityDomestic stoves or rangesLighting and heating apparatusElectric machineryScreen filter

The invention provides a novel efficient oil fume purification device, relates to the technical field of oil fume purification devices, and solves the problem that it is troublesome to detach a filter screen for cleaning, the novel efficient oil fume purification device comprises a shell, the top of the shell is communicated with an exhaust pipe, the exhaust pipe is provided with a suction pump, the lower end of the shell is provided with a main air inlet pipeline, and a partition plate is arranged in the main air inlet pipeline; a partition plate is arranged in the main air inlet pipeline and divides the main air inlet pipeline into a first air inlet pipe and a second air inlet pipe, filter screens are arranged in the first air inlet pipe and the second air inlet pipe, an opening located below the filter screens is formed in the partition plate, the upper end of the opening is rotationally connected with a rotating shaft, and the rotating shaft is fixedly connected with a baffle matched with the inner wall of a pipeline of the first air inlet pipe and the inner wall of a pipeline of the second air inlet pipe. The rotating shaft is connected with a self-locking motor, the self-locking motor is connected with a processor, and a cleaning assembly used for flushing the filter screen is arranged above the partition plate. A structure capable of cleaning the filter screen is arranged in the oil smoke purification device, so that automatic cleaning can be realized without dismounting the filter screen.

Owner:四川佰利华厨具设备工程有限公司

A rock compression-shear test device in the process of dry-wet cycle

ActiveCN105181483BSimple structureEasy to operateMaterial strength using steady shearing forcesCyclic processEngineering

The invention belongs to the field of geotechnical engineering, and in particular relates to a compression-shear testing apparatus for a rock in a dry-wet cyclic process. The apparatus comprises an angle-variable compression-shear unit, and a compression machine for vertically applying load onto the angle-variable compression-shear unit; the apparatus also comprises a reservoir, water injection equipment for carrying out moisture saturation treatment on a rock sample in the angle-variable compression-shear unit, and heating equipment for carrying out hot-gas drying treatment on the rock sample in the angle-variable compression-shear unit. The angle-variable compression-shear unit is located in the reservoir, and the reservoir is communicated with the water injection equipment and the heating equipment. By adopting the compression-shear testing apparatus, the integration of rock sample dry-wet cyclic treatment and a shear test is realized, and the apparatus has the advantages of simple structure, convenient operation, low cost, wide application range and long service life; the rock samples in different states after different dry-wet cyclic times can be accurately simulated, shear test research is carried out on the rock samples, and moreover, failure load and displacement of the rock samples in the vertical direction in the shear test process can be recorded in real time.

Owner:ANHUI INST OF BUILDING RES & DESIGN

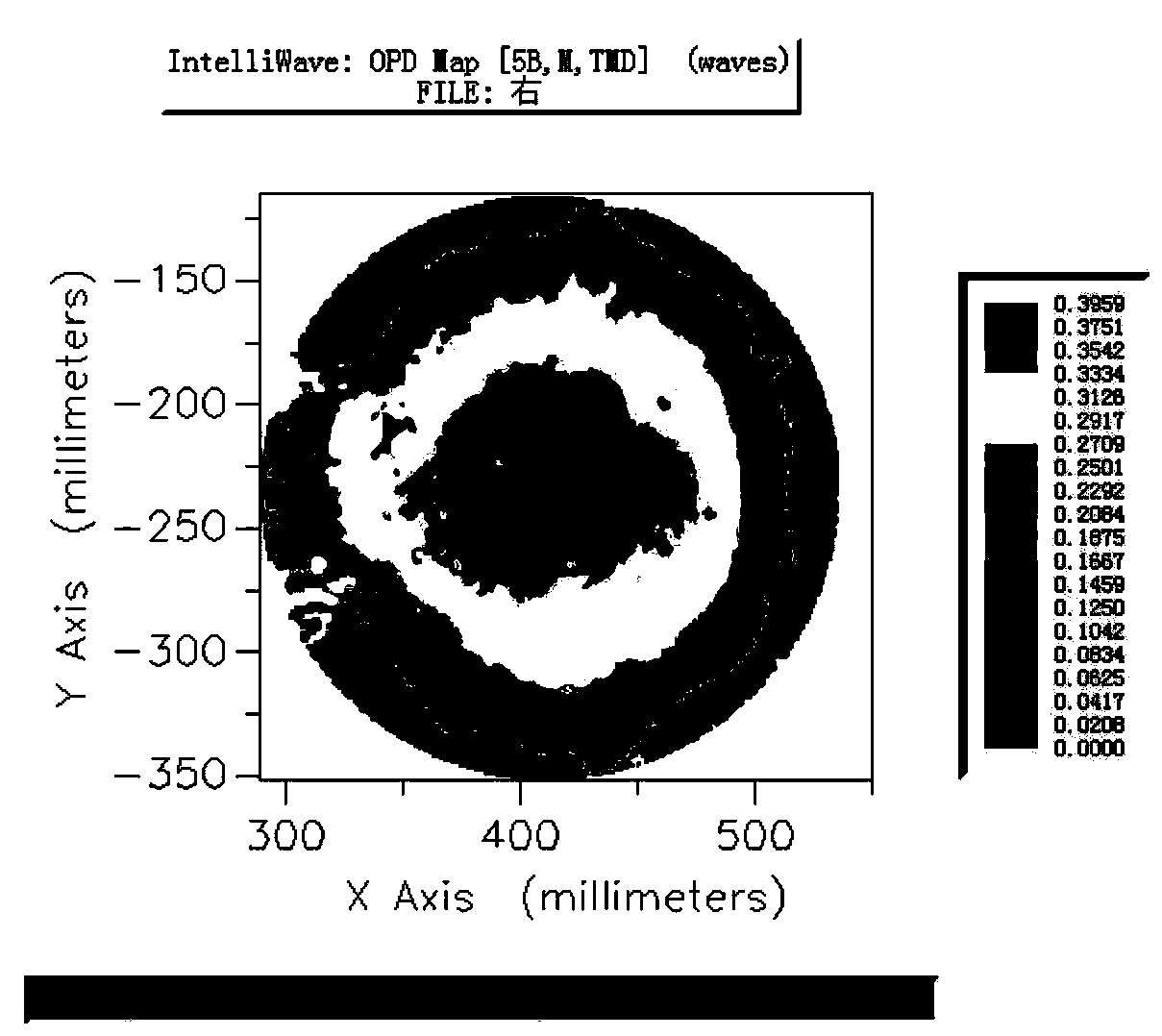

A chemical polishing method for germanium flat mirrors using electric field effect to enhance the pH of the processing area

ActiveCN110328607BAvoid scratchesAvoid direct contact wearLapping machinesAqueous dispersionsSilver pasteOxygen ions

The invention discloses a germanium plane mirror chemical polishing method by using an electric field effect to improve acidity and basicity of a processing area. The germanium plane mirror chemical polishing method comprises the following steps of manufacturing a high dielectric constant vacuum sucker and a high dielectric constant polishing disc; coating high-temperature silver pastes on the nonworking end surfaces of the polishing disc and a base disc, connecting electrodes, and carrying out insulating treatment; and vacuumizing a germanium plane mirror on the porous ceramic base disc, andpolishing with a chemical polishing solution. The polishing principle of the method is that the high dielectric constant ceramic polishing disc is used, after the polishing disc and the vacuum adsorption ceramic base disc are connected with electrodes, a strong electric field is generated in a polishing area, and hydrogen ions or hydrogen oxygen ions move to the workpiece surface, so that the surface acidity and alkalinity of a workpiece are improved, the corrosiveness of the polishing solution to the workpiece surface is improved, and under the shear action of hydraulic pressure fluid, the surface of the workpiece is subjected to chemical non-contact polishing. According to the germanium plane mirror chemical polishing method by using the electric field effect to improve acidity and basicity of the processing area, the pH value of the workpiece surface can be controlled by the electric field, and through chemical non-contact polishing, the quality of the workpiece surface is improved, and the surface wear is avoided.

Owner:嘉兴知酷客信息科技有限公司

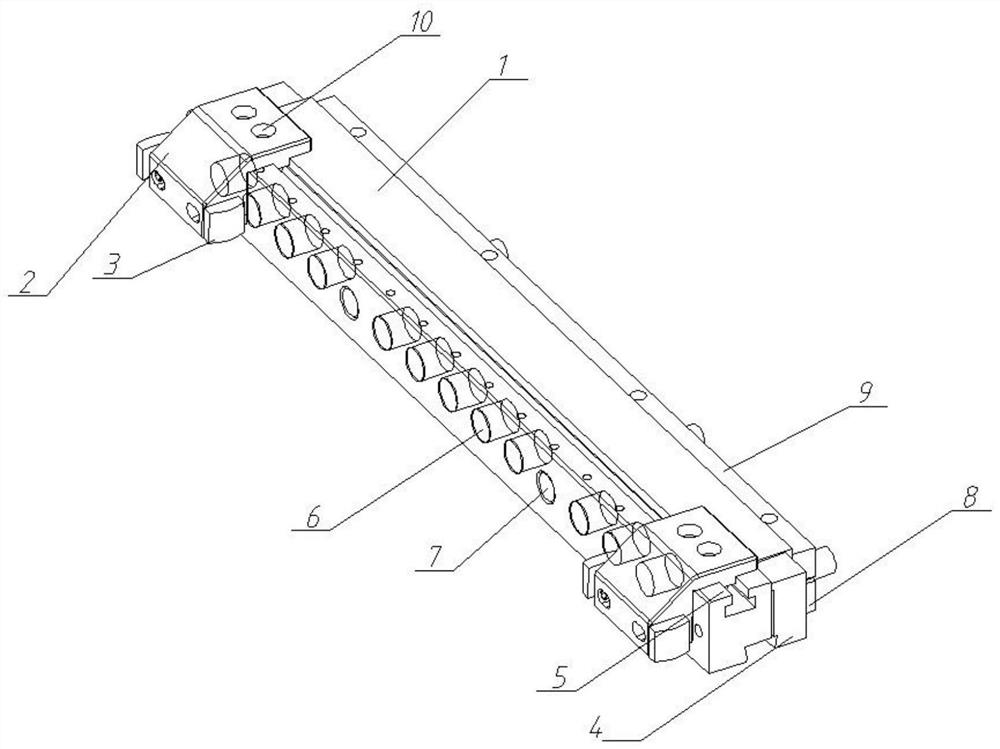

A feeding and positioning device for a laser tailor welding line

InactiveCN108857053BExtend your lifeGuaranteed elastic functionLaser beam welding apparatusWeld lineLaser soldering

Owner:长春宝友解放钢材加工配送有限公司

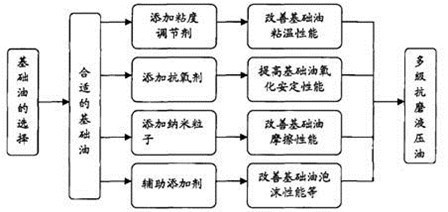

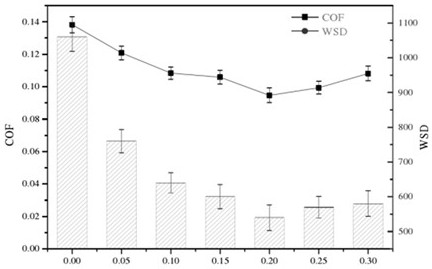

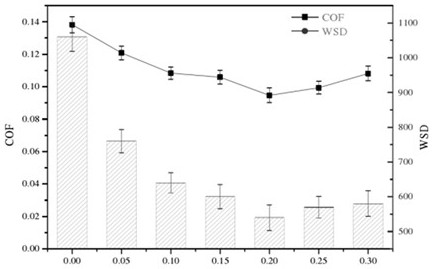

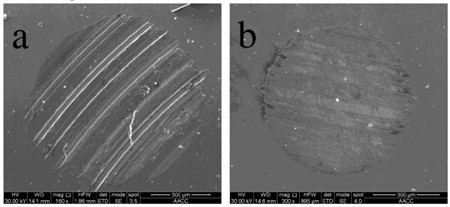

A kind of preparation method of anti-wear hydraulic oil

ActiveCN113355149BLow toxicityImprove the lubrication effectLubricant compositionThermodynamicsNanoparticle

Owner:江苏万标检测有限公司

Preparation method of anti-wear hydraulic oil

ActiveCN113355149ALow toxicityImprove the lubrication effectLubricant compositionNanoparticlePhysical chemistry

The invention discloses a preparation method of anti-wear hydraulic oil, wherein the preparation method comprises the following steps: (1) evaluating the comprehensive performance of various base oils, and selecting the base oil with high comprehensive performance and reasonable price; (2) measuring the oil-water separation property, the foam characteristic, the condensation point and the anti-rust property in the presence of water of the base oil; (3) modifying the base oil; (4) friction performance test: on a four-ball machine, testing the influence of nanoparticles and an extreme pressure anti-wear agent on the friction performance of the hydrogenated base oil, analyzing the microscopic surface morphology of wear scars and the types, valence states and contents of the surface elements of the wear scars by adopting an optical contourgraph and a photoelectron spectrometer, researching the friction mechanism of a lubricating additive, and finding out a proper proportioning scheme; and (5) developing the multi-stage anti-wear hydraulic oil. The comprehensive performance of the hydraulic oil is improved by compounding a plurality of functional additives and a small amount of auxiliary additives through an optimal proportioning scheme of a single-factor additive.

Owner:江苏万标检测有限公司

Soft connecting method for coasts and large-scale aquaculture netting

ActiveCN103598128AImprove securityExtended service lifeClimate change adaptationSeaming textilesReinforced concreteEngineering

The invention relates to a soft connecting method for coasts and large-scale aquaculture netting. The method is characterized by including: the antifouling ultra-high molecular weight polyethylene netting is made through warp knitting; a reinforced concrete pile is disposed on each of the left coast and the right coast; a standing reinforced concrete pile is disposed at the joint of each coast and the netting, and a vertical lacing line for hanging the netting is disposed on each standing reinforced concrete pile; one end of each of a left coast soft connecting netting horizontal lacing line and a right coast soft connecting netting horizontal lacing line is connected with the corresponding reinforced concrete pile, the other end each of a left coast soft connecting netting horizontal lacing line and a right coast soft connecting netting horizontal lacing line is fixedly tied to the corresponding standing reinforced concrete pile, and each of a left coast soft connecting netting vertical lacing line and a right coast soft connecting netting vertical lacing line is fixedly tied to the corresponding vertical lacing line, for hanging the netting, of the corresponding standing reinforced concrete pile; the left coast soft connecting netting and the right coast soft connecting netting are connected between the reinforced concrete piles; a reinforced concrete weir is poured between the standing reinforced concrete piles, and net hanging horizontal lacing lines are disposed on the surface of the weir; the edge lacing lines of the netting are fixedly tied to the vertical lacing lines, for hanging the netting, of the standing reinforced concrete piles, the lower lacing lines of the netting are fixedly tied to the net hanging horizontal lacing lines, and the floater lacing lines of the netting are fixedly tied to the standing reinforced concrete piles.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

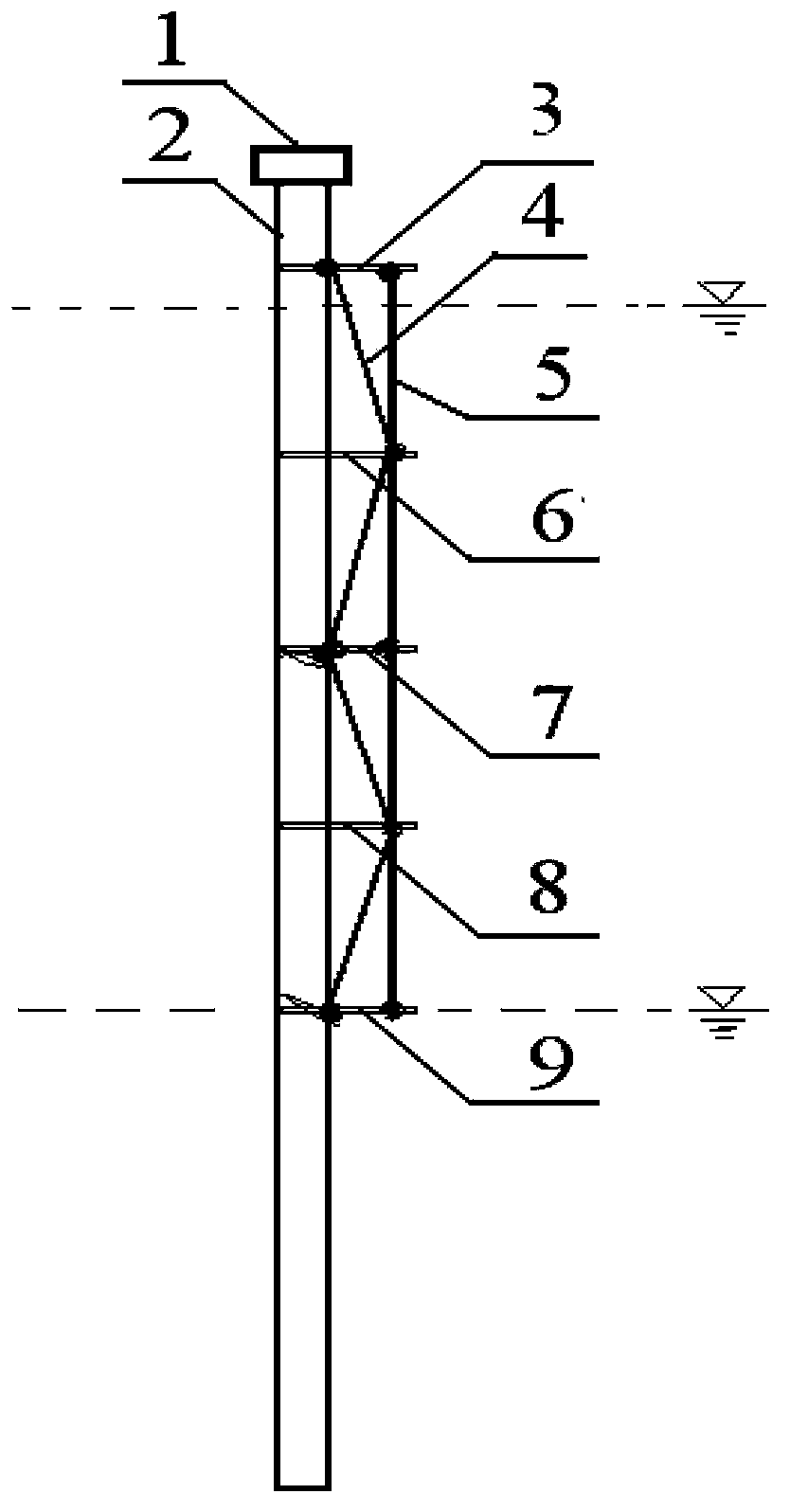

Upright pile for surrounding cultivation net

InactiveCN103430878BIncrease wind and current performanceImprove performanceClimate change adaptationPisciculture and aquariaReinforced concrete columnPolyvinyl chloride

The invention relates to an upright pile for surrounding a cultivation net. The upright pile utilizes a reinforced concrete upright column and is characterized by utilizing a combined structure consisting of a reinforced concrete upright pier, the reinforced concrete upright column, upright pile arm frames, an upright pile pulling rope and an upright pile hanging net force headrope; as to the reinforced concrete upright column, the outer diameter is 50cm, the length is 21m and the wall thickness is 10cm; anti-fouling paint for ships is painted on the outer surface of the reinforced concrete column, and an upright pier is arranged at the upper end of the reinforced concrete upright column; cylindrical nylon rods are utilized as the upright pile arm frames; a high-strength polyethylene monofilament rope passes through a PVC (polyvinyl chloride) coating canvas pipe to form the upright pile hanging net force headrope; the upright pile hanging net force headrope and the upright pile arm frames are fixed; the upright pile arm frames are arranged at intervals of 2.5m from a 2.5m-position from the top end of the reinforced concrete upright column; an ultra-high-strength rope is taken as the upright pile pulling rope for connecting the reinforced concrete upright column, the upright pile hanging net force headrope and the upright pile arm frames, all connection parts are bound sequentially, and the upright pile for surrounding the cultivation net is obtained.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Soft connecting method for coasts and large-scale aquaculture netting

ActiveCN103598128BImprove securityExtended service lifeClimate change adaptationSeaming textilesReinforced concreteRebar

The invention relates to a soft connecting method for coasts and large-scale aquaculture netting. The method is characterized by including: the antifouling ultra-high molecular weight polyethylene netting is made through warp knitting; a reinforced concrete pile is disposed on each of the left coast and the right coast; a standing reinforced concrete pile is disposed at the joint of each coast and the netting, and a vertical lacing line for hanging the netting is disposed on each standing reinforced concrete pile; one end of each of a left coast soft connecting netting horizontal lacing line and a right coast soft connecting netting horizontal lacing line is connected with the corresponding reinforced concrete pile, the other end each of a left coast soft connecting netting horizontal lacing line and a right coast soft connecting netting horizontal lacing line is fixedly tied to the corresponding standing reinforced concrete pile, and each of a left coast soft connecting netting vertical lacing line and a right coast soft connecting netting vertical lacing line is fixedly tied to the corresponding vertical lacing line, for hanging the netting, of the corresponding standing reinforced concrete pile; the left coast soft connecting netting and the right coast soft connecting netting are connected between the reinforced concrete piles; a reinforced concrete weir is poured between the standing reinforced concrete piles, and net hanging horizontal lacing lines are disposed on the surface of the weir; the edge lacing lines of the netting are fixedly tied to the vertical lacing lines, for hanging the netting, of the standing reinforced concrete piles, the lower lacing lines of the netting are fixedly tied to the net hanging horizontal lacing lines, and the floater lacing lines of the netting are fixedly tied to the standing reinforced concrete piles.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

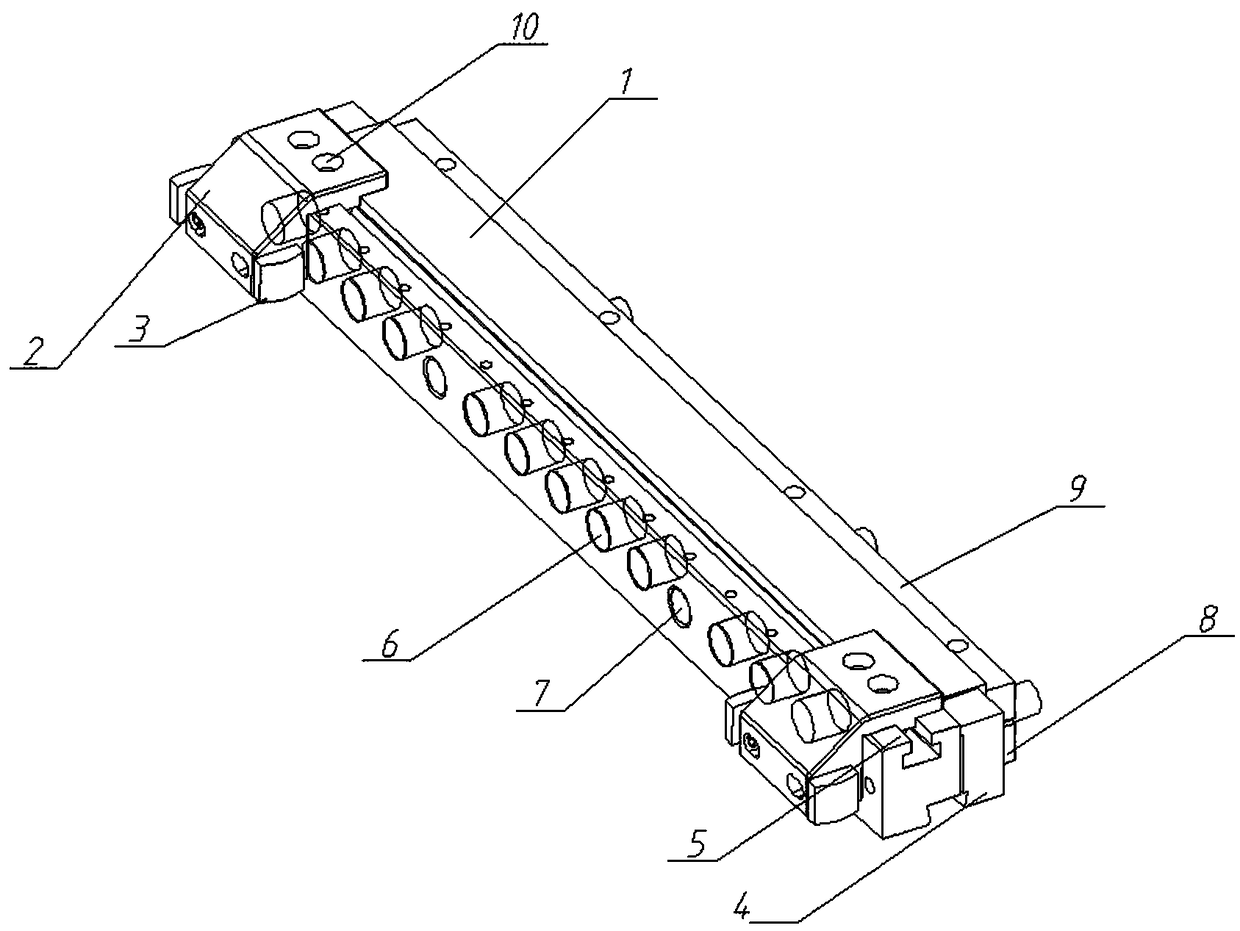

Feeding and positioning device of laser splicing and welding line

InactiveCN108857053AExtend your lifeGuaranteed elastic functionLaser beam welding apparatusContact typeEngineering

The invention relates to the technical field of the laser welding processing and in particular to a feeding and positioning device of a laser splicing and welding line. The feeding and positioning device of the laser splicing and welding line comprises a positioning device body, a positioning base, a positioning sleeve, a pressing block, a positioning base pressing block, a permanent magnet, a sensor, a sensor lower fixing block, a sensor upper fixing block, a bolt, a spring and a jackscrew. A BALLUFU inductive Global-type sensor is selected for replacing an original elastic contact-type sensor, and mechanical collision and contact to the sensor is eliminated, so service life of the sensor is greatly improved. In addition, the spring is used so that the positioning sleeve can be guaranteedto have an elastic function, and to adapt an accident error of a welding joint length of a plate material, so an occurrence rate of misalignment defective products is reduced. Through increasing thenumber of magnets, reliability of a top support of a welding joint is enhanced. Through a design that a magnetic face is lower than a top support face, direct contact and wear of the magnets and the welding joint is avoided, so the magnets do not need to be replaced, and the welding joint does not adsorb chips of the magnets, so a phenomenon that quality of the welding joint is affected because the positioning device collides with the chips is eliminated.

Owner:长春宝友解放钢材加工配送有限公司

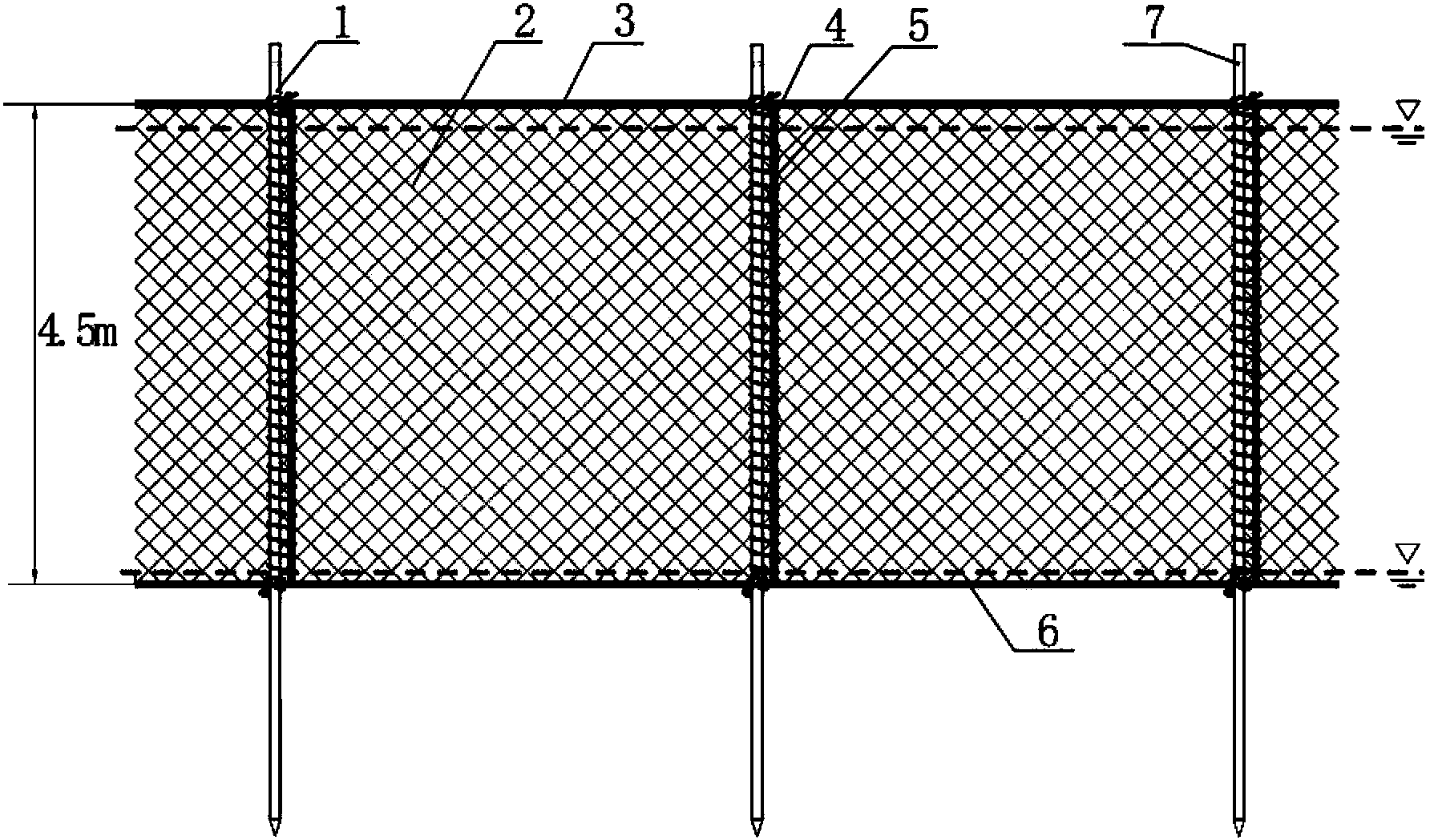

Connection method for seashore and netting gear net

ActiveCN103609494BExtended service lifeImprove equipment levelClimate change adaptationPisciculture and aquariaHorizontal forceReinforced concrete

The invention discloses a connection method for seashore and a netting gear net. According to the connection method, the netting gear net and reinforced concrete stand columns are used, wherein a cork line, a lower line, a left margin line and a right margin line are mounted on the netting gear net. The connection method is characterized in that a net hanging vertical force line is mounted on each reinforced concrete stand column; the vertical force lines are located on the side far away from the seashore; reinforced concrete dikes are formed by pouring reinforced concrete between the seashore and the reinforced concrete stand columns so that the seashore, the reinforced concrete dikes and the reinforced concrete stand columns can form a closely-connected whole; reinforced concrete horizontal net mounting surfaces are formed in a pouring mode between the reinforced concrete dikes, wherein the reinforced concrete horizontal net mounting surfaces are 4.5m away from the water surface; an ultra-high molecular weight polyethylene stranded rope is mounted on each reinforced concrete horizontal net mounting surface to serve as a net hanging horizontal force line; the margin lines of the netting gear net are fixedly connected with the net hanging vertical force lines on the reinforced concrete stand columns in a binding mod; the lower line of the netting gear net is fixedly connected with the net hanging horizontal force lines in a binding mode; the end portion of the cork line of the netting gear net is fixedly connected with the reinforced concrete stand columns in a binding mode.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method of fitting large fishing tackle net between two shores

ActiveCN103598127BReduce stressPrevent fish escape from the bottomDamsClimate change adaptationReinforced concrete columnEngineering

A method of fitting large fishing tackle net between two shores is characterized in that a reinforced concrete column is driven to 2.5m of the sea bed at an intersection of large fishing tackle net and each of left and right shores, a reinforced concrete dyke is cast between the reinforced concrete column and each of the left and right shores, a reinforced concrete horizontal net weir is cast between the two reinforced concrete dykes, a hanger horizontal lacing line is fixed on the top of the reinforced concrete horizontal net weir, a left side line of the large fishing tackle net is fixedly tied and connected to a hanger vertical lacing line on the left reinforced concrete column, a lower line of the large fishing tackle net is fixedly tied and connected to the hanger horizontal lacing line, a right side line of the large fishing tackle is fixedly tied and connected to a hanger vertical lacing line on the right reinforced concrete column, and finally, the ends of float lines of the large fishing tackle net are fixedly tied and connected to the left and right reinforced concrete columns.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Assembly type prefabricated stair hoisting hanger

PendingCN114148887AAvoid missing edges and cornersPrecise positioningSafety gearClassical mechanicsEngineering

The invention relates to an assembly type prefabricated stair hoisting hanger, which consists of an angle steel bracket, a steel wire rope, a basket screw and a hoisting point connecting piece, the angle steel bracket adopts angle steel to be welded into a rectangular structure, the length and the welding size of the angle steel are determined according to the lifting point position of the prefabricated stair, and four corners of the angle steel bracket are drilled; the upper end of the steel wire rope is connected with the lifting hook, and the lower end of the steel wire rope penetrates through a hole in the angle steel support and then is connected with the upper end of the turnbuckle, and the lower end of the turnbuckle is connected with the lifting point connecting piece through the steel wire rope. The turn buckle screw is composed of round steel, steel sleeves and a screw, the two ends of the round steel are welded to the two steel sleeves, the welding interval angle of the round steel is 120 degrees, the screw penetrates through the steel sleeves at the two ends, one end of the screw is welded to a round hanging ring, the hanging rings at the two ends of the turn buckle screw are connected with the steel wire rope, and the screw penetrating through the steel sleeves at the two ends is turned in a positive and negative mode. The hanging bracket can ensure that the prefabricated staircase can be accurately positioned and quickly mounted in the hoisting process, and mounting deflection and deviation are avoided.

Owner:SINOHYDRO BUREAU 7 CO LTD

A detachable material guide mechanism for a belt conveyor

ActiveCN110759036BAvoid direct contact wearReduce use costRollersClassical mechanicsStructural engineering

The invention discloses a detachable material guide mechanism for a belt conveyor, comprising two support bases, the two support bases are arranged opposite to each other, and a guide roller mechanism is installed in the middle of the two support bases, The two ends of the installation guide roller mechanism are respectively fixed to the two supporting bases. This belt conveyor uses a detachable material guide mechanism, which is different from the prior art. The method is detachable, so that the wear-resistant plate of the material guide groove can be disassembled and replaced after long-term use and wear, so as to effectively save the use cost of the equipment and ensure normal and efficient material guide. At the same time, through the set elastic structure , can effectively avoid direct contact wear of the wear-resistant plate, and cooperate with the lifting mechanism, so that the wear-resistant plate can be raised when the material guide is not needed, further avoiding scratching and wear, so as to effectively protect the wear-resistant plate.

Owner:湖南宝烽设备股份有限公司

Compression-resistant fireproof cable

PendingCN114864167AAvoid the spread of open flamesAvoid direct contact wearClimate change adaptationInsulated cablesIgnition pointOpen fire

A pressure-resistant fireproof cable disclosed by the present invention comprises a cable body and a cable core arranged in the cable body, the outer wall of the cable core is provided with a cable core protection layer, and a protection sheet is used for performing pressure-resistant protection on the cable body. The matching connection between the splicing clamping block and the splicing clamping groove is used for reinforcing the connection between the protection sheet and the cable body. According to the compression-resistant fireproof cable, firstly, anti-impact protection can be carried out on the exterior of the cable body by using the protection sheet, and anti-impact protection can be carried out on the interior of the cable by using the characteristic of elastic metal of the internal heat dissipation metal strips, and secondly, the metal strips and the protection sheet are connected through the heat conduction vertical strips, so that the heat dissipation performance of the cable is improved. Heat can be rapidly dissipated in a heat conduction mode, meanwhile, the characteristic that the memory alloy of the metal strip can recover to the original shape at high temperature can be utilized, when open fire occurs in the cable, the high temperature of the open fire is utilized to promote the metal strip to rapidly recover to the original shape and wrap an ignition point, and spread of the open fire is effectively avoided.

Owner:张莉

A vibration damping device for a diaphragm coupling and a vibration damping method thereof

ActiveCN112324813BIncreased resonance bandwidthReduce damage rateYielding couplingNon-rotating vibration suppressionCouplingClassical mechanics

A vibration damping device for a diaphragm coupling, comprising an intermediate shaft, the intermediate shaft is a sleeve-shaped structure with a large diameter at both ends and a small diameter in the middle, and the two ends are respectively connected with an intermediate flange and an outer flange, The intermediate flange and the intermediate shaft are connected by a plurality of bolts III, and a plurality of dynamic vibration absorbing members are evenly distributed along the circumferential direction in the large diameter hole of the intermediate shaft. A plurality of groups of diaphragms are arranged in the outer flange, and the diaphragm groups are connected with the intermediate flange and the outer flange through several bolts I. The diaphragm group consists of a plurality of diaphragms and a plurality of damping elements arranged in parallel and installed. The inner hole of the diaphragm group is sleeved with a flange I, the flange I is stepped, and a stopper is installed on the inner side of the diaphragm group. The blue I, the diaphragm group and the block are connected by several bolts II. The placement of the diaphragm group effectively increases the resonance bandwidth. The dynamic vibration absorption device coexists with axial vibration absorption and radial vibration absorption. Power transmission and structural strength.

Owner:JIANGSU UNIV OF SCI & TECH

Anti-attachment sea cucumber pool fence

InactiveCN103430873BImproved anti-adhesion functionSolve the problem of anti-adhesionClimate change adaptationPisciculture and aquariaPolypropyleneUltimate tensile strength

The invention discloses an anti-attachment sea cucumber pool fence, which comprises bamboo poles, plastic-coated waterproof canvas, a rhombic copper alloy mesh, strong-strength polyethylene monofilaments, ultra-high molecular weight polyethylene mesh wires and eight-strand polypropylene ropes. The anti-attachment sea cucumber pool fence is characterized in that grooves are dug in the periphery of a sea cucumber pool; plastic-coated waterproof canvas sleeves are manufactured and sleeved outside the bamboo poles; the bamboo poles sleeved with the canvas are uniformly arranged in the grooves in the periphery of the sea cucumber pool; the rhombic copper alloy mesh has a mesh side length of 1cm, a wire diameter of 1mm and a height of 4m; perpendicular lacing lines are arranged at an interval of 3m in the length direction of the rhombic copper alloy mesh, and the two mesh ends of the rhombic copper alloy mesh are connected into a ring; upper and lower horizontal steel cables are arranged on the upper and lower edges of the ring-shaped rhombic copper alloy mesh respectively; the ring-shaped rhombic copper alloy mesh is sequentially and perpendicularly assembled on the bamboo poles sleeved with the canvas on the periphery; the lower horizontal steel cable of the ring-shaped rhombic copper alloy mesh is tightly attached to the bottoms of the grooves; waste meshes are filled in the grooves in the periphery, and sandy soil is filled and compacted in the grooves; the eight-strand polypropylene ropes are tied to the top ends of the bamboo poles sleeved with the canvas, and the other ends of the eight-strand polypropylene ropes are fixedly tied to timber piles.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com