Plastic powder cooling conveyor

A technology for cooling conveyors and conveyors, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve problems such as waste, inconvenience for users to maintain and dredge, and affect production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

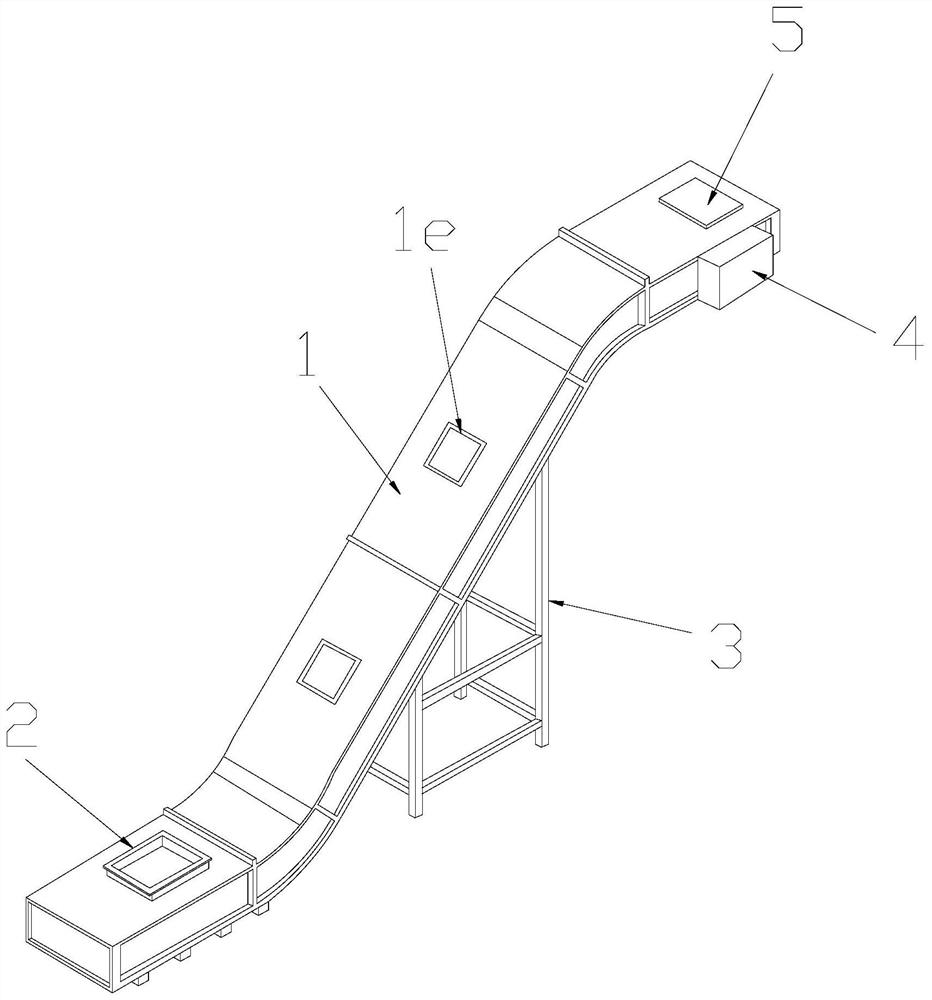

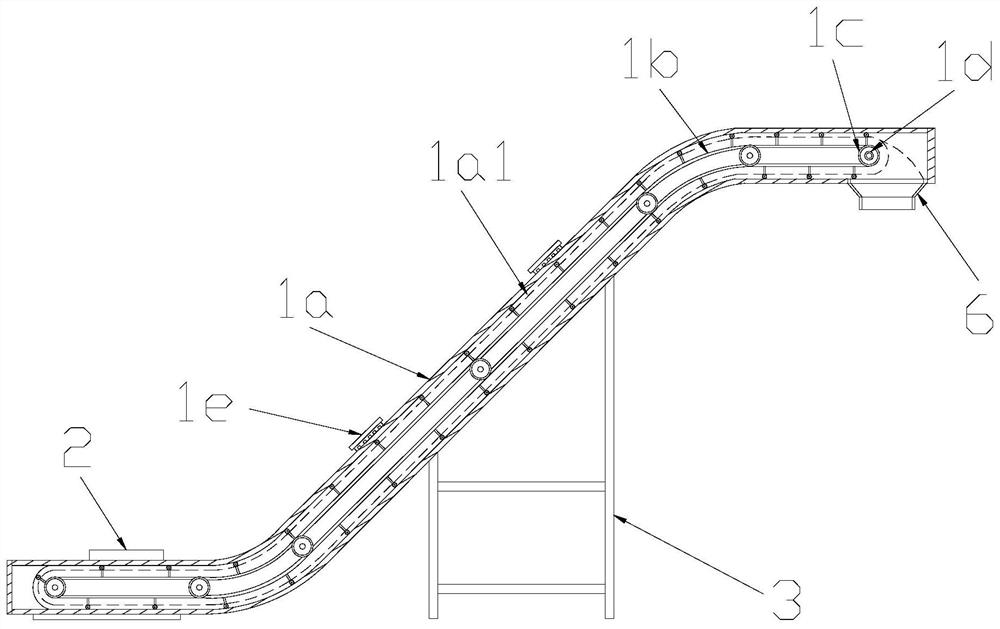

[0026] see Figure 1-Figure 4 , the present invention provides a plastic powder cooling conveyor, the structure of which includes a powder conveyor 1, a feed hopper 2, a support frame 3, a drive motor 4, an inspection cover 5, and a hopper 6. The bottom of the powder conveyor 1 A support frame 3 is provided below, and the powder conveyor 1 and the support frame 3 are flexibly connected. One end of the powder conveyor 1 is provided with a feed hopper 2, and the powder conveyor 1 and the feed hopper 2 are An integrated structure, the other end of the powder conveyor 1 is provided with an inspection cover 5 and a discharge hopper 6 respectively, and the inspection cover 5 and the discharge hopper 6 are connected to the powder conveyor 1. The powder conveyor 1. A driving motor 4 is installed on the surface of the other end;

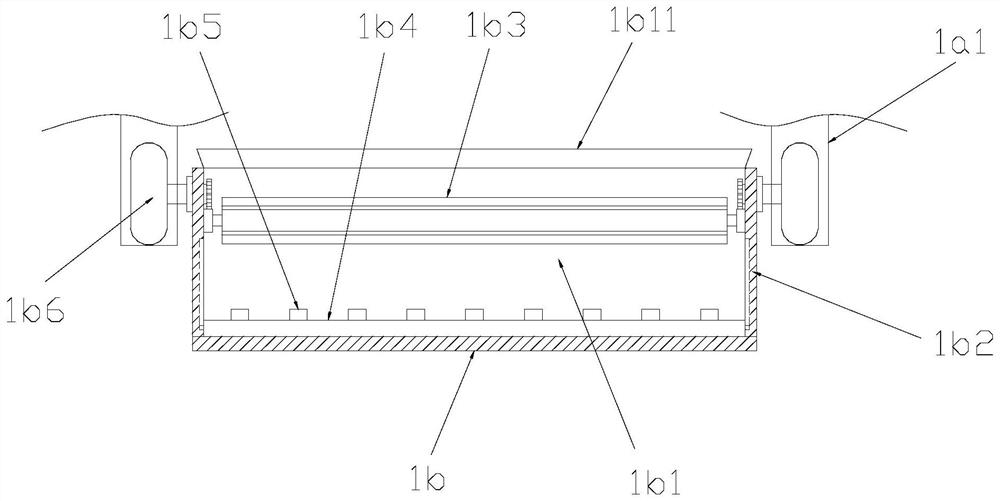

[0027] The powder conveyor 1 is composed of a body 1a, a conveyor belt 1b, a driving roller 1c, a rotating shaft 1d, and a ventilation cover 1e. The body 1a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com