Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Avoid affecting the process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

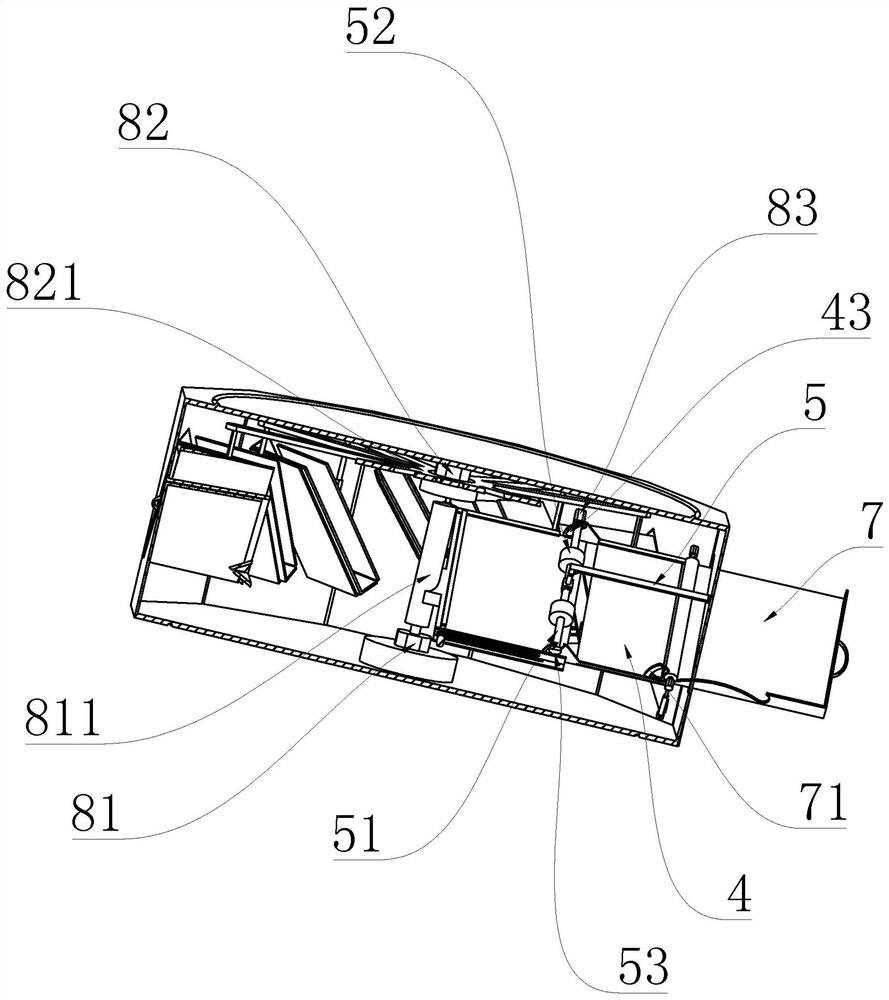

Display panel, manufacturing method thereof and display device

ActiveCN112670323AReduce adhesionImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsComposite material

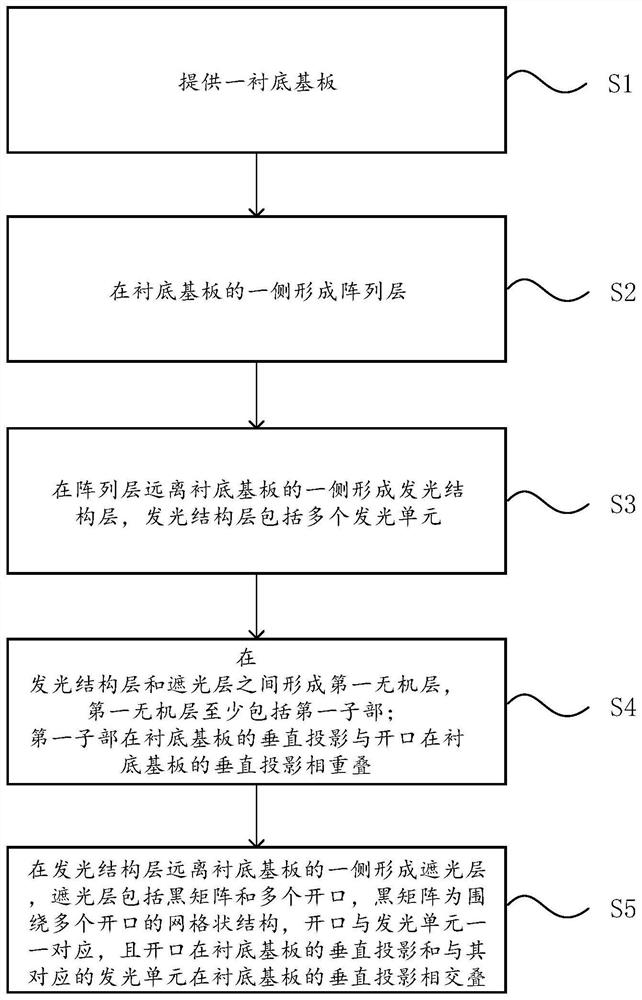

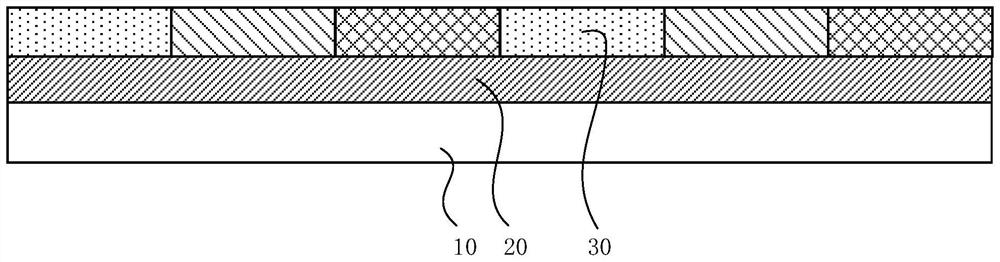

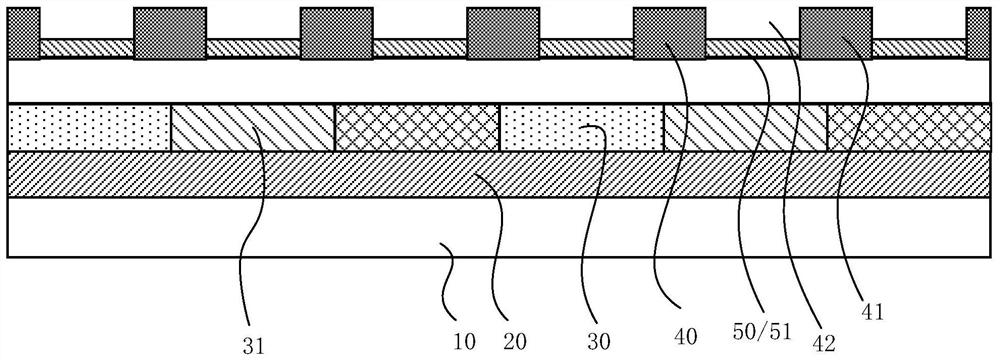

The invention discloses a display panel, a manufacturing method thereof and a display device, and relates to the technical field of display. The manufacturing method of the display panel comprises the following steps: providing a substrate; forming an array layer on one side of the substrate; forming a light-emitting structure layer on one side, far away from the substrate, of the array layer, wherein the light-emitting structure layer comprises a plurality of light-emitting units; forming a shading layer on one side, far away from the substrate, of the light-emitting structure layer, wherein the shading layer comprises a black matrix and a plurality of openings; before the opening is formed, forming a first inorganic layer between the light emitting structure layer and the light shielding layer, wherein the first inorganic layer at least comprises a first sub-part, and the vertical projection of the first sub-part on the underlayer substrate is overlapped with the vertical projection of the opening on the underlayer substrate. The problem that in the prior art, large-area black photosensitive material residues exist in an opening area of a black matrix in a color filter, the subsequent manufacturing process of a color filter part is affected, and therefore the display quality of a display panel is affected is solved.

Owner:HUBEI YANGTZE IND INNOVAION CENT OF ADVANCED DISPLAY CO LTD

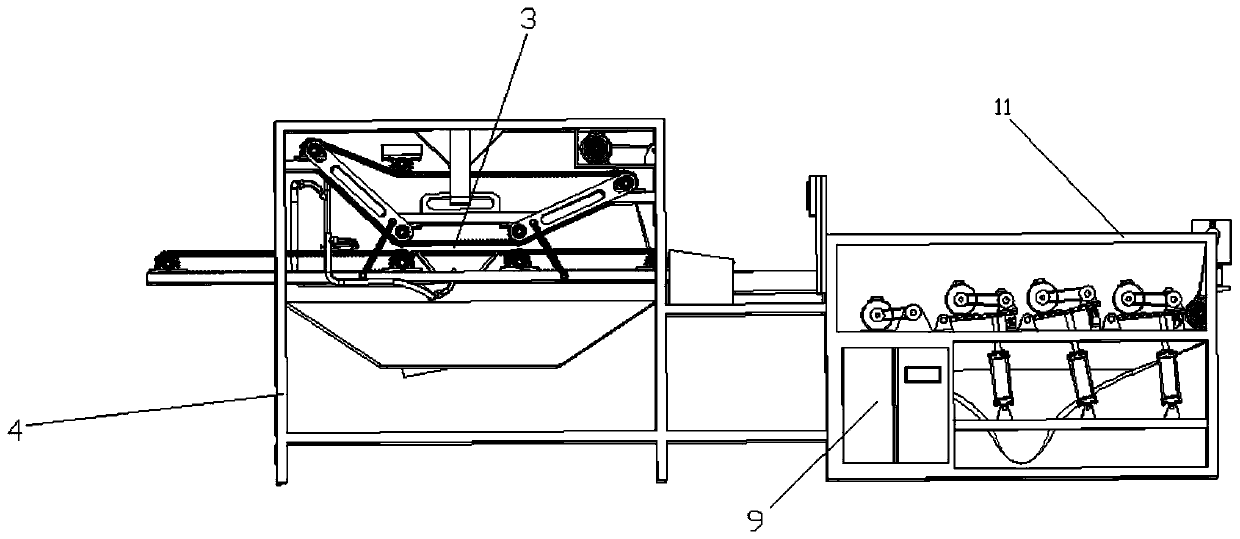

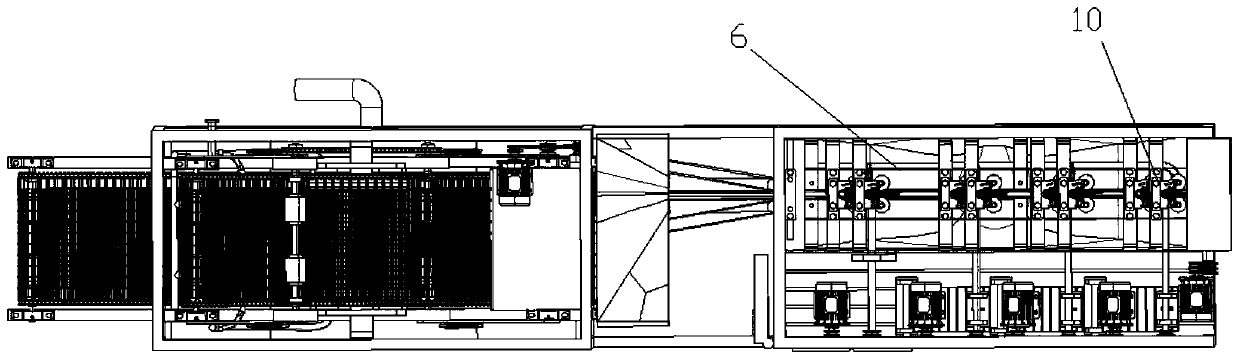

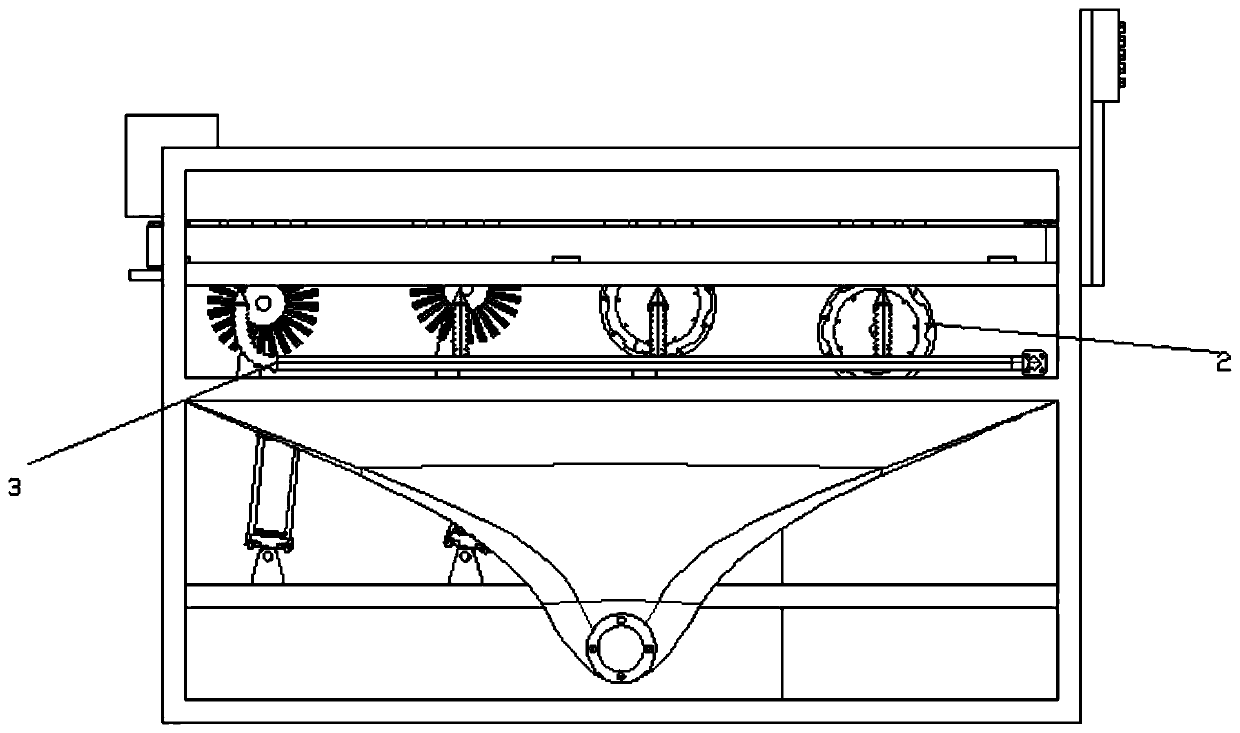

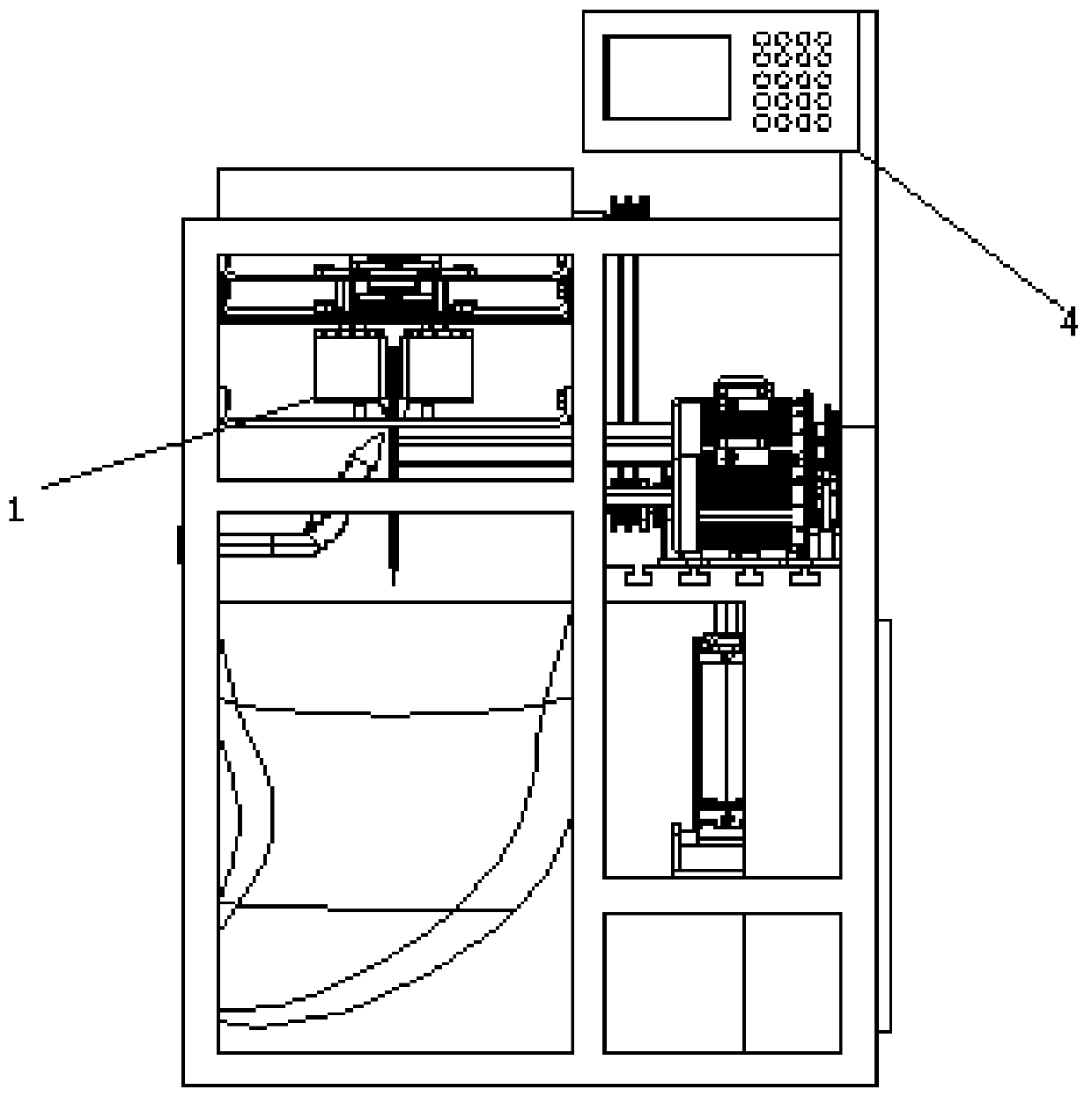

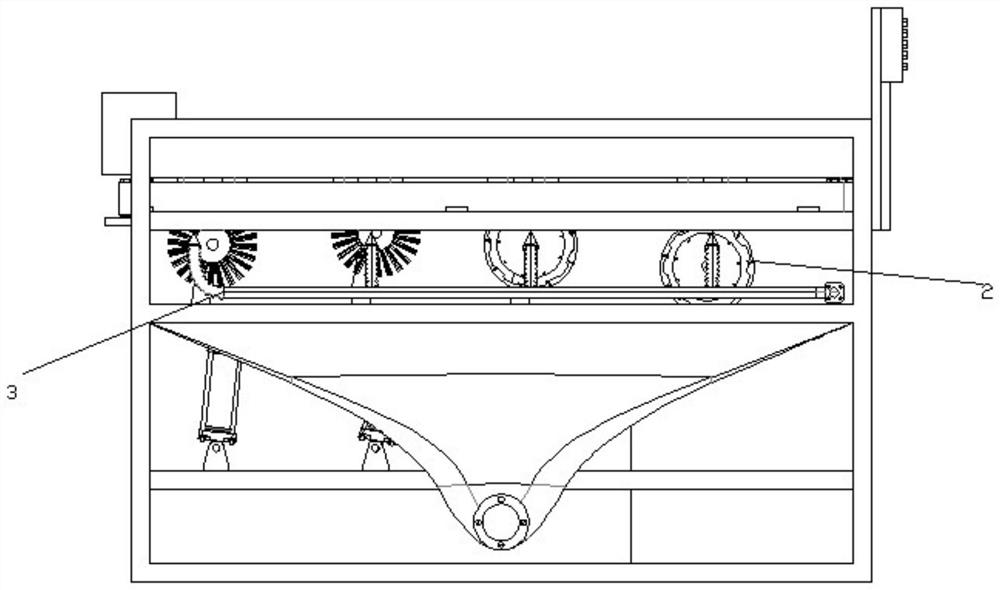

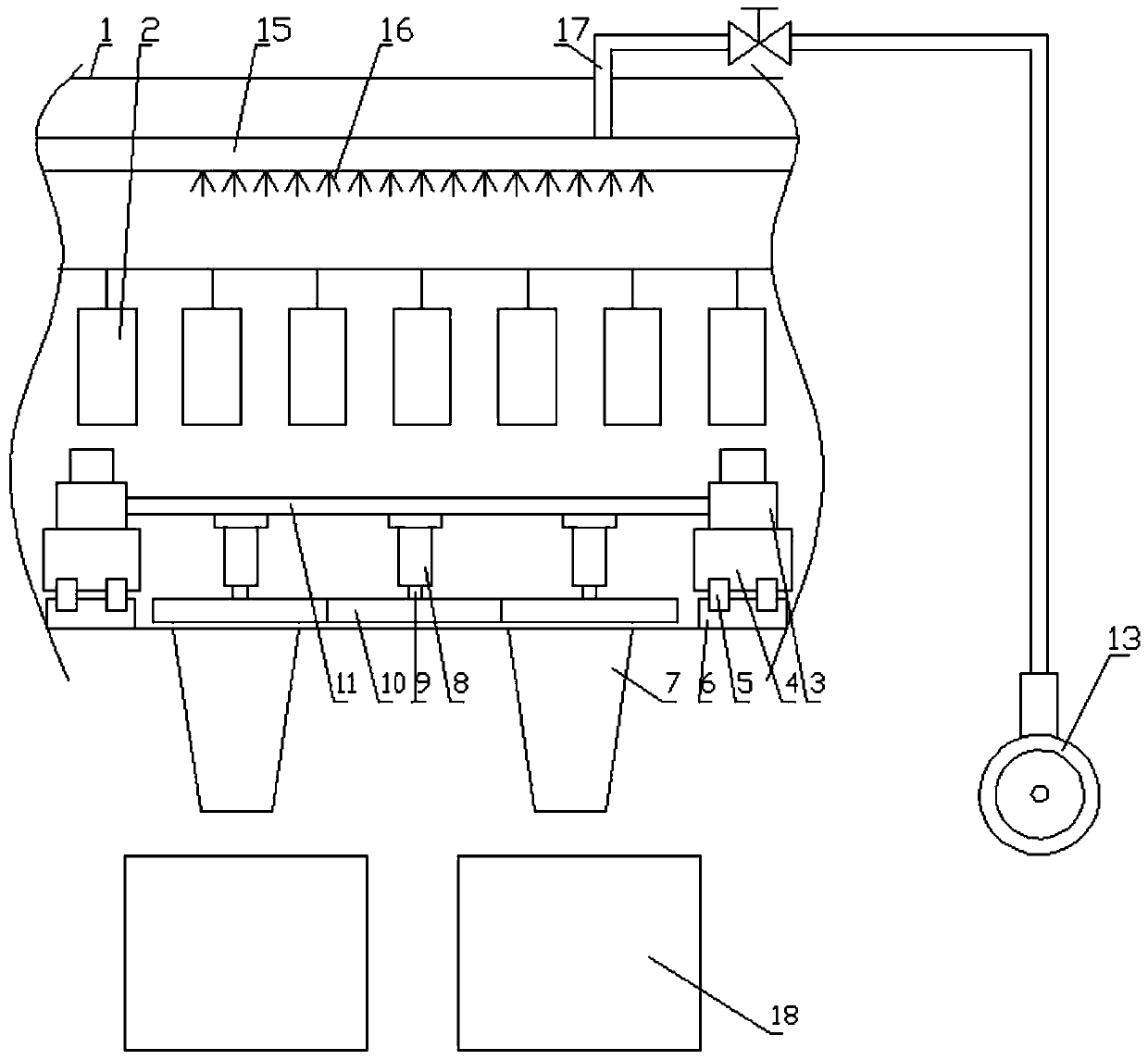

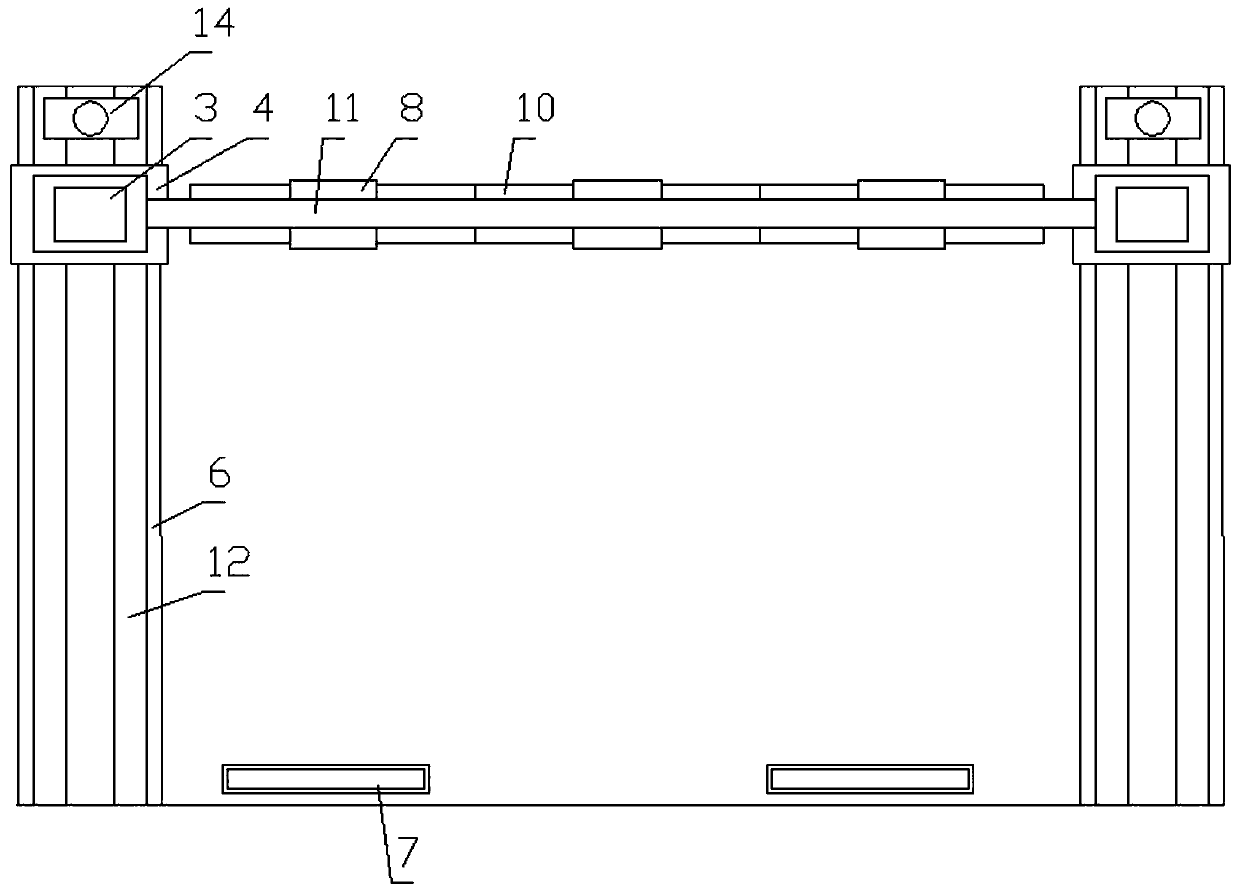

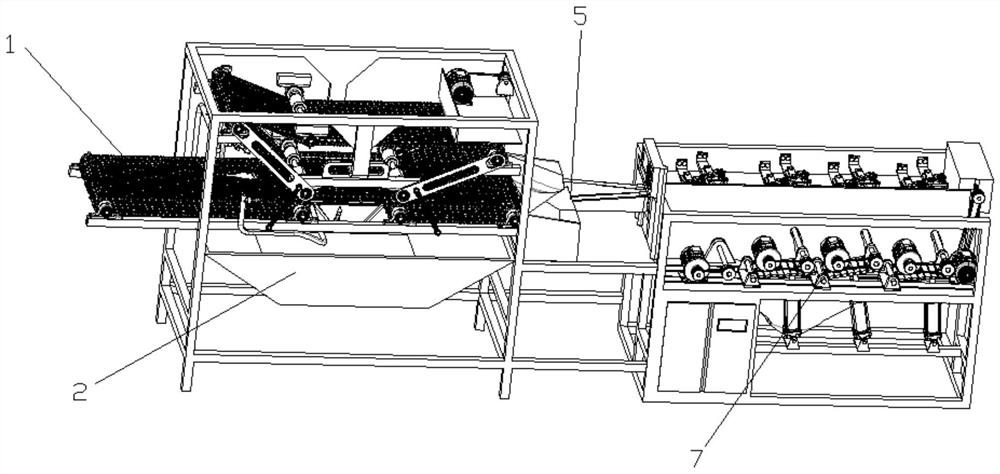

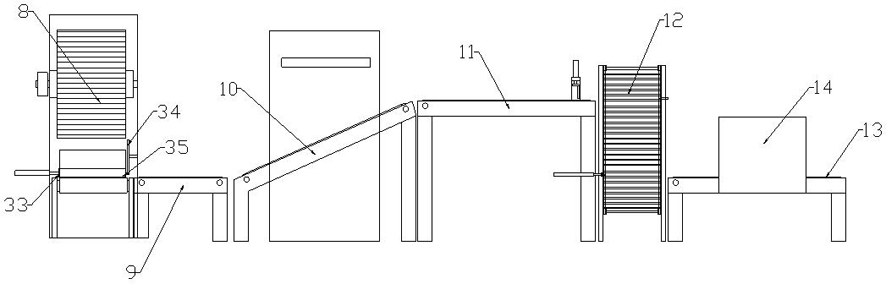

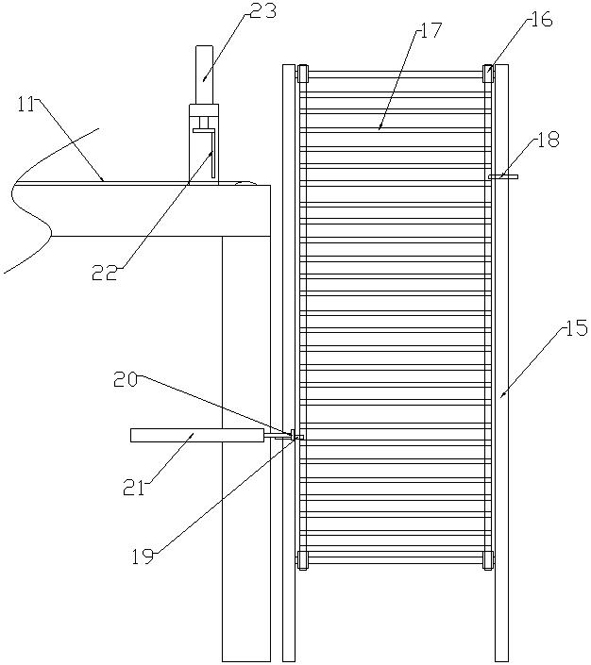

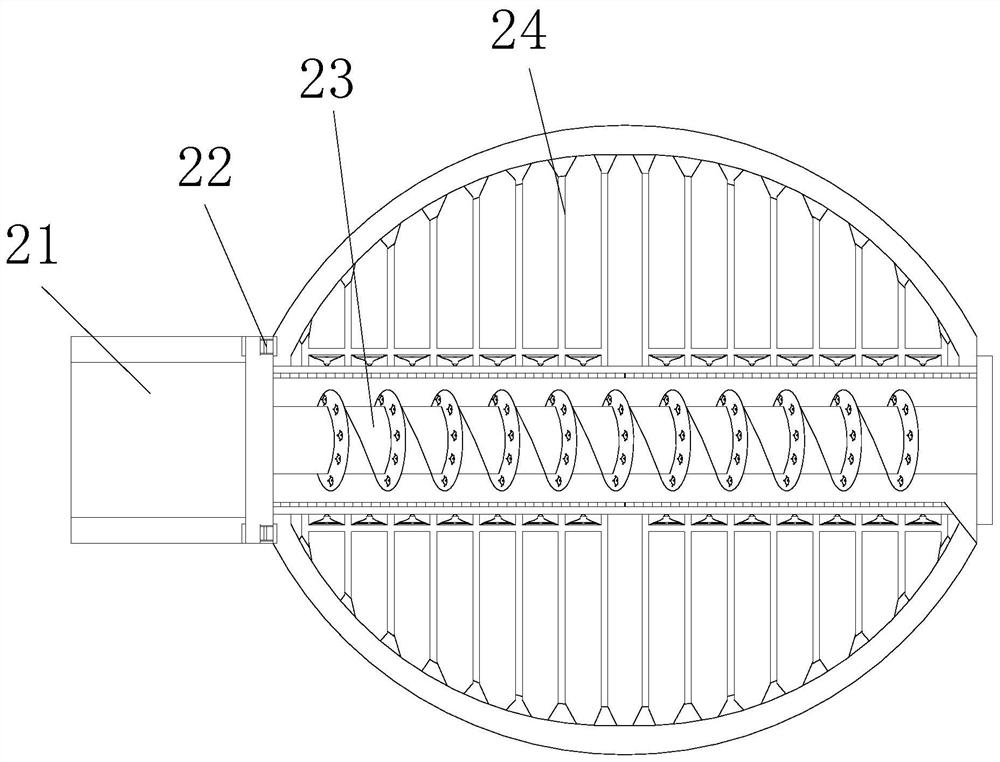

Descaling and gutting integrated machine for fish

ActiveCN111528262ANo damageEfficient processingFish washing/descalingFish arrangingEngineeringMechanical engineering

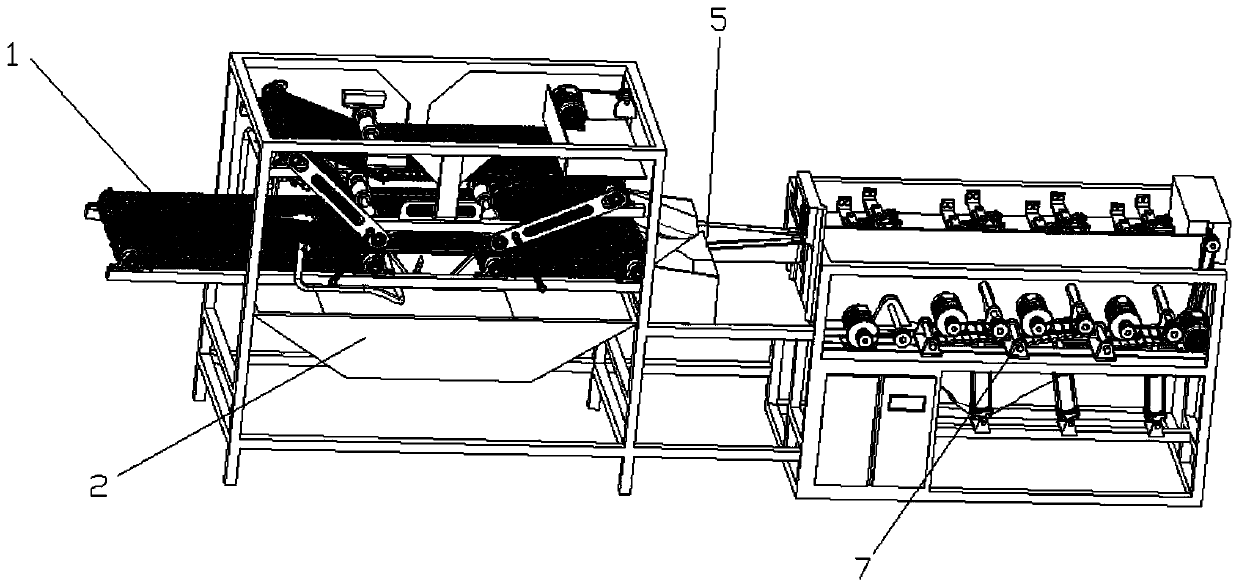

The invention relates to the technical field of processing equipment for fish, in particular to a descaling and gutting integrated machine for fish. The descaling and gutting integrated machine comprises a descaling drive mechanism, a descaling water spray mechanism, a descaling clamping mechanism, a descaling rack, a descaling and gutting engagement mechanism, a gutting drive mechanism, a guttingmechanism, a gutting water spray mechanism, a control mechanism, gutting clamping mechanisms and a gutting rack. By adopting a double-knife and double-brush gutting mode of employing automatic lifting cylinders, gutting is clean and thorough, and damage to a fish body is avoided. A simple and effective cant engagement device is designed between a descaling part and a gutting part, so that the fish body can be effectively turned over in a manner that a fish belly is downward to be transported to the gutting part as long as the fish body is placed in a manner that a fish head is forward and thefish belly is toward a center line of a descaling plate during descaling and material transporting.

Owner:DALIAN POLYTECHNIC UNIVERSITY

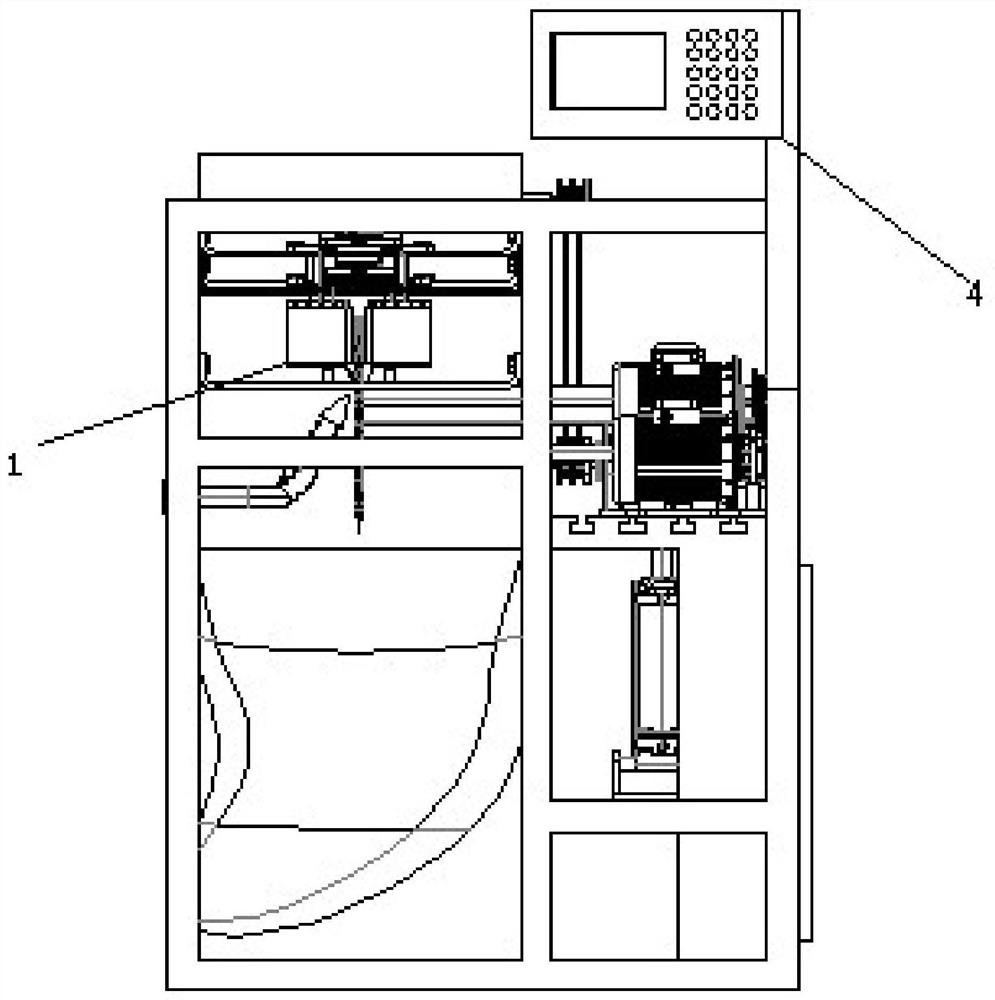

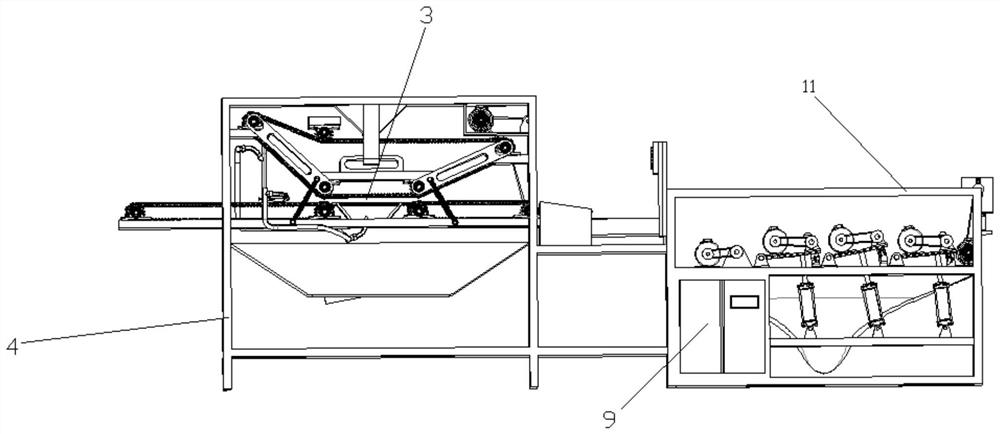

Fish viscera removing and cleaning device

The invention discloses a fish viscera removing and cleaning device, which comprises a transmission mechanism, a viscera removal mechanism, a water sprinkling device, a control system, a clamping mechanism and a rack. Compared with other existing viscera removing machines, the viscera removing device provided by the invention is characterized in that after an internal fixed laparotome opens the fish belly, a single-side fixed movable belly supporting clip opens the fish belly until viscera removal processing is finished, a forward-rotation fish viscera cutter and two viscera removal hair brushes with opposite self-rotation directions can be designed to be elevatable, a control program is set to effectively realize cooperation among cutters, and in addition, a high-pressure water injectiondevice is arranged between every two cutters so as to achieve an effect on efficiently removing viscera and automatically cleaning.

Owner:山东名成海洋科技有限公司

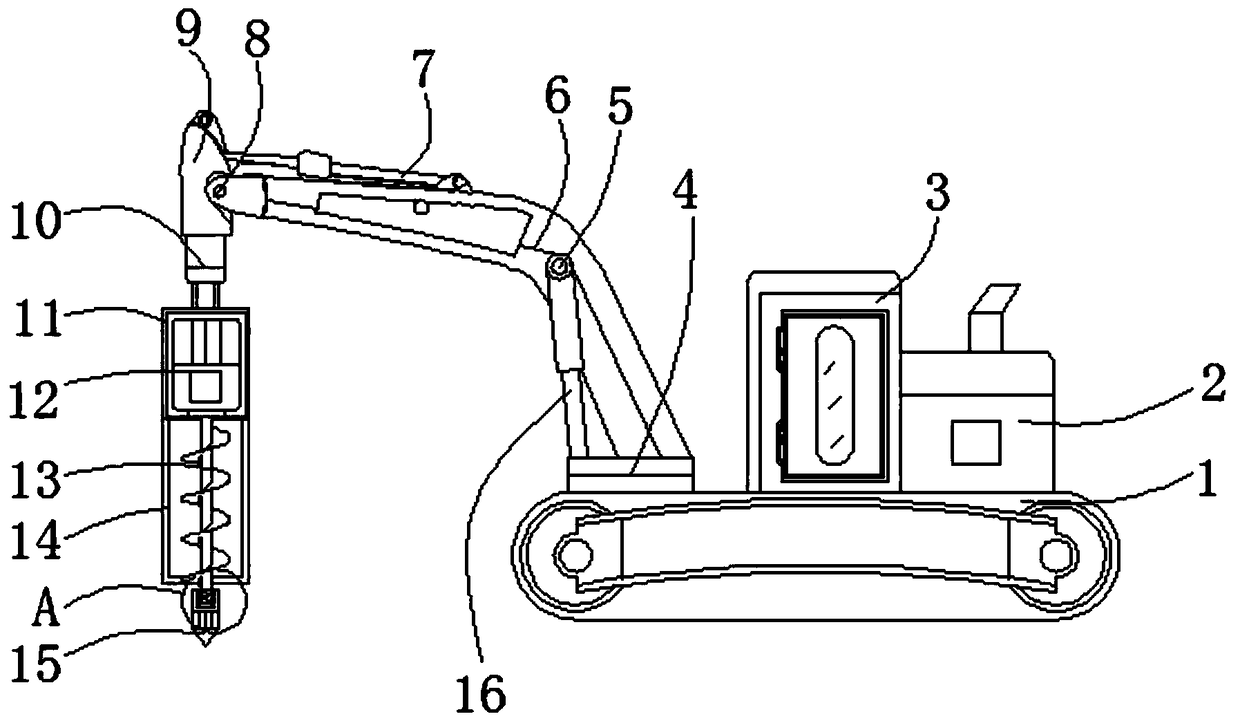

Ground drilling machine capable of pumping soil and reducing sound for petroleum drilling and production

InactiveCN109281609AAvoid enteringConsistent forceEarth drilling toolsSurveyControl roomScrew thread

The invention relates to a ground drilling machine capable of pumping soil and reducing sound for petroleum drilling and production. The ground drilling machine comprises a movable base, a second hydraulic rod and sound reducing cotton. A transmission box is arranged above the movable base, a control room is arranged on the left side of the transmission box, the transmission box and the control room are fixedly connected, and the transmission box and the movable base are movably connected. A support seat is arranged on the left side of the top end of the movable base, a main machine arm is connected to the top of the support seat, and a third hydraulic rod is disposed on the outer side of the main machine arm. The ground drilling machine has the beneficial effects that the ground drillingmachine adopts the arrangement of a drill bit, an internal thread, an external thread, a screw rod and the second hydraulic rod, the drill bit forms a detachable structure through the internal thread,the external thread and the screw rod, and before performing drilling and production work on an area to be subjected to drilling and production through the drill bit, the drill bit is subjected to screwing and fixing operation by an operator, so that the inner thread on the inner side of the top of the drill bit and the outer thread on the bottom end outer wall of the screw rod are screwed together.

Owner:广州顺途信息科技有限公司

Cooling device for automobile part cutting

PendingCN106514020AComplete separationImprove cutting effectLaser beam welding apparatusPistonLaser cutting

The invention belongs to the field of machining and particularly discloses a cooling device for automobile part cutting. The cooling device for automobile part cutting comprises a fixing seat. One end of the fixing seat is provided with a clamping mechanism. A laser cutting mechanism is arranged in the middle of the fixing seat and comprises a supporting frame. A first rotating shaft is rotationally connected to the supporting frame. The work end of the first rotating shaft is statically connected with an eccentric wheel. A laser cutter is arranged on the edge of the eccentric wheel. A second rotating shaft is further statically connected with the eccentric wheel. The other end of the fixing seat is connected with a cooling mechanism. The cooling mechanism comprises a cylinder body, a piston, a water inlet, a water outlet, a water outlet pipe, a crankshaft and a connecting rod. The work end of the water outlet pipe is arranged in the first rotating shaft in a penetrating manner and is aligned with part raw materials. The crankshaft is connected with the second rotating shaft. The cooling device for automobile part cutting can cool finished part products obtained after laser cutting and prevent the finished part products from being fused with the part raw materials in the cutting process.

Owner:重庆寅悦恒工贸有限公司

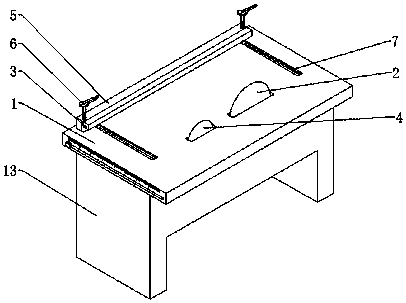

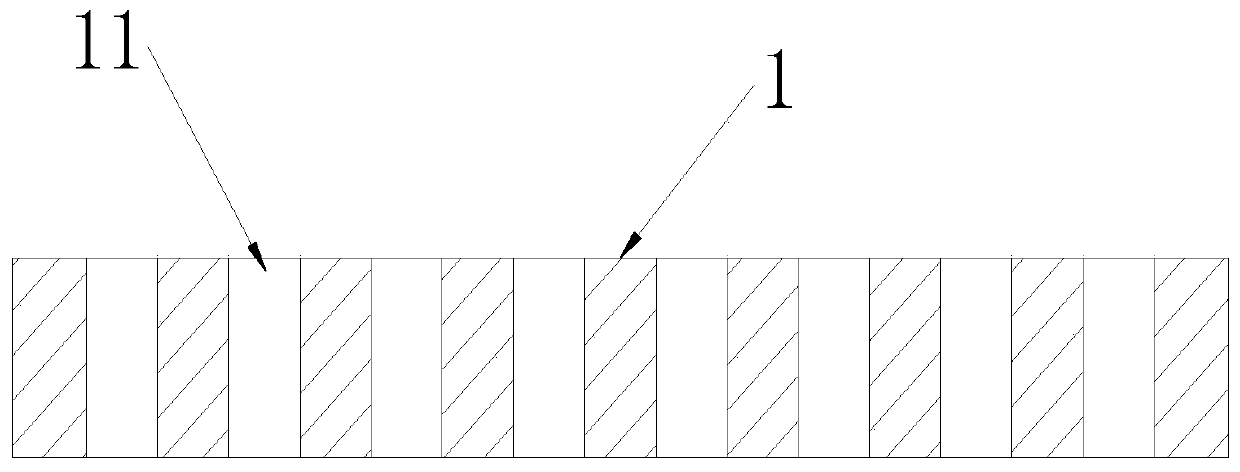

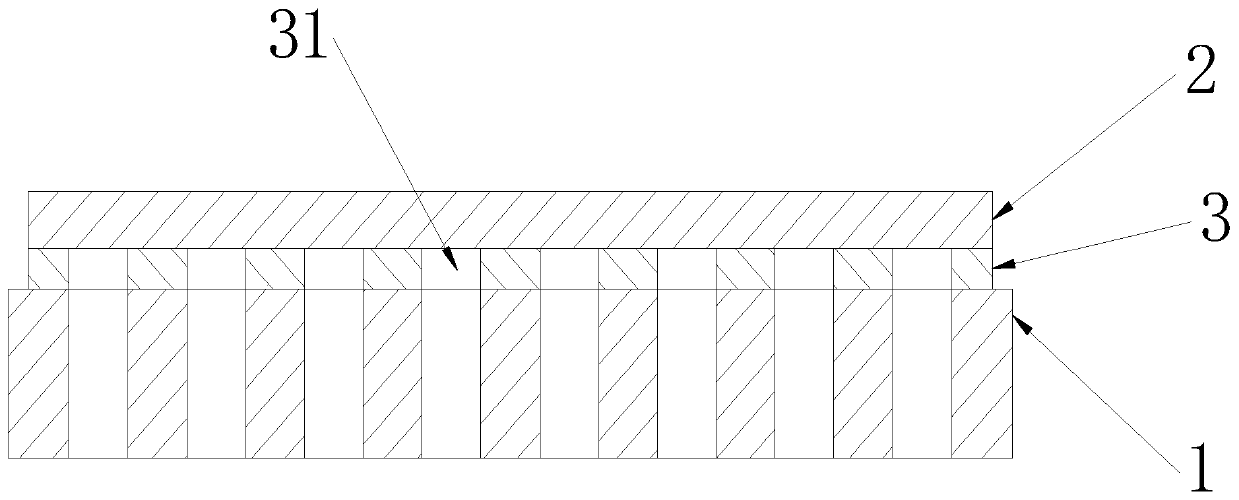

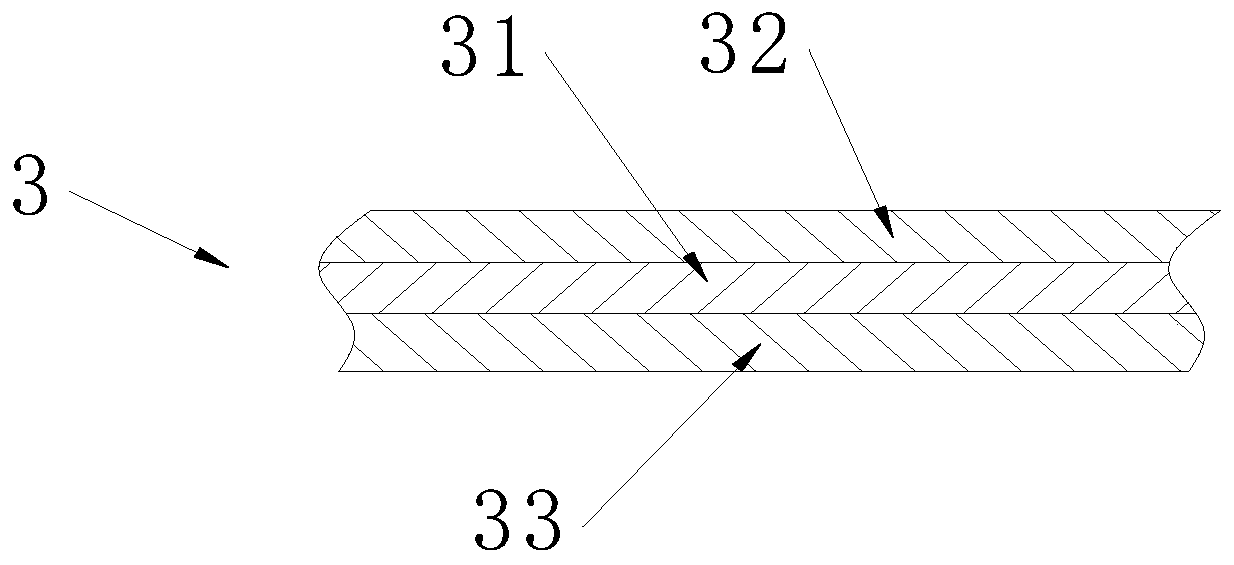

Laminated board edge-breakage-proof bench saw

InactiveCN109291141APrevent intrusionAvoid affecting the processGuide fencesCircular sawsThrough transmissionEngineering

The invention discloses a laminated board edge-breakage-proof bench saw. The laminated board edge-breakage-proof bench saw comprises a cutting table, a bench saw backer and a base; the bench saw backer is connected with a clamping block through a hand-screwing screw at the top end; two sliding blocks are disposed at the two ends of the bottom of the bench saw backer; the sliding blocks are connected with tightening screwing handles through threaded rods; a large saw blade and a small saw blade are in transmission connection with driving rollers on output shafts of a first motor and a second motor correspondingly through transmission rollers and belts; two damping columns are disposed at the bottom end of the inner wall of the base; and damping sponge is disposed at the top ends of the damping columns. A laminated board is limited through the clamping block and is prevented from vertically shaking during cutting, edge breakage of the laminated board can be effectively prevented during cutting, the damping sponge at the top ends of the damping columns makes contact with the bottom end of the cutting table, a certain absorption capacity for vibration caused during cutting can be achieved, edge breakage caused by vibration during cutting is further reduced, finally the small saw blade assists in preliminary grooving, the large saw blade cuts off materials, and the possibility of edge breakage is further lowered.

Owner:宿迁市三泰木业有限公司

Method for producing wafer by combining composite adhesive film with through hole glass carrier plate structure

PendingCN111599743AAvoid affecting the processAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingWaferAdhesive

The invention discloses a method for producing a wafer by combining a composite adhesive film with a through hole glass carrier plate structure. The invention is characterized in that the method for producing the wafer includes the steps of S1, forming holes in the glass carrier plate; S2, adhering the composite adhesive film to a glass carrier plate, enabling the wafer to be accurately aligned tothe glass carrier plate by adopting an optical mechanism, then placing the front surface of the wafer on the composite adhesive film, and adhering the wafer to the glass carrier plate by adopting a film laminating, pressing and heating mode; S3, removing the composite adhesive film in a glass window hole, and thinning crystal grains. According to the production method of the wafer, the compositeadhesive film and the windowed glass carrier plate are combined together to replace a traditional adhesive, so that the situation that the subsequent process is influenced due to the fact that a window / TGV communication hole is blocked by uneven coating and blocking of the adhesive is avoided; the glass carrier plate with the through holes and the wafer are bonded together through the composite adhesive film, so that damage to the wafer caused by windowing after bonding is avoided, the production efficiency is improved, and the production cost is reduced.

Owner:绍兴同芯成集成电路有限公司

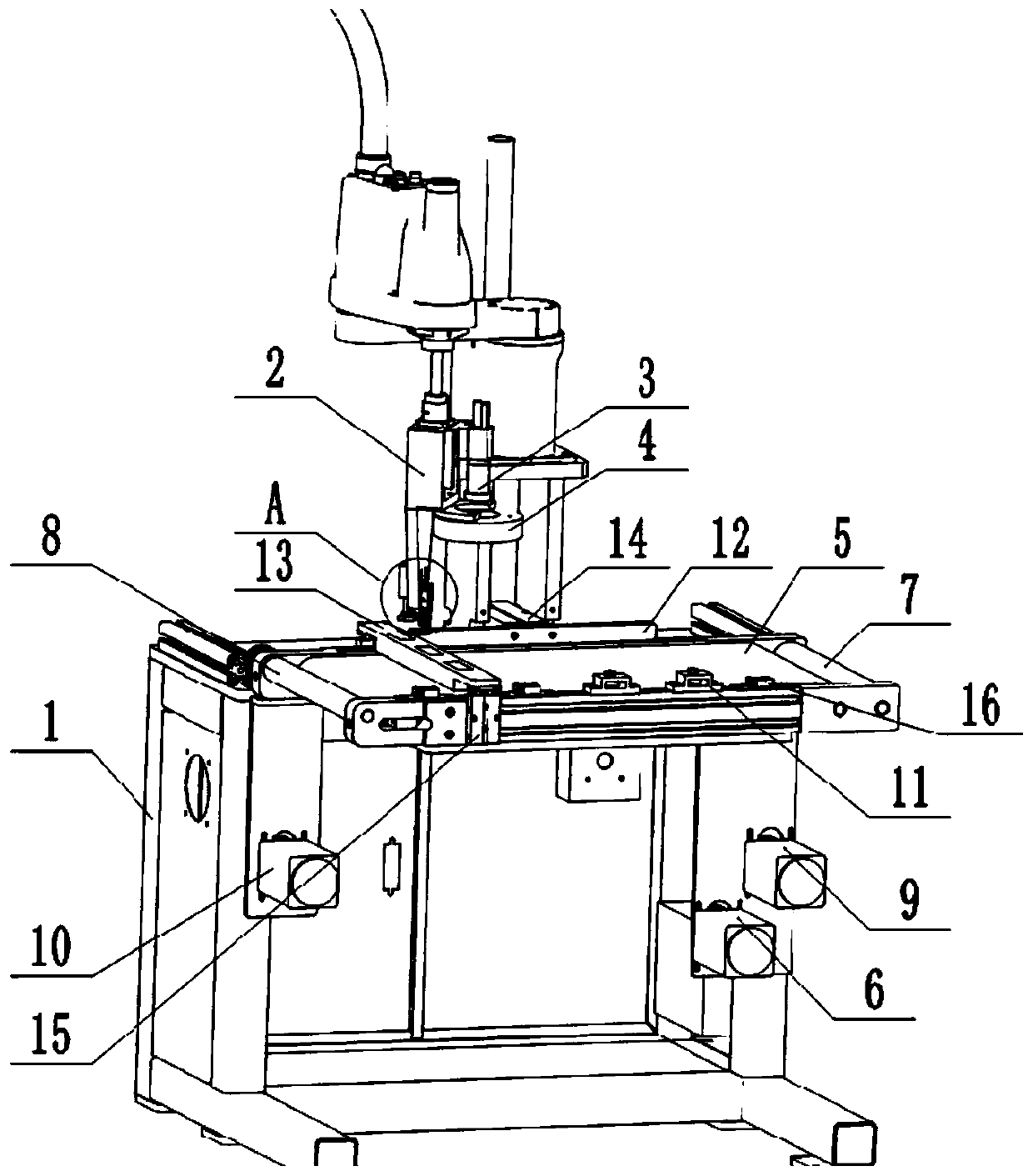

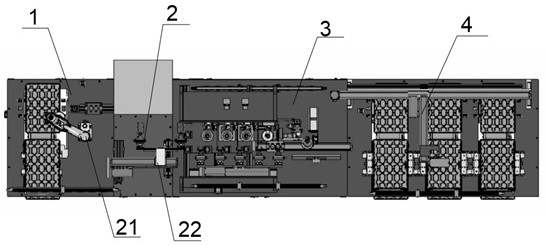

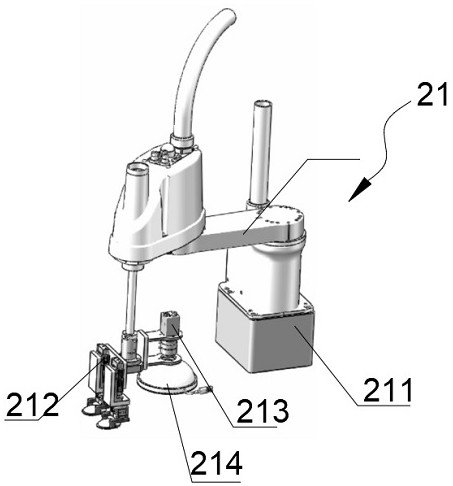

Full automatic wire tidying machine

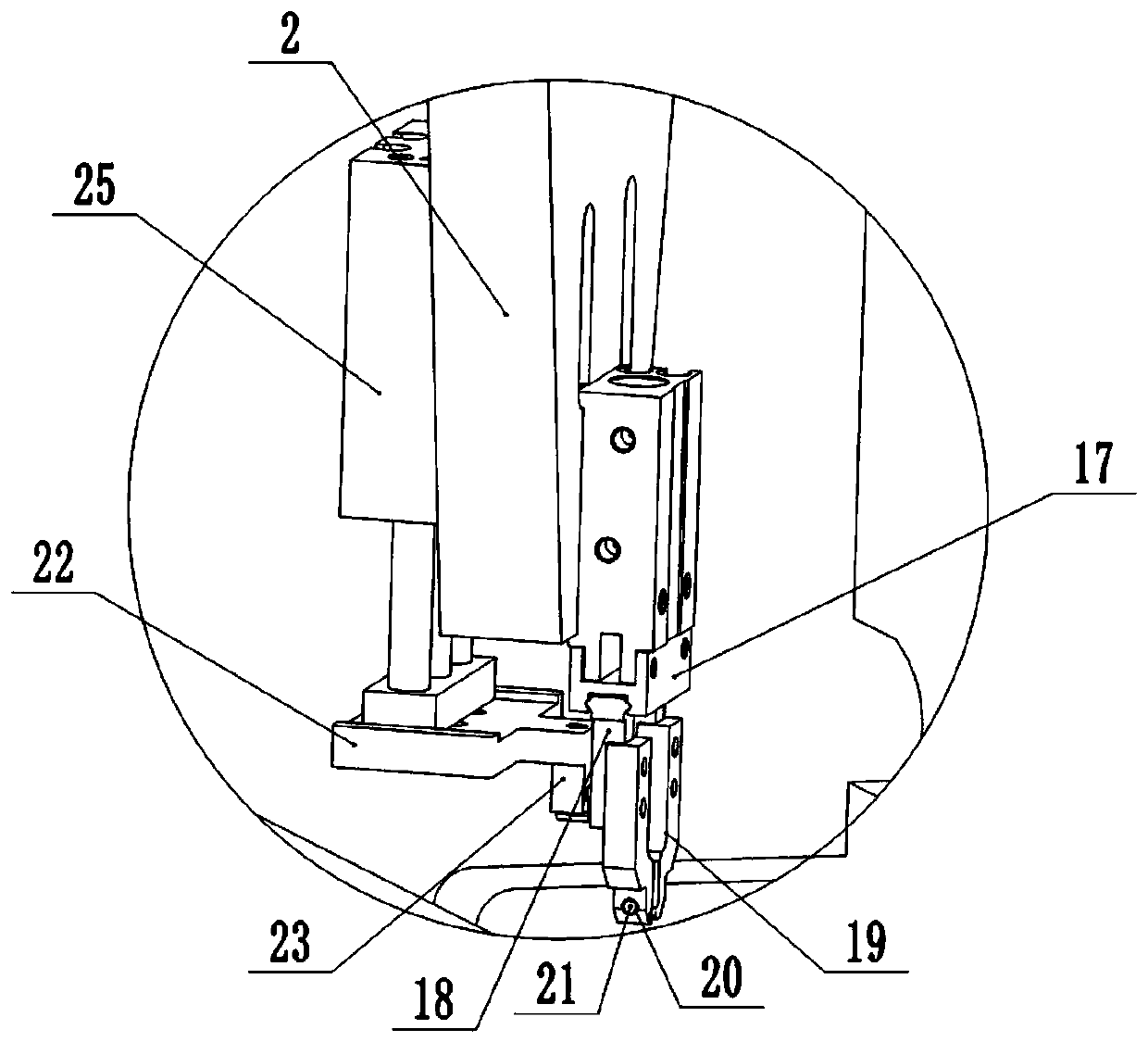

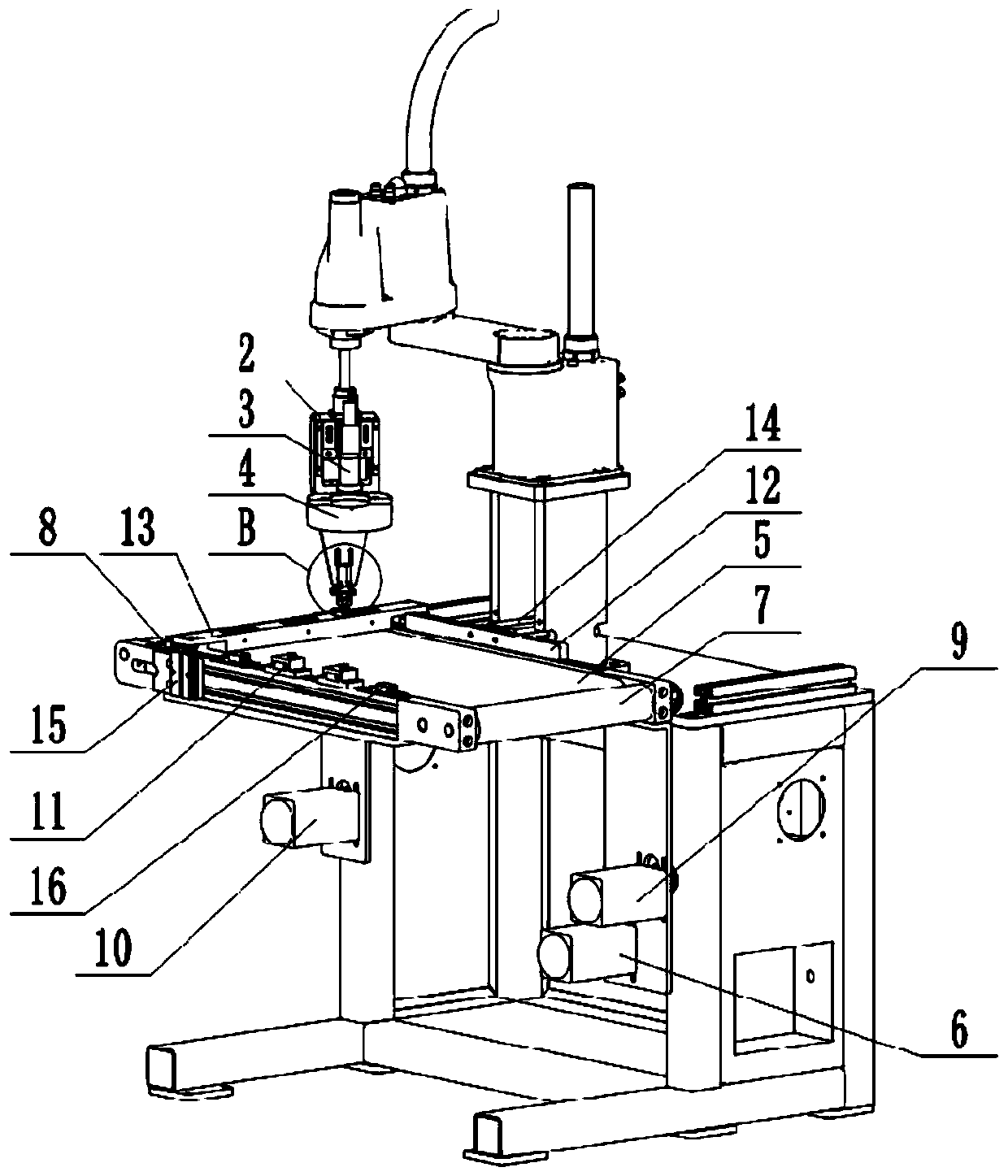

InactiveCN111451740AShorten the timeImprove efficiencyMetal working apparatusEngineeringFully automated

The invention relates to the technical field of automatic assembly equipment, and discloses a full automatic wire tidying machine. The full automatic wire tidying machine comprises a rack. A mechanical arm, a material conveying mechanism, a locating mechanism and a wire taking and pressing mechanism are arranged on the rack, and the wire taking and pressing mechanism is arranged on the mechanicalarm. The locating mechanism comprises a check block fixedly arranged on the rack and a push plate arranged on the rack in a sliding manner, and the check block and the push plate are arranged oppositely. The wire taking and pressing mechanism comprises a wire taking assembly and a wire pressing assembly. The wire taking assembly comprises a pneumatic finger, the pneumatic finger comprises two clamping fingers, a clamping arm is fixedly connected to each clamping finger, and a clamping jaw used for wire taking is formed by the two clamping arms. The wire pressing assembly comprises a press plate used for wire pressing and a drive part used for driving the press plate to press wires. The full automatic wire tidying machine can be used for solving the problems that in the prior art, due to the adoption of the manual wire tidying manner, work efficiency and the percent of pass of products are low.

Owner:重庆泰美自动化科技有限公司

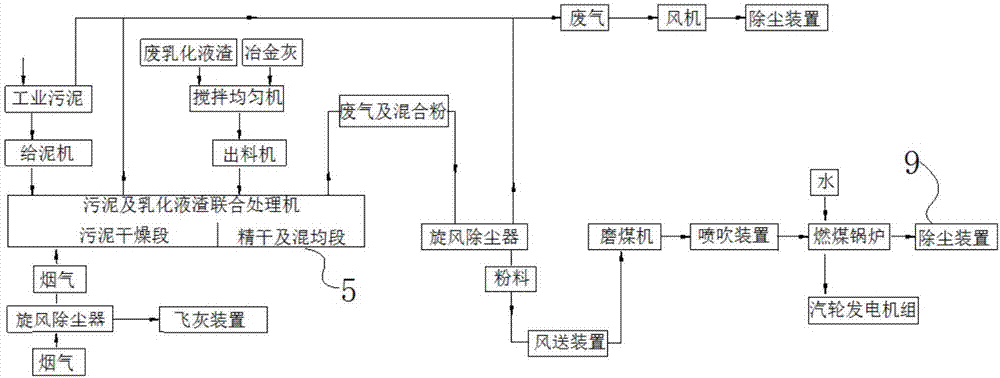

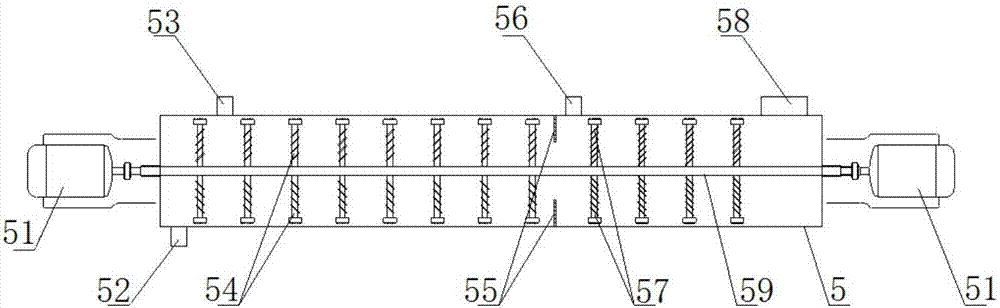

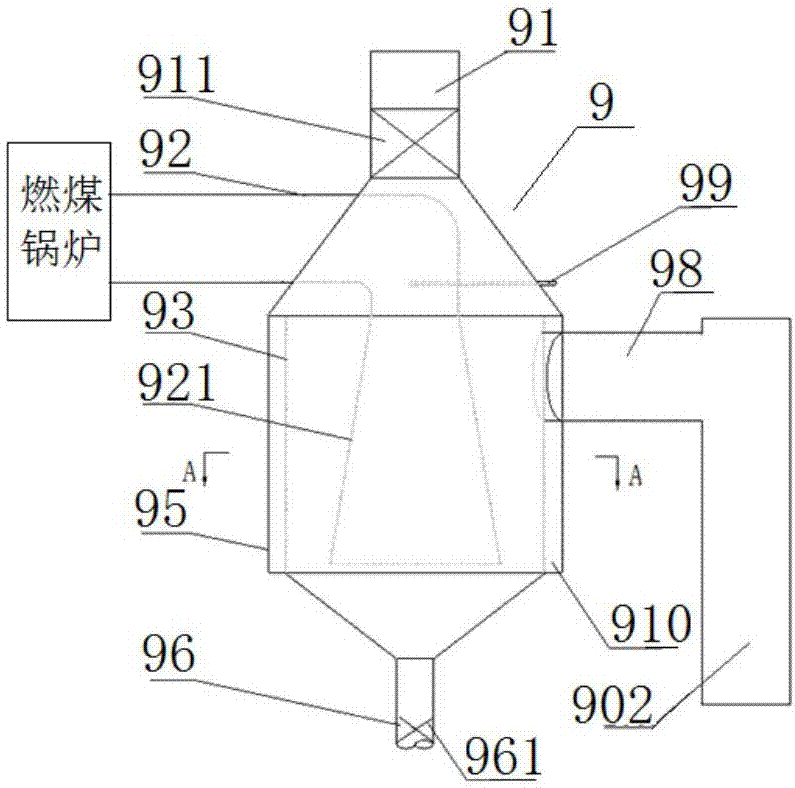

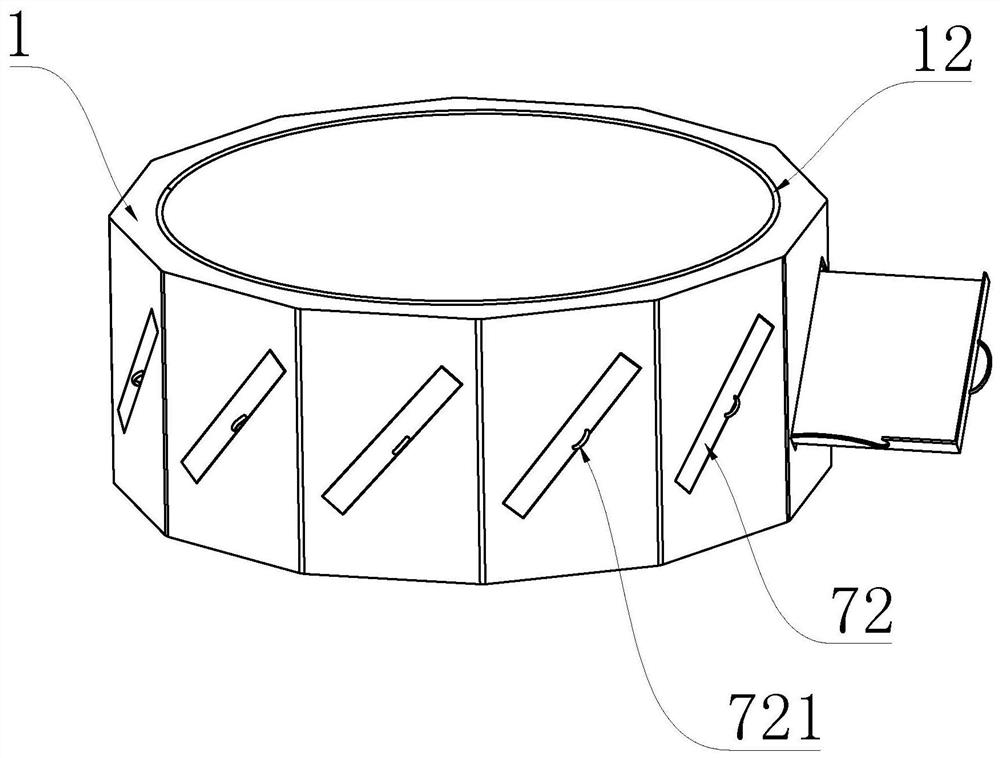

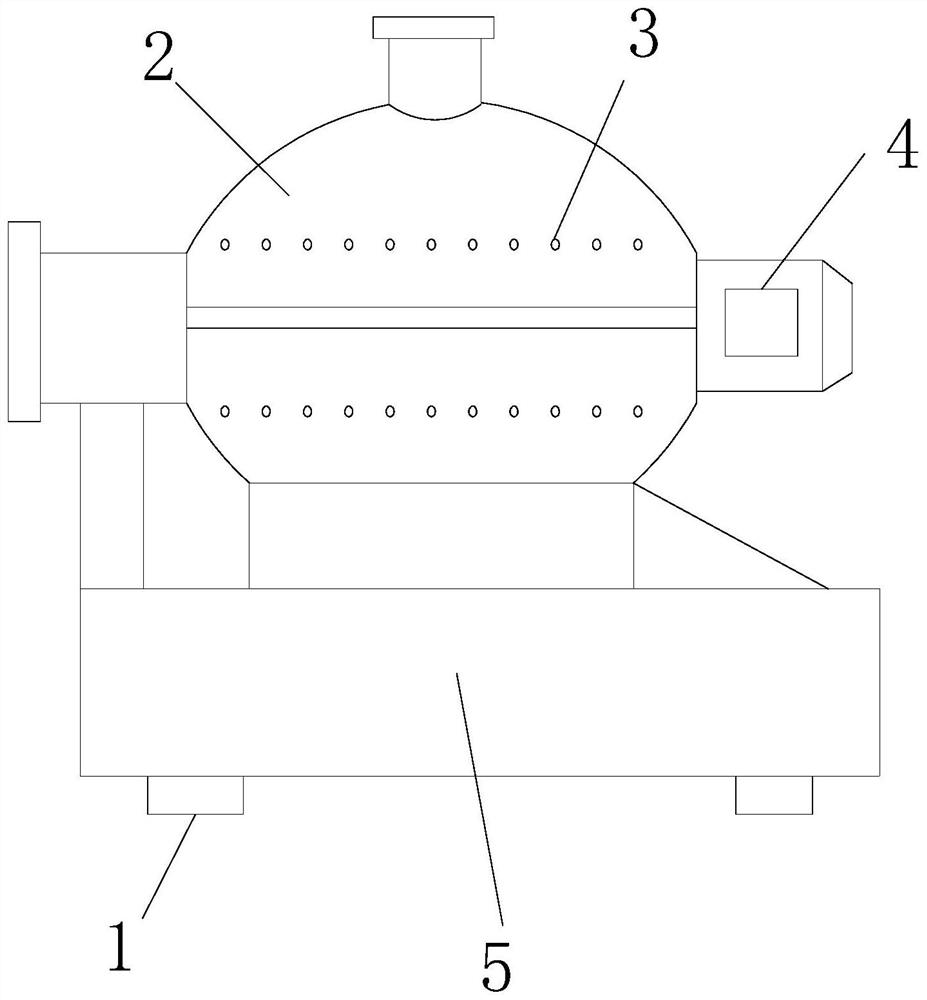

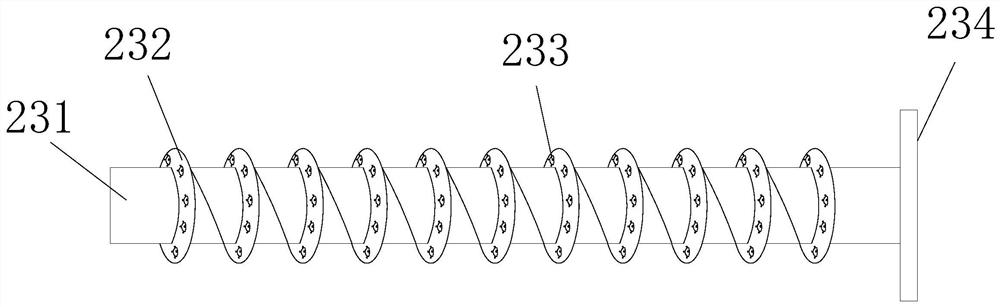

Industrial sludge, waste emulsion slag and metallurgical ash joint treatment system and power generation process thereof

The invention discloses an industrial sludge, waste emulsion slag and metallurgical ash joint treatment system and a power generation process thereof, and belongs to the technical field of dangerous waste comprehensive treatment and heat energy utilization. The joint treatment system comprises a sludge feeding machine, a uniform stirring machine, a discharging machine, an air supply device, a coal mill, a blowing device, a coal-fired boiler, a steam turbine generator unit, a sludge and emulsion slag joint treatment machine and a dust removal device. The sludge and emulsion slag joint treatment machine is wholly of a horizontal bucket structure and comprises a drive shaft penetrating the center line of a bucket body, the two ends of the drive shaft are in transmission connection with an electric motor, the periphery of the drive shaft is fixedly connected with a scraper spiral stirrer, and a sludge inlet, a high-temperature smoke inlet, an emulsion slag inlet and a discharging outlet are formed in the bucket body. The problems that in the prior art, when industrial sludge, waste emulsion slag and metallurgical ash are independently treated, soil and water are polluted, bad smells are easily generated, treatment cost is high, and the boiler dust-containing waste smoke is low in treatment efficiency are solved.

Owner:马钢集团设计研究院有限责任公司

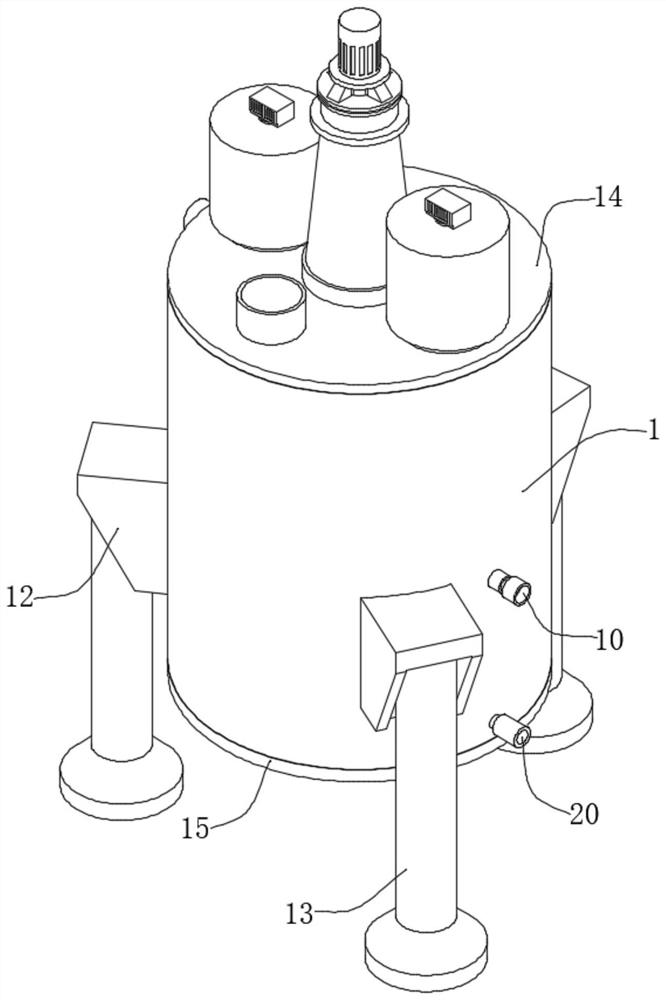

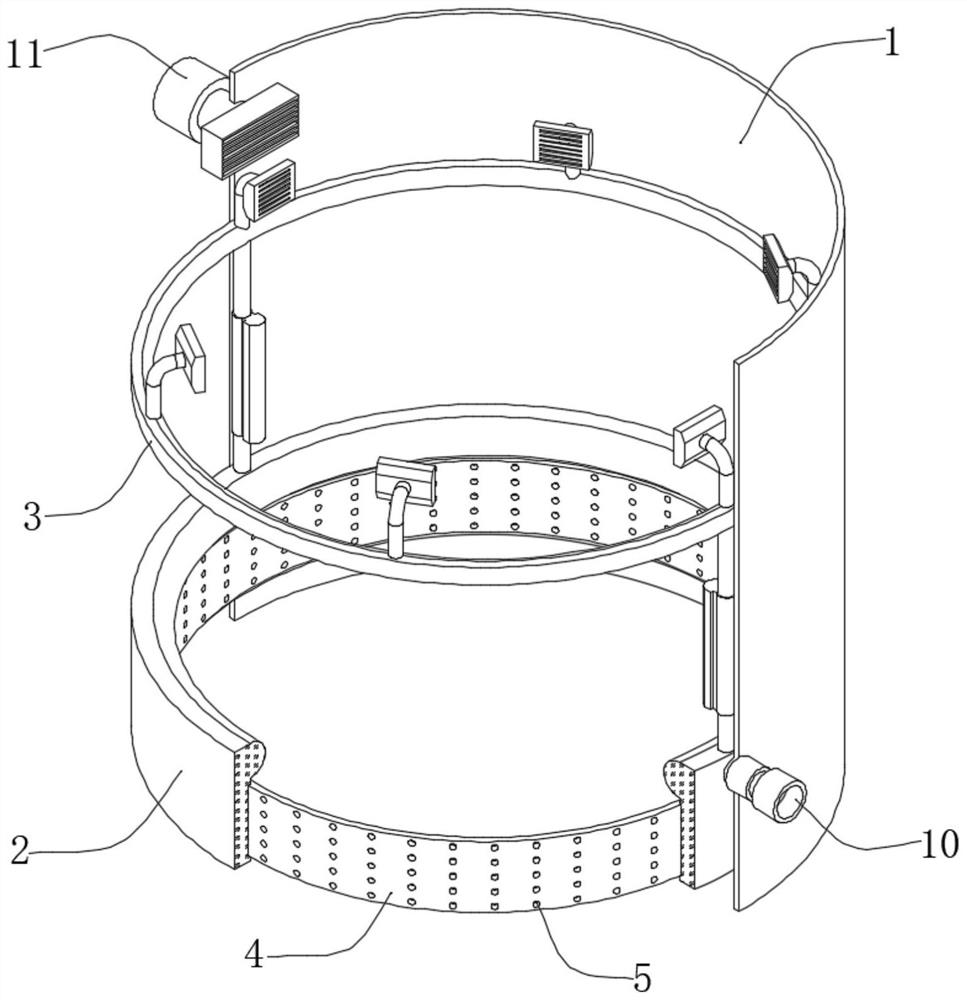

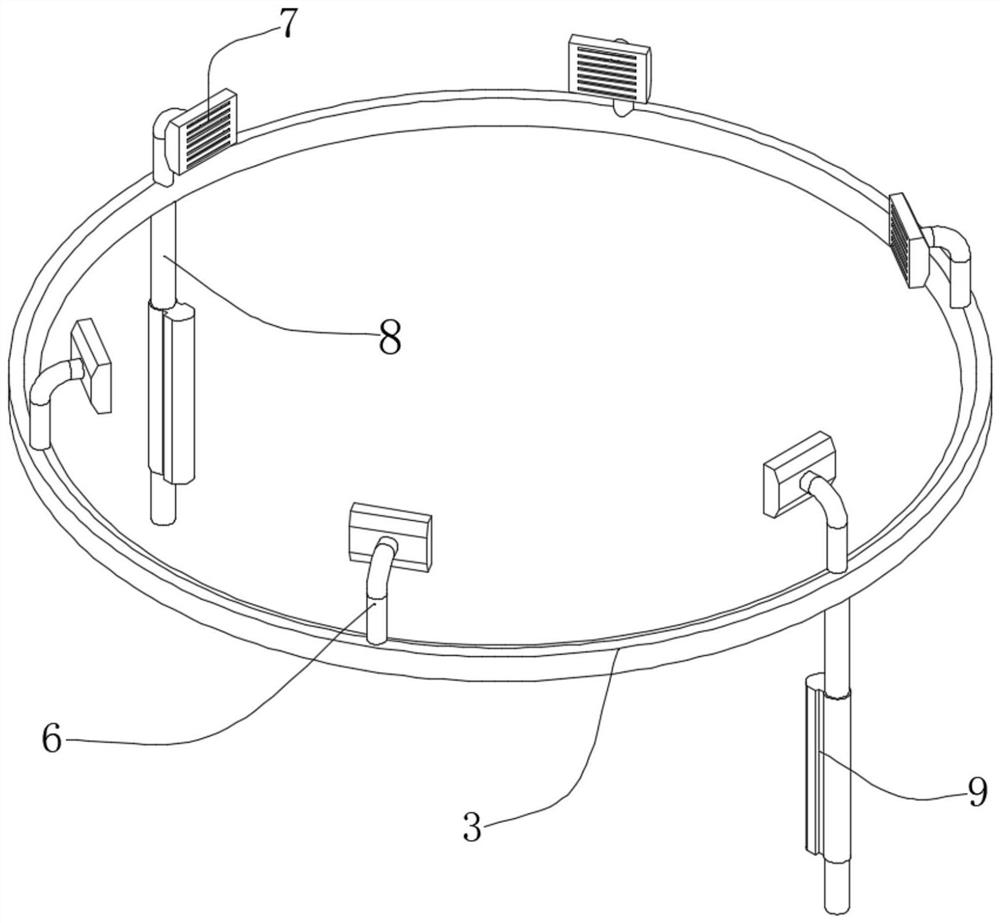

High-yield cyclic acid synthesis method

PendingCN114671773AImprove contact effectImprove catalytic hydrogenation effectOrganic compound preparationAmino-carboxyl compound preparationPtru catalystPhysical chemistry

The invention belongs to the technical field of cyclic acid synthesis, particularly relates to a high-yield cyclic acid synthesis method, and aims to solve the problems that an existing reaction kettle lacks a special catalytic hydrogenation structure, the reaction time is long after hydrogen is added, and the hydrogenation effect is poor. Adding a sulfuric acid solution with the mass fraction of 5-7%, a platinum catalyst and the pretreated aminomethylbenzoic acid into a reaction kettle body from a feeding hole of a synthesis mechanism according to the weight ratio of 2: 1: 6, closing the feeding hole of the reaction kettle body, and starting a device; after the heating plate is electrified, the electrical bar heats a solution in the reaction kettle body, after the temperature of the reaction solution reaches a preset temperature, the motor drives the shaft rod to rotate, and the stirring assembly mixes and stirs the reaction solution.

Owner:江西照阳科技有限公司

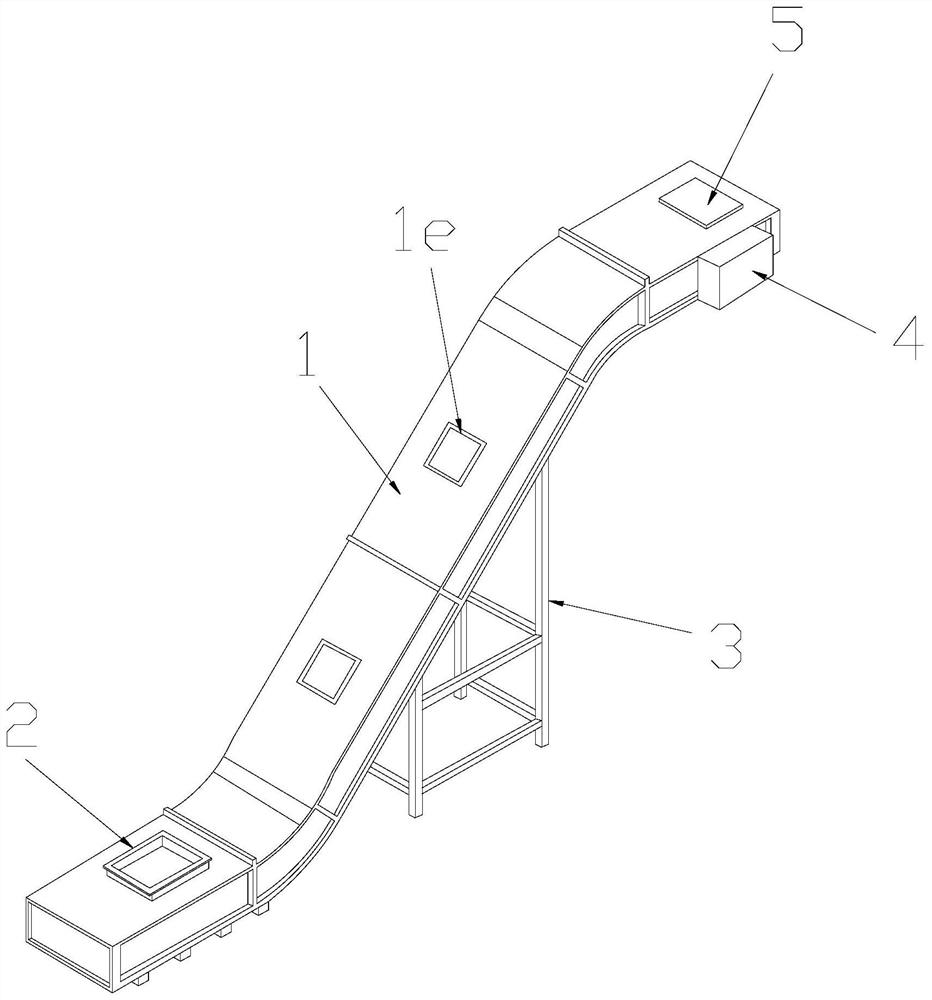

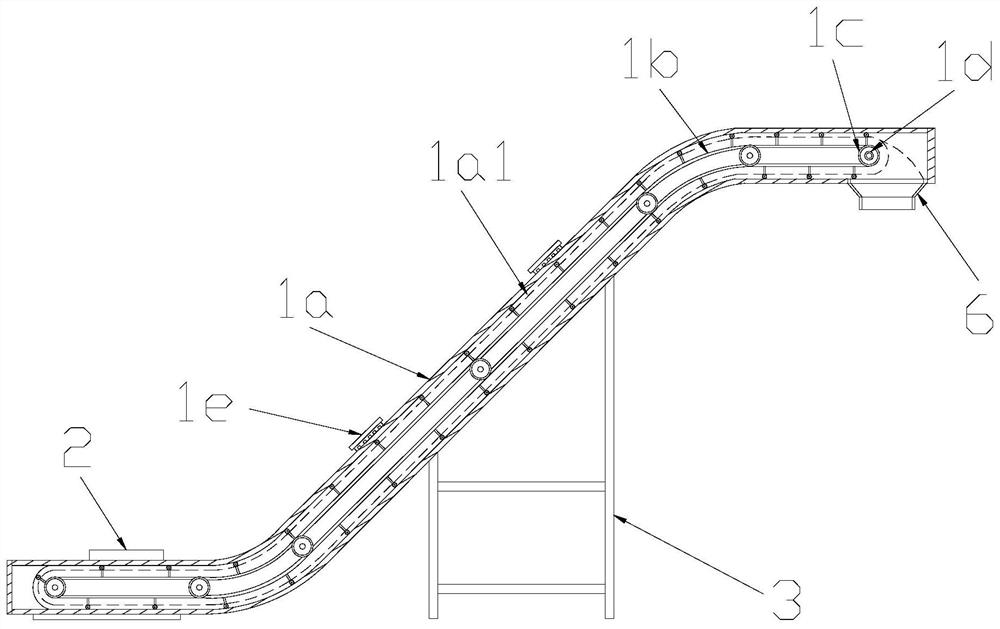

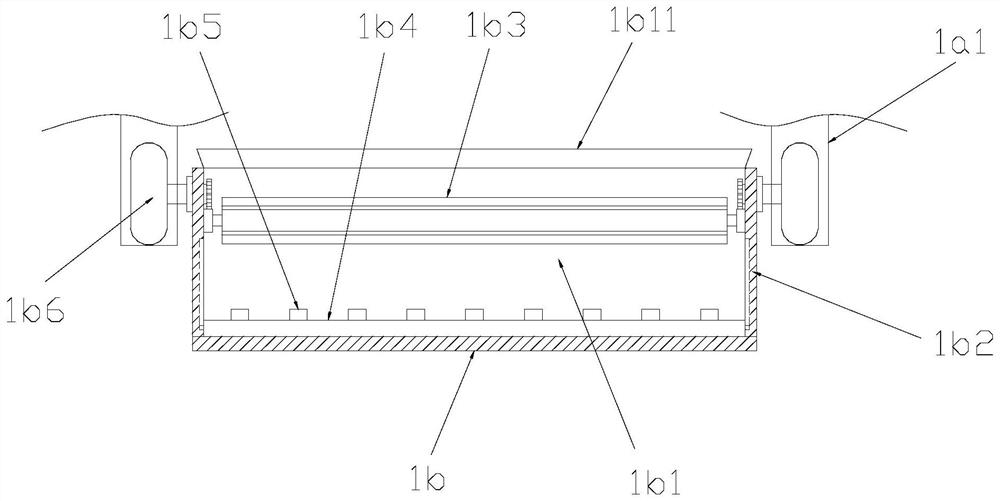

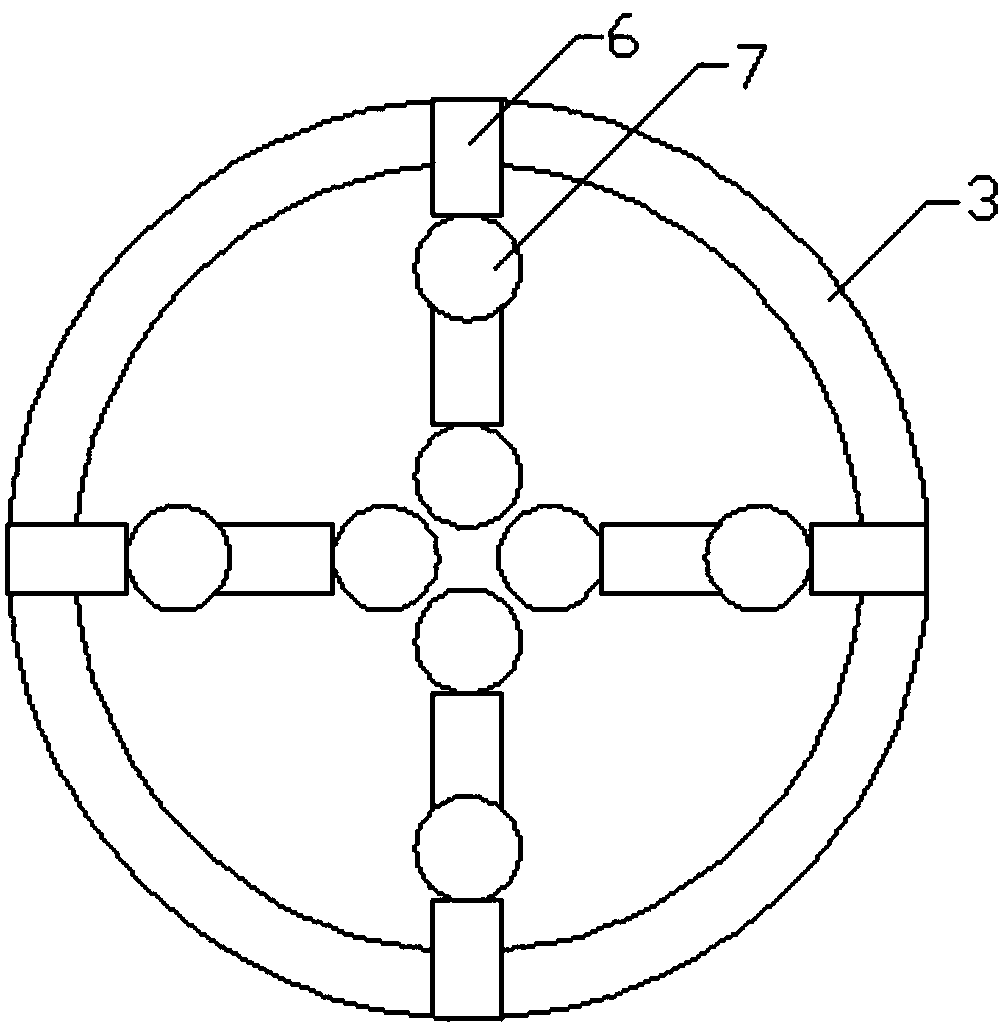

Plastic powder cooling conveyor

InactiveCN111846776AAvoid floating aroundAvoid cloggingConveyorsCleaningElectric machineryEngineering

The invention discloses a plastic powder cooling conveyor. The plastic powder cooling conveyor structurally comprises a powder conveyor body, a feeding hopper, a supporting frame, a driving motor, anaccess cover and a discharging hopper, the powder conveyor body disperses and pushes plastic powder through a pushing partition plate, and therefore the heat dissipation effect and the plastic powderdispersion effect can be achieved; the powder conveyor utilizes the positioning sliding rails to hang the climbing wheels, the situation that the conveying belt sinks inwards and conveying is affectedis avoided, the plastic powder is leveled through the leveling mechanism, the situation that the plastic powder drifts around due to the influence of a little air flow is avoided, and the powder is flattened through the sweeping rods; heat of plastic powder can be rapidly cooled, the situation that the next procedure is influenced by the heat of the plastic powder is avoided, the plastic powder can be flexibly pushed to be discharged by shaking a soft plate, a partition plate is pushed to clean the inner wall of the powder conveyor through soft rubber strips, and the situation that long-timeaccumulation of the inner wall of the powder conveyor influences pushing of the partition plate to slide is avoided.

Owner:张梅琼

Easily installed integrated wiring device

InactiveCN109904803AReduce volumeIncrease the amount of wiringElectrical apparatusEngineeringElectrical and Electronics engineering

Owner:SHAANXI HUABANG TECH DEV CO LTD

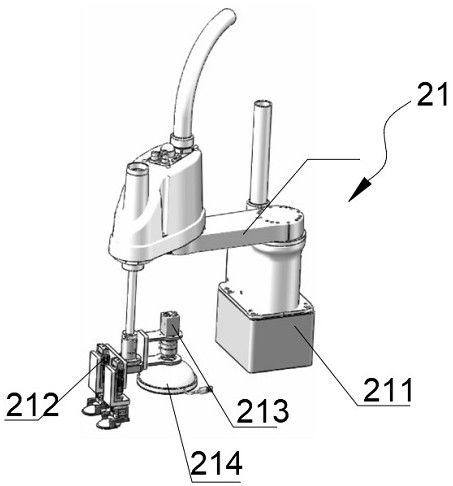

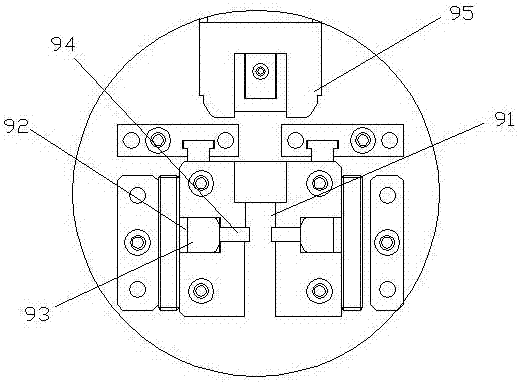

A gripping device for a semiconductor handling apparatus having a collision prevention function

InactiveCN109037140AAvoid damageAnti-collision effectSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention discloses a gripping device of a semiconductor handling device having a collision prevention function, include support column, A base is fixedly installed on the outer surface of the upper end of the support column, and a turntable is arranged above the base, A contact column and a fixing plate are fixedly installed on the outer surface of the upper end of the turntable, and the turntable is positioned on one side of the fixing plate; a support plate is fixedly installed on the outer surface of the front end of the turntable; an expansion and contraction mechanism is arranged onthe outer surface of the fixing plate; and the expansion and contraction mechanism comprises movable arms which are movably installed on the outer surfaces on both sides of the fixing plate near the front end. As that invention is use, At first, that surface of the substrate is intact to avoid affect the subsequent process treatment; secondly, the length of the telescopic mechanism can be easily adjust according to the depth of the semiconductor substrate box by a user; furthermore, the rotation angle of the telescopic mechanism is prevented from being too large to misplace the substrate, andthe accuracy of the substrate position is increased. The substrate can be prevented from being damaged by collision.

Owner:浙江雅市晶科技有限公司

A fish decontamination cleaning device

The invention discloses a fish cleaning device, which comprises a transmission mechanism, a cleaning mechanism, a water spray device, a control system, a clamping mechanism and a frame. Compared with other existing visceral removing machines, after the internal fixed laparotomy knife of the visceral removing device provided by the present invention planes the fish belly, the unilaterally fixed movable belly support clamp will stretch the fish belly until it is removed. After the dirty processing is completed, a forward-rotating dirt-removing knife and two dirt-removing brushes with opposite rotation directions are designed to be liftable. The control program is set to effectively realize the cooperation between multiple tools, and each tool is set to There is a high-pressure water spray device to achieve the effect of efficient dirt removal and automatic cleaning.

Owner:山东名成海洋科技有限公司

Ink defect detection method for multiple lenses

ActiveCN112255248AGuaranteed to be verticalPrevent movementMaterial analysis by optical meansOptical apparatus testingStructural engineeringMechanical engineering

The invention discloses an ink defect detection method for multiple lenses. The method adopts the following detection equipment comprising a feeding station, a carrying station, a detection station and a discharging station, and is characterized in that the feeding station comprises a feeding table, the feeding table is used for feeding and detecting the multiple lenses, the carrying station is used for grabbing and carrying the multiple lenses, the detection station is used for detecting defects of multiple lenses, the discharging station is used for carrying and sending out the multiple lenses, a first air cylinder and a second air cylinder are arranged on the two transverse sides of the feeding table, a fixing table is arranged on one longitudinal side of the feeding table, a tray is fixed to the fixing table, a lifting elevator is arranged on one side of the tray, an unloading belt is arranged on one side of the bottom of the lifting elevator, the carrying station is arranged on one side of the feeding station, the carrying station comprises a mechanical arm and a carrying shaft, and the beneficial effects of being high in detection efficiency and detection precision are achieved.

Owner:荣旗工业科技(苏州)股份有限公司

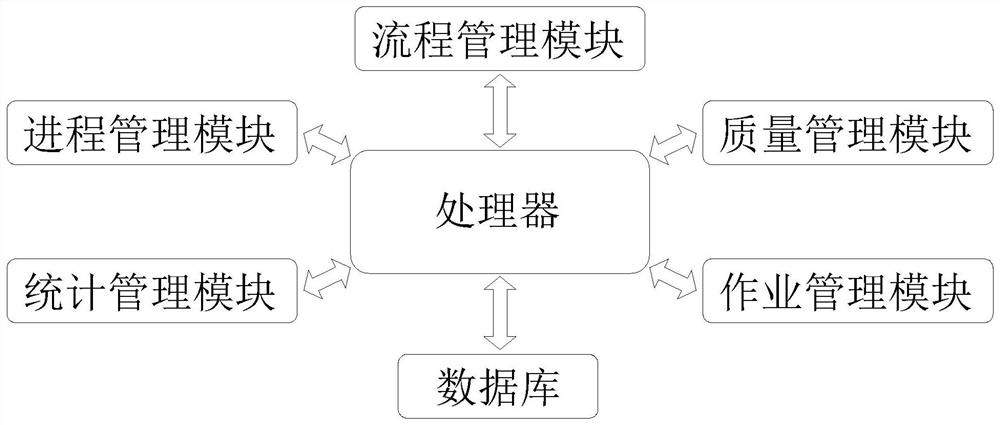

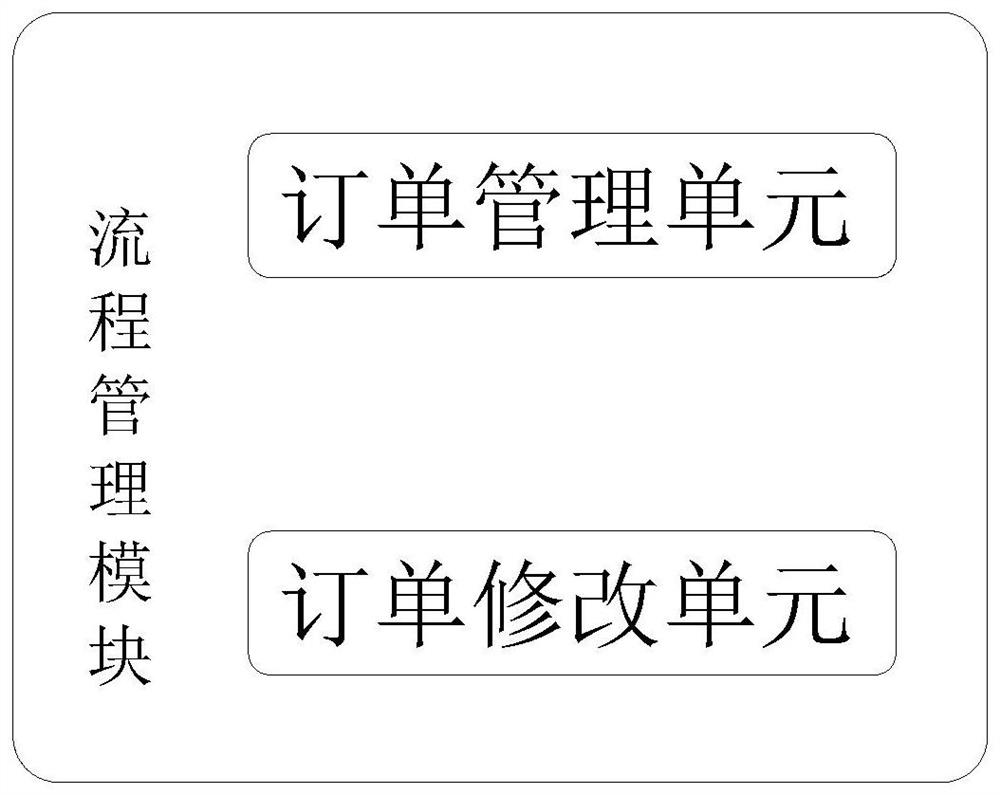

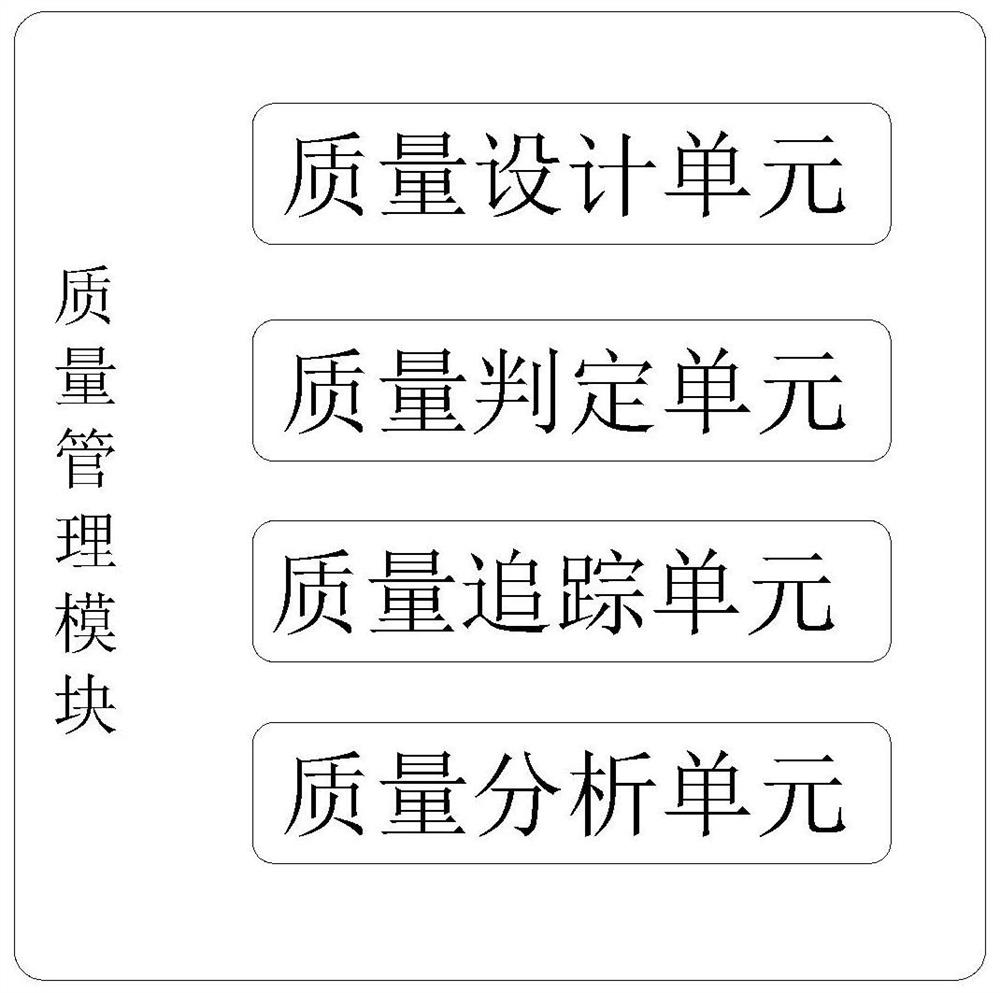

MES-based production and manufacturing order system

PendingCN112116413AAvoid affecting pass rateAvoid affecting the processOffice automationBuying/selling/leasing transactionsBusiness enterpriseOrder system

The invention relates to the technical field of MES systems, and discloses an MES-based production and manufacturing order system, which comprises a process management module, a quality management module, a process management module, a statistical management module, an operation management module, a processor and a database. The process management module is in communication connection with the processor, serves as an organizer of enterprise production activities, compiles an optimal operation plan, arranges various orders, and reasonably arranges the orders according to related data. Accordingto the MES-based production and manufacturing order system, order information is collected, feasibility is analyzed, the situation that the requirements for orders are too high and the percent of pass of the orders is affected is avoided, in addition, the processing procedures of the orders are reasonably planned, the orders are scheduled, order arrangement disorder and procedure influence are avoided, management and tracking are conducted through the production process, the quality of products is strictly controlled, the percent of pass of the products is improved, the state of orders can bechecked through the system, and management is convenient.

Owner:XIN FENG ELECTRICAL(SHENZHEN) CO LTD

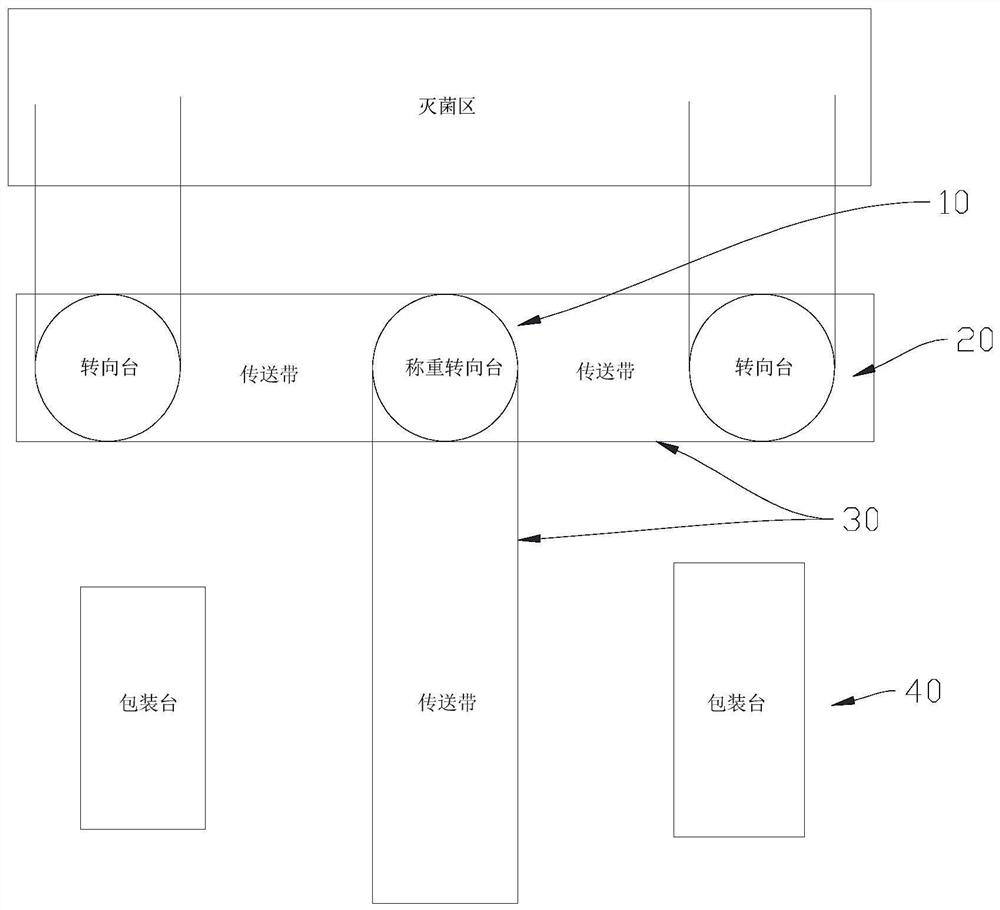

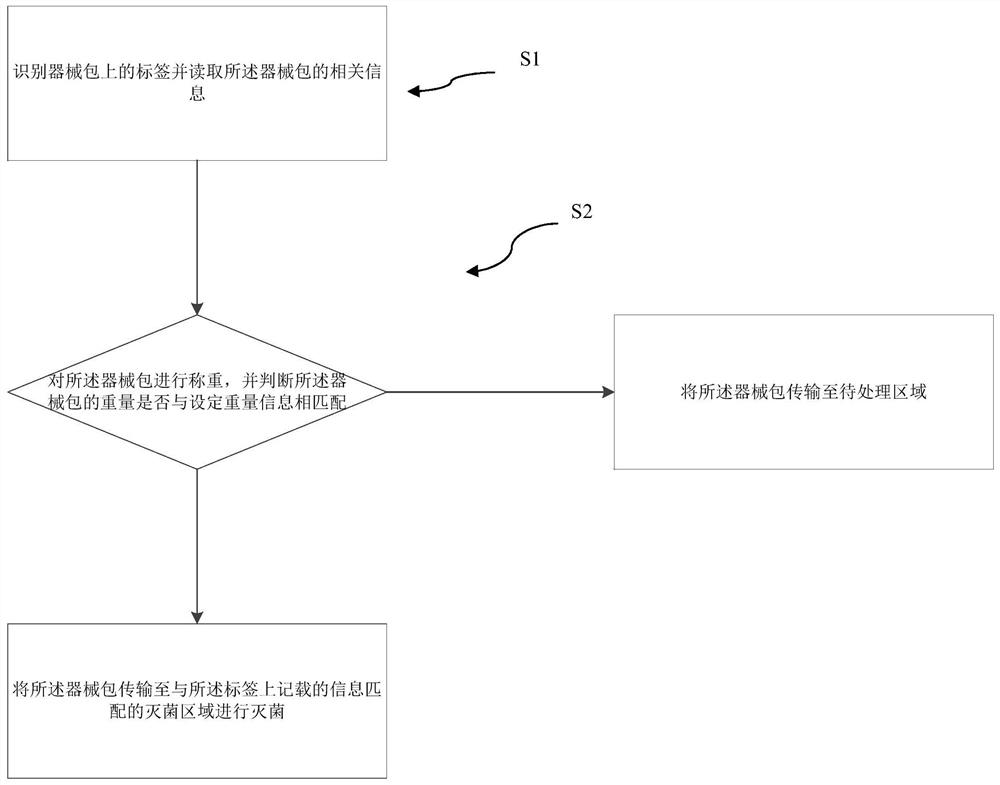

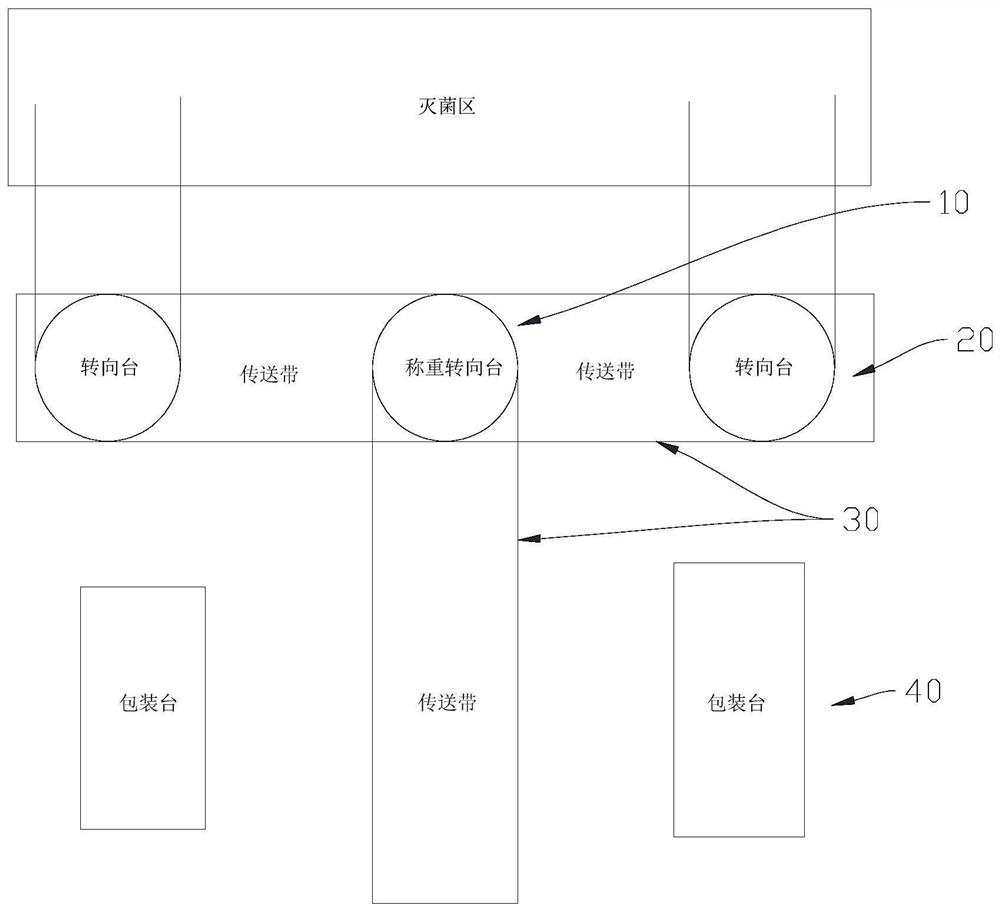

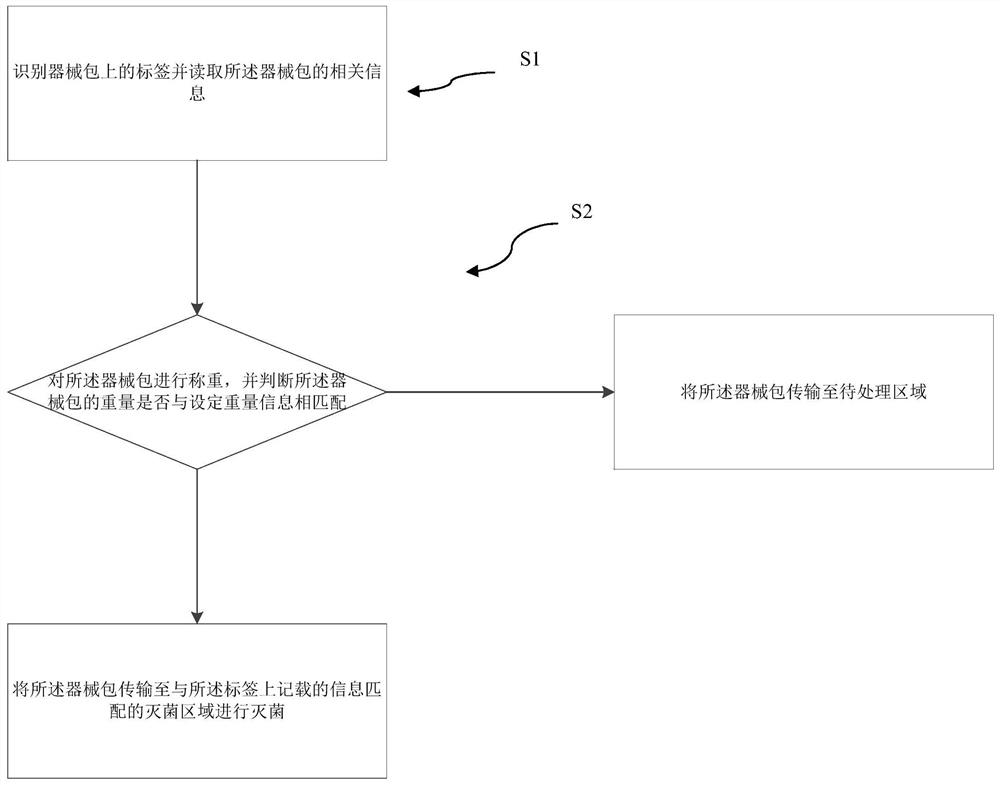

Automatic conveying system and method for instrument set sterilization

ActiveCN112722760AAvoid choosing mistakesAvoid affecting the processSensing detailsMemory record carrier reading problemsIdentification deviceBiomedical engineering

The invention relates to an automatic conveying system and method for instrument set sterilization. An instrument set is provided with a label for recording information of instruments in the instrument set. The automatic conveying system for instrument set sterilization comprises a first identification device for sensing and identifying the label on the instrument set, and a first weighing device for weighing the instrument set, and a conveying mechanism used for conveying the instrument set to a sterilization area matched with the identification information of the first identification device or a to-be-processed area according to the weighing information of the first weighing device and the identification information of the first identification device. The automatic conveying system for instrument set sterilization can be used for automatically conveying instrument sets, saves manpower and material resources, and can check the number of instruments in the instrument sets in real time, avoid influencing the operation process of a patient, and avoid selection errors of sterilization modes.

Owner:THE UNIV OF HONG KONG SHENZHEN HOSPITAL

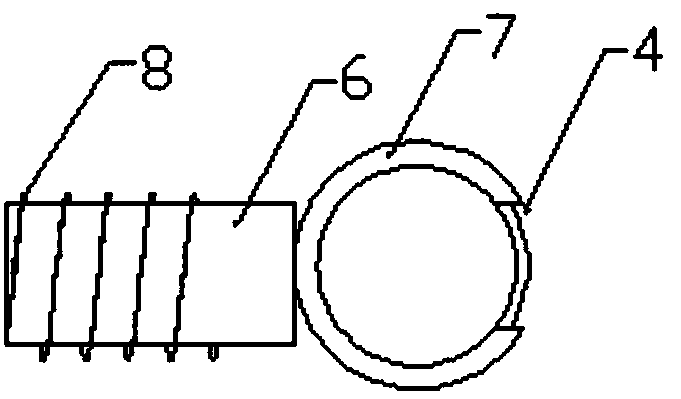

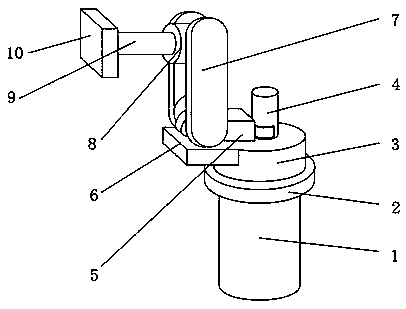

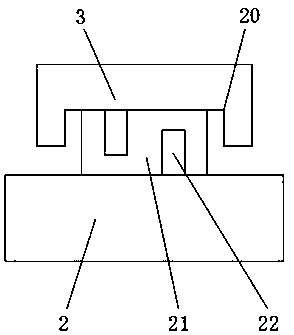

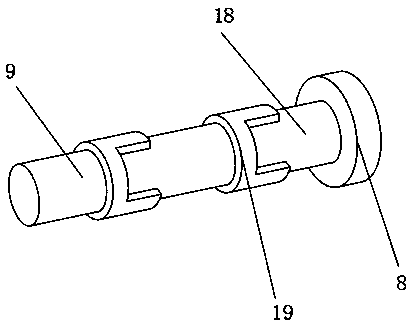

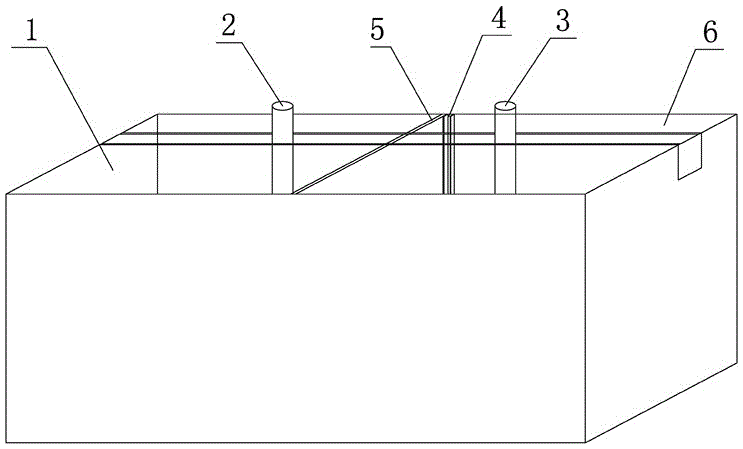

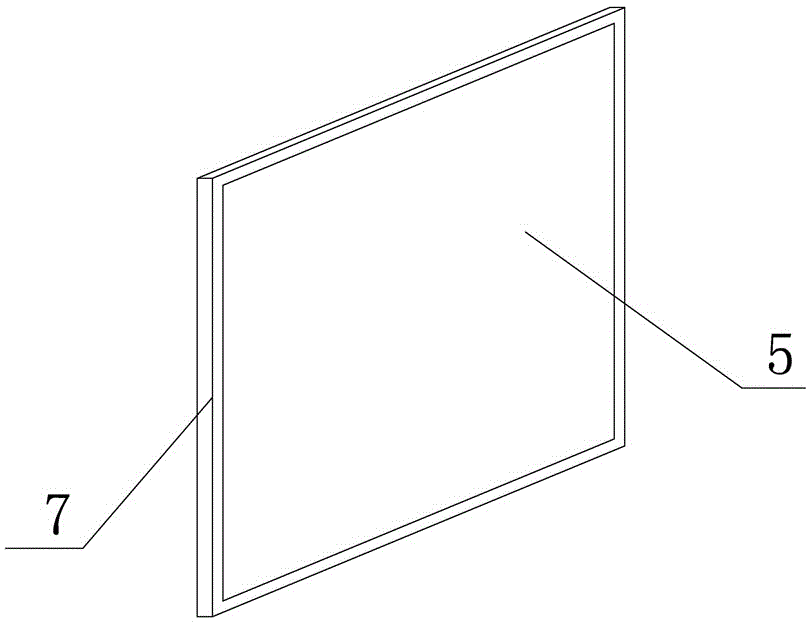

Technology system for preparing small-molecule inhibitor through electrolysis method

InactiveCN105821440AEasy to cleanAvoid affecting the processCellsElectrolytic organic productionEngineeringTechnology system

The invention relates to a technology system for preparing small-molecule inhibitor through an electrolysis method. The technology system comprises an electrolytic cell, a cathode (2) and an anode (3) and further comprises a diaphragm board. A guide-in groove (4) is formed in the inner wall of the electrolytic cell, and the diaphragm board is inserted in the guide-in groove (4) and divides the electrolytic cell into a cathode electrolytic cell (1) and an anode electrolytic cell (6). The diaphragm board comprises a frame (7) and a diaphragm (5). The technology system is suitable for preparing glutathione.

Owner:JIANGSU CHENGXIN PHARMA

Chip removal system convenient for collection for mold production

PendingCN110978607AAvoid affecting the processHigh degree of automationDirt cleaningCleaning using toolsSpray nozzleProcess engineering

The invention relates to a chip removal system convenient for collection for mold production. The chip removal system comprises first ventilation pipes, air spraying nozzles, second ventilation pipes,an air device for air spraying and a collecting device, wherein the first ventilation pipes are arranged in a box body of a treatment system at intervals and above a suspended mold to be treated or asuspended part for mold production, and the collecting device is arranged in the box body below the suspended mold to be treated or the suspended part for the mold production. According to the system, a workpiece suspended below the air spraying nozzles can be subjected to air spraying and chip purging operation through the air spraying nozzles, purged chips fall to the bottom of the inner bottomof the box body, and then the collecting device can be used for collecting the chips, so that the chips are prevented from affecting the proceeding of the process; and the system is high in automation degree, time-saving and labor-saving, the working efficiency is improved, and convenience is brought to production.

Owner:天津开山金属模具科技有限公司

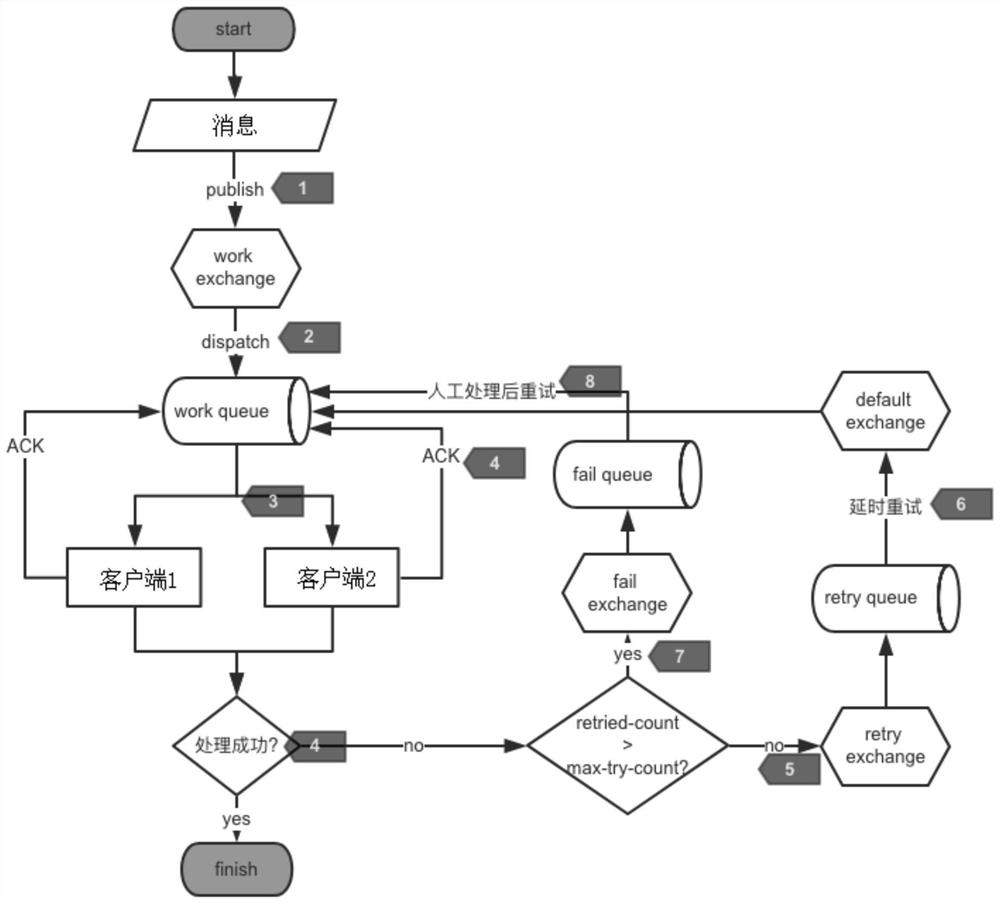

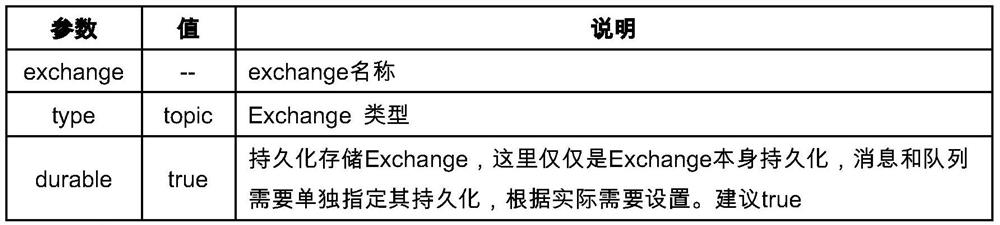

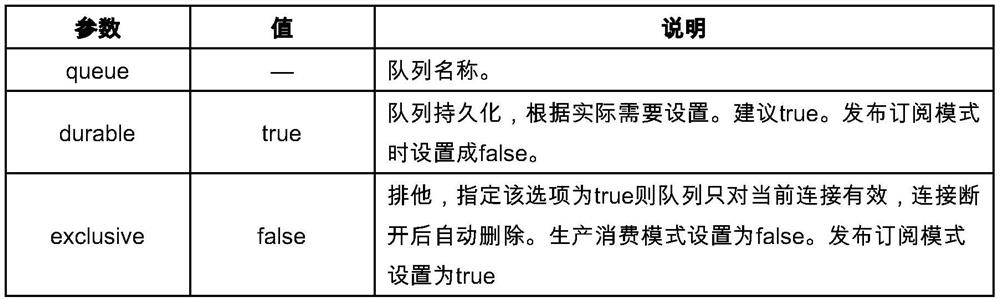

A rabbitmq-based asynchronous message retry method, system and system construction method

ActiveCN110224922BImprove integrityGuaranteed execution efficiencyTransmissionExpiration TimeSystem construction

The invention discloses a RabbitMQ-based asynchronous message retry method, system and system construction method. The system construction method includes: steps of configuring exchanges, steps of configuring queues and steps of binding queues to exchanges, through the method. Build the system. The message retry method includes: in the normal message consumption process, the step of retrying the message that fails to be processed for a limited number of times, and the step of manually processing the message that exceeds the number of retries; there is a delay in the retry of the message mechanism, the delay mechanism is based on the expiration time set for the message. The invention can automatically divert and retry the failed messages, avoiding the impact on the process and long-term occupation of the system resources, and the set manual intervention can ensure the reliable consumption of the messages. The invention can set the retry interval of the message and improve the flexibility of the system.

Owner:CHENGDU LUXINGTONG INFORMATION TECH

Device package sterilization automatic transmission system and device package sterilization automatic transmission method

ActiveCN112722760BAvoid choosing mistakesAvoid affecting the processSensing detailsMemory record carrier reading problemsIdentification deviceTransfer mechanism

The invention relates to an automatic transmission system for sterilization of instrument packs and an automatic transmission method for sterilization of instrument packs. The instrument pack is provided with a label recording information of the instruments in the instrument pack. The first identification device of the label on the equipment bag, the first weighing device for weighing the equipment bag, the weighing information according to the first weighing device and the identification information of the first identification device The instrument package is transferred to a transfer mechanism of a sterilization area or an area to be treated that matches the identification information of the first identification device. The instrument package sterilization automatic transmission system can be used for automatic transmission of the instrument package, saving manpower and material resources, and can check the number of instruments in the instrument package in real time, so as to avoid affecting the operation process of the patient, and to avoid wrong selection of sterilization methods.

Owner:THE UNIV OF HONG KONG SHENZHEN HOSPITAL

An intelligent ironing and compacting filing cabinet

ActiveCN111685500BPrevent the phenomenon of flying outImprove ironing effectBook cabinetsBook-troughsEngineeringPaper sheet

Owner:深圳市厚朴空间智能家具有限公司

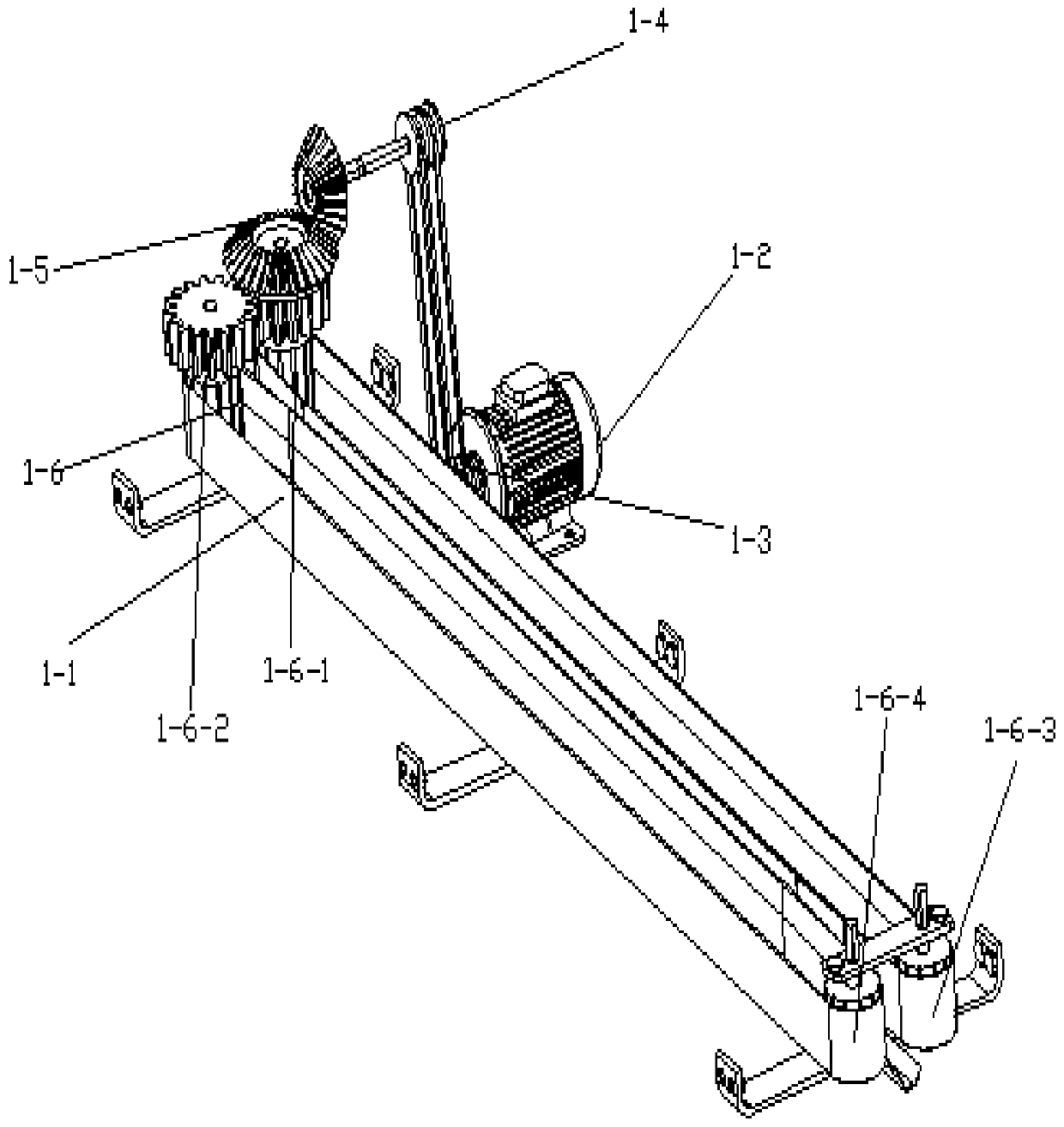

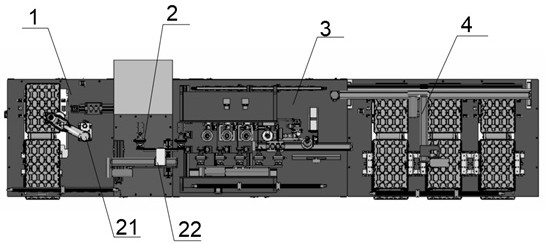

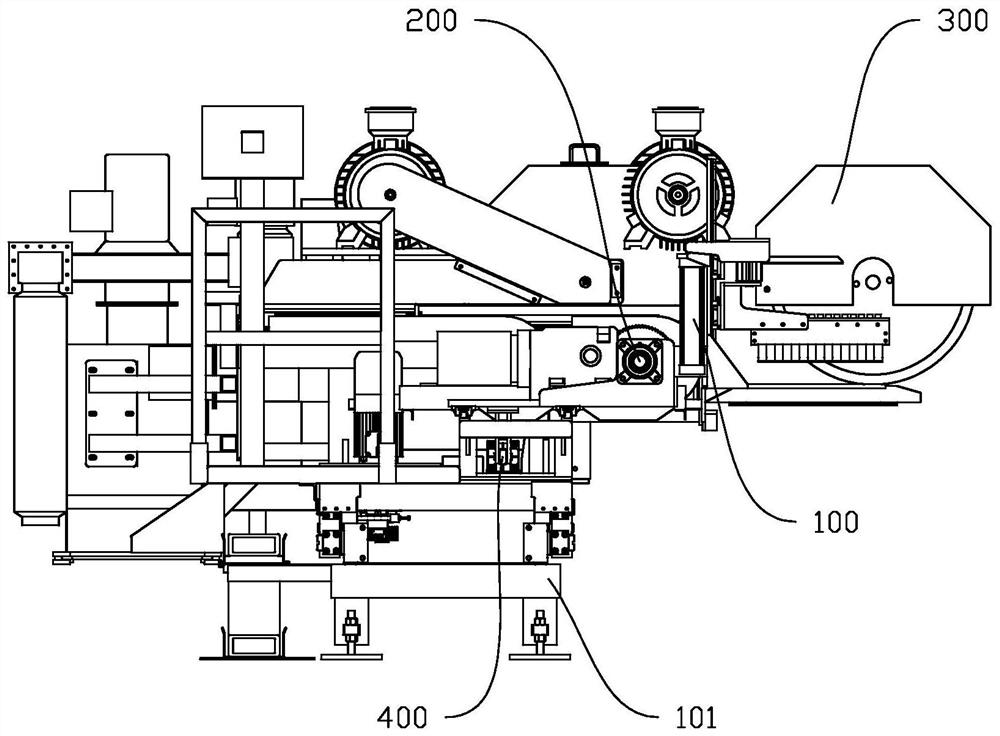

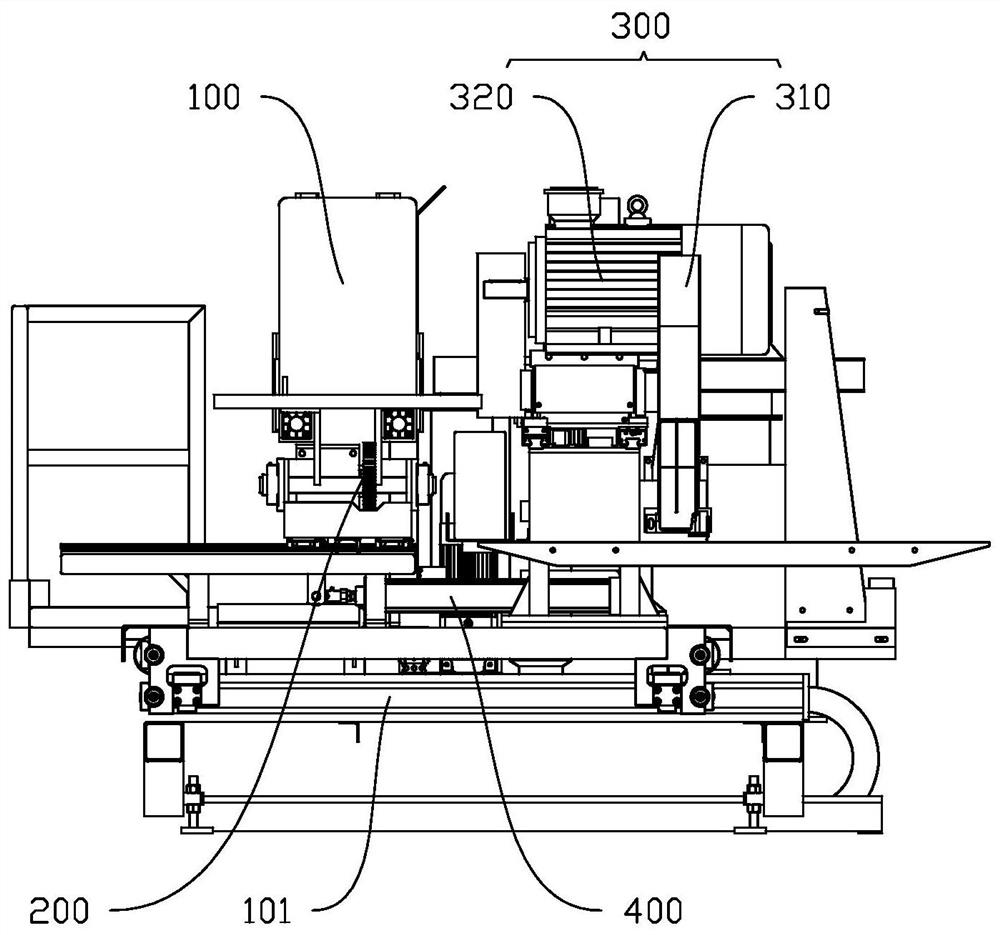

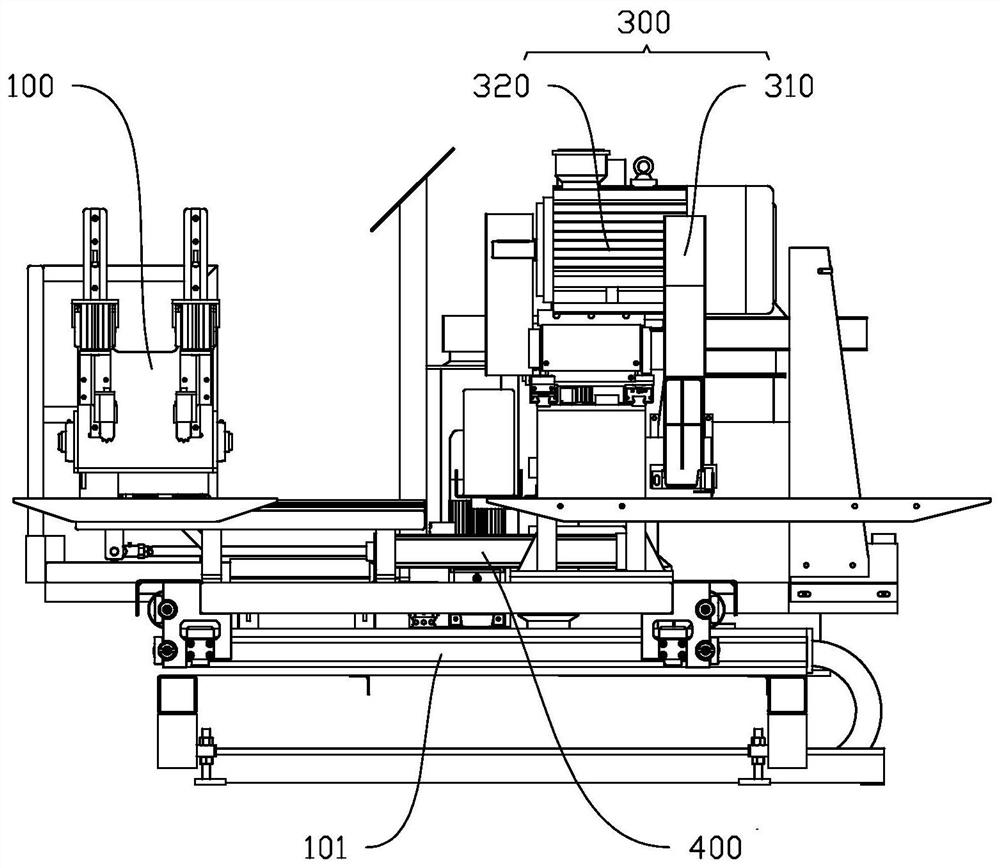

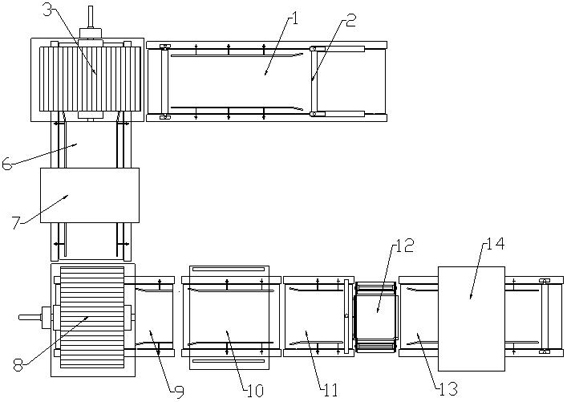

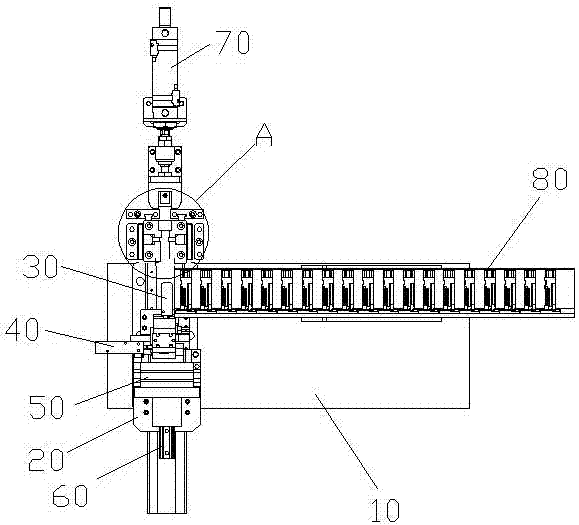

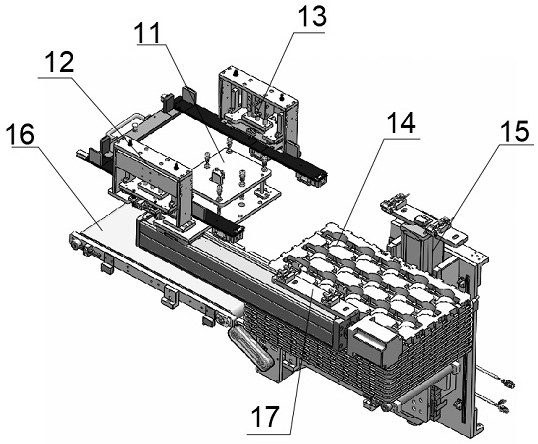

Sampling mechanism for traction sawing system

ActiveCN112676639AImprove work efficiencyAvoid affecting the processMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

The invention discloses a sampling mechanism for a traction sawing system. The sampling mechanism is characterized by comprising a lifting pressing mechanism, a rotating mechanism, a sawing mechanism and an extendable mechanism, wherein the lifting pressing mechanism is connected with the rotating mechanism, the extendable mechanism is arranged at the bottom of the rotating mechanism, the rotating mechanism rotates to put down the lifting pressing mechanism, the lifting pressing mechanism presses a profile, the sawing mechanism saws and samples the profile, and after sampling is completed, the extendable mechanism extends to separate a sampled material from the profile, so that sawing is prevented from being influenced, the rotating mechanism rotates to lift the lifting pressing mechanism to wait for workers to take the sampled material and prevent the process of sawing of the profile from being influenced, compared with traditional halting sampling, the sampling mechanism can achieve non-halting sampling, and does not influence the production process, and the sawn sampled material can be partially taken down from the sampling mechanism after being cooled, so that a worker is prevented from being scalded by the sampled material, the working efficiency of the traction sawing system is improved, and the material can be taken under the condition that the production is not influenced.

Owner:佛山市法比澳挤压机械科技有限公司

A fish descaling and visceral all-in-one machine

ActiveCN111528262BNo damageEfficient processingFish washing/descalingFish arrangingFish processingEngineering

The patent of the invention relates to the technical field of fish processing equipment, in particular to a fish descaling and visceral all-in-one machine, which includes a descaling transmission mechanism, a descaling water spray mechanism, a descaling clamping mechanism, a descaling frame, a descaling Dirt removal connecting mechanism, dirt removal transmission mechanism, dirt removal mechanism, dirt removal water spray mechanism, control mechanism, dirt removal clamping mechanism and dirt removal frame. The invention provides a double-knife double-brush type dirt removal method that can be automatically lifted by using a cylinder, which is clean and thorough without damaging the fish body; the invention designs a simple and effective cleaning method between scale removal The inclined connection device only needs to place the fish head forward and the fish maw towards the center line of the descaling plate when descaling and conveying, so that the fish can be effectively turned over and conveyed to the descaling part with the maw facing down.

Owner:万峰生物科技(大连)有限公司

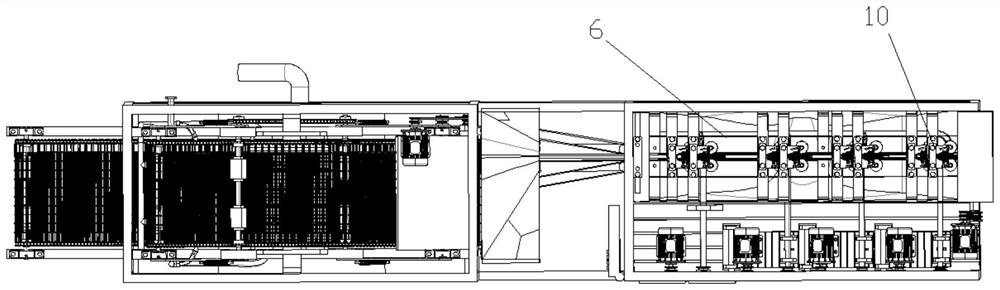

A kind of etching magnesium plate production device and method

ActiveCN114261177BImprove cooling effectShorten conveying lengthForme preparationProcess engineeringAssembly line

The present invention proposes a production device and method for etching magnesium boards. The production device includes a first conveyor belt, the feeding end of the first conveyor belt is provided with a first feeding mechanism for loading materials one by one, and the discharge end is provided with a The first rotary dryer, the lower end of the first rotary dryer is provided with a second conveyor belt, the top of the second conveyor belt is provided with a coater, and the discharge end of the second conveyor belt is provided with a second rotary dryer The lower end of the second rotary dryer is provided with a third conveyor belt, and the discharge end of the third conveyor belt is sequentially provided with a fourth conveyor belt inclined upward, a horizontal conveyor belt, a feeding mechanism and The fifth conveyor belt, a film laminating machine is arranged above the fifth conveyor belt. The invention realizes the assembly line production and processing of the etched magnesium plate, and the assembly line is short, occupies less land, reduces manual transfer, and improves production efficiency.

Owner:河南精镁新材料有限公司

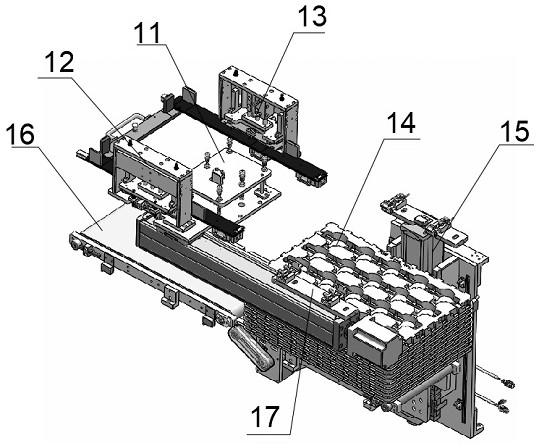

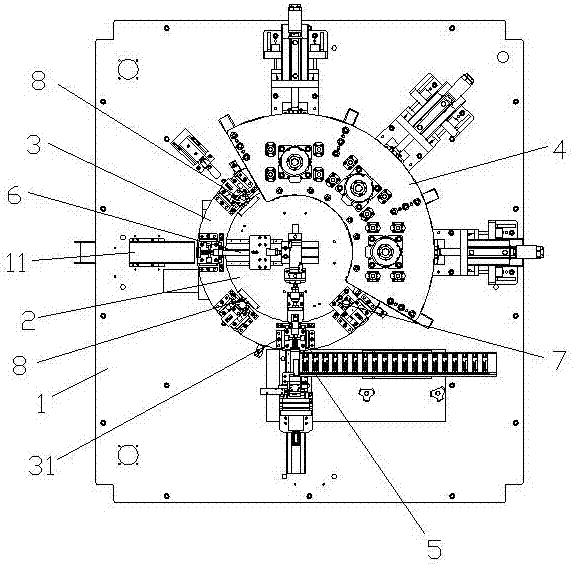

A device for automatic deburring and grinding

ActiveCN105458406BRealize multiple protectionAvoid Multiple ProtectionsMetal working apparatusEngineeringInjection molding process

The invention discloses a device for automatic deburring and grinding. The device comprises a bottom disc. A center disc and a rotary disc which are consistent in height are arranged above the bottom disc. A plurality of product fixing seats are arranged on the rotary disc along the circumferential line of the rotary disc at equal intervals. A feeding device and a material collecting opening are formed in the positions, on the outer side of the rotating disc, of the bottom disc. At least one set of symmetric deburring devices are arranged above and below the feeding device and the position, with the material collecting opening, of the rotary disc. The deburring devices comprise lower pressing plates and pressing plates which can move vertically relative to the lower pressing plates. The pressing plates are provided with a plurality of guide grooves used for blades to pass through. According to the device for automatic deburring and grinding, due to automatic feeding and the deburring devices, the process of automatic deburring of products is achieved, meanwhile, a product detection device is used for detecting whether residual residues exists in through holes of products or not in the injection molding process before deburring is conducted, the phenomenon of needle breaking in the later-stage deburring process is avoided, in addition, negative-pressure detection and buffering springs are used for protecting the blades during deburring, multiple protection on the blades is achieved, and the phenomenon that the process is influenced by blade breaking is avoided.

Owner:昆山艾博机器人股份有限公司

Ink Defect Detection Method for Multiple Lens

ActiveCN112255248BGuaranteed to be verticalPrevent movementMaterial analysis by optical meansOptical apparatus testingEngineeringStructural engineering

Owner:荣旗工业科技(苏州)股份有限公司

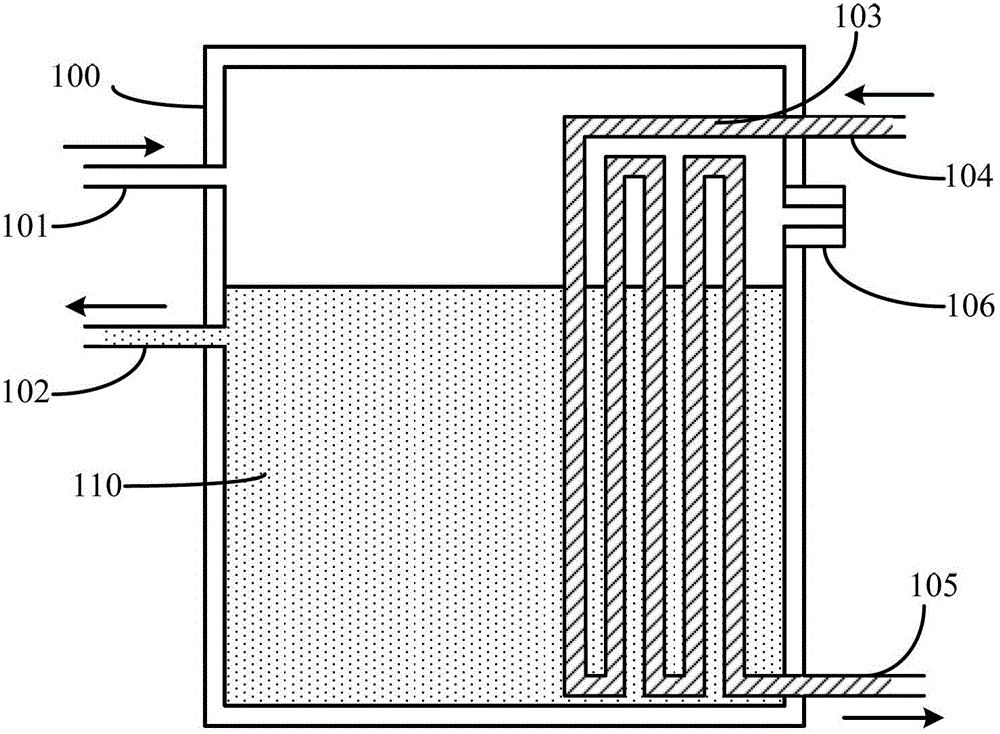

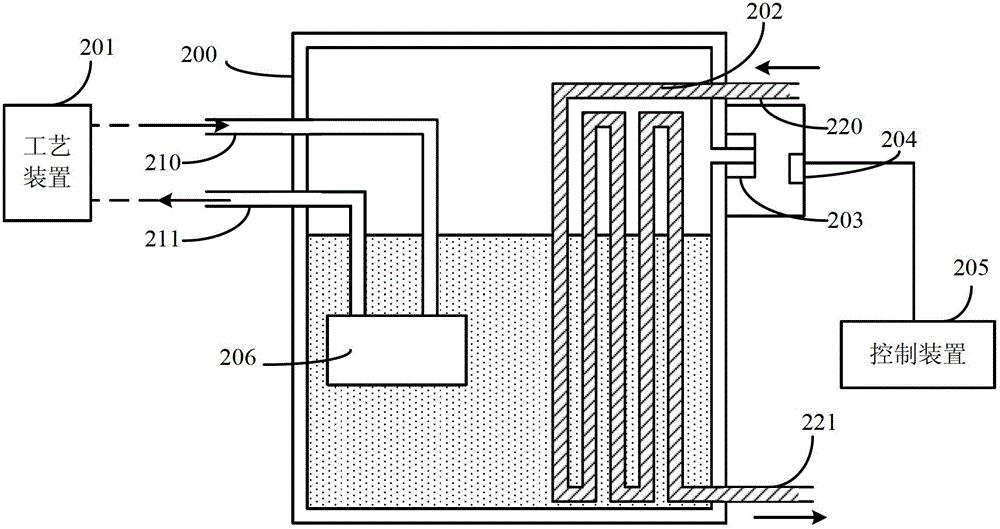

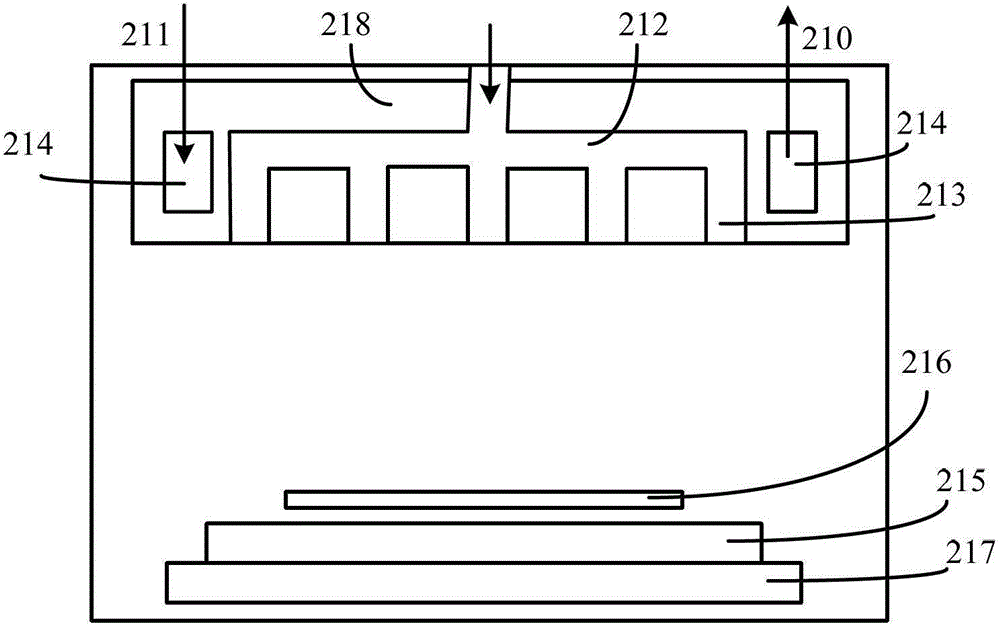

Process water device

ActiveCN103307847BTroubleshootingReduce production accidentsSemiconductor/solid-state device manufacturingWater channelWater leak

A process water device comprises a water channel used for carrying liquid, a cool water pipeline in the water channel, a water filling nozzle on the side wall of the water channel, a water leakage detection device fixed on the surface of the outer wall of the water channel, and a control device used for receiving a detection signal transmitted by the water leakage detection device to stop the work of the process device, wherein the liquid is used for conducting heat replacement on a semiconductor manufacturing process device, the cool water pipeline is partially or all located below the liquid level of the water channel and is used for cooling the liquid in the water channel, the liquid is filled in the water channel through the water filling nozzle, the water leakage detection device corresponds to the water filling nozzle in position, and the water leakage detection device is used for detecting whether the water filling nozzle leaks water and transmitting the detection signal when the amount of water leaked from the water filling nozzle reaches the preset amount. The safety of the process water device is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Humidification device for aquatic feed making machine through atomization, diversion, rotation and dispersion

ActiveCN109700060BPrevent coagulation and agglomerationHumidification works effectively and evenlyFeeding-stuffElectric machineProcess engineering

The invention discloses a humidifying device for an aquatic feed making machine through atomization, diversion, rotation, and dispersion. The structure includes: a support pad, an intelligent humidifying device, a water outlet, a power motor, and a fixed base. The power motor is located on the right end surface of the intelligent humidifying device and It is fixedly connected with the intelligent humidification device. The outlet hole is set on the outer end face of the intelligent humidification device and is fixedly connected with the intelligent humidification device at the same time. Through the through-fitting of the internal arc tube and the dispersing tube, and connecting the dispersing tubes through small tubes, a certain The dispersing output pipeline, and the moisture inside the pipeline is synchronized, and is directly sprayed on the feed, and the movable shaft rotated by the power motor makes the dispersing frame stir so that the internal feed is repeatedly moved, so as to achieve the uniformity of the internal feed Humidification, while acting directly on the feed, can improve the efficiency of moisture use.

Owner:台州市记顺泵业有限公司

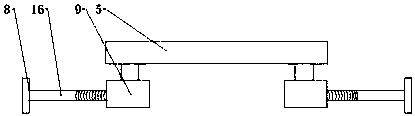

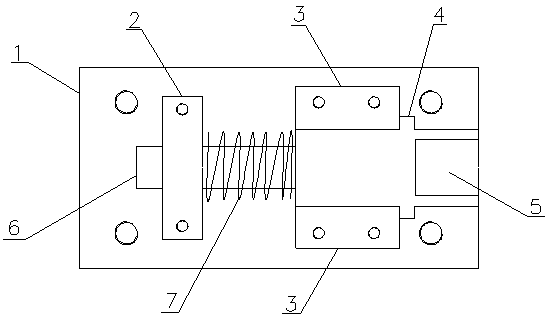

Elastic support for automobile stabilizer bar tip forging equipment

ActiveCN103658480AEliminate axial forcePlay the role of elastic supportForging/hammering/pressing machinesClassical mechanicsStructural engineering

The invention provides an elastic support for automobile stabilizer bar tip forging equipment. The elastic support comprises a base plate (1) fixed on a machine tool. A rear supporting block (2) and a guide positioning block (3) are fixedly arranged on the base plate; a front supporting block (4) is inserted in the guide positioning block (3); a fastening slot (5) with an horizontal opening is arranged on the right side of the front supporting block (4), the left side of the front supporting block (4) is connected to one end of a spring guide pin (6 )horizontally, and the other end of the spring guide pin (6) is inserted in the rear supporting block (2); a spring (7) is sleeved on the spring guide pin (6) between the front supporting block (4) and the rear supporting block (2). The spring device arranged between the front supporting block and the rear supporting block can eliminate axial action force generated during forging of stabilizer bars effectively and function in elastic supporting, thereby preventing bending during forging of the stabilizer bars and then avoiding influences to the subsequent processes.

Owner:安庆市恒瑞达汽车零部件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com