Rotating conveying device

A technology of rotating feeding and feeding ports, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items. The location requirements are too high, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are only examples for clarifying the present invention, rather than limiting the embodiment of the present invention. For those of ordinary skill in the art, on the basis of the following descriptions, other different forms of changes or changes can also be made, and these obvious changes or changes that belong to the spirit of the present invention are still within the protection scope of the present invention middle.

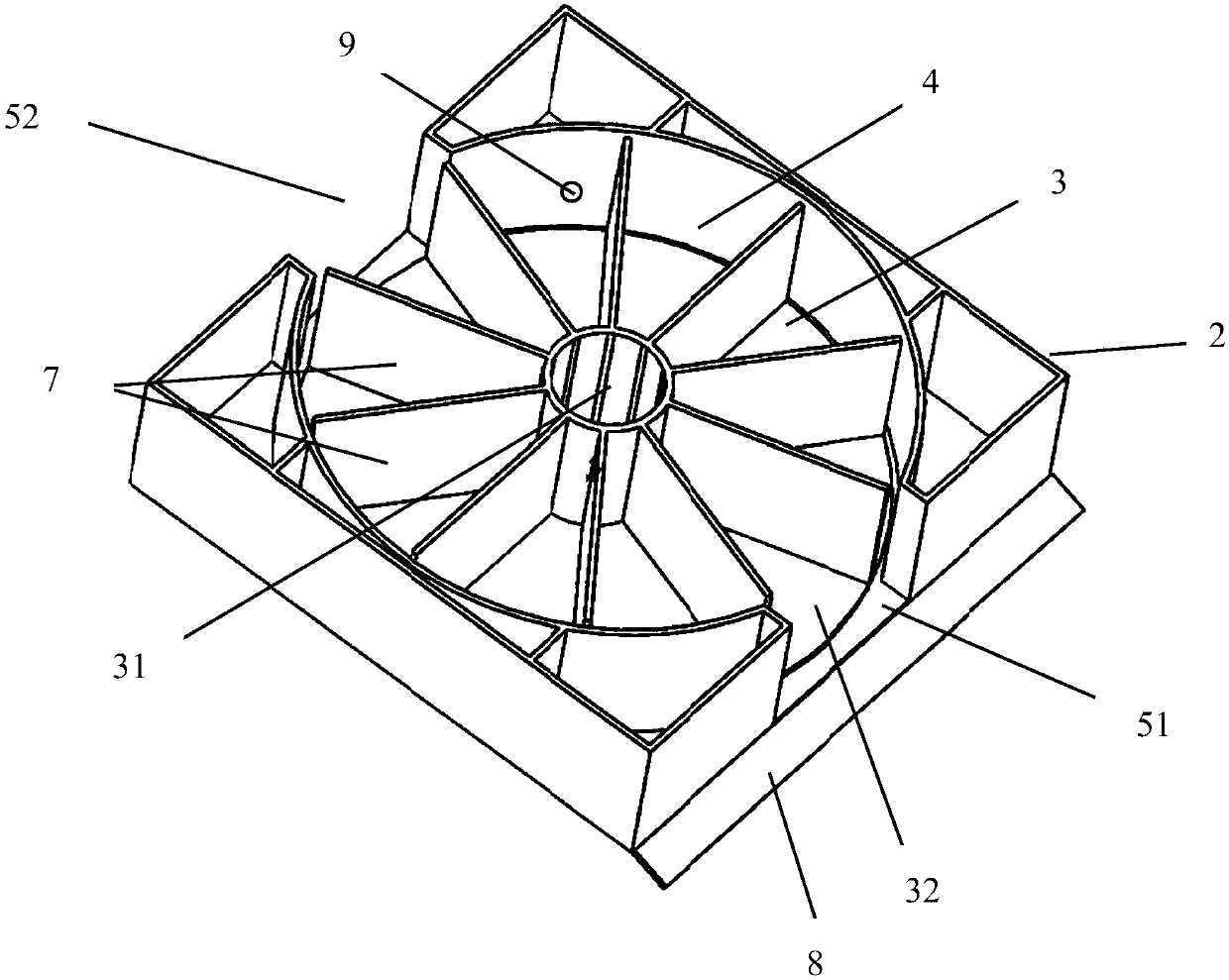

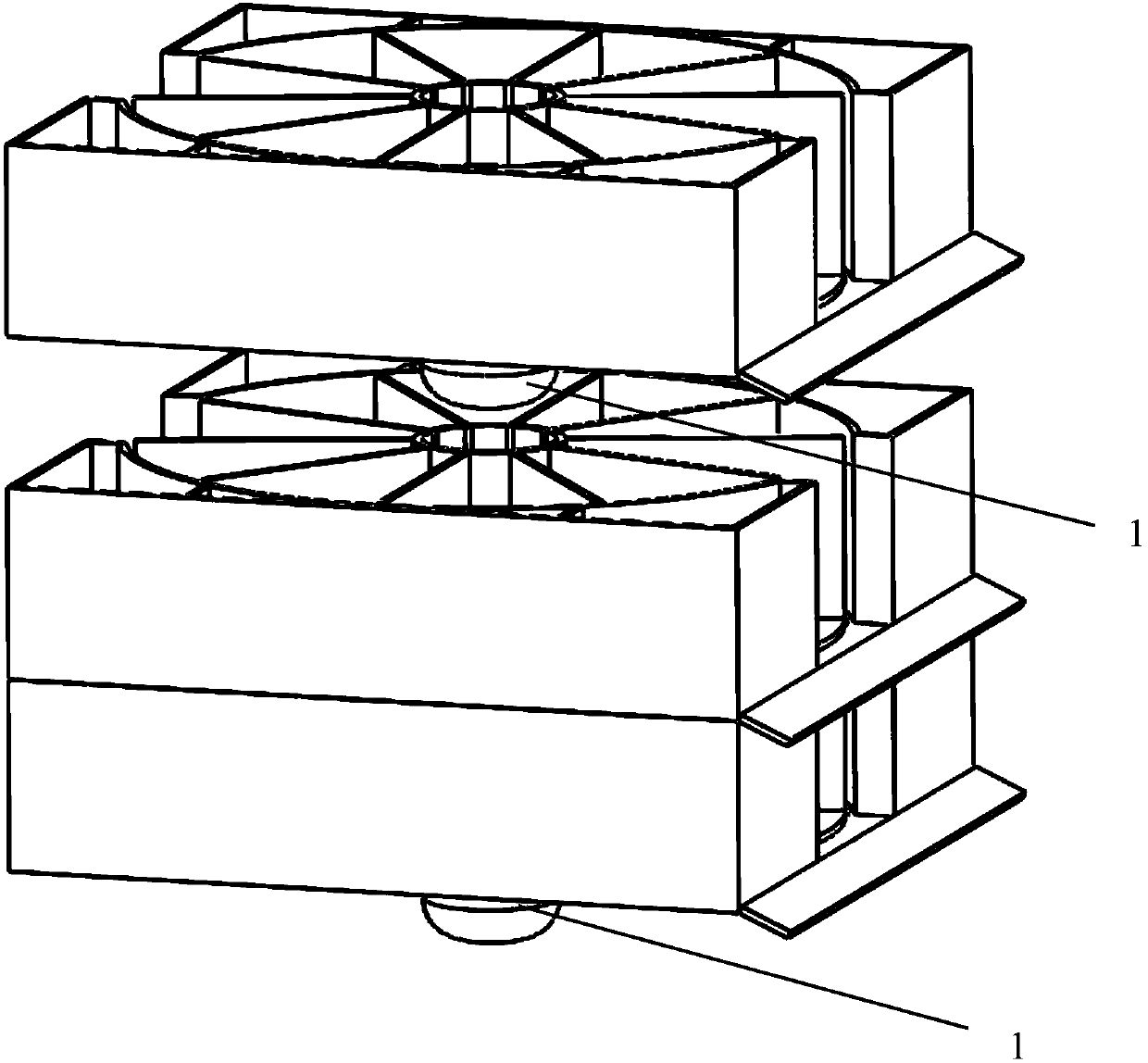

[0025] Such as Figure 1-2 As shown, a rotary feeding device includes a motor 1, and it also includes an outer frame 2 and a split rotating wheel 3. The center of the outer frame 2 is a vertically arranged cylindrical cavity 4, which is located in the cylindrical cavity 4 The front and rear directions of the front and rear direction are respectively provided with feed ports, and the feed ports communicate with the interior of the cylindrical cavity 4, and the split rotating wheel 3 is coaxially sleeved in the cylindrical cavity 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com