Concrete floor lower-plate hanging-template template system capable of high-quality demoulding and supporting and disassembling method of concrete floor lower-plate hanging-template template system

A formwork system and concrete technology, applied in formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve problems such as missing edges and corners of lowering boards, difficult control of formwork joint nodes, etc., to avoid missing edges Corner drop, small deviation of geometric dimensions, simple production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

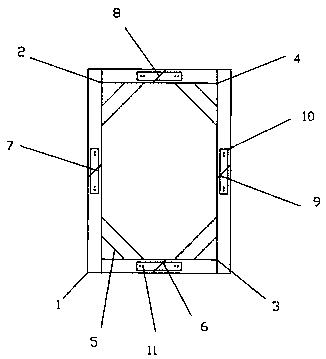

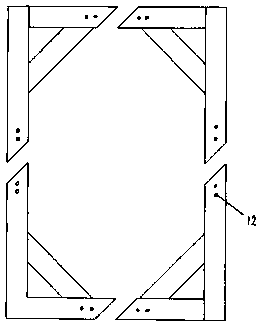

[0019] A hanging formwork system for concrete floor lowering slabs with high-quality demoulding, including left front L-shaped square steel formwork 1, left rear L-shaped square steel formwork 2, right front L-shaped square steel formwork 3 and right rear L-shaped square steel formwork 4 , the other two ends outside the central top of the L-shaped square steel formwork are defined as the head and tail respectively, and the left front L-shaped square steel formwork 1, the left rear L-shaped square steel formwork 2, the right front L-shaped square steel formwork 3 and the right rear The L-shaped square steel formwork 4 is spliced end to end to form an overall formwork system in the shape of a "back". The head end and tail end of each L-shaped square steel formwork are processed into wedge-shaped surfaces. The end-to-end splicing of the steel formwork is all joined together in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com