A rock compression-shear test device in the process of dry-wet cycle

A test device and dry-wet cycle technology, applied in the field of geotechnical engineering, can solve the problems of complex test instruments, high cost, and complicated operation, and achieve the effects of improving test accuracy, low cost, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

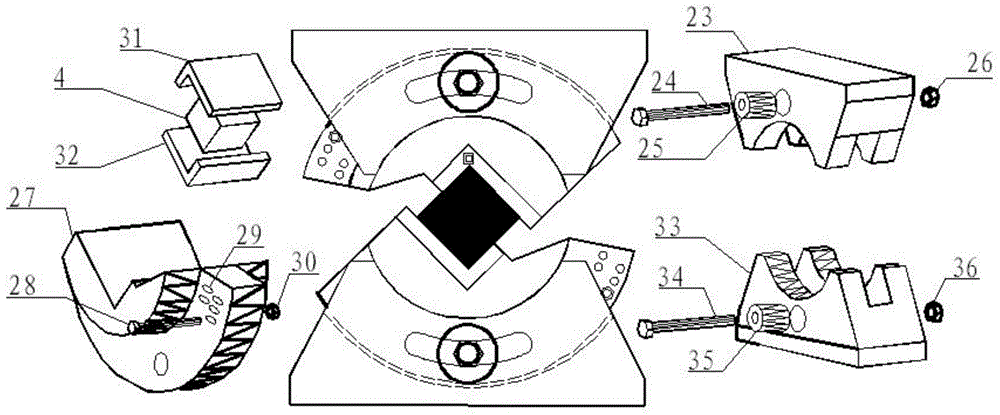

[0035] Combine below figure 1 , 2 The structure and working principle of the present invention are further described:

[0036]A compression-shear test device for rocks in the dry-wet cycle process, including a variable-angle compression-shear unit 5, and a press that applies a load vertically to the variable-angle compression-shear unit 5, the device also includes a liquid reservoir 6, a variable-angle Water injection equipment for water-saturated treatment of the rock sample 4 in the compression-shear unit 5, heating equipment for hot gas drying treatment of the rock sample 4 in the variable-angle compression-shear unit 5, the variable-angle compression-shear unit 5 is located in the liquid reservoir 6, The liquid reservoir 6 communicates with water injection equipment and heating equipment. When in use: first, carry out dry-wet circulation treatment on the rock sample 4 in the variable-angle compression-shear unit 5, that is, inject water into the liquid reservoir 6 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com