Method for removing dioxin in waste incineration flue gas and equipment thereof

A waste incineration and dioxin technology, which is applied in the field of waste gas treatment, can solve the problems of increasing the amount of powdered activated carbon, consuming large powdered activated carbon, and limited dioxin removal rate, achieving significant effect, increased specific surface area, The effect of improving the adsorption utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Flue gas flow: 83816m 3 / h, dioxin concentration: 5ng / m 3 . (The above values are converted to 11% oxygen content on a dry basis)

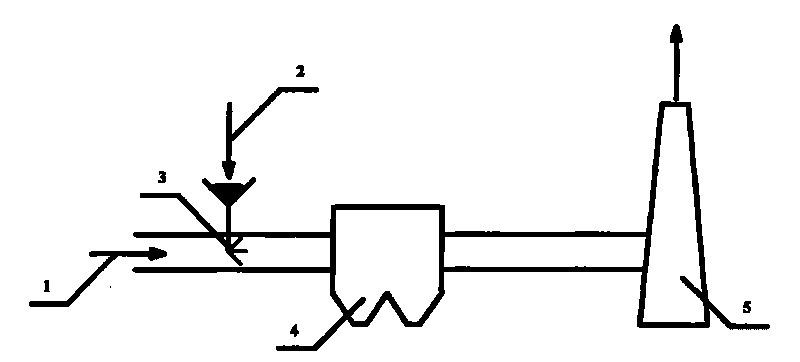

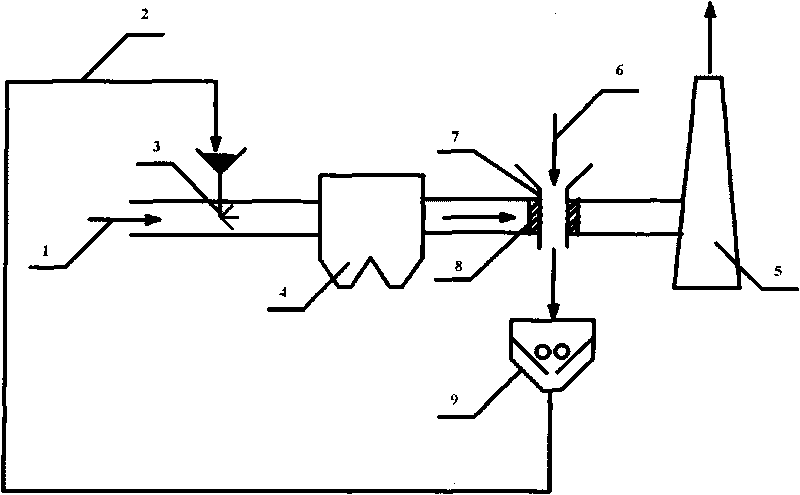

[0018] First, 6kg / h powdered activated carbon 2 is sprayed into the flue through a venturi injector 3, and the dioxins in the waste incineration flue gas are initially removed, and then the flue gas enters the bag filter 4 for dust removal, and the remaining trace dust is in the When the flue gas flows through the inlet of the filter device 7, it is intercepted by about 10kg of activated carbon fibers 8. After the flue gas passes through the filter device 7, dioxin is successively adsorbed on the granular activated carbon 6 and about 20kg of activated carbon fiber 8 at the outlet of the flue gas, and the content is reduced to 0.02ng / m 3 , discharged through the chimney 5. The granular activated carbon 6 removed from the bottom of the filtering device 7 enters the pulverizer 9 and is pulverized into powdered activated carbon 2, and the...

Embodiment 2

[0021] Flue gas flow: 92500m 3 / h, dioxin concentration: 10ng / m 3 . (The above values are converted to 11% oxygen content on a dry basis)

[0022] First, 10kg / h powdered activated carbon 2 is sprayed into the flue through the venturi injector 3, and the dioxins in the waste incineration flue gas are initially removed, and then the flue gas enters the bag filter 4 for dust removal, and the remaining trace dust is in the When the flue gas flows through the inlet of the filter device 7, it is intercepted by about 10kg of activated carbon fibers 8. After the flue gas passes through the filter device 7, dioxins are successively adsorbed on the granular activated carbon 6 and about 40kg of activated carbon fibers 8 at the outlet of the flue gas, and the content is reduced to 0.02ng / m 3 , discharged through the chimney 5. The granular activated carbon 6 removed from the bottom of the filtering device 7 enters the pulverizer 9 and is pulverized into powdered activated carbon 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com