Active high-flow drainage device

A high-flow, active technology, used in safety devices, drainage, mining equipment, etc., can solve problems such as affecting the process of mine extraction, accumulation of water in extraction pipelines, and poor drainage of drains, saving human resources. Cost, cost savings, effect of reduced maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

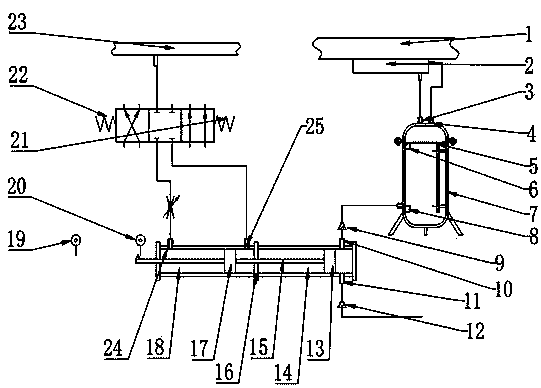

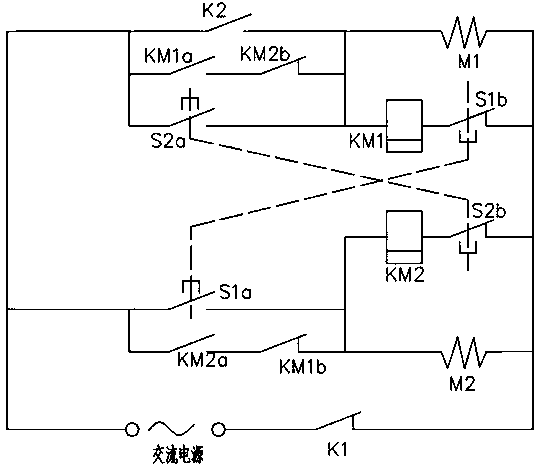

[0020] The technical solution adopted by the present invention is an active large-flow water discharge device, such as figure 1 As shown, the active large-flow water discharge device of the present invention includes a water collection box 7 and a filter screen 5 in the water collection box 7, and the water inlet 3 at the upper end of the water collection box 7 communicates with the water storage tank 2 on the lower side of the extraction pipe 1 through a pipeline. The upper end of the water collection tank 7 is provided with a constant pressure port 4 connected to the atmosphere; the upper and lower ends of the side walls of the water collection tank 7 are respectively provided with a high water level contact switch 6 and a low water level contact switch 8; the water outlet of the water collection tank 7 passes through the pipeline It communicates with the water inlet 10 of the gas-liquid mixing cylinder with the first one-way valve 9; the cylinder body of the gas-liquid mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com