Anti-attachment sea cucumber pool fence

A sea cucumber pond and anti-adhesion technology, which is applied in fish farming, application, climate change adaptation, etc., can solve problems such as discarding and environmental pollution, and achieve the effects of increasing service life, improving economic benefits, and avoiding direct contact wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

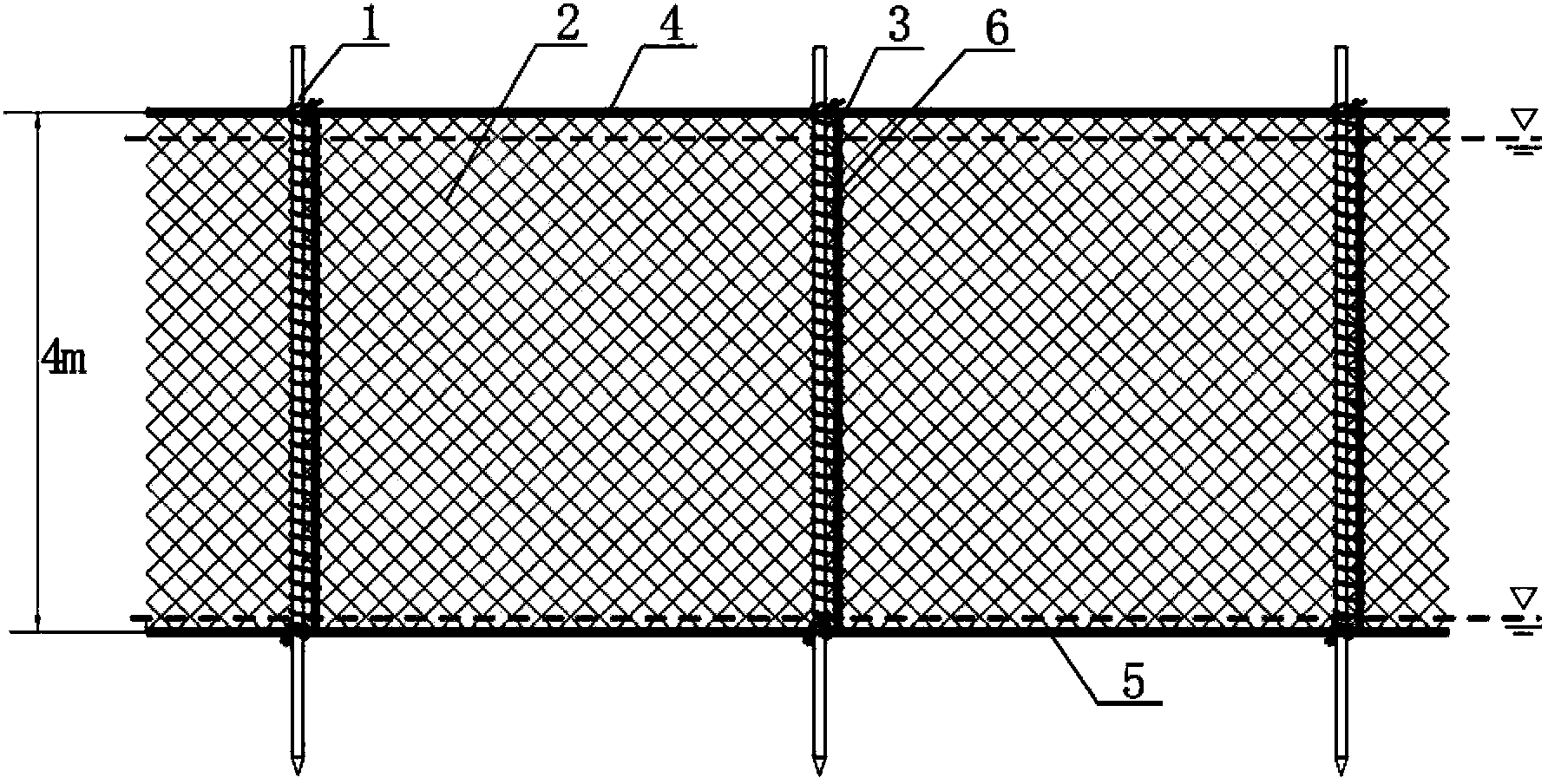

[0008] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

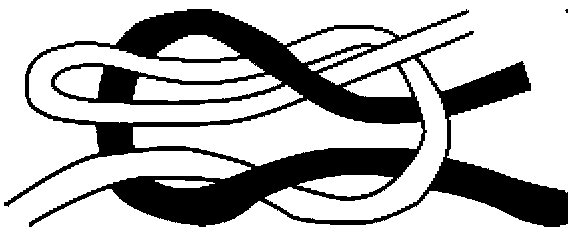

[0009] The technical scheme of the present invention adopts bamboo poles, plastic-coated waterproof canvas, copper alloy orthorhombic mesh, high-strength polyethylene monofilament, ultra-high molecular weight polyethylene mesh wire and eight-strand polypropylene rope, and is characterized in that it is first twisted with NX30 / 90 large steel The thread machine processes 32 high-strength polyethylene monofilaments with a diameter of 0.2mm and a breaking strength of 64.4cN / tex into a high-strength polyethylene monofilament rope yarn with a twist of 88T / m, and then processes 17 high-strength polyethylene monofilament rope yarns in the same way. The high-strength polyethylene monofilament rope yarn; then use the ZG8 strand-making machine to process 6 high-strength polyethylene monofilament rope yarns into 1 high-strength polyethylene monofilament rope strand w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com