Technology system for preparing small-molecule inhibitor through electrolysis method

A technology of small molecule inhibitor and process system, applied in electrolysis process, electrolysis components, electrolysis organic production, etc., can solve problems such as large environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

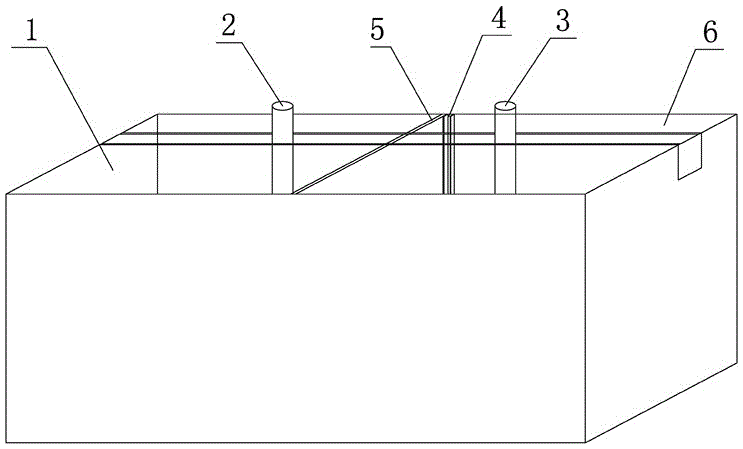

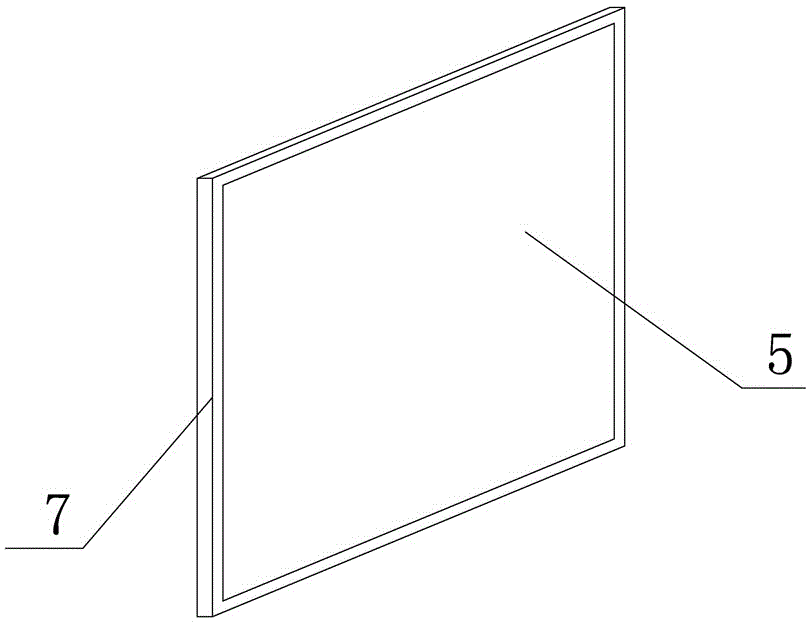

[0013] Such as figure 1 , figure 2 , a process system for preparing small molecule inhibitors by electrolysis, including an electrolytic cell, a cathode 2, an anode 3, and a diaphragm plate, an introduction groove 4 is arranged on the inner wall of the electrolytic cell, and the diaphragm plate is inserted into the introduction groove 4 , the electrolytic cell is divided into a negative electrolytic cell 1 and a positive electrolytic cell 6; the diaphragm plate includes a frame 7 and a diaphragm 5.

[0014] In this embodiment, the frame of the diaphragm plate includes a concave frame and a main frame, the concave frame is embedded in the main frame, and the four sides of the diaphragm 5 are embedded between the concave f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com