Linkage braking railway vehicle wheel stopper

A technology for braking rails and wheel stops, which is applied in the direction of brakes interacting between braking elements and rails, railway braking systems, railway car body parts, etc. Insufficient safety factor, staff safety cannot be guaranteed, etc., to achieve the effect of shortening the braking working time, low processing cost, and avoiding direct contact wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

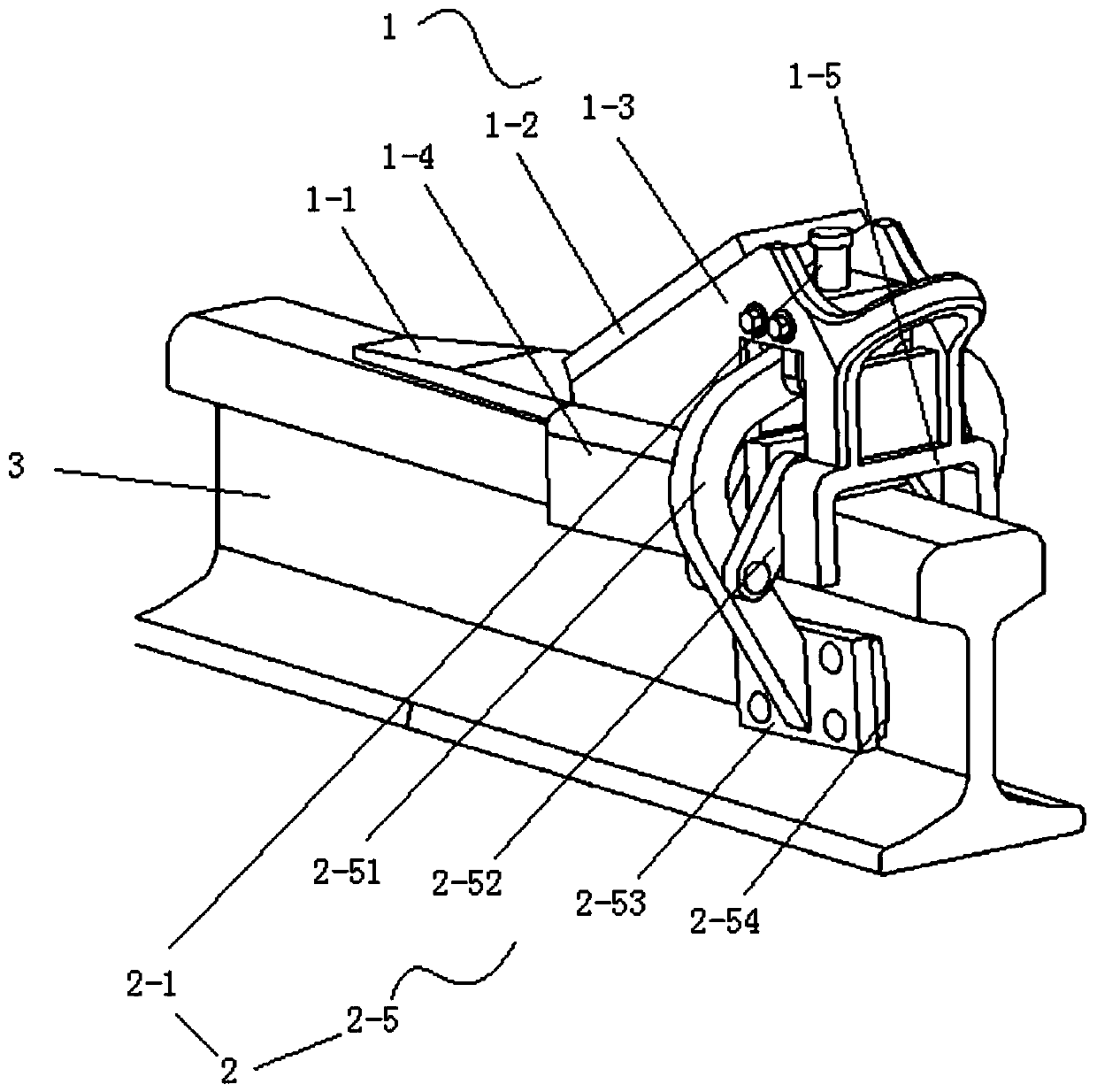

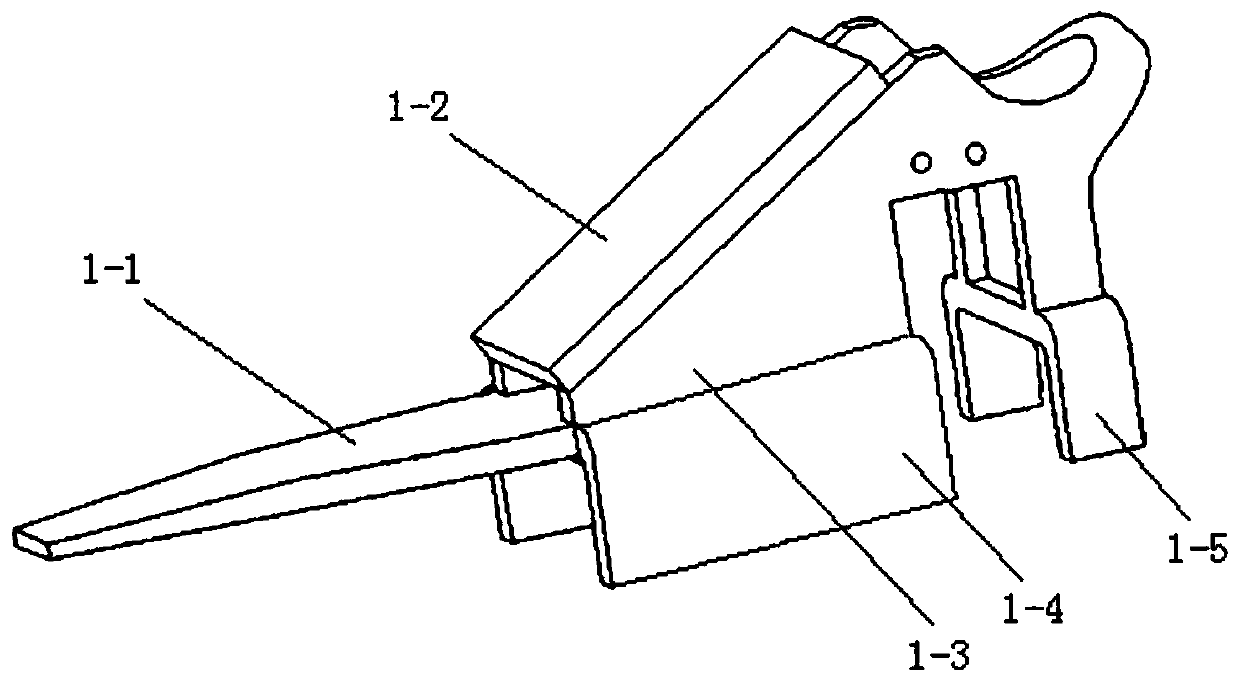

[0025] combine Figure 1-4 , a wheel stopper for a linked brake rail vehicle, comprising a body 1 and a linked brake device 2, the linked brake device 2 is clamped in the body 1, the body 1 is pressed to drive the linked brake device 2 to brake, and the linked brake The device 2 includes a pressure-bearing component 2-0, and the pressure-bearing component 2-0 is linked with a linkage component 2-5; the longitudinal displacement of the pressure-bearing component 2-0 drives the lateral displacement of the linkage component 2-5. When in use, the device is placed on the track 3, the wheels roll and touch and press the device body 1, the body 1 and the upper surface of the track 3 generate friction; the body 1 is pressed to drive the pressure-bearing component 2-0 of the linkage brake device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com