Adjustable rubber cutter

A rubber cutting machine, adjustable technology, applied in the direction of metal processing, etc., can solve the problems of changing and adjusting the finished rubber cutting, large buffer vibration noise, easy wear of the cutter, etc., to achieve high cutting precision, large transmission ratio, and high cutting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

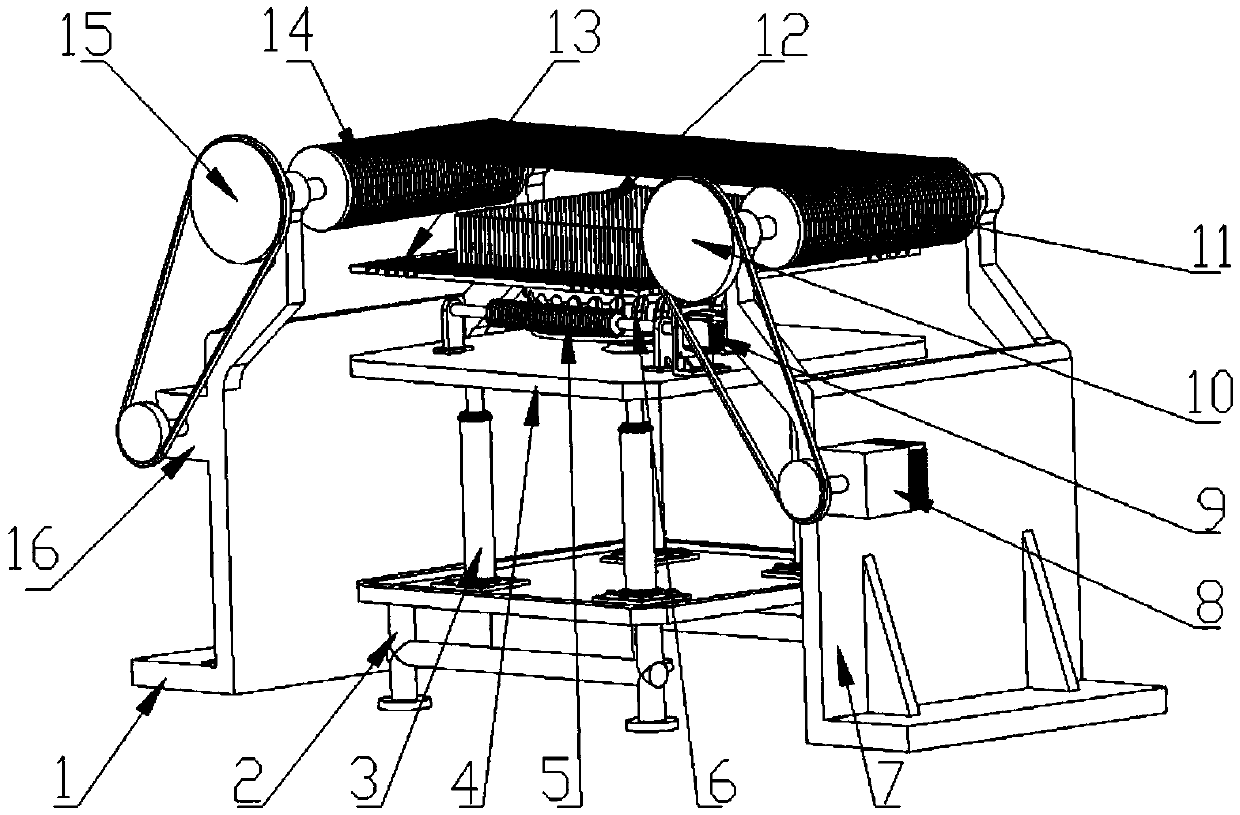

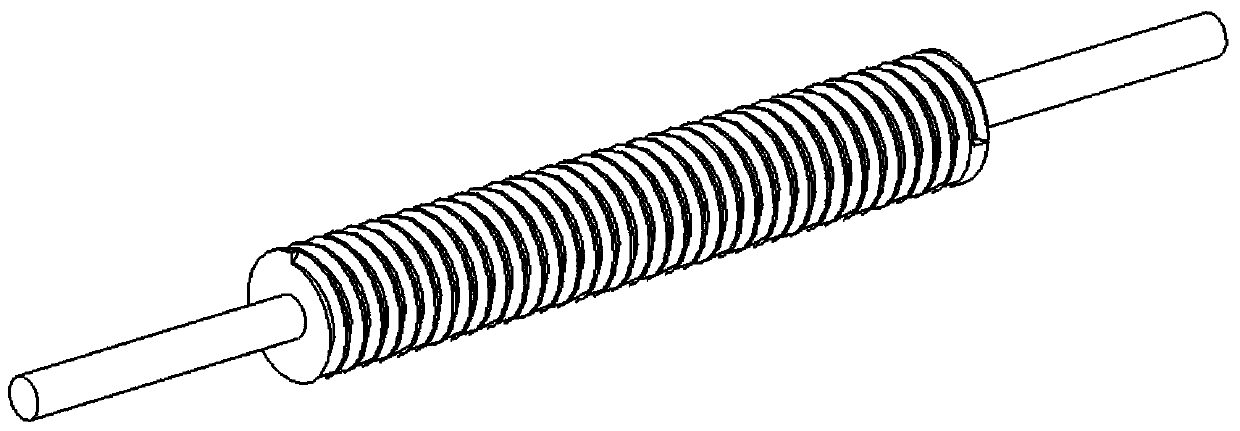

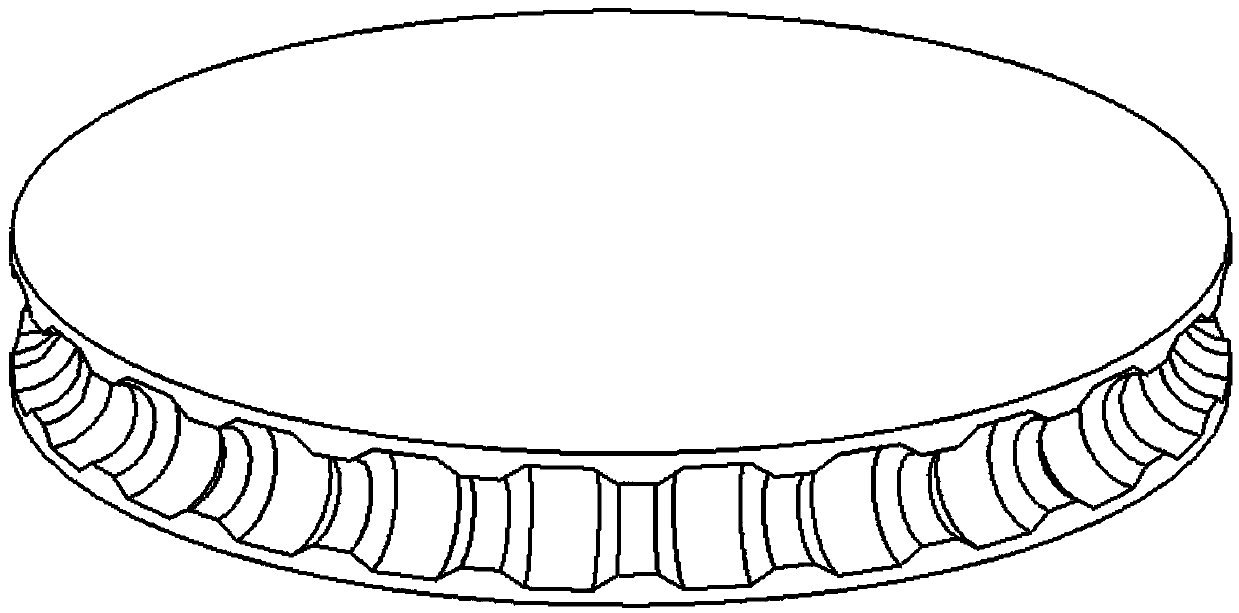

[0019] The present invention provides an adjustable rubber cutting machine for existing deficiencies, such as figure 1 As shown, it includes the first bracket 1 and the second bracket 7 arranged in a symmetrical structure, the transmission device and the control device arranged on the first bracket 1 and the second bracket 7 in a symmetrical structure, and the first bracket 1 and the second bracket 7 between the base 2, the pressing bar device 3, the workbench 4, the worm 5, the worm wheel 6, the rubber cutting mold 12, and the mold adjusting base plate 13; the lower end of the pressing bar device 3 is located on the base 2, and its upper end is fixed on the working The lower surface of the table 4; the worm 5 is connected through two protruding connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com