Assembly type prefabricated stair hoisting hanger

A prefabricated and stair technology, used in safety devices, transportation and packaging, load hanging components, etc., can solve problems such as the impact of on-time inspection and acceptance of sub-projects, substandard installation of prefabricated stairs, and misalignment of ladder plate installation. Improve the installation efficiency and installation quality, the adjustment method is convenient and fast, and avoid the effect of missing edges and corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

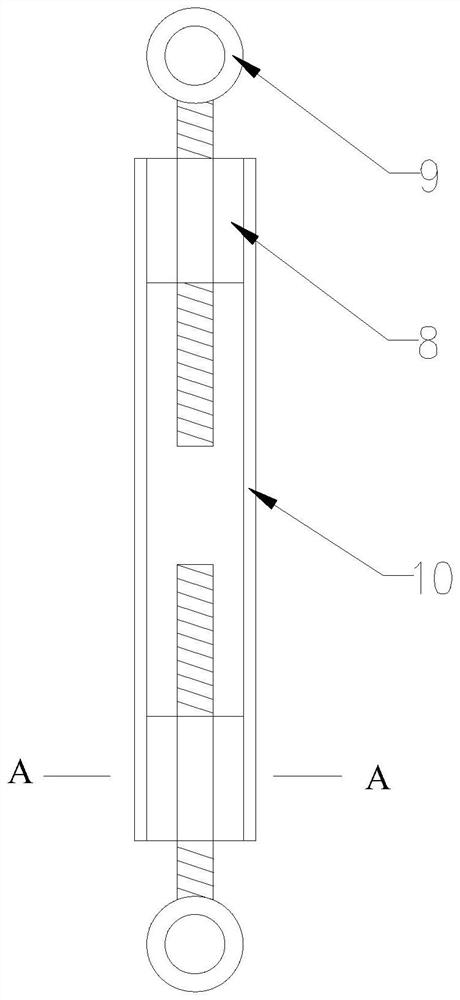

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, see Figure 1-Figure 5 , The present invention provides a prefabricated prefabricated staircase hoisting hanger, the hanger is composed of an angle steel bracket 2, a steel wire rope 11, a turnbuckle screw 3, and a hanging point connector 5. The angle steel bracket 2 adopts 4 ∠75*75*5 angle steel welded into a rectangular structure. The length and welding size of the angle steel are determined according to the position of the lifting point of the prefabricated staircase 4. Drill holes in the four corners of the angle steel bracket 2 with a diameter of 30mm, and install rubber in the holes. Gasket 12. Rubber washer 12 can adopt outer diameter 30mm, internal diameter 20mm, the rubber spacer of height 50cm, rubber spacer is installed on the four corners of angle steel support 12, and steel rope 11 passes in rubber washer 12 and it is protected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com