Elastic support for automobile stabilizer bar tip forging equipment

A technology of elastic support and stabilizing rod, applied in elastic support. field to achieve the effect of eliminating axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

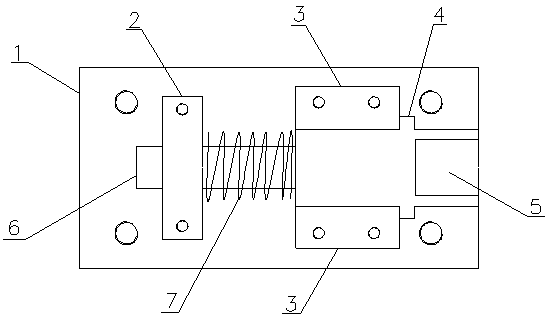

[0018] figure 1 It is a preferred embodiment of the present invention, which shows a kind of elastic support for the forging equipment of the end of the automobile stabilizer bar. The elastic support includes a bottom plate 1 fixed on the end of the machine tool. The front support block 4, rear support Block 2 and guide positioning block 3, a spring guide post 6 is connected between the front support block 4 and the rear support block 2, one end of the spring guide post 6 is horizontally connected to the left side of the front support block 4, and the other end is sleeved on the rear support block. In the block 2, the rear support block 2 limits the front and rear of the spring guide post 6, so that the spring guide post 6 is only allowed to move in its axial direction, and the right side of the front support block 4 is provided with a horizontal opening slot 5 , the shape of the draw-in slot 5 is adapted to the end of the stabilizer bar, and the end of the stabilizer bar is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com