Chip removal system convenient for collection for mold production

A technology of mold and hopper, applied in the field of chip removal system for mold production, can solve the problems of inconvenient production, time-consuming and labor-intensive, etc., and achieve the effects of convenient production, improved work efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0021] The devices, structures, positions and connections not described in detail in the present invention can be understood as common knowledge in this field.

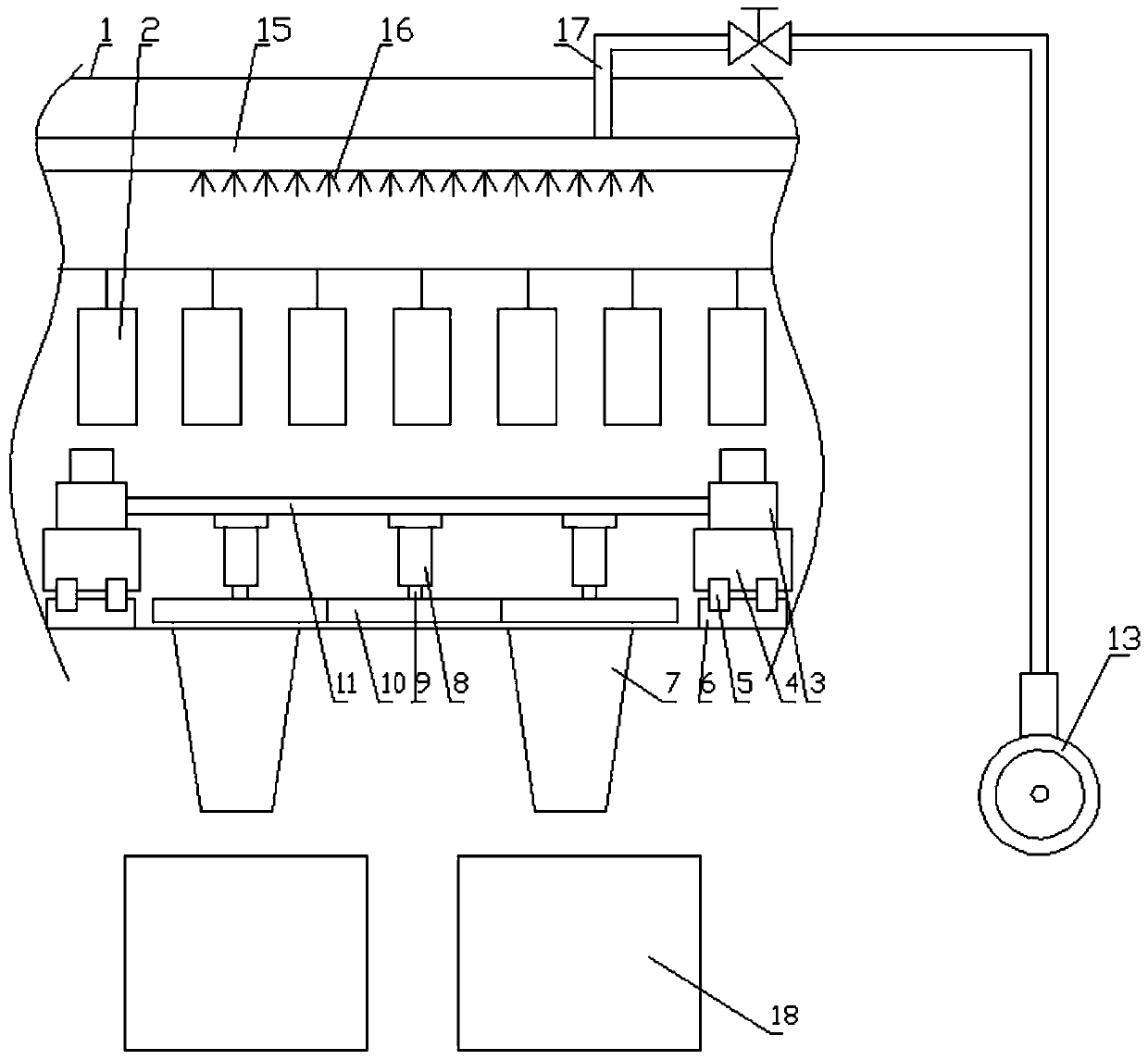

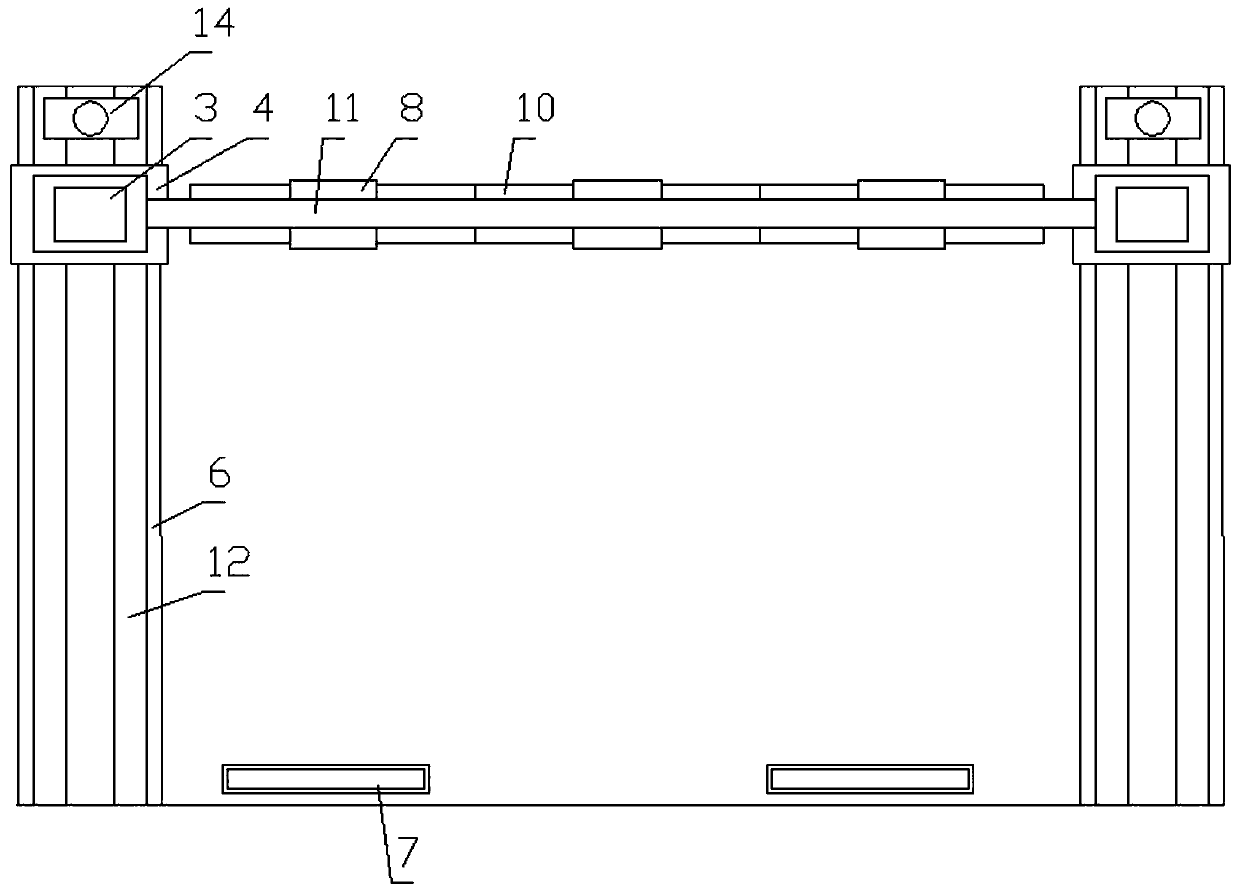

[0022] A chip removal system for mold production that is convenient for receiving materials, such as figure 1 and figure 2 As shown, the system includes a first air pipe 15, an air nozzle 16, a second air pipe 17, a gas device 13 for jetting and a receiving device;

[0023] The first air pipe is arranged at intervals in the box body 1 of the processing system, above the suspended mold to be processed or the parts 2 used for mold production. The first air pipe is arranged along the horizontal direction. On the lower bottom surface of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com