Full automatic wire tidying machine

An automated and fully automated technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low product qualification rate and low work efficiency, reduce the possibility of damage, improve efficiency, and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

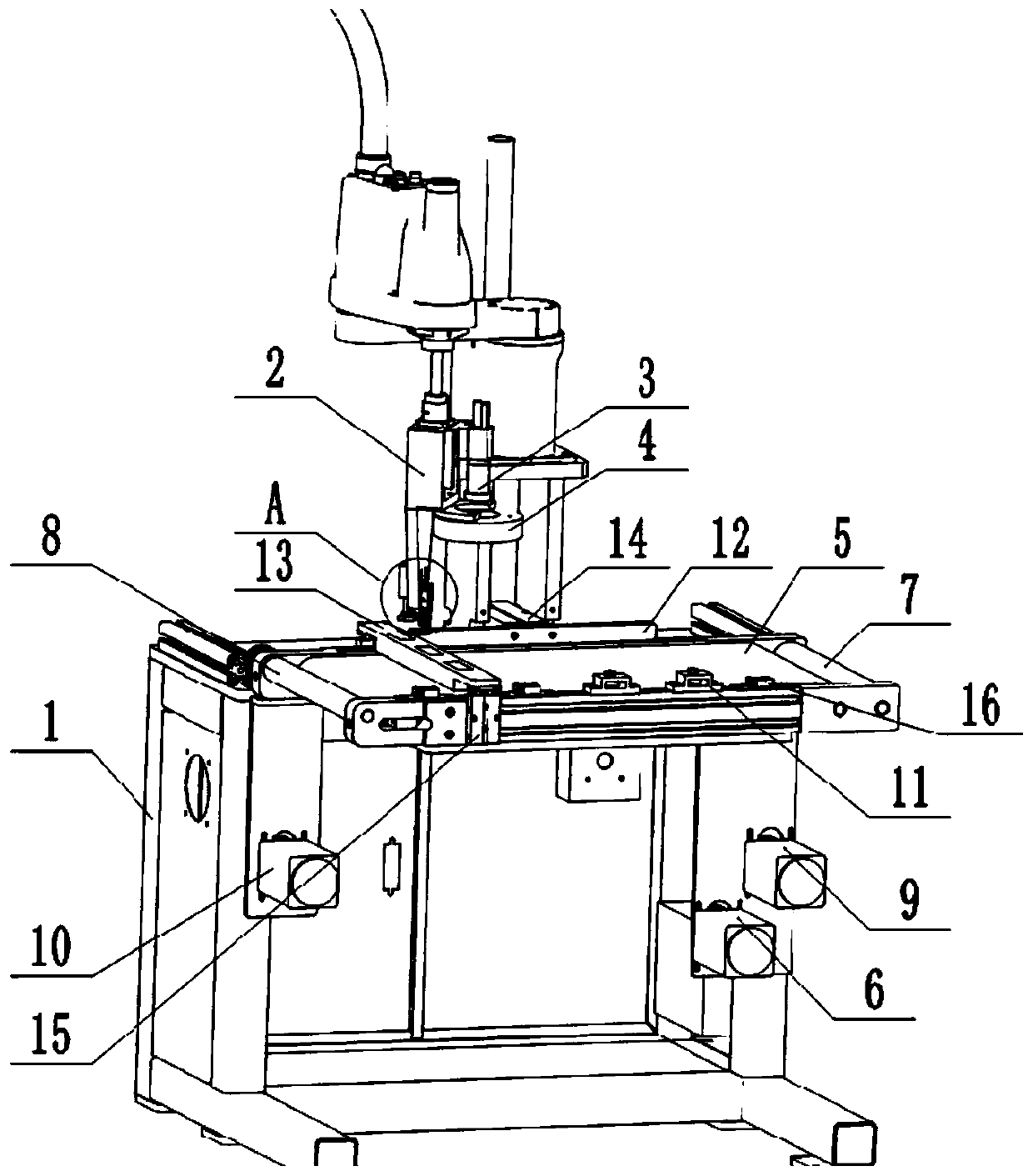

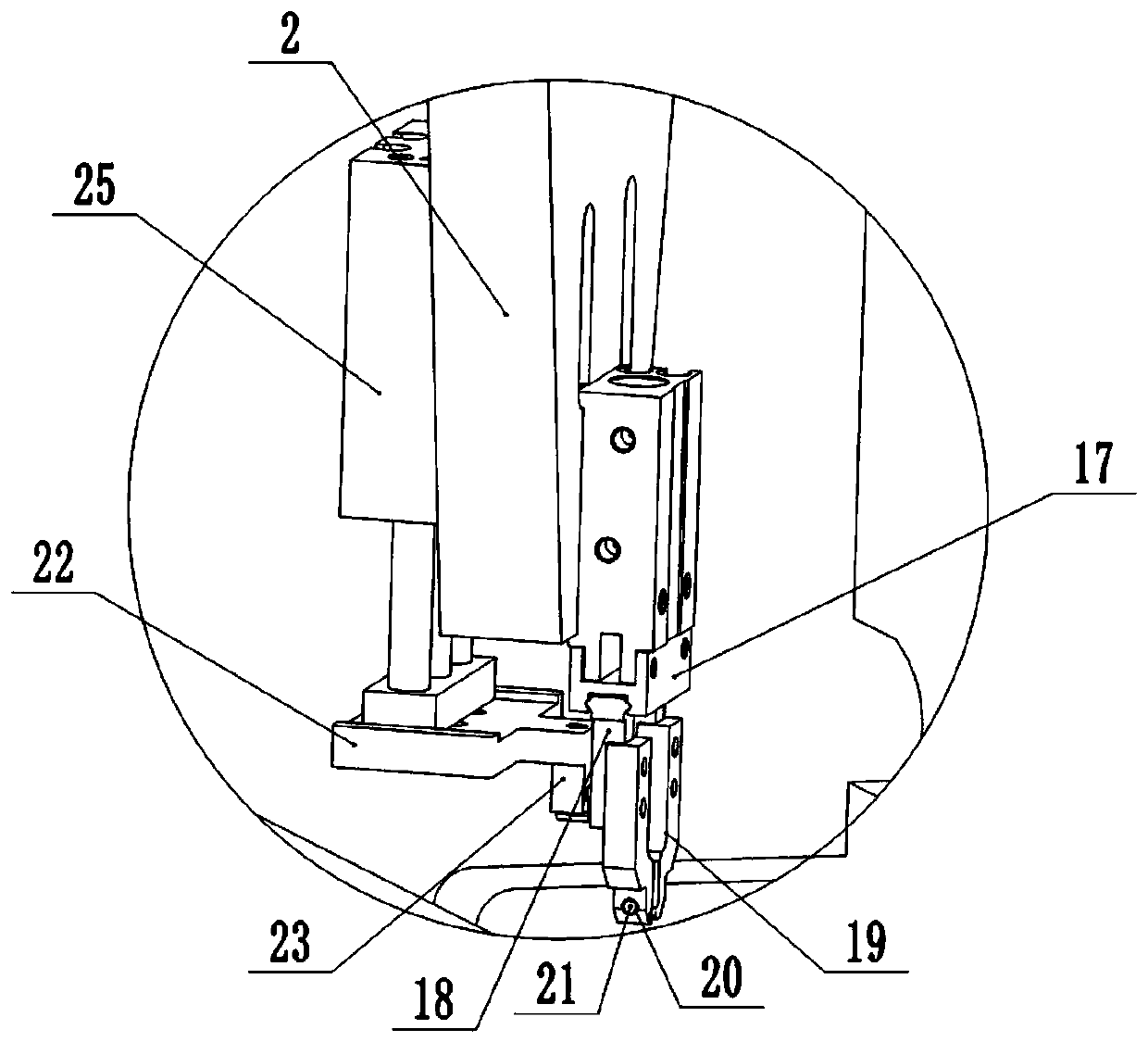

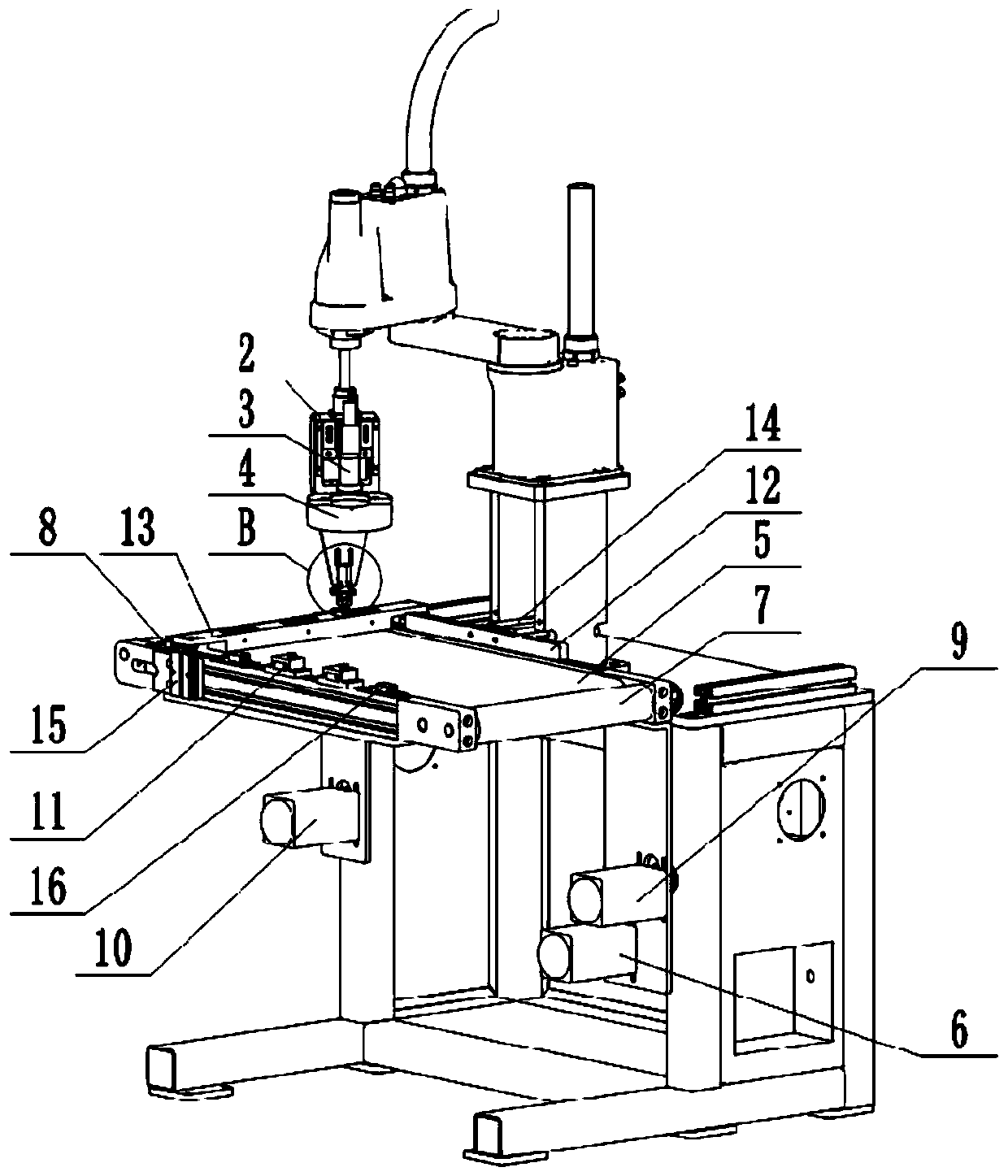

[0026] The reference signs in the drawings of the description include: frame 1, mechanical arm 2, camera 3, lamp 4, conveyor belt 5, first motor 6, input roller 7, output roller 8, second motor 9, third motor 10 , block 11, push plate 12, baffle plate 13, first cylinder 14, second cylinder 15, position sensor 16, pneumatic finger 17, clamp finger 18, clamp arm 19, through hole 20, guide rod 21, horizontal plate 22 , Riser 23, briquetting block 24, the 3rd cylinder 25.

[0027] The embodiment is basically as attached Figure 1 to Figure 4 Shown:

[0028] The fully automatic wire management machine includes a frame 1, on which a mechanical arm 2, a material conveying mechanism, a positioning mechanism, and a thread-taking mechanism are arranged, and the thread-taking mechanism is arranged on the mechanical arm 2. The mechanical arm 2 is fixed with a camera mechanism by bolts, the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com