Method for producing wafer by combining composite adhesive film with through hole glass carrier plate structure

A composite, glass technology, applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of uniform coating layer, wafer damage, difficult to form, etc., to reduce production costs and avoid damage , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for producing a wafer with a composite adhesive film combined with a through-hole glass carrier structure, the method for producing the wafer includes the following steps:

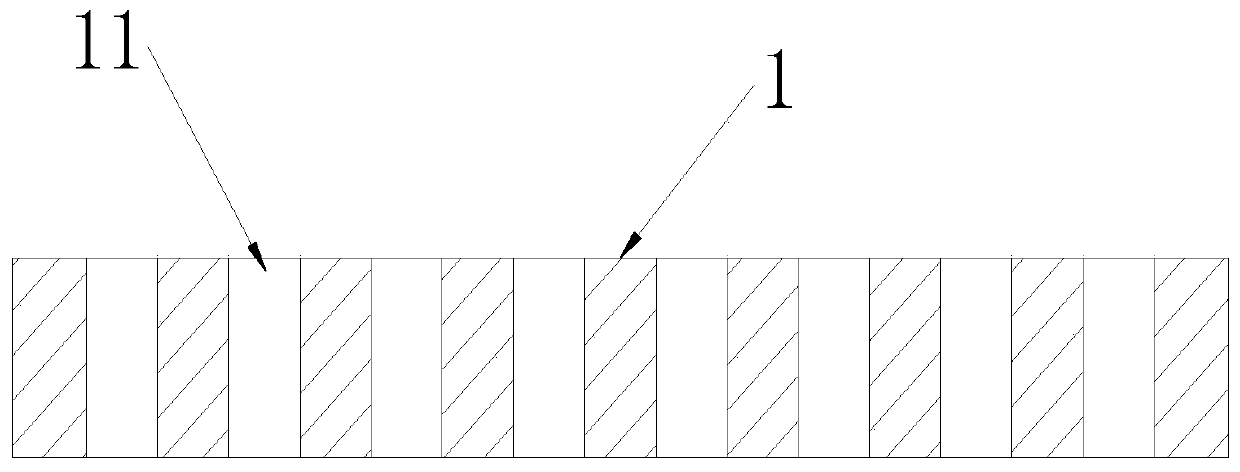

[0033] S1: Holes on the glass carrier

[0034] Through the yellow photomask pattern process, laser laser or etching process, the glass carrier 1 is opened with a pattern of window opening / TGV (via through glass carrier), and a glass window hole 11 is formed on the glass carrier 1, such as figure 1 shown.

[0035] S2: Wafer bonding on glass carrier

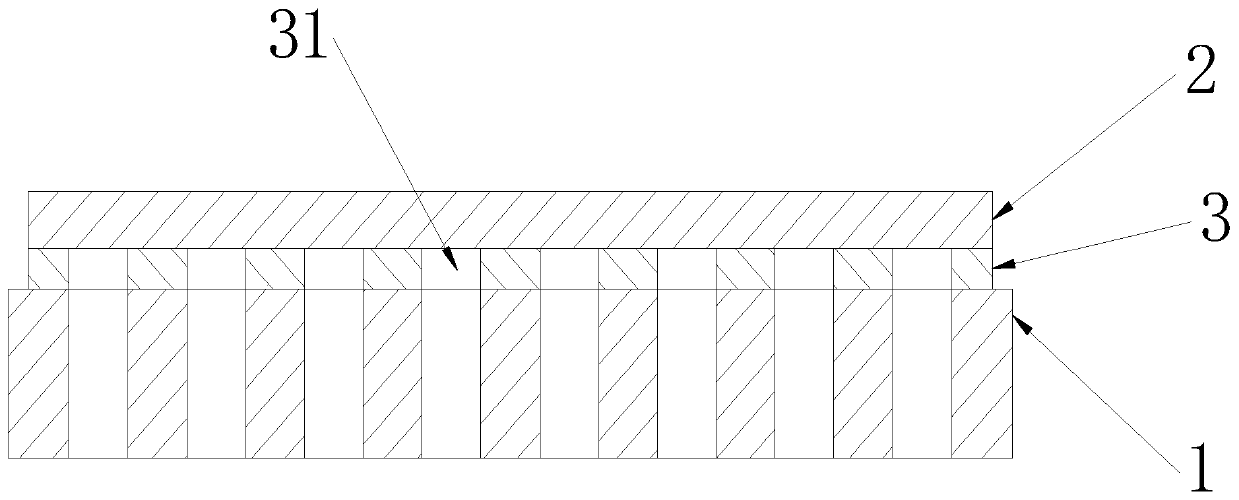

[0036] Paste the composite adhesive film 3 on the glass carrier 1, use an optical mechanism to accurately align the wafer 2 with the glass carrier 1, place the front of the wafer 2 on the composite adhesive film 3, and use the lamination pressure Bonding and heating the wafer 2 on the glass carrier 1, such as figure 2 shown.

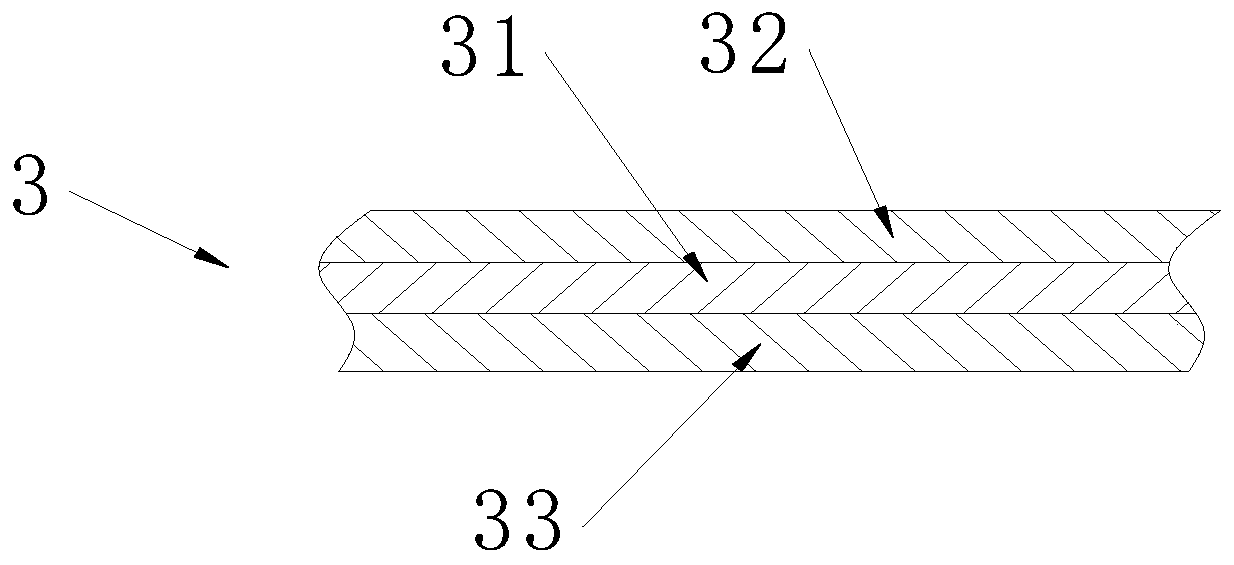

[0037] The composite adhesive film 3 includes a composite layer 32 , a heat treatment layer 31 and a UV light layer...

Embodiment 2

[0047] A method for producing a wafer with a composite adhesive film combined with a through-hole glass carrier structure, the method for producing the wafer includes the following steps:

[0048] S1: Holes on the glass carrier

[0049] Through the yellow photomask pattern process, laser laser or etching process, the glass carrier 1 is opened with a pattern of window opening / TGV (via through glass carrier), and a glass window hole 11 is formed on the glass carrier 1, such as figure 1 shown.

[0050] S2: Wafer bonding on glass carrier

[0051] Paste the composite adhesive film 3 on the glass carrier 1, use an optical mechanism to accurately align the wafer 2 with the glass carrier 1, place the front of the wafer 2 on the composite adhesive film 3, and use the lamination pressure Bonding and heating the wafer 2 on the glass carrier 1, such as figure 2 shown.

[0052] The composite adhesive film 3 includes a composite layer 32 , a heat treatment layer 31 and a UV light layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com