Upright pile for surrounding cultivation net

A technology of upright piles and aquaculture nets, applied in the field of aquaculture nets, can solve problems such as affecting the normal growth and development of aquaculture fish, poor overall wind and wave resistance of the nets, and affecting the cost and benefit of net aquaculture, so as to avoid seawater corrosion. Risk, performance excellence, effect of improved antifouling and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

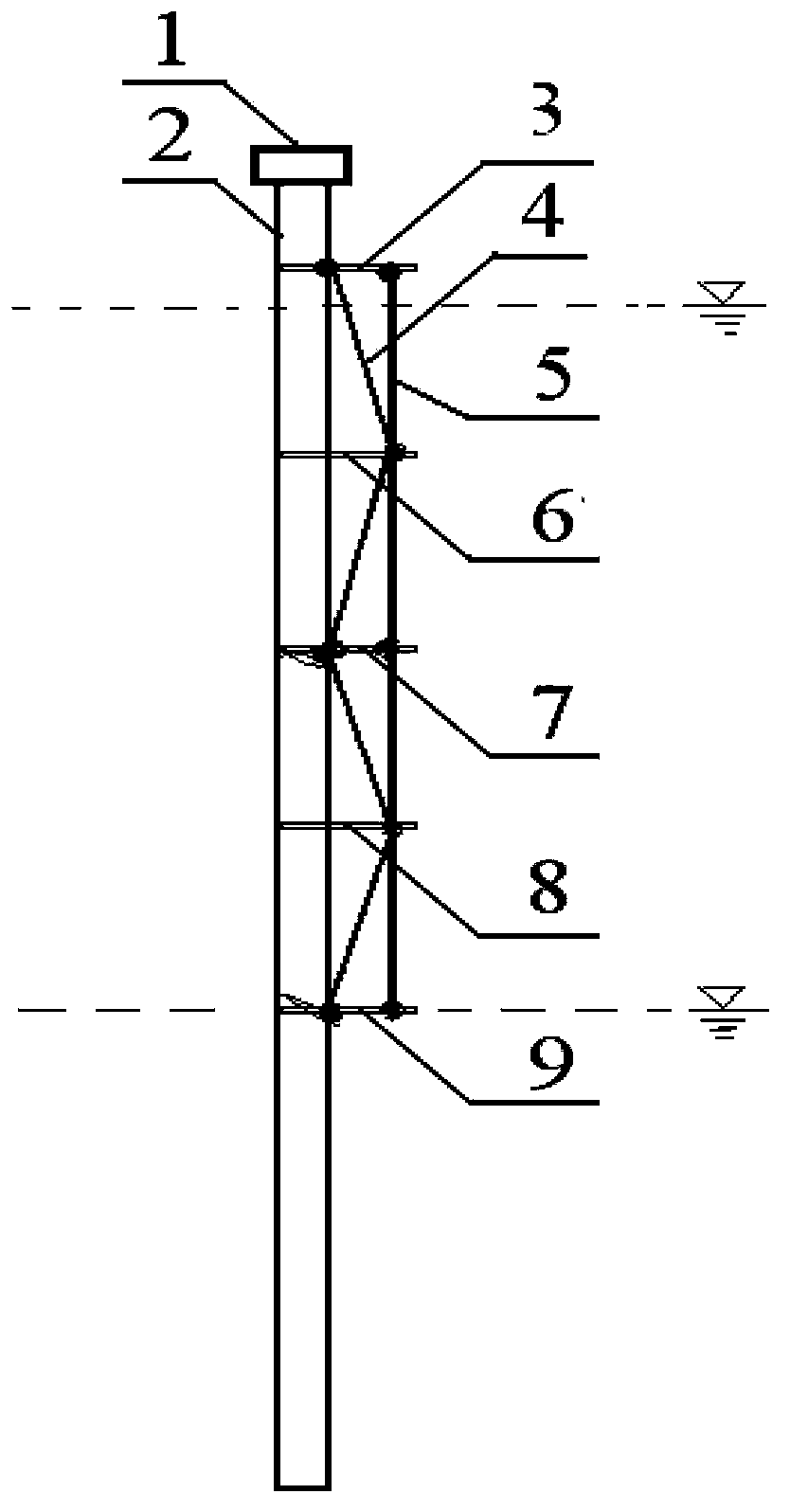

[0008] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

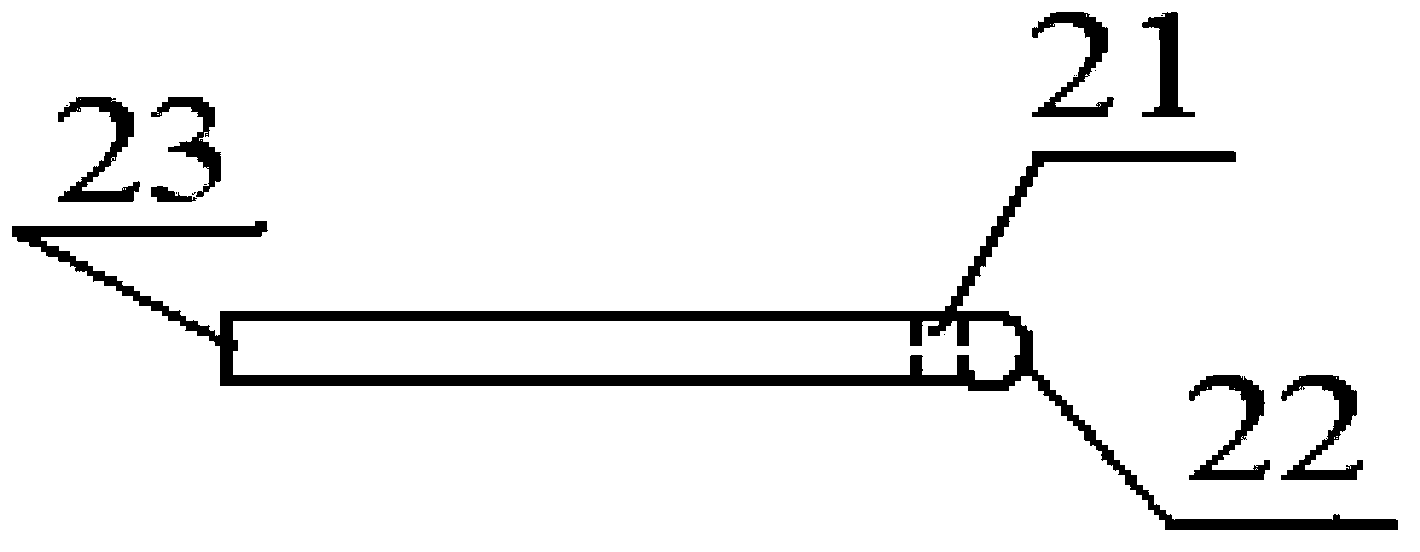

[0009] The invention adopts reinforced concrete column, channel steel, nylon rod, PVC coated canvas, ultra-high-strength rope, marine antifouling paint, high-strength polyethylene monofilament (hereinafter referred to as HSPE monofilament), and the column pile adopts "reinforced concrete column pier + Reinforced concrete column + column pile arm frame + column pile traction rope + column pile hanging grid" combined structure; first use a twisting machine (such as NX30 / 90 large steel twisting machine) to twist 72 wires with a diameter of 0.2mm The HSPE monofilament with a strength of 7.34g / D is processed into a HSPE monofilament rope yarn with a twist of 66 twists / meter, and then 155 HSPE monofilament rope yarns are processed in the same way; ) Processing 52 pieces of HSPE monofilament rope yarn into one HSPE monofilament rope strand according to the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com