A gripping device for a semiconductor handling apparatus having a collision prevention function

A technology for handling equipment and grabbing devices, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems affecting the process, the length of the inconvenient grabbing distance, and the difficulty in controlling the relative rotation angle of the turntable and the base. To achieve the effect of preventing damage to the substrate surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The following is attached Figure 1-4 The present invention is described in further detail.

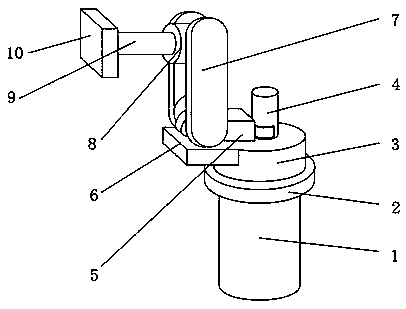

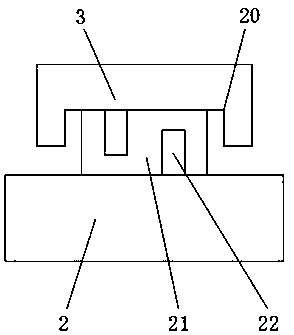

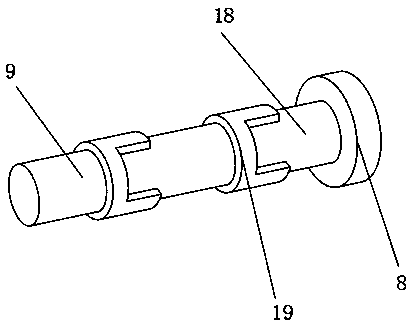

[0031] A grabbing device for semiconductor handling equipment with an anti-collision function, such as Figure 1-2 As shown, the support column 1 is included, the power is turned on, the base 2 is fixedly installed on the upper outer surface of the support column 1, the turntable 3 is arranged above the base 2, the support plate 6 is fixedly installed on the front end outer surface of the turntable 3, and on the fixed plate The outer surface of 5 is provided with a telescopic mechanism, through the cooperation of the telescopic mechanism and the grasping mechanism, the semiconductor substrate is grasped, and the contact column 4 and the fixed plate 5 are fixedly installed on the outer surface of the upper end of the turntable 3, and the turntable 3 is located on one side of the fixed plate 5 , make the turntable 3 rotate around the base 2 at a certain angle, fix it with the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com