Single downdraft electric driving pump structure capable of automatically balancing axial force

A submersible electric pump and automatic balancing technology, which is applied in the direction of pumps, pump devices, non-variable pumps, etc., can solve the problems of not being able to bear the axial thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

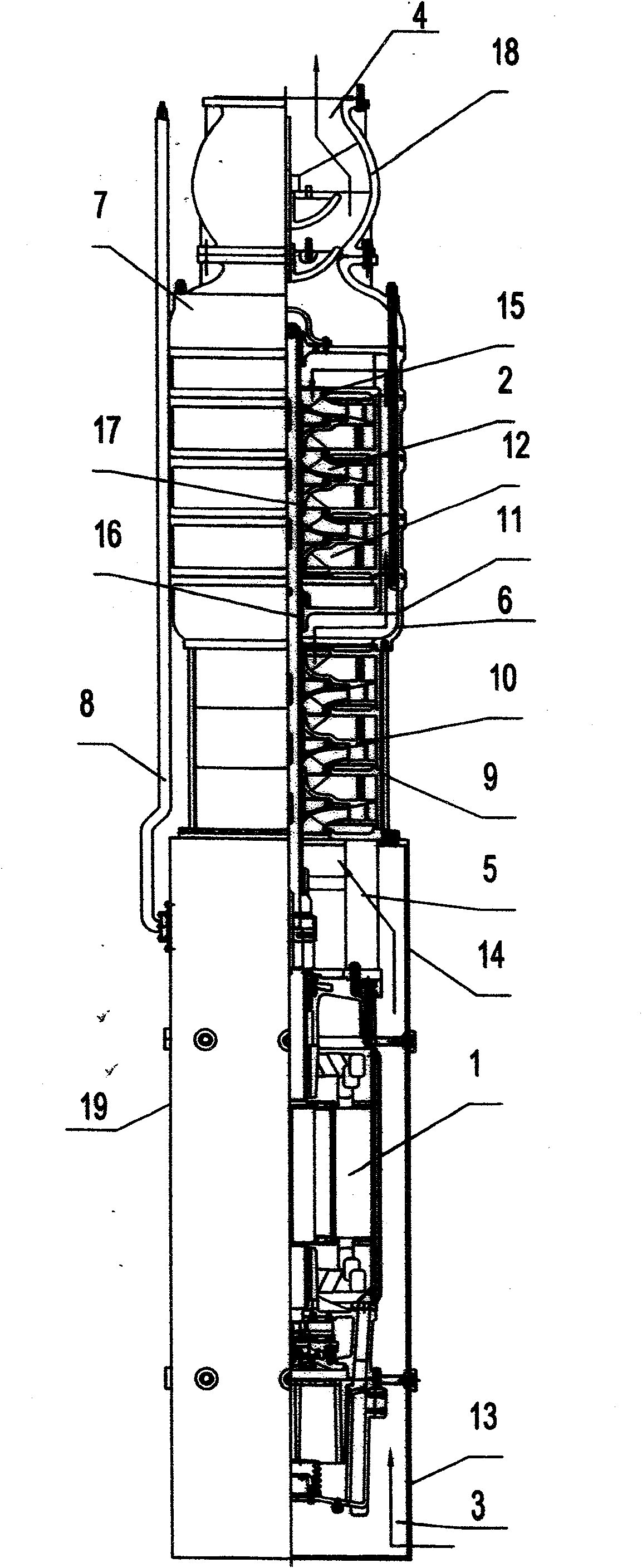

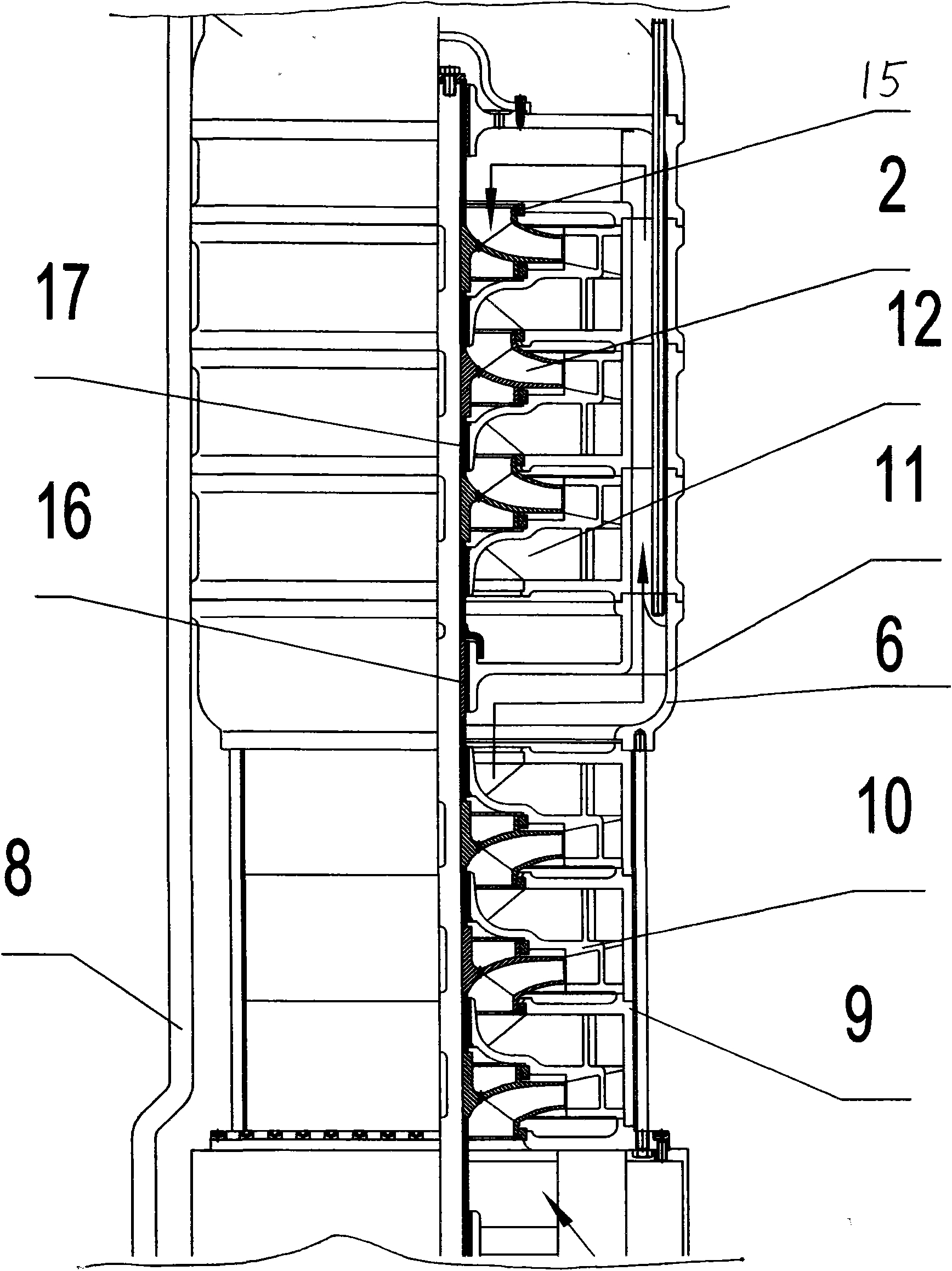

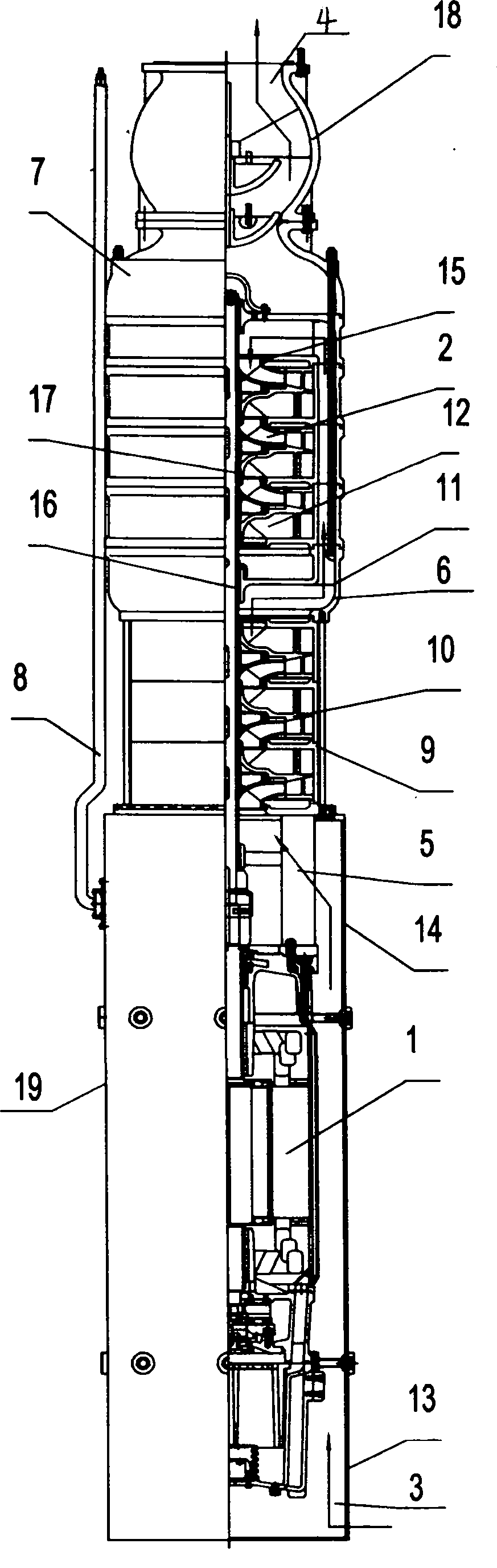

[0016] Such as figure 1 As shown, the structure of the present invention is a submersible electric pump with downward suction, single suction and automatic balance axial force, including a pump body, a motor 1, an impeller 2, a water inlet 3 and a water outlet 4 of the pump body, and the whole pump body is provided with a constant pressure cover 19 , the water inlet is set at the lower end of the pump body as a down-suction structure, including the water inlet section 5, the middle water diversion section 6 and the upper water outlet section 7 from bottom to top, and the motor is installed at the position of the water inlet section; the motor is connected with The cable 8 is drawn out, and the impeller is installed in the middle water diversion section. The middle water diversion section is composed of a multi-stage pump. The lower pump body 9 is provided with a positive guide vane 10, and the upper pump body 11 is provided with a reverse guide vane 12. , the positive guide va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com