Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

179results about How to "Automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

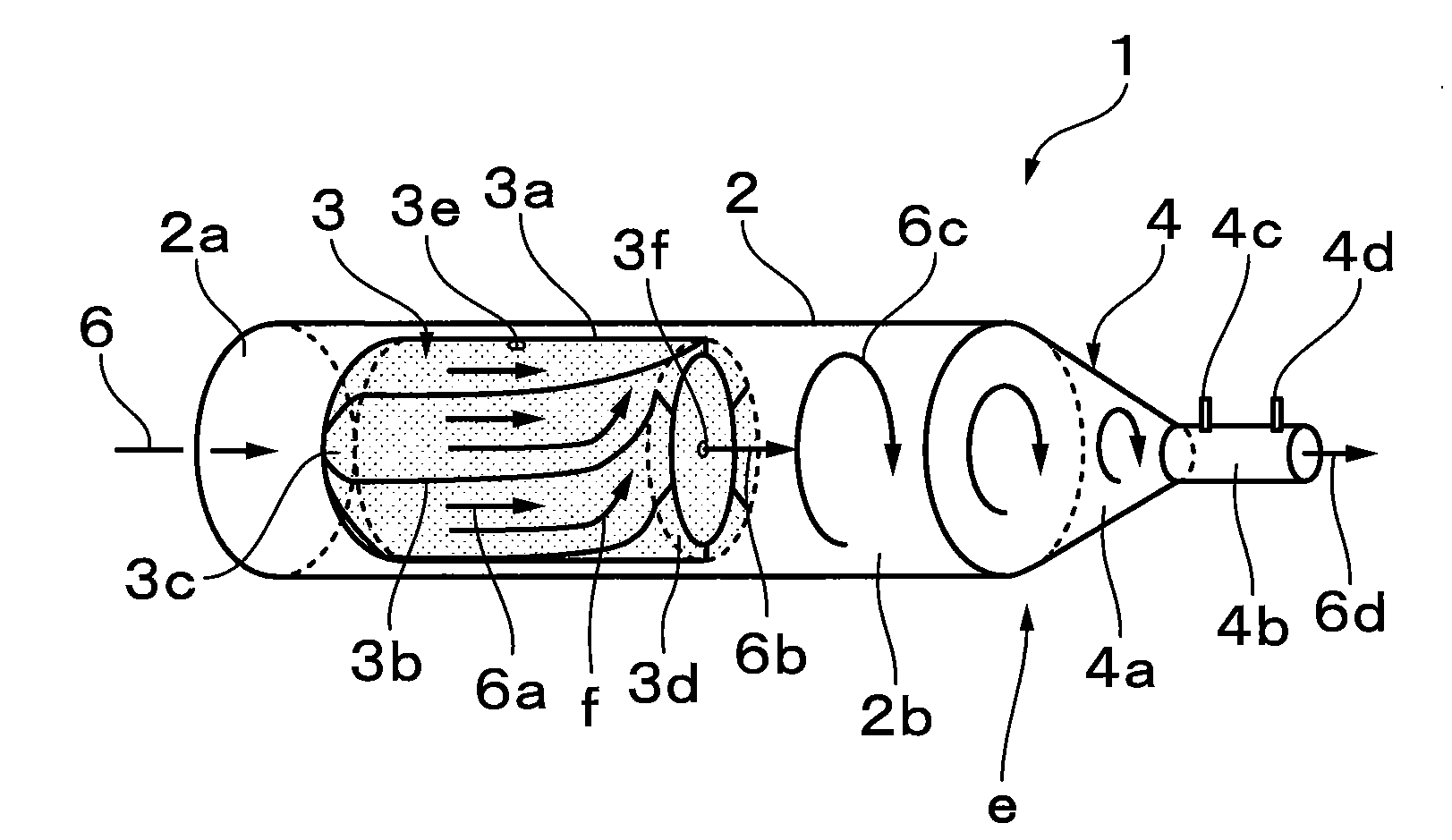

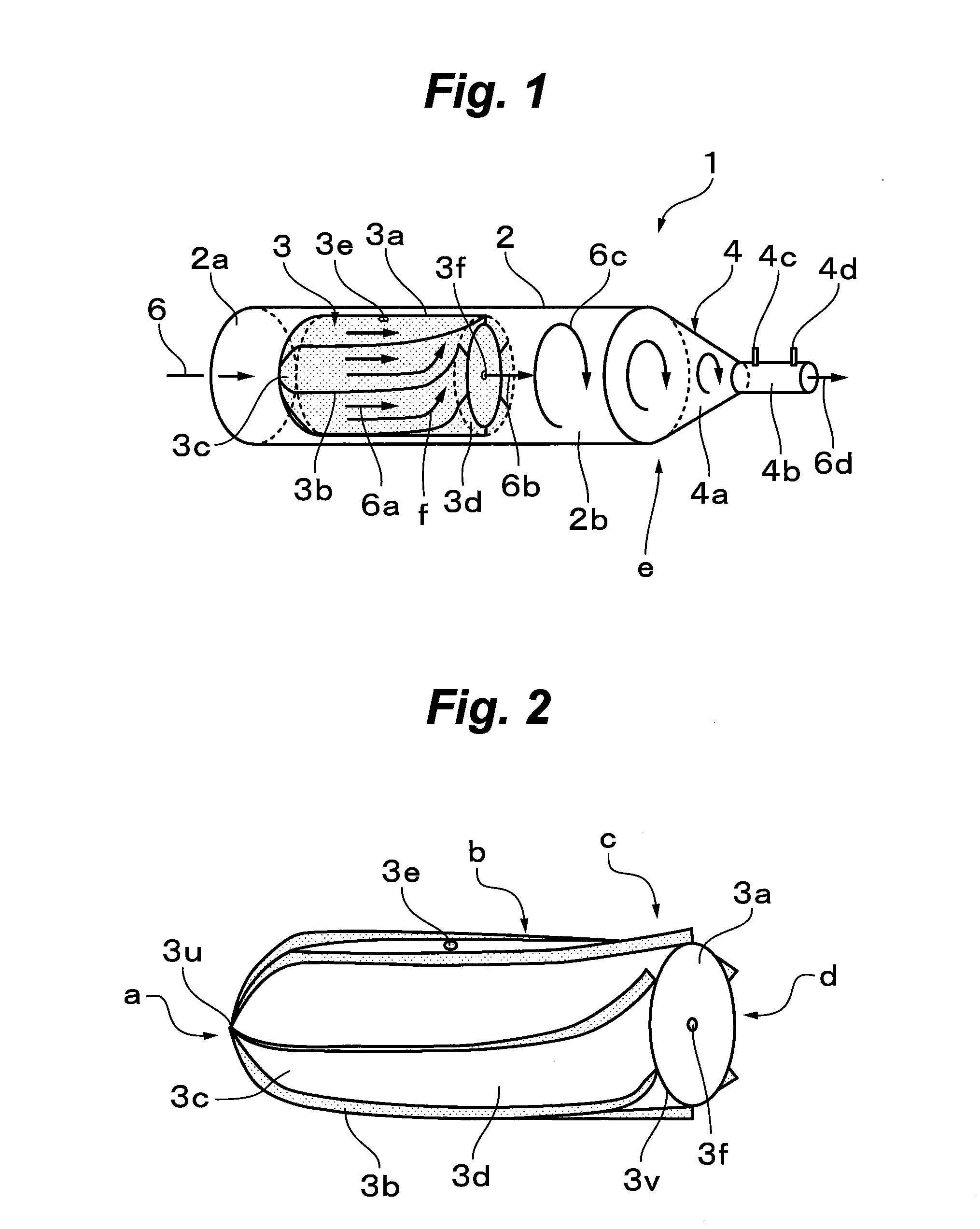

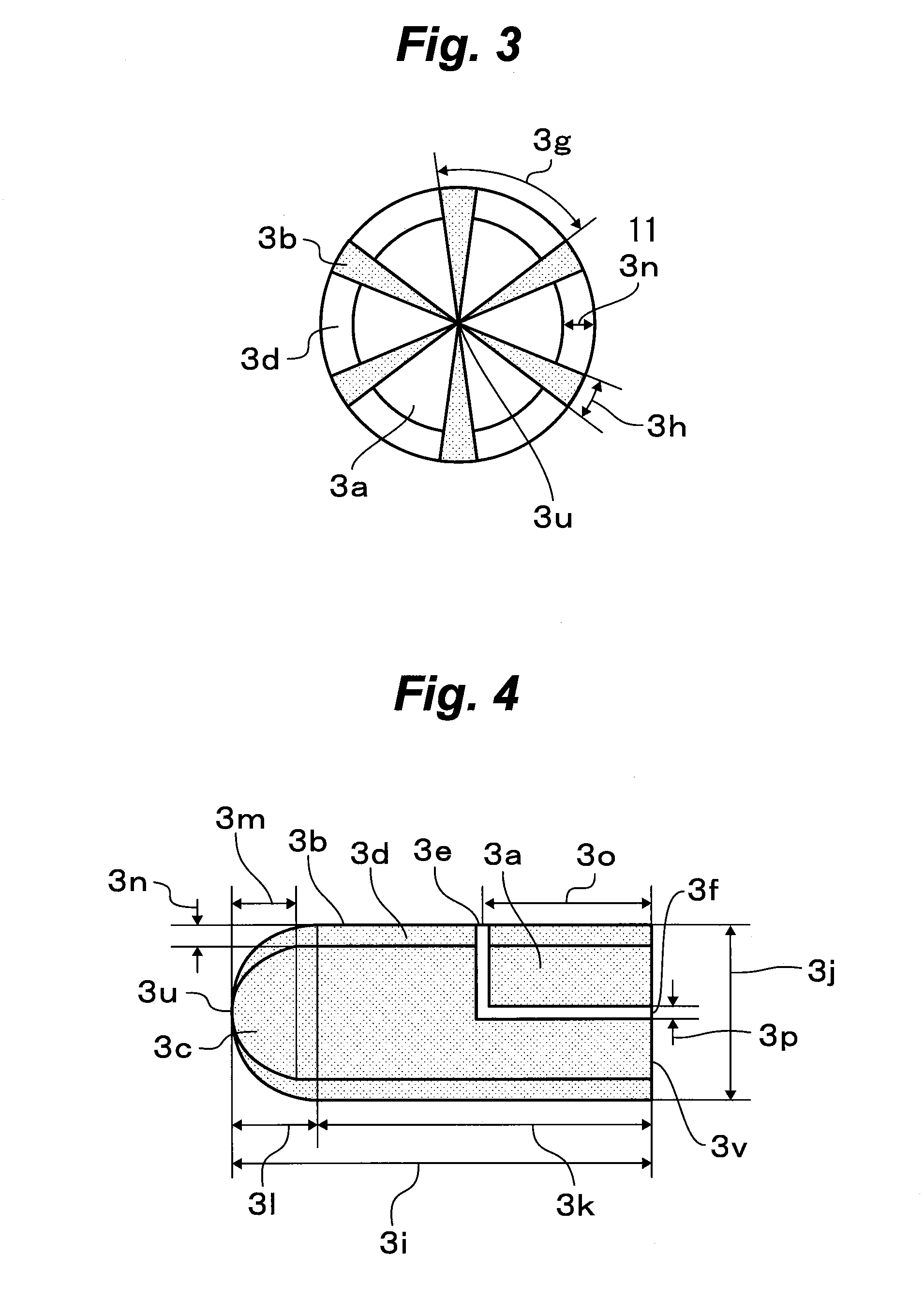

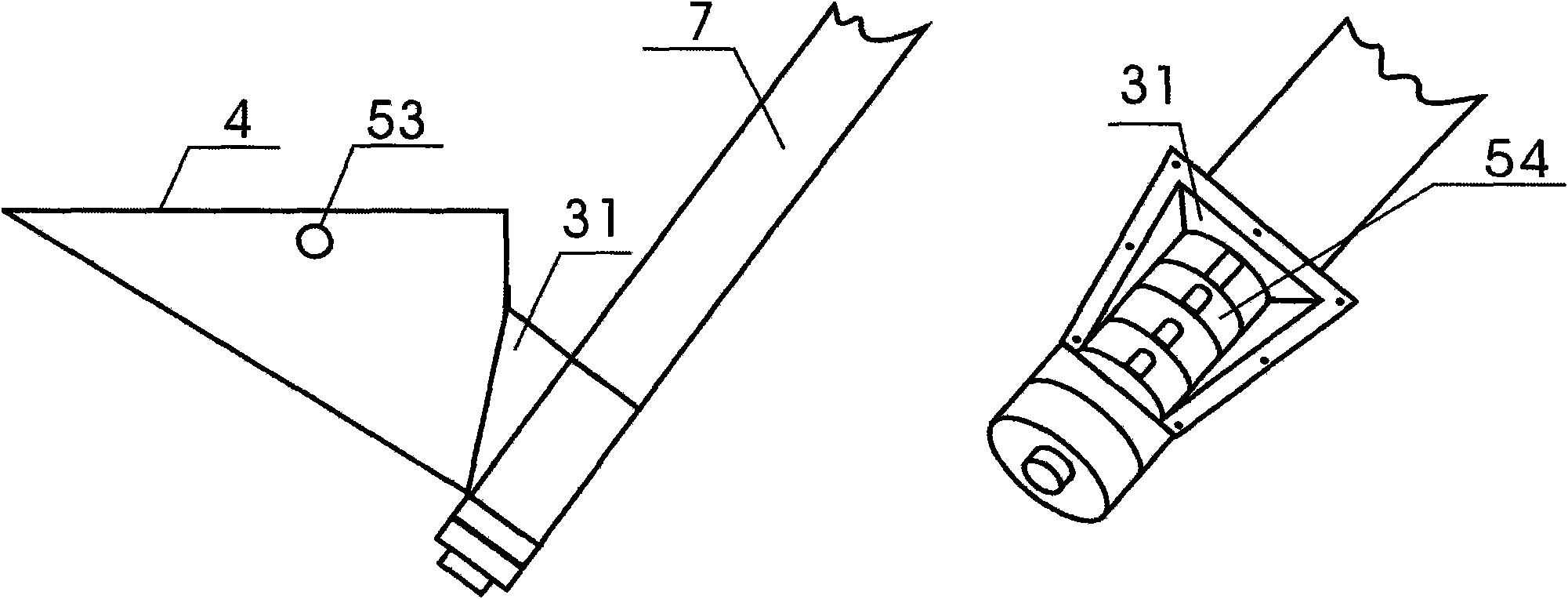

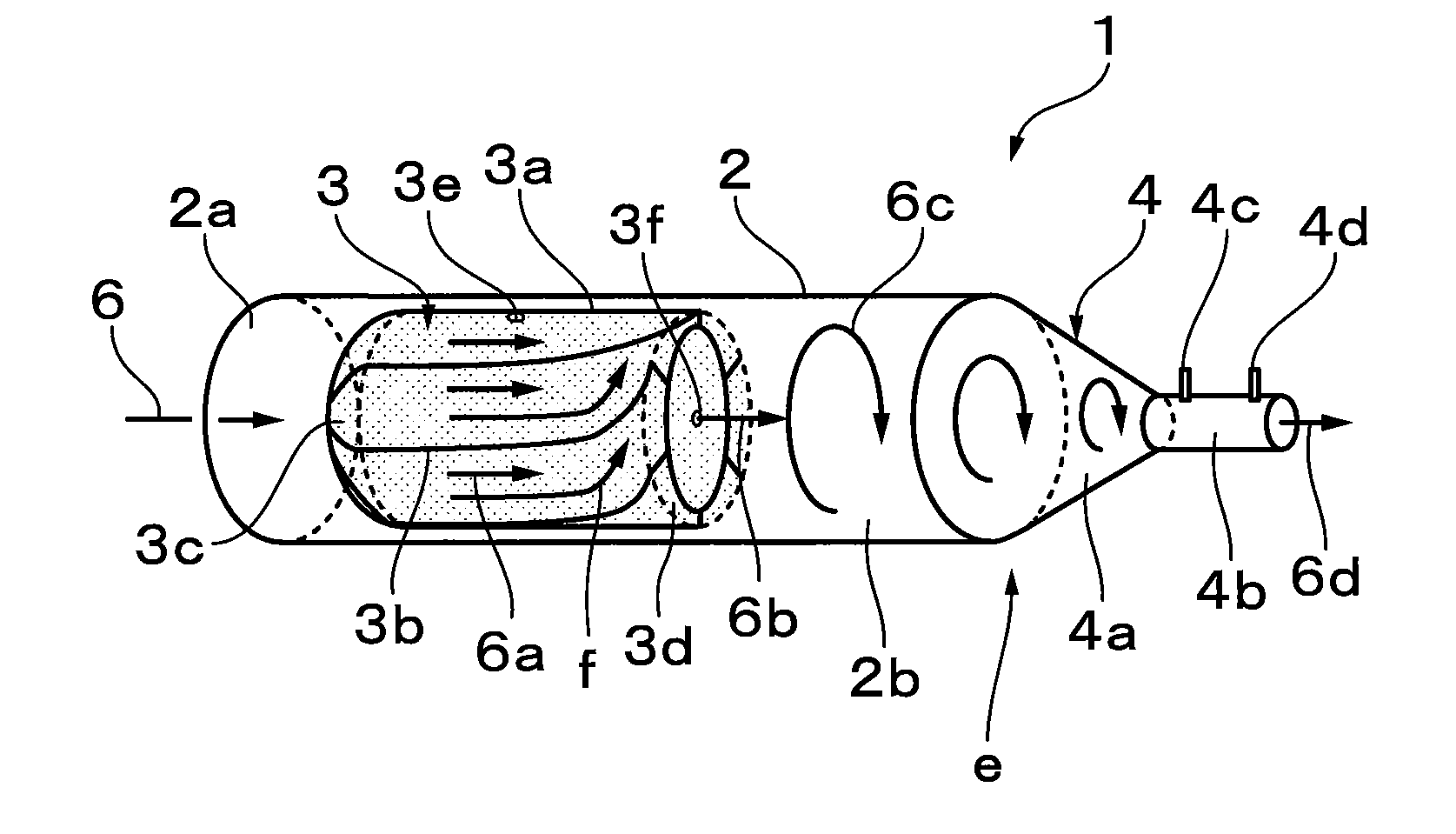

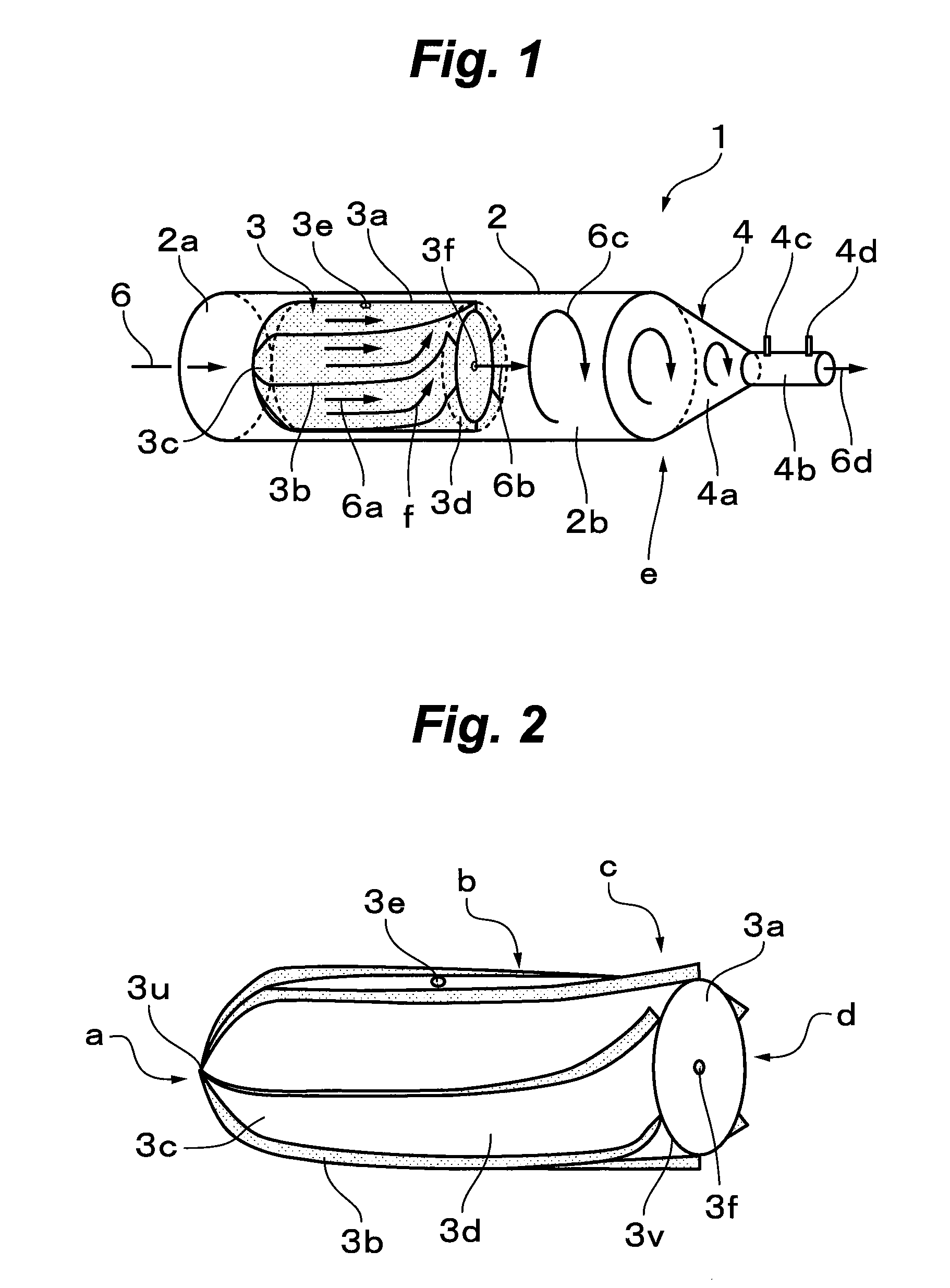

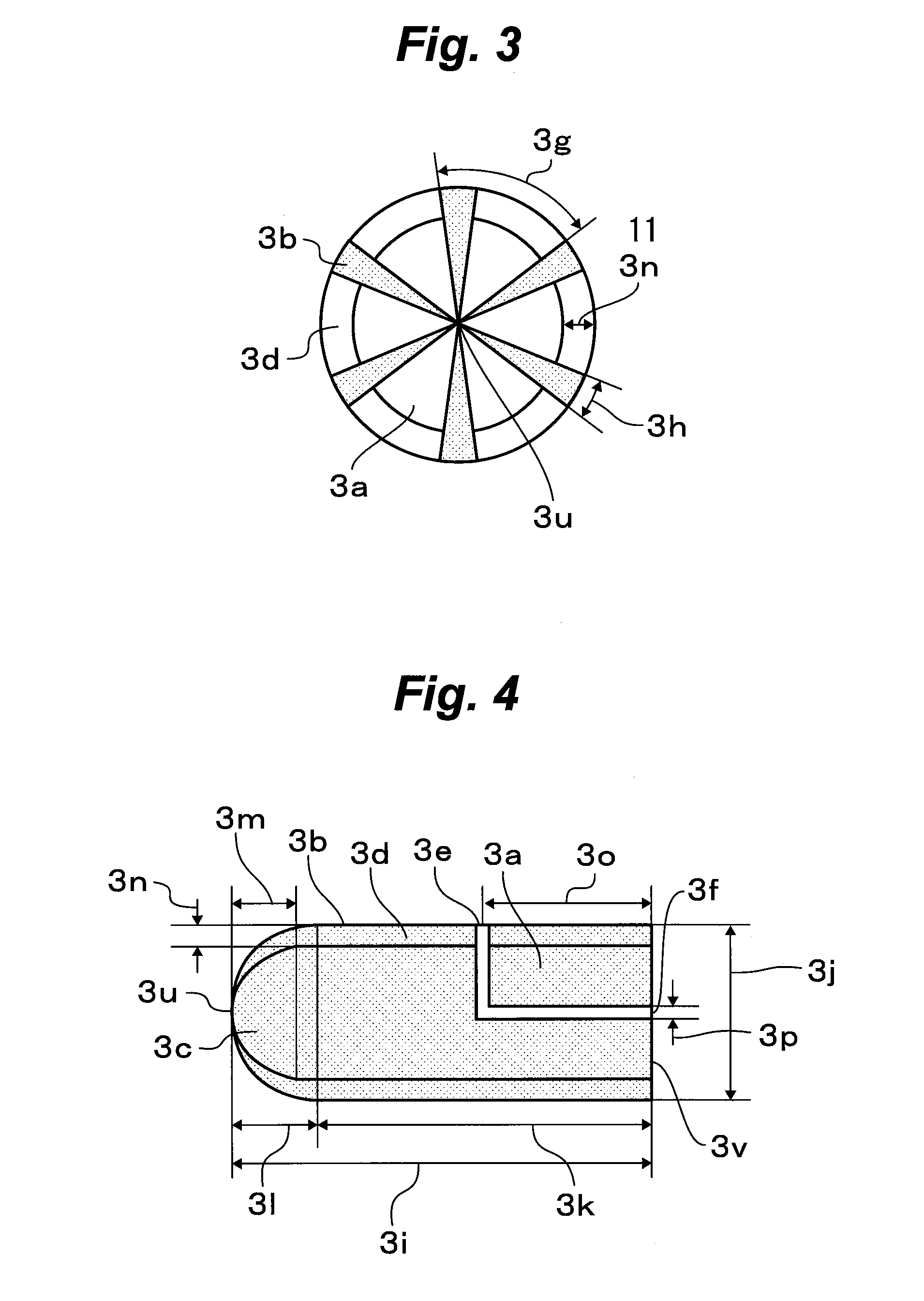

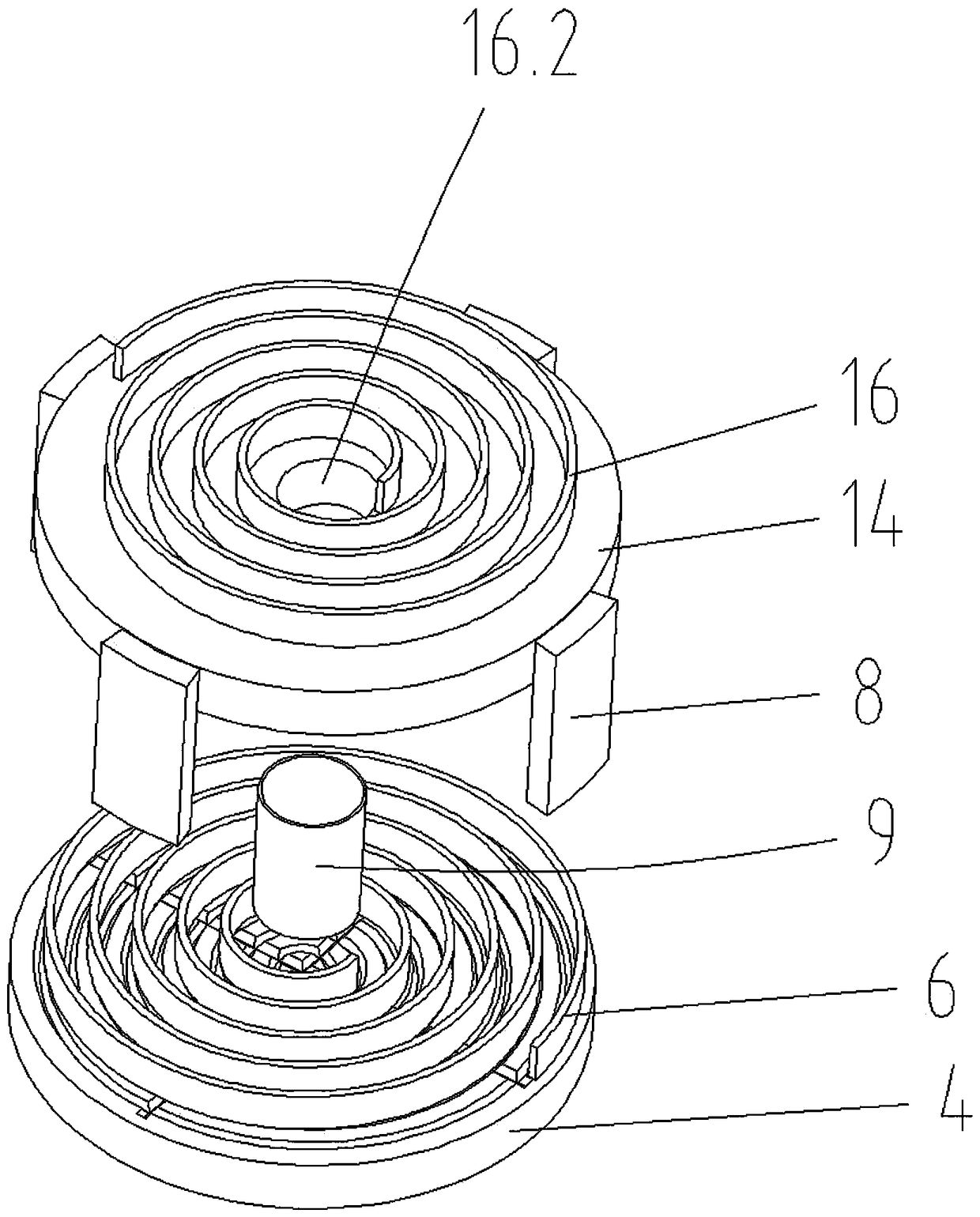

Micro-Bubble Generator, Vortex Breakdown Nozzle for Micro-Bubble Generator, Vane Swirler for Micro-Bubble Generator, Micro-Bubble Generating Method, and Micro-Bubble Applying Device

InactiveUS20080197516A1Efficient productionContact areaFlow mixersTransportation and packagingMicro bubbleWaste management

There is provided a micro-bubble generator including a swirling-flow generating vane nozzle and vortex breakdown nozzle connected coaxially to each other. The swirling flow generating vane nozzle produces a swirling flow of a liquid having a gas introduced to the center thereof from a gas feeding unit. The swirling flow is supplied to a flow constricting section included in the vortex breakdown nozzle to provide micro bubbles from a vortex breakdown section also included in the vortex breakdown nozzle.

Owner:UNIV OF TSUKUBA

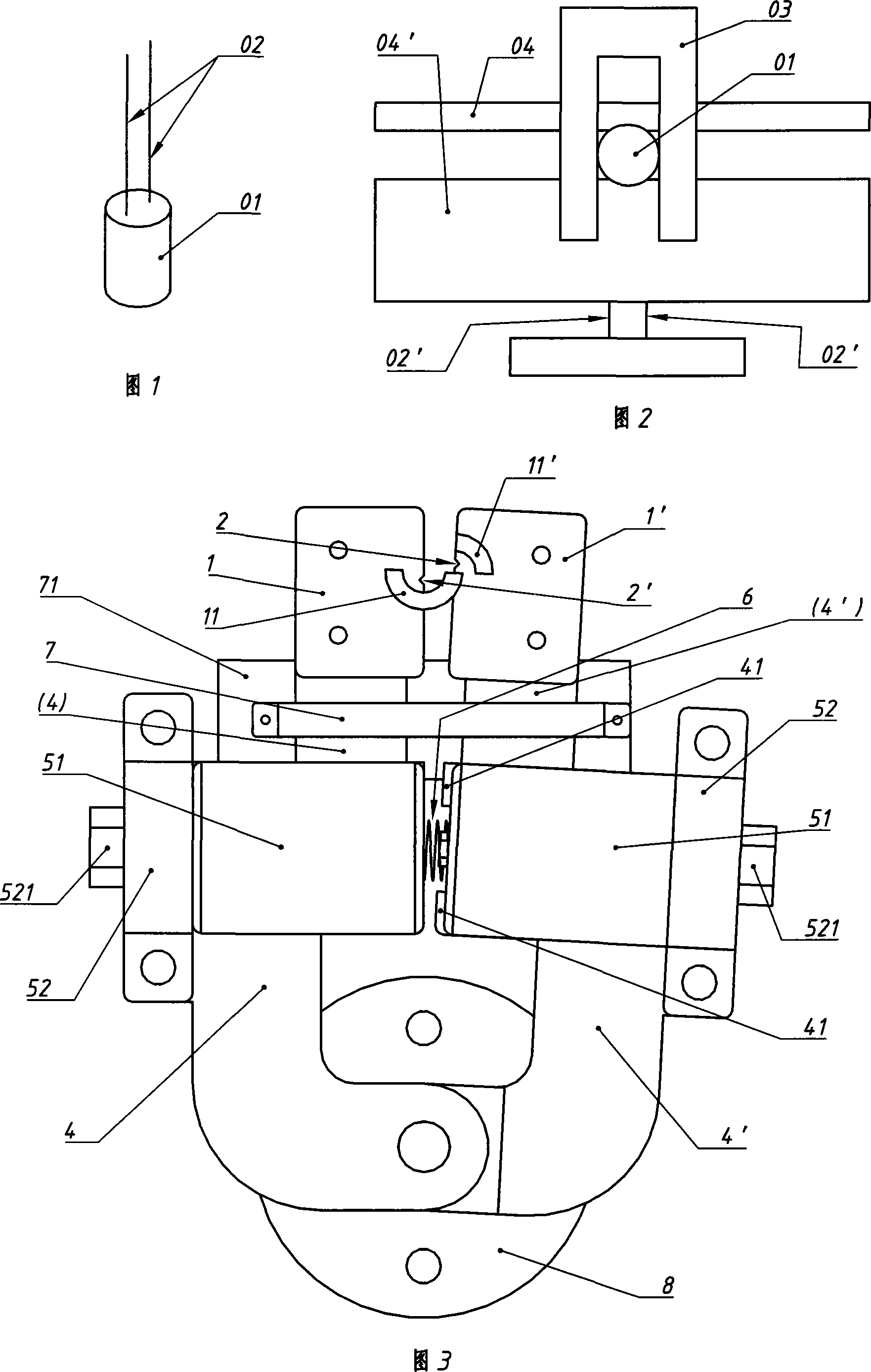

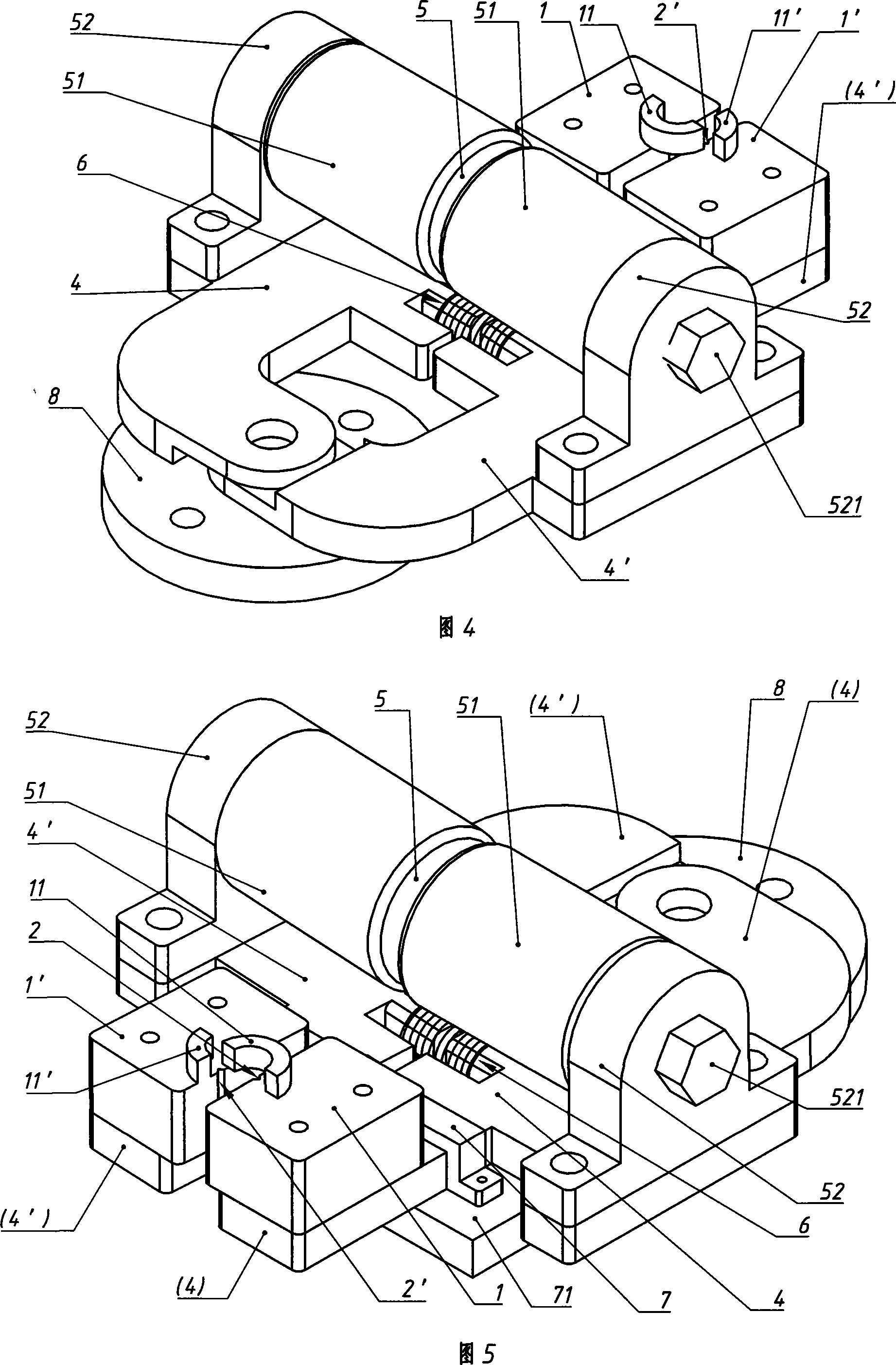

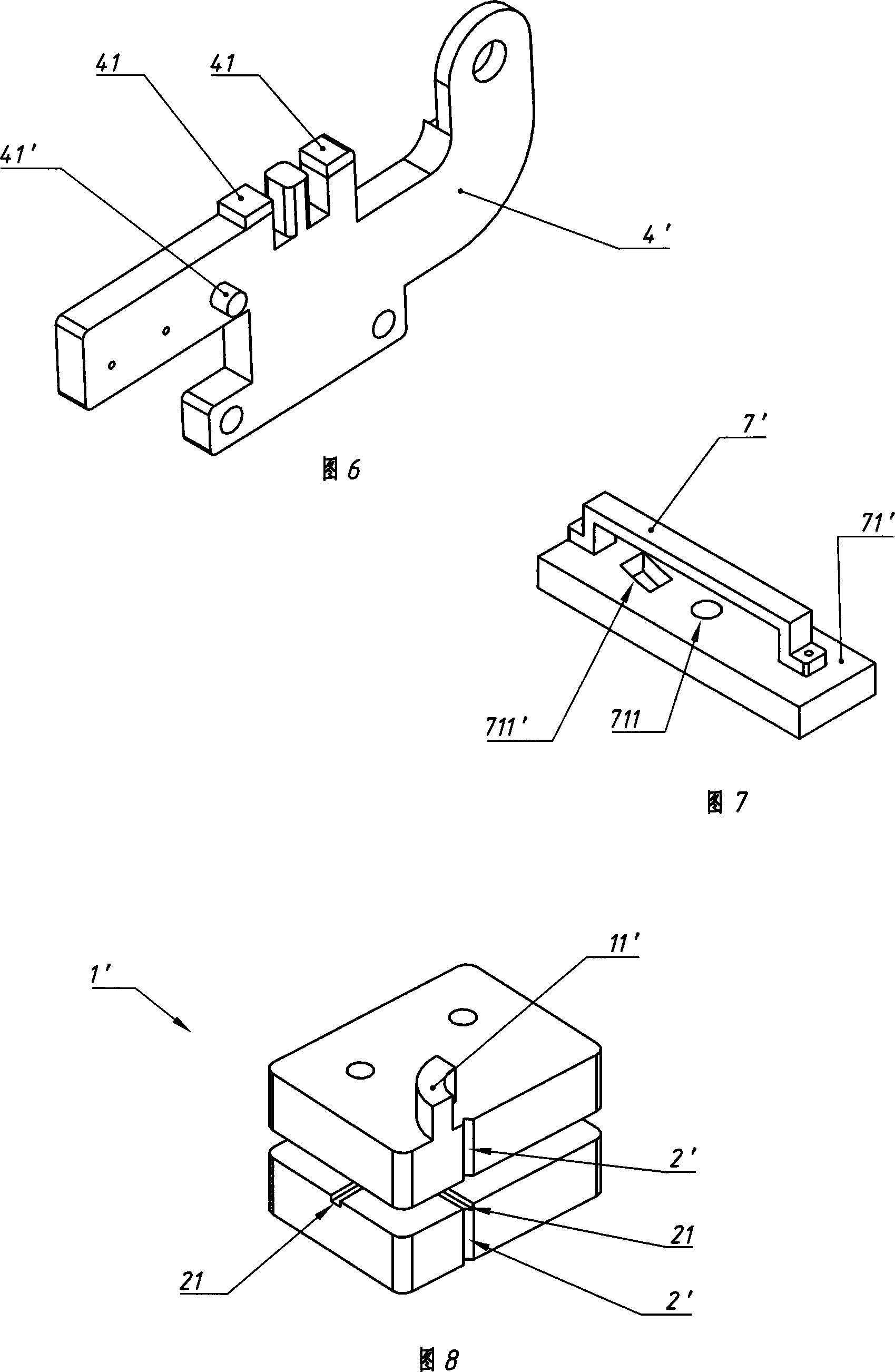

Clamp in use for testing LED

InactiveCN101093230AImprove accuracyIncrease success rateElectrical measurement instrument detailsIndividual semiconductor device testingEngineeringMechanical engineering

A fixture used for carrying out LED detection is prepared for forming hinge clamping-plate by a fixed clamping plate arm swing clamping plate arm in order to hold LED, setting electric magnetic iron and reset spring between two said clamping plate arms, arranging space block to limit closing degree of clamping plate on at least one clamping plate arm and setting a pair of material-receiving paws on end of two said clamping plate arms for holding tested LED.

Owner:CHONGQING UNIV

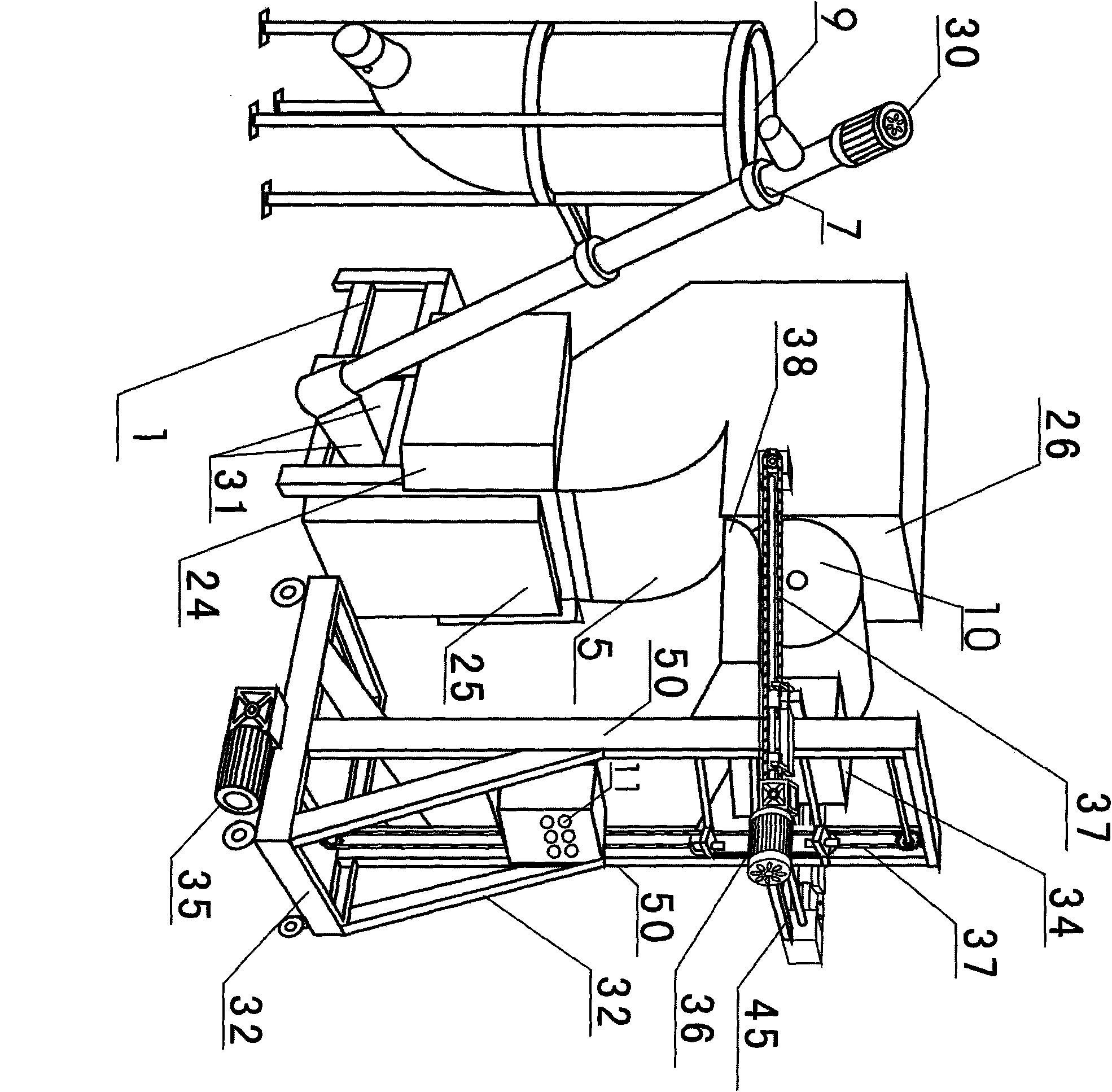

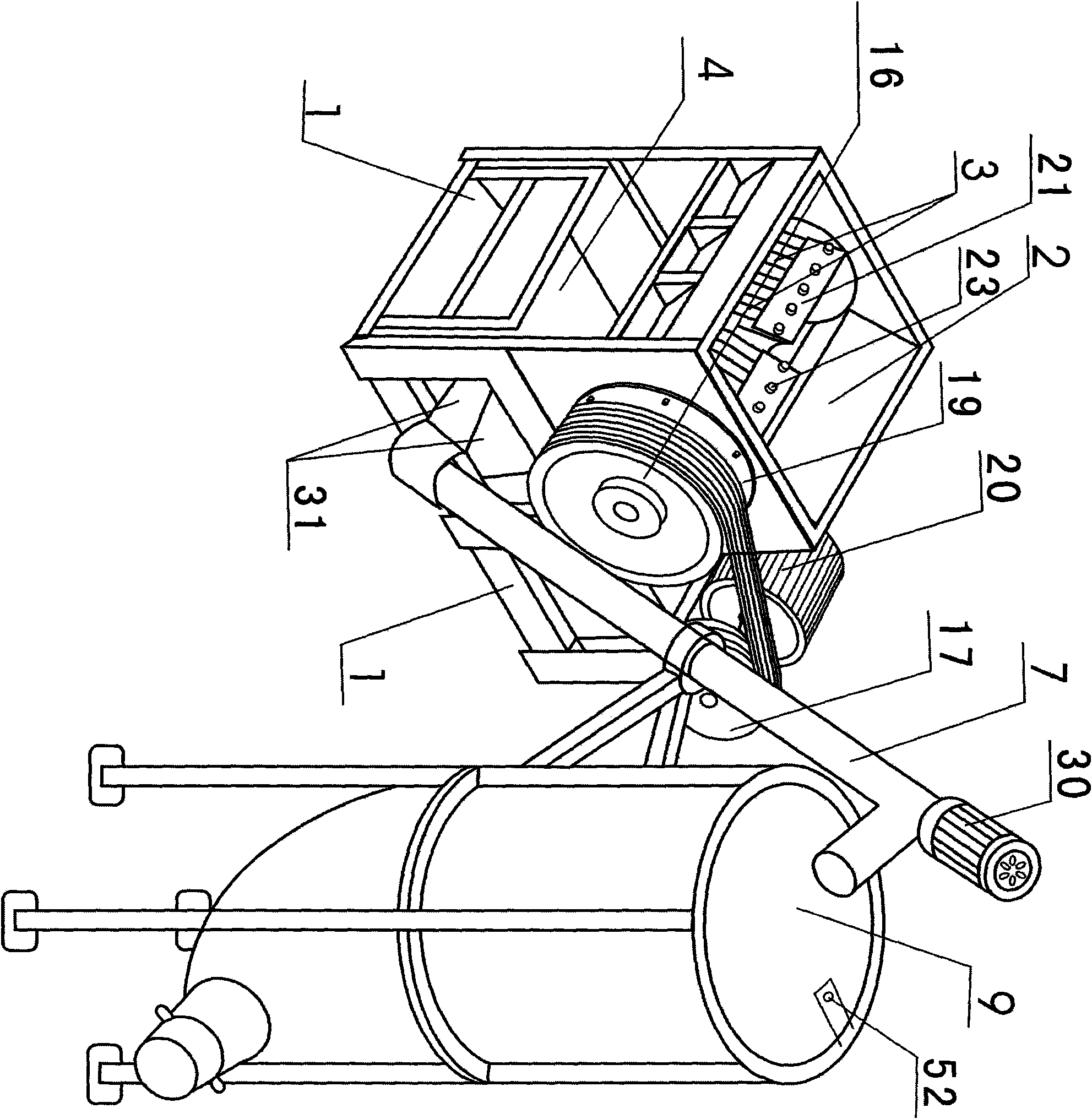

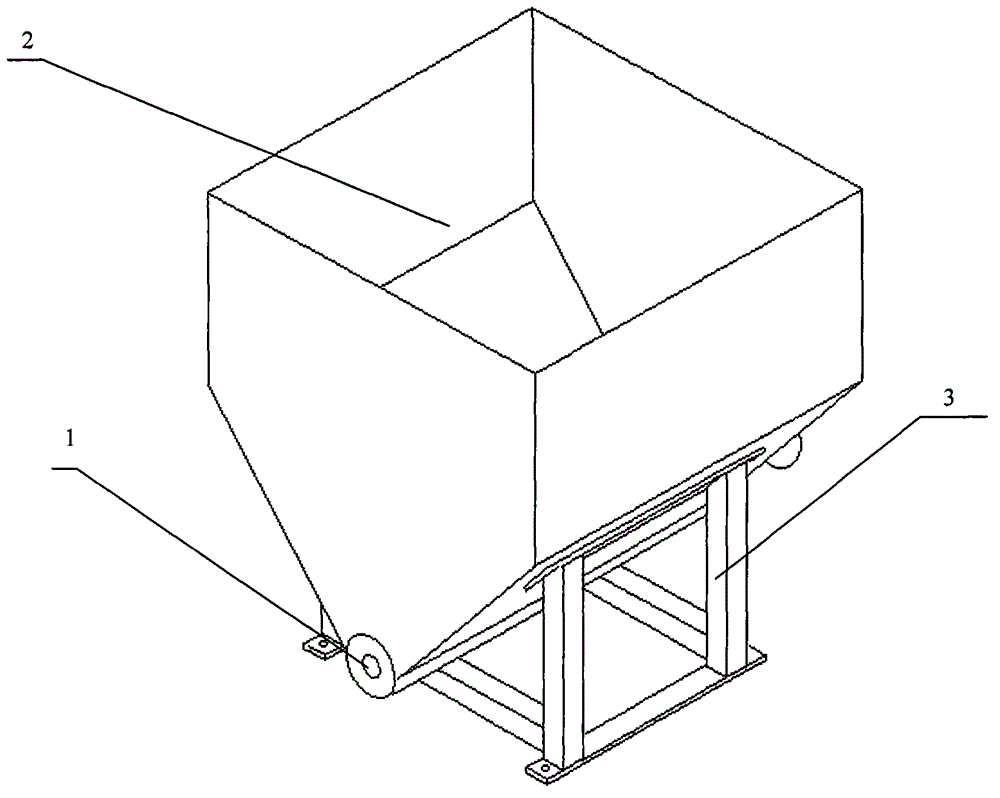

Automatic high-efficiency plastic crusher

ActiveCN101987485AFeeding safetyReduce deliveryPlastic recyclingGrain treatmentsResource savingEngineering

The invention relates to a plastic processing device, in particular to an automatic high-efficiency plastic crusher of coiled corners remained after a container is produced through thermal formation. The automatic high-efficiency plastic crusher is characterized by comprising a crusher main body base frame, a crusher crushing chamber, a crusher cover, a crusher main body transmission device, a blanking hopper, a screen device, a feeding helical rod, a feeding lifting device, a storage barrel and a distribution box, wherein the crusher crushing chamber is arranged above the front of the crusher main body base frame, the crusher cover is arranged above the crushing chamber, a feeding hole is arranged above the cover, the screen device is arranged below a crushing tool apron in the crusher crushing chamber, and the blanking hopper is arranged in the base, i.e. below the screen device. A fastening main transmission motor is arranged above the rear of the crusher main body base frame. The invention has the advantages of high efficiency, automation, environment protection, sanitation, safety and reliability, convenience and rapidness, time and labor saving, resource saving, attractive appearance and durability.

Owner:广东祺兴包装实业有限公司

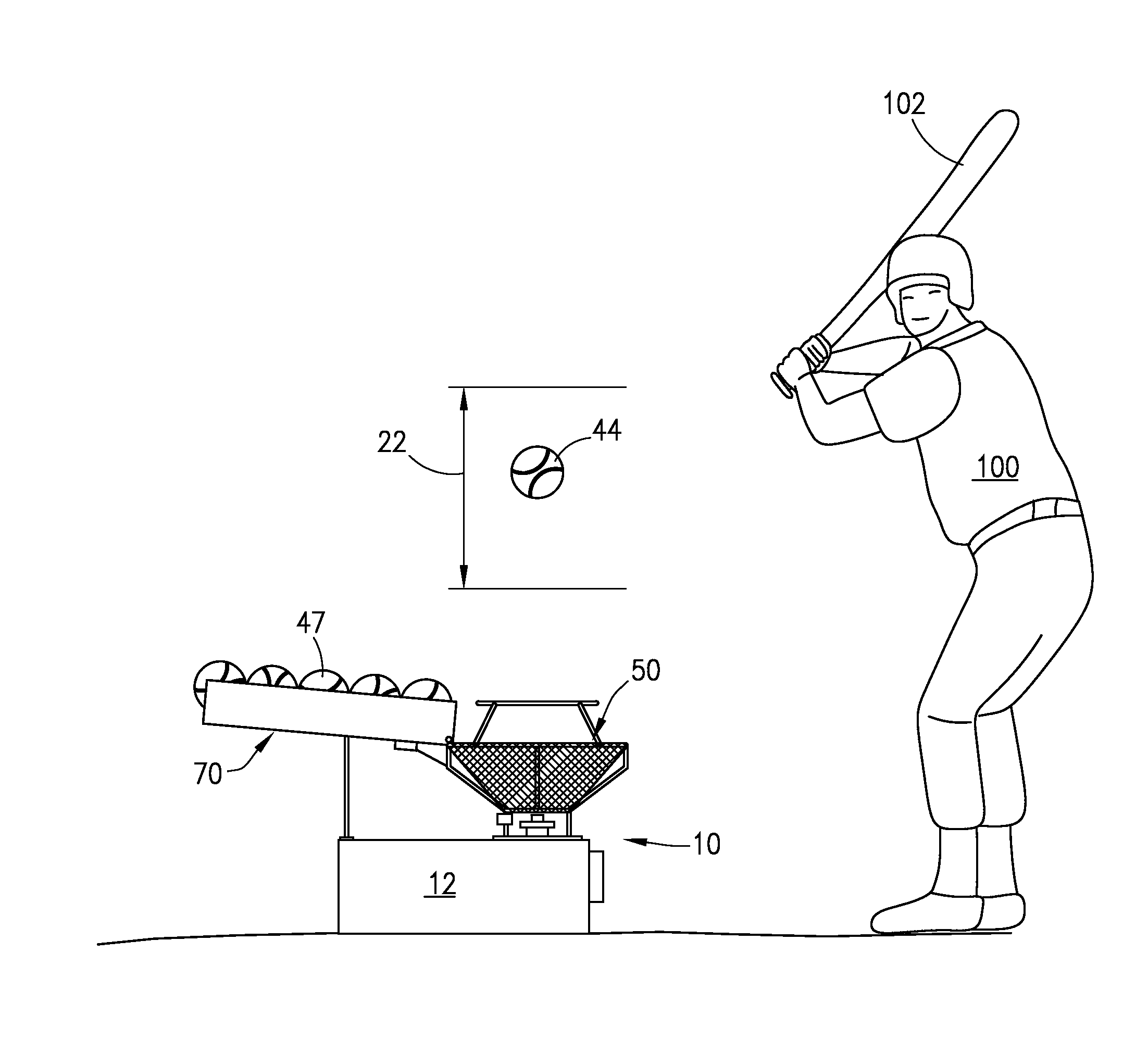

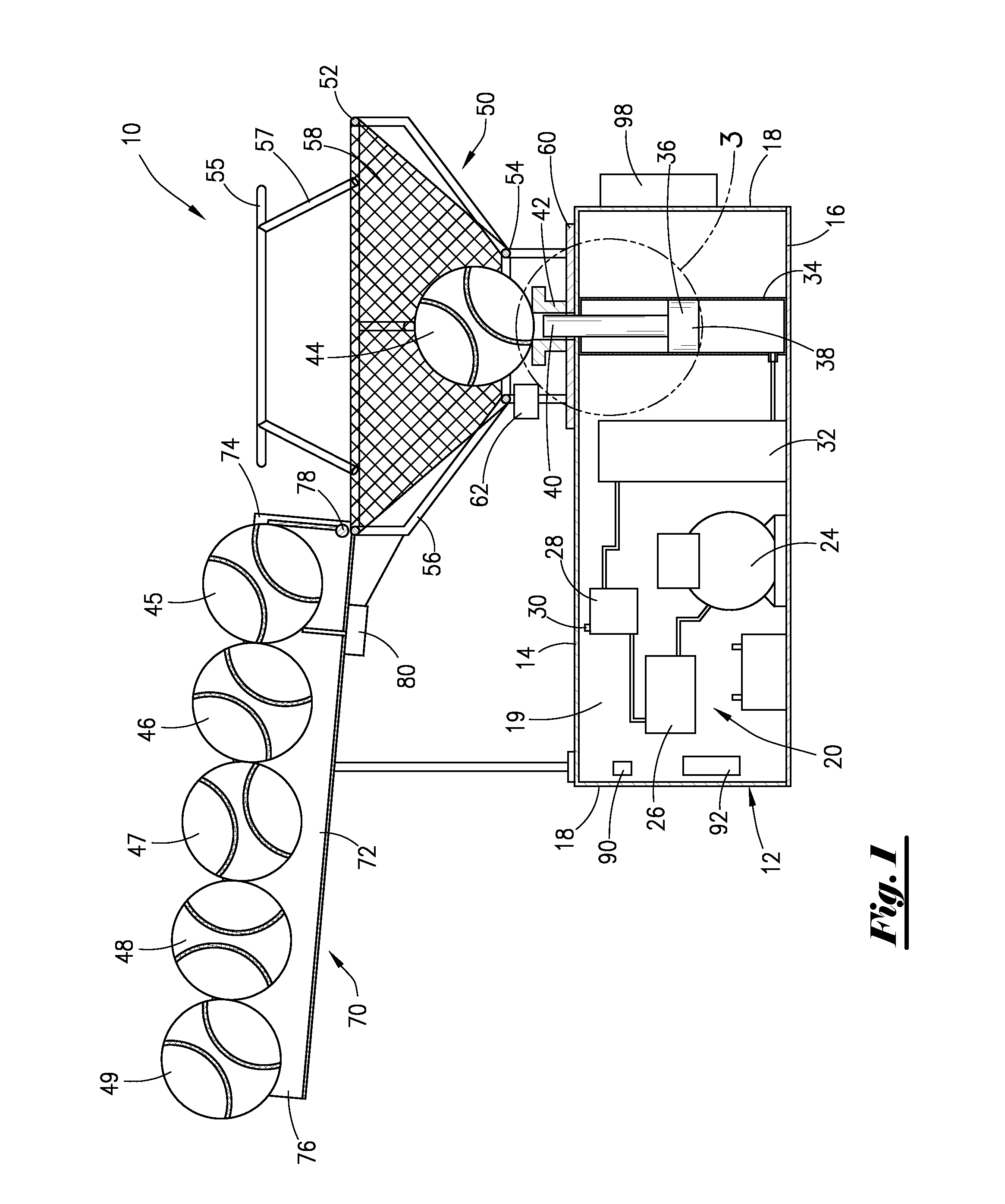

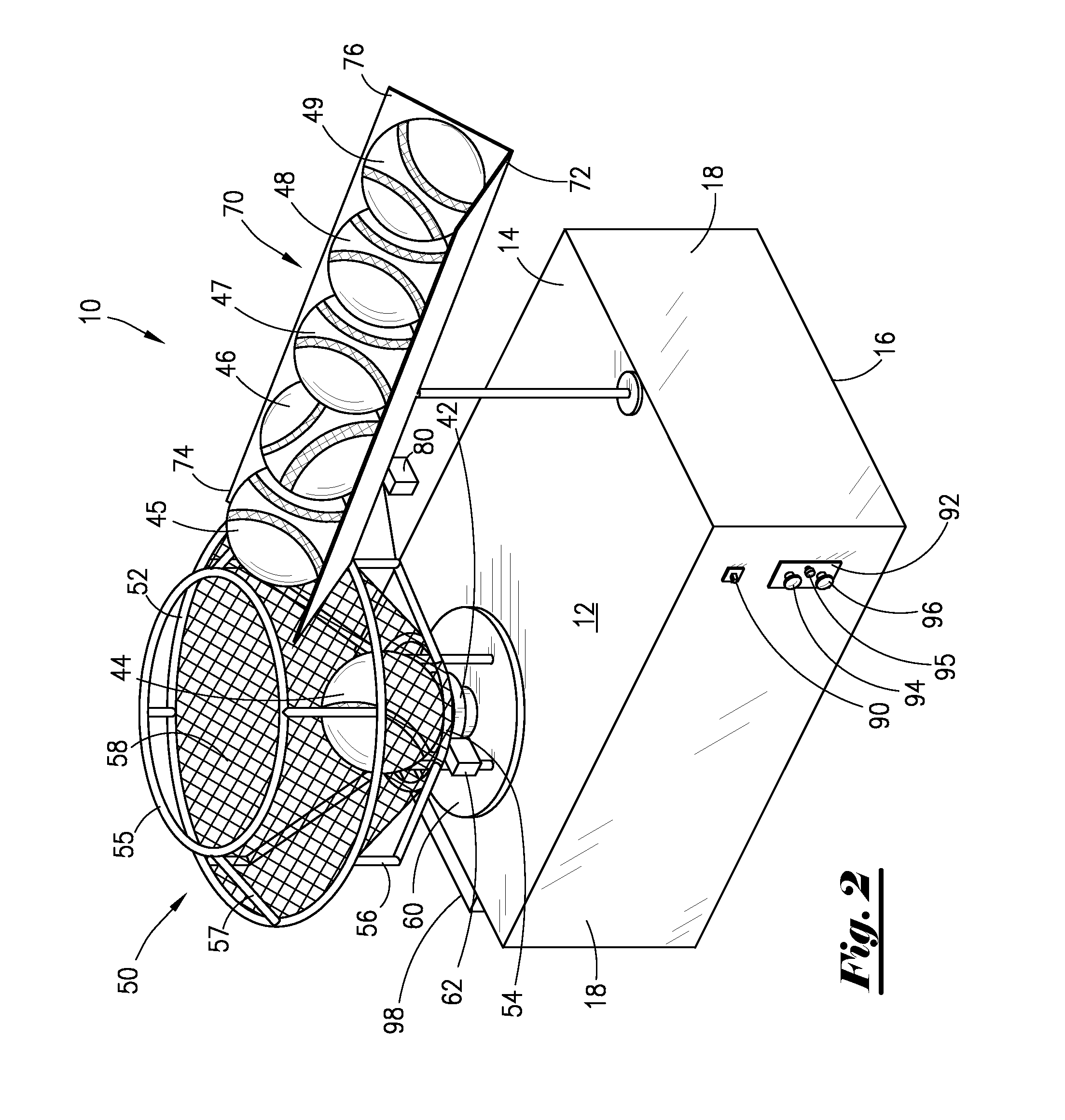

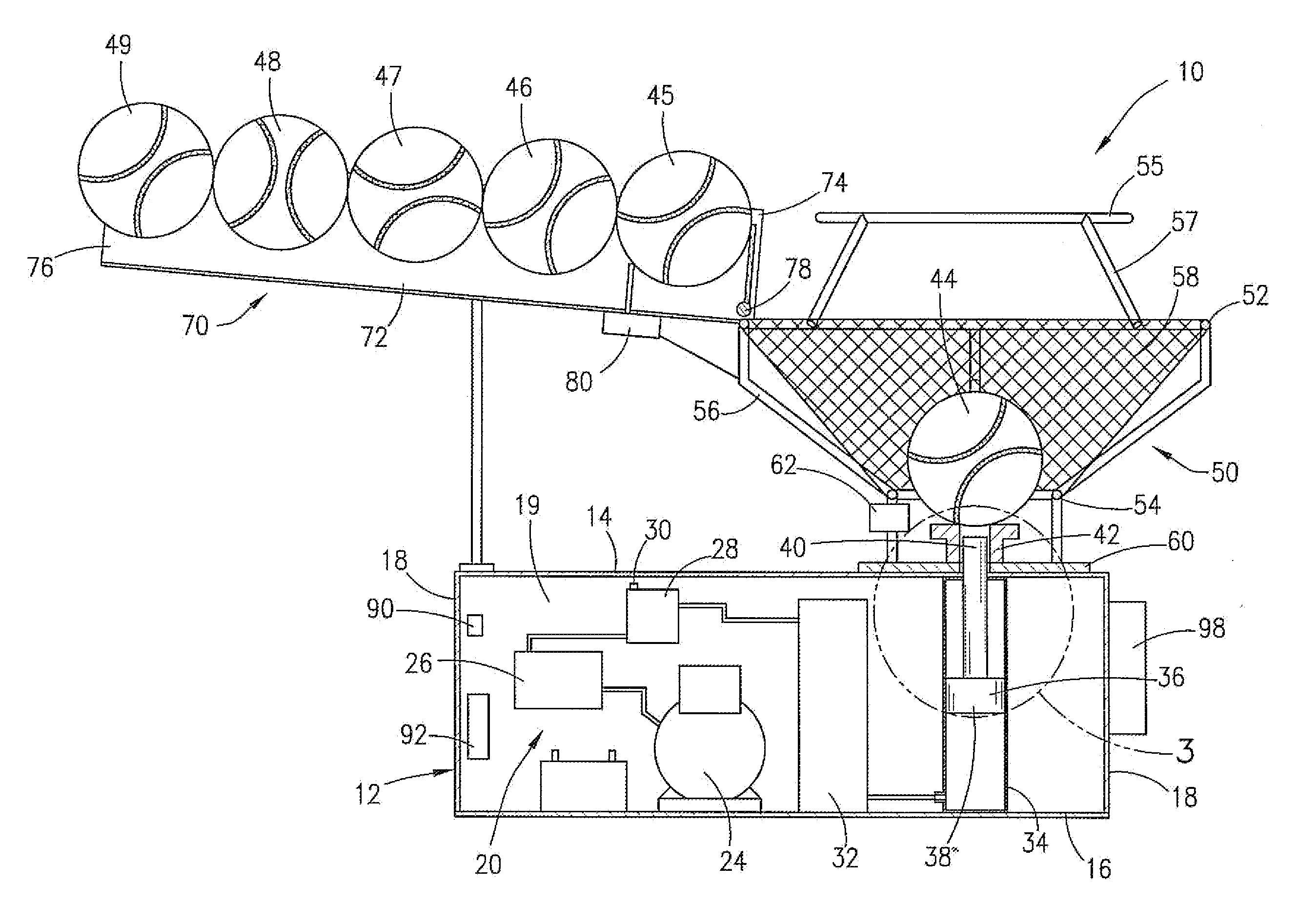

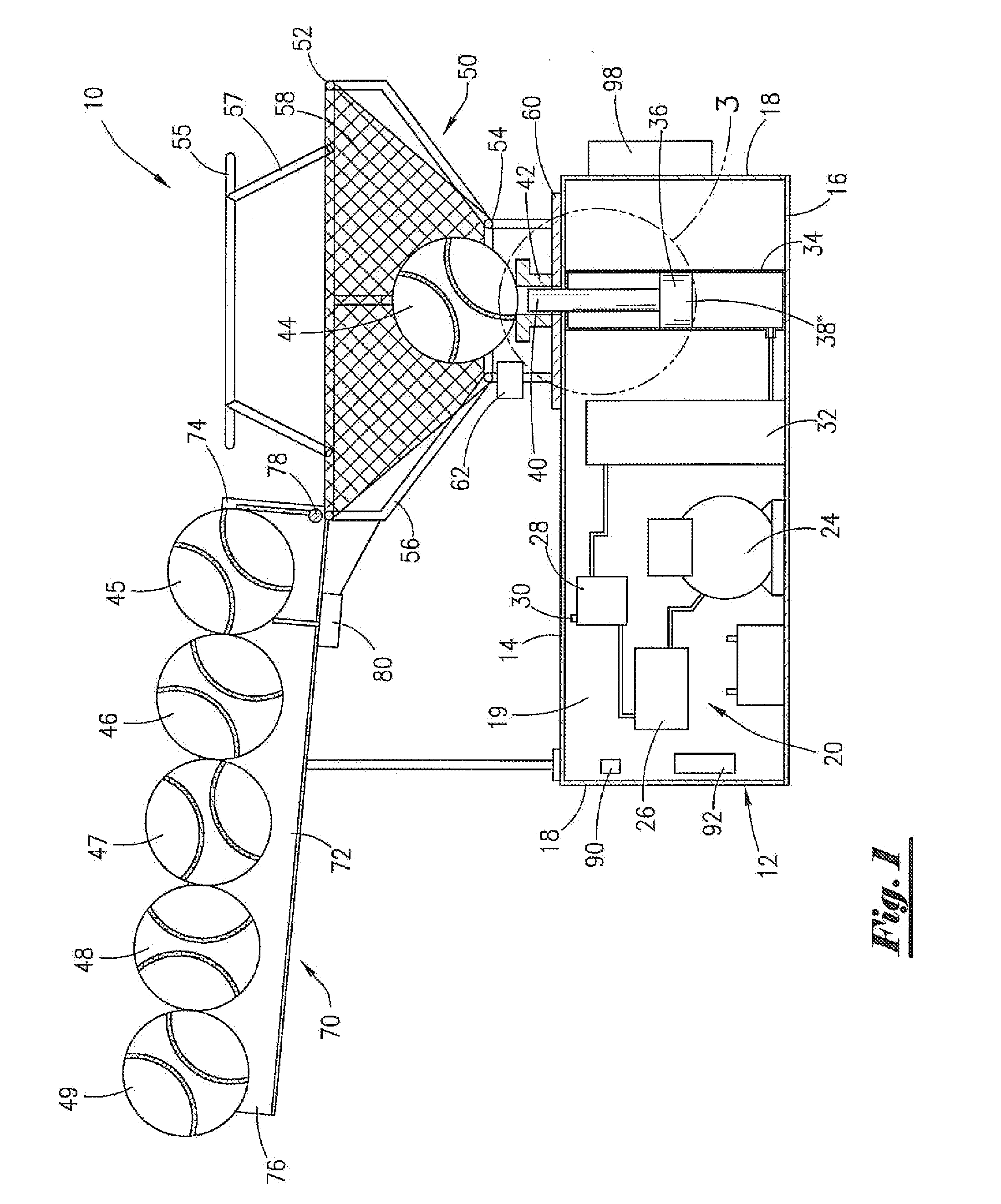

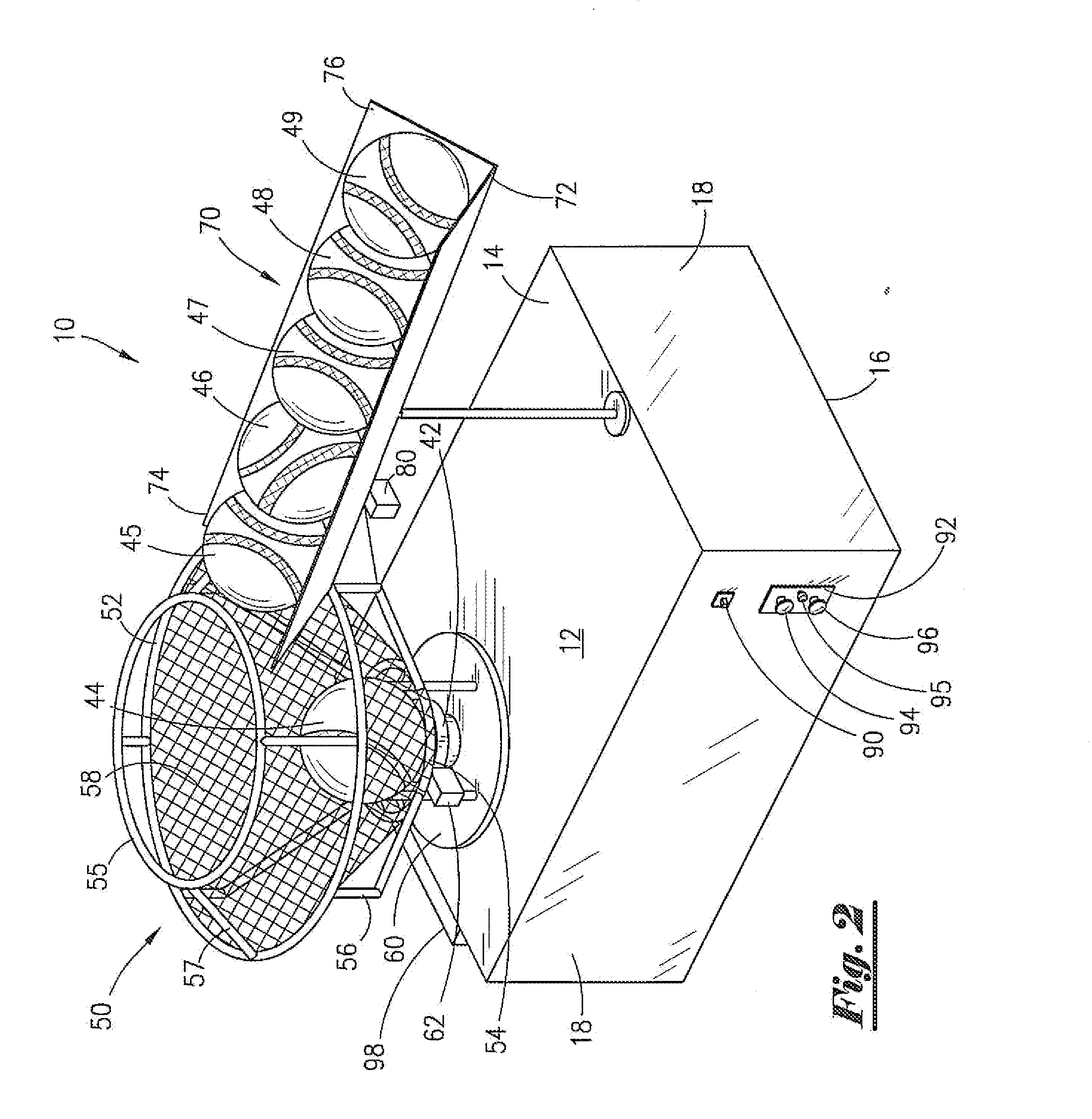

Portable batting device and method

InactiveUS7958880B1Cheap to makeEasy to operateBall sportsCompressed gas gunsFunnel shapeClassical mechanics

A portable batting device that includes a housing, a pneumatically operated ball launching assembly partially disposed within the housing, and a funnel-shaped ball capturing assembly positioned on the top side of the housing. The launching assembly launching a first ball upward into a hitting zone so that a batter may attempt to hit the first ball with a bat. The hitting zone is at a predetermined and adjustable vertical height. The ball capturing assembly receives the first ball should the batter swing the bat and not hit the ball and funnels the first ball into position for a subsequent launch by the launching assembly. The batting device may have a ball feeding assembly operatively associated with the ball capturing assembly.

Owner:BATTERS DREAM

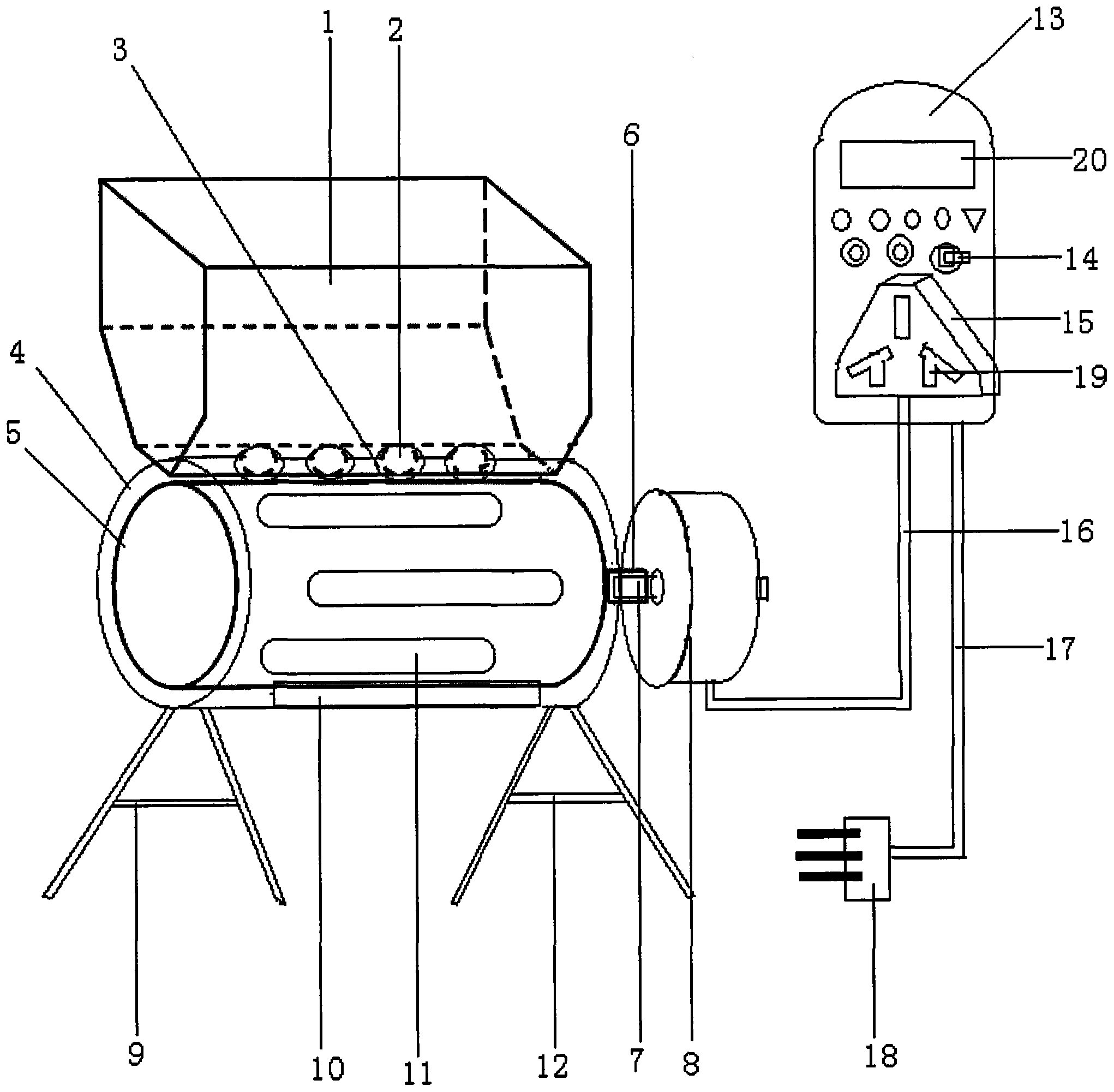

Control method for automatically and accurately feeding pregnant sows

InactiveCN104155920ARich volumeEasy to eatProgramme total factory controlAnimal husbandryProximity sensorEar tag

The invention relates to a control method for automatically and accurately feeding pregnant sows. A combination of a feeding controller, computer client software, a storage hopper, a blanking motor and a trough is included, and electronic ear tags of the sows, an RFID antenna system, a wireless WIFI network, a proximity sensor, entrance and exit doors of a fully-mechanical channel and a linked control mechanism are also included. The control method comprises that 1) only one pregnant sow enters a feeding device at one time, and the ear tag is automatically identified; 2) according to the set feeding amount, the controller interacts with the proximity sensor to control blanking, quantitative ingestion and residual material for at least twice; and 3) a computer client queries the ingestion data of the controller, modifies the control parameters as the total feeding amount and the ending date of feeding. According to the method, individual electronic automatic identification, modularized computer control, sensor control and the feeding controller are combined, so that the sows can be accurately fed to an optimal state according to daily ration required by the physiological and labor nutrient.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI +1

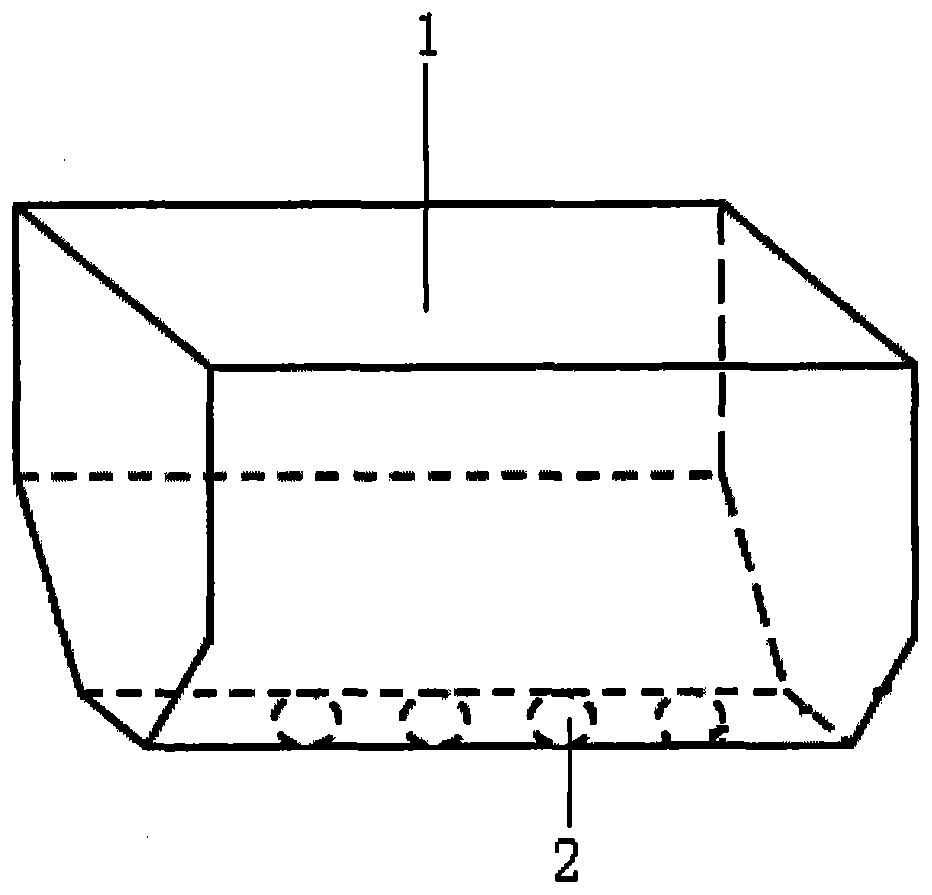

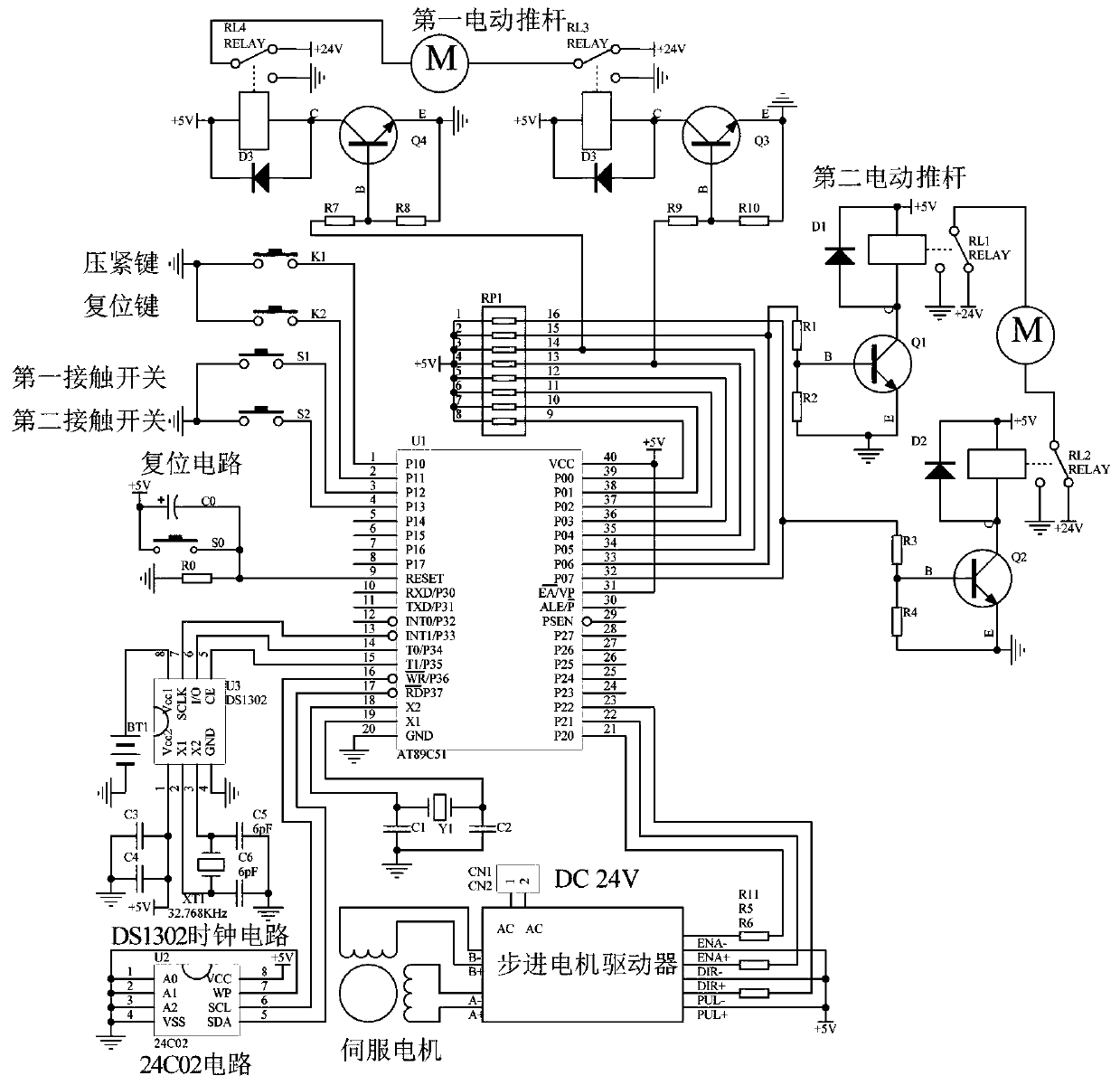

Timed feeding device for fish tank

The invention provides timed feeding device for a fish tank. The timed feeding device comprises a feed bucket; a discharging hole is formed in the bottom part of the feed bucket; the feed bucket is fixed to be above a fixed outer barrel; an outer barrel hole aligning with the discharging hole is formed in the top part of the fixed outer barrel; a left bracket is fixed to the left side of the bottom part of the outer barrel, and while a right bracket is fixed to the right side of the bottom part of the outer barrel; a discharging port is formed in the middle of the bottom part of the outer barrel; a rotating inner barrel is mounted in the outer barrel, and a concave groove is formed in the rotating inner barrel; a slow motor is fixedly connected to the center of the right side of the rotating inner barrel; a motor plug is inserted in a household timer socket. According to the timed feeding device for the fish tank, the motor of the existing household electronic timer rotating front louvers fan is utilized, the feed bucket is manufactured through a small quadrate plastic box, the fixed outer barrel and the rotating inner barrel are manufactured through plastic vials, and thus the economy and practicability are maximized; bait can be automatically, timely and quantitatively fed to aquarium fish within a certain time without people operation. The timed feeding device for the fish tank brings an economic and simple timed automatic fish feeder which is flexible to set the feeding time and control the feeding quantity.

Owner:杨晓彬

Micro-bubble generator, vortex breakdown nozzle for micro-bubble generator, vane swirler for micro-bubble generator, micro-bubble generating method, and micro-bubble applying device

InactiveUS7997563B2Reduce energy lossImprove conversion efficiencyFlow mixersUsing liquid separation agentMicro bubbleWaste management

There is provided a micro-bubble generator including a swirling-flow generating vane nozzle and vortex breakdown nozzle connected coaxially to each other. The swirling flow generating vane nozzle produces a swirling flow of a liquid having a gas introduced to the center thereof from a gas feeding unit. The swirling flow is supplied to a flow constricting section included in the vortex breakdown nozzle to provide micro bubbles from a vortex breakdown section also included in the vortex breakdown nozzle.

Owner:UNIV OF TSUKUBA

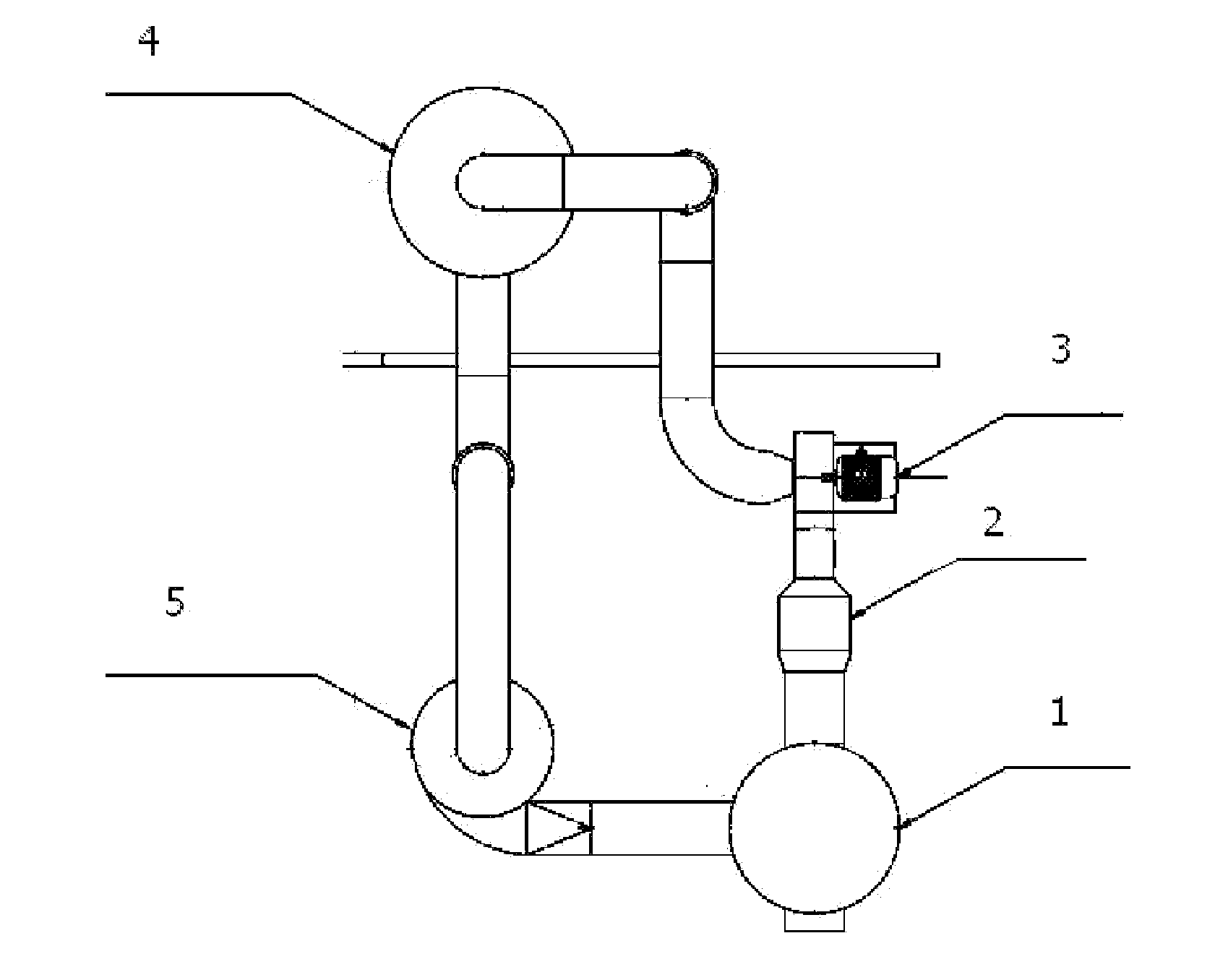

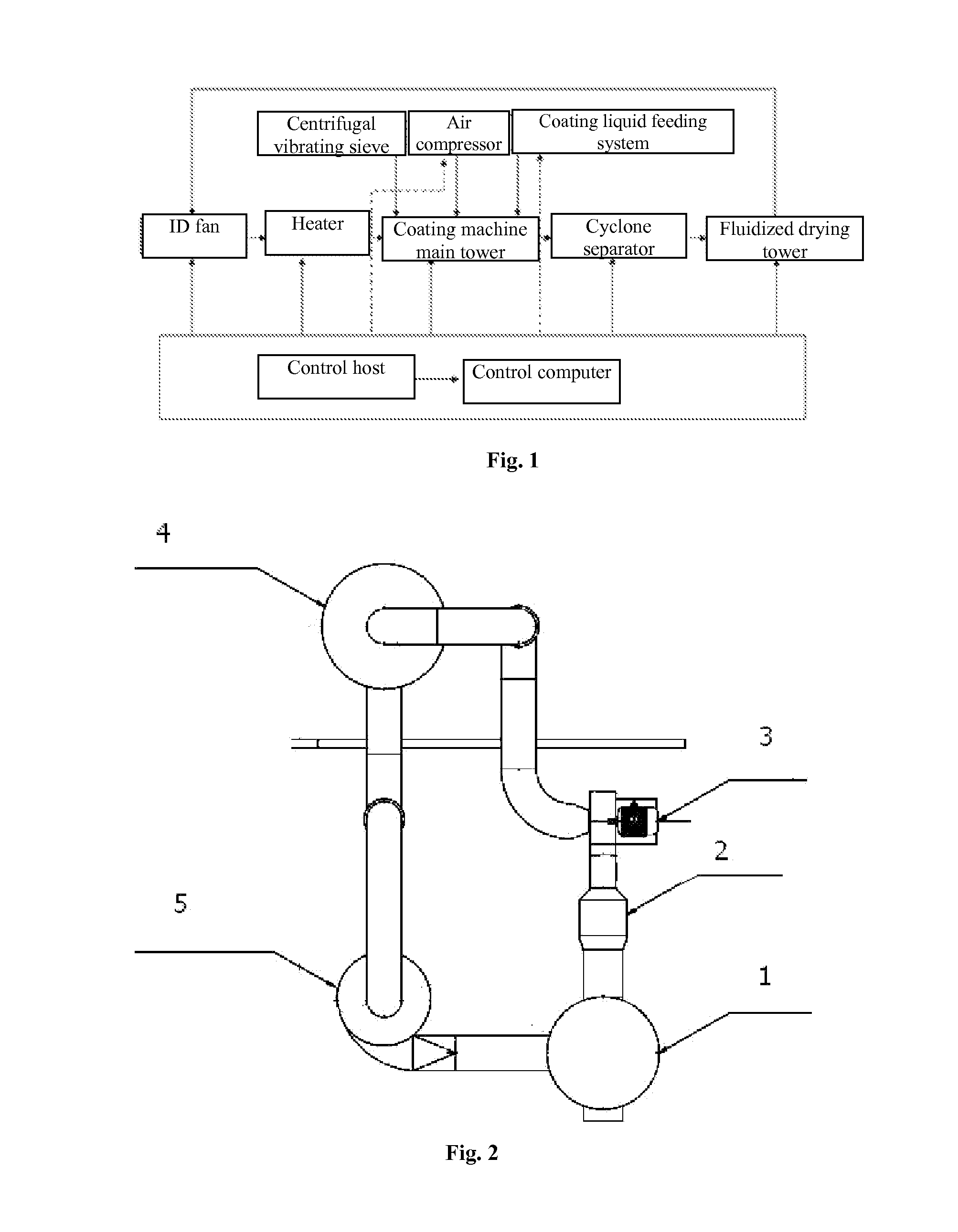

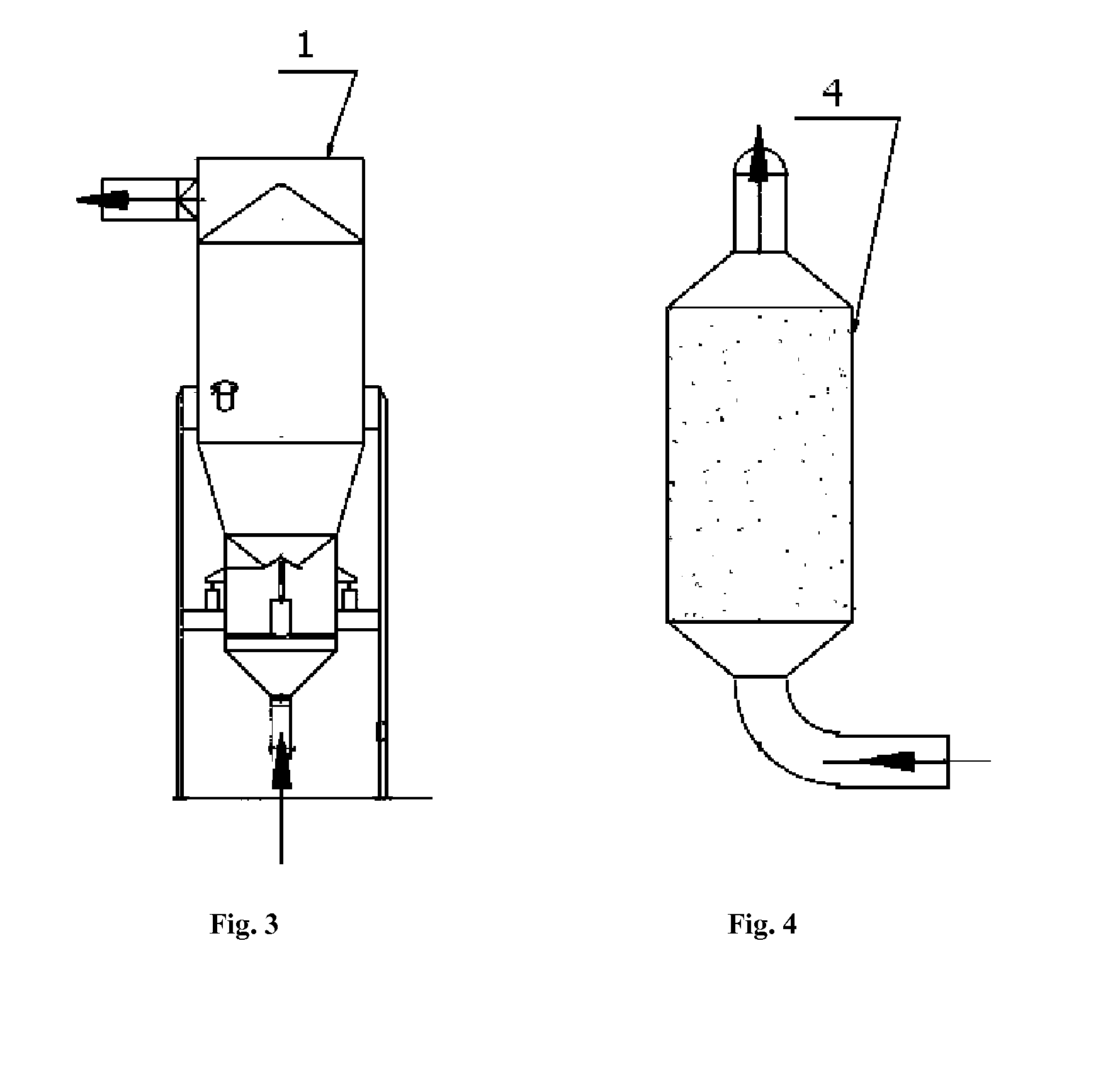

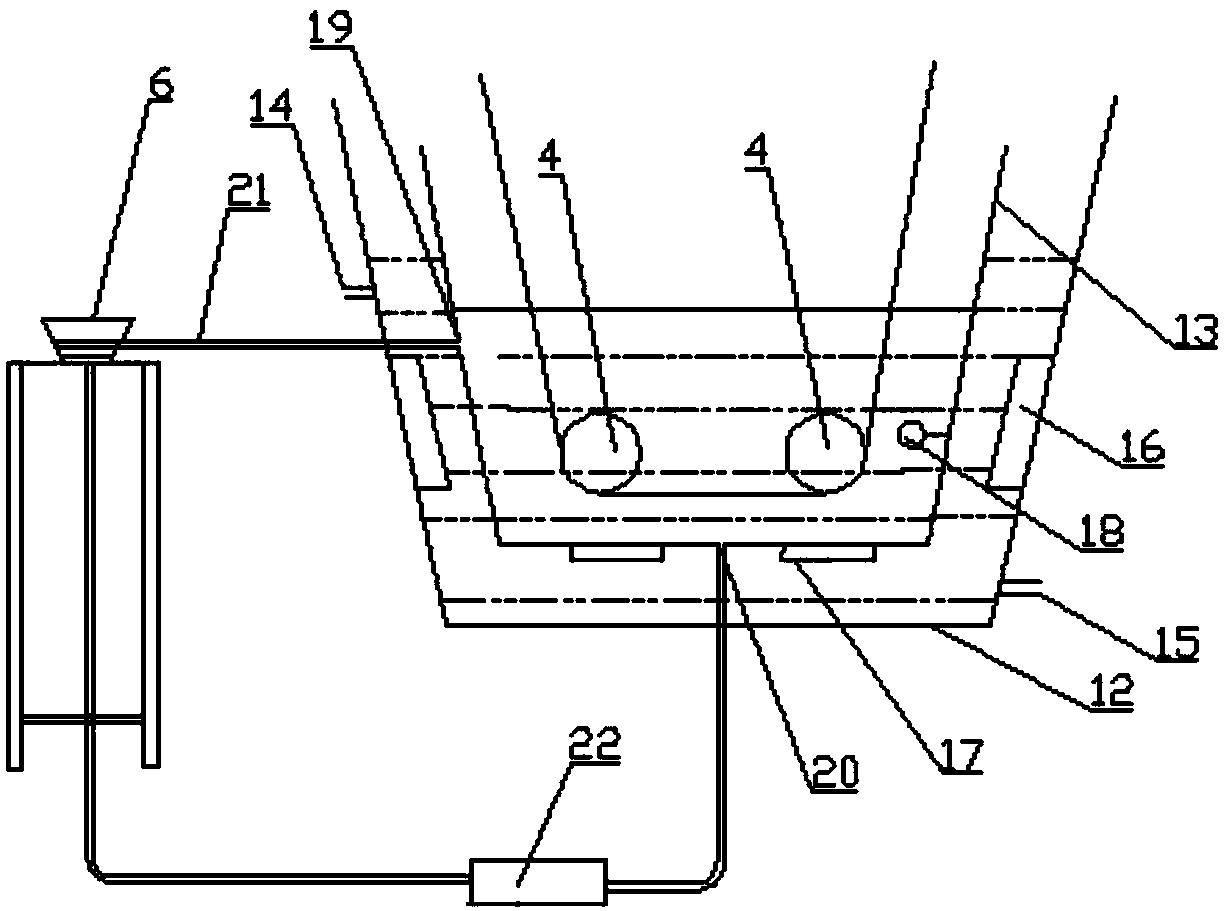

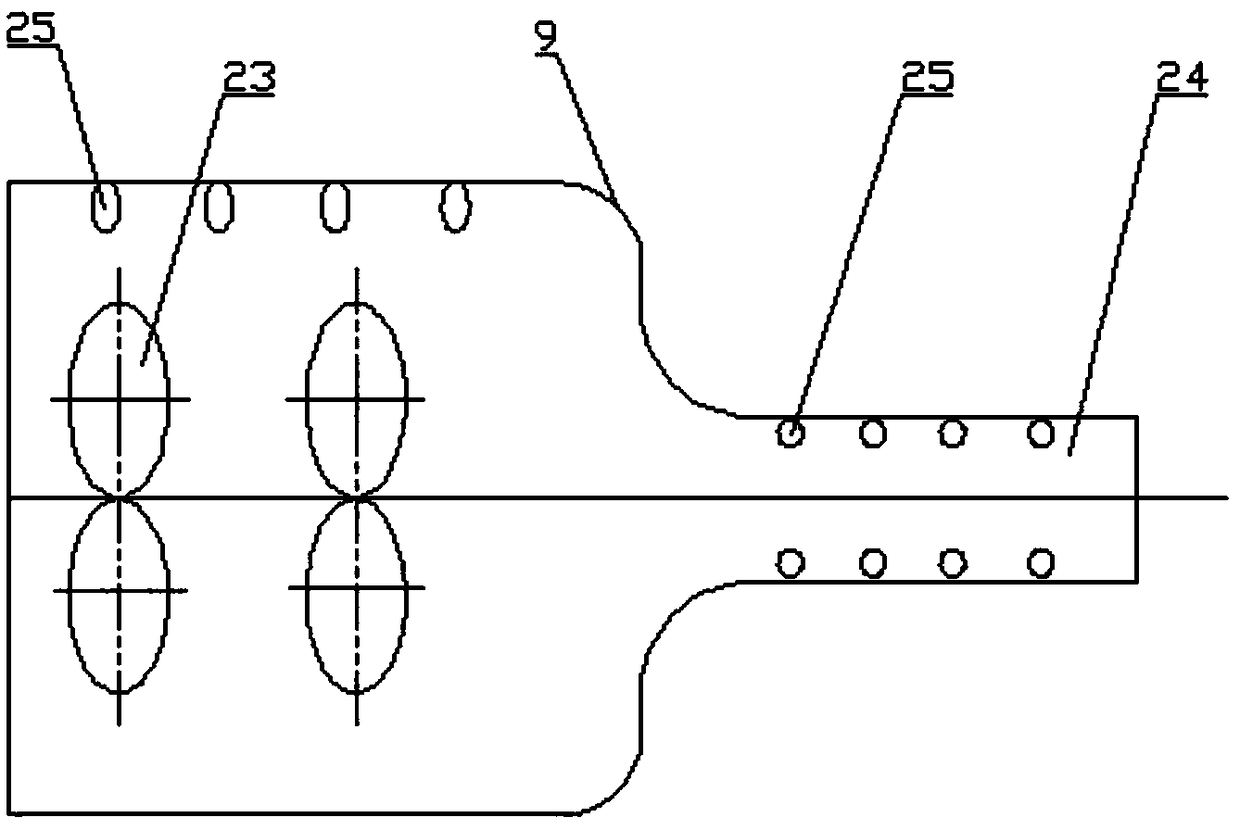

Method for Preparing Controlled Release Fertilizer with Water-Based Coating on the Basis of Closed Circulating Fluidized Bed, and Device therefor

ActiveUS20150210603A1Wasting of large amountReduce energy consumptionLiquid surface applicatorsChemical industryWater basedAir cycle

Disclosed is a method for making a controlled release fertilizer with water-based coating using a closed large numerically controlled fluidized bed and a device therefor: collecting a granular fertilizer with a suitable granule size into a barrel; sucking the same into a coating cavity by negative pressure and making the same fluid; directing a water-based coating liquid into a spray gun, then spraying the liquid onto the surface of the fertilizer granules after nebulization; collecting the impurities in the air discharged from the coating cavity by means of a cyclone separator; dehumidifying the air discharged from the cyclone separator by means of a fluidized drying tower; and then the coating is completed. The closed large numerically controlled fluidized bed coating machine has a fluidized bed coating machine main tower, a cyclone separator, a fluidized drying tower, a blower, a heater, an air compressor, a coating liquid inlet system and a control system, and is characterized in that it has a closed air circulation system, and is provided with a dehumidifying mechanism and a water condensing mechanism for the fluidized drying tower. The present invention can reduce energy consumption, increase heating efficiency and has moisture-absorbing function; it can prevent the spray gun from blocking; it has the function of automatic feeding, which improves the efficiency of coating; therefore it is important for the achievement of a water-based coating process.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Self-help stomach tube food injector with controllable speed and temperature

InactiveCN106619137AReduce labor intensityAutomatic feedingFeeding-tubesAutomatic controlMicro motor

The invention discloses a self-help stomach tube food injector with controllable speed and temperature, which comprises a fixed shell, an injector, a driving device, a controller, a stomach tube and a temperature controller, wherein the fixed shell is provided with an injector fixing groove; the injector is placed in the injector fixing groove and comprises a sleeve and a push rod, the sleeve is detachably fixed in the injector fixing groove, an injection head at the front end of the sleeve is stretched out of the fixed shell, and the push rod is sheathed in the sleeve in a horizontally moving manner; the driving device is fixed at the tail of the fixed shell and comprises a micro motor, a shaft sleeve, a screw and a screw sleeve, the output shaft of the micro motor is connected with the tail of the screw through the shaft sleeve, and the screw sleeve is sheathed at the front end of the screw and is in contact with the push rod in the injector; the controller is installed on the driving device; and the stomach tube and the temperature controller are sheathed in the front end of the sleeve. The self-help stomach tube food injector with controllable speed and temperature can realize automatic and uniform feeding and automatic control over feeding time through the controller, and does not need manual operation in the whole course, thus alleviating the feeding labor intensity for a nurse or a family member of a patient.

Owner:邓红玉

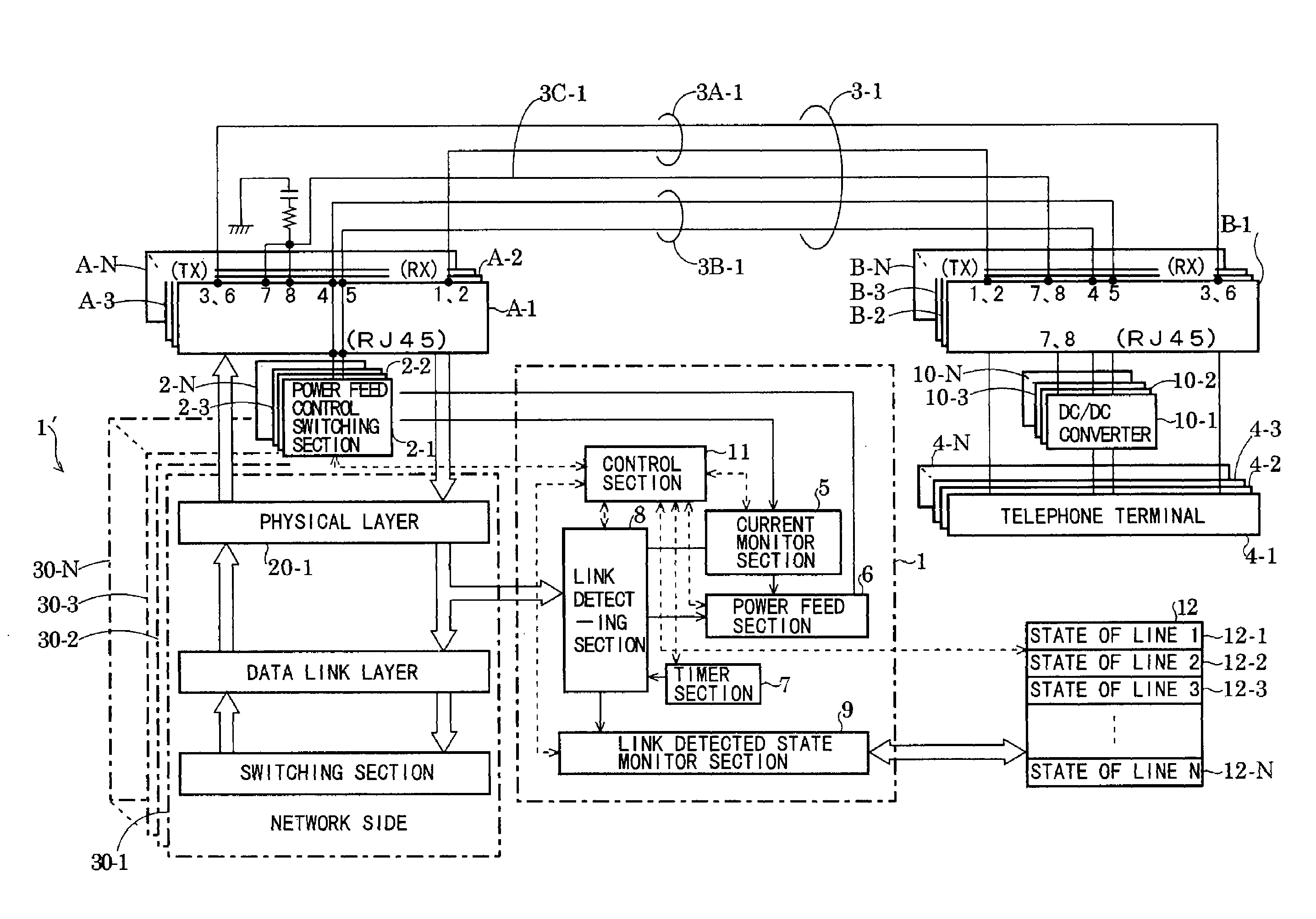

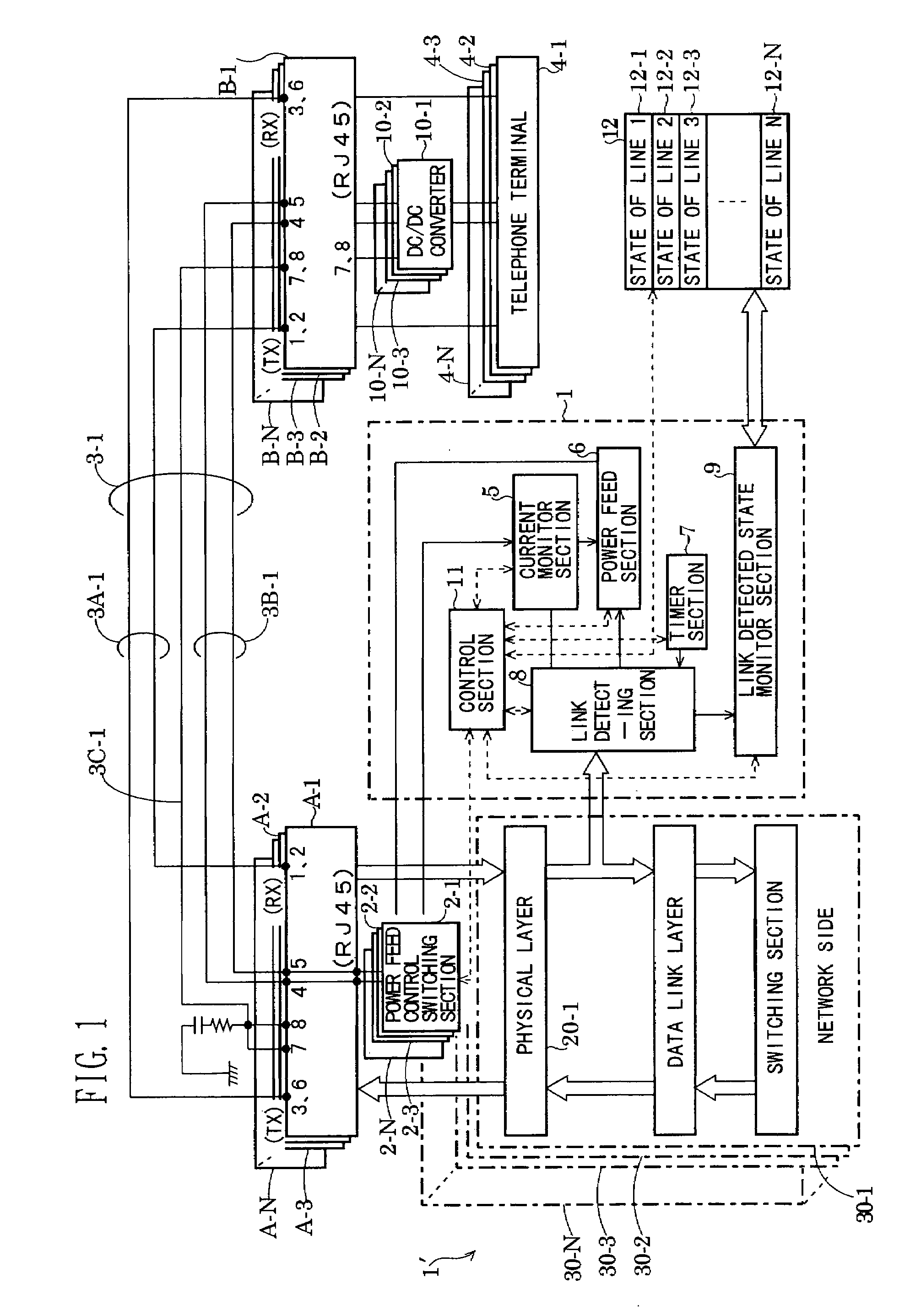

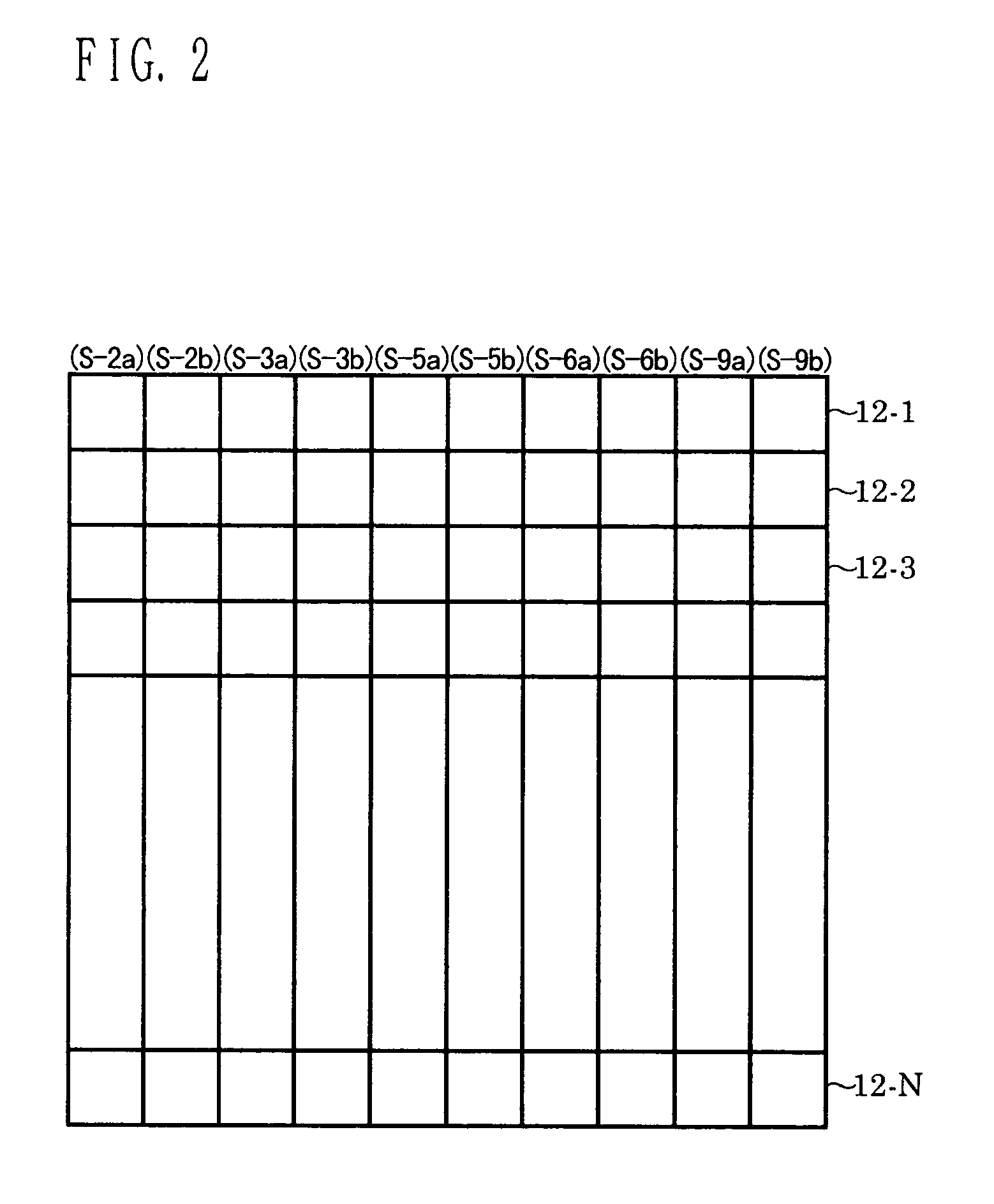

Power feeding system for telephone terminal in LAN

InactiveUS7242764B2Simple structureAutomatic feedingInterconnection arrangementsError preventionTelephone terminalEngineering

Terminals are connected via cables in a star-shaped fashion with respect to a HUB in a LAN. Each of the cables includes therein signal lines and power feed lines. The HUB includes therein a power feed section. The power feed section and the power feed lines of each cable are connected to measure a value of current which flows in the power feed lines. If it is judged based on the measured current value that the terminal connected to the corresponding cable is a telephone terminal, the power feeding to the corresponding power feed lines is continued. On the other hand, if the terminal is judged to be a terminal other than the telephone terminal, the power feeding is stopped.

Owner:OKI ELECTRIC IND CO LTD

Portable Batting Device and Method

InactiveUS20110203562A1Cheap to makeEasy to operateBall sportsCompressed gas gunsEngineeringFunnel shape

A portable batting device that includes a housing, a pneumatically operated ball launching assembly partially disposed within the housing, and a funnel-shaped ball capturing assembly positioned on the top side of the housing. The launching assembly launching a first ball upward into a hitting zone so that a batter may attempt to hit the first ball with a bat. The hitting zone is at a predetermined and adjustable vertical height. The ball capturing assembly receives the first ball should the batter swing the bat and not hit the ball and funnels the first ball into position for a subsequent launch by the launching assembly. The batting device may have a ball feeding assembly operatively associated with the ball capturing assembly.

Owner:BATTERS DREAM

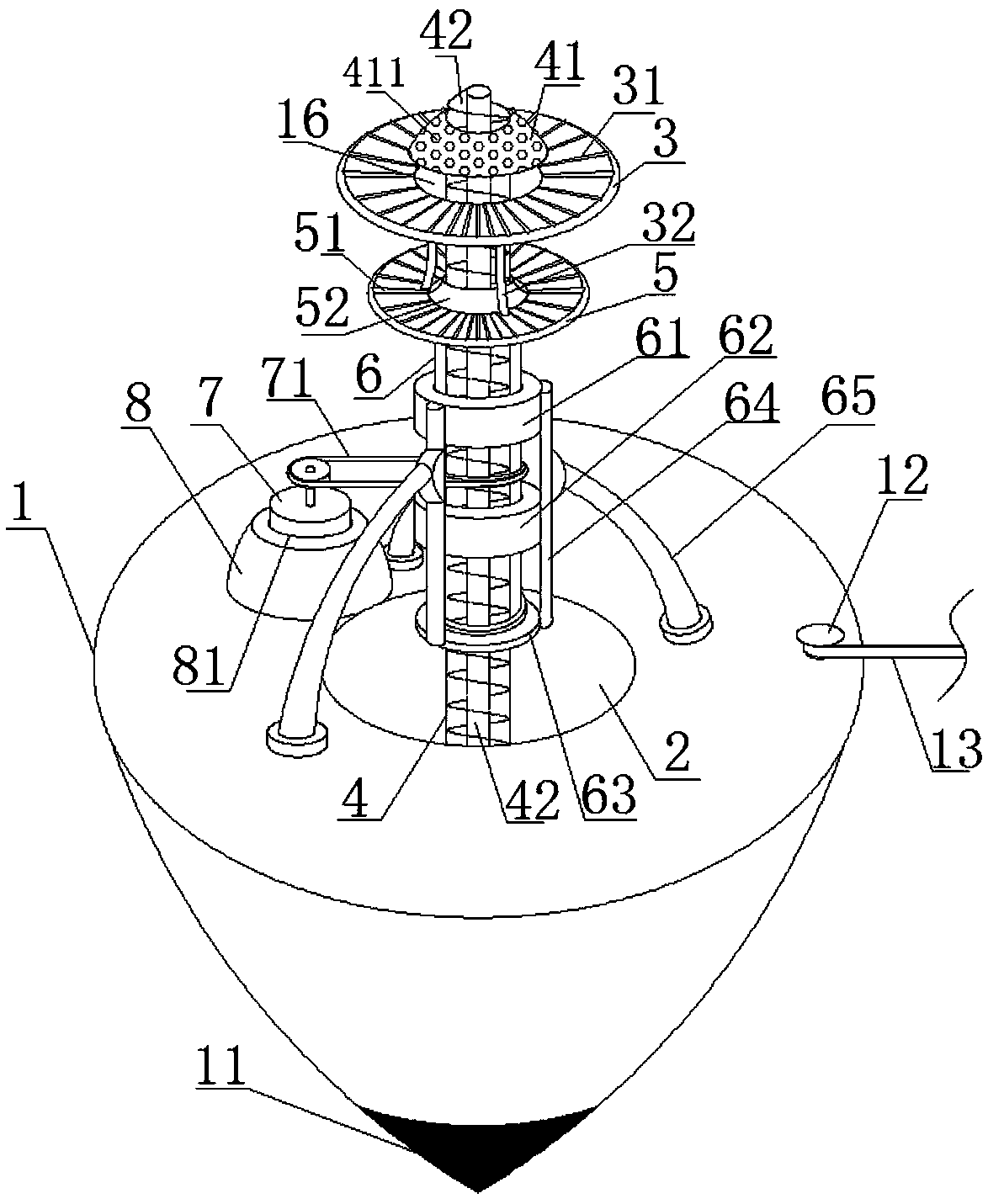

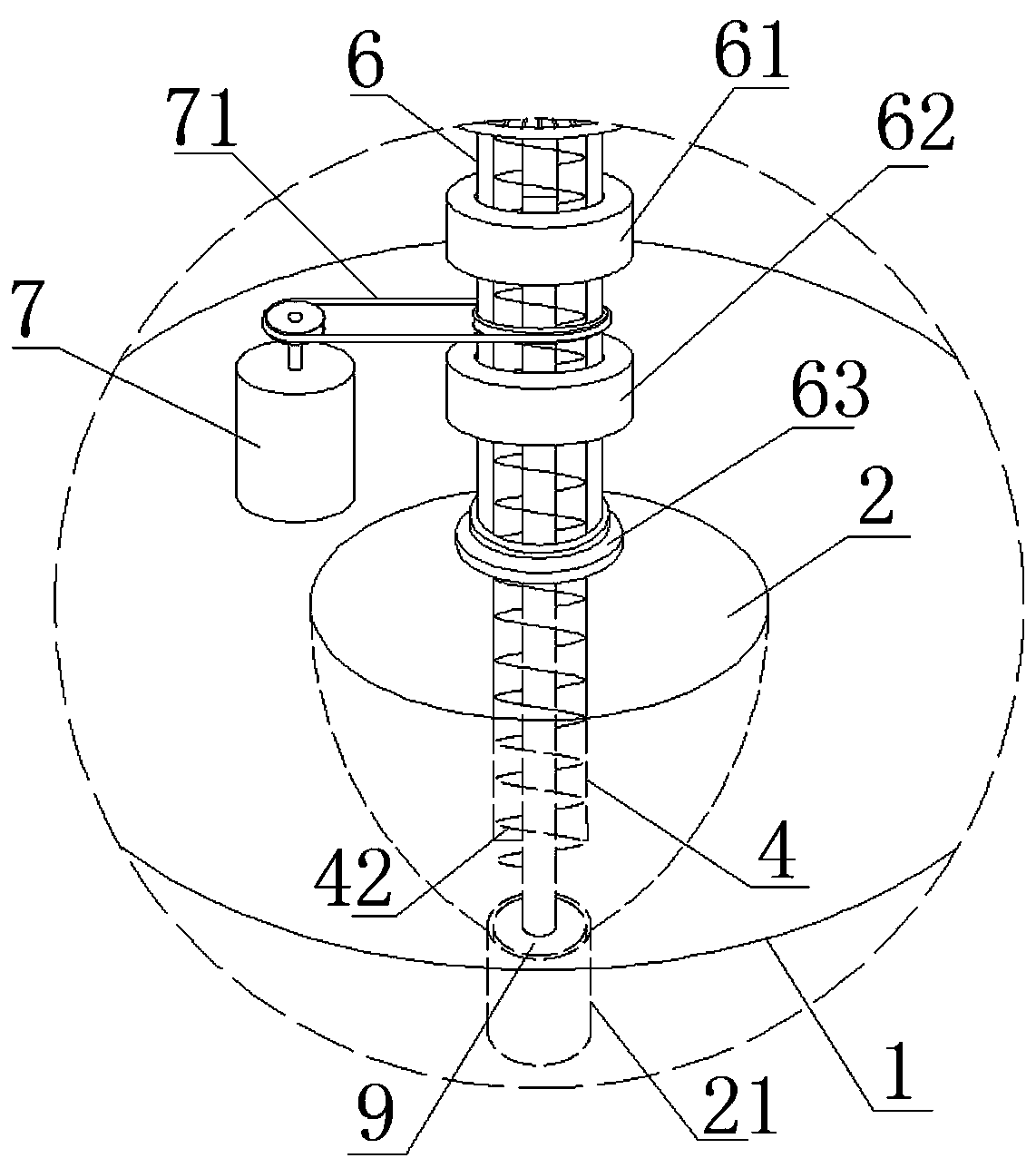

Device for throwing fish food on water surface

PendingCN109430139AThrow evenlyAutomatic feedingClimate change adaptationPisciculture and aquariaEngineeringFood storage

The invention relates to a device for throwing fish food on the water surface. The device includes a floating platform, a food storage groove formed in the middle of the upper end face of the floatingplatform, an upper annular discharging turntable arranged on the upper portion of the food storage groove and a vertically fixed material conveying pipe. The lower end of the material conveying pipeis inserted into the food storage groove, and the upper end of the material conveying pipe passes through an inner ring of the upper annular discharging turntable to the upper portion of the upper annular discharging turntable; the circumferential surface of the upper portion of the material conveying pipe is sleeved with an umbrella-shaped upper guide cove; the inside of the material conveying pipe is sleeved with a spiral shaft, the upper end of the spiral shaft is slightly higher than the upper end face of the material conveying pipe, and fish food in the food storage groove is conveyed tothe upper end of the material conveying pipe, falls down, and then guided by the upper guide cover to the upper annular discharging turntable. The upper surface of the upper annular discharging turntable is uniformly provided with several convex first separation strips. The device can achieve automatic feeding and uniformly throw the fish food around.

Owner:辛幼霞

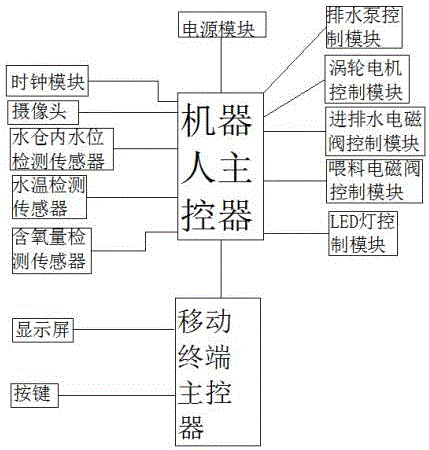

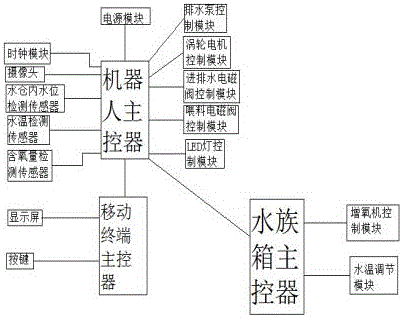

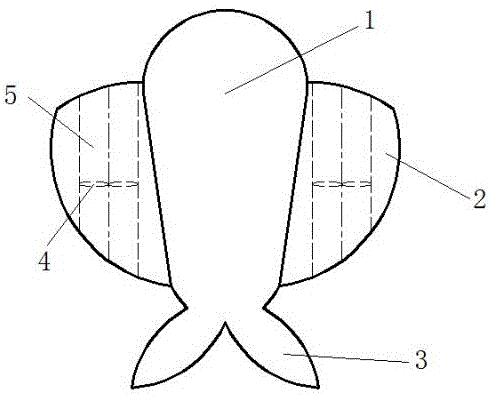

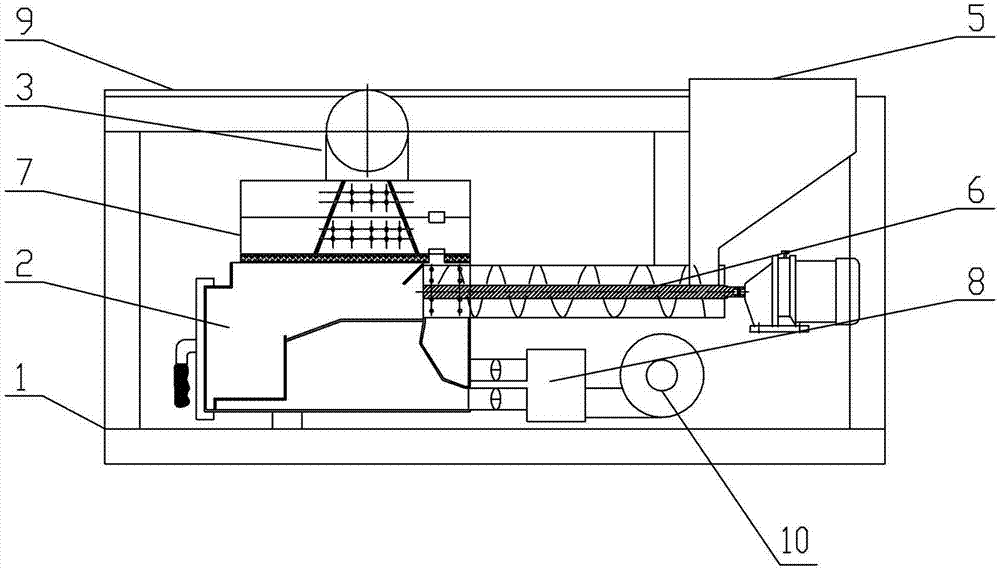

Aquarium robot control system, aquarium system and aquarium system control method

InactiveCN106386635AControlled feedingAutomatic feedingPisciculture and aquariaProgramme control in sequence/logic controllersAutomatic controlSolenoid valve

The invention discloses an aquarium robot control system, an aquarium system and an aquarium system control method. The aquarium robot control system includes a robot master controller; and the robot master controller is connected to a power supply module, a turbine motor control module, a water feeding and draining solenoid valve control module, a water drainage pump control module, a feeding solenoid valve control module, and LED lamp control module, a clock module, a camera and a water cabin water level detection sensor. The aquarium system includes the aquarium robot control system. A master controller of the aquarium system is connected to an automatic aerator control module and a water temperature adjustment module. The aquarium robot control system can automatically control a aquarium robot to feed fishes and can clean water. The aquarium system can adjust the temperature of water and the oxygen content of the water, thereby facilitating growth of the fishes.

Owner:成都创慧科达科技有限公司

Ornamental fish jar control system

InactiveCN106054724AGood effectAutomatic feedingProgramme controlComputer controlTemperature controlOxygen monitoring

The invention relates to an ornamental fish jar control system including a CPU module terminal, a user's mobile phone APP terminal or control panel is connected to a network WIFI module through a P2P network mode, the WIFI module sends the mobile phone APP terminal data to the CPU module terminal in a serial transmission manner, and the CPU module terminal controls the ornamental fish jar according to the time set by the APP terminal or the control panel. An automatic feeder, an oxygen monitoring processing subsystem, a sterilization module, a PH value detection processing subsystem, a water hardness monitoring processing subsystem, a constant temperature heating system, a leakage protection system, an intelligent fish library, a light sensing subsystem, a temperature control subsystem and a water level sensing subsystem of the control system are connected with the CPU module terminal. The intelligent control system can solve the problems that an ornamental fish jar is incapable of automatic feeding, temperature control, and water level control.

Owner:沈立峰

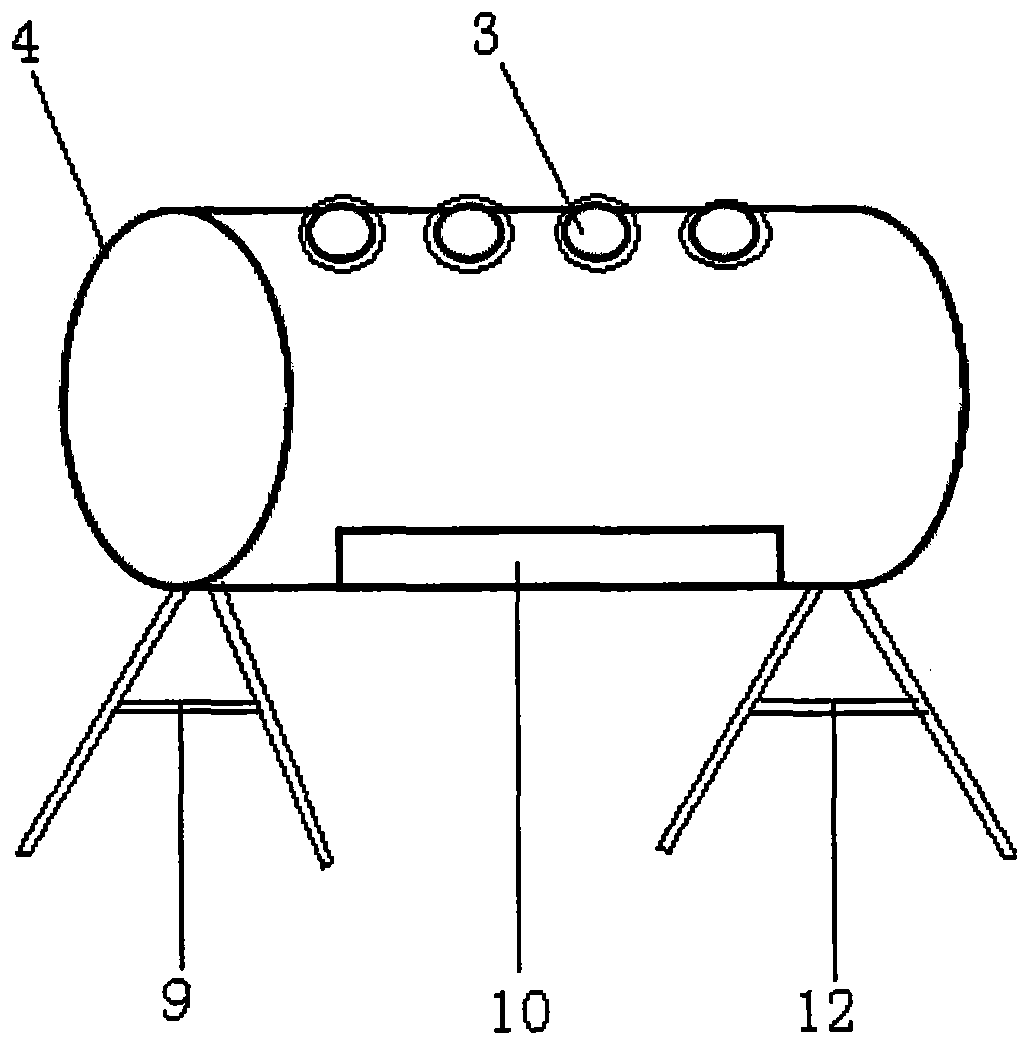

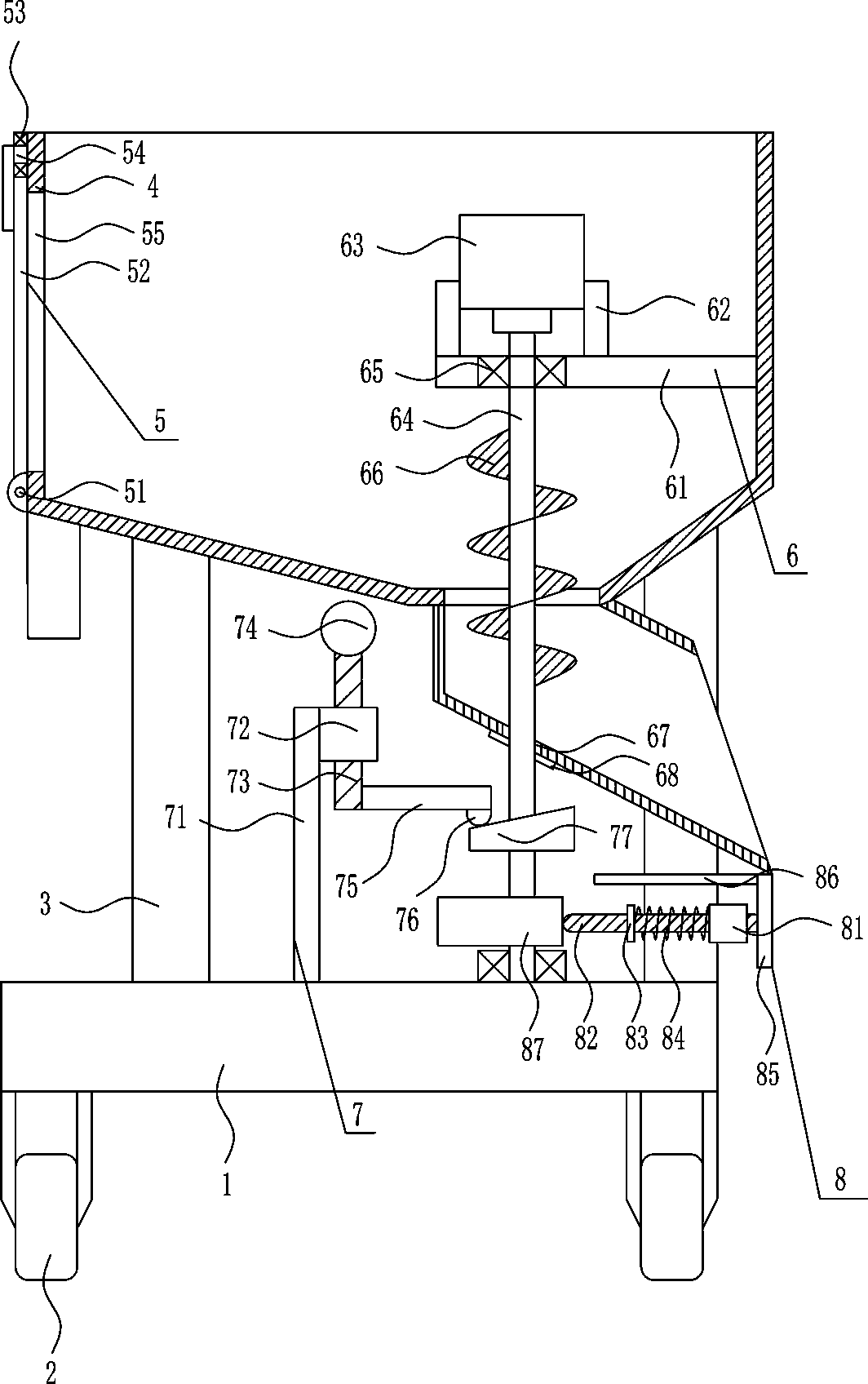

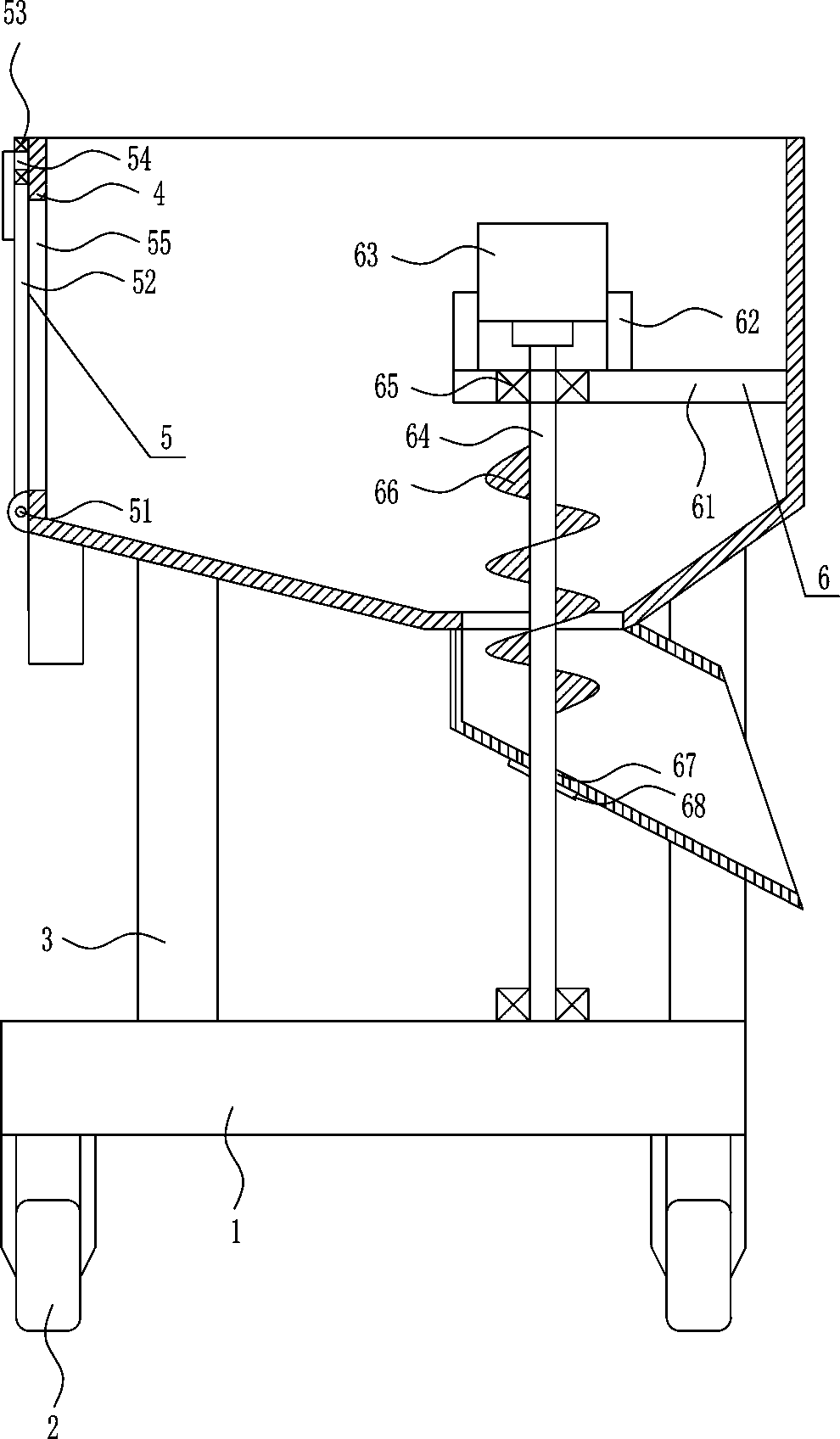

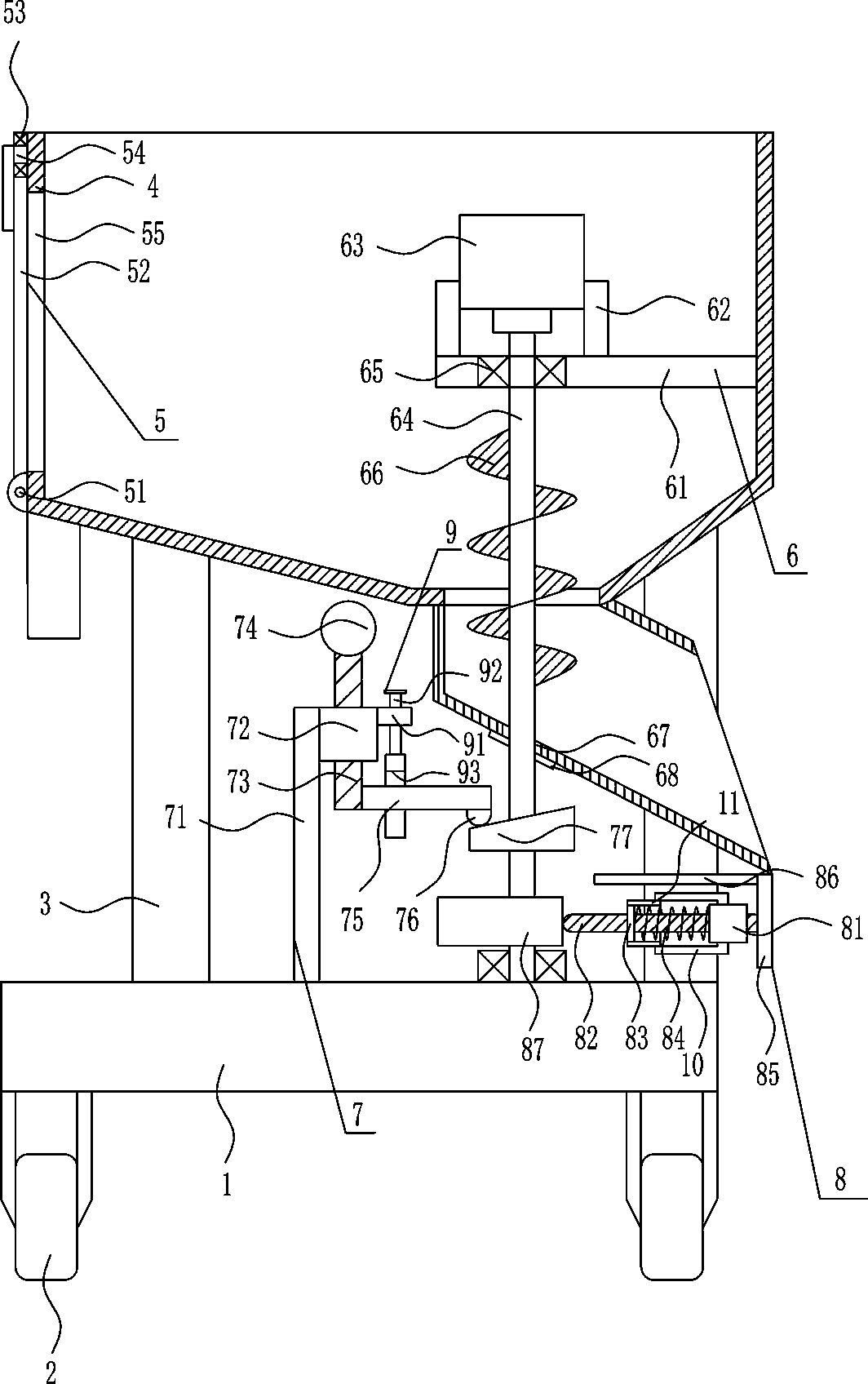

Biomass particle burner

InactiveCN103542404AReduce labor intensitySimple structureLump/pulverulent fuel feeder/distributionThermodynamicsProcess engineering

The invention relates to a burner, and especially relates to a biomass particle burner. The biomass particle burner comprises an outer frame; the lower inner part of the outer frame is provided with a combustion apparatus; a hearth is arranged at the upper inner part of the outer frame, above the combustion apparatus; a flame outlet pipe is transversely arranged on the outer surface of the hearth, and the flame outlet pipe and the hearth are communicated; one side of the outer frame is provided with a feed box; an feed outlet of the feed box is provided with a spiral automatic feeder unit; a feed outlet of the spiral automatic feeder unit is communicated with the combustion apparatus; a secondary air inlet device and a third air inlet device are arranged between the combustion apparatus and the hearth; and an oxygen supply regulation apparatus is arranged on one side of the bottom of the combustion apparatus, and the oxygen supply regulation apparatus and the combustion apparatus are communicated. The biomass particle burner is simple in structure; design is reasonable; automatic feeding and automatic deslagging can be realized; slag bonding caused by fuel after combustion is avoided; air distribution is reasonable; complete combustion of fuel is realized, so that it is benefit for environment protection; operation and utilization are convenient; labour intensity of workers is reduced; and the biomass particle burner is suitable for popularization and application.

Owner:高海华

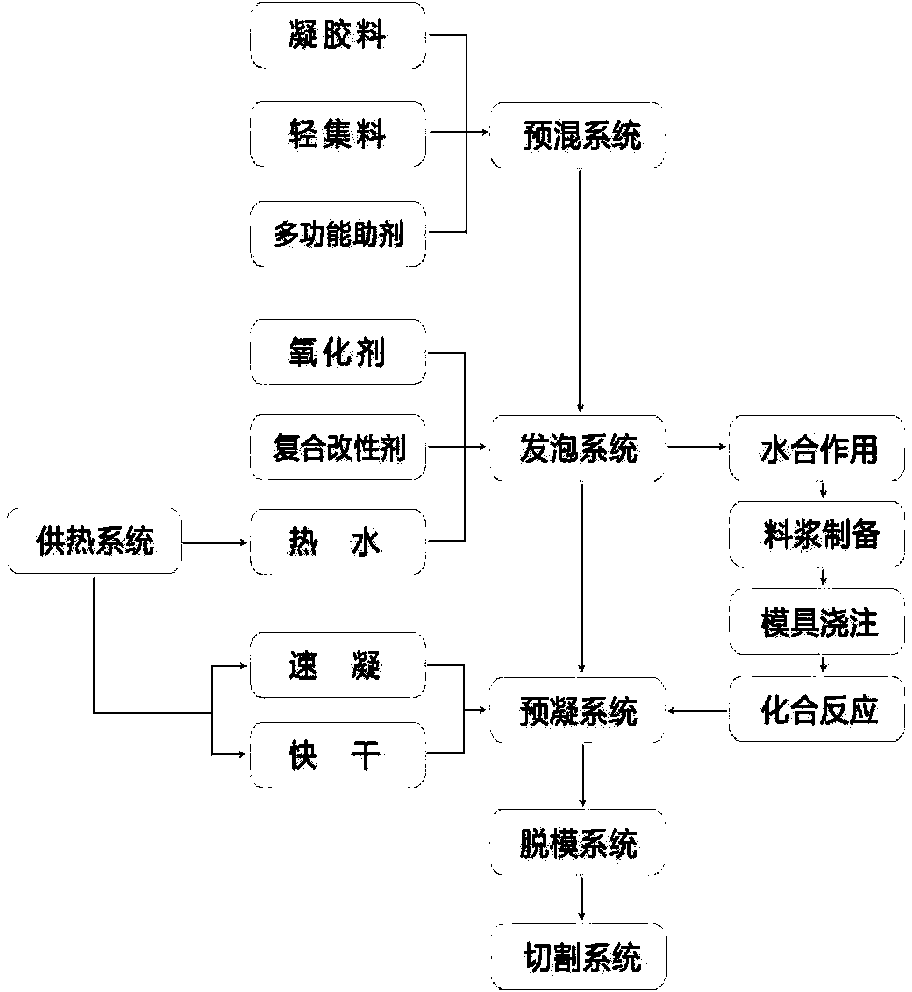

Process for preparing composite foamed cement

ActiveCN104193385AHigh degree of automationStrong capacityCeramicwareProcess engineeringManufacturing engineering

The invention discloses a process for preparing composite foamed cement. The process comprises the following steps: premixing, namely, uniformly mixing a gel material, lightweight aggregate and a multifunctional additive, subsequently preparing the above components into premix, and storing the premix in a storage tank for later use; foaming, namely, feeding the premixed premix and hot water into a stirring tank, stirring for 5 minutes, sequentially adding a composite modifier and an oxidant into the stirring tank, and continuously stirring for 5 minutes, thereby obtaining slurry; pre-coagulating, namely, filling the foamed slurry into a mold box of a pre-coagulating kiln, simultaneously supplying hot water into the pre-coagulating kiln continuously so as to foam and expand the slurry inside the mold box, thereby preparing the composite foamed cement, and standing the composite foamed cement in the mold box for 6-8 minutes, thereby forming a composite foamed cement initial set object; and demolding and cutting, namely, demolding and cutting the pre-coagulated composite foamed cement initial set object into a plate material, thereby preparing the formed composite foamed cement. The composite foamed cement prepared by using the process is high in mechanical strength, free of foaming, high in foaming strength, rapid to coagulate and dry, short in demolding time and free of maintenance period, can save the space, the energy, the labor and the time, and can be cut in a wet manner.

Owner:HUBEI KAILIFENG GREEN BUILDING MATERIALS DEV CO LTD

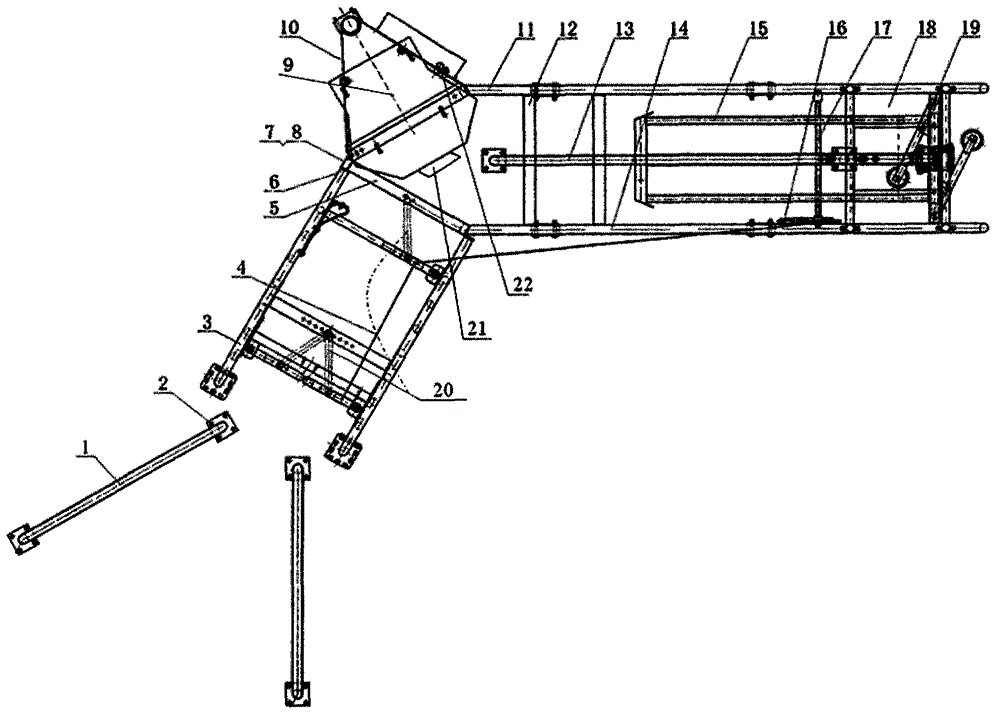

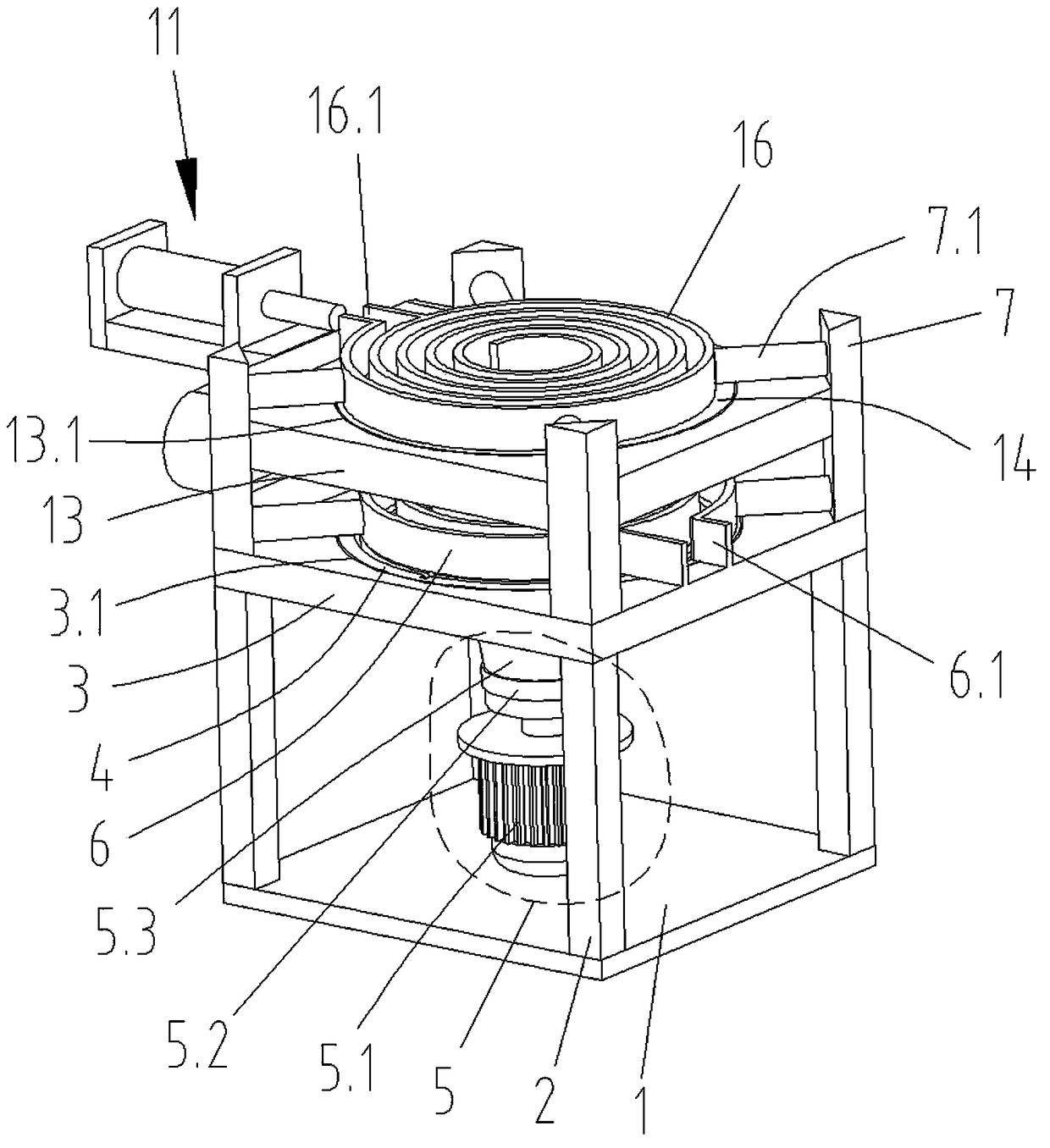

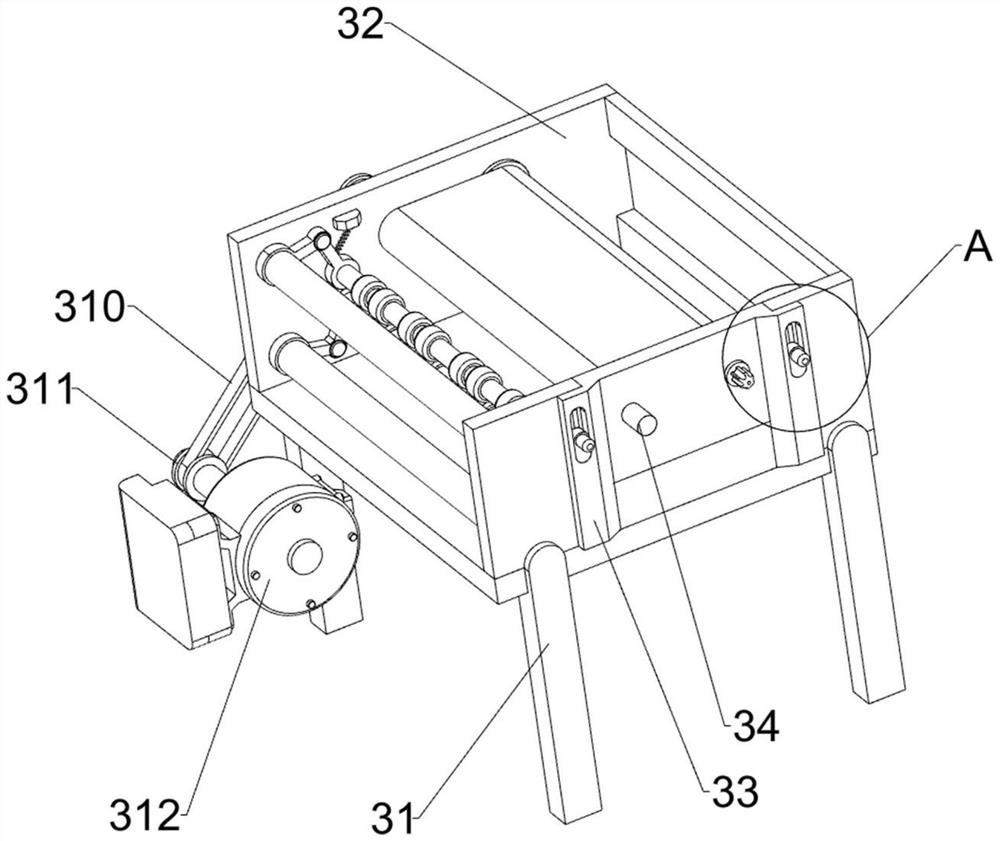

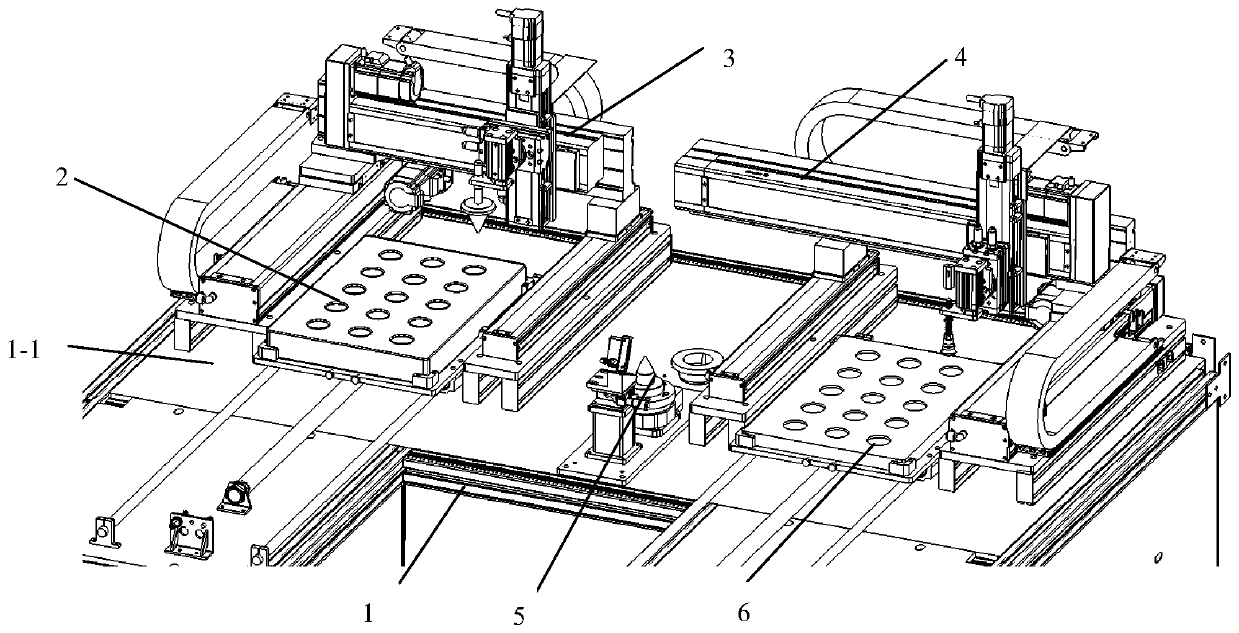

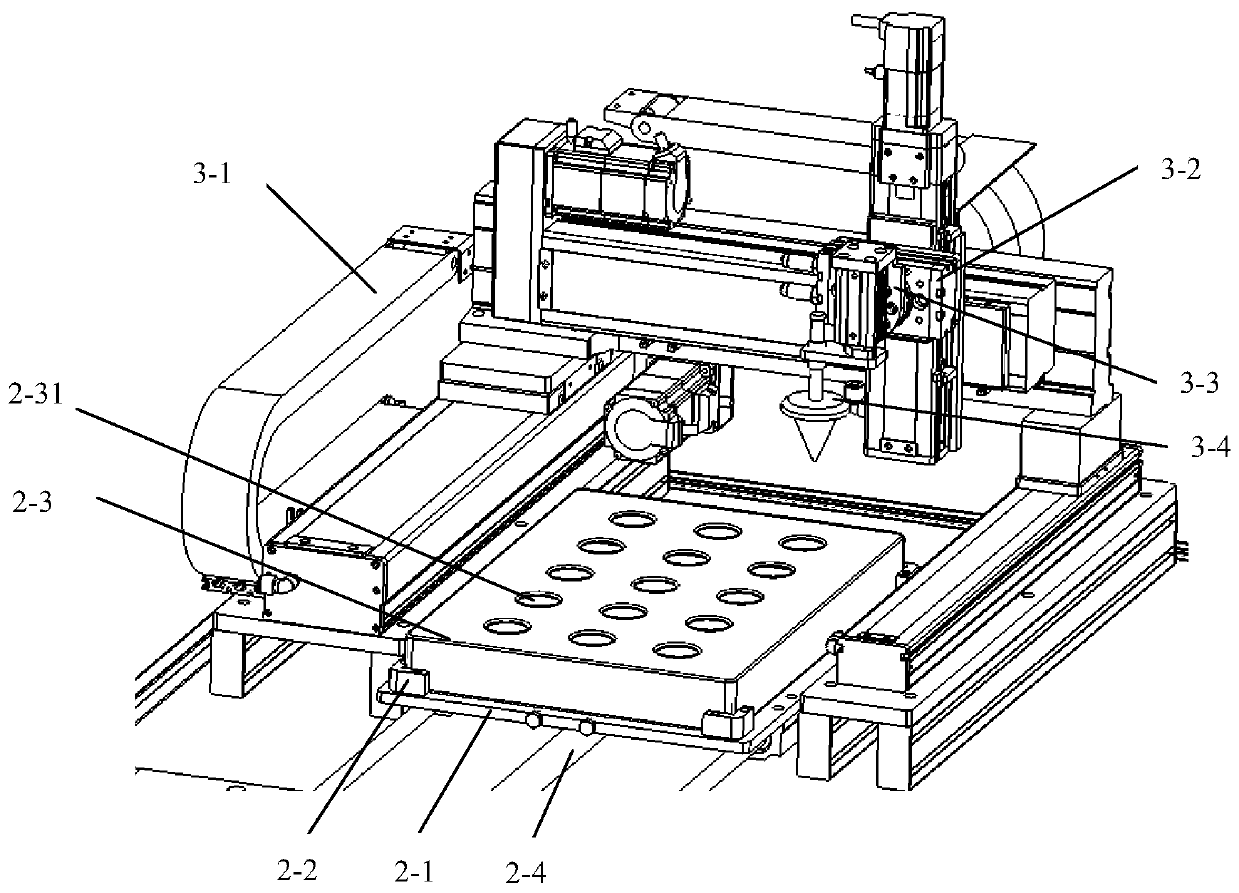

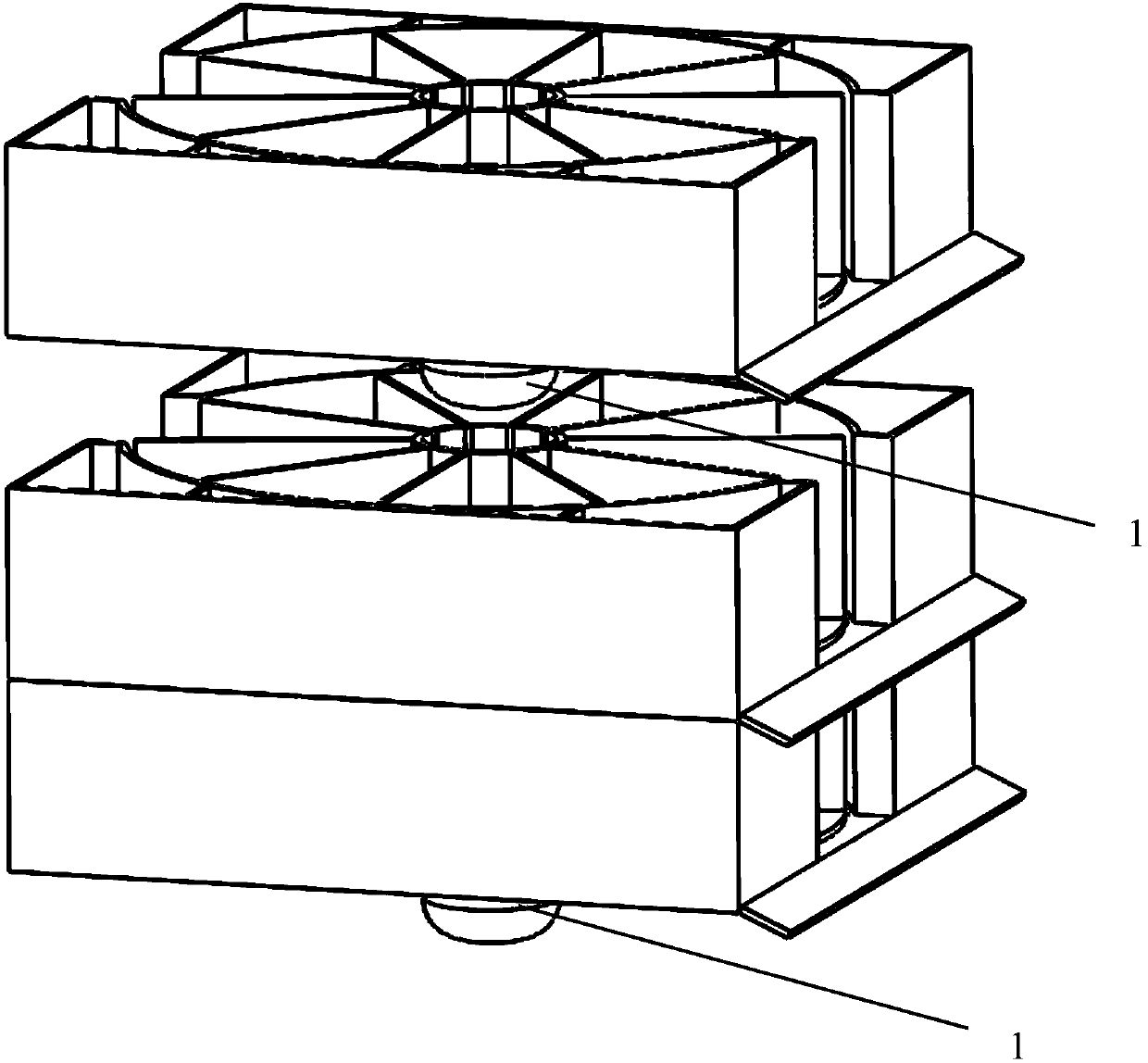

Double-layer grinding machine capable of achieving automatic feeding

ActiveCN108274386AIncrease productivityEasy to operateGrinding drivesLapping machinesBatch productionEngineering

The invention discloses a double-layer grinding machine capable of achieving automatic feeding. The double-layer grinding machine comprises a first base plate and a second base plate. A first throughhole is formed in the center of the first base plate, and a first grinding disk is connected into the first through hole in a rotating fit mode. A second through hole is formed in the center of the second base plate, and a second grinding disk is connected into the second through hole in a rotating fit mode. A power device is further arranged below the first grinding disk. A first material guide disk is arranged above the first base plate, and a second material guide disk is arranged above the second base plate. A material guide hole is formed in the center position of the second material guide disk, and a material guide pipe is connected into the material guide hole in a matched mode. A feeding channel is further formed in the upper edge of the second base plate. A feeding device is further arranged on the feeding channel. The double-layer grinding machine capable of achieving automatic feeding has the advantages that the double-layer grinding machine capable of achieving automatic feeding is suitable for grinding small-diameter round workpieces, and rough grinding and fine grinding can be conducted at the same time; and moreover, automatic feeding can be achieved and the grindingmachine is suitable for batched production operations.

Owner:阜阳市战千里知识产权运营有限公司

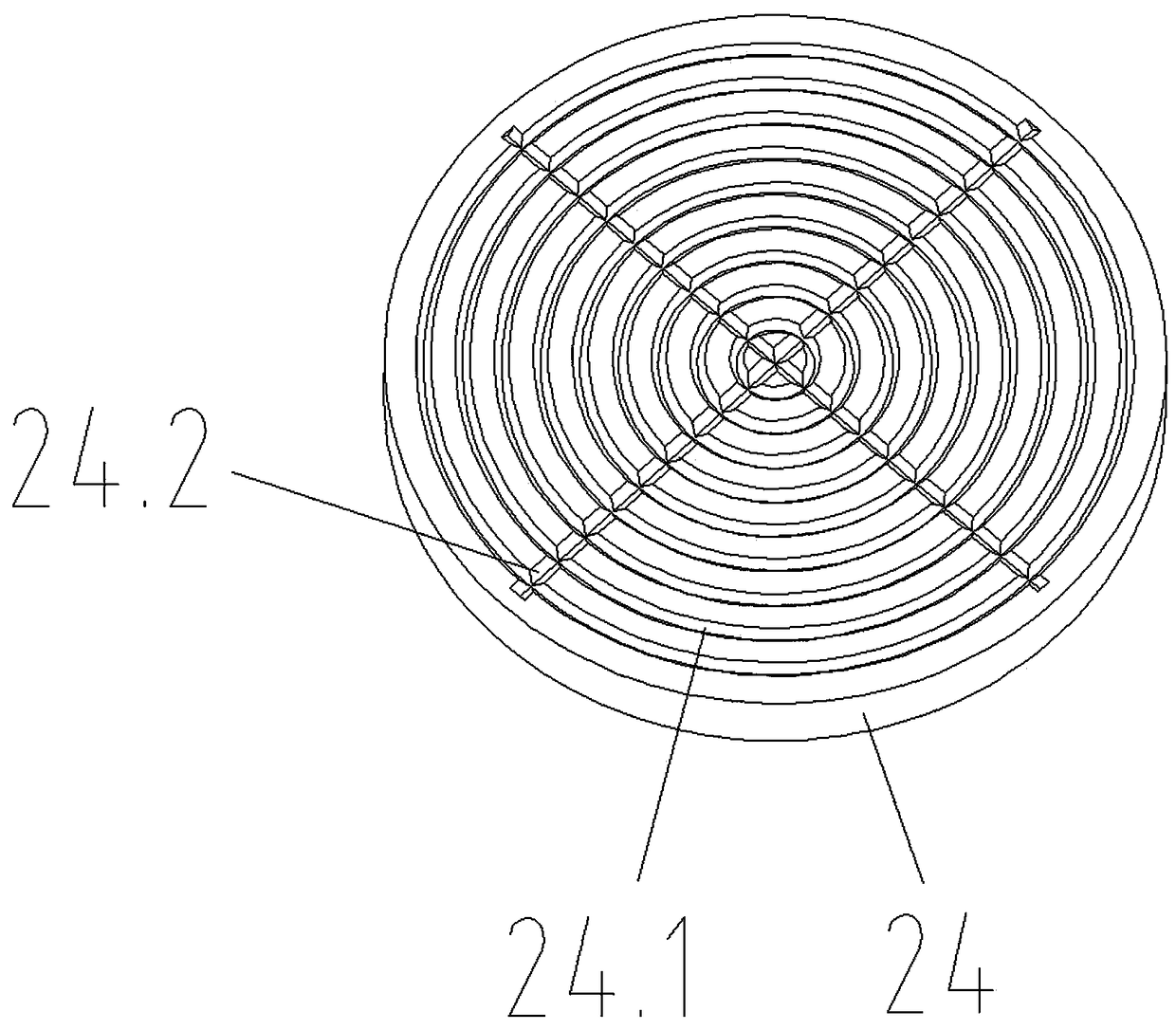

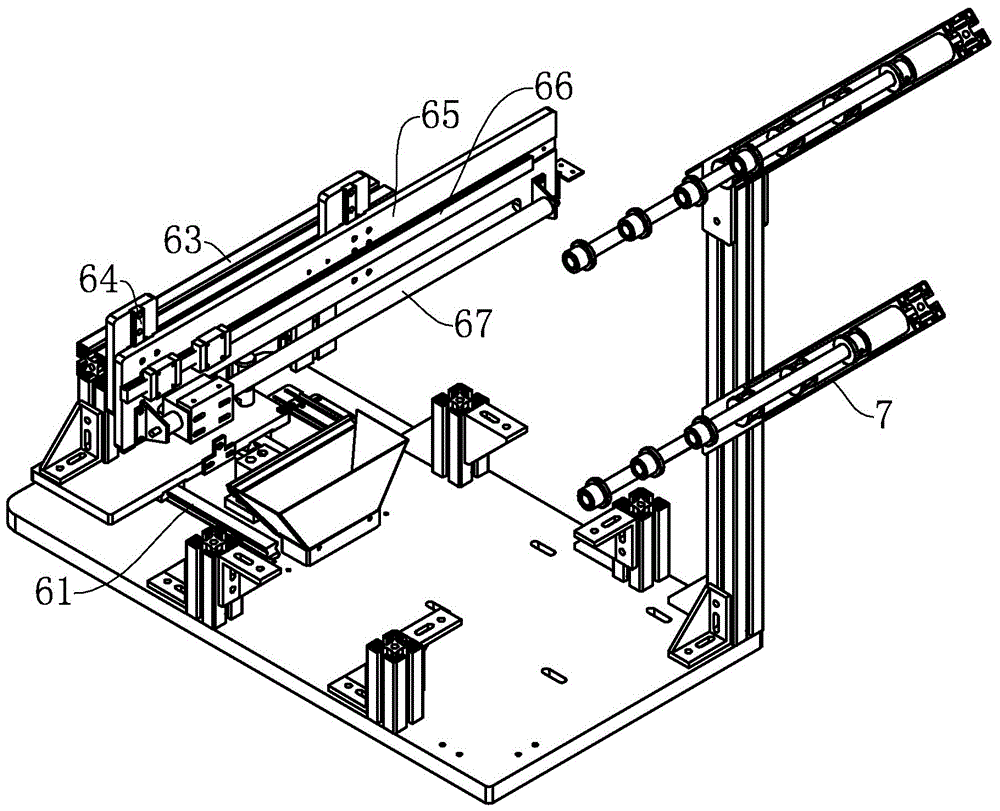

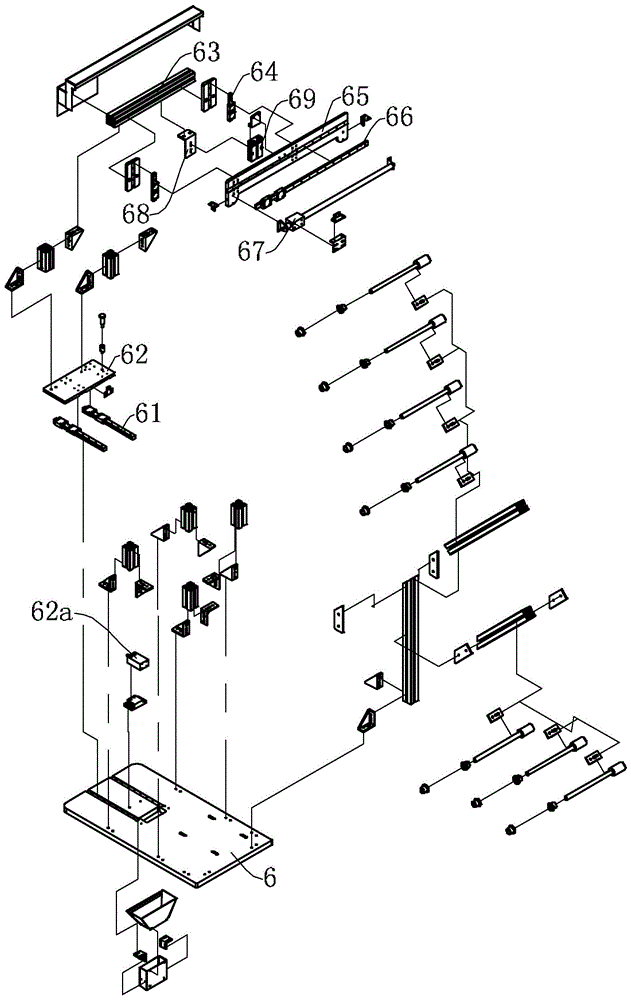

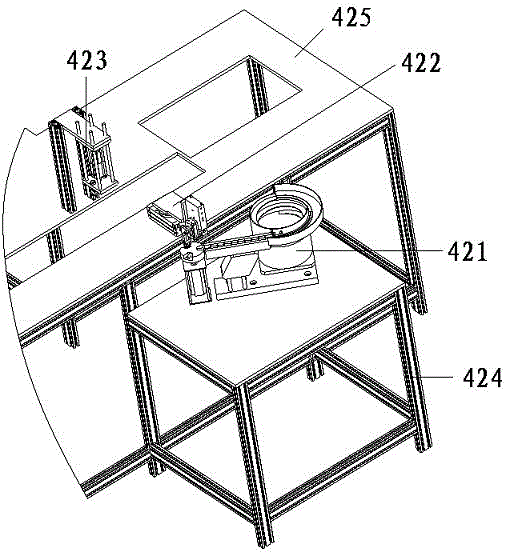

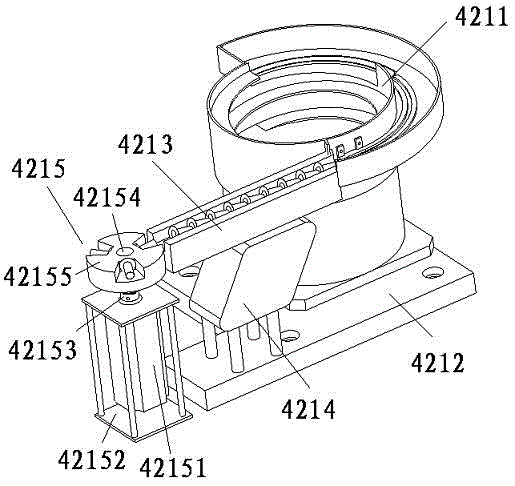

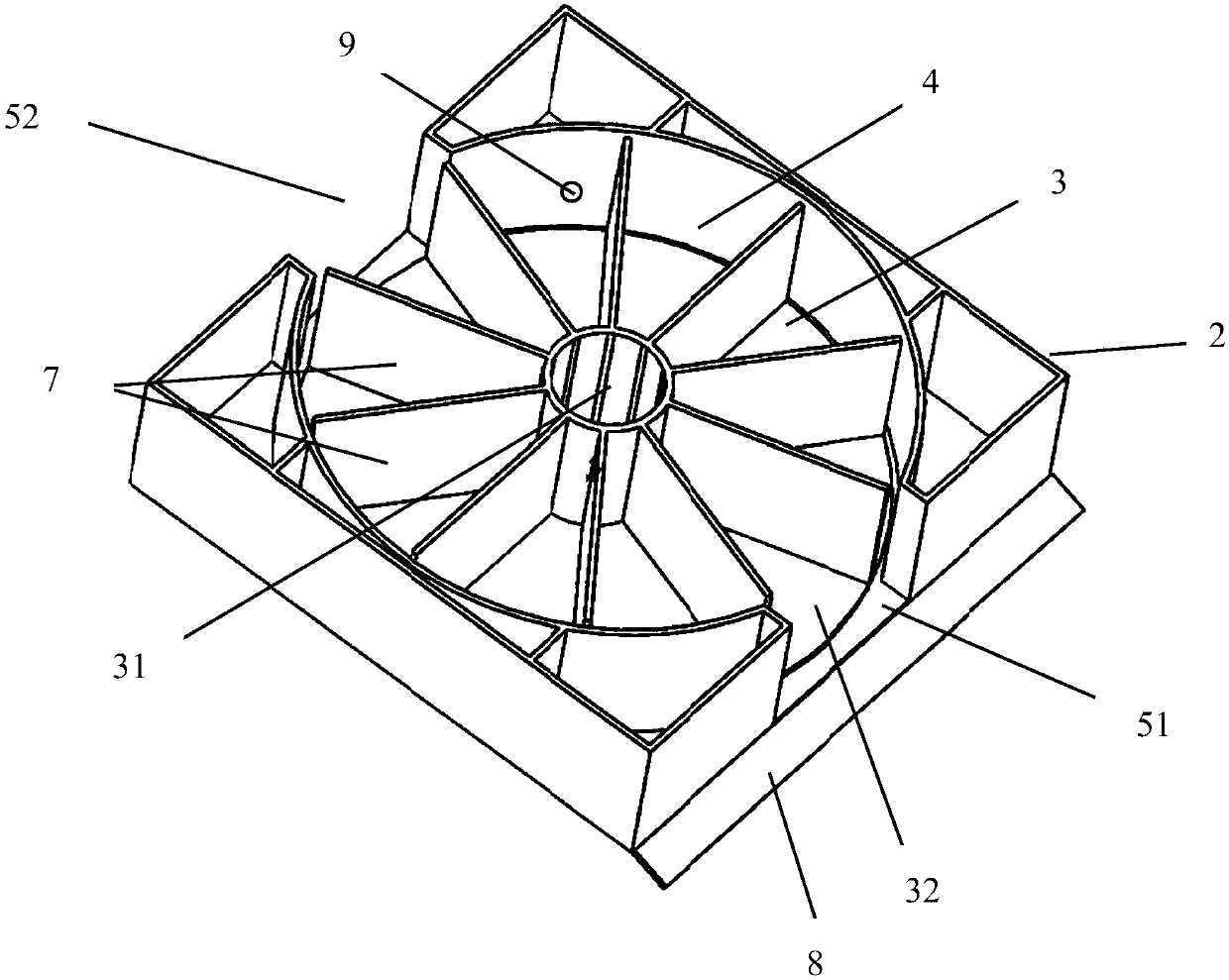

Rotary distributing mechanism

Owner:BOZHON PRECISION IND TECH CO LTD

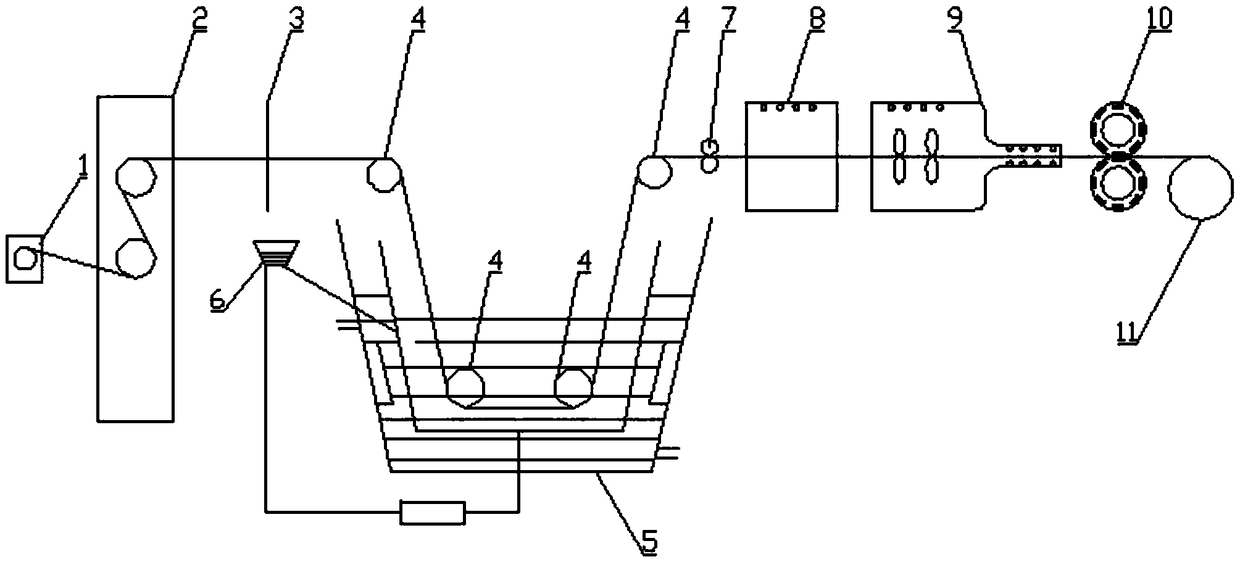

Forming device for preparing continuous fiber reinforced thermoplasticity prepreg through ultrasonic suspension liquid method

The invention discloses a forming device for preparing continuous fiber reinforced thermoplasticity prepreg through an ultrasonic suspension liquid method. The forming device sequentially comprises ayarn frame, a tension system, a yarn separating system, a guide roller, an ultrasonic wave suspension liquid powder groove system, an airflow powder feeding system, a guide mechanism, a drying chamber, a fusion chamber, a cooling system and a rolling system. According to the forming device, the ultrasonic wave suspension liquid powder groove system can avoid powder agglomeration and gathering; theairflow powder feeding system can achieve automatic precise feeding according to needs, and the prepreg can be distributed in resin beneficially; a transcrystallinity generation chamber in the fusionchamber can increase the transcrystallinity generation rate of the resin, and the interface bonding strength of fiber and the resin is improved; and the cooling speed of the cooling system can be adjusted, the thermoplasticity resin crystallinity degree is controllable, and the covering performance of the prepreg can be adjusted beneficially according to needs.

Owner:XIAN TECH UNIV

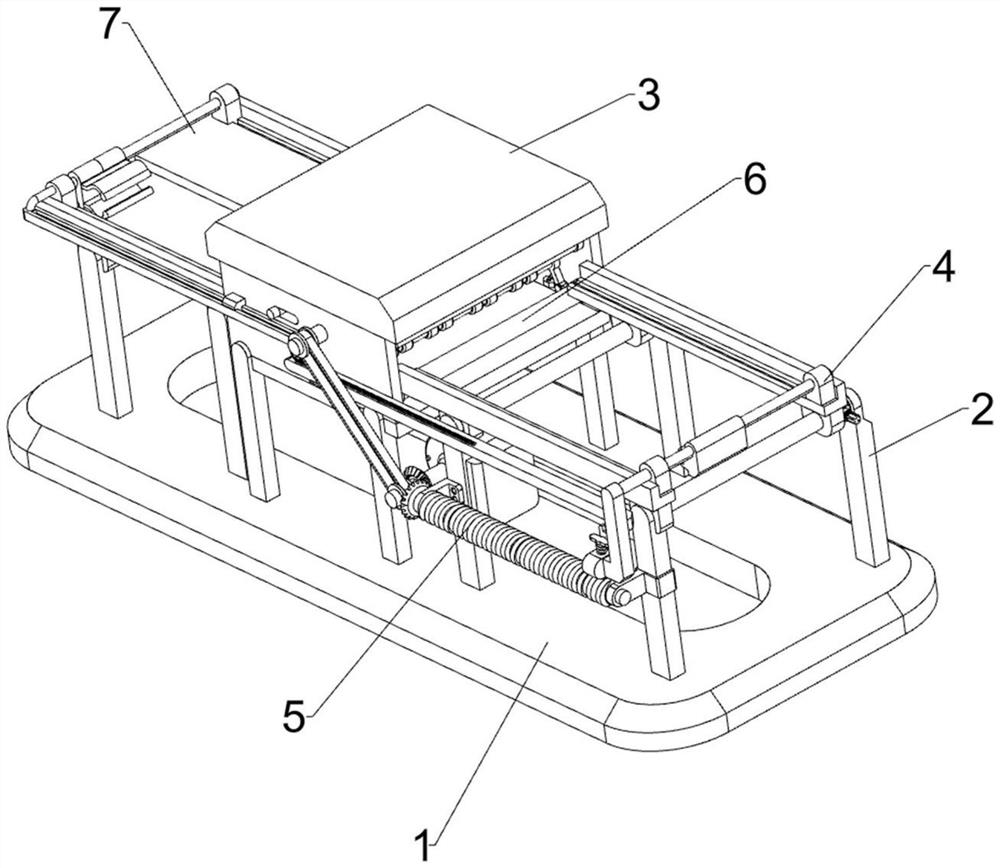

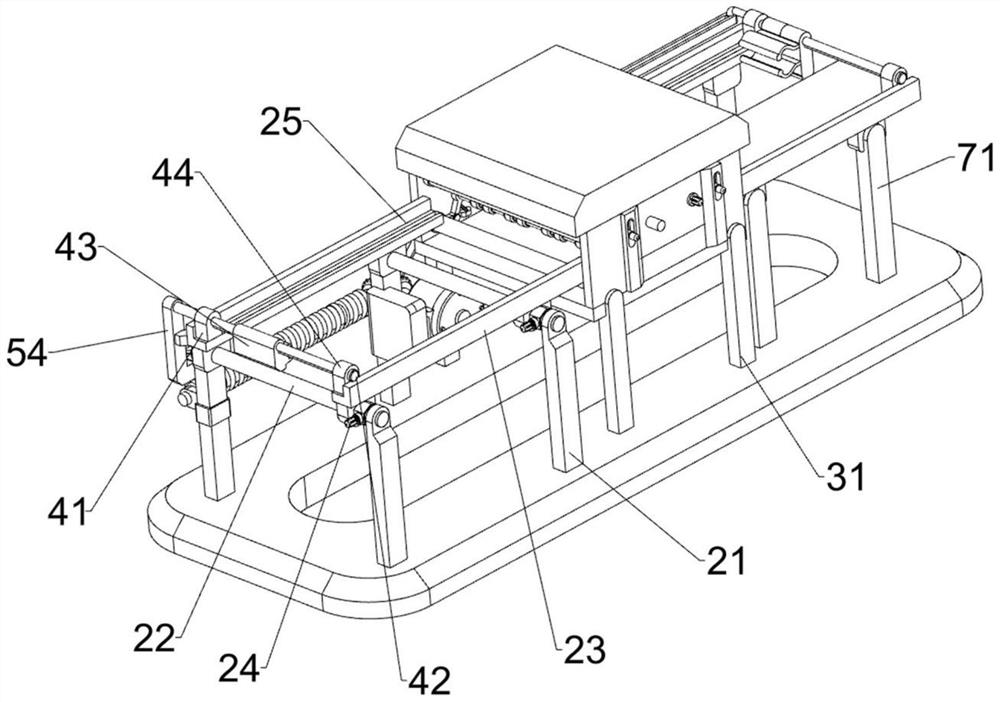

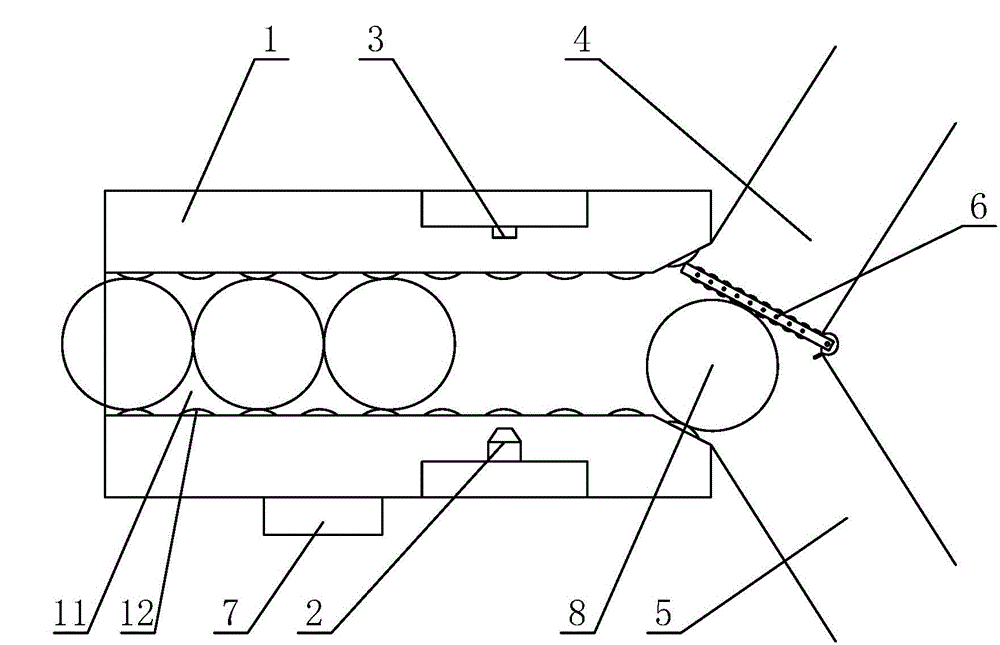

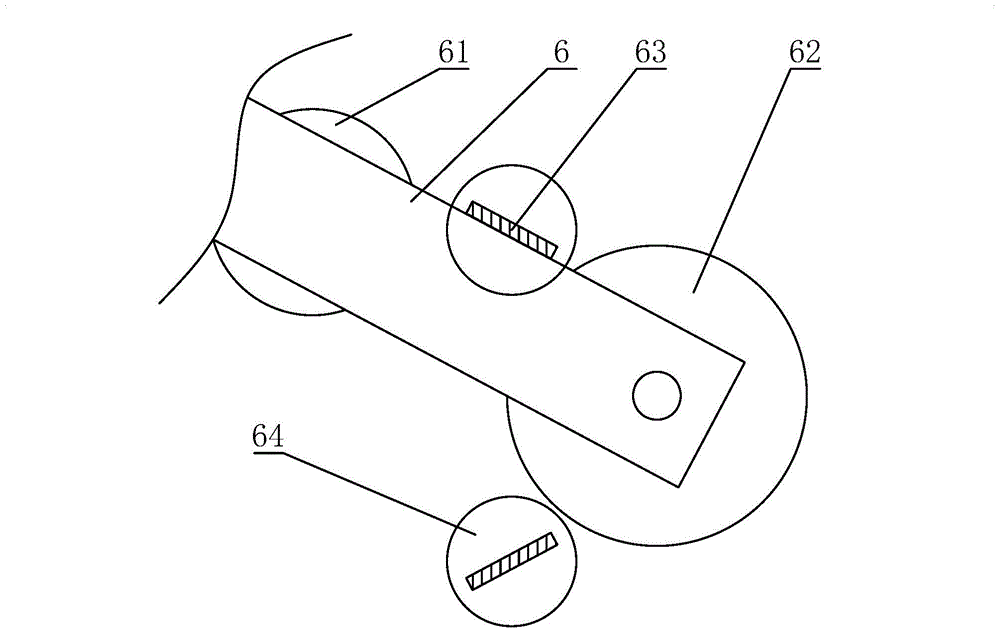

Surface fine polishing device based on PS plate production

ActiveCN112720126AImprove work efficiencyImprove grinding effectGrinding drivesGrinding feedersEngineeringEmery paper

The invention relates to a polishing device, in particular to a surface fine polishing device based on PS plate production. The surface fine polishing device based on PS plate production is used for achieving the technical purposes of being capable of automatically feeding, fixing and polishing PS plates and good in polishing effect. The surface fine polishing device based on PS plate production comprises a bottom plate, a feeding mechanism, a polishing mechanism and a pushing mechanism, wherein the feeding mechanism is arranged on one side of the top of the bottom plate, the polishing mechanism is arranged in the middle of the top side of the bottom plate, and the pushing mechanism is arranged on the feeding mechanism. Through cooperation of the feeding mechanism, the polishing mechanism and the pushing mechanism, the PS plates can be automatically polished, the working efficiency of a user is improved, abrasive paper can be replaced by the user, and the polishing effect is good; and through an auxiliary moving mechanism, the PS plates can be automatically fed, and time and labor are saved.

Owner:南丰县致诚科技有限公司

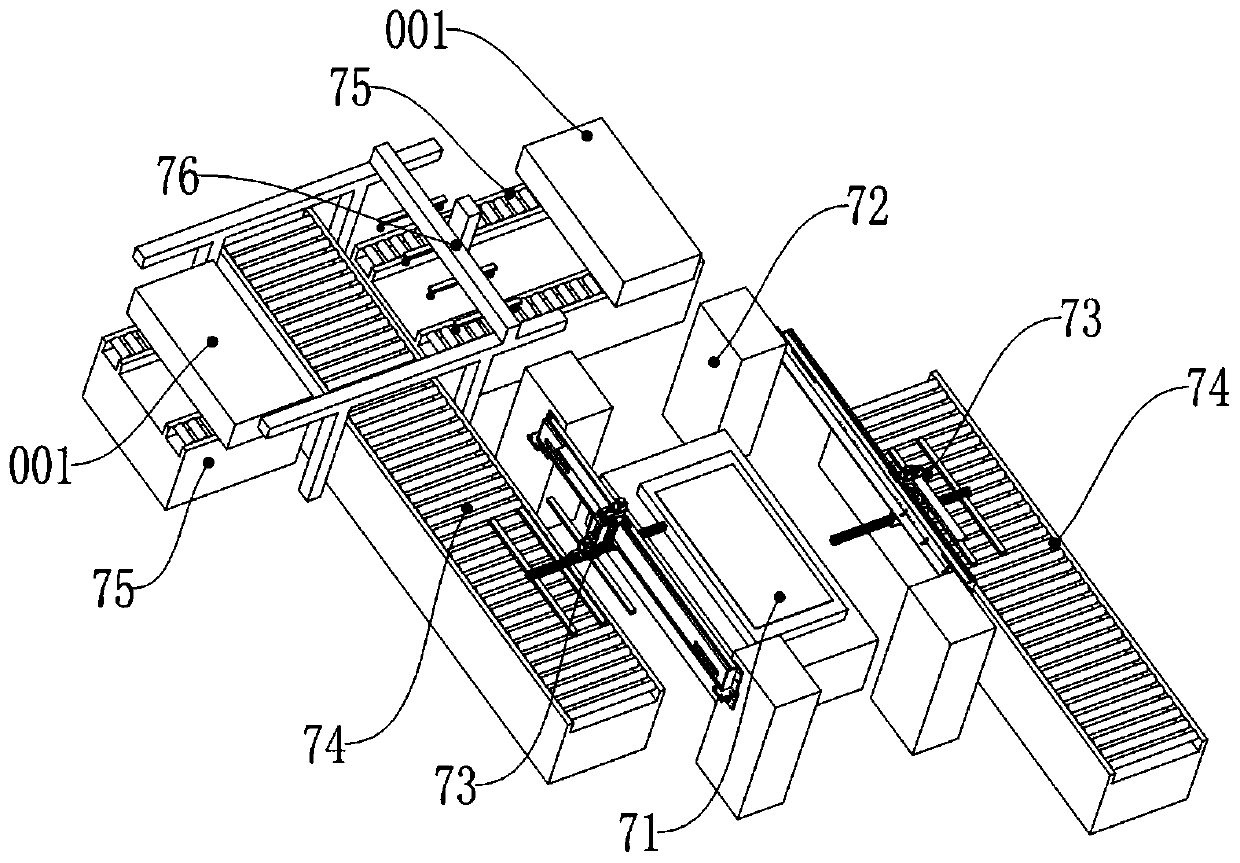

Punch machining center

PendingCN110479891AAutomatic feedingMetal-working feeding devicesPositioning devicesPunch pressDrive wheel

A punch machining center is characterized by comprising a punch press, a punching rack, a material conveying manipulator, a feeding conveying line, a moving conveying line and a feeding manipulator device, wherein a material conveying lifting motor is arranged on a lifting fixing plate, and the output end of the material conveying lifting motor is coaxially equipped with a material conveying lifting driving wheel; one end of the material conveying lifting screw rod is rotatably arranged on the lifting fixing plate, and a material conveying lifting driven wheel is matched with the lifting fixing plate; the material conveying lifting conveyor belt is connected with the material conveying lifting driving wheel and the material conveying lifting driven wheel; a lifting slide seat is provided with a material conveying lifting nut seat; and a material conveying lifting screw rod is matched with the material conveying lifting nut seat. The punch machining center is capable of automatically conveying articles and sending the articles to the punch through the material conveying manipulator, and after the punch completes machining, the material conveying manipulator takes the articles out ofthe punch, so that the steps of automatically feeding, punching and discharging the articles are realized.

Owner:佛山市中机一超机器人科技有限公司

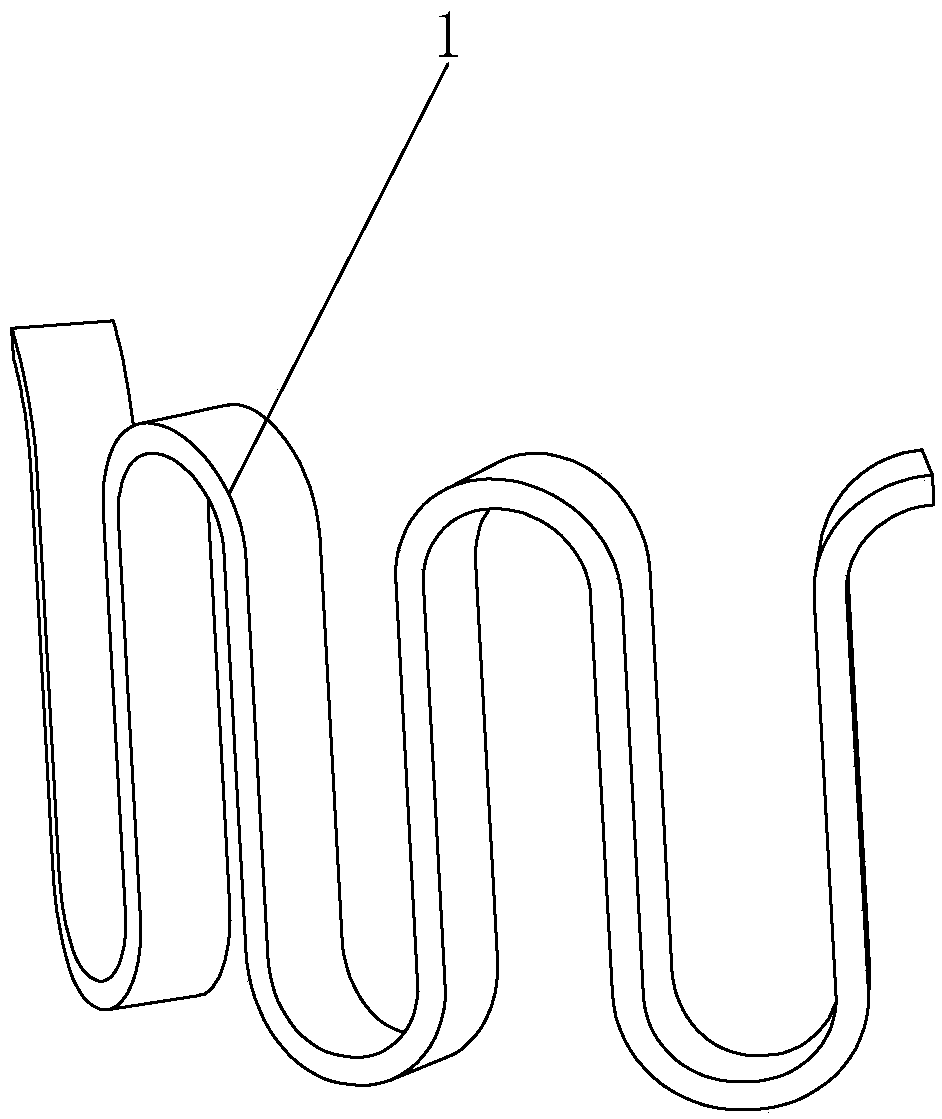

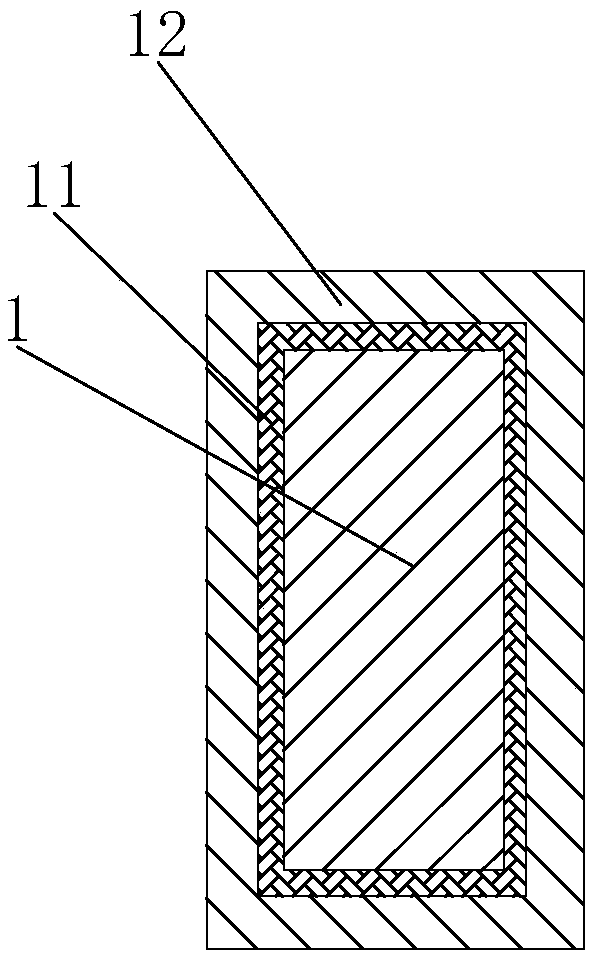

Coupler serpentine spring and production technology thereof

ActiveCN107855390AImprove protectionReduces the possibility of galvanic corrosionLow internal friction springsSolventElectrochemical corrosion

The invention relates to the technical field of springs, and discloses a coupler serpentine spring. The coupler serpentine spring comprises a spring body, and the outer wall of the spring body is coated with a fluorocarbon coating layer. The coupler serpentine spring has the following advantages and effects that a fluorocarbon coating layer is smeared on the spring body, by means of the good chemical inertness of the fluorocarbon coating layer, the fluorocarbon coating layer is resistant to acid, alkali, salt and other chemical substances and a plurality of chemical solvents, accordingly, thespring body can be well protected through the fluorocarbon coating layer, and finally, the possibility that electrochemical corrosion occurs to the serpentine spring can be decreased.

Owner:浙江骏马弹簧制造有限公司

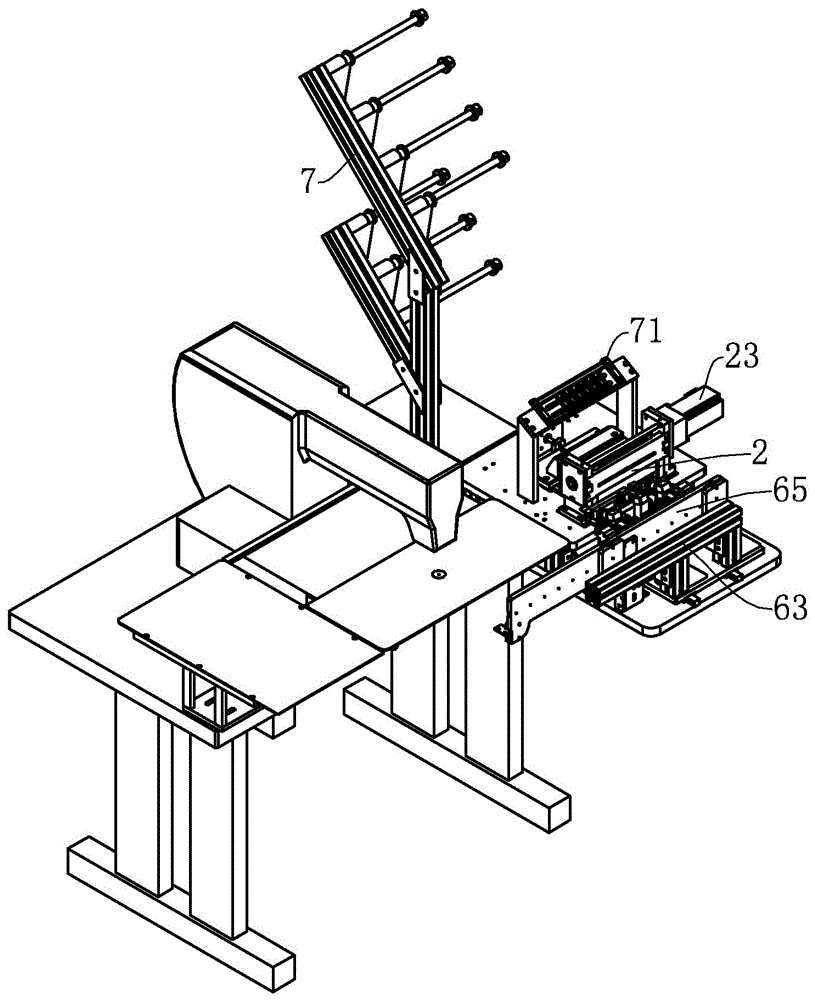

Feeding mechanism of braided band sewing machine

The invention discloses a feeding mechanism of a braided band sewing machine. The feeding mechanism comprises a working platen, wherein a feeding guide rail is fixed to the working platen, a feeding fixing plate capable of sliding back and forth is arranged on the feeding guide rail, a section bar cross rod is fixed to the feeding fixing plate and is provided with a lifting guide rail, a feeding installation plate is fixed to the lifting guide rail, a material clamping installation seat capable of performing horizontal movement in the left-right direction is arranged on the feeding installation plate and is provided with a side plate, convex fixing bodies are arranged at two ends of the side plate respectively, a press pin installation table is arranged in the middle of the side plate, and a gap is reserved between the press pin installation table and any one convex fixing body, a middle press pin assembly for clamping a plurality of braided band side by side is arranged in the middle of the press pin installation table, and an auxiliary press pin assembly for clamping a single braided band is arranged in the gap.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

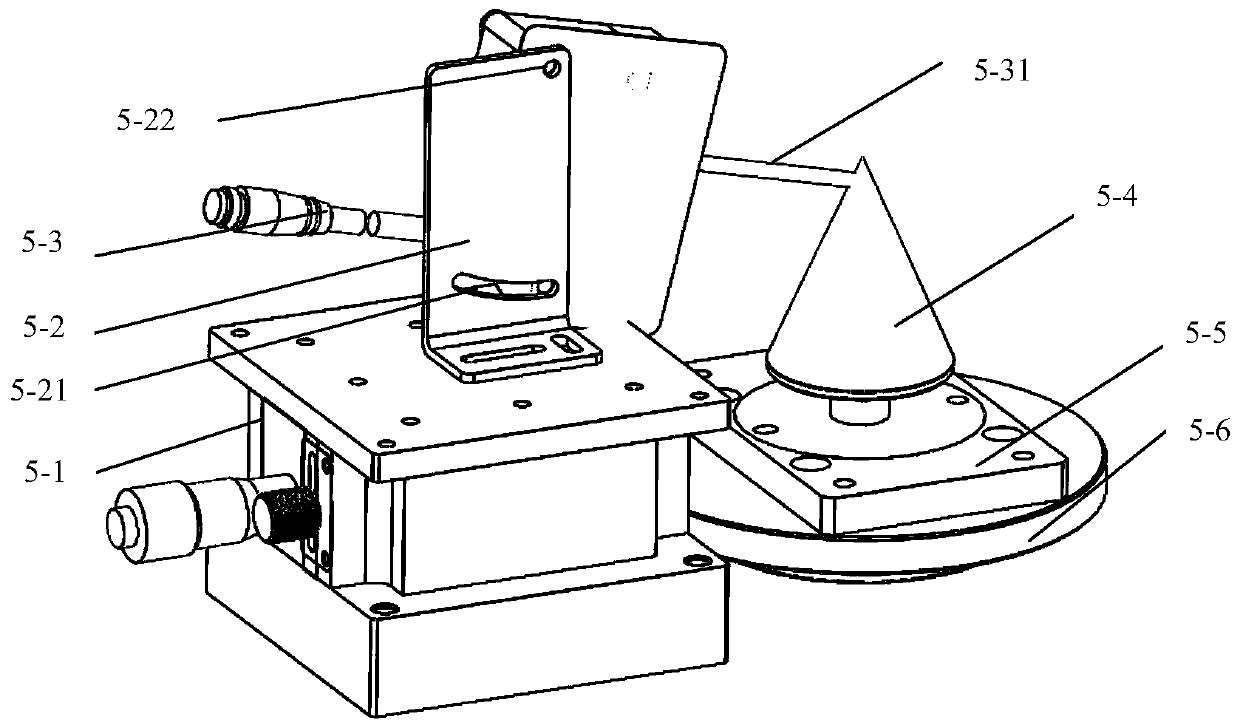

Device for detecting liner thickness and wall thickness difference

ActiveCN110823108AReduce scratchesReduce the impactDirt cleaningUsing optical meansLaser rangingEngineering

The invention discloses a device for detecting liner thickness and a wall thickness difference, and relates to the technical field of wall thickness detection. The device for detecting the liner thickness and the wall thickness difference comprises an adjusting base and a turntable, wherein a vertical mounting plate is arranged on the adjusting base, and an angle-adjustable laser range finder is arranged on the vertical mounting plate; and the turntable is arranged on a light receiving side of the adjusting base, a magnetic base is arranged at the upper end of the turntable, and a liner mold is arranged on the magnetic base. According to the device for detecting the liner thickness and the wall thickness difference, the laser emitted by the laser range finder is used for measuring the liner thickness and the wall thickness difference, a non-contact measurement mode is adopted, the detection precision is improved, the scratch on the surface of a liner is reduced, and the magnetic base is used for achieving rapid replacement of the liner mold.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

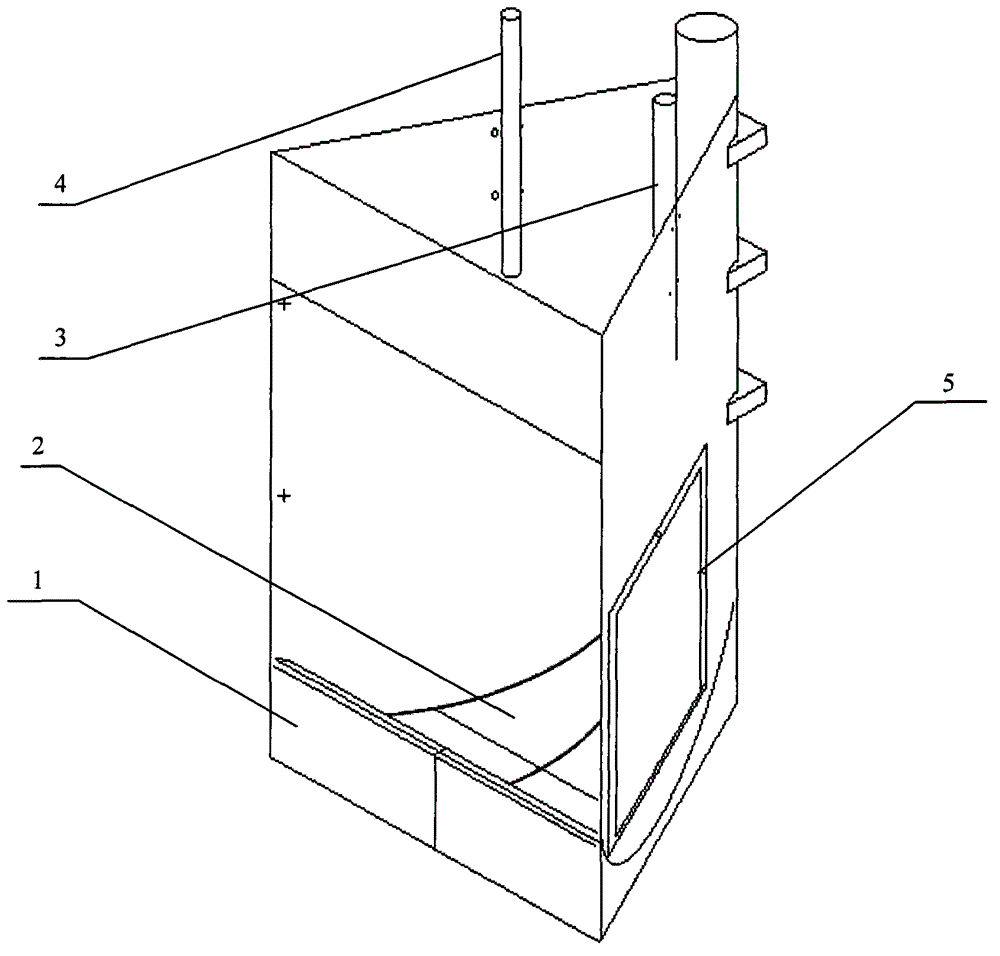

Trough forage adding device for livestock farm

InactiveCN108184701AAutomatic feedingIncrease profitAnimal feeding devicesAnimal ForagingEngineering

The invention relates to a livestock device, in particular to a trough forage adding device for a livestock farm. In order to solve the technical problems, the trough forage adding device which automatically feed livestock with forage, is high in forage utilization rate and small in cost resource is provided. In order to solve the technical problems, the trough forage adding device comprises a bottom plate and the like, wherein wheels are arranged at the bottom of the bottom plate, fixing rods are vertically connected with the left side and the right side of the top of the bottom plate, a feeding hopper is connected between the tops of the fixing rods, a loading mechanism is installed on the left side of the feeding hopper, and a conveying mechanism is installed in the feeding hopper. By the cooperation of the loading mechanism and the conveying mechanism, forage for the livestock farm is added into a trough; meanwhile, by optimizing a knocking mechanism and a dispersing mechanism, theeffects of automatically feeding the livestock with the forage and being high in forage utilization rate and small in cost resource.

Owner:钟凤娣

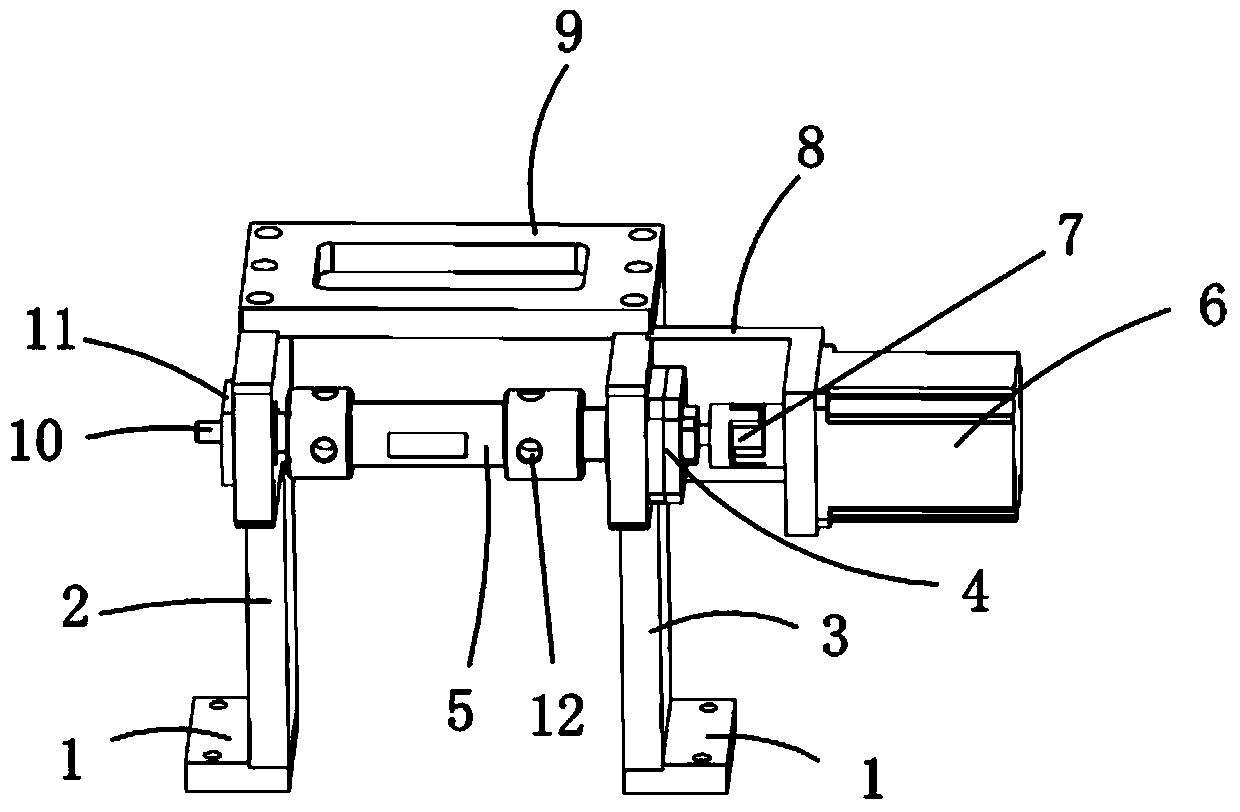

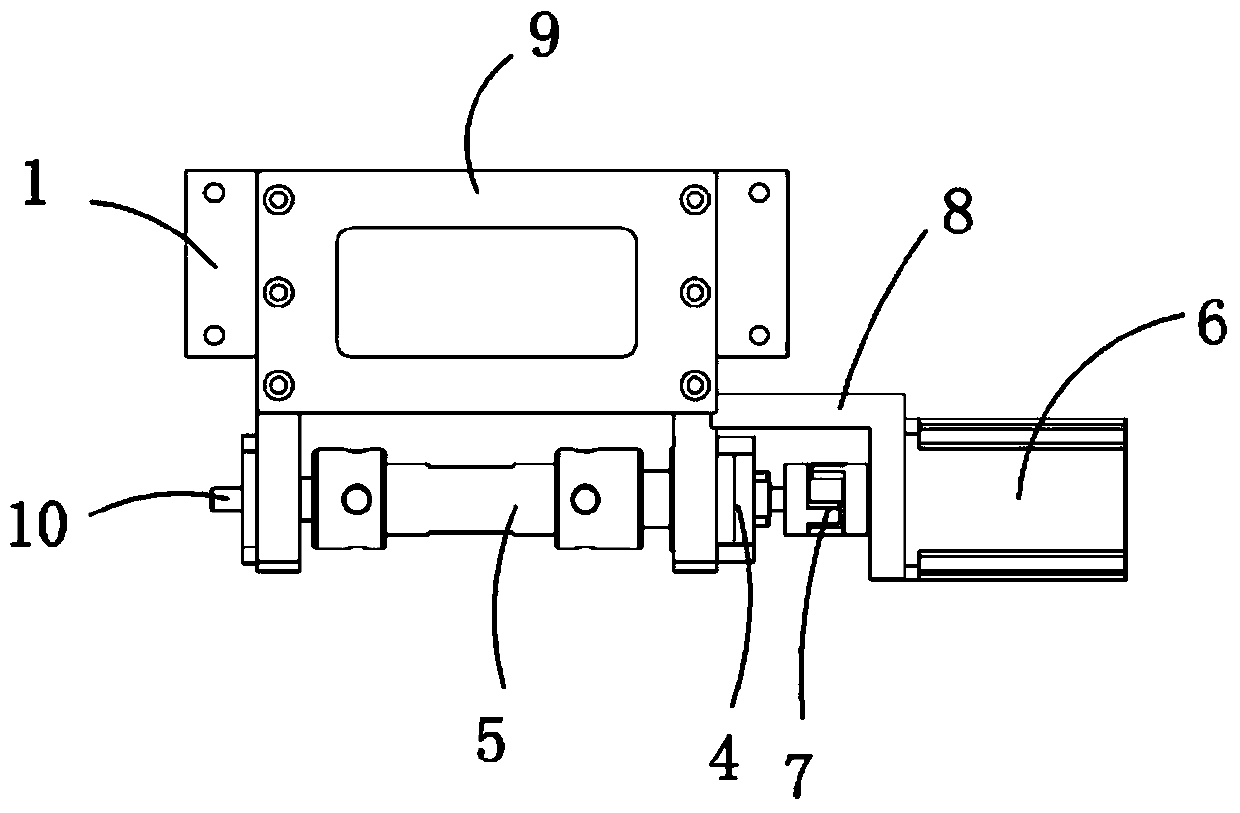

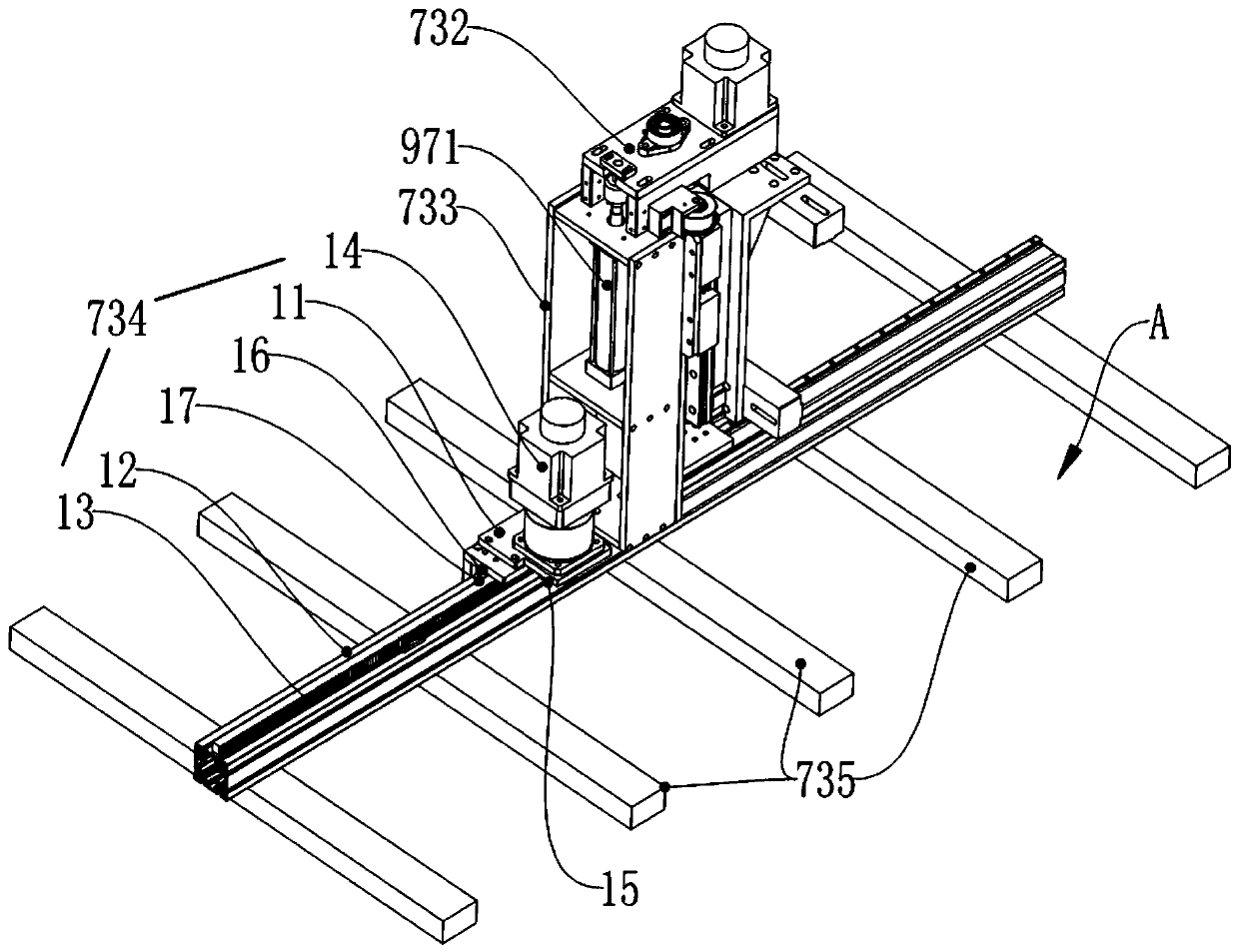

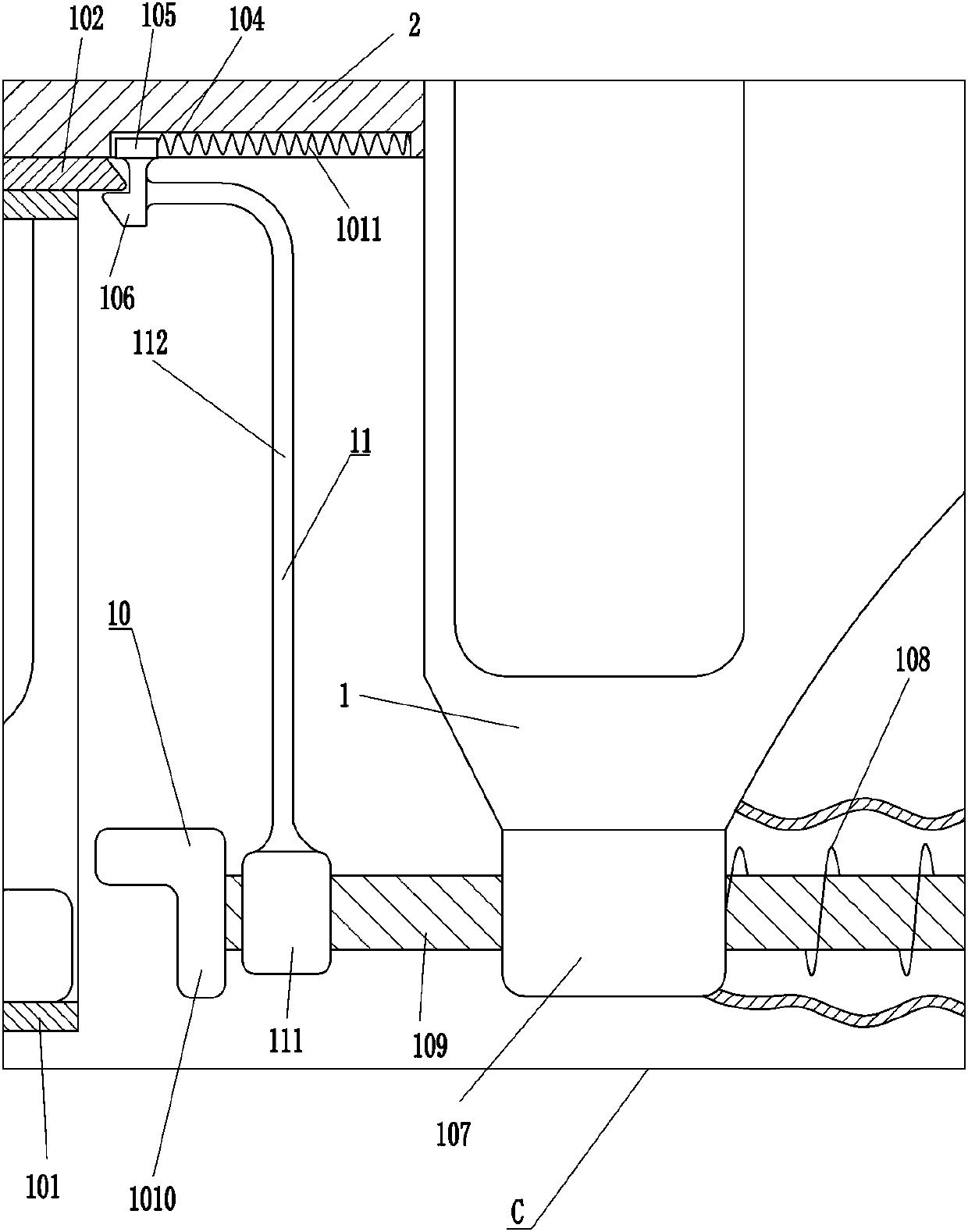

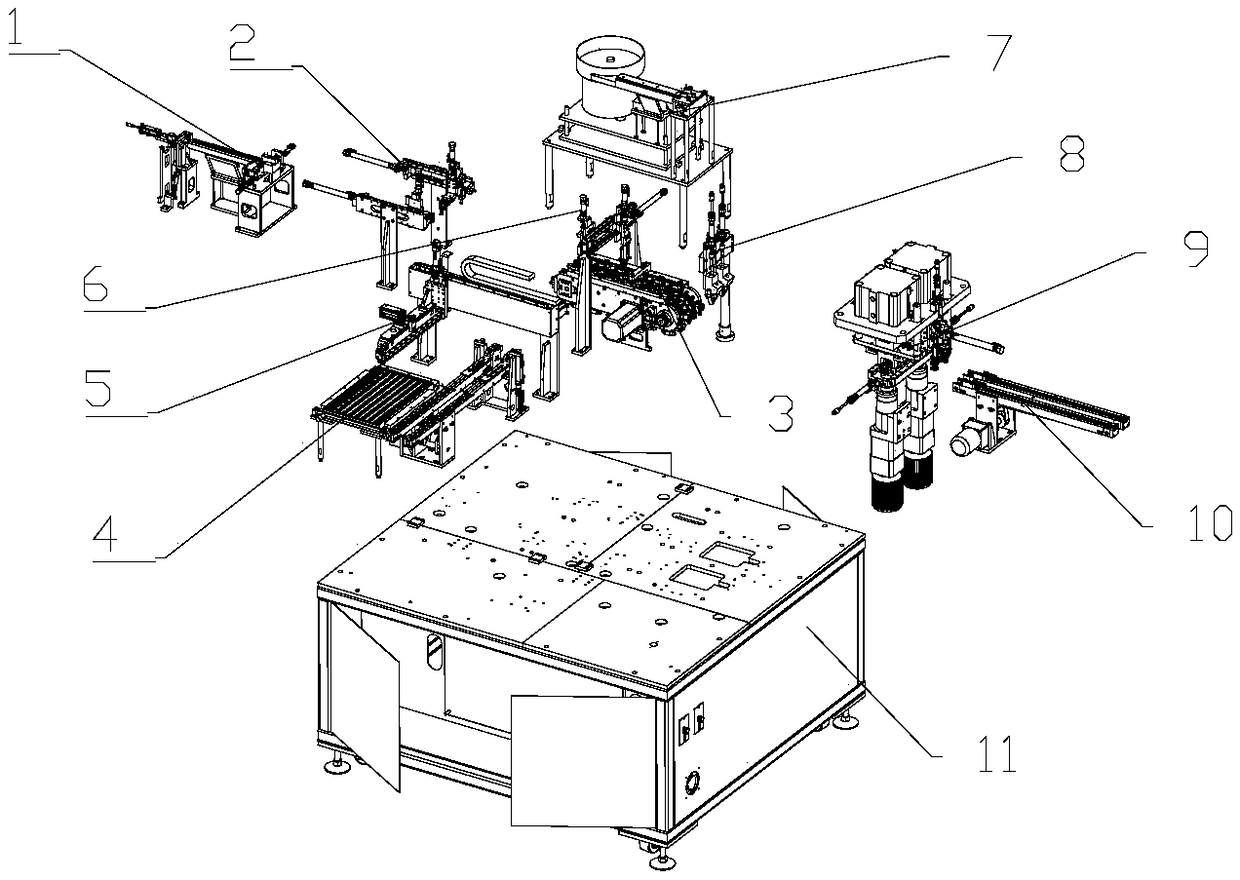

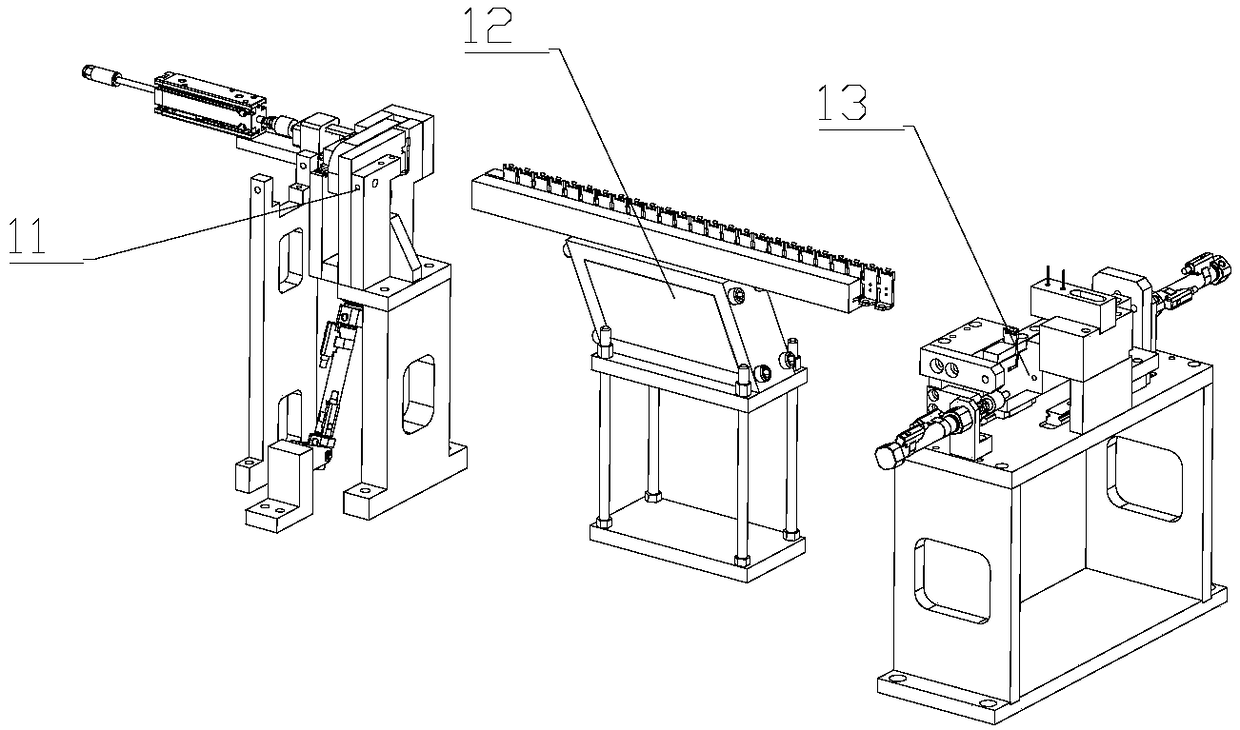

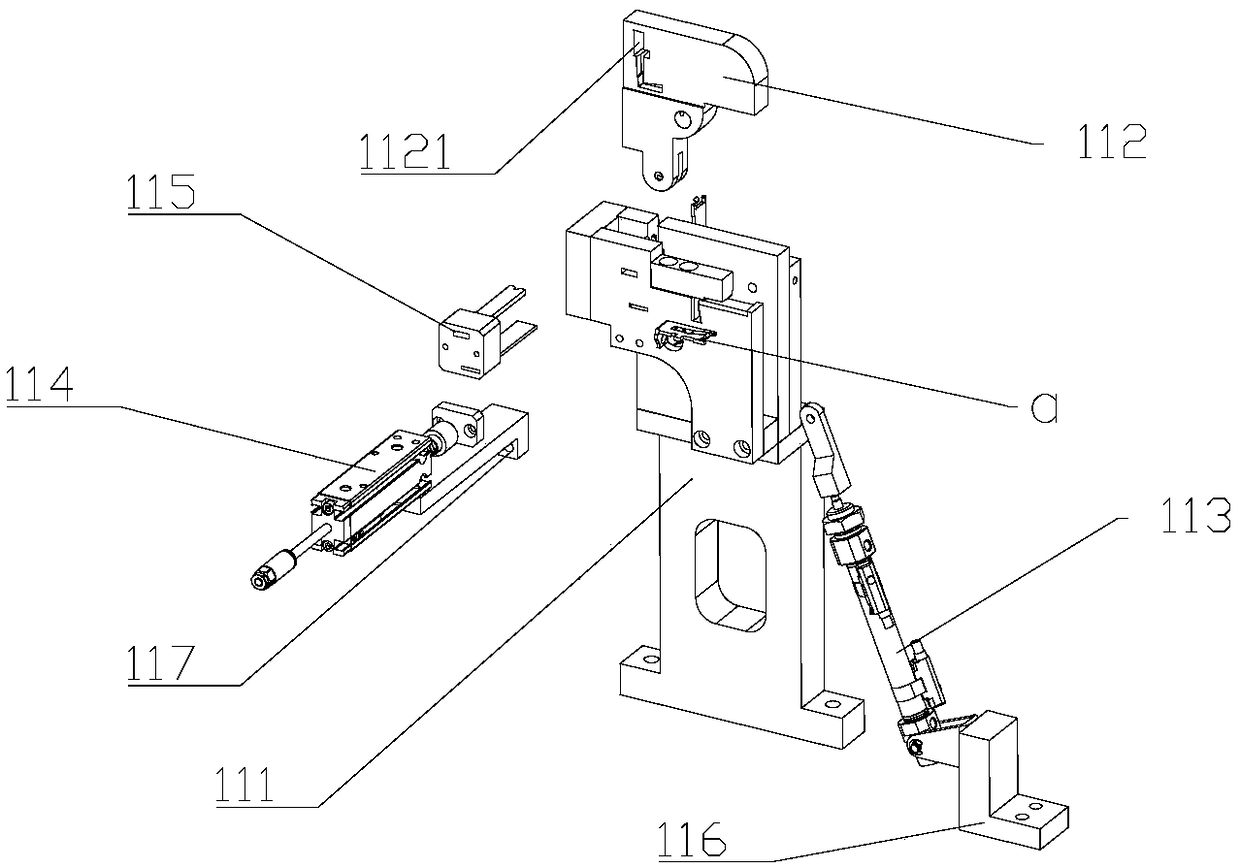

Lining supply and press-in device of automobile door hinge assembly line

InactiveCN104959805AAvoid wastingAutomate assemblyVehicle componentsMetal working apparatusAssembly lineEngineering

The invention discloses a lining supply and press-in device of an automobile door hinge assembly line. The lining supply and press-in device of the automobile door hinge assembly line comprises a lining supply device, a lining feeding manipulator and a lining press-in device. A lining flat clamping cylinder of the lining feeding manipulator is located above the lining supply device, and the lining press-in device is arranged on the rear side of the lining feeding manipulator. The lining supply device comprises a lining material vibrating plate, a lining material plate installation plate, a lining linear feeder, a lining linear vibrator and a lining installation device. The lining material vibrating plate is fixed to the upper plane of a material plate installation frame through the lining material plate installation plate. A discharge opening of the lining material vibrating plate is connected with the lining linear feeder, the lining linear feeder is fixed to the lining linear vibrator, and the outlet of the lining linear feeder faces towards a lining installation mould of the lining installation device. By means of the mode, automatic feeding and assembling can be achieved, labor is saved, and resource waste is avoided.

Owner:SUZHOU ISHIMARU ERI PML PRECISION MECHANISM CO LTD

Fastening part screwing-in machine for building steel plate abut joint

ActiveCN110757405AImprove balanceImprove securityMetal-working hand toolsConstruction engineeringStructural engineering

The invention relates to a fastening part screwing-in machine, in particular to a fastening part screwing-in machine for building steel plate abut joint. A worker can be conveniently kept balanced, and safety is high. The fastening part screwing-in machine for building steel plate abut joint comprises a holding handle, a fixed plate, a placing assembly and the like. The side face of the holding handle is fixedly connected with the fixed plate, the placing assembly is placed on the holding handle, a rotating assembly drives a nut to rotate clockwise, a pushing assembly can drive a bolt to moveupwards, the bolt can be screwed in the nut, two steel plates are connected, accordingly, a worker can finish the operation through the single hand, the worker can be conveniently kept balanced, and safety is high. Through an automatic loading assembly, the bolt can be pushed to an L-shaped plate in a guide sleeve, automatic loading is achieved, and the machine is rapid and convenient.

Owner:滁州力天建筑工程有限公司

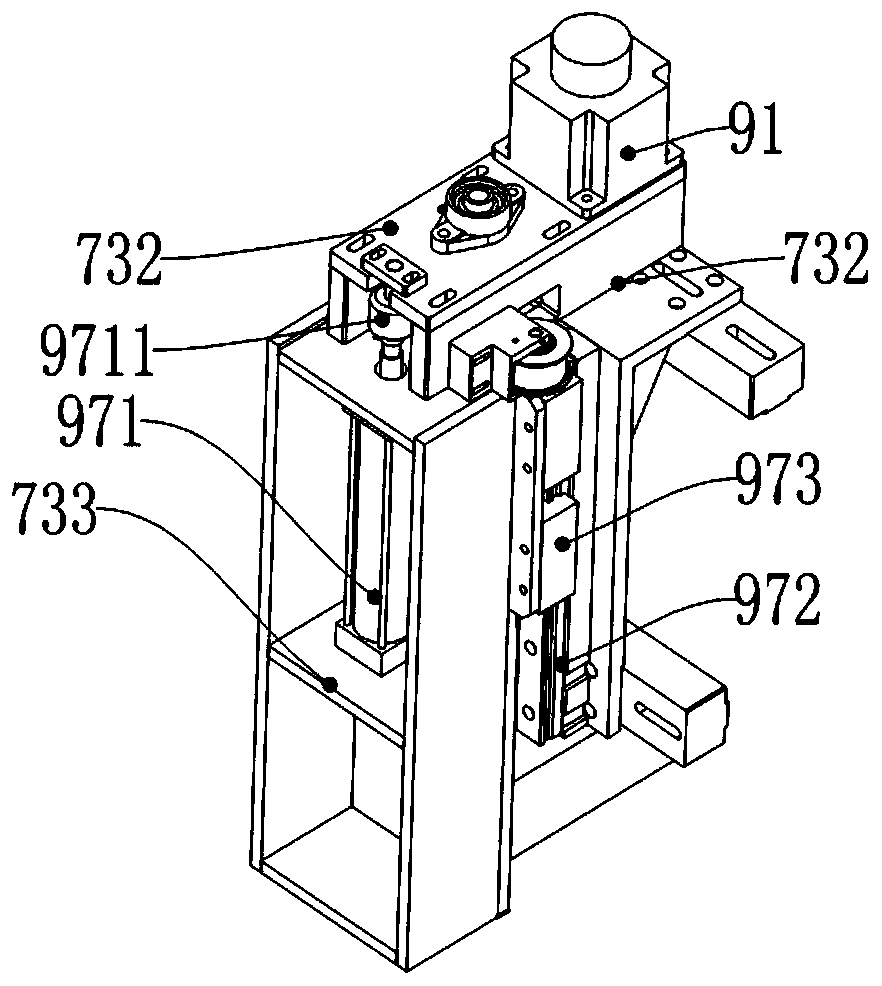

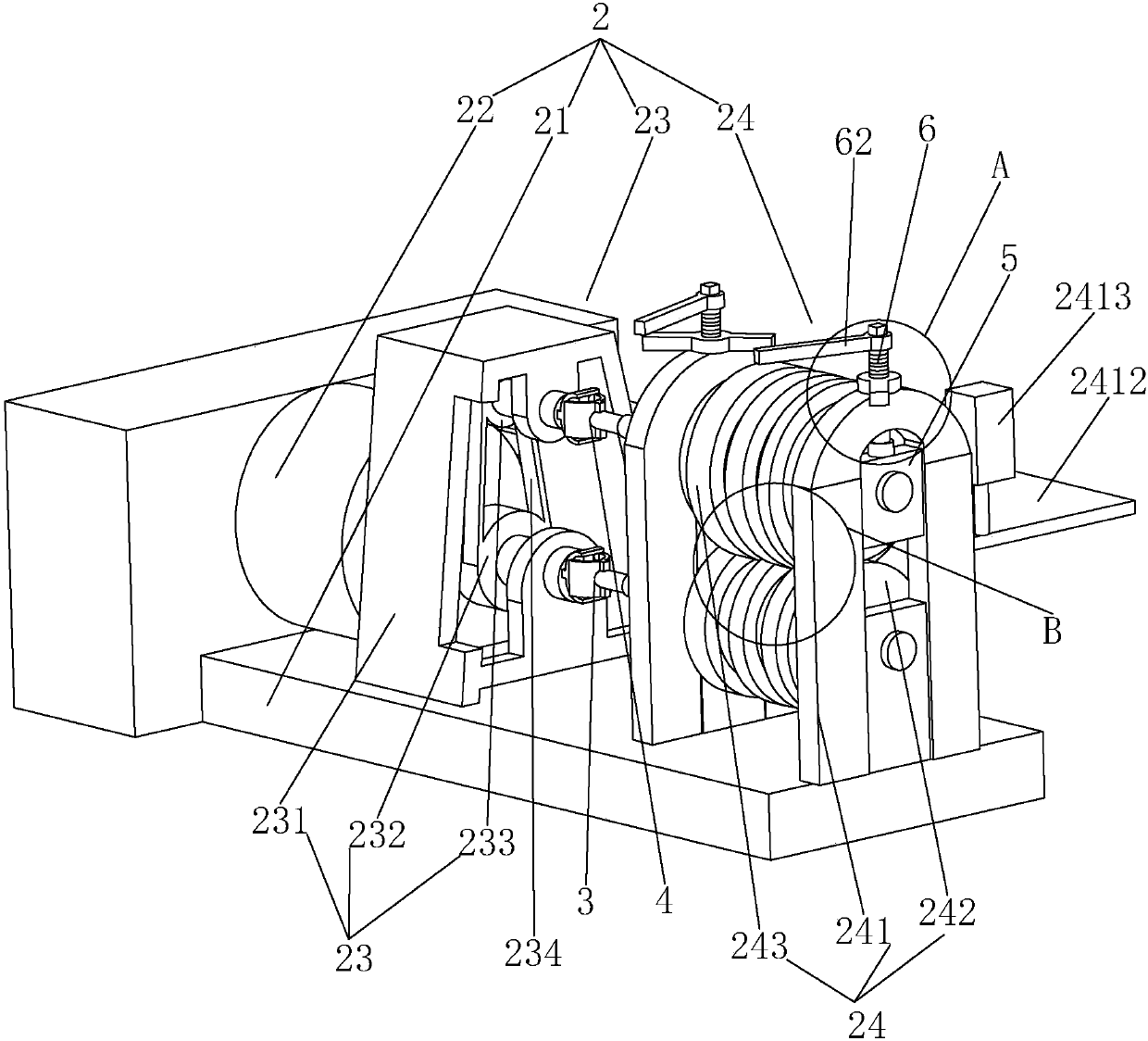

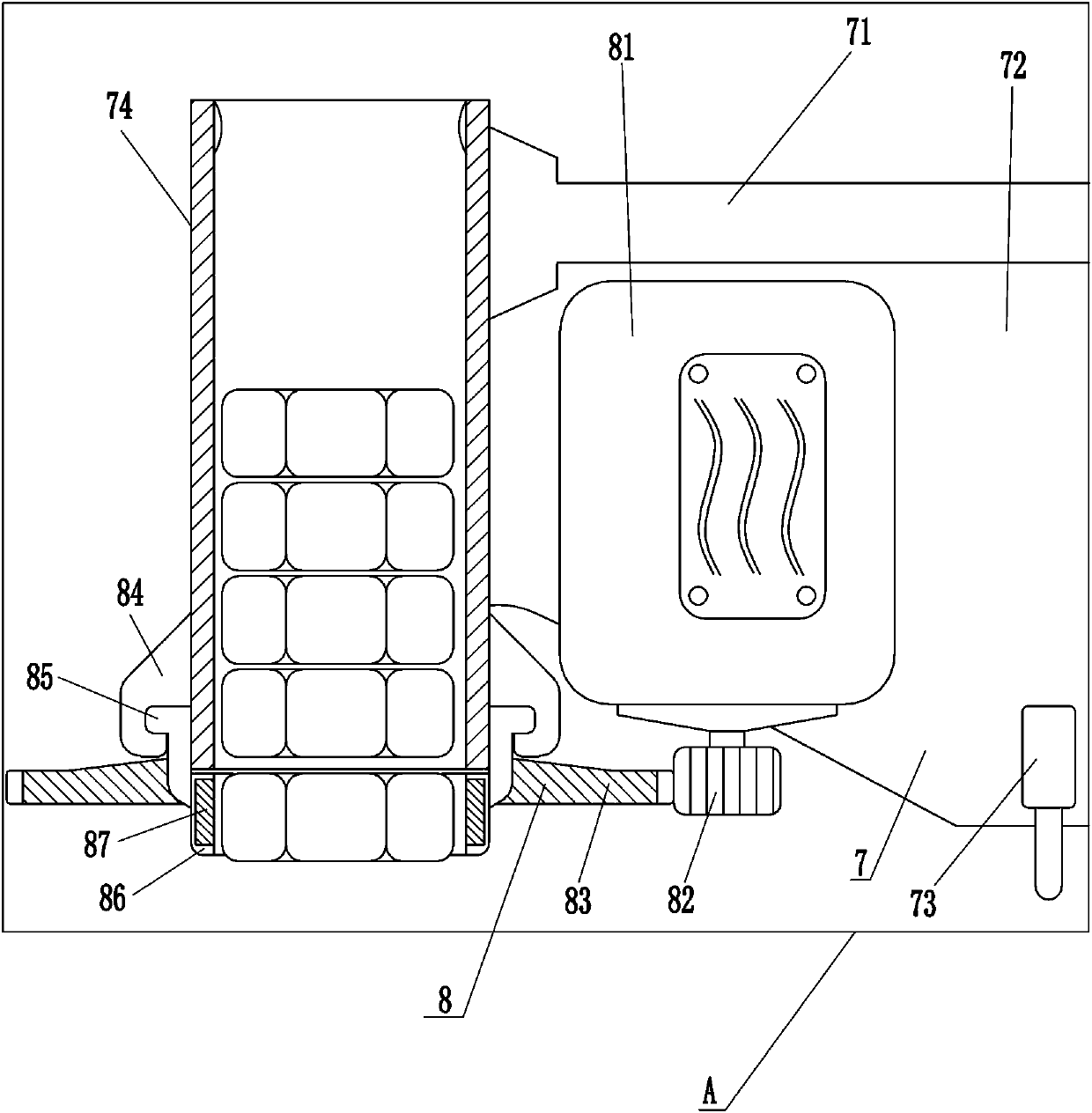

Inductance component automatic assembly device

ActiveCN109103008ASolve the flexibility problemImprove feeding efficiencyInductances/transformers/magnets manufactureEngineeringInductor

The invention relates to the field of production of inductance component. An inductance component automatic assembly device comprises a frame and a spring loading device, a first conveying manipulatordevice, a jig conveying device, a coil body feeding device, a second conveying manipulator device, a third conveying manipulator device, an iron core feeding device, an iron core loading device and apressure riveting device on the frame. The advantages of the inductive element automatic assembly equipment are automatic and efficient assembly of shrapnel, coil body and iron core.

Owner:SHENZHEN TOP FLIGHT TECH CO LTD

Rotating conveying device

PendingCN107564182ANo need to deliberately adjust the placement angleNo need to deliberately adjust the placementCoin-freed apparatus detailsApparatus for dispensing discrete articlesMotor driveElectric machinery

Owner:山东显柜网络科技有限公司

High workpiece and short workpiece separating tool

The invention discloses a high workpiece and short workpiece separating tool. The high workpiece and short workpiece separating tool comprises a conveying passage. A conveying groove is formed in the conveying passage. High workpieces and short workpieces are placed in the conveying groove so as to be conveyed. Conveying rolling wheels are arranged on the two sides of the conveying groove. Two laser reflectors are arranged on the upper portion and the lower portion of the right side of the conveying passage. A laser receiving plate is arranged on the left side of a conveying belt in a matched mode. A high workpiece discharging passage and a short workpiece discharging passage are both connected to the rear end of the conveying passage, and the high workpiece discharging passage and the short workpiece discharging passage incline downwards. A separation plate is arranged at the discharging end of the conveying passage. A driving motor is arranged at the rear end of the separation plate. A driven wheel is also arranged on the separation plate. Through holes are formed in the high workpiece discharging passage and the short workpiece discharging passage correspondingly. Baffles are arranged in the through holes. A driving component is connected to the lower end of each baffle. A controller is further arranged on the conveying passage. The controller is electrically connected with the laser receiving plate, the driving motor and the driving components. By the adoption of the high workpiece and short workpiece separating tool, the high workpieces can be automatically separated from the short workpieces.

Owner:WUXI QINGYANG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com