Positive and reverse rotation control system of green fodder feeding roller

A control system, feeding roller technology, applied in cutting equipment, agricultural machinery and tools, applications, etc., can solve the problems of complex operation, high labor intensity, etc., achieve high measurement accuracy, convenient maintenance, and solve the effect of mechanism blockage failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

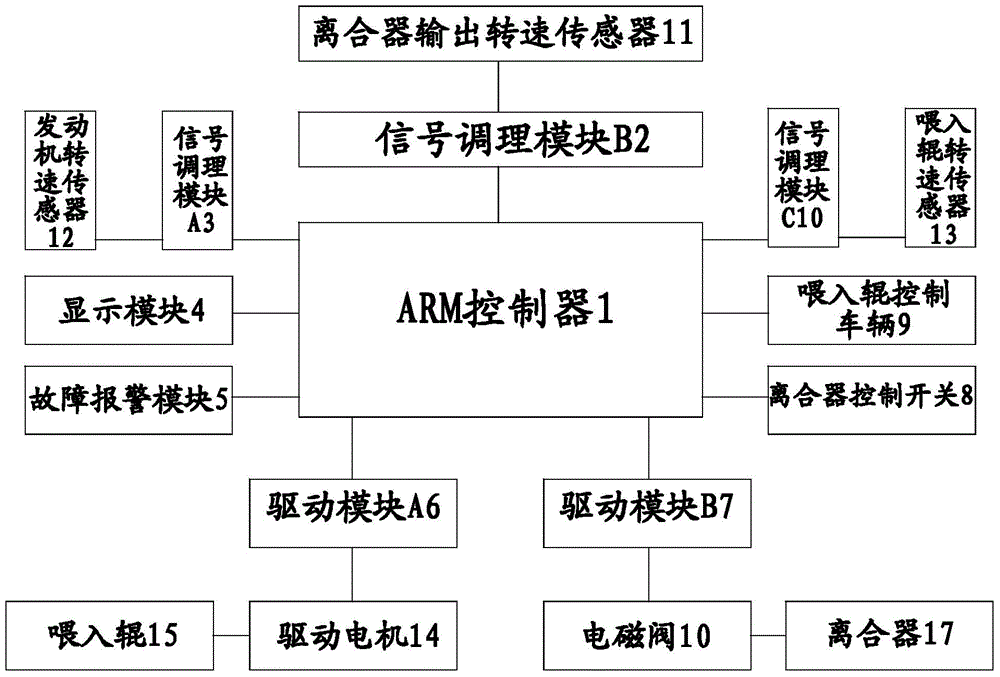

[0008] figure 1 It is a structural schematic diagram of the forward and reverse control system of green fodder feeding rollers of the present invention. The forward and reverse control system of green fodder feeding rollers includes ARM controller 1, signal conditioning module B2, signal conditioning module A3, display module 4, fault alarm module 5, Drive module A6, drive module B7, clutch control switch 8, feed roller control handle 9, signal conditioning module C10, clutch output speed sensor 11, engine speed sensor 12, feed roller speed sensor 13, drive motor 14, feed roller 15. Solenoid valve 16, clutch 17; where:

[0009] The ARM controller 1 is connected with the signal conditioning module B2, the signal conditioning module A3, the display module 4, the fault alarm module 5, the driving module A6, the driving module B7, the clutch The control switch 8, the feed roller control handle 9, and the signal conditioning module C10 are connected, the signal conditioning module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com