Clamp in use for testing LED

A technology for detecting fixtures and fixtures, which is applied in the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems that affect the success rate of the probe lighting LED, cannot be disassembled, and high maintenance costs, and can meet the needs of manual labor. Feeding and automatic feeding, improving accuracy and success rate, the effect of product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

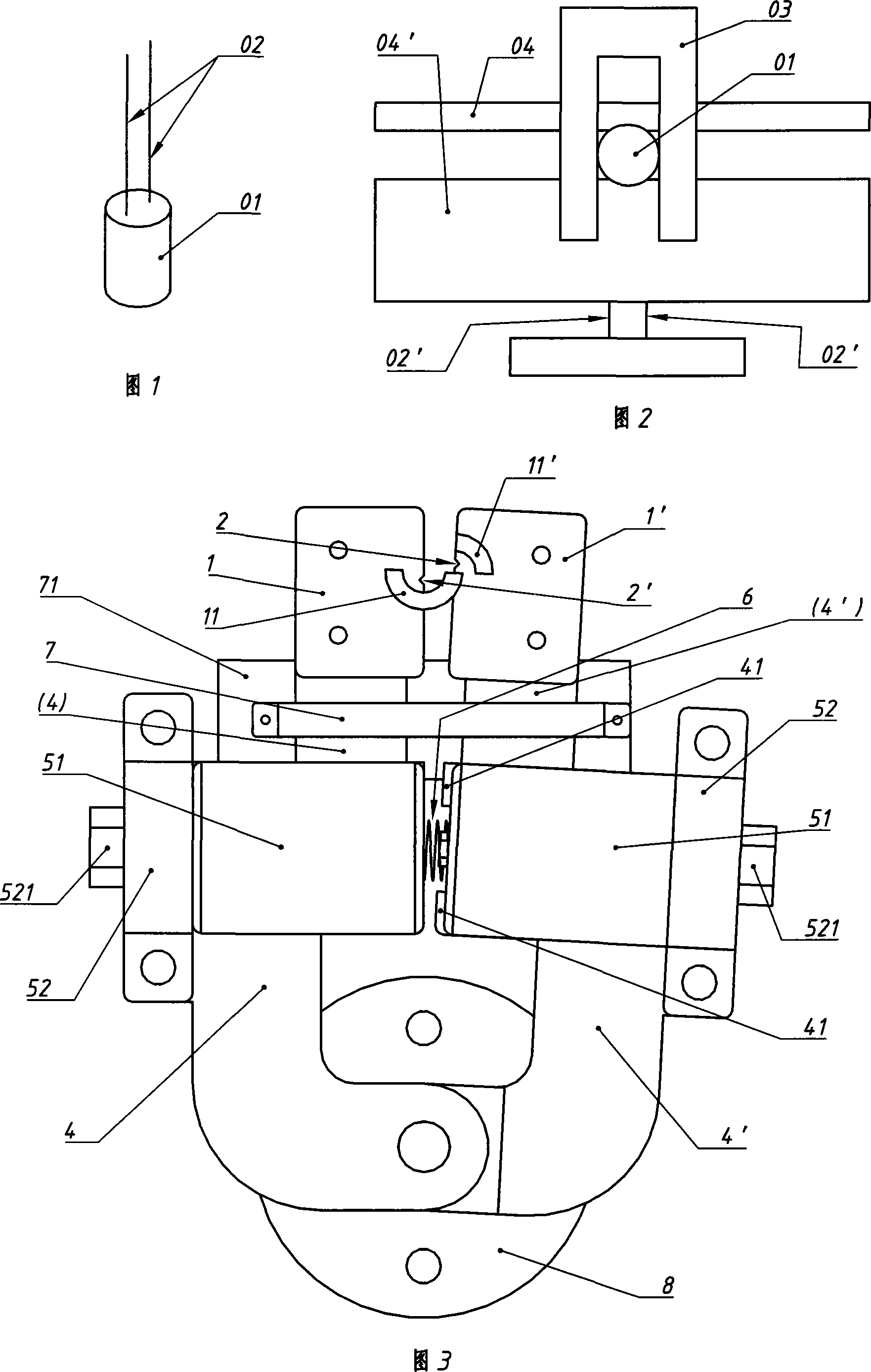

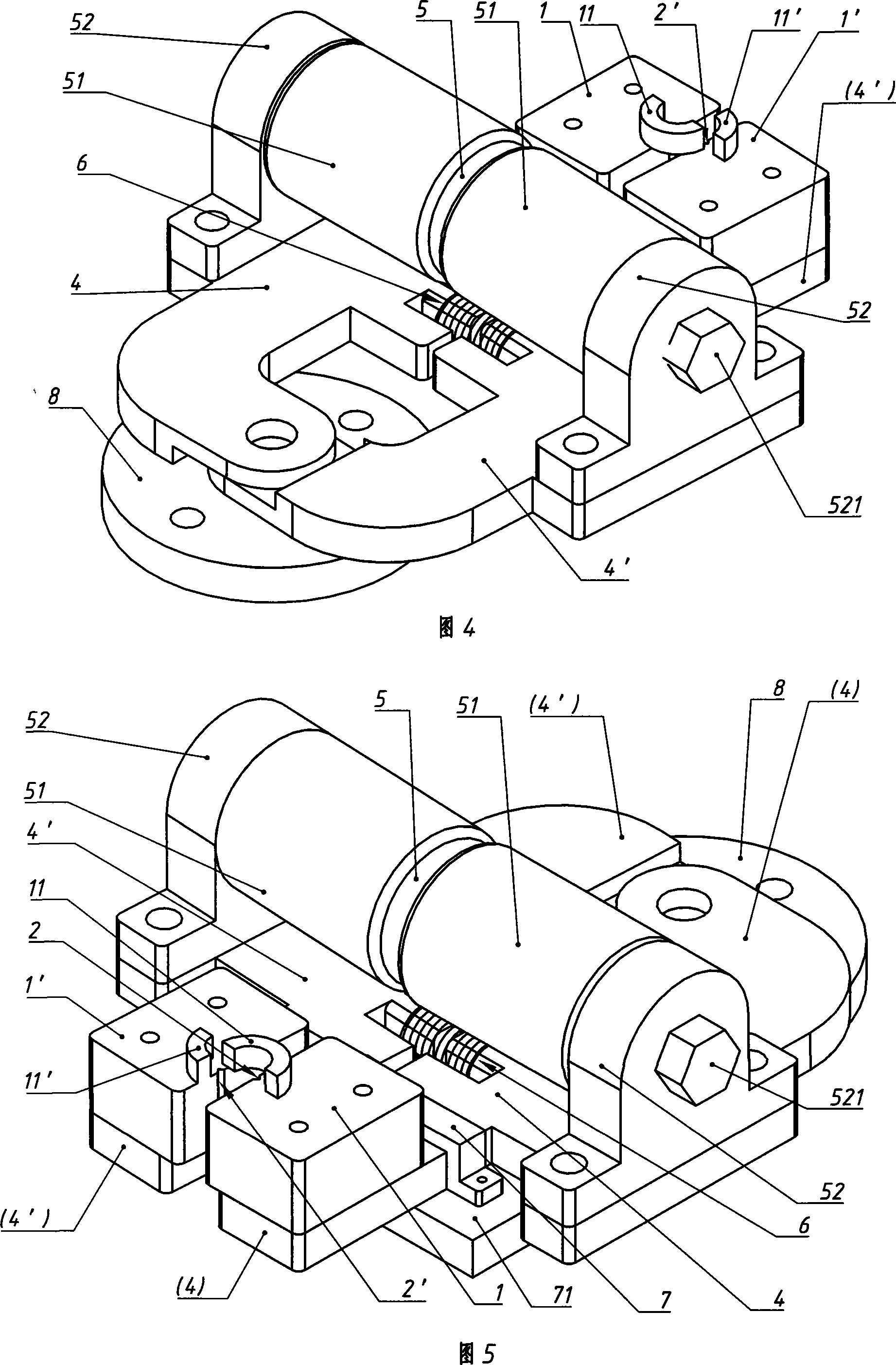

[0022] Embodiment 1 (with reference to the part marked 41 among Fig. 3 and Fig. 6):

[0023] The limiting part of this example is a limiting block 41 or a limiting nail installed on the inner side of a splint arm (swinging clamping arm 4' in the figure), and the limiting block 41 or limiting nail is opposite to another splint arm (In the figure, the inner surface of the fixed splint arm 4) is directly matched with it to limit the closing degree of the two splint arms (4, 4'); there is a straddle on the two splint arms (4, 4') Prevent them (4, 4 ') from excessively expanding the Π-shaped anti-expansion frame 7 (referring to Fig. ) on a pallet 71 below, wherein the fixed splint arm 4 is fixed together with the Π-shaped anti-expansion frame 7 or the pallet 71 with its outer surface against the inner surface of one side of the ∏-type anti-expansion frame 7 When the return spring 6 stretches the two splint arms (4, 4') until the inner surface of the other side of the anti-expansio...

Embodiment 2

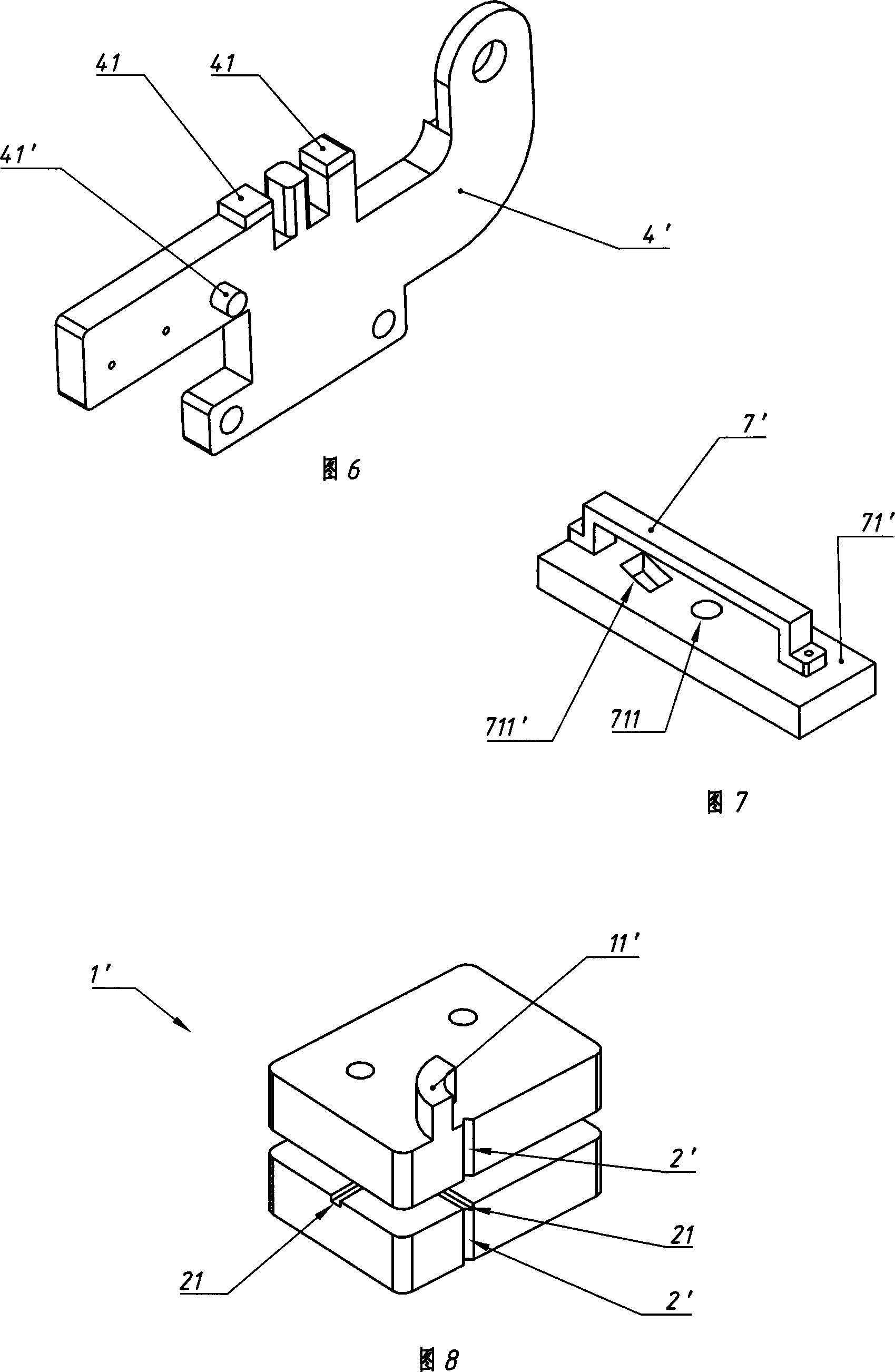

[0025] Embodiment 2 (with reference to the part marked 41' in Fig. 7 and Fig. 6):

[0026] In this example, two splint arms (4, 4') are straddled with a Π-shaped anti-error frame 7' that prevents them (4, 4') from staggering up and down. The two ends are fixed on a pallet 71' below the two splint arms (4, 4'), and the fixed splint arm 4 is fixed together with the ∏-type error-proof frame 7' or the pallet 71'. The limiting part of this example is the limiting pin 41' installed on the lower part of the swing splint arm 4', and the supporting plate 71' has an arc-shaped hole 711' matching the limiting pin 41'. What limits the closing degree of these two splint arms (4, 4') is that the inner surface of one end of the arc-shaped hole 711' on the pallet 71' that is finally fixed together with the fixed splint arm 4 is the limit pin 41' When the back-moving spring 6 stretches the two splint arms (4, 4 ') to the limit pin 41 ' and when the other end inner surface of the arc hole 711 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com