Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Avoid clogging failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

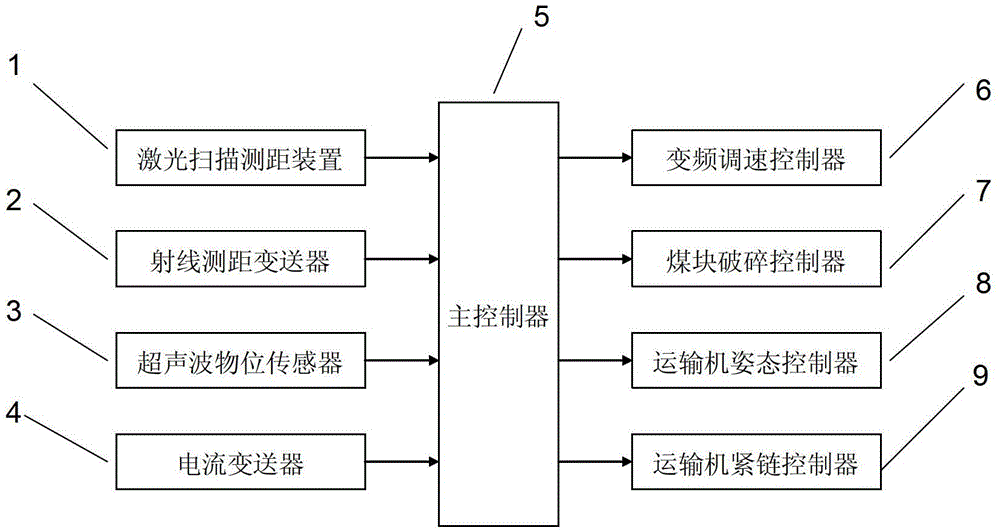

Intelligent control system and control method for scraper conveyer

InactiveCN103144936AAdjust posture in timeAvoid tooth skippingControl devices for conveyorsCurrent transducerAttitude control

The invention provides an intelligent control system and a control method for a scraper conveyer, which belong to the intelligent control systems for coal mine exploitation. The intelligent control system for the scraper conveyer comprises a laser scanning ranging device, a ray ranging transmitter, an ultrasonic level sensor, a current transducer, a master controller, a variable frequency and speed regulation controller, a coal crushing controller, a conveyor gesture controller and a conveyor chain stretching controller, wherein the laser scanning ranging device, the ray ranging transmitter, the ultrasonic level sensor and the current transducer transmit detection signals to the master controller in a wireless communication manner, and the master controller sends control instructions to the variable frequency and speed regulation controller, the coal crushing controller, the conveyor gesture controller and the conveyor chain stretching controller in the wireless communication manner. The running state of the scraper conveyer is mastered at any time and corresponding devices are controlled timely through monitoring of the laser scanning ranging device, the ray ranging transmitter, the ultrasonic level sensor and the current transducer, so that the scraper conveyer can be operated in an optimum running state.

Owner:CHINA UNIV OF MINING & TECH

Air conditioner based on pipeline blocking self-diagnosis method

InactiveCN105588285AAvoid clogging failureAvoid damageMechanical apparatusSpace heating and ventilation safety systemsElectricityData acquisition

The invention discloses an air conditioner based on a pipeline blocking self-diagnosis method. Existing hardware facilities, such as an indoor environment temperature sensor and an indoor coil pipe temperature sensor, of an air conditioner are mainly utilized for collecting, analyzing and processing data by adding control logic. According to the air conditioner, the aims that in the first-time power-on trial run process after installation of the air conditioner, pipeline blocking faults generated by product manufacturing or pipeline blocking faults generated by installation are automatically eliminated in advance, and damage of long-time run with the faults to a compressor and other core valuable components is avoided are mainly achieved. The method has the beneficial effects of being simple, reliable, low in cost and easy to popularize.

Owner:青岛工学院

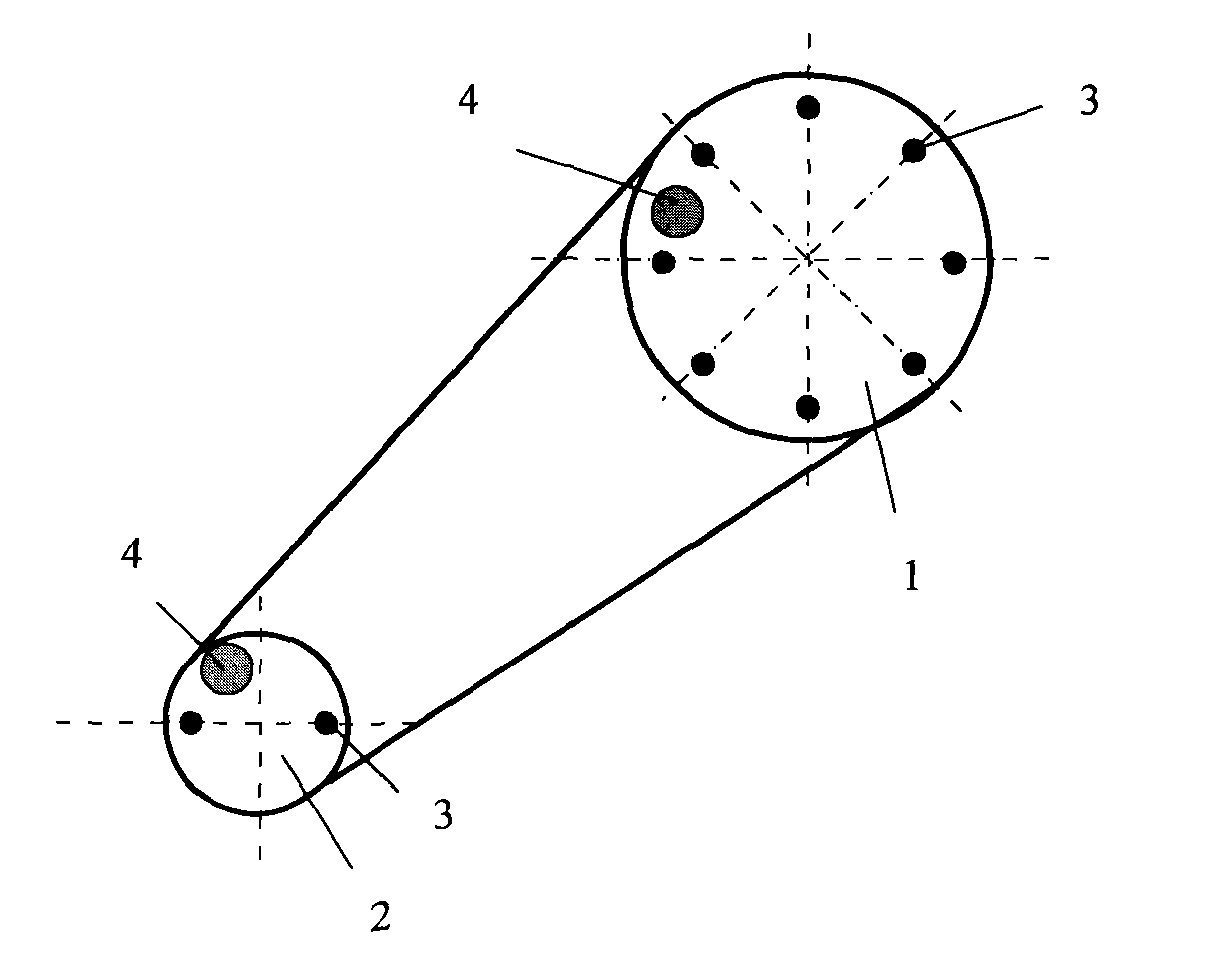

Precaution and alarming method for combined harvester threshing cylinder plugging fault

InactiveCN101595786AAvoid clogging failureImprove the level of intelligenceMowersPower beltEngineering

The invention relates to a precaution and alarming method for preventing a combined harvester threshing cylinder from plugging fault. In the method, two Hall sensors are used, one sensor is arranged on a belt pulley of an output power shaft, and the other sensor is arranged on an input power belt pulley of the threshing cylinder; transient impulse cycles of upper wave of the two wheels are synchronously measured to extract a first order difference, a second order difference, a relative speed ratio, a slip ratio, difference cumulative sum to as plugging fault portent characteristic quantity of transient impulse cycle; priority and weight are endowed on the characteristic quantity according to the contribution in identifying plugging fault; the three decisions of normal operation, plugging precaution and alarming are made on the premise of combining the plugging default portent characteristic standard model bank with judgment rules; sound and light are used for prompting the driver to carry out correct measurement in time. The invention has the advantages of automatically adapting to the forwarding speed and change of feeding quantity of the harvester, thus effectively preventing the combined harvester from plugging default to improve intelligent level and harvesting efficiency of the combined harvester and reduce loss caused by plugging.

Owner:JIANGSU UNIV

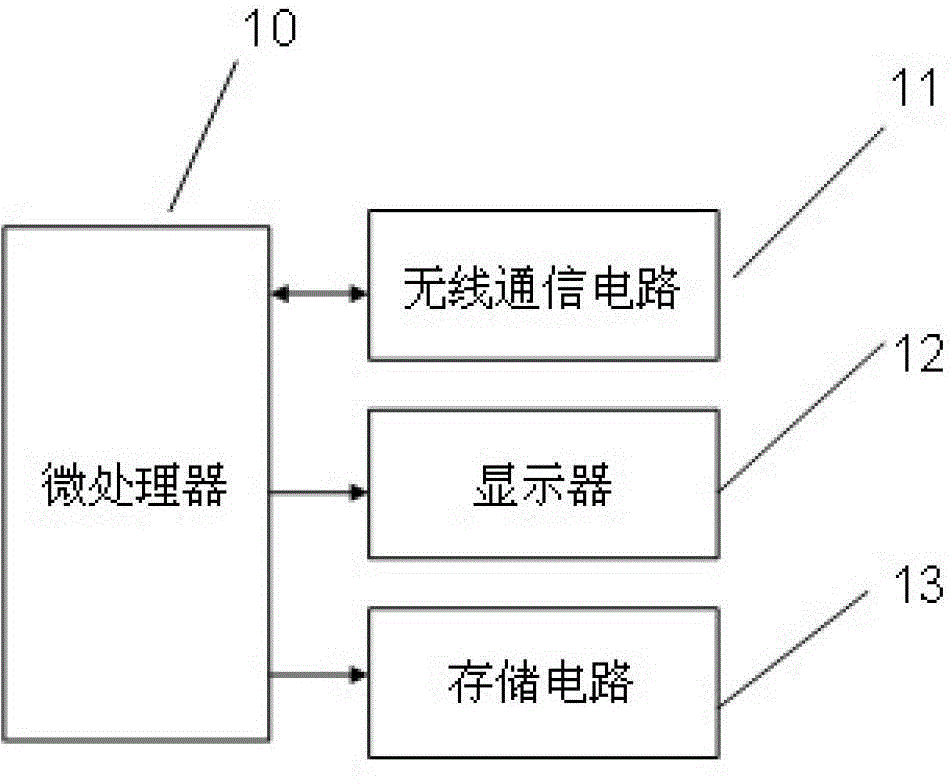

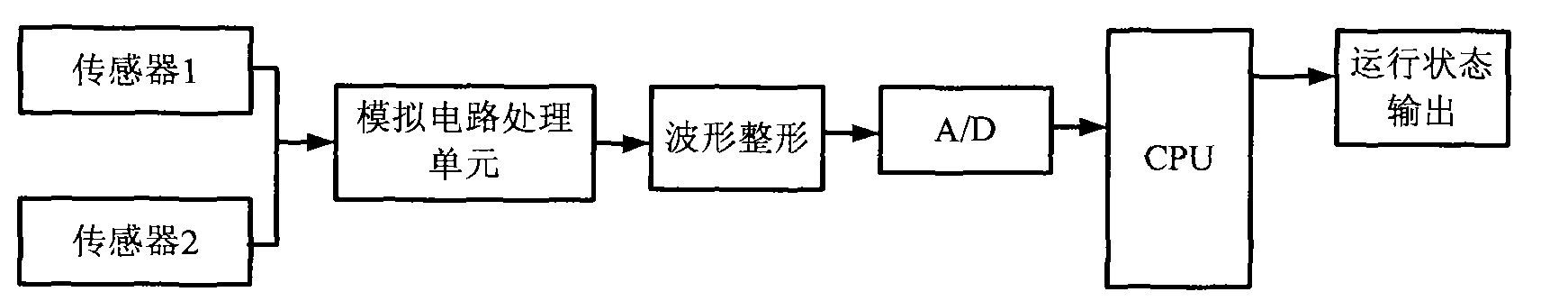

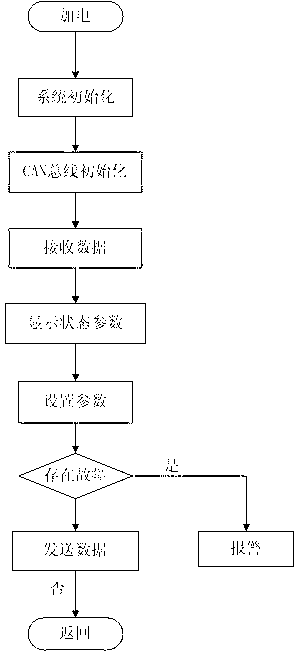

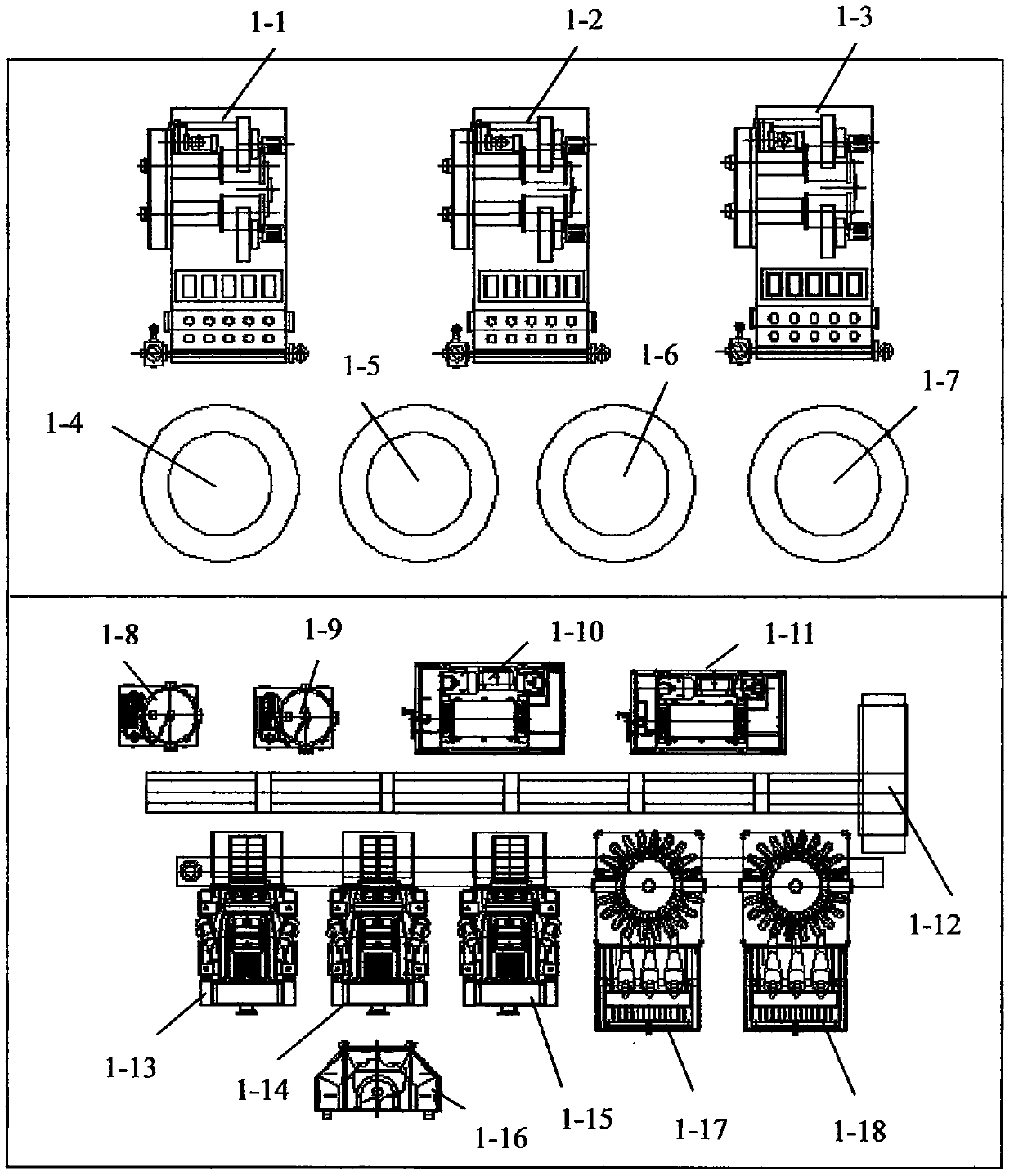

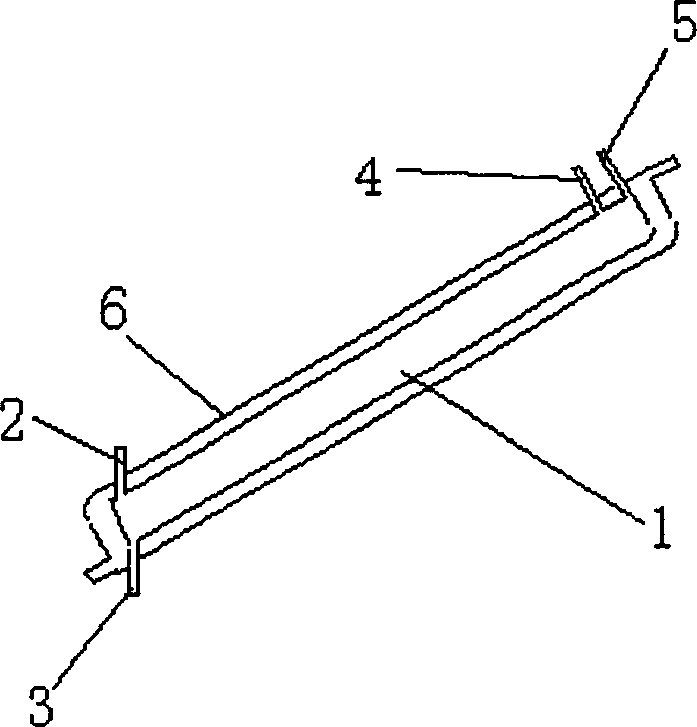

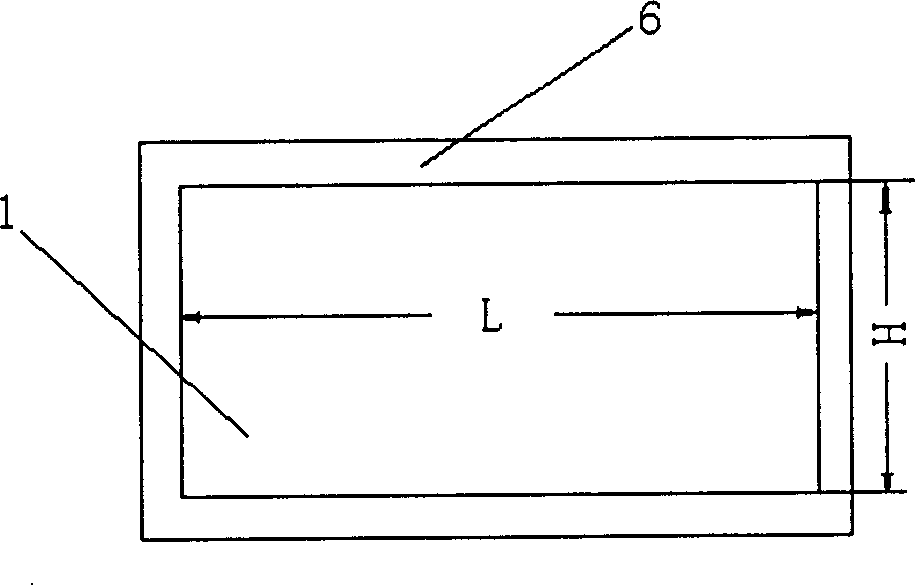

Intelligent control system for cotton picker

InactiveCN103019123ARealization of online production measurementAvoid clogging failureProgramme control in sequence/logic controllersText displayAutomatic control

The invention discloses an intelligent control system for a cotton picker. The system uses a microcomputer controller PC104 and an image-text display for monitoring and controlling the cotton picker. The human-computer interaction interface of the system is complied with LabView. The system comprises the microcomputer controller PC104 (1), an automatic row aligning subsystem (2) of the cotton picker, an online cotton yield predicting subsystem (3), an automatic control subsystem (4) for controlling travelling speed of the cotton picker, a parameter detecting and state monitoring subsystem (5) of the cotton picker, the image-text display (6) and a CAN (controller area network) bus (7). The controller (1) receives data transmitted by the automatic row aligning subsystem (2), the online cotton yield predicting subsystem (3), the automatic control subsystem (4), the parameter detecting and state monitoring subsystem (5) and the like through the CAN bus (7), and control of the cotton picker is achieved through data processing or boundary condition comparison. By the system, intelligence of the cotton picker is improved, especially control of state parameter monitoring, automatic row aligning, online yield predicting, travelling speed of the cotton picker is improved, and accordingly optimal control of the cotton picker is achieved.

Owner:SHANGHAI UNIV

Blood separating gel and preparation method thereof

ActiveCN102872616AGood compatibilityInhibit migrationPreparing sample for investigationLiquid separationChemistryWhite oil

The invention discloses a blood separating gel. The blood separating gel is prepared by uniformly mixing the following components in part by mass: 5-20 parts of SEBS, 20-60 parts of white oil, 15-60 parts of diethylhexyl phthalate, 1-20 parts of hydrophobic nano-silica and 0.5-5 parts of hydrophilic nano-silica, and the density of the separating gel is 1.030-1.075 g / cm<3> at 25 DEG C. The invention also provides a preparation method of the blood separating gel. The separating gel disclosed by the invention is stable, is convenient to use, has favorable thixotropy, is easy in centrifugation and good in separating effect, not only can bear irradiation sterilization of Gamma rays but also is insoluble in blood plasma or blood serum to interfere detection results, and causes less influence to the environment during medical waste incineration. The preparation method provided by the invention is simple, and is short in production period, high in efficiency, mature in process, easy to control and convenient to popularize.

Owner:CHENGDU ZHONGRUIDA TECH

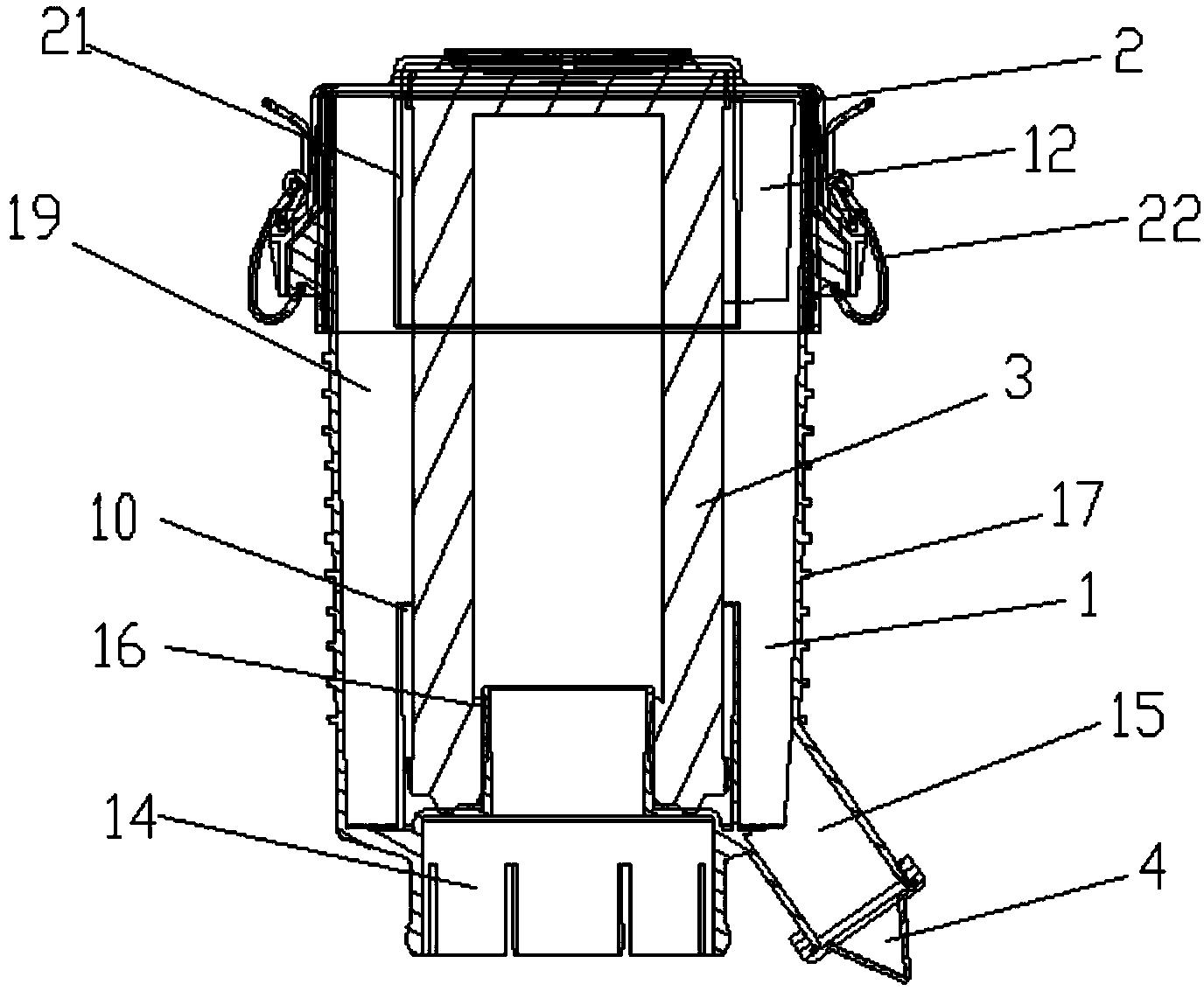

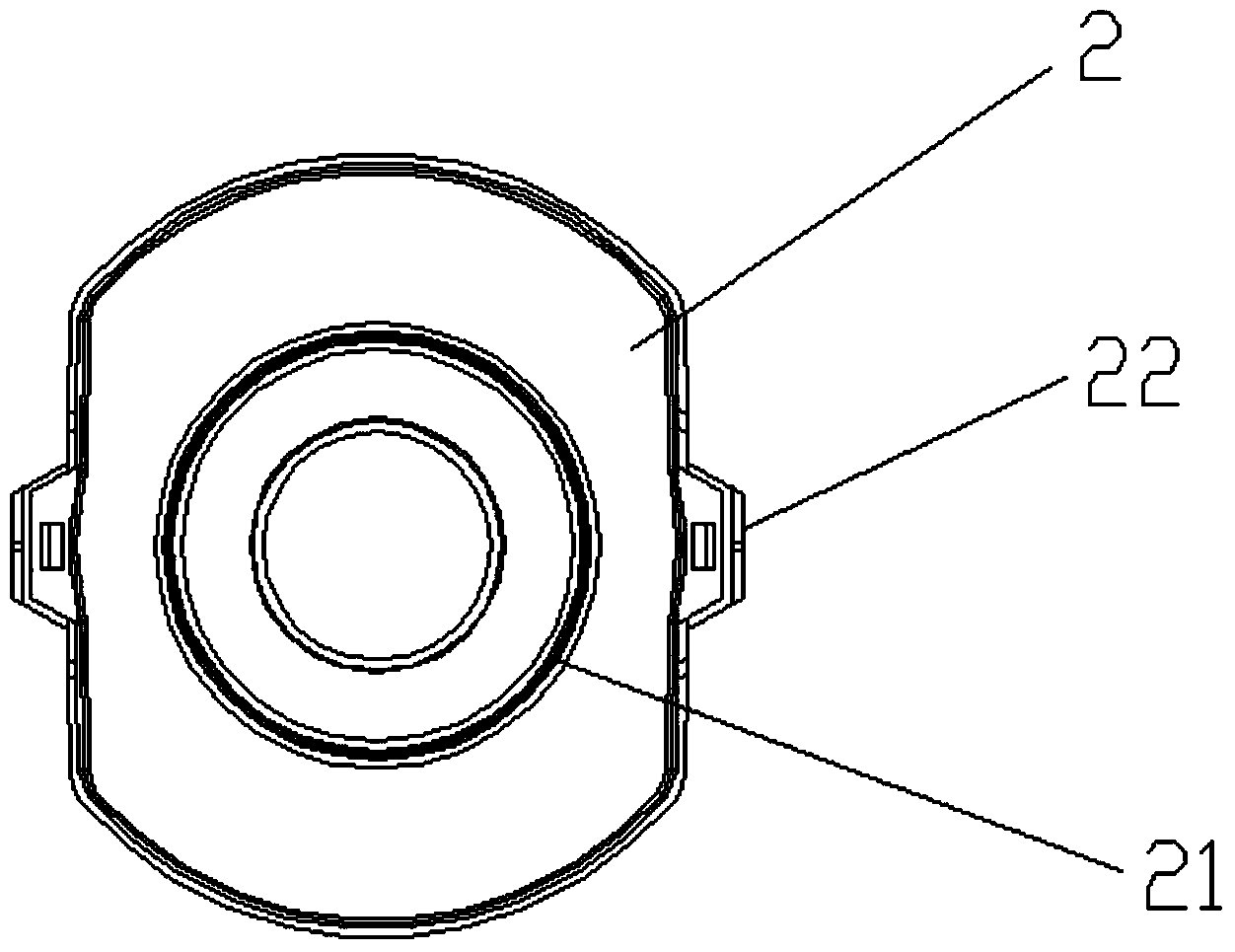

Combined-type granulator

ActiveCN106422974AAchieve maximum surfaceAchieve superficialityGranulation by pressingForeign matterSoft materials

The invention belongs to a wet material granulation principle and an equipment combination process, and particularly relates to a combined-type granulator. The combined-type granulator comprises a plurality of layers of combined box bodies, a temporary storage feed bin and a plurality of layers and groups of roller mills. Each group of roller mills is equipped with a rotary joint, a cleaning blade, an elastic stripping frame, a material baffle and a guide plate; a waste gas emptying interface is also arranged on each of the box bodies, and an air inlet at a lowest layer of the granulator is arranged on a bracket. The linear velocity of a tooth surface and the flow rate of volume of a rotary drum of each of the roller mills at a second layer are higher than those of a rotary drum of each of the roller mills at a first layer, and the linear velocity of a tooth surface and the flow rate of volume of a rotary drum with a reticular tooth socket or a single radial tooth socket of each of the roller mills at an adjacent lower layer are designed according to the volume properties of materials in the area. According to the granulator disclosed by the invention, hard foreign matters can be stripped, and simple granulation of soft materials in a cream state, a paste state, a slurry state and the like can be realized; meanwhile, caky and blocky materials can be pulled into monomer granules, soft and hard materials can simultaneously enter into the granulator, and granules at an outlet have a plurality of pores and are in an irregular shape.

Owner:张元才

Preparation method of polyvinyl alcohol/chitosan gel bead

ActiveCN109438732AModerate densitySmall sizeTreatment with microorganism supports/carriersBoric acidPVA - Polyvinyl alcohol

The invention discloses a preparation method of a polyvinyl alcohol / chitosan gel bead. The preparation method of the polyvinyl alcohol / chitosan gel bead comprises the steps of using polyvinyl alcoholand chitosan as raw materials, using NaOH as a physical cross-linking agent, using saturated boracic acid and CaCl2 as a chemical cross-linking agent and adopting physical and chemical alternate cross-linking, enabling polyvinyl alcohol molecules and chitosan molecules to be entangled by using a physical hydrogen bond and chemical ester bond double bonding structure to form a stable gel bead withdiameter of about 3 mm. Firstly, the NaOH is adopted to reinforce a hydrogen bond between the polyvinyl alcohol molecules and the chitosan molecules through physical cross-linking, so that the gel forms a uniform pore structure from inside to outside; and secondly, through chemical cross-linking of the boracic acid and the CaCl2, ester bond bonding between the polyvinyl alcohol and the chitosan isformed, so that the strength and elasticity of the gel are improved. The preparation method of the polyvinyl alcohol / chitosan gel bead, disclosed by the invention, has the advantages that a shortcoming that the gel bead obtained by one-step physical cross-linking is likely to dissolve out and break is overcome, and phenomenons that the gel beads are likely to adhere to each other and form a compact shell layer on the surfaces due to one-step chemical cross-linking is avoided.

Owner:XI AN JIAOTONG UNIV

PVA/chitosan spherical biological carrier and preparation method thereof

ActiveCN107445289AEasy to makeEnhanced mass transferWater contaminantsTreatment with microorganism supports/carriersSludgeBiocompatibility Testing

The invention discloses a PVA / chitosan spherical biological carrier and a preparation method thereof. According to the PVA / chitosan spherical biological carrier, PVA and chitosan are taken as the raw materials, non-toxic NaOH and ethanol are taken as crosslinking agents, and molecules of PVA and chitosan are bonded by covalent bonds through chemical crosslinking to form a three-dimensional structure, so as to obtain the PVA / chitosan spherical biological carrier; and the PVA / chitosan spherical biological carrier is doped with zero-valent iron, so as to obtain PVA / chitosan / zero-valent iron spherical biological carrier. By utilizing NaOH, the covalent bonds between the molecules of PVA and chitosan are reinforced, the material does not swell in water; by doping zero-valent iron, the strength and sluicing resistance of the material are improved. The material is non-toxic, porous, moderate in density and size, good in biocompatibility, capable of accelerating sludge granulation culture, effectively increasing sludge activity and maintaining excellent mass transfer performance and can be used as the biological carrier for culturing granule sludge in an organic wastewater biological treatment reactor. The preparation method is simple, mild in reaction conditions and convenient for industrial production.

Owner:XI AN JIAOTONG UNIV

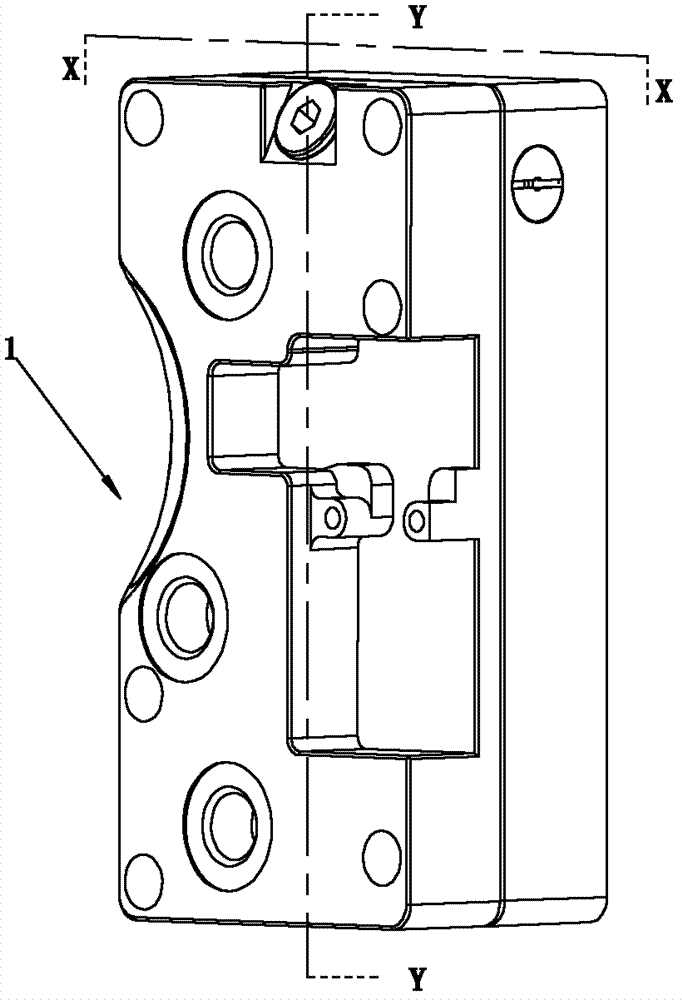

Selective catalytic reduction (SCR) metering injection pump urea crystal dissolving device

The invention discloses a selective catalytic reduction (SCR) metering injection pump urea crystal dissolving device which comprises a pump body and a mixing cavity installed inside the pump body, the side wall of the mixing cavity is provided with an orifice, the pump body is further provided with a flow guide pipeline, at least one chamber is formed inside the pump body, the chamber is communicated with the orifice, one end of the flow guide pipeline is communicated with fluid, and the other end of the flow guide pipeline is communicated with the chamber. The SCR metering injection pump urea crystal dissolving device is simple in structure and ingenious in design, and only purified water is required to be injected into the flow guide pipeline to dissolve reducing agent crystal inside the pump body. Meanwhile, dirt inside the SCR metering injection pump urea crystal dissolving device can be washed away, atomized reducing agents are prevented from diffusing into an air cylinder cavity to cause blocking faults of the pump body, and maintenance is convenient.

Owner:SUZHOU POWERGREEN EMISSION SOLUTION SYST

Barreled water vending machine

PendingCN108010195AGuarantee safety and reliabilityAvoid impact damageCoin-freed apparatus detailsApparatus for dispensing discrete articlesButt jointWater requirement

The invention discloses a barreled water vending machine. The barreled water vending machine comprises a machine shell and several goods storage shelves arranged in the machine shell and distributed in the X axis, the goods storage shelves are divided into multiple layers of goods storage platforms in the Z axis, goods taking platforms in butt joint with the goods storage platforms are arranged atthe front end of the machine shell, and the goods storage platforms tilt to the front end of the machine shell and are provided with multiple conveying mechanisms formed by arranging multiple idler wheels in the Y axis; limiting mechanisms controlling barreled water to be conveyed to the goods taking platforms are arranged at the front ends of the goods storage platforms and comprise levers, front stop levers and rear stop levers, wherein the front stop levers and the rear stop levers are arranged at the two ends of the levels in the X axis respectively. By designing the idler wheels of the multi layers of the tilting goods storage platforms, the safety and reliability in the goods delivering process of barreled water are guaranteed, and people's household drinking water requirements arealso greatly met.

Owner:ZHONGSHAN ZHONGXING AUTOMATION TECH CO LTD

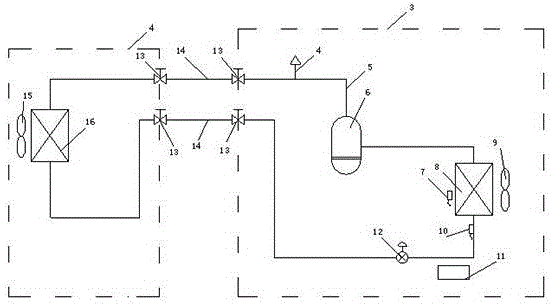

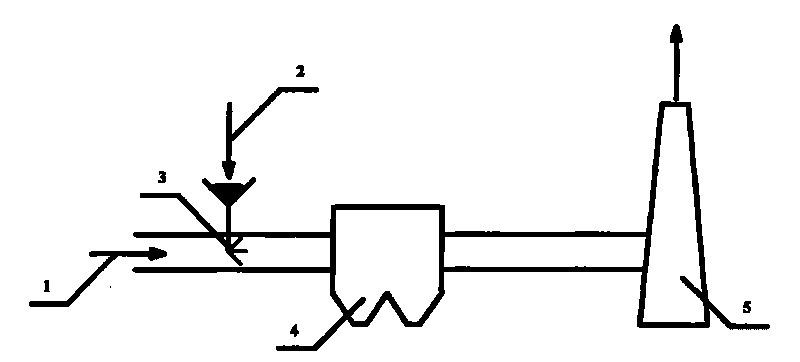

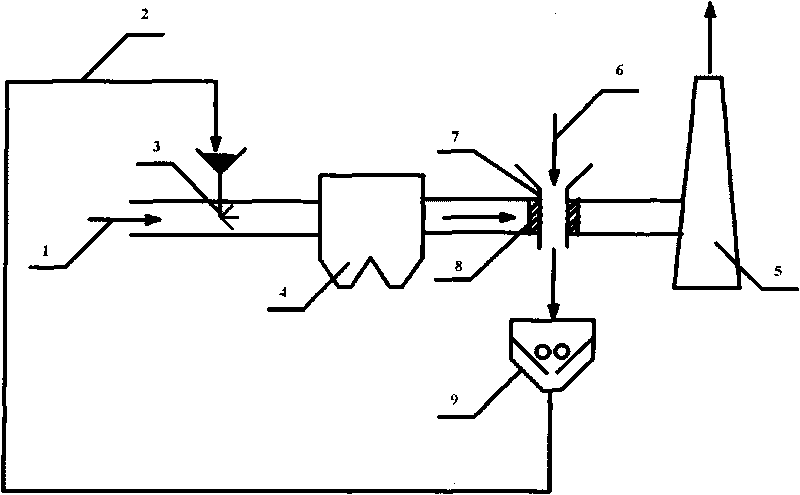

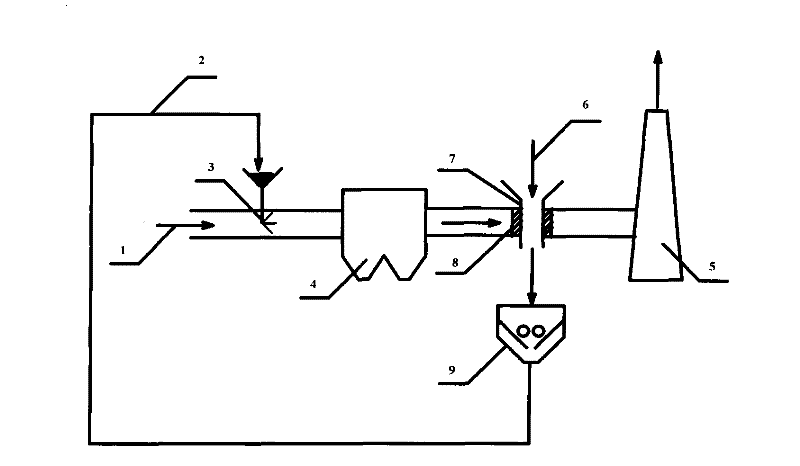

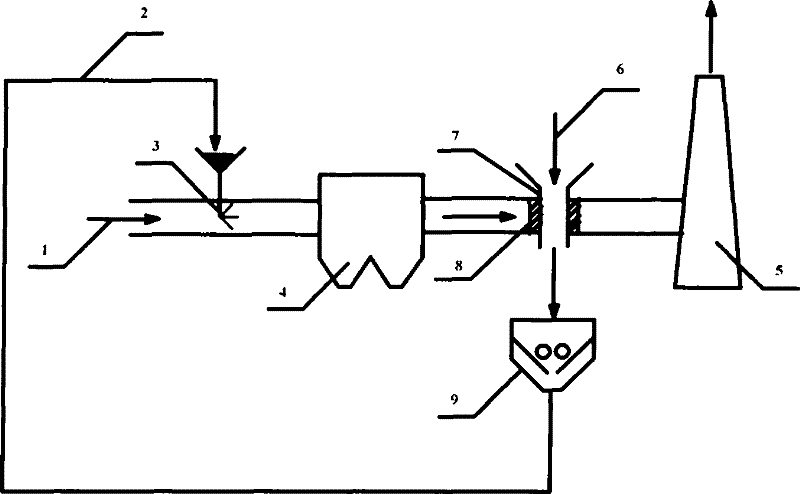

Method for removing dioxin in waste incineration flue gas and equipment thereof

ActiveCN101708424AAvoid clogging failureStrong interceptionHuman health protectionDispersed particle filtrationFiltrationAtmospheric air

The invention discloses a method for removing dioxin in waste incineration flue gas, which comprises the following steps of: a) first adopting a combined process of a Venturi jet and a dry dust collector to remove the dioxin; b) then adopting filtration equipment to remove the dioxin; c) allowing granular activated carbon absorbing the dioxin to be discharged through the bottom of the filtration equipment and enter a crushing machine to be crushed into powdery activated carbon; d) supplying the powdery activated carbon to the Venturi jet for use; and e) discharging purified waste incineration flue gas which is output from a flue gas outlet of the filtration equipment into the atmosphere through a chimney. The invention also discloses equipment for implementing the method. The method and the equipment can increase the removal rate of the dioxin and reduce operating cost.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

Air filter with dust exhaust hole

InactiveCN104329194AReduce containingAvoid clogging failureCombustion-air/fuel-air treatmentMachines/enginesAir filterLocking mechanism

The invention discloses an air filter with a dust exhaust hole. The air filter comprises a shell and an upper cover, wherein one end of the shell is provided with an opening used for placing a filter element; the outer wall of the end provided with the opening is provided with two symmetrical air inlets; the other end of the shell is provided with a mounting hole connected with a diesel air inlet pipe, and the dust exhaust hole; a mounting groove used for containing the filter element is arranged in the end provided with the opening; the upper cover covers the end, which is provided with the opening, of the shell, and is locked by a locking mechanism; the inner side of the upper cover is provided with an air guide screen which enables air entering the air filter to form spiral airflow; a space jointly formed by the upper cover and the shell performs a filter element fixing function. Air which enters the air filter of the single cylinder diesel is preliminarily filtered to reduce fine particles contained in air entering an air cylinder and avoid the blockage and the failure of the filter element of the air filter of the diesel as much as possible.

Owner:江苏常工动力机械有限公司

Waste-free environment-friendly recovery method for copper-containing difficult-to-treat material

PendingCN114214520AAvoid clogging failureReduced impact on crystallized product qualityPolycrystalline material growthFrom normal temperature solutionsLead smeltingPhysical chemistry

The invention relates to a waste-free environment-friendly recovery method for copper-containing difficult-to-treat materials, which comprises the following steps of: crushing the materials, grinding into ore pulp, and filtering to obtain ore grinding filter residues and ore grinding filtrate; carrying out low-acid iron leaching on the ore grinding filter residues, filtering to obtain low-acid leaching filter residues and low-acid leaching filtrate, recycling the ore grinding filtrate, neutralizing to be neutral by using acid waste liquid when the alkali concentration and impurities rise, and filtering to return to ore grinding for use; carrying out oxidation iron precipitation on the low-leaching filtrate, neutralizing until the pH value is 3-5, blowing compressed air at the temperature of 80-85 DEG C to oxidize low-valent iron ions so as to form iron colloidal precipitate, filtering to obtain neutralized purified liquid and neutralized iron precipitation slag, returning the neutralized purified liquid to low-acid iron leaching operation, and returning the neutralized iron precipitation slag to lead smelting and slagging; carrying out high-temperature high-acid oxygen pressure leaching on the low-leaching filter residues, and filtering to obtain high-leaching filtrate and high-leaching filter residues; cooling and saturating the high-leaching filtrate to separate out a copper sulfate crystal product, and feeding high-leaching filter residues to lead for smelting to recover lead and silver. The method is easy to operate, treats waste with waste, is low in cost, and efficiently recycles valuable metal in an environment-friendly manner without three wastes.

Owner:蒙自矿冶有限责任公司

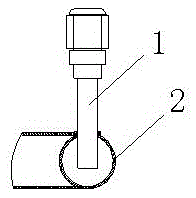

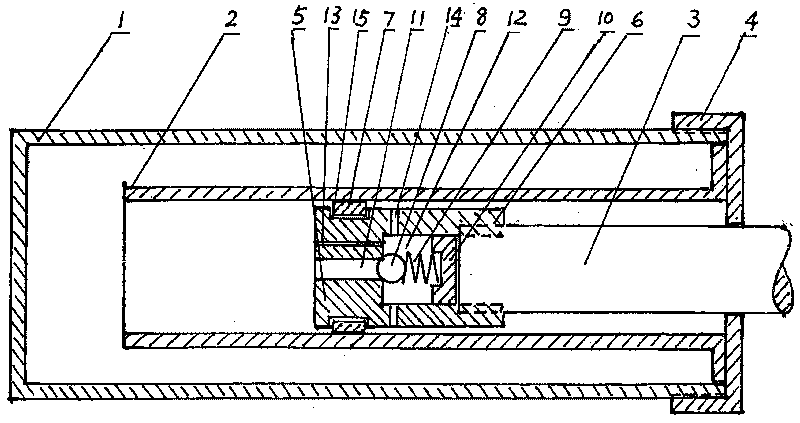

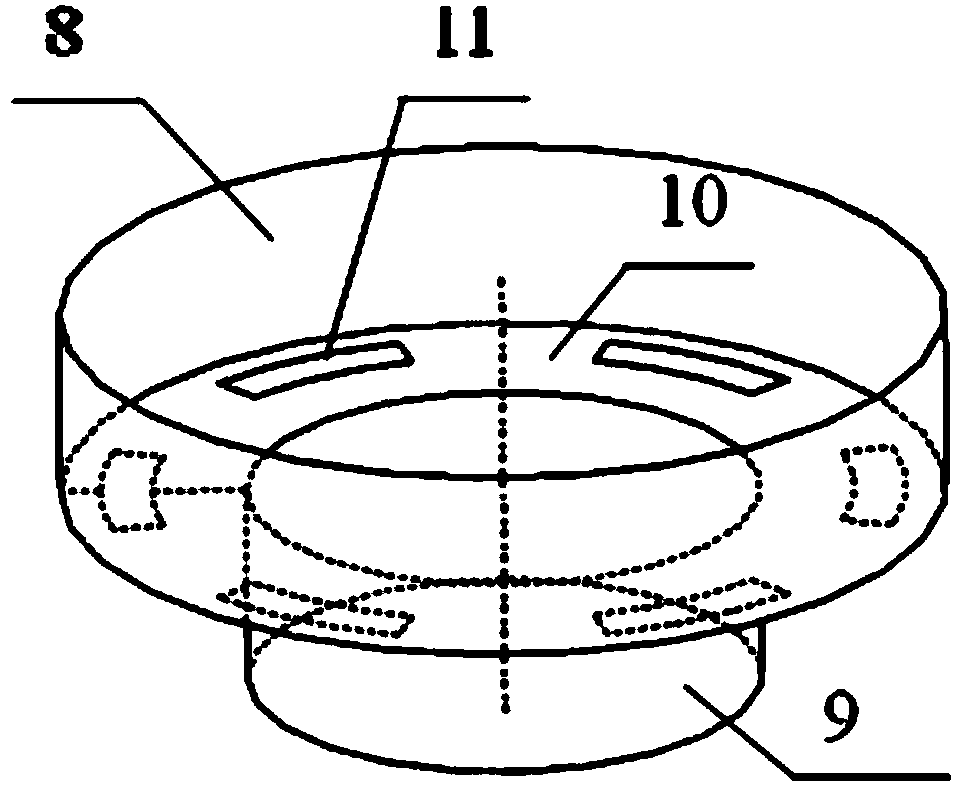

Connecting rod-ball valve type hydraulic damping device for vehicle

InactiveCN101722810AAvoid clogging failureHigh working reliabilityResilient suspensionsPiston ringEngineering

The invention discloses a connecting rod-ball valve type hydraulic damping device for a vehicle, which belongs to the technical field of hydraulic damping devices for vehicles. The technical problem to be solved is to provide the connecting rod-ball valve type hydraulic damping device in which a throttle valve is arranged on a connecting rod. The technical scheme for solving the technical problem is that: the device comprises an outer cylinder, an inner cylinder, a piston connecting rod, an end cover of the outer cylinder and the throttle valve, wherein a left end of the outer cylinder is closed, while a right end is provided with the end cover of the outer cylinder which can be detached from the outer cylinder; a left end of the inner cylinder is open, the inner cylinder is arranged in the outer cylinder, a right end of the inner cylinder is arranged on the end cover of the outer cylinder, and a damping fluid is contained between the outer cylinder and the inner cylinder; the throttle valve comprises a valve body, a piston ring, a ball valve core, a spring and a spring seat, wherein the outside diameter of the valve body is slightly less than the inside diameter of the inner cylinder, the valve body is provided with a two-step hole, a left section hole of the two-step hole is a main oil hole, while a right section hole is the ball valve core hole; and the ball valve core, the spring and the spring seat are arranged in the ball valve core hole. The connecting rod-ball valve hydraulic damping device for the vehicle is used for the damping of the vehicle. The device has the advantages of avoiding the blockage fault of the main oil hole caused by the deformation of a valve plate, improving the working reliability of the damping device, and prolonging the service life of the damping device.

Owner:黄明改

Water plugging seepage-proofing method for recharge well

ActiveCN103526780APrevent upwellingIncrease the safety reserve of water blocking and anti-seepageProtective foundationDrinking water installationButt jointMeasuring instrument

The invention discloses a water plugging seepage-proofing method for a recharge well. The method includes the steps that firstly, a steel disc ring is premade, and a clamping groove is welded on a well casing in advance; a rubber balloon is placed in the clamping groove and pressurized, so that the clamping groove is filled with the rubber balloon, a sediment tube of the recharge well, a filter and the well casing are connected in a butt joint mode, fixed and then submerged in a well hole, and a gravel filter layer and a clay ball water resisting layer are constructed; the well casing is sleeved with the steel disc ring, the steel disc ring is submerged to the well hole, when the reading number of a pressure measuring instrument is synchronously increased along with the submergence of the steel disc ring, deflation and pressure reduction are conducted on the rubber balloon, the steel disc ring is quickly submerged until the steel disc ring can not continue submerging, the lower portion of the steel disc ring is pressed in the clamping groove, the rubber balloon is extruded in the gap between the clamping groove and the steel disc ring, and eventually a concrete water plugging layer is constructed. According to the method, plugging failure of the filter layer caused by inevitable well casing disturbance in the well completion construction process and recharge water upwelling in the running process of the recharge well can be effectively avoided, even inclination of the well casing can be reduced or avoided, and by the cooperation of other recharge water preprocessing measures, eventually normal working of the recharge well can be guaranteed.

Owner:TIANJIN UNIV

Method for removing dioxin in waste incineration flue gas and equipment thereof

ActiveCN101708424BAvoid clogging failureStrong interceptionHuman health protectionDispersed particle filtrationFlue gasFiltration

The invention discloses a method for removing dioxin in waste incineration flue gas, which comprises the following steps of: a) first adopting a combined process of a Venturi jet and a dry dust collector to remove the dioxin; b) then adopting filtration equipment to remove the dioxin; c) allowing granular activated carbon absorbing the dioxin to be discharged through the bottom of the filtration equipment and enter a crushing machine to be crushed into powdery activated carbon; d) supplying the powdery activated carbon to the Venturi jet for use; and e) discharging purified waste incinerationflue gas which is output from a flue gas outlet of the filtration equipment into the atmosphere through a chimney. The invention also discloses equipment for implementing the method. The method and the equipment can increase the removal rate of the dioxin and reduce operating cost.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

Water plugging seepage-proofing method for recharge well

ActiveCN103526780BPrevent upwellingIncrease the safety reserve of water blocking and anti-seepageProtective foundationDrinking water installationButt jointMeasuring instrument

The invention discloses a water plugging seepage-proofing method for a recharge well. The method includes the steps that firstly, a steel disc ring is premade, and a clamping groove is welded on a well casing in advance; a rubber balloon is placed in the clamping groove and pressurized, so that the clamping groove is filled with the rubber balloon, a sediment tube of the recharge well, a filter and the well casing are connected in a butt joint mode, fixed and then submerged in a well hole, and a gravel filter layer and a clay ball water resisting layer are constructed; the well casing is sleeved with the steel disc ring, the steel disc ring is submerged to the well hole, when the reading number of a pressure measuring instrument is synchronously increased along with the submergence of the steel disc ring, deflation and pressure reduction are conducted on the rubber balloon, the steel disc ring is quickly submerged until the steel disc ring can not continue submerging, the lower portion of the steel disc ring is pressed in the clamping groove, the rubber balloon is extruded in the gap between the clamping groove and the steel disc ring, and eventually a concrete water plugging layer is constructed. According to the method, plugging failure of the filter layer caused by inevitable well casing disturbance in the well completion construction process and recharge water upwelling in the running process of the recharge well can be effectively avoided, even inclination of the well casing can be reduced or avoided, and by the cooperation of other recharge water preprocessing measures, eventually normal working of the recharge well can be guaranteed.

Owner:TIANJIN UNIV

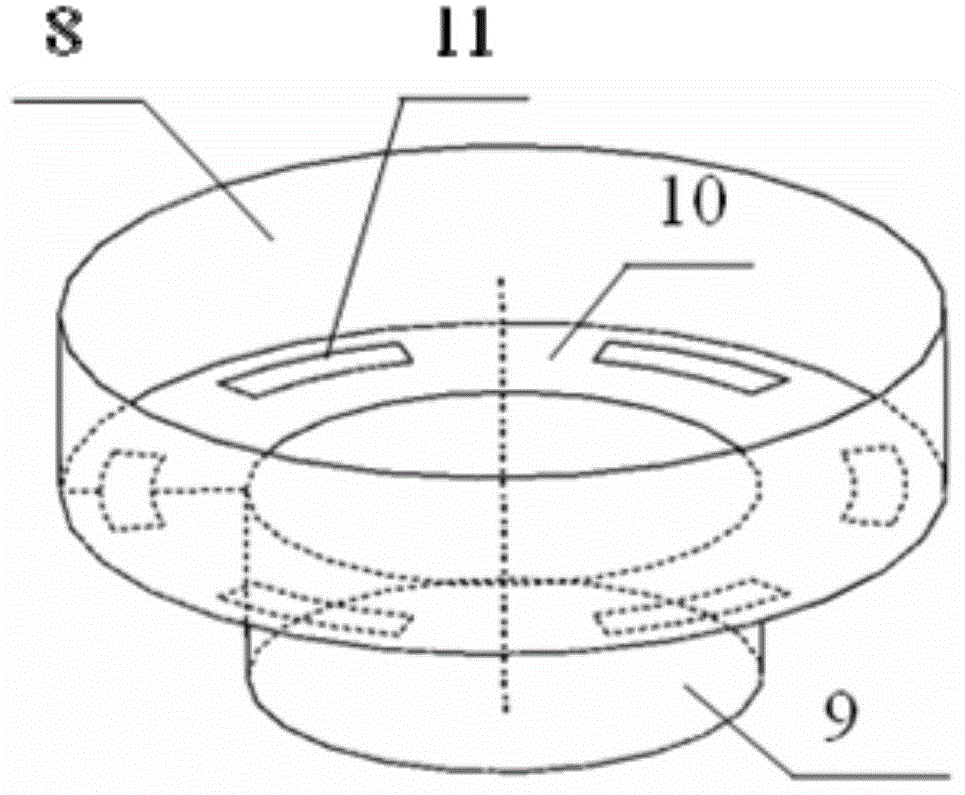

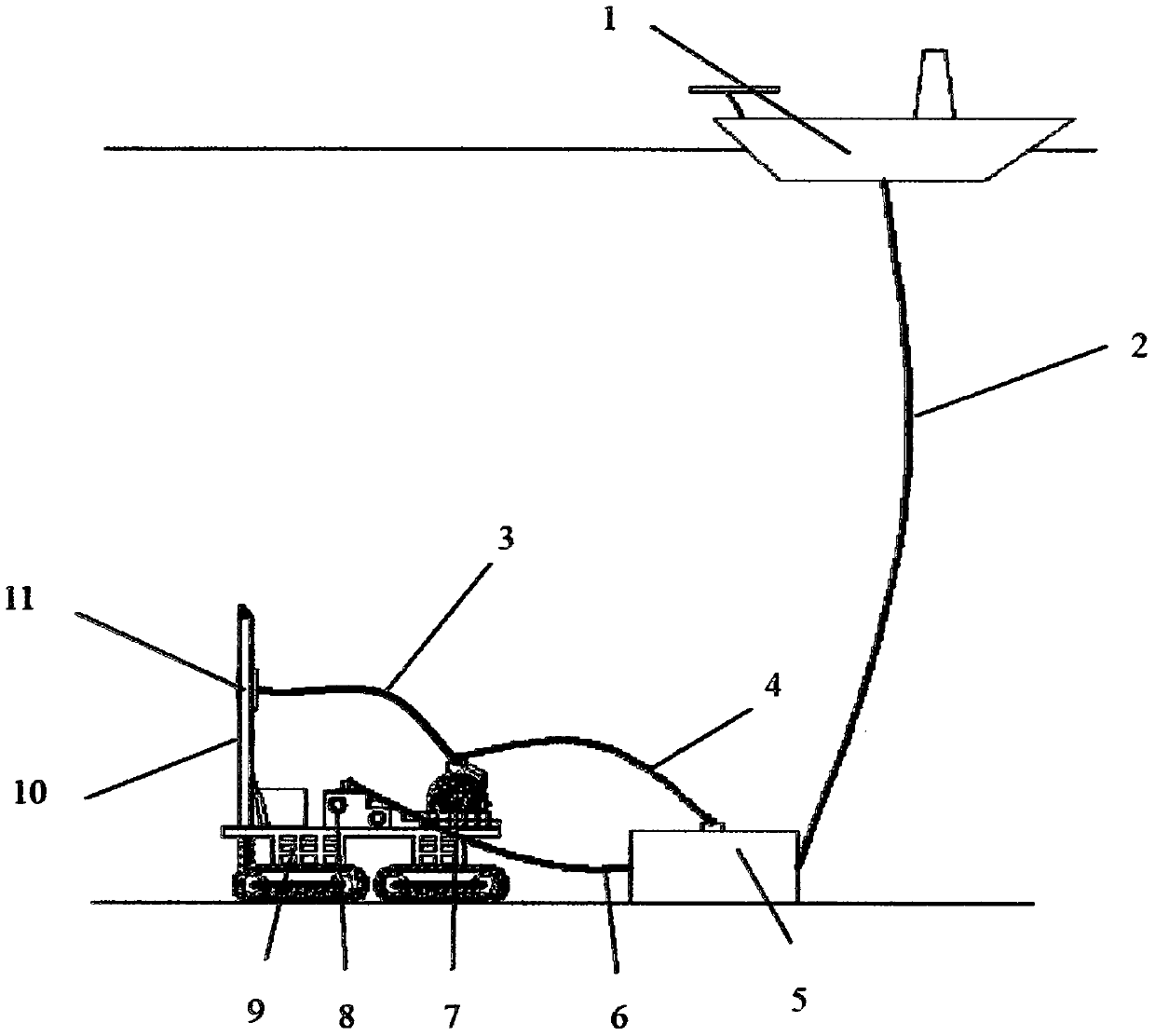

Undersea drilling rig mud circulation system and method

The invention discloses an undersea drilling rig mud circulation system and method, and relates to the technical field of deep-water drilling equipment. The undersea drilling rig mud circulation system comprises an auxiliary ship, an umbilical cord cable, a coiled tubing tensioning section, a coiled tubing mud input pipeline, an undersea mud treatment device, a wellhead mud recovery pipeline, coiled tubing, a wellhead device, an undersea drilling rig base, an injection head and a derrick; one end of the umbilical cord cable is connected with the auxiliary ship, and the other end of the umbilical cord cable is connected with the undersea mud treatment device for providing a channel for injecting mud into the seafloor and returning the mud to the auxiliary ship; and the undersea mud treatment device is used for outputting the mud injected from the umbilical cord cable to the coiled tubing mud input pipeline, filtering the mud returned from the wellhead mud recovery pipeline, and then outputting the mud to the auxiliary ship through the umbilical cord cable. The undersea drilling rig mud circulation system and method have the advantages that the conveying distance is long, and the service life is long.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

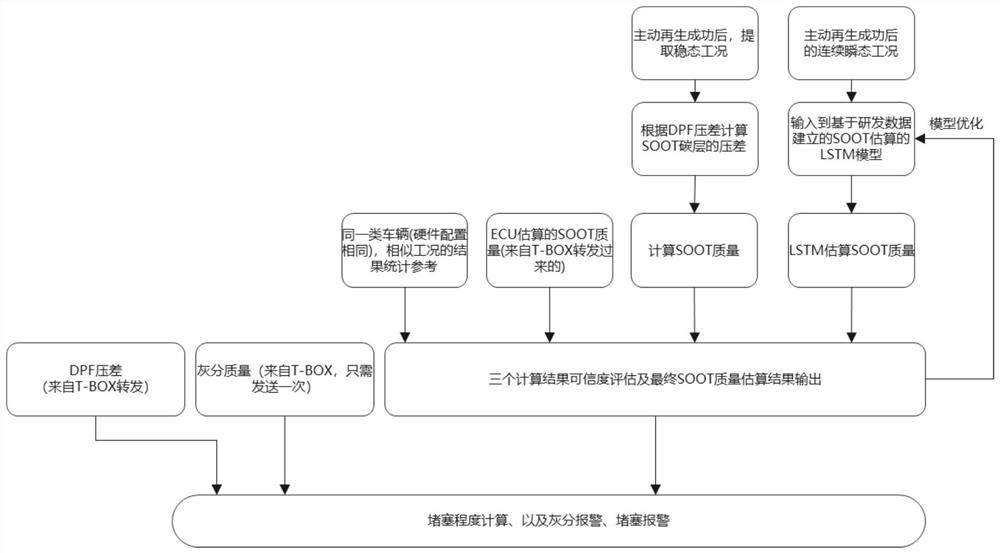

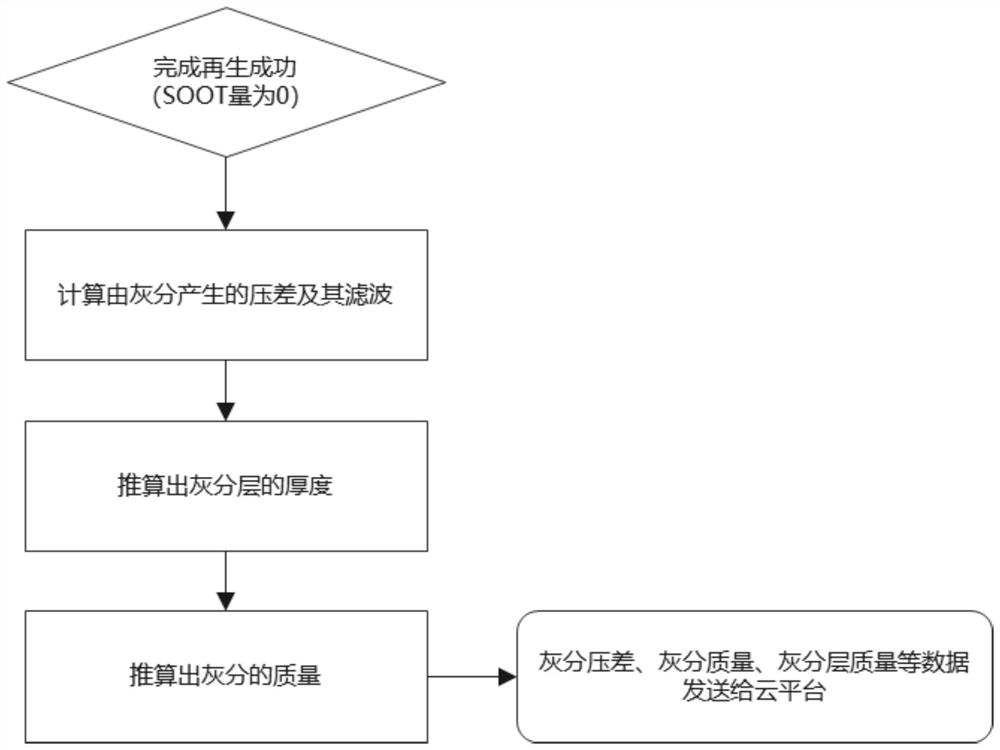

Diesel vehicle DPF pre-diagnosis system and method

PendingCN113882936AAvoid fuel consumptionAvoid emissions deteriorationInternal combustion piston enginesExhaust treatment electric controlIn vehicleEngineering

The invention provides a diesel vehicle DPF pre-diagnosis system and method, and relates to the technical field of DPF pre-diagnosis. The diesel vehicle DPF pre-diagnosis system comprises a remote vehicle-mounted terminal, a vehicle networking cloud platform, a mobile terminal, an ECU and a WEB terminal, the vehicle networking cloud platform communicates with the mobile terminal through TCP / IP, the WEB terminal communicates with the vehicle networking cloud platform through TCP / IP, the vehicle networking cloud platform communicates with the remote vehicle-mounted terminal through 4G / 5G, and the ECU communicates with the remote vehicle-mounted terminal through CAN. According to the diesel vehicle DPF pre-diagnosis system and the method, oil consumption and emission deterioration caused by large-degree blockage of the DPF can be avoided, DPF burnout or corresponding serious faults caused by DPF blockage and OBD fault missing report can be avoided, the consistency of the DPF can be evaluated, DPF batch accidents can be avoided, early warning and driver guidance can be performed in advance, and DPF blockage faults can be avoided.

Owner:苏州智慧车芯科技有限公司

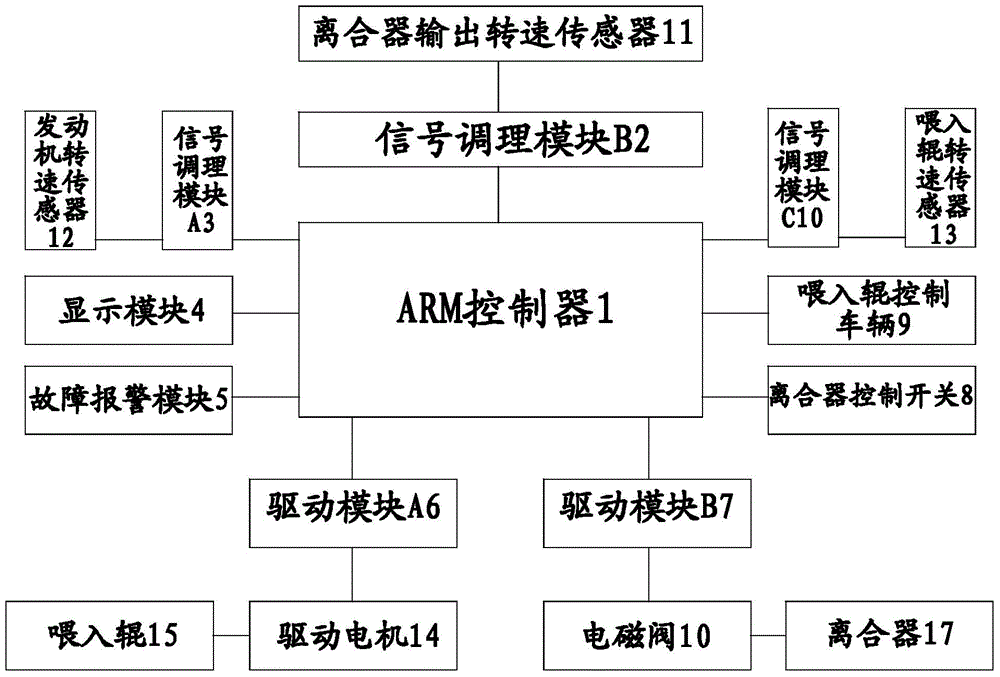

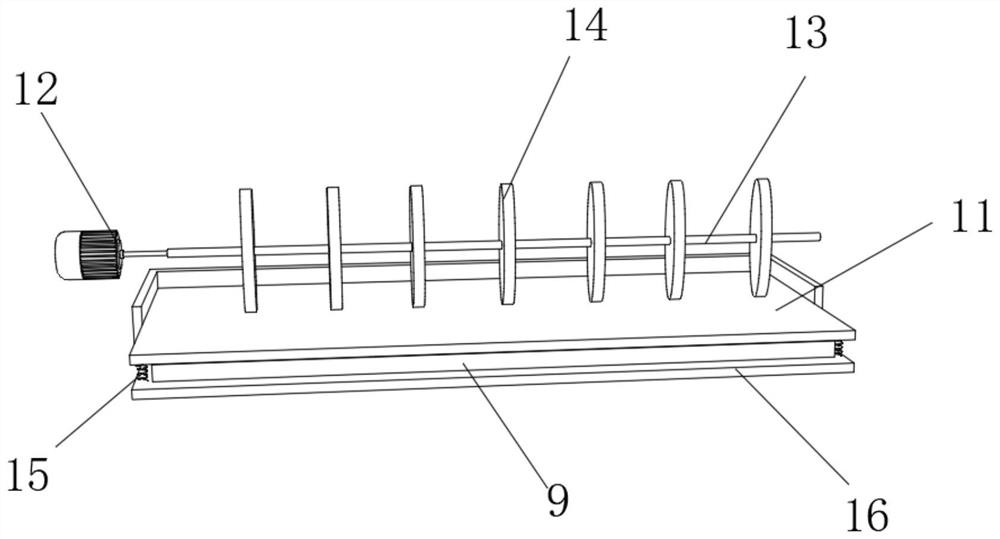

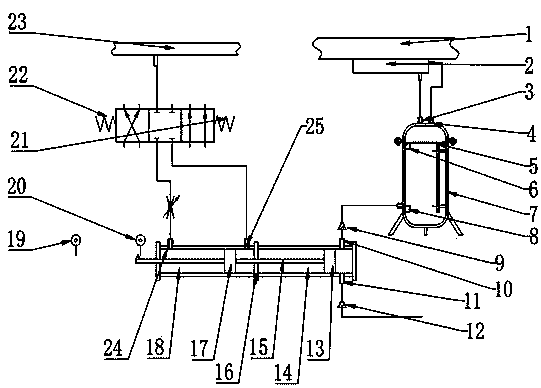

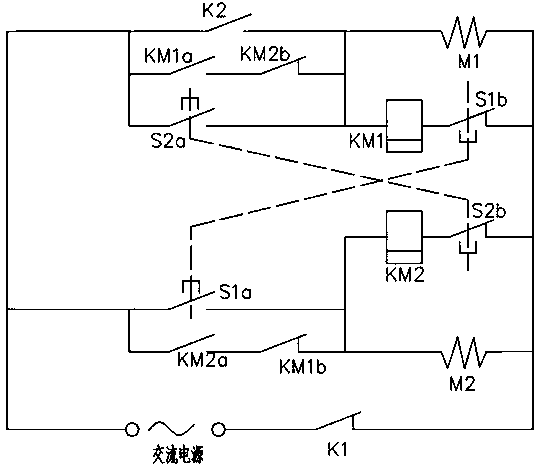

Positive and reverse rotation control system of green fodder feeding roller

InactiveCN104686104ATroubleshoot mechanism blockageSimple system structureCuttersDrive motorFarm machine

The invention discloses a positive and reverse rotation control system of a green fodder feeding roller, belonging to the technical field of agricultural machinery control. The positive and reverse rotation control system of the green fodder feeding roller is characterized by comprising an ARM controller (1), a signal conditioning module B (2), a signal conditioning module A (3), a display module (4), a failure warning module (5), a driving module A (6), a driving module B (7), a clutch control switch (8), a feeding roller control handle (9), a signal conditioning module C (10), a clutch output rotational speed sensor (11), an engine rotational speed sensor (12), a feeding roller rotational speed sensor (13), a driving motor (14), a feeding roller (15), an electromagnetic valve (16) and a clutch (17). Compared with the prior art, the inventive system has the advantages of simple structure, convenient installation and debugging, high reliability, high measurement accuracy, low power consumption, easy popularization and promotion, and convenient maintenance.

Owner:刘扬

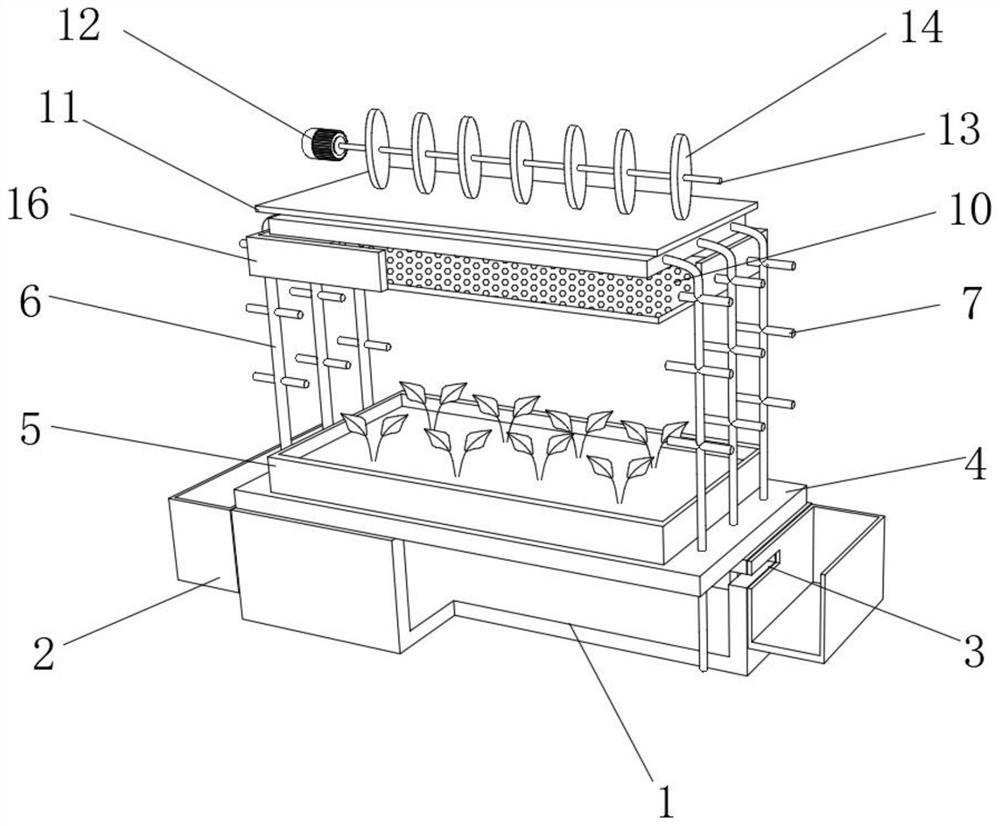

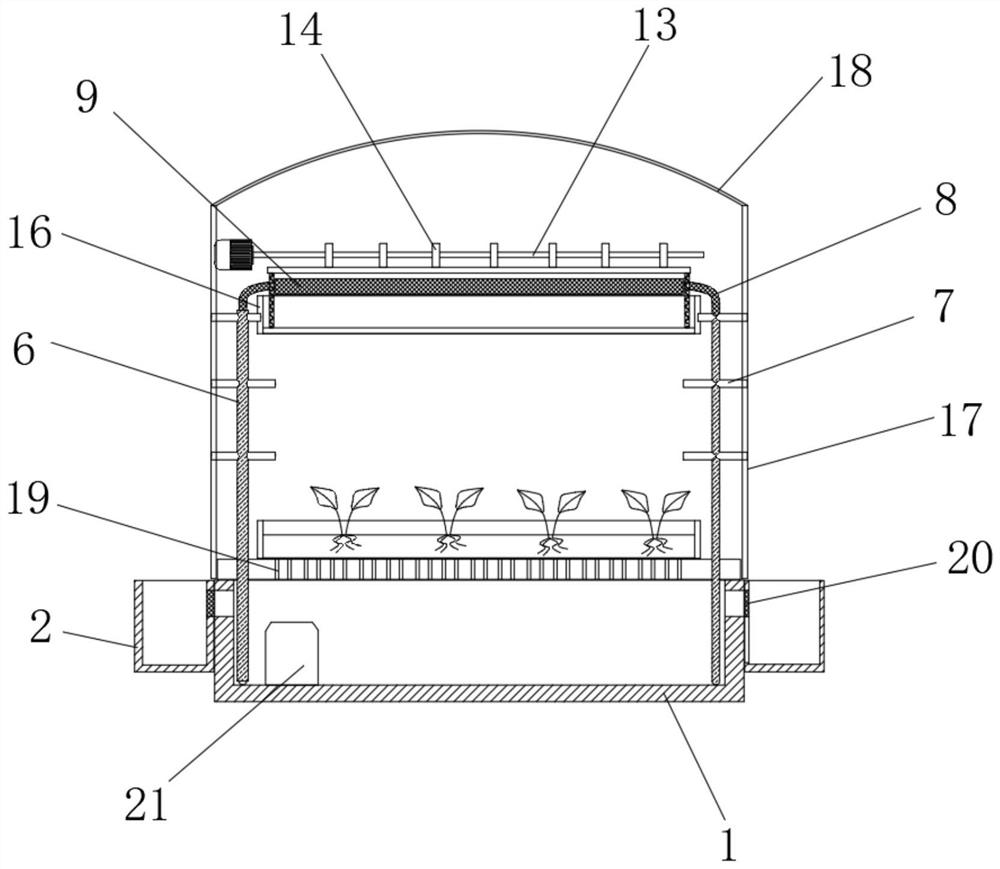

Water supplementing device for agricultural greenhouse planting

InactiveCN112293110AAvoid clogging failurePrevents conditions prone to frost crackingClimate change adaptationGreenhouse cultivationGreenhouseAgricultural engineering

The invention belongs to the technical field of agricultural greenhouse planting tools, particularly relates to a water supplementing device for agricultural greenhouse planting, and provides the following scheme for solving the problems that in the irrigation manner of a water supplementing device for agricultural greenhouse planting in the prior art, a water suction pump is blocked by granular medicine, and a water pipe is prone to frost cracking in cold winter. The water supplementing device comprises a reservoir and a greenhouse framework with the upper end connected with an arc-shaped top, the lower end of a cultivation base is fixedly connected with the reservoir, a plurality of insertion holes are formed at the side end of the cultivation base, supporting pipes are fixedly insertedinto the insertion holes, elastic water absorption cotton slivers are inserted into the supporting pipes, and water absorption cotton blocks are fixedly connected to the upper ends of the elastic water absorption cotton slivers; and a water squeezing mechanism is arranged at the top end in the greenhouse framework. Compared with the manner that irrigation is conducted through a water suction pumpin the prior art, the manner that water transfer irrigation is conducted through absorbent cotton can effectively solve the problem that the water suction pump is blocked and breaks down, and meanwhile the water pipe can be effectively prevented from frost cracking in cold winter.

Owner:李克兰

Seed discharging device allowing clay to be conveniently removed and used for seeder

InactiveCN109699254AEasy to operateGuaranteed uptimeAgricultural machinesCleaning using toolsEngineeringUltimate tensile strength

The invention discloses a seed discharging device allowing clay to be conveniently removed and used for a seeder. The seed discharging device comprises a seeder seed storage box, a seeder seed discharging structure, a mixing structure, a clay removing adjusting structure, a first protective plate, a second protective plate and a clay removing structure, the seeder seed storage box is installed onthe seeder, an inclined guiding plate is integrally arranged at the bottom of the seeder seed storage box, the first protective plate is integrally arranged on the part, on one side of the seeder seedstorage box, of the inclined guiding plate, and the second protective plate is integrally arranged on the part, on the other side of the seeder seed storage box, of the inclined guiding plate. The seed discharging device is reasonable and simple in structure and convenient to use; the labor intensity of a seeding worker is effectively lowered, farming efficiency is improved, during seeding, clayremoving treatment is conducted on a seeder seed discharging rotary disc, cleanliness of the seeder seed discharging rotary disc is guaranteed, it is avoided that soil adheres to the seeder seed discharging rotary disc, a seed discharging device is blocked, and the effect of removing clay is guaranteed.

Owner:潘艾欣

Floor drain with anti-plugging, anti-backflow water seal and insert-and-pull type installation structure

PendingCN110067299AAvoid clogging failureGood sealing effectFatty/oily/floating substances removal devicesSewerage structuresIrrigationEngineering

The invention discloses a floor drain with anti-plugging, anti-backflow, water seal and an insert-and-pull installation structure. The floor drain mainly includes a water collecting tank and a drainage pipe installed in a middle hole of the water collecting tank; the bottom of the drainage pipe is fixedly connected with a water storage cap with an opening upwards, and the water storage cap communicates with the lower part of the drainage pipe; an annular cover plate is connected with the drainage pipe located at the upper end port of the water storage cap in a sleeving mode; the annular coverplate can cover the upper end port of the water storage space precisely under the actions of no water pressure and self-weight or self-elasticity; and under the action of the water pressure, the jointpart of the annular cover plate and the water storage space is opened to enable water to flow out. The floor drain with anti-plugging, anti-backflow, water seal and an insert-and-pull installation structure has the advantages of plugging and back-irrigation proofing, good water sealing effect, simple structure, and easy installation and maintenance.

Owner:徐州寰鼎机械科技有限公司

Active high-flow drainage device

The invention discloses an active high-flow drainage device. The active high-flow drainage device comprises a water collecting tank, a filter screen in the water collecting tank, and a control circuit. A high-water-level contact switch and a low-water-level contact switch are arranged at the upper end and the lower end of the side wall of the water collecting tank respectively; a water outlet of the water collecting tank is communicated with a water inlet of a pneumatic-and-hydraulic mixing cylinder through a pipeline; the air-and-hydraulic mixing cylinder is divided into a pneumatic cylinder on the left side and a hydraulic cylinder on the right side, and a pneumatic piston and a hydraulic piston are connected to the same piston rod; a drainage outlet is formed in the lower side of the right end of the hydraulic cylinder. Pneumatic power is fed into the pneumatic cylinder, and the pneumatic piston drives the hydraulic piston to carry out reciprocating motion so that water suction and drainage operation can be carried out. According to the active high-flow drainage device, slag can be efficiently filtered out, stable high-flow drainage operation can be carried out, automatic drainage operation can be actively carried out, drainage efficiency is improved, the slag is effectively filtered out, blocking failures are avoided, small waste slag can be drained in a forced mode, and the maintenance and cleaning frequency is reduced.

Owner:HUAINAN MINING IND GRP

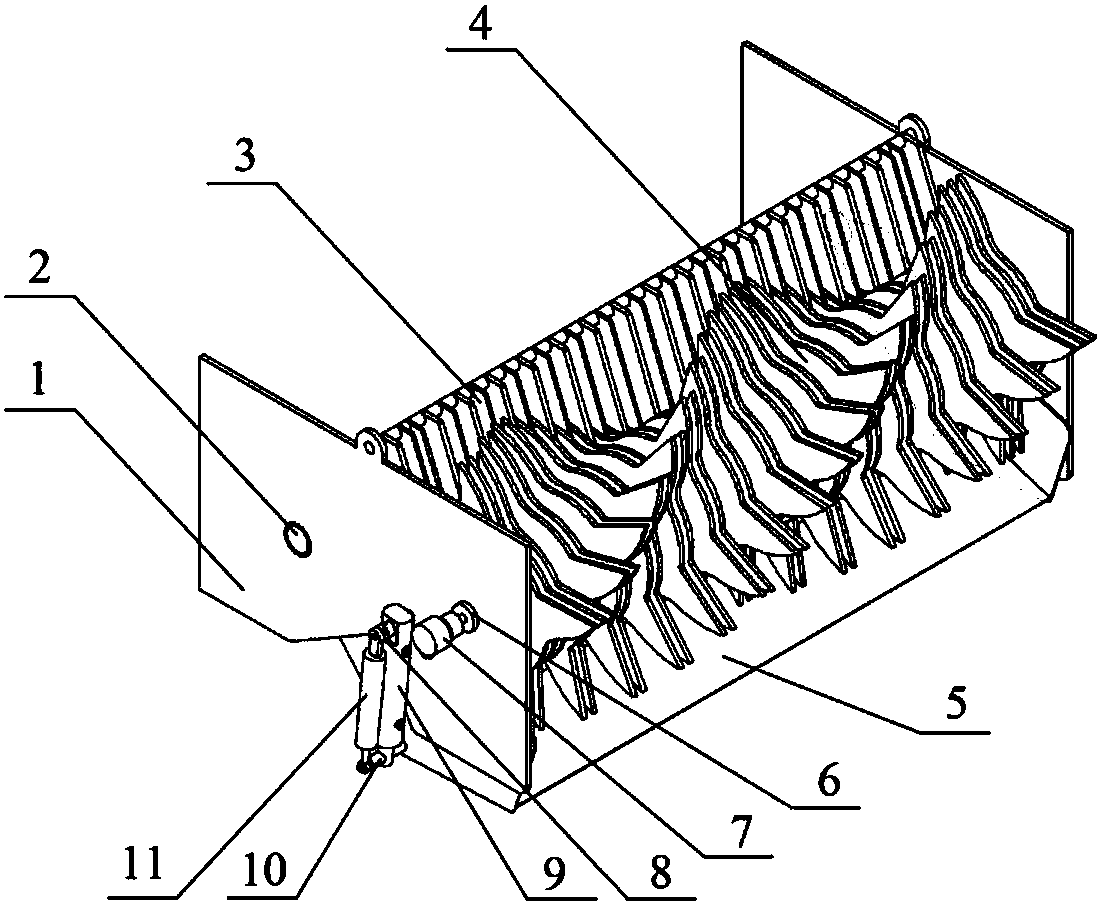

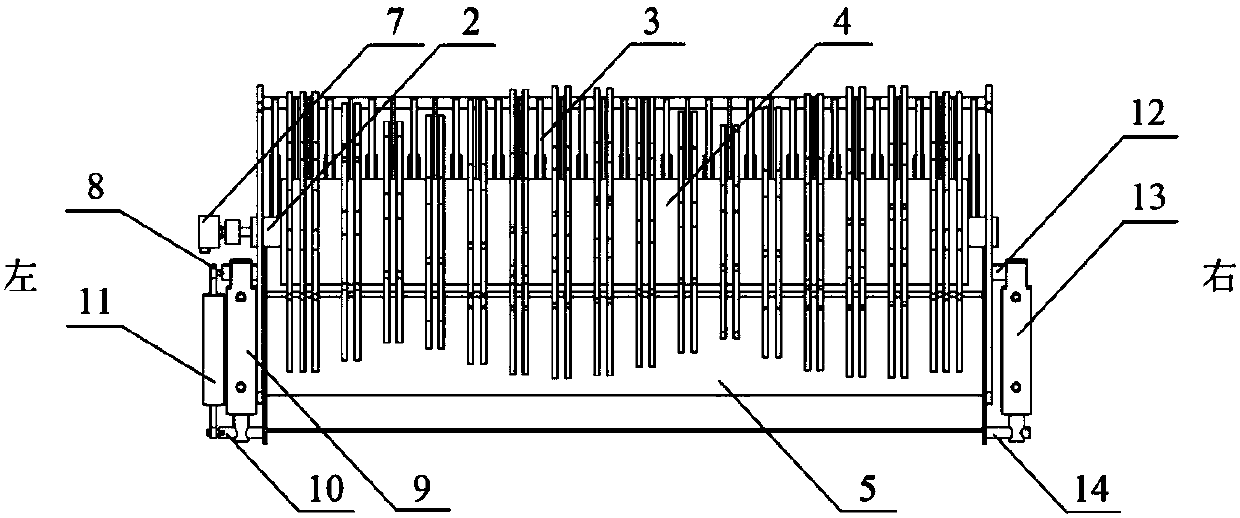

A round baler feed port opening adaptive control system and its control method

ActiveCN106884816BEnsure safetyAvoid clogging failureFluid-pressure actuator testingLoadersElectricityControl system

The invention provides an adaptive control system and control method for the opening of the feeding port of a round baler, including a feeding device, a rotary encoder, a displacement sensor, a hydraulic adjustment system and a controller; the input ends of the controller are respectively connected to the The rotary encoder, displacement sensor, oil pressure sensor 1 and oil pressure sensor 2 are electrically connected, and the output end is electrically connected to the electromagnetic reversing valve through an interlock controller; and the rate of change of rotational speed as the input, and the position of the piston rod as the output, establish a fuzzy control model for the opening of the feeding opening of the feeding device, and control the piston rods of the left cylinder and the right cylinder through the three-position four-way electromagnetic reversing valve The active adjustment of the extension and retraction under the hydraulic drive realizes the self-adaptive control of the opening of the feeding opening, reduces the instability of the bundling performance caused by the uneven feeding amount, and avoids the blockage of the feeding knife roller caused by the sudden increase of the feeding amount. , Improve the working life of the feeding parts, the working efficiency and reliability of the whole machine.

Owner:JIANGSU UNIV

A kind of preparation method of alkali-catalyzed PVA gel beads

Owner:XI AN JIAOTONG UNIV

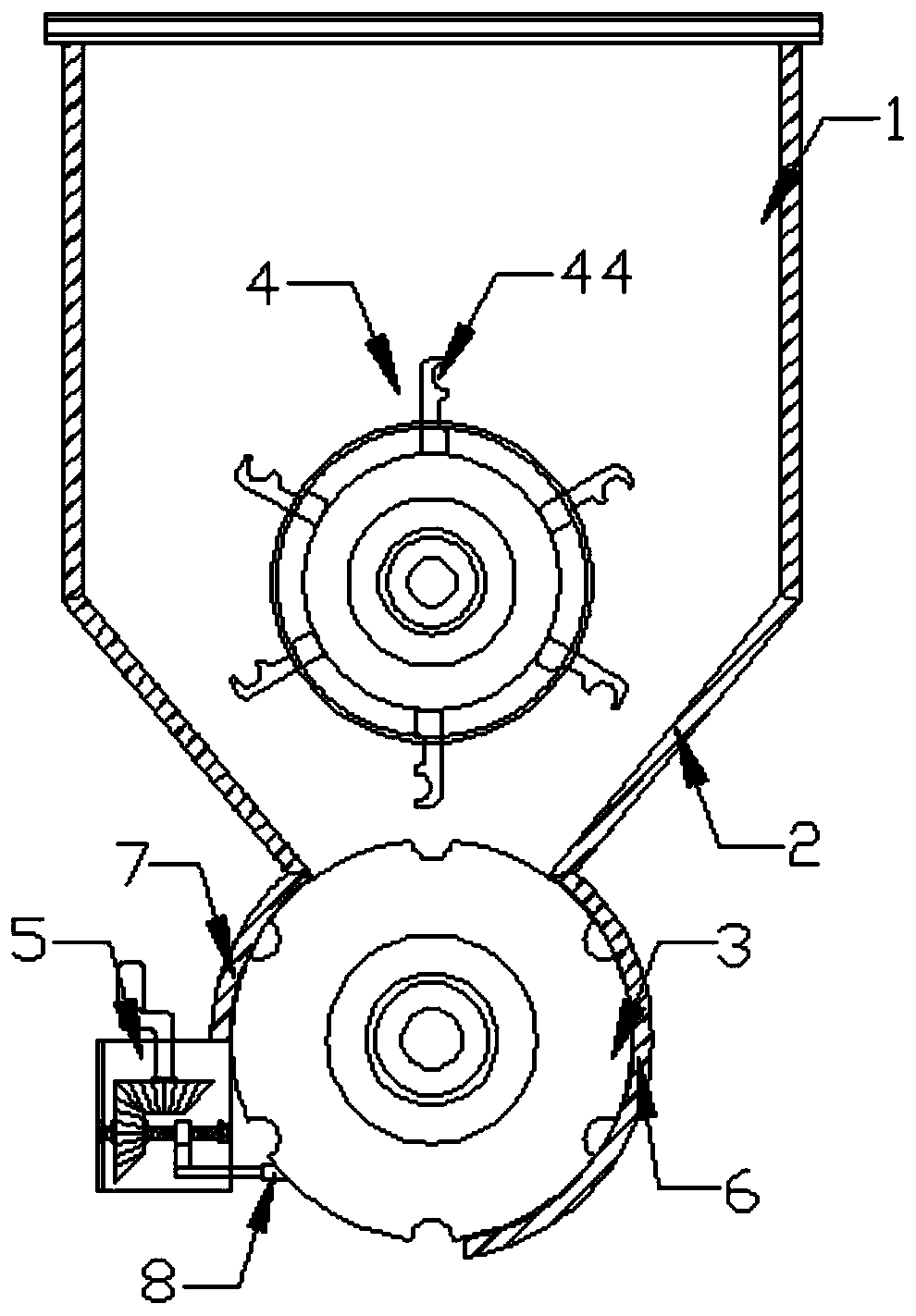

An automatic bacteria material bagging machine

ActiveCN105230346BLabor intensiveReduce labor intensityCultivating equipmentsMushroom cultivationEngineeringDistributor

The invention provides an automatic fungus material bagging machine. The automatic fungus material bagging machine comprises a round working platform, rack stand columns for fixing and supporting the round working platform is arranged under the round working platform, an annular baffle encircling the round working platform is arranged on the edge of the round working platform, a transmission main shaft is installed in the center of the round working platform and provided with a discharging hopper, and a conical distributor is installed on the upper portion of the discharging hopper; spiral feeders are arranged on the round working platform, and racks for fixing and supporting the spiral feeders are arranged under the corresponding spiral feeders. A fungus material to be bagged is in a motion state all the time before being bagged, the amount of the fungus material entering the spiral feeder is controllable, and suspending and blocking faults in the fungus material bagging process are effectively avoided.

Owner:林培森

Method for preparing disodium hydrogen phosphate from glyphosate mother liquor by using ECO technology

InactiveCN107902825AReduce the chance of corrosionAvoid clogging failureWater treatment parameter controlWater contaminantsGlyphosateWastewater

The invention discloses a method for preparing disodium hydrogen phosphate from a glyphosate mother liquor by using an ECO technology, and belongs to the field of chemical engineering production. Themethod comprises the following steps: (1) adjusting the pH value of the glyphosate mother liquor, and adding the adjusted mother liquor into an MVR evaporator; (2) completely transferring the obtainedmaterial into a crystallization kettle, and carrying out normal pressure crystallization; (3) carrying out solid-liquid separation after the material is crystallized; (4) carrying out normal pressuredegradation in a catalytic degradation tower; (5) carrying out heat exchange on the degraded wastewater to cool the wastewater to room temperature, transferring the cooled wastewater into an extraction tank, carrying out cooling and crystallization, pumping the obtained crystallized extract into a two-in-one filter press, and filtering the crystallized extract; and (6) washing the filtered solidwith water two times, discharging the washed solid, and packaging the solid for sale. The MVR evaporator is used to carry out concentration, so the purity of the product is ensured; and the electrocatalytic oxidation technology is used to catalytically degrade the glyphosate wastewater, so the disodium hydrogen phosphate can be obtained, the phosphorus resource and the salt resource can be recovered, and the cost is saved.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

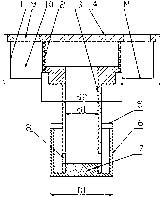

Combined crushing granulation dryer

ActiveCN106422974BAchieve maximum surfaceAchieve superficialityGranulation by pressingForeign matterSoft materials

A combined granulator, comprising a multilayer combined box body (11), a temporary feed storage bin (01), and multiple layers and groups of rolling mills. Each group of rolling mills is provided with a rotary joint (04), a cleaning blade (05), an elastic stripping frame (14), a material baffle (07), and a guide plate. The box body is further provided with a waste gas evacuation port (03), and a support is provided with an air inlet (12) at the lowest layer of the granulator. The tooth surface linear velocity and the volumetric flow rate of a rotating drum of each rolling mill (08) at the second layer are higher than those of a rotating drum of each rolling mill (02) at the first layer; the ratios of the tooth surface linear velocities and the volumetric flow rates of the rotating drums having meshed tooth slots or individual radial tooth slots of adjacent rolling mills at the lower layer can be adjusted according to the volume of materials in the region. The granulator can not only strip hard foreign matters, but also simply granulate a soft material, such as cream, paste, and slurry. In addition, the granulator can also directly pull caky and blocky materials into monomer granules, so that soft and hard materials can simultaneously enter the granulator, and granules at an outlet are porous and irregular in shape.

Owner:张元才

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com