Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Allow for any form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

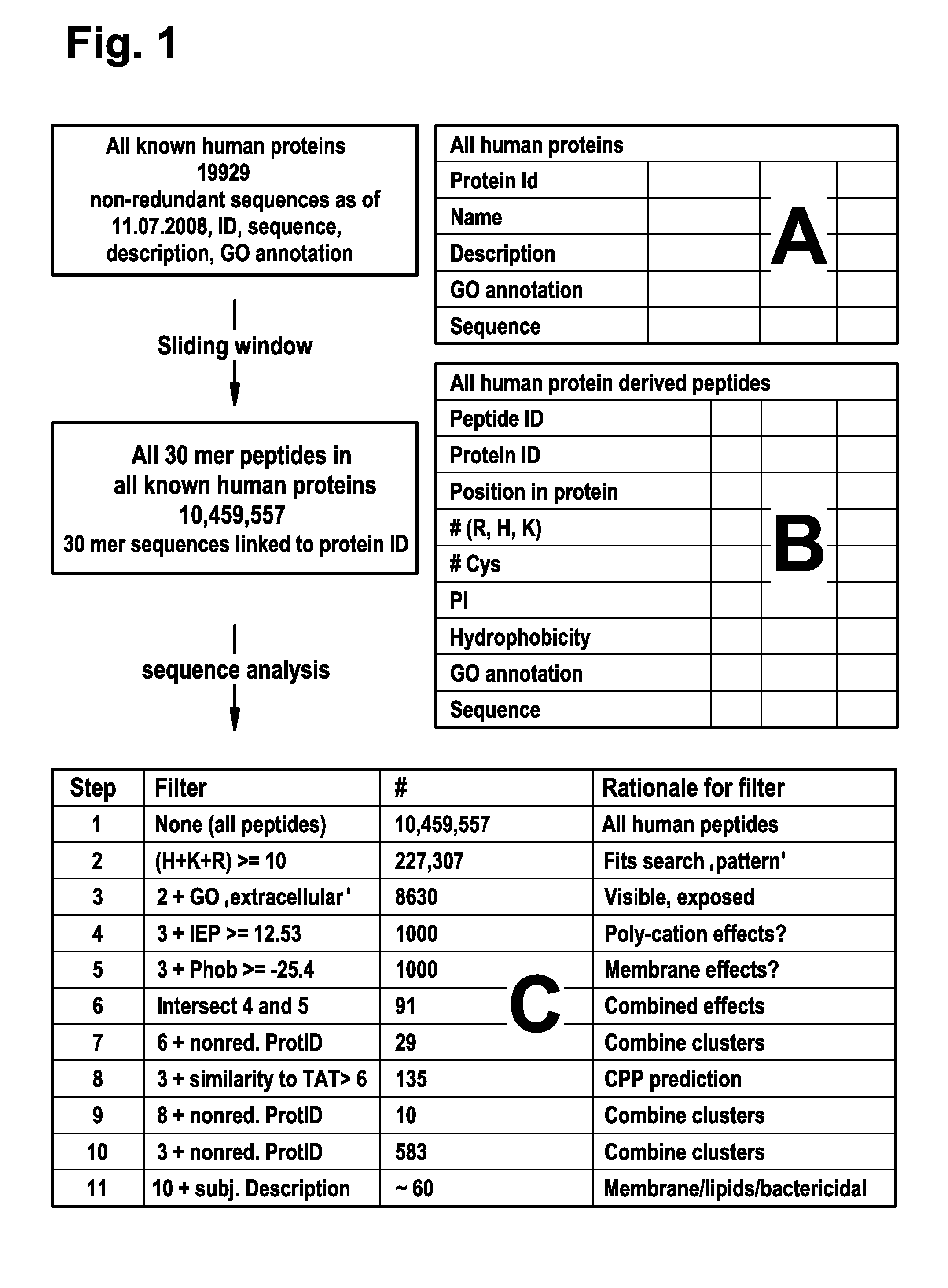

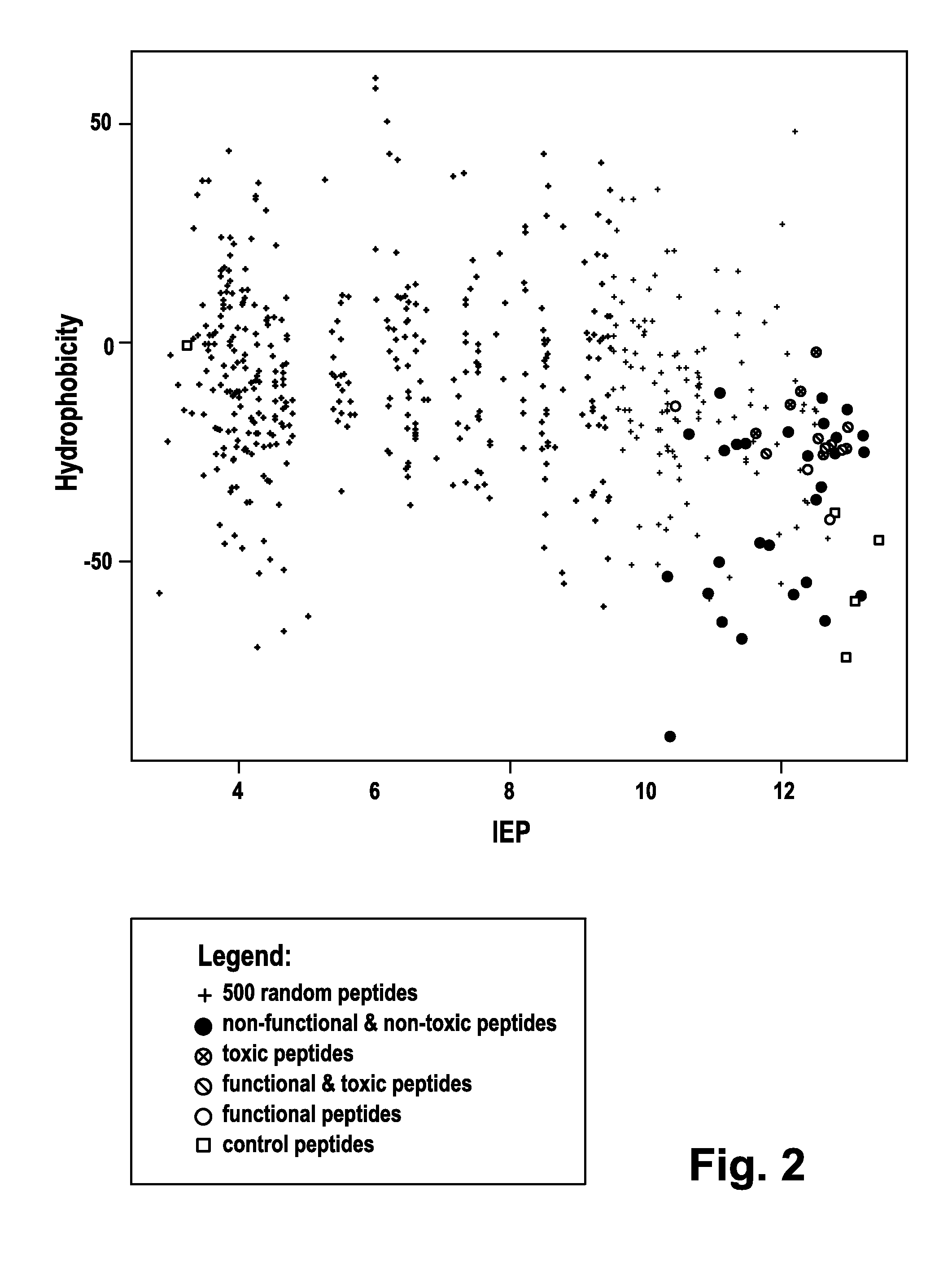

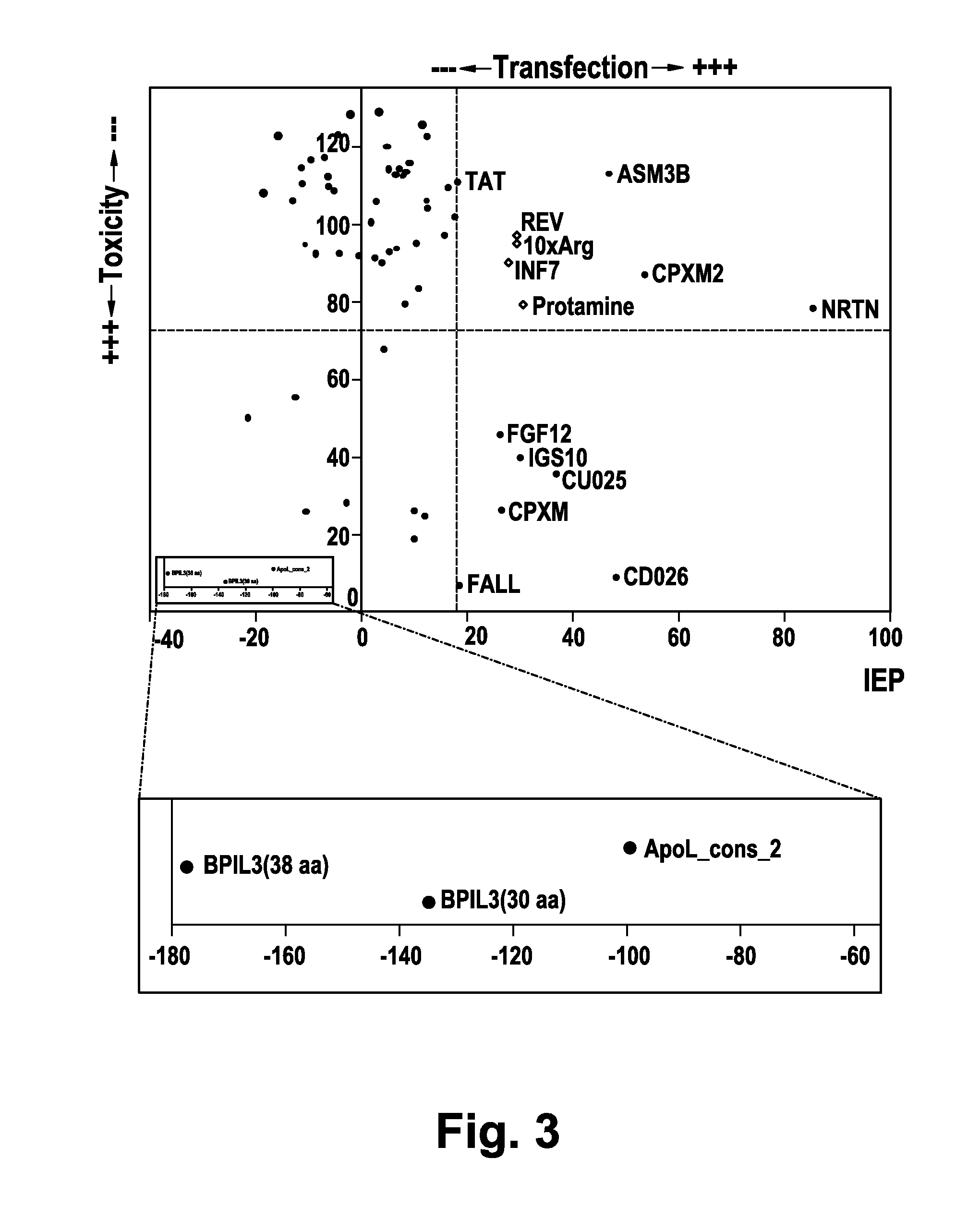

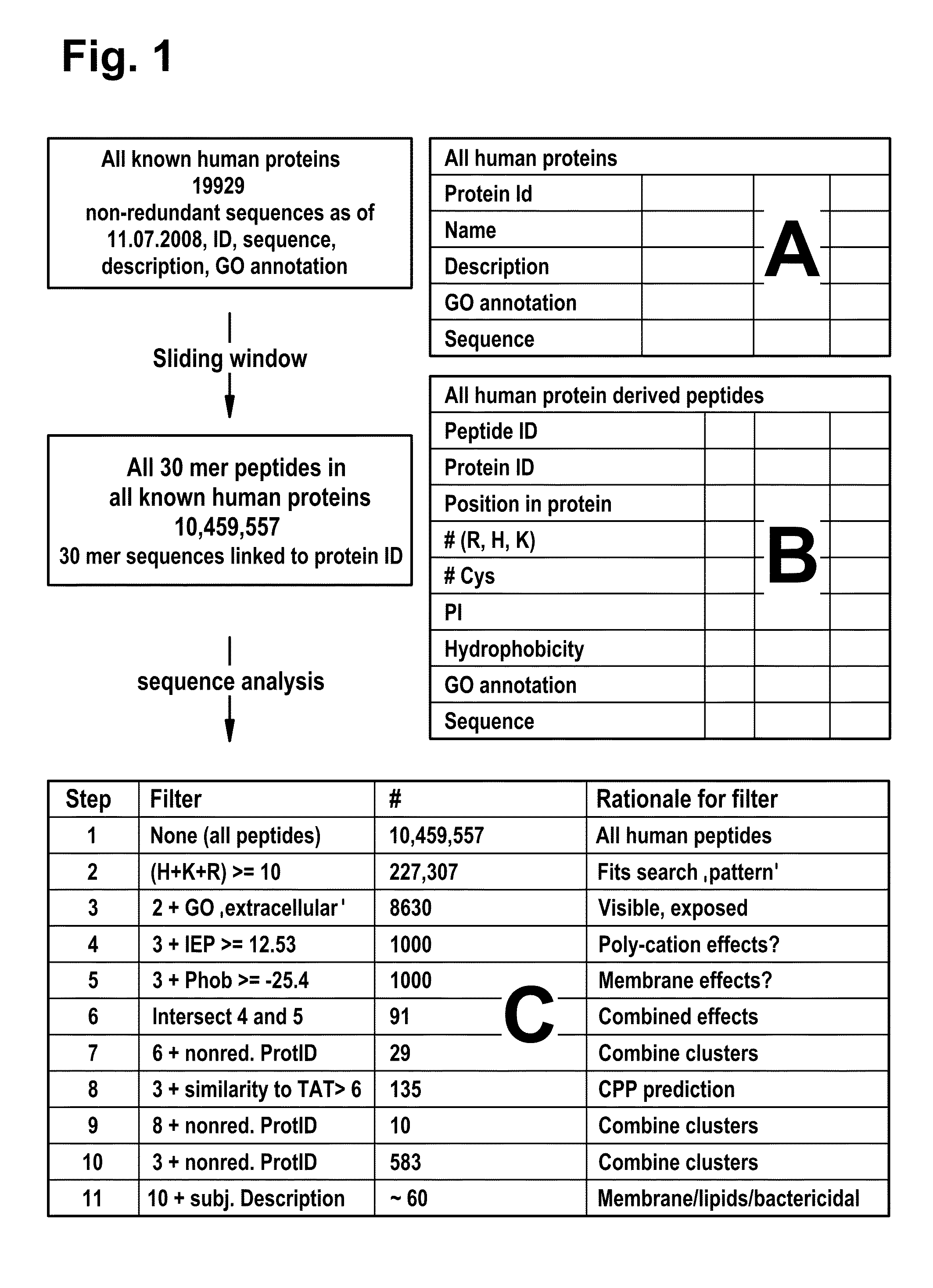

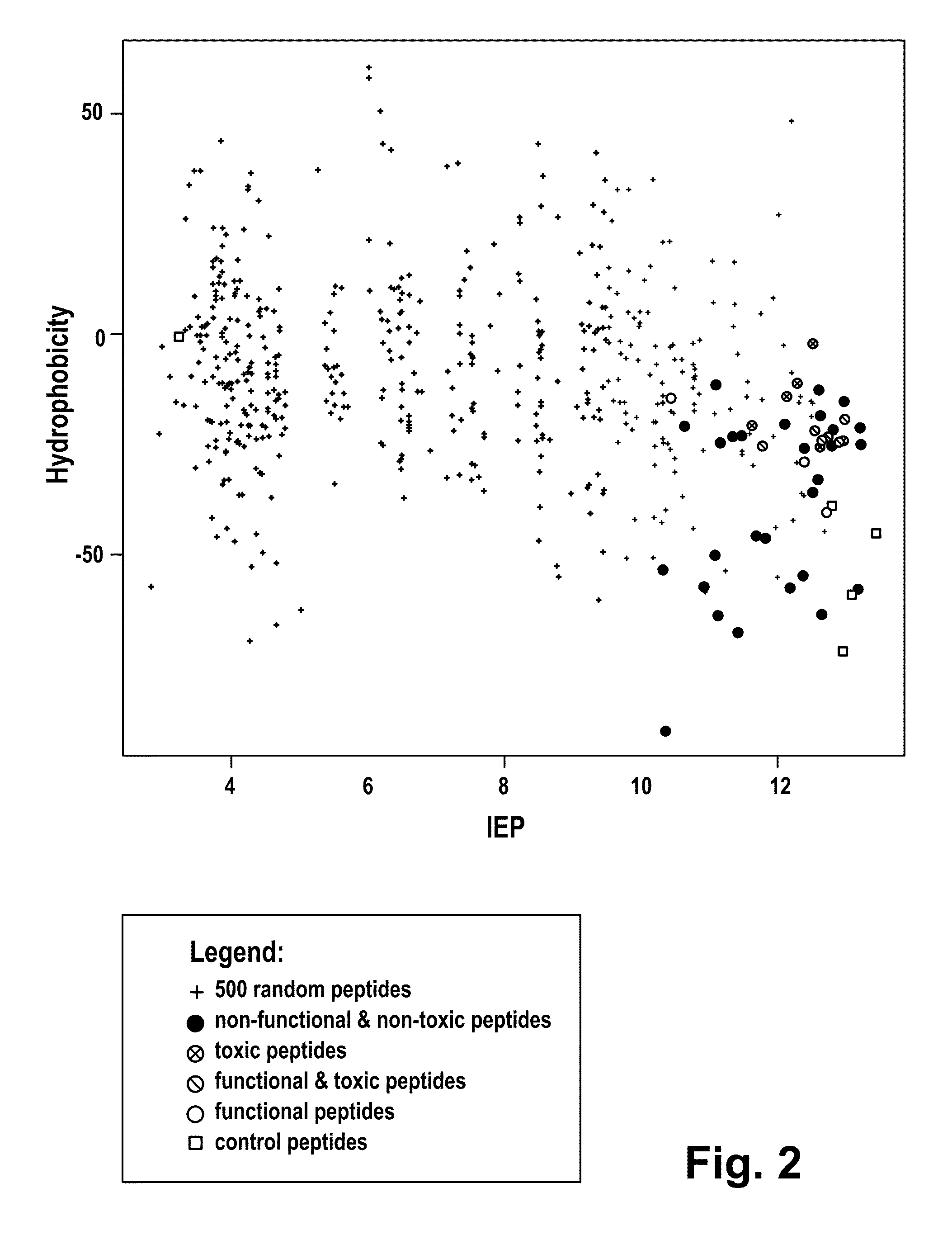

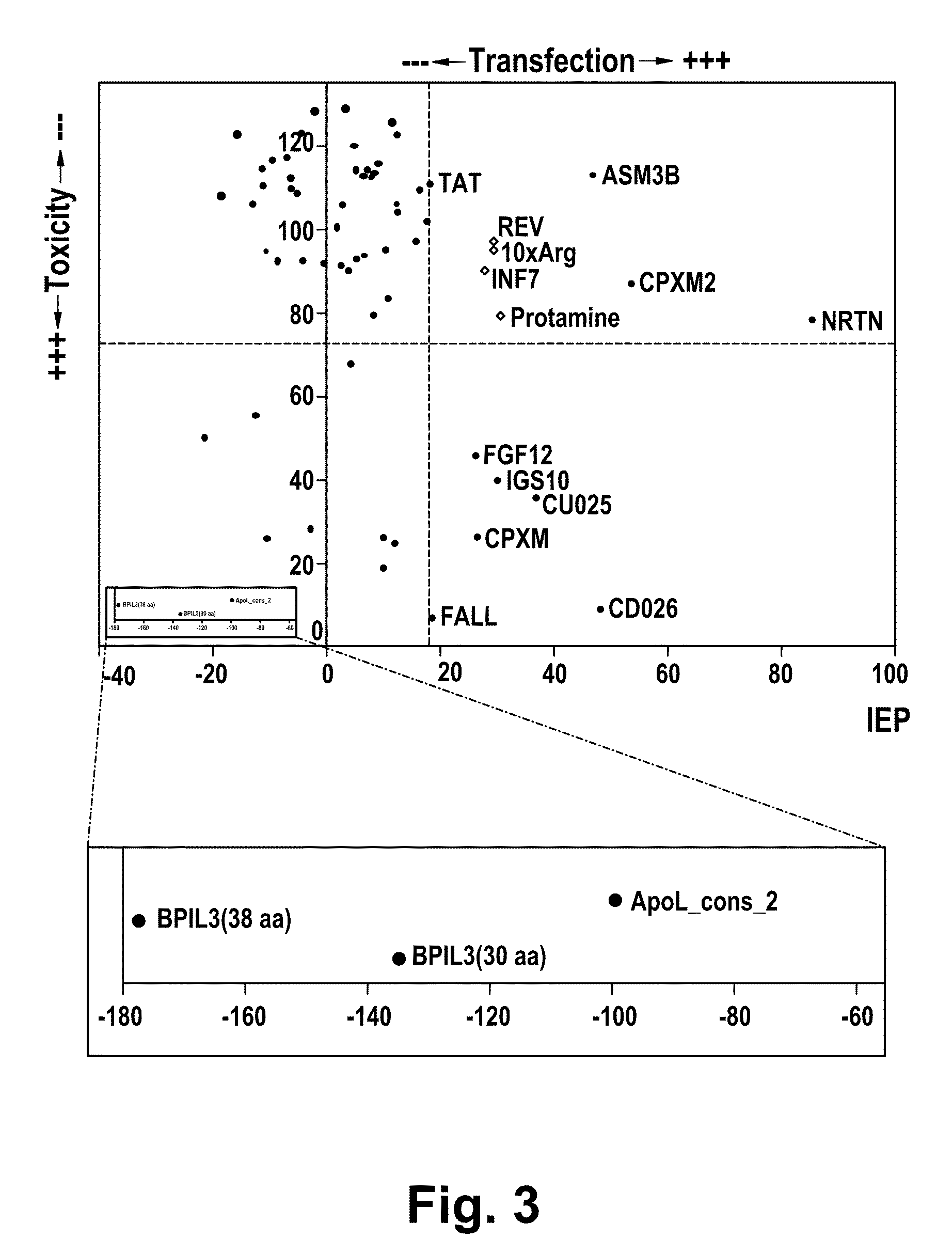

Cell-penetrating peptides and uses thereof

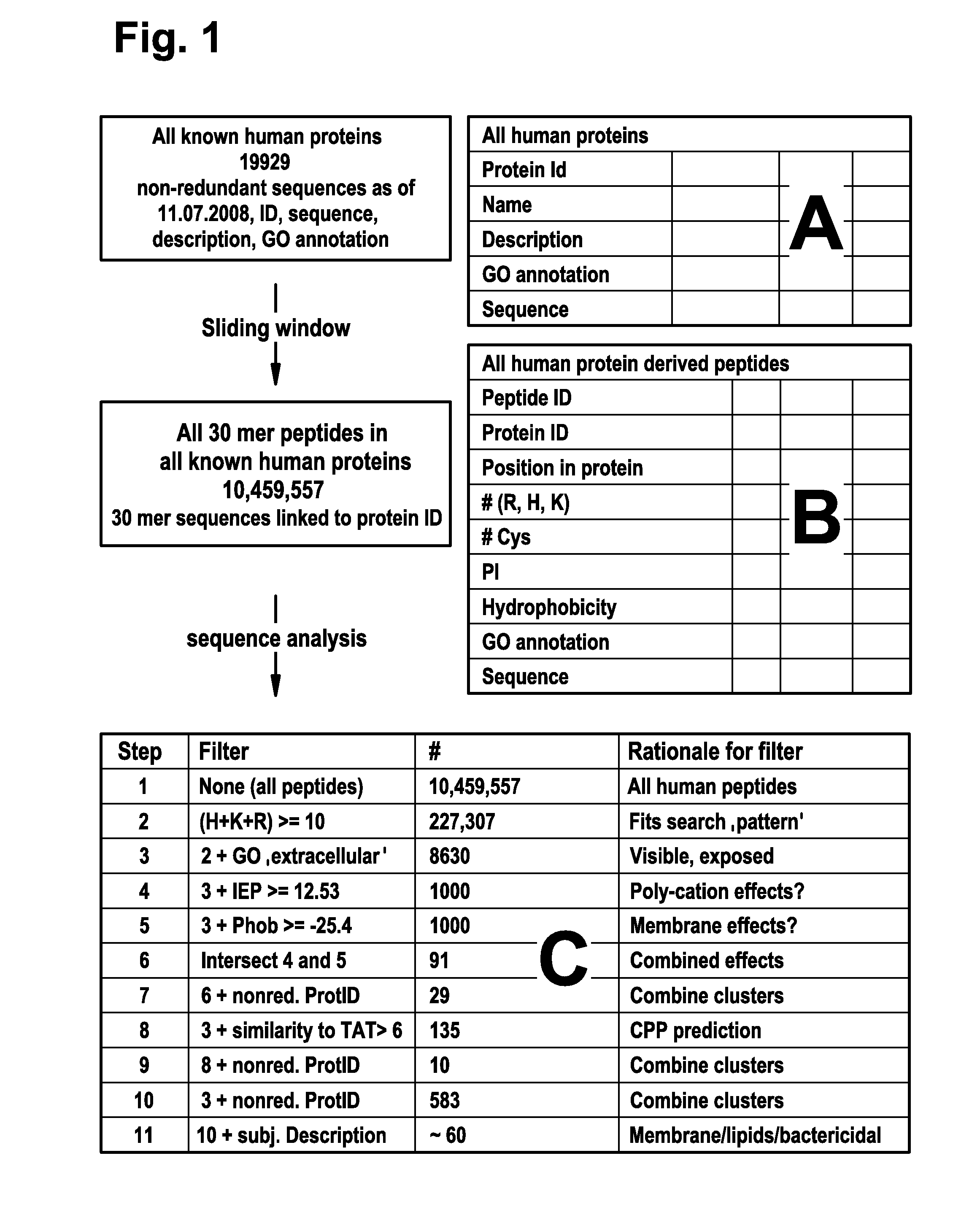

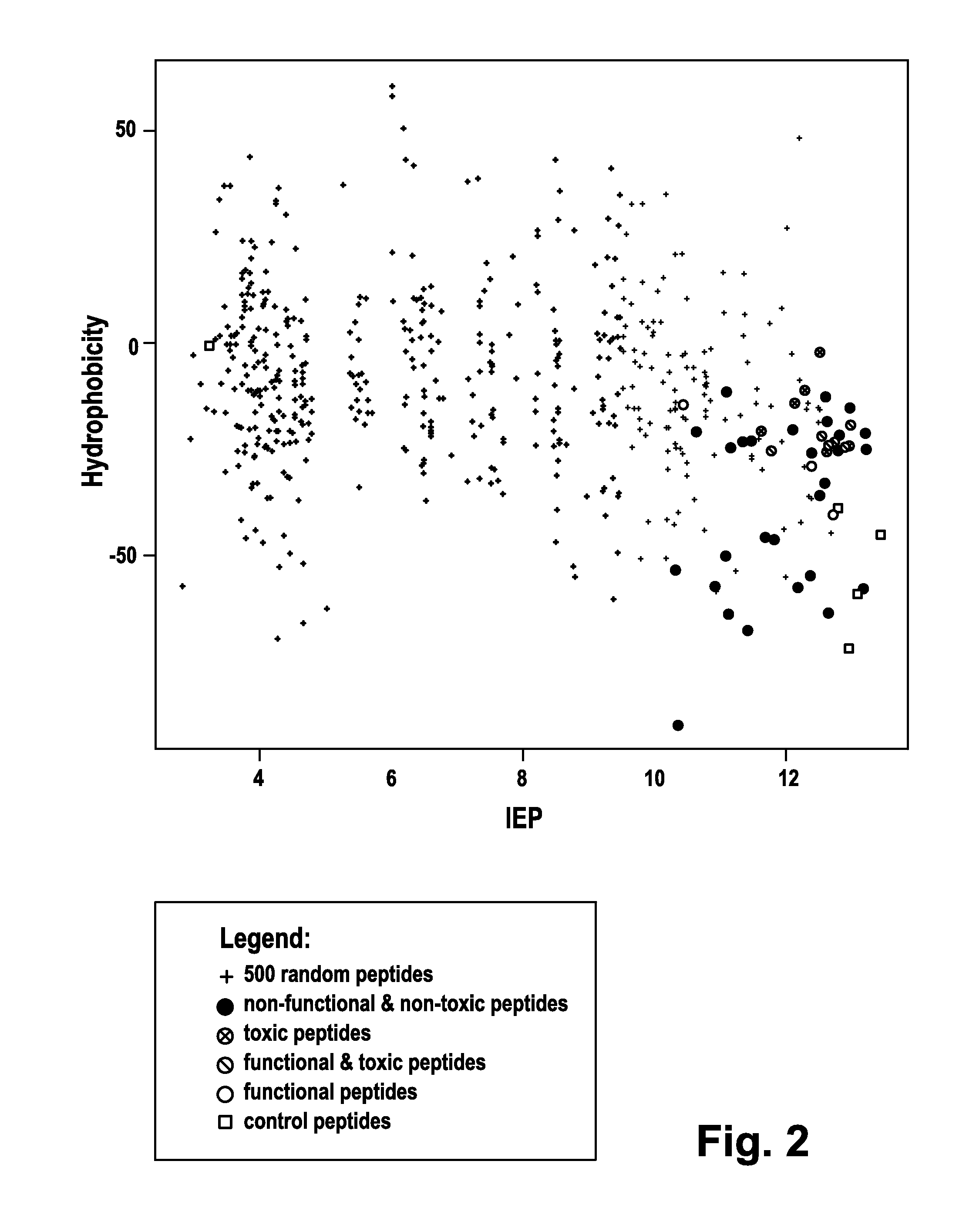

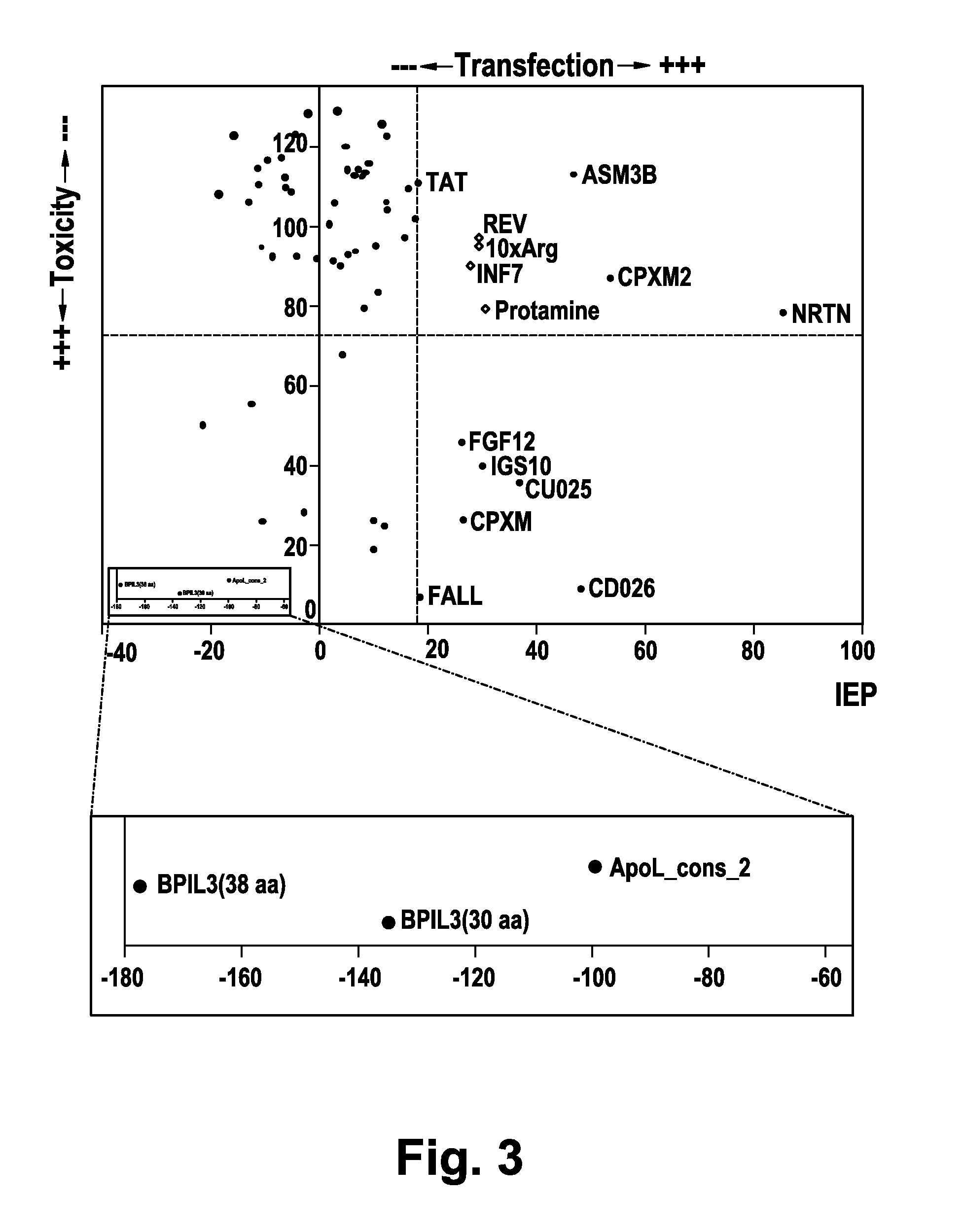

The present invention relates to the identification and functional characterization of human cell-penetrating peptides (CPPs) and their use; in particular as transfection vehicles.

Owner:F HOFFMANN LA ROCHE INC

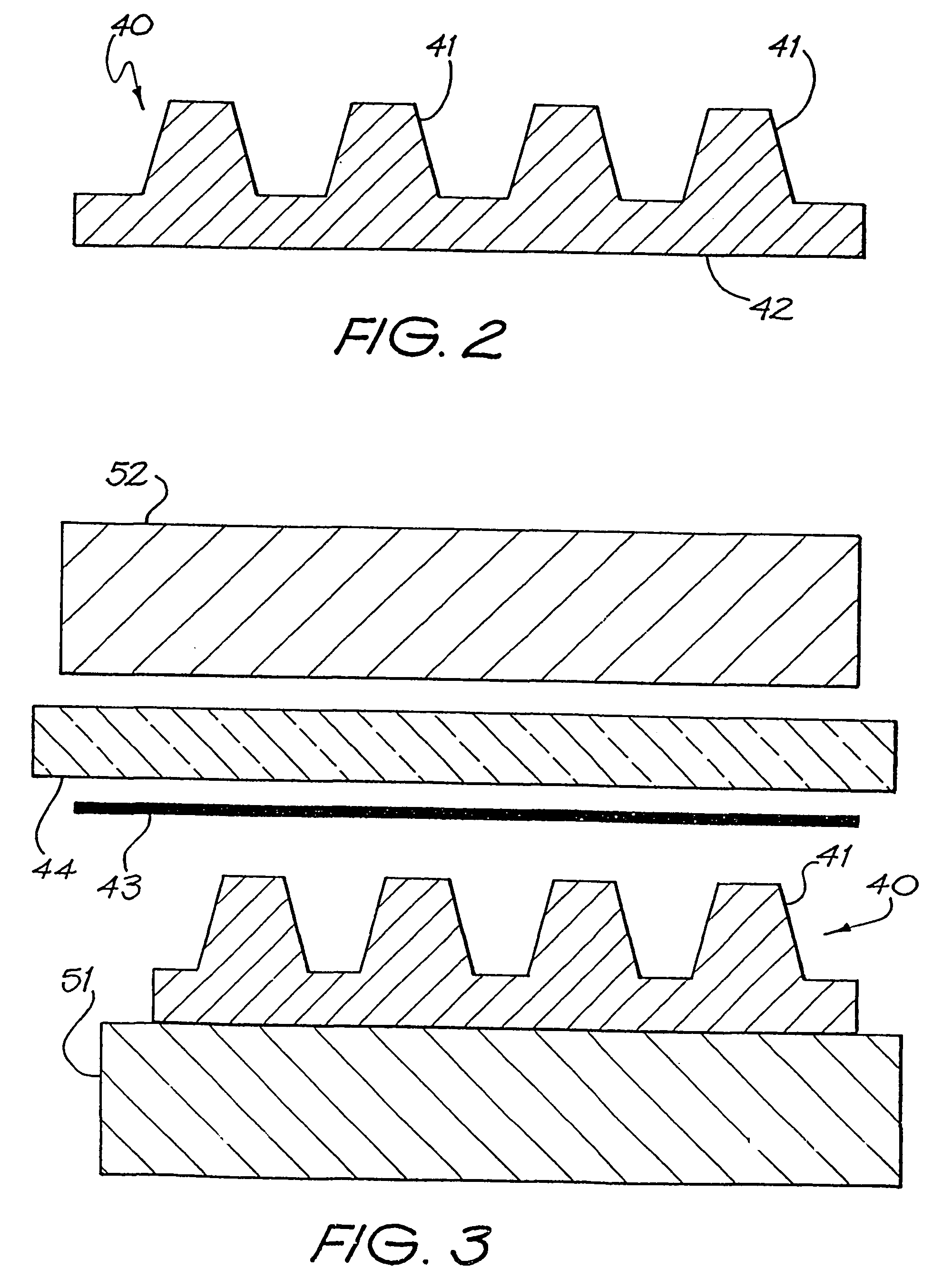

Process for manufacturing electronically conductive components

InactiveUS20070251082A1Allow for any formElectrical transducersHead electrodesElectrical resistance and conductanceConductive materials

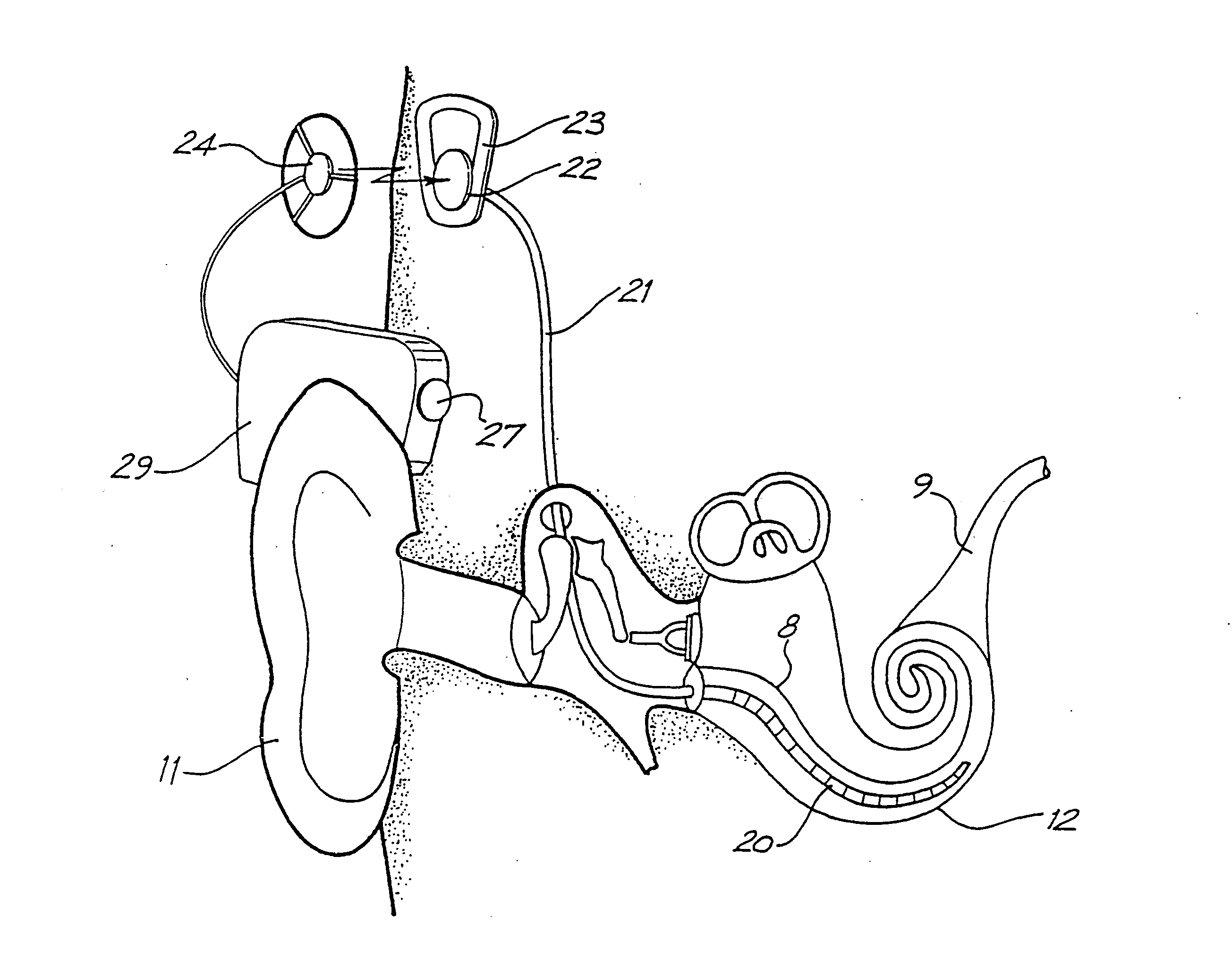

A method of forming a device, such as an electrode array for a cochlear implant. The method comprises a step of forming a predetermined pattern of relatively electrically conductive regions and relatively electrically resistive regions in a sheet of biocompatible electrically conductive material, such as platinum foil. The method can comprise a step of working on the sheet to remove predetermined portions therefrom to form the one or more discrete relatively conducting regions. The step of working on the sheet can comprise embossing the sheet, cutting or slicing the sheet, or using electrical discharge machining (EDM) to remove unwanted portions of the sheet, the EDM equipment having a cutting tool comprising an electrode.

Owner:COCHLEAR LIMITED

Aluminum alloy sheet for lithographic printing plate

InactiveUS20050013724A1Improve uniformityGood coarsening effectPlate printingFoil printingAlloySoftening

The present invention provides an aluminum alloy sheet for a lithographic printing plate which allows pits to be uniformly formed by electrochemical roughening, and excels in strength and heat softening resistance. The aluminum alloy sheet for a lithographic printing plate includes 0.1-0.3% of Mg, more than 0.05%, but 0.5% or less of Zn, 0.2-0.6% of Fe, 0.03-0.15% of Si, 0.02% or less of Cu, and 0.003-0.05% of Ti, the remainder being Al and impurities. The aluminum alloy sheet may include more than 0.05%, but 0.3% or less of Mn.

Owner:SUMITOMO LIGHT METAL INDS LTD +1

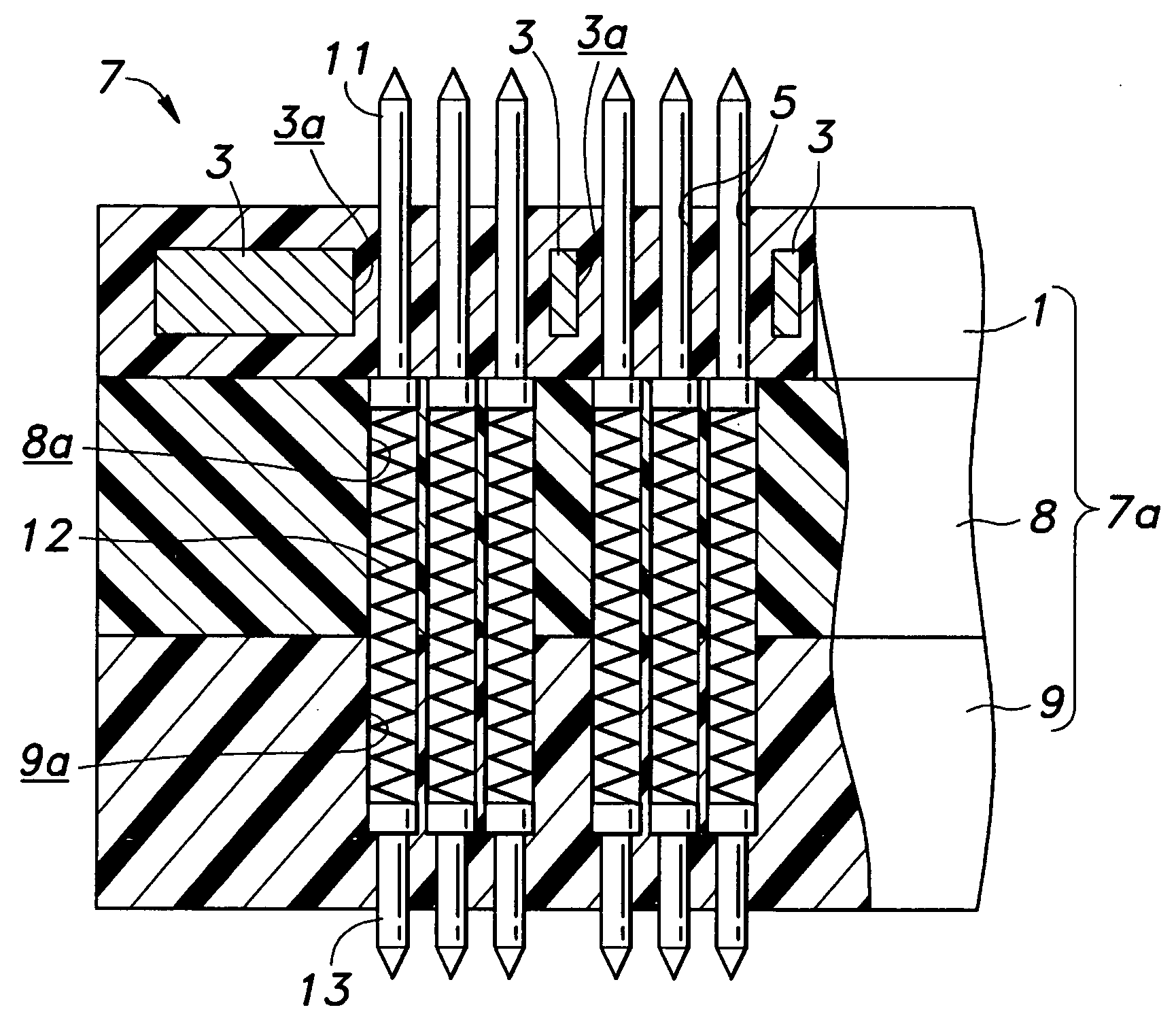

Process for manufacturing electrically conductive components

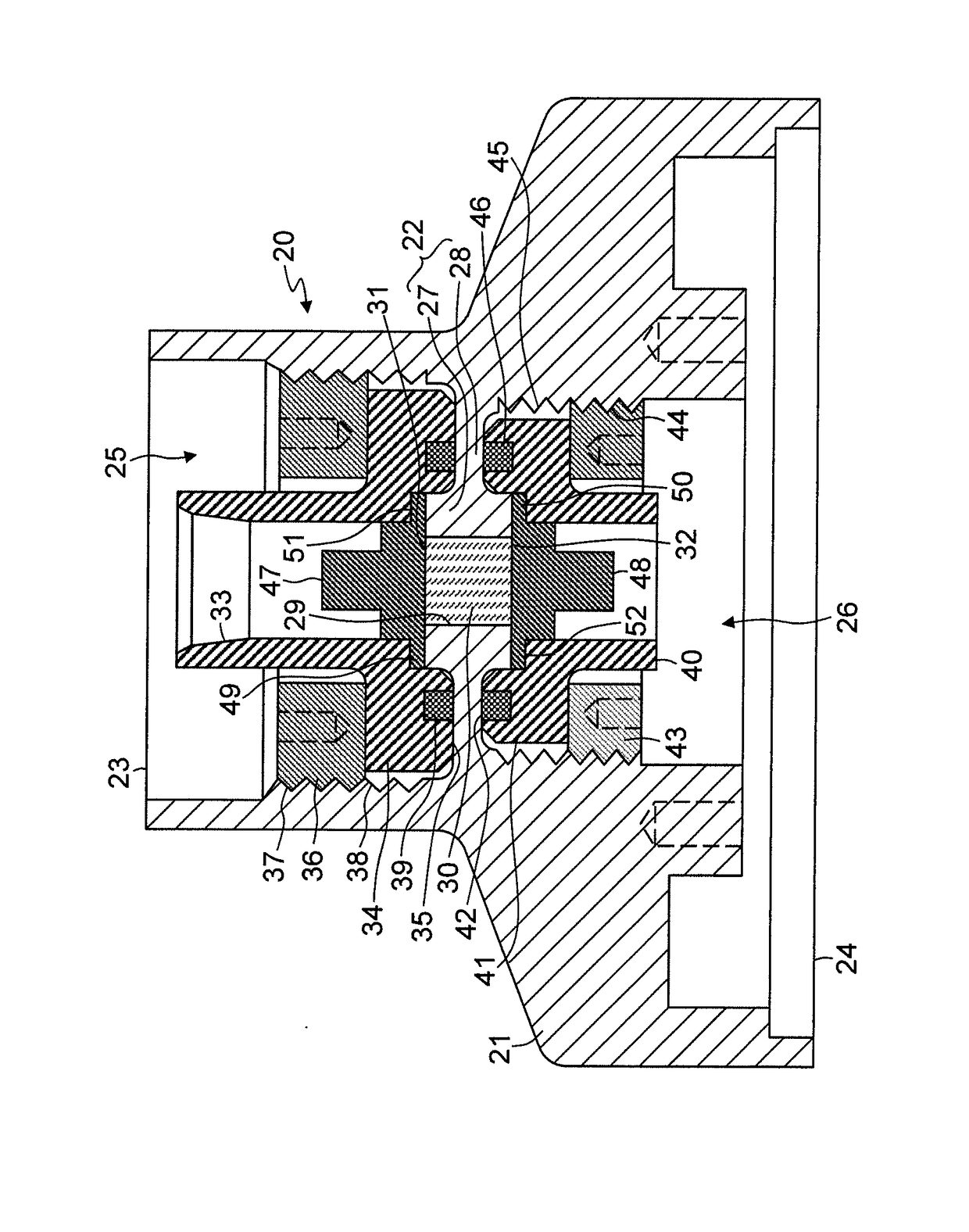

InactiveUS7240416B2Minimise such pittingNot be excludedEar treatmentWave amplification devicesElectrical resistance and conductancePlatinum foil

A method of forming a device, such as an electrode array for a cochlear implant. The method comprises a step of forming a predetermined pattern of relatively electrically conductive regions and relatively electrically resistive regions in a sheet of biocompatible electrically conductive material, such as platinum foil. The method can comprise a step of working on the sheet to remove predetermined portions therefrom to form the one or more discrete relatively conducting regions. The step of working on the sheet can comprise embossing the sheet, cutting or slicing the sheet, or using electrical discharge machining (EDM) to remove unwanted portions of the sheet, the EDM equipment having a cutting tool comprising an electrode.

Owner:COCHLEAR LIMITED

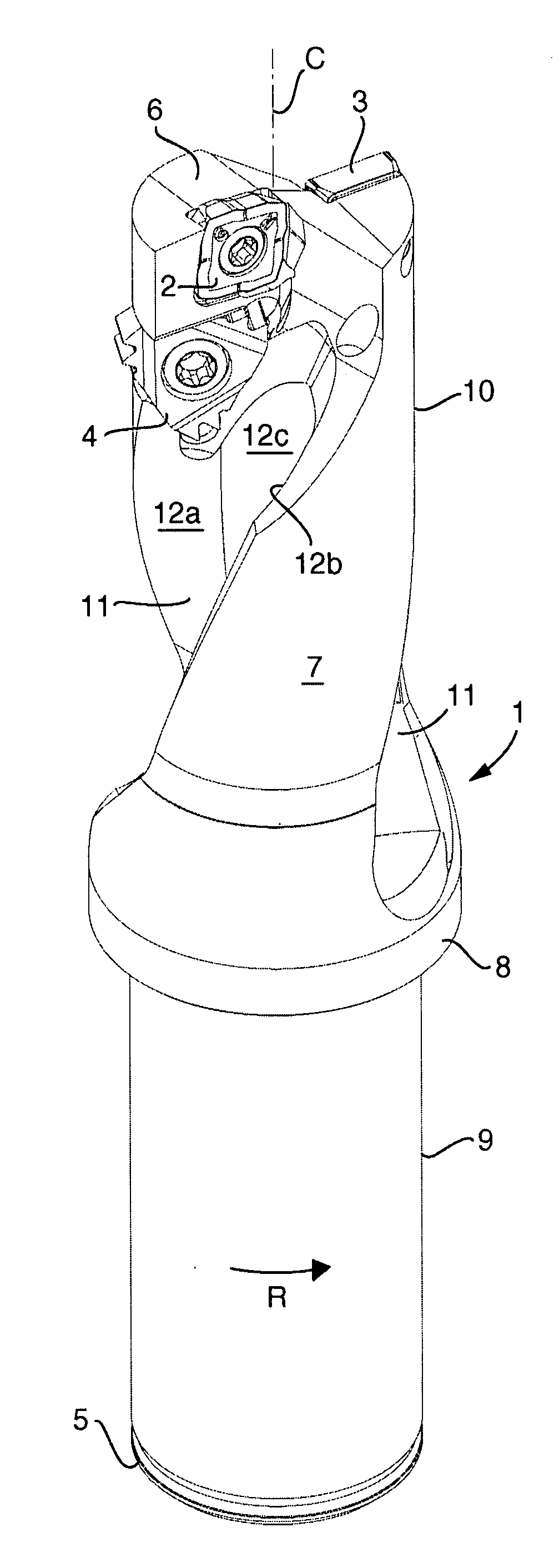

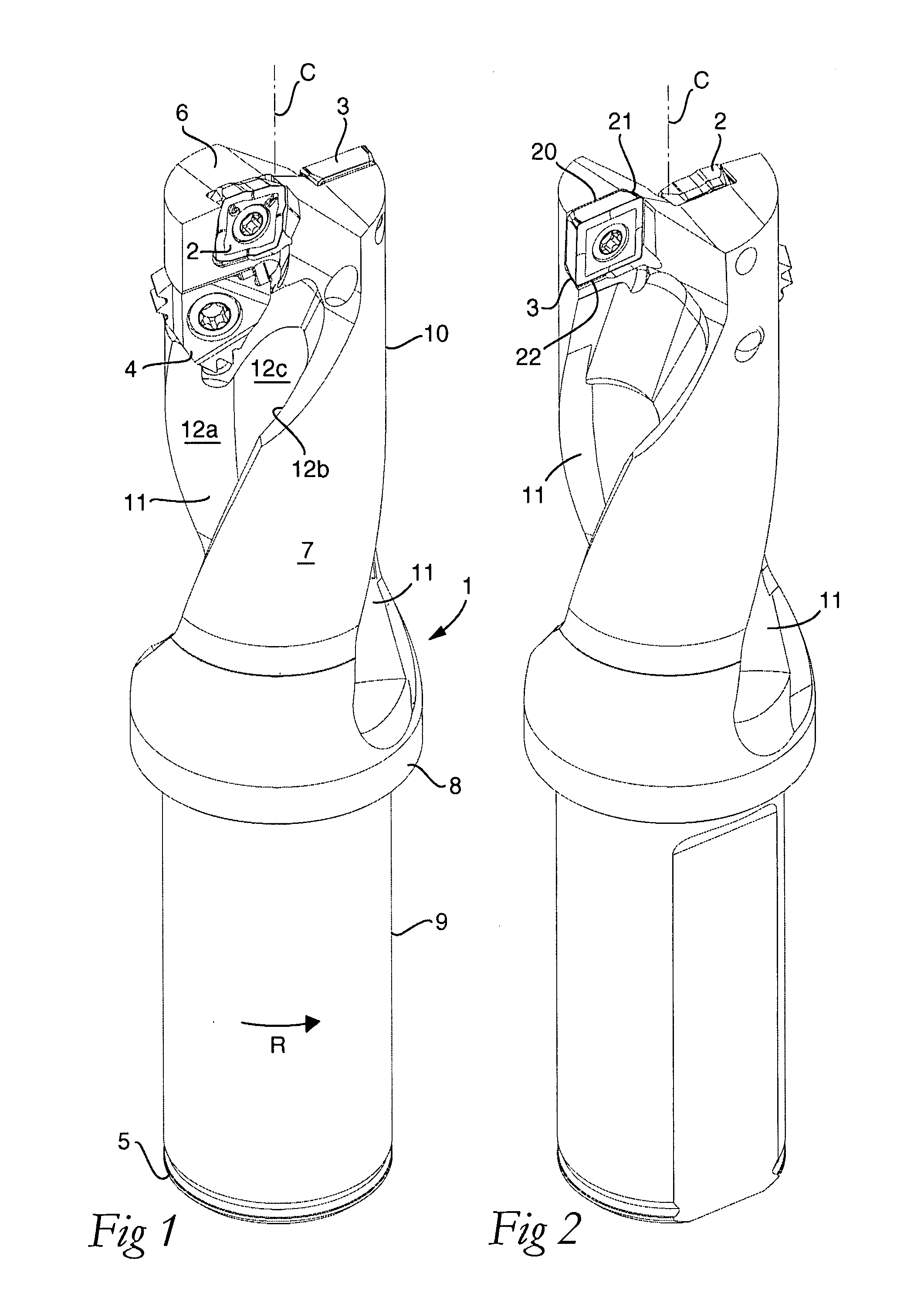

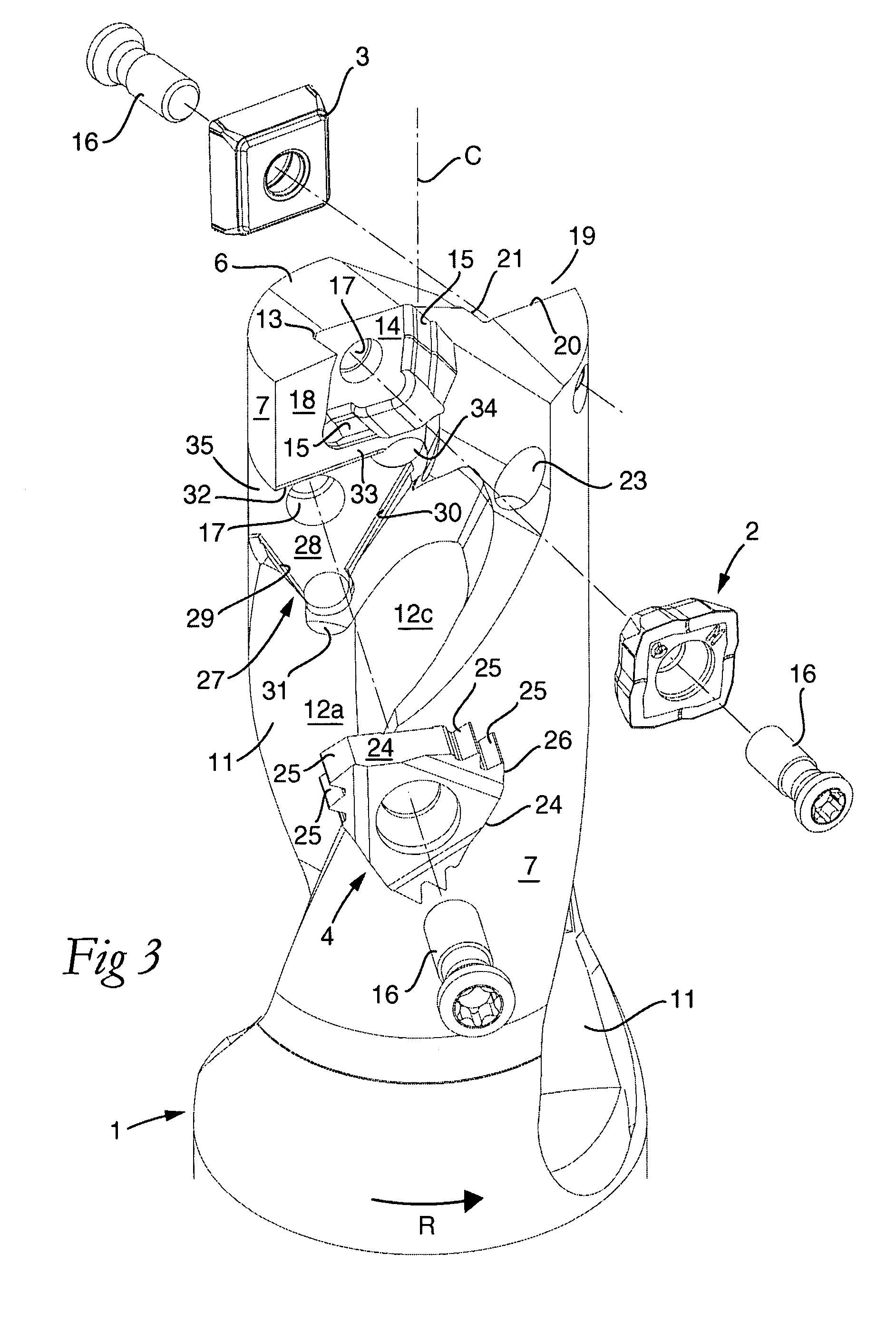

Rotatable multi-operation tool for chip removing machining, and a basic body therefor

InactiveUS20080170921A1Increase flexibilityAllow for any formThread cutting toolsDrilling machinesMachiningEngineering

A rotatable multi-operation tool for chip removing machining, including a plurality of replaceable cutting inserts of different types, and a basic body that is rotatable around a center axis and includes a rear end and a front end from which there is extending rearward an envelope surface in which at least one chip space, delimited by two opposite side surfaces, is countersunk, which opens in the envelope surface and in the front end. A first cutting insert is mounted in a first insert seat that is formed in one side surface of the chip space and situated in the immediate vicinity of the front end and included in a cavity that opens in the front end for the cutting insert to partly protrude axially forward from the front end. A second cutting insert, of a type other than the first cutting insert, is mounted in a second insert seat, which is formed in the same side surface as the first insert seat and situated axially behind the first insert seat. The second insert seat is included in a cavity that opens in a part of the envelope surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

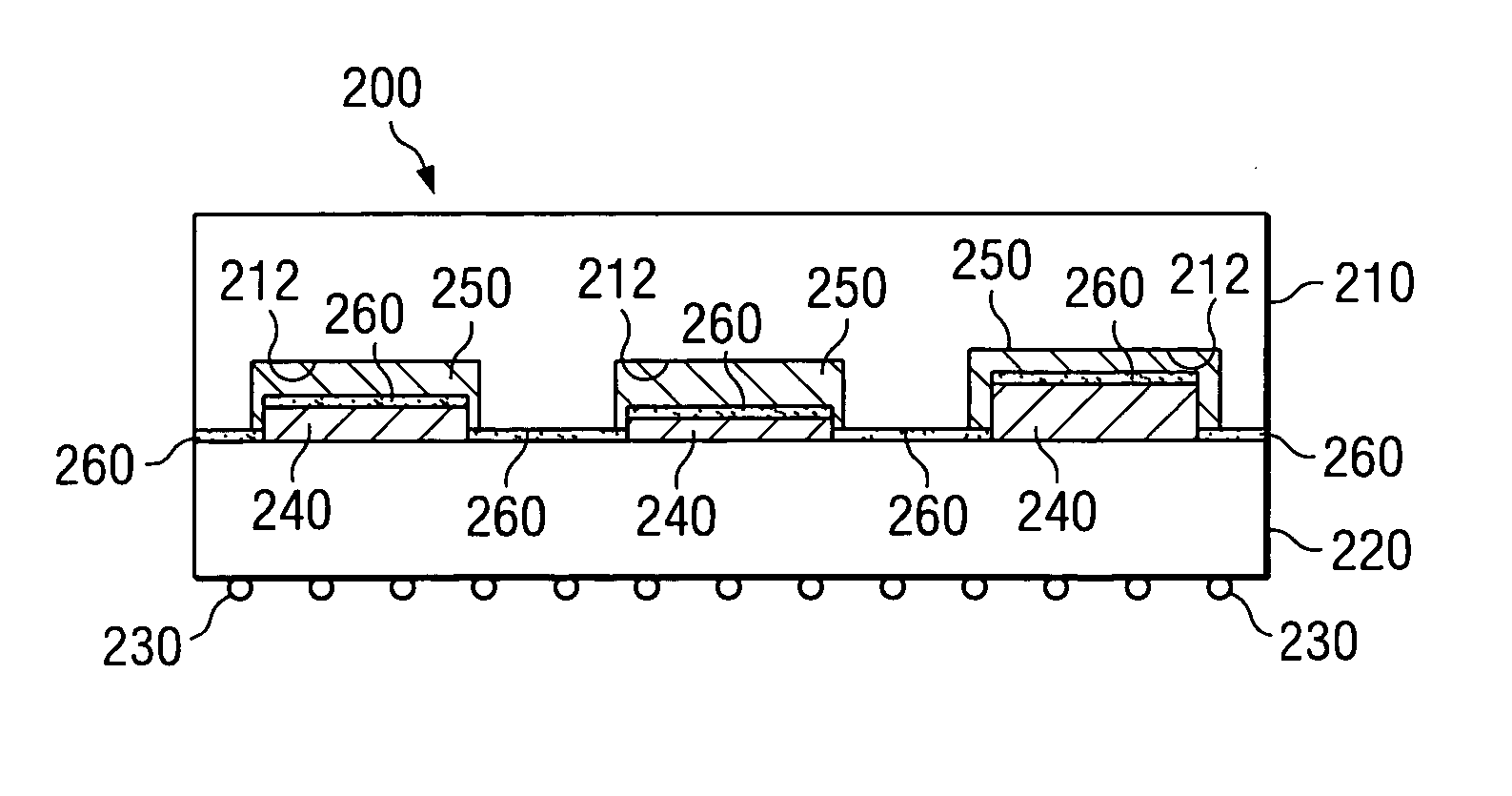

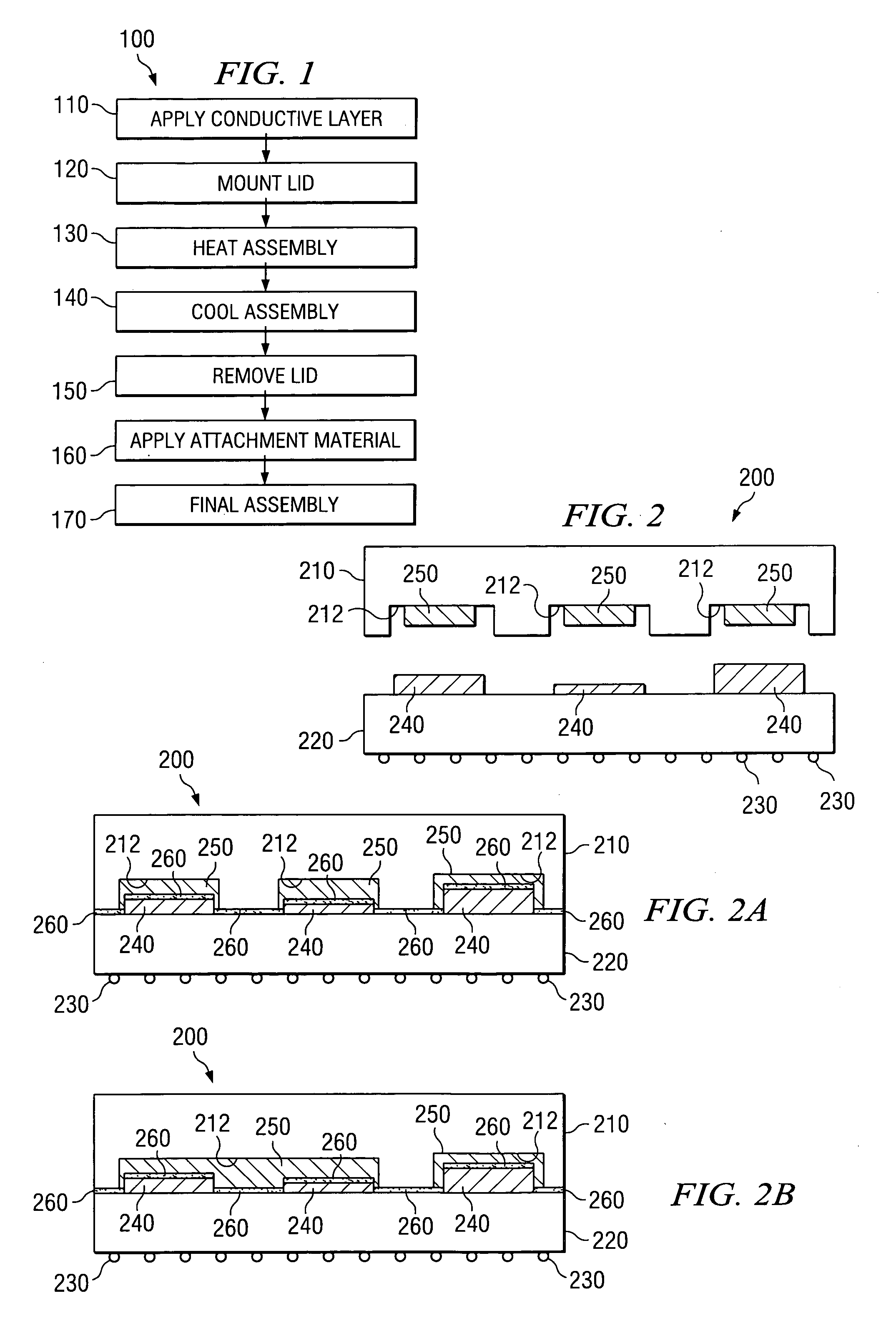

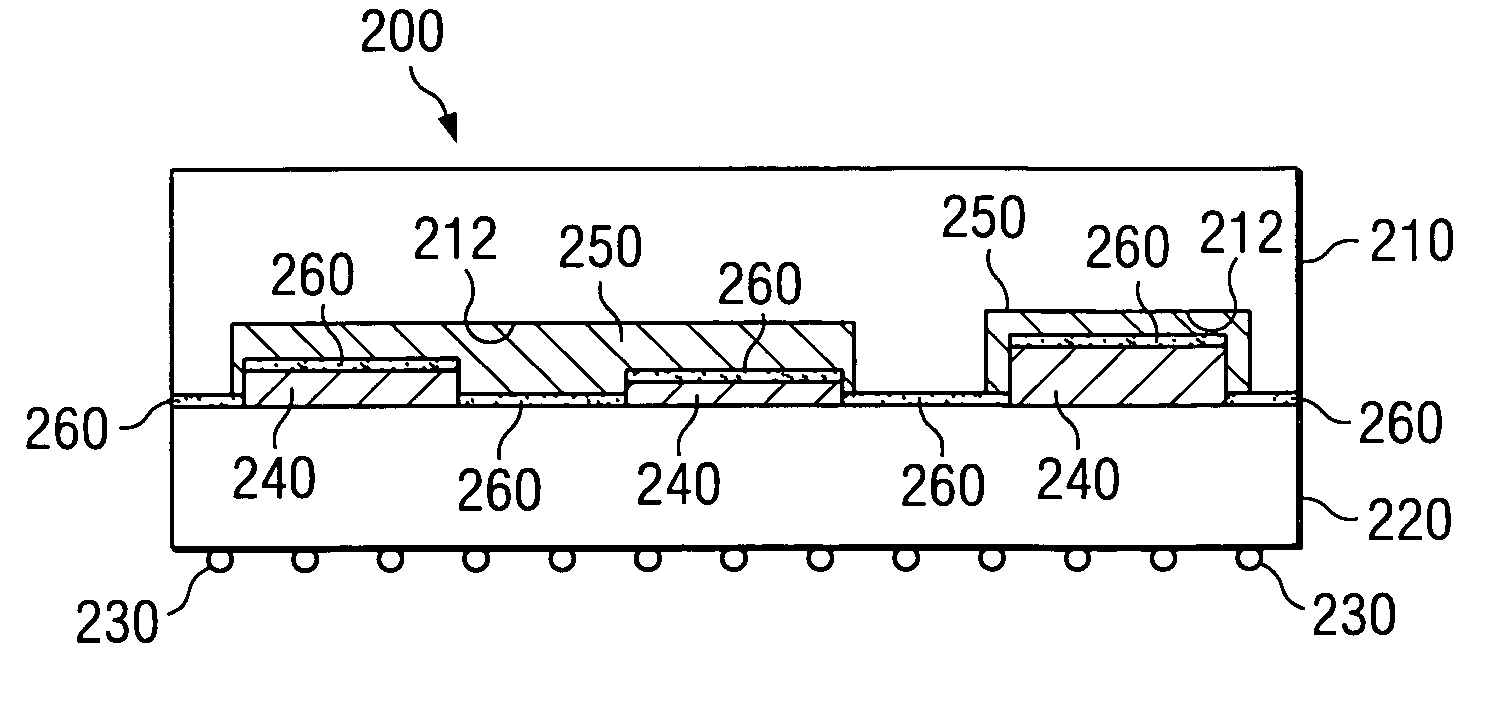

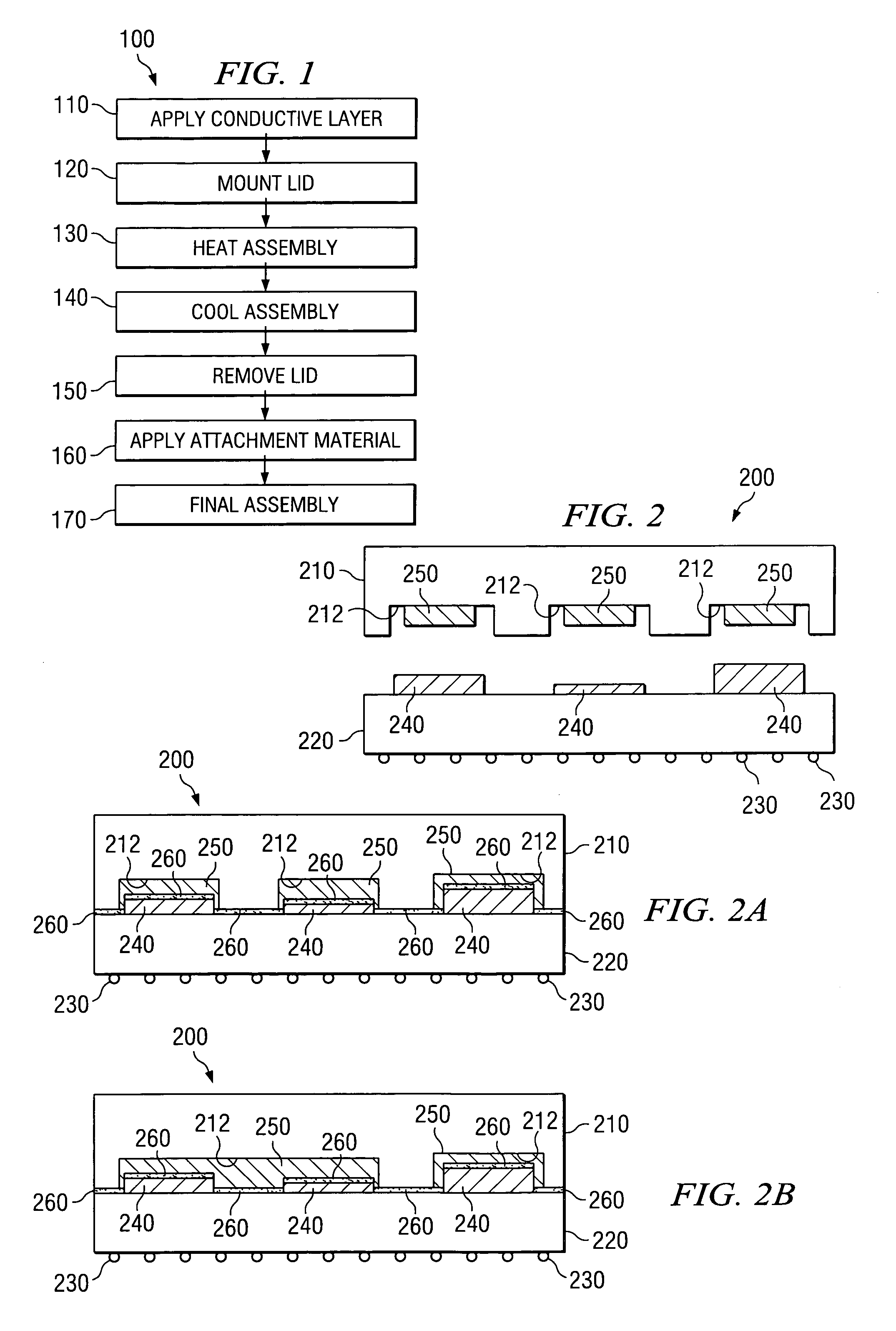

System and method for high performance heat sink for multiple chip devices

ActiveUS20050146021A1Increase thermal conductivityUniform dimensionSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

A custom-molded heat sink corresponds to an individual substrate and includes a heat sink lid having at least one cavity corresponding to at least one die mounted on a substrate. A conductive layer is deposited in the at least one cavity that substantially fills the space between the at least one cavity and the at least one die when the lid is coupled to the substrate.

Owner:TEXAS INSTR INC

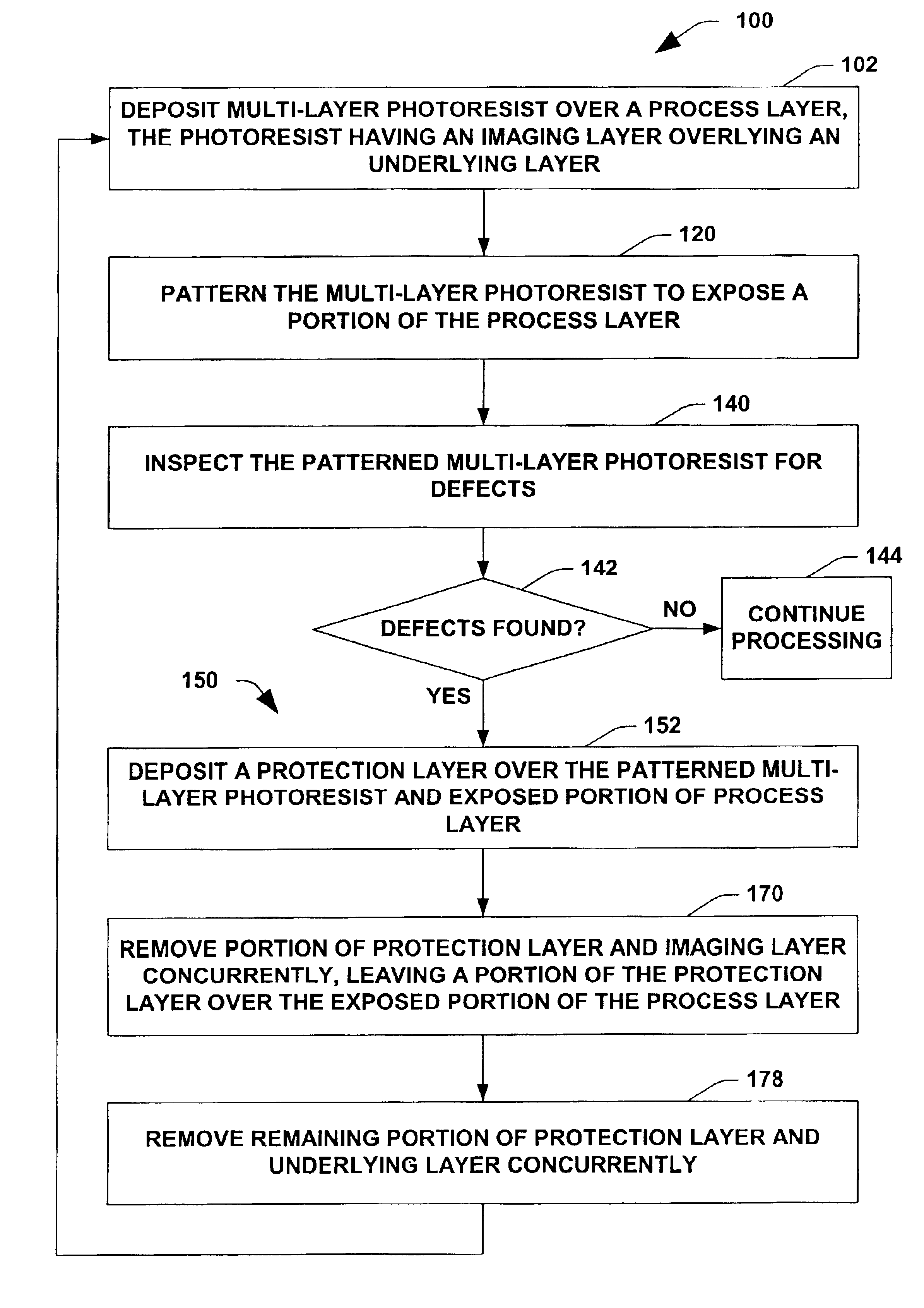

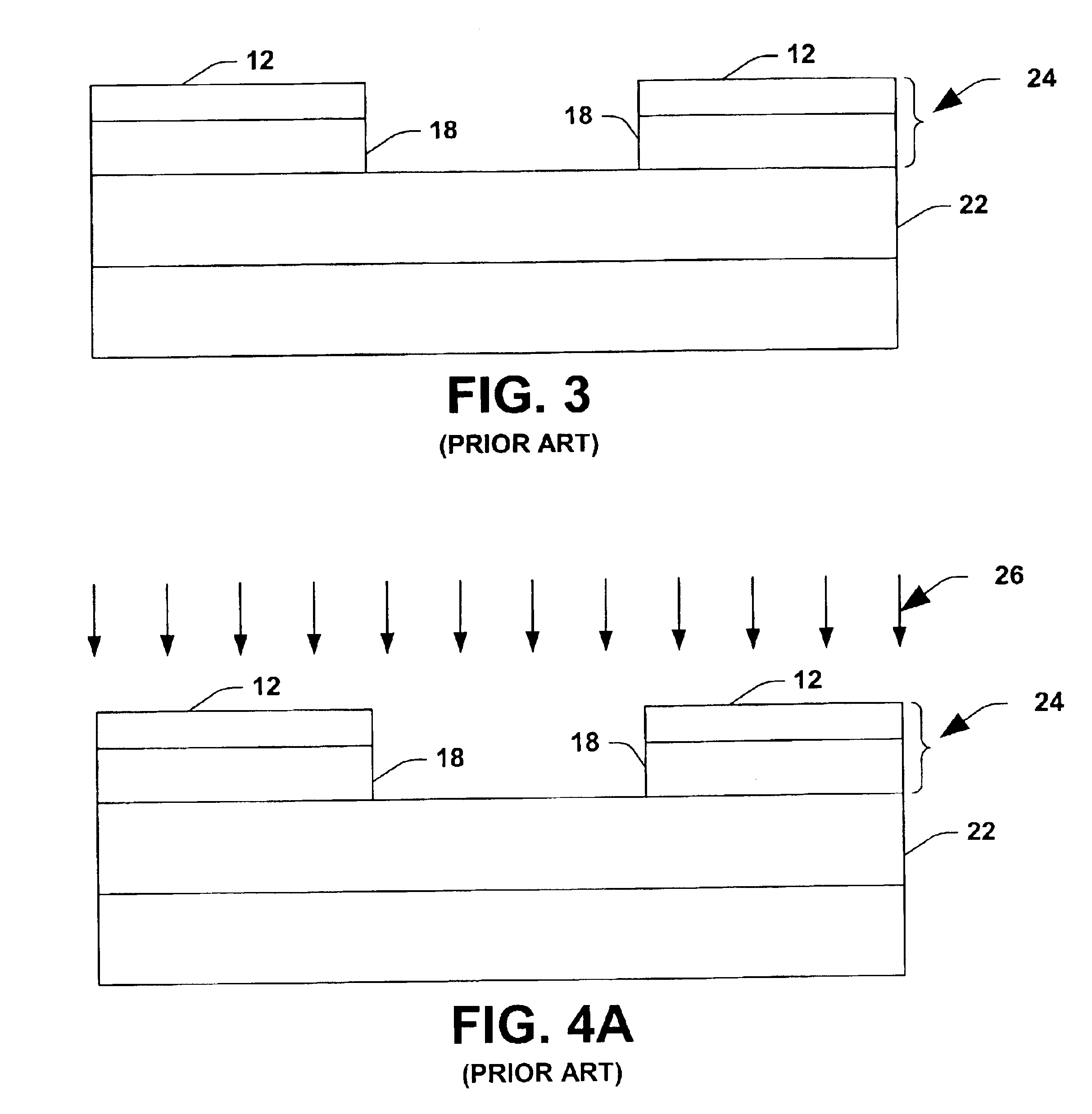

Method for reworking a multi-layer photoresist following an underlayer development

InactiveUS6872663B1Low selectivity etchLow selectivitySemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusPhotoresistResist

A method of processing a semiconductor device is disclosed and comprises patterning a multi-layer photoresist which comprises an imaging layer overlying an underlying layer. The patterning of the resist defines an exposed portion of an underlying process layer. The method further comprises inspecting the patterned multi-layer photoresist for defects and re-working the patterned multi-layer photoresist upon a failed inspection. The re-work process comprises depositing a protection layer over the patterned multi-layer photoresist and over the exposed portion of the underlying process layer. A portion of the protection layer and the imaging layer are then removed in a concurrent manner while leaving a remaining portion of the protection layer covering the exposed portion of the underlying process layer. A remaining portion of the protection layer and the underlying layer are then removed in a concurrent manner and such removal does not adversely impact the process layer.

Owner:GLOBALFOUNDRIES INC

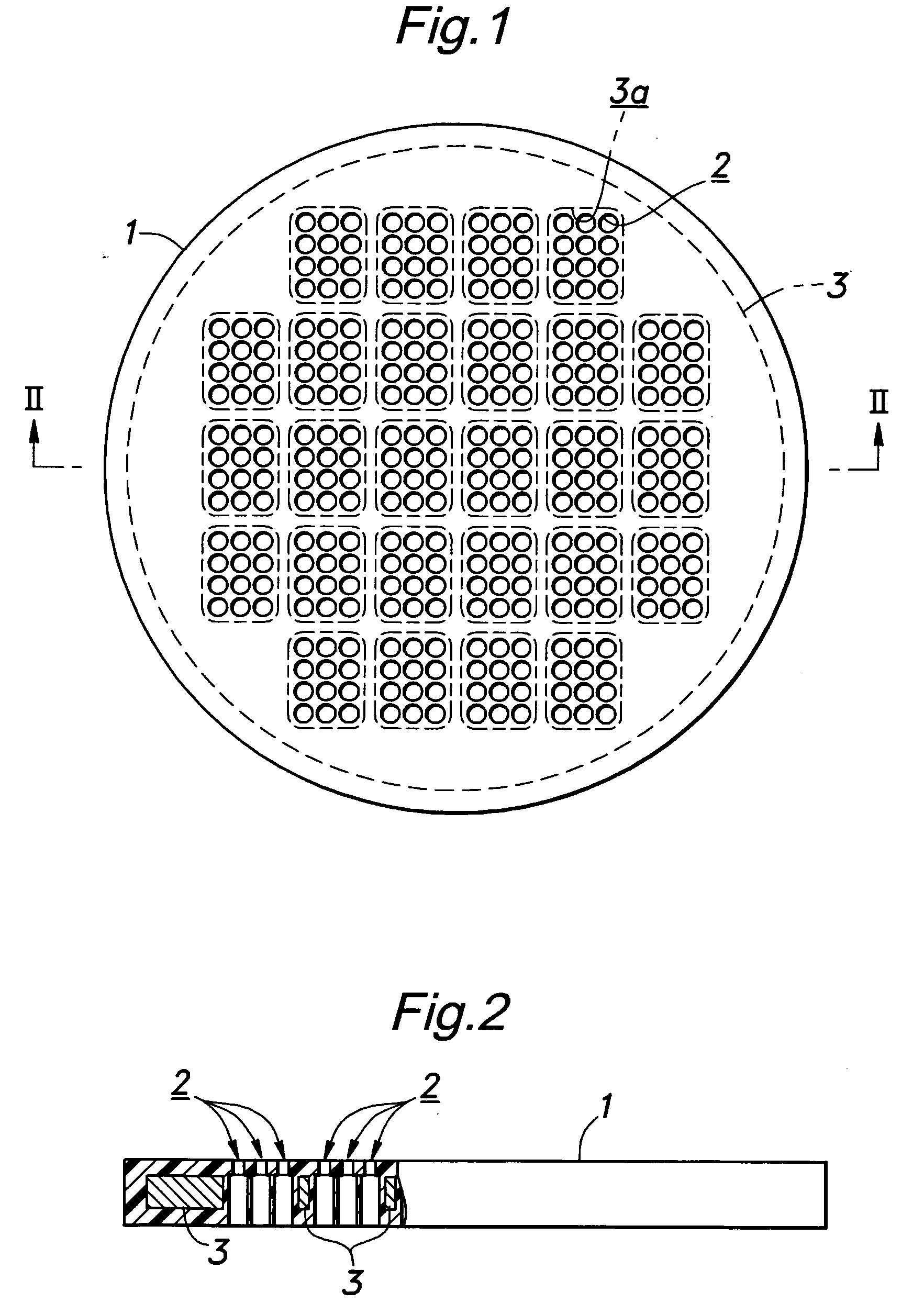

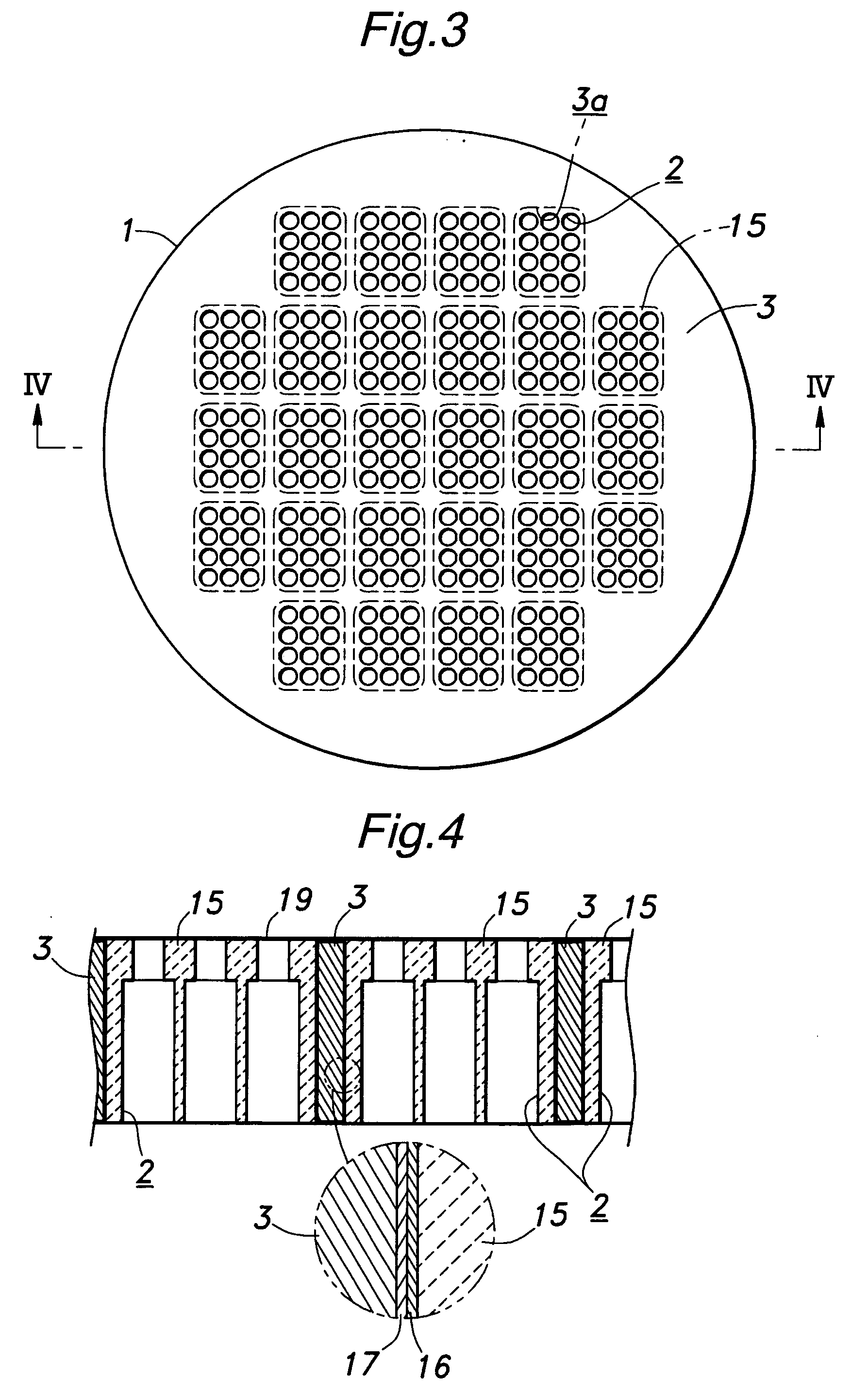

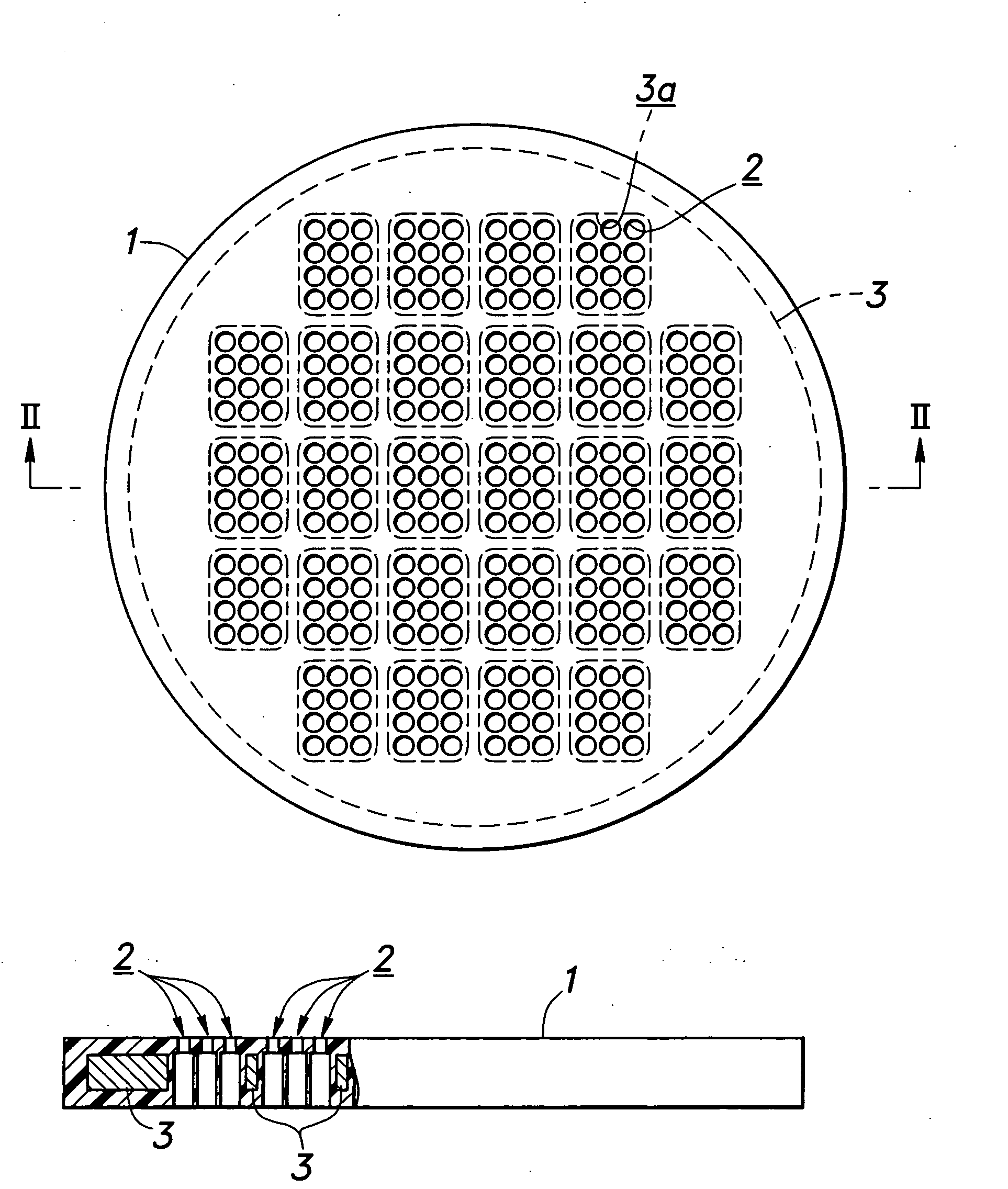

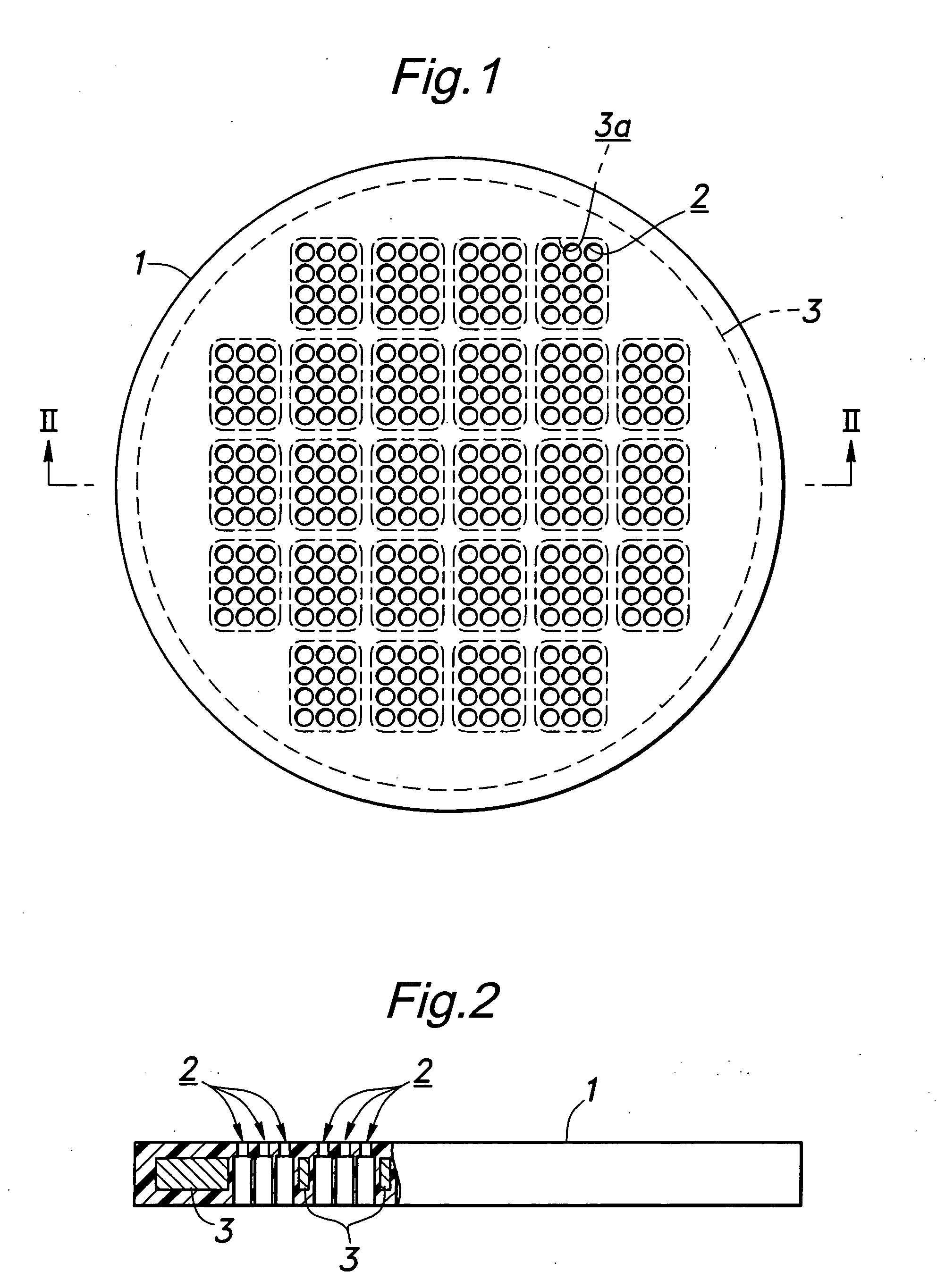

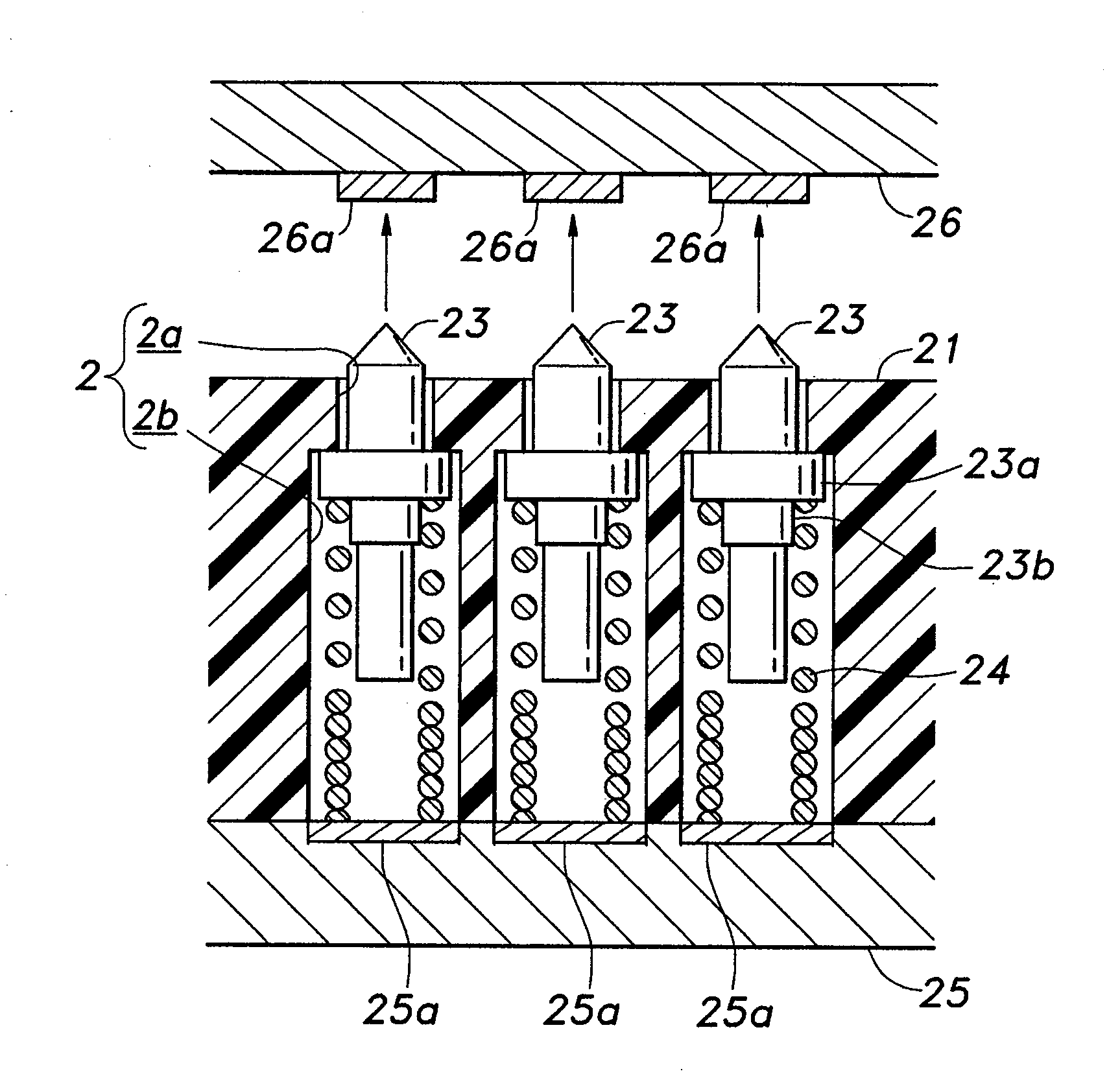

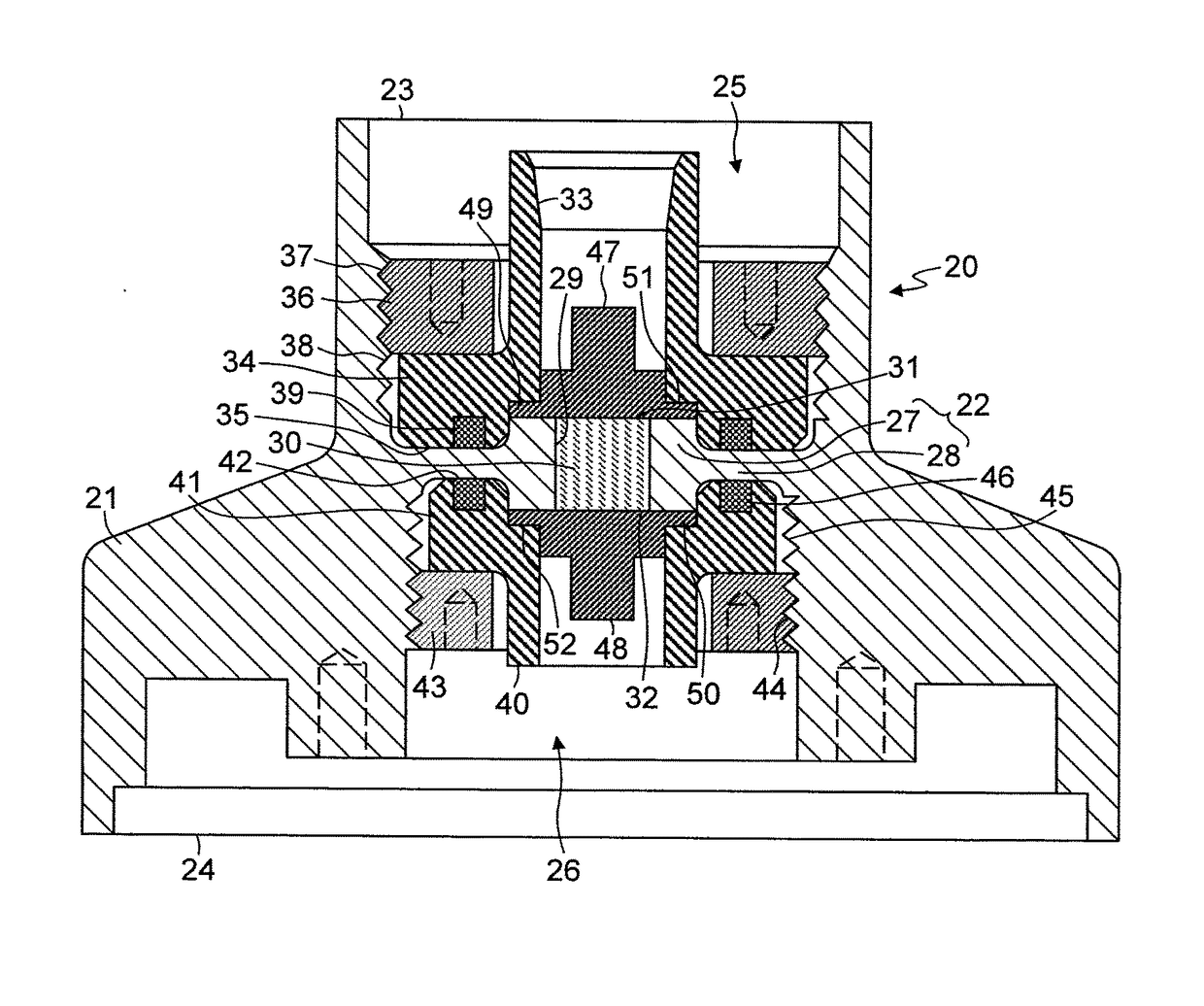

Support member assembly for conductive contact members

InactiveUS20050266734A1Simple processEnsure positioning accuracySemiconductor/solid-state device testing/measurementElectronic circuit testingPlastic materialsThermal deformation

Provided is a support member assembly suitable for use in a contact probe head comprising a support member formed with a plurality of holder holes for supporting conductive contact members in a mutually parallel relationship, and a reinforcing member integrally formed with the support member and extending in a part of the support member devoid of any holder holes. The reinforcing member increases the overall mechanical strength of the support member assembly, and prevents the thermal deformation of the support member. Because the holder holes are formed in the support member made of material suitable for forming holes, such as plastic material and ceramic material, the holder holes can be formed at high precision and at low cost.

Owner:NHK SPRING CO LTD

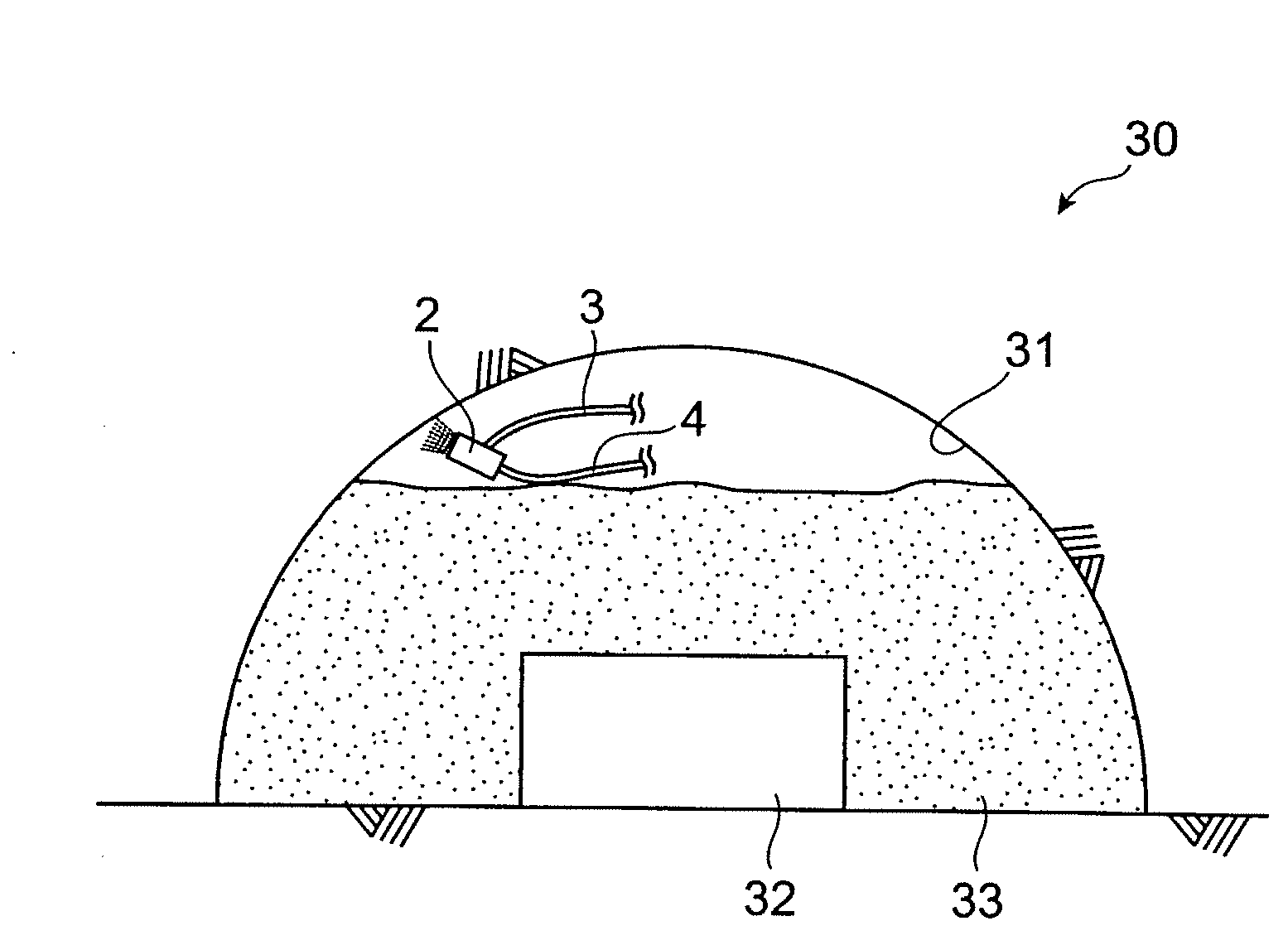

System and method for high performance heat sink for multiple chip devices

ActiveUS6979899B2Improve thermal conductivityAllow for any formSemiconductor/solid-state device detailsSolid-state devicesHeat spreader

A custom-molded heat sink corresponds to an individual substrate and includes a heat sink lid having at least one cavity corresponding to at least one die mounted on a substrate. A conductive layer is deposited in the at least one cavity that substantially fills the space between the at least one cavity and the at least one die when the lid is coupled to the substrate.

Owner:TEXAS INSTR INC

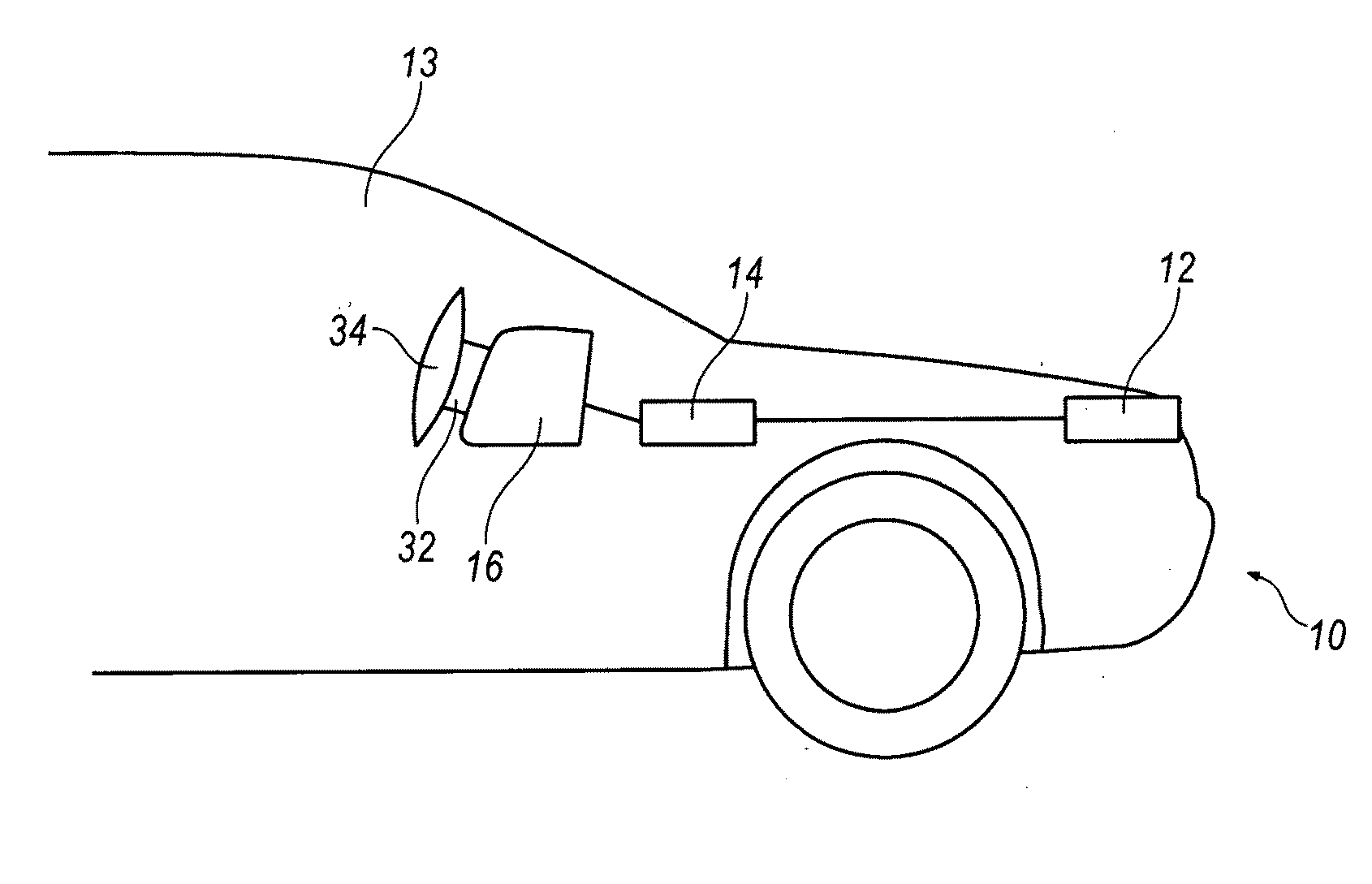

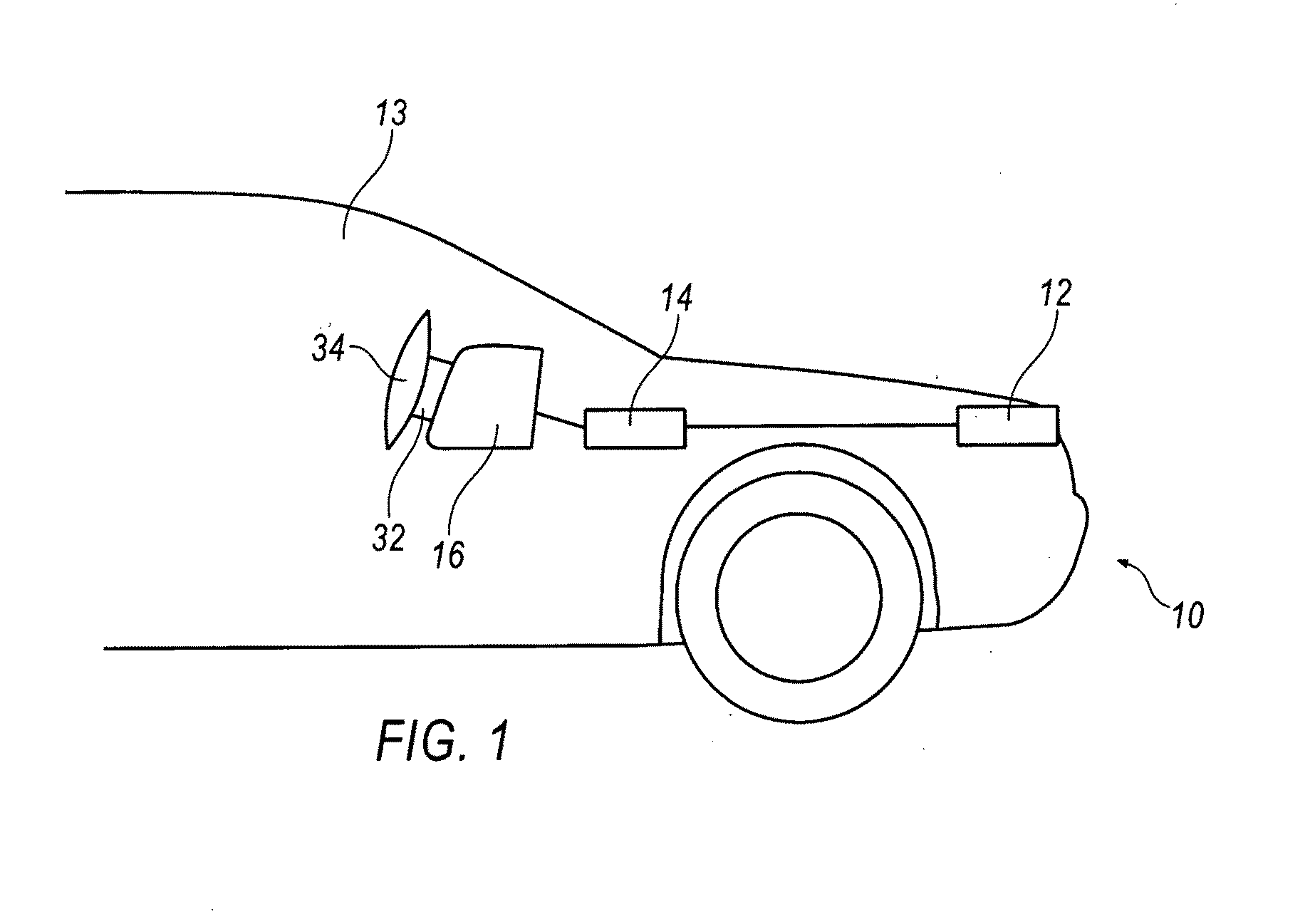

Blur display for automotive night vision systems with enhanced form perception from low-resolution camera images

InactiveUS20090016571A1Highly pixilatedFacilitate cognitionTelevision system detailsImage enhancementCamera imageNight vision

The present invention relates to a night vision system human machine interface and particularly to an HMI display that provides enhanced road scene imagery from low resolution cameras.

Owner:FORD GLOBAL TECH LLC

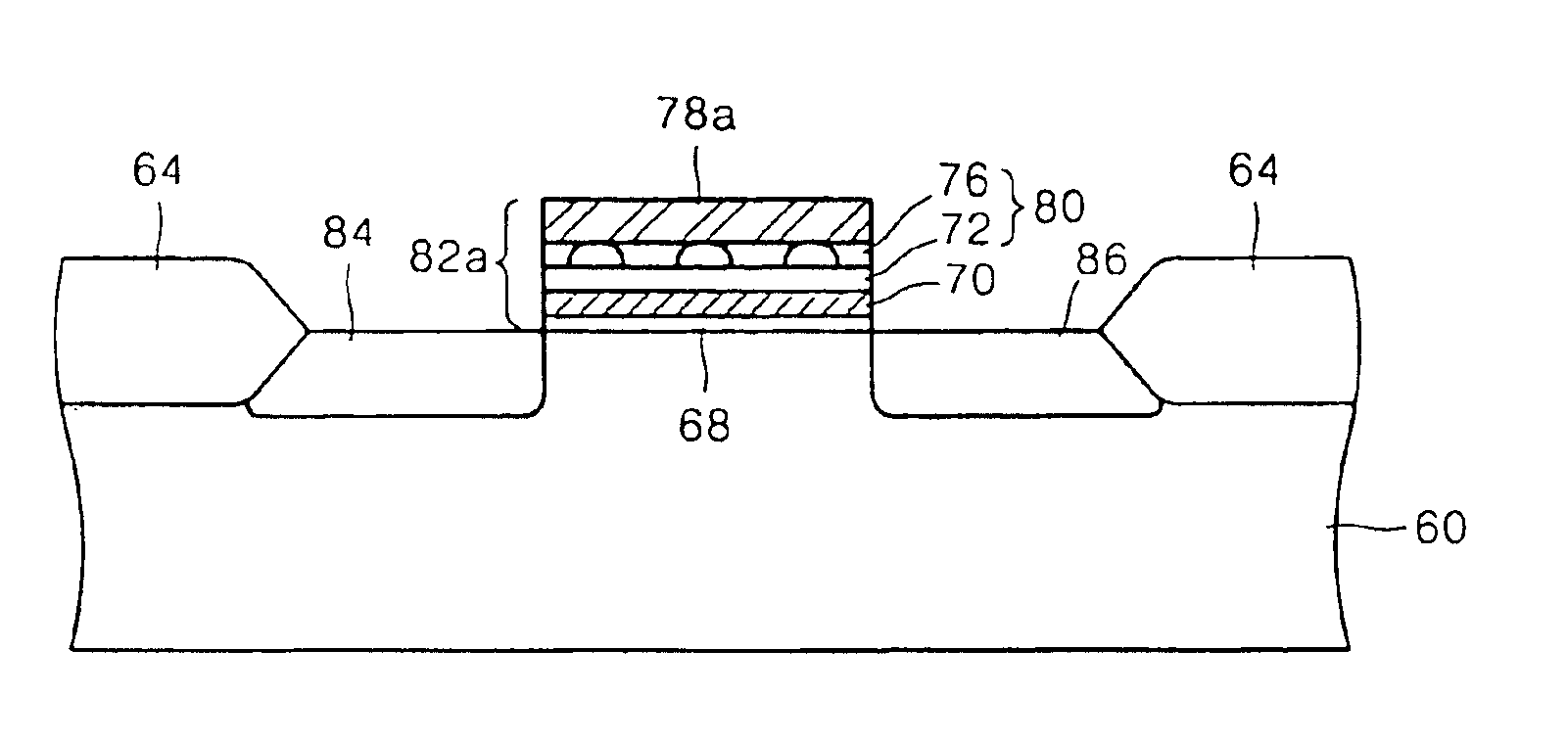

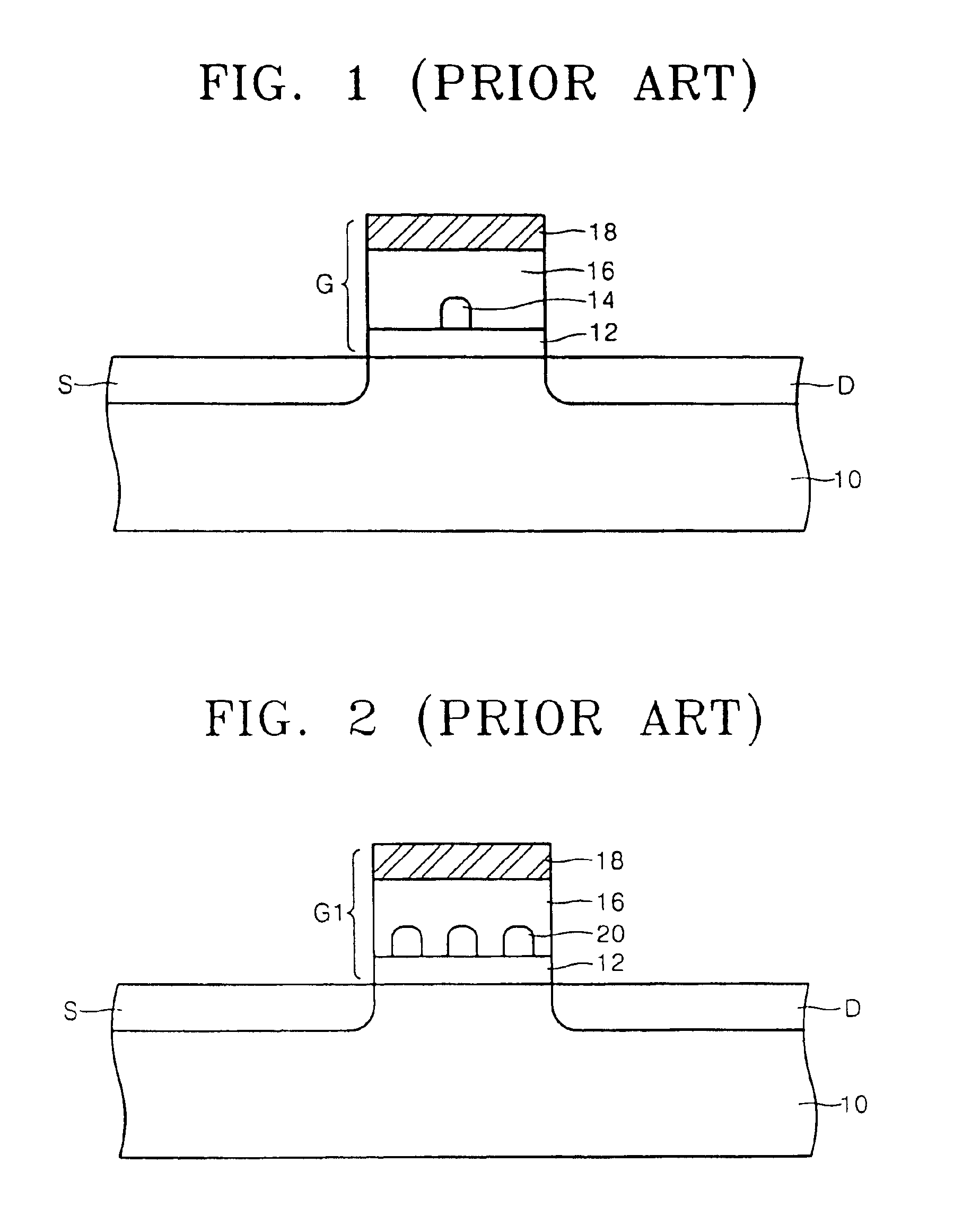

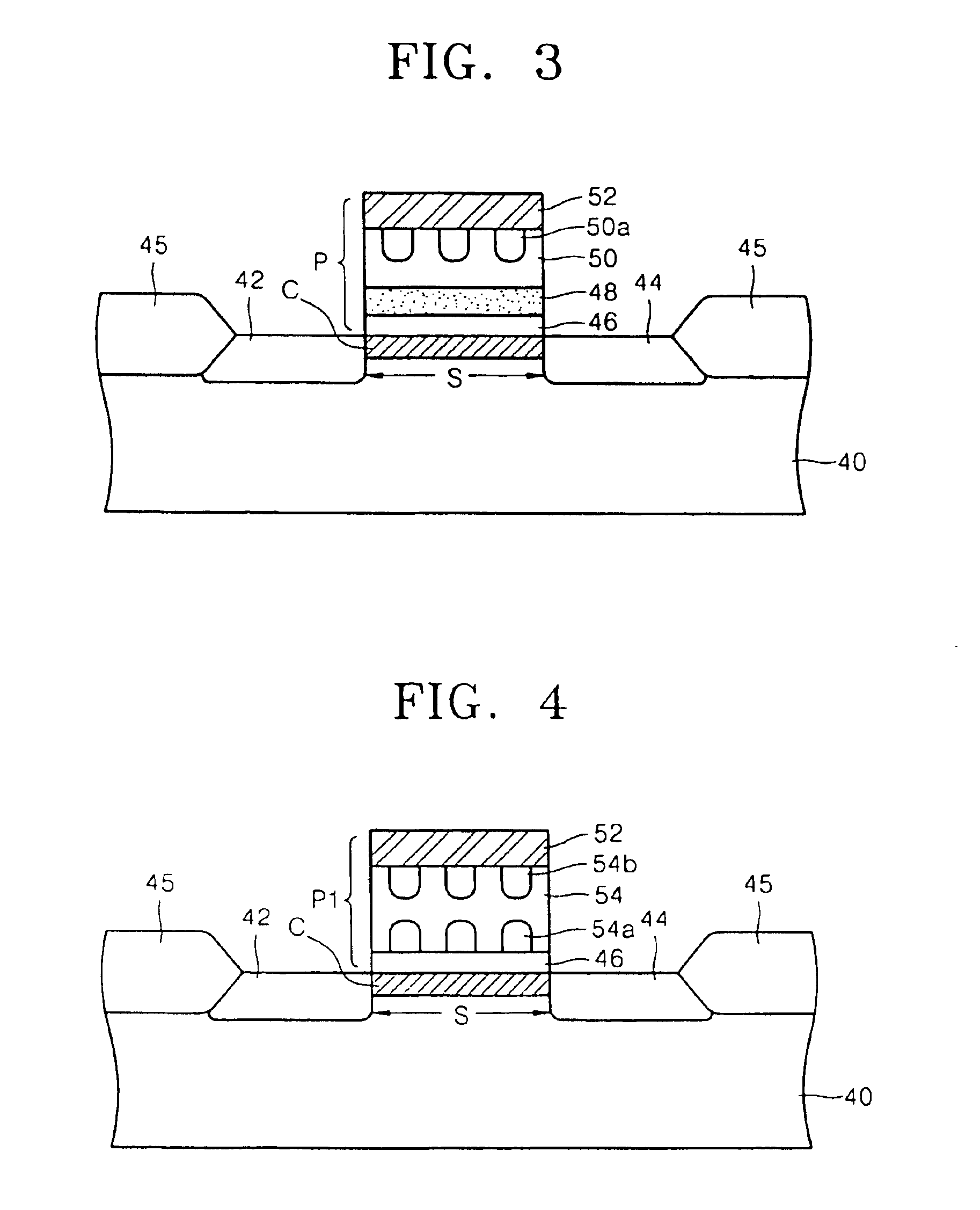

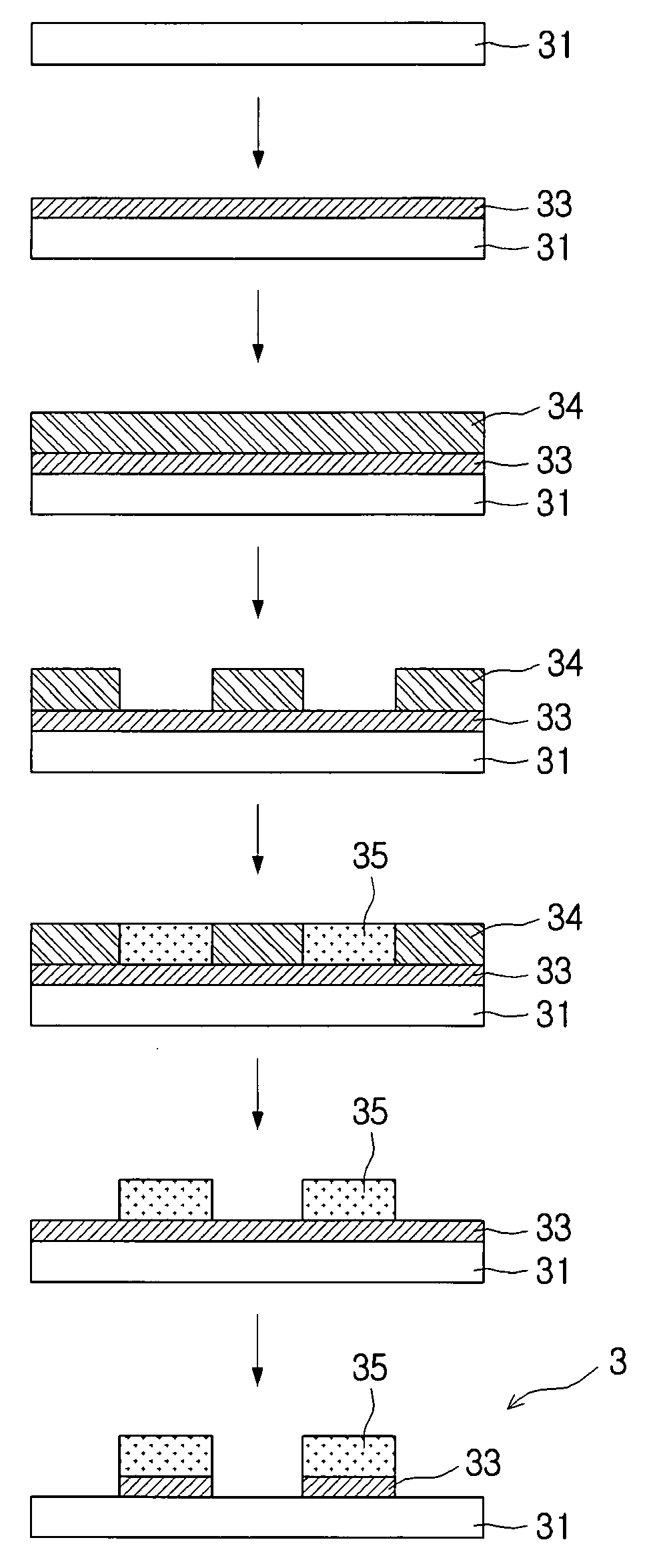

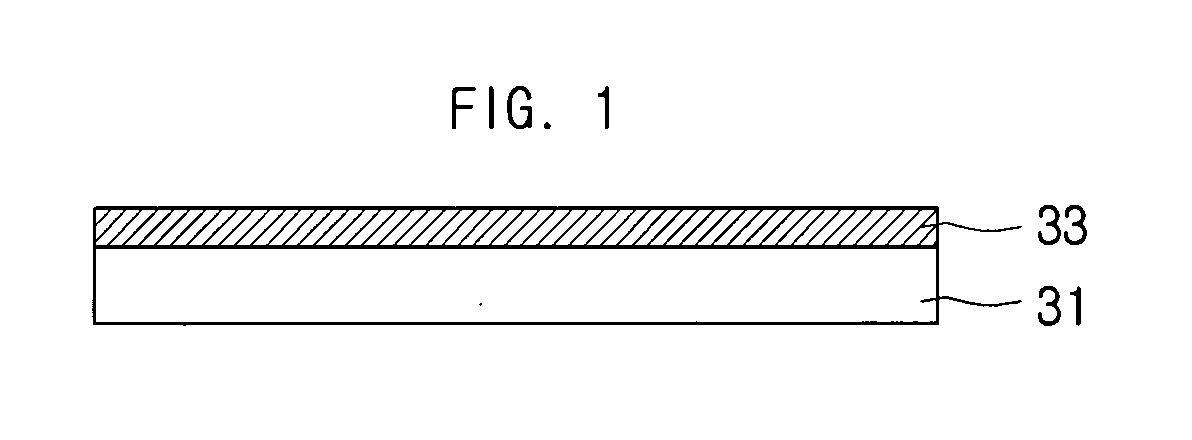

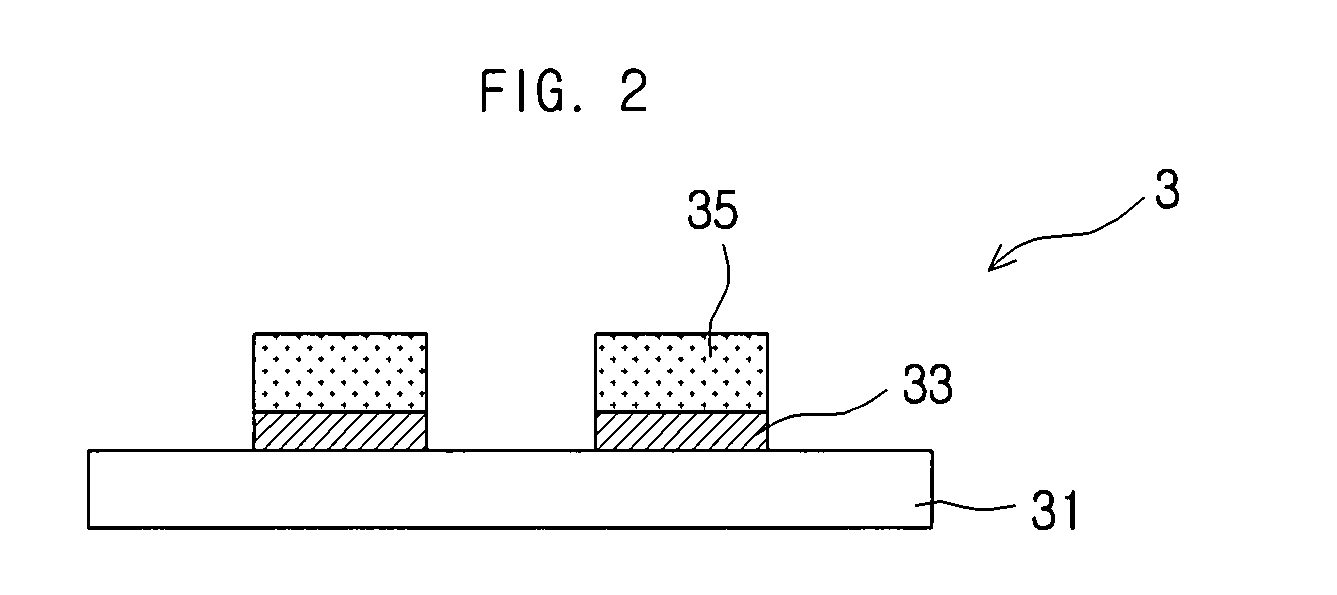

Method for manufacturing a single electron memory device having quantum dots between gate electrode and single electron storage element

In a method for manufacturing a single electron memory device including a single electron storage element in a gate lamination pattern formed on a nano-scale channel region of a MOSFET, formation of the gate lamination pattern includes sequentially forming a lower layer and a single electron storage medium for storing a single electron tunneling through the lower layer on a substrate, forming an upper layer including a plurality of quantum dots on the single electron storage medium, forming a gate electrode layer on the upper layer to be in contact with the plurality of quantum dots, and patterning the lower layer, the single electron storage medium, the upper layer, and the gate electrode layer, in reverse order.

Owner:SAMSUNG ELECTRONICS CO LTD

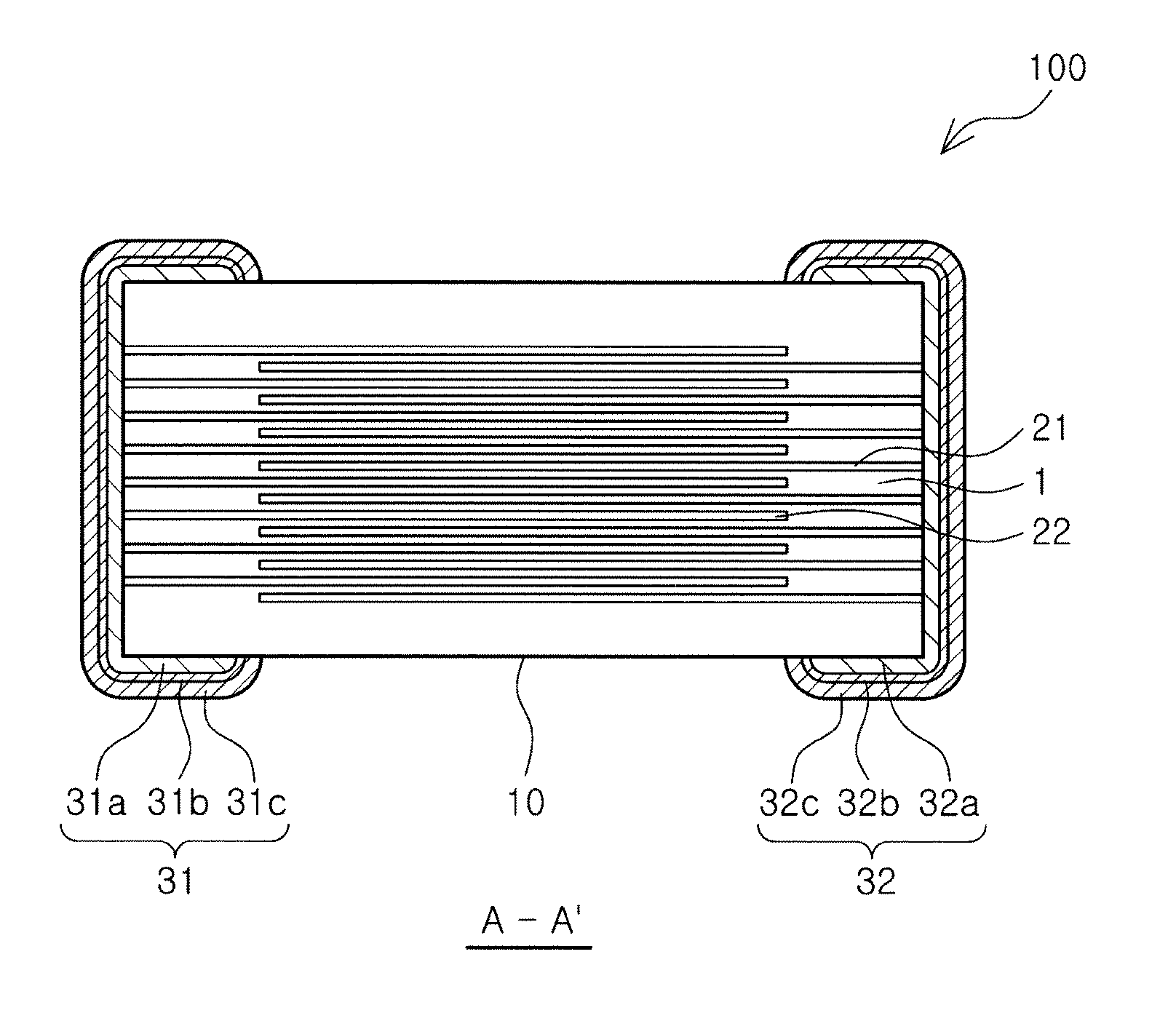

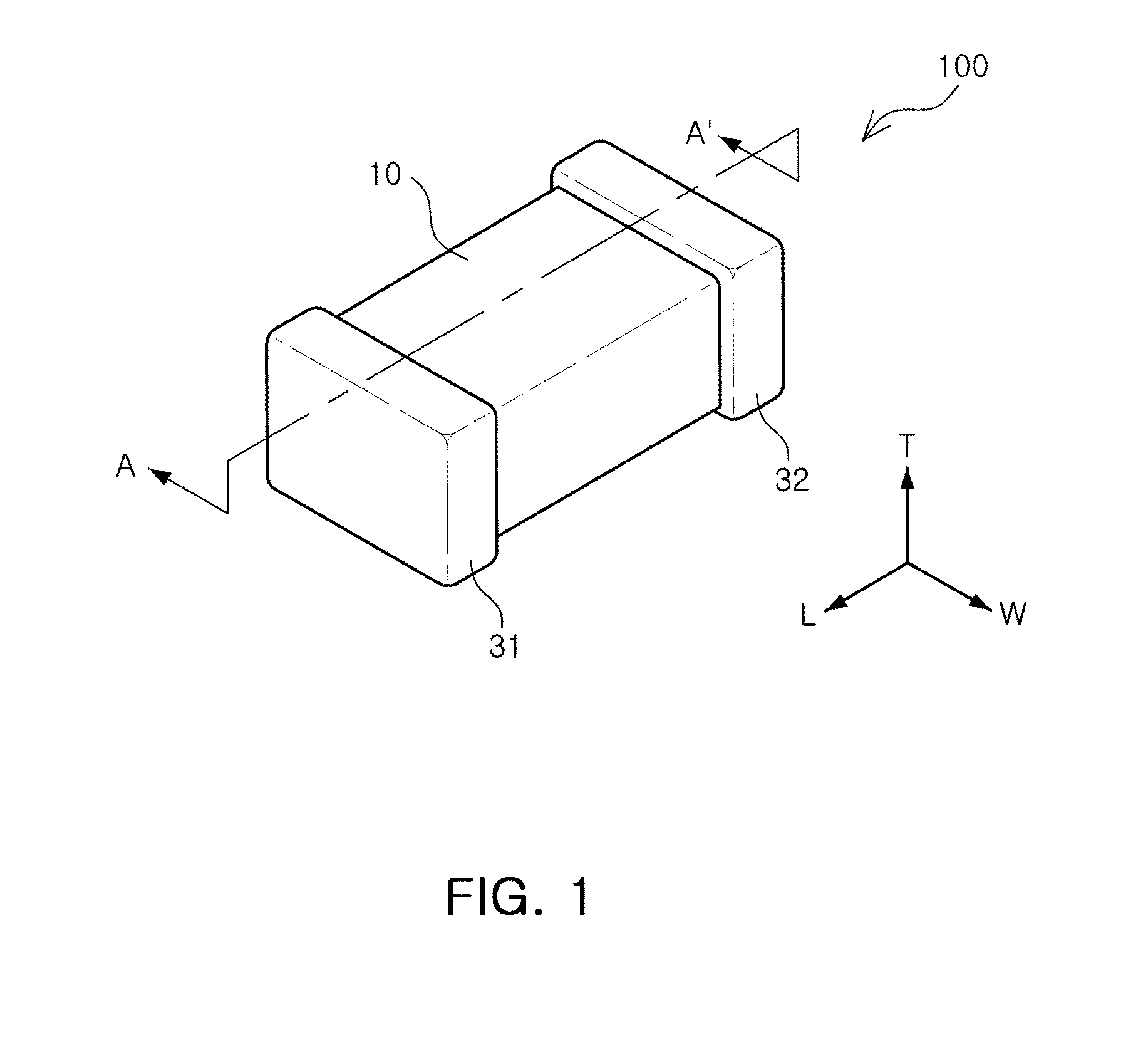

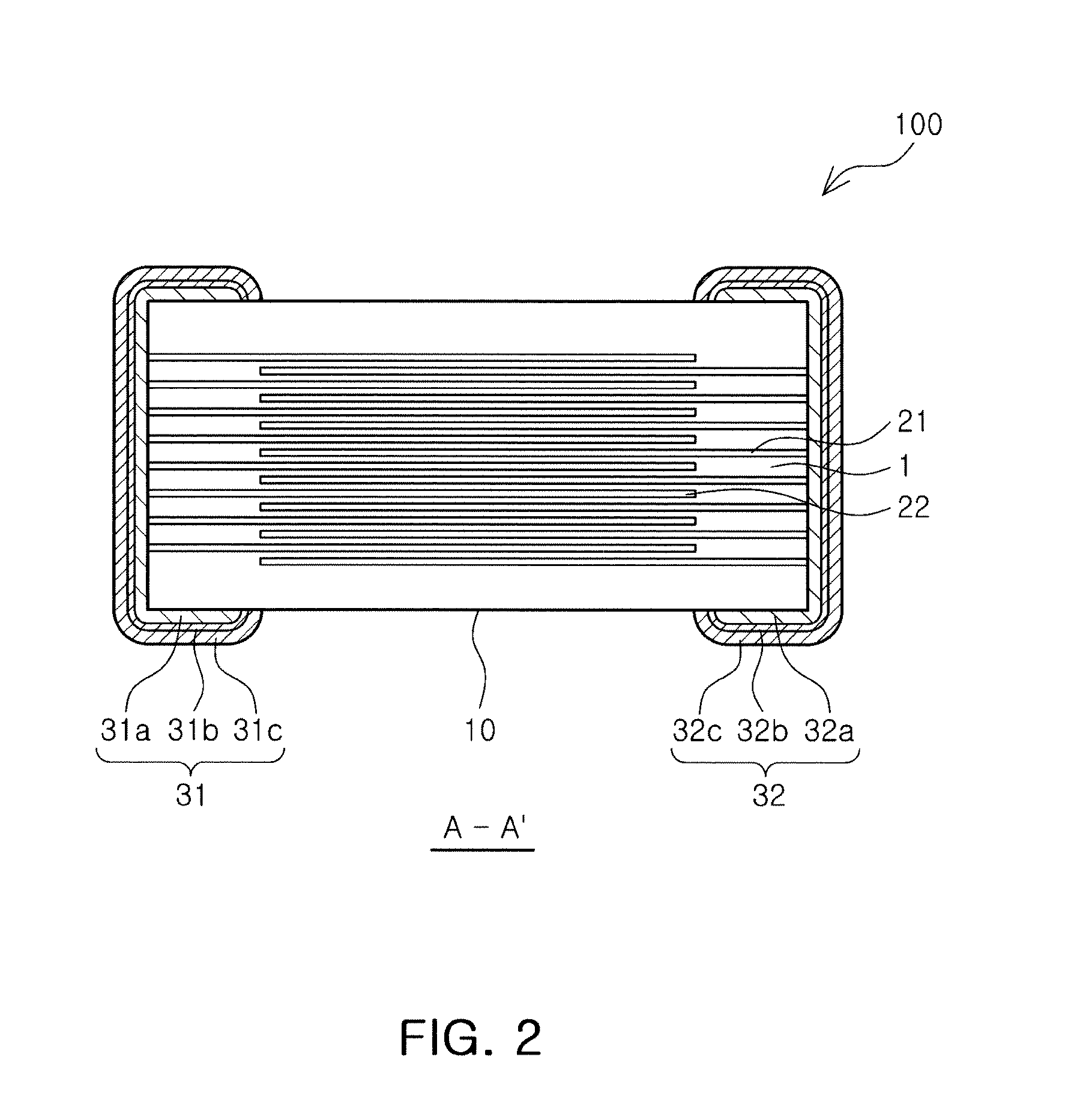

Electronic component and manufacturing method thereof

InactiveUS20130155573A1Allow for any formFixed capacitor electrodesFixed capacitor dielectricCeramic sinteringAlloy

There is provided an electronic component including a ceramic sintered body having a plurality of internal electrodes formed therein, and external electrodes formed on an outer surface of the ceramic sintered body. Each of the external electrodes includes a copper (Cu) electrode layer electrically connected to the internal electrodes, a copper (Cu)-tin (Sn) alloy layer formed on an outer surface of the electrode layer, and a tin (Sn) plating layer formed on an outer surface of the alloy layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Cell-penetrating peptides and uses thereof

The present invention relates to the identification and functional characterization of human cell-penetrating peptides (CPPs) and their use; in particular as transfection vehicles.

Owner:F HOFFMANN LA ROCHE & CO AG

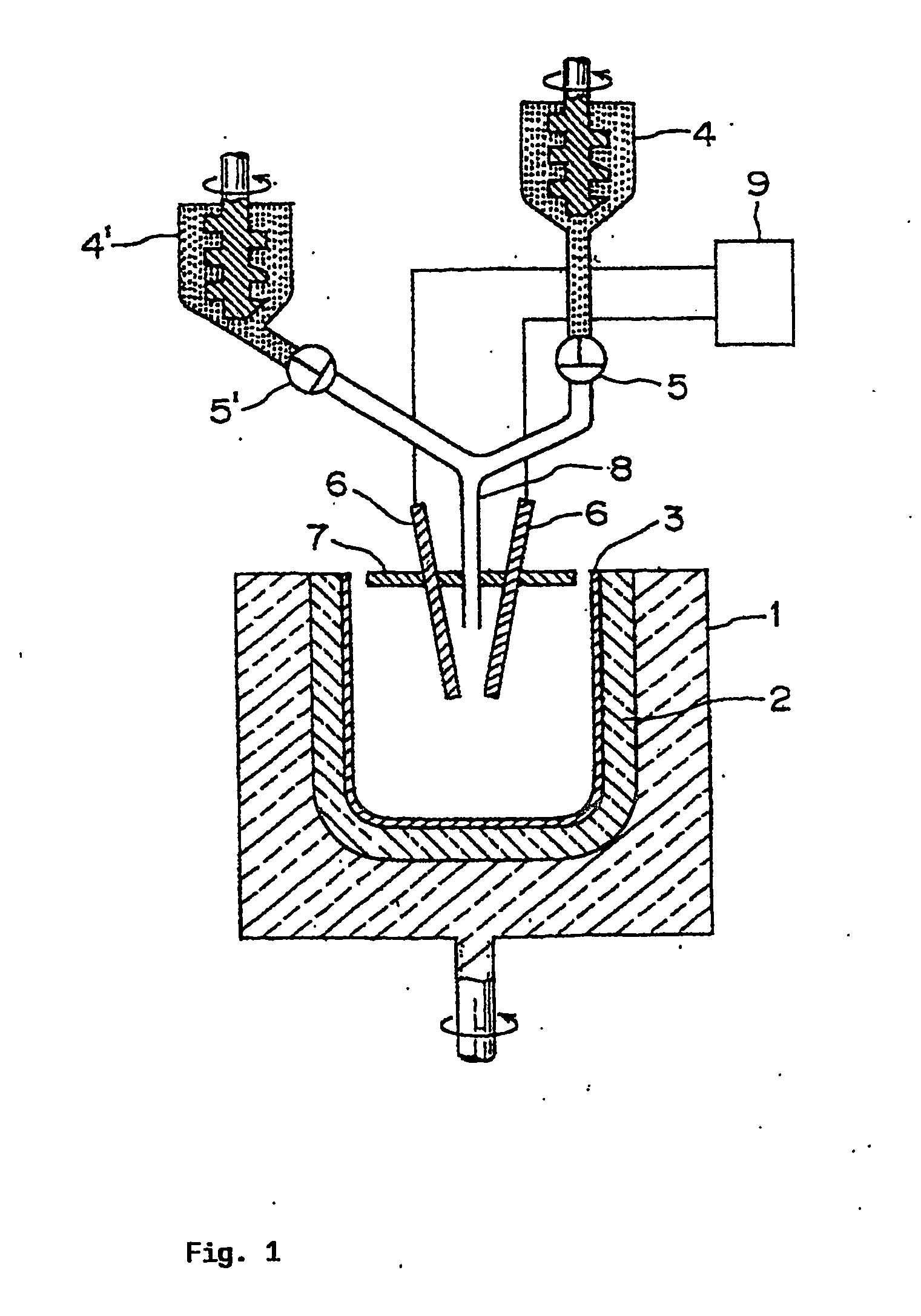

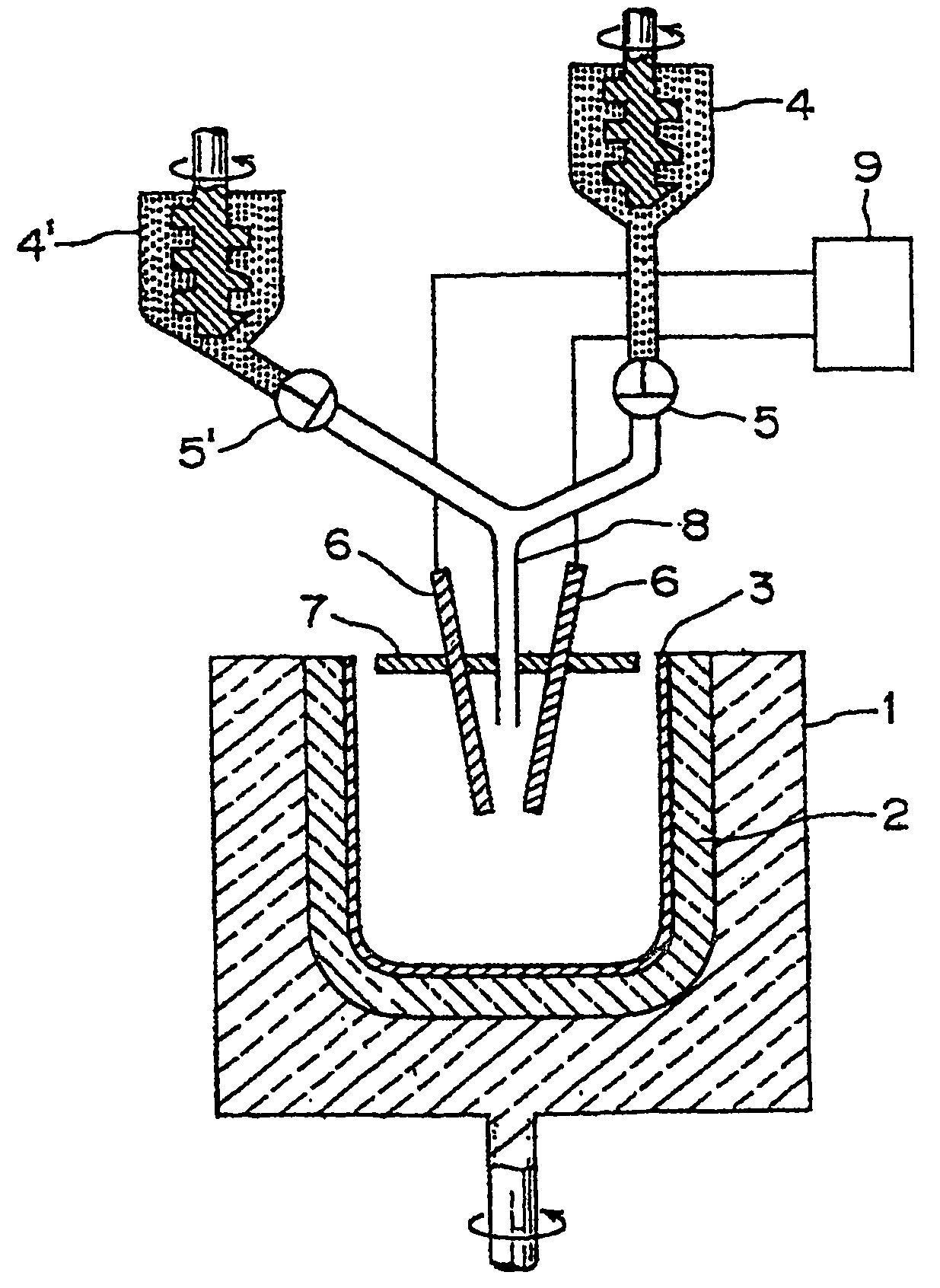

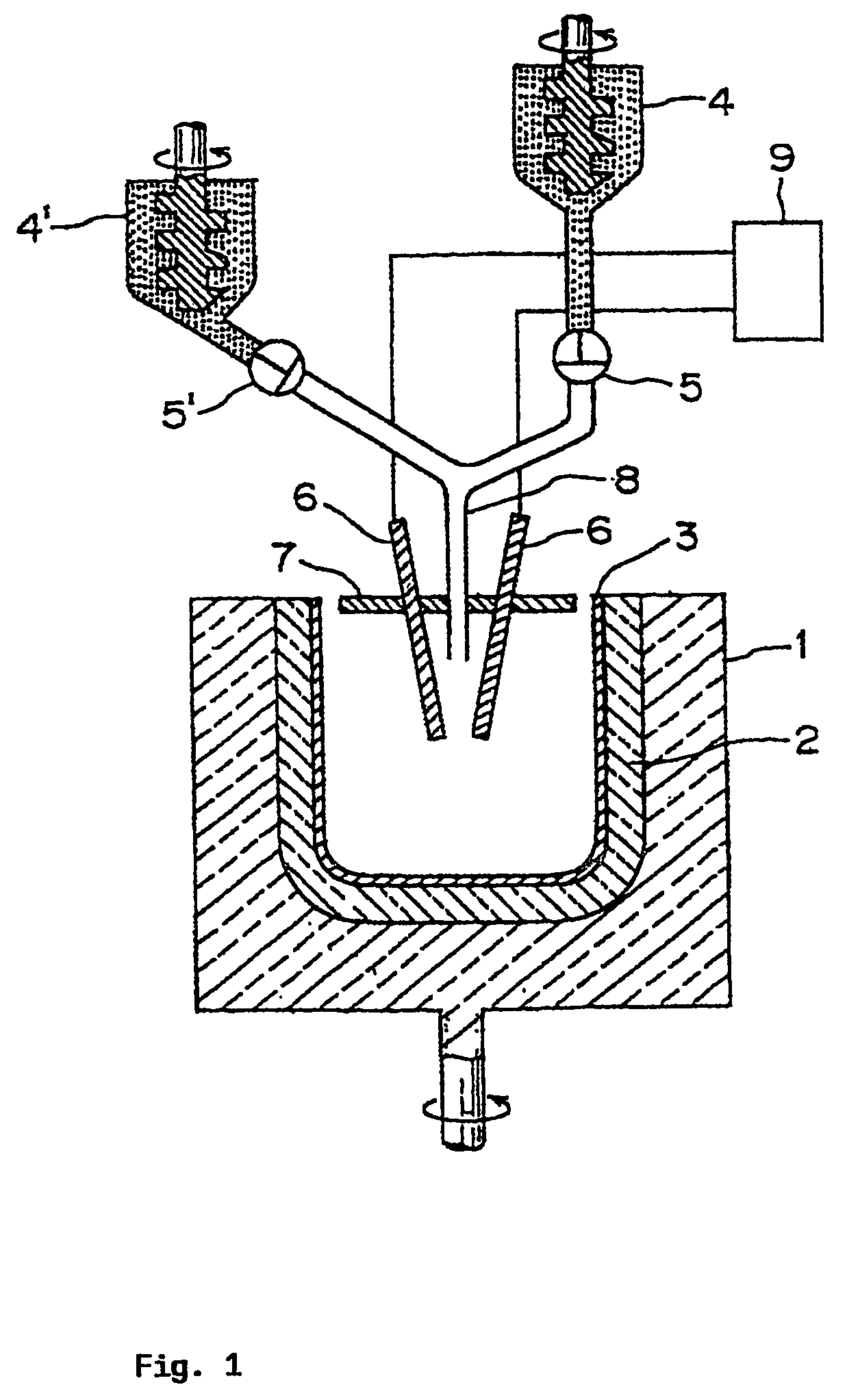

Mehtod for producing quartz glass crucible for use in pulling silicon single crystal and quartz glass crucible produced by said method

InactiveUS20060174651A1Reduce heat resistance requirementsReduce pressurePolycrystalline material growthBy pulling from meltCrucibleSingle crystal

The present invention refers to a method for producing a quartz glass crucible for use in pulling silicon single crystal, said crucible having at least a double-layer structure comprising a pore-free transparent inner layer and an opaque base body or outer layer having pores, characterized in that at least the base body is formed with a silica powder maintained in a gas having a mixing ratio of 0.0005 to 0.0065 kg / kg (dry gas), and a quartz glass crucible produced by said production method. The obtained crucible has an average OH group concentration of 50 ppm or lower and is capable of suppressing the vibration occurring on the surface of silicon melt during pulling the silicon single crystal. Further the obtained crucible suffers less deformation of the crucible on pulling the silicon single crystal.

Owner:HERAEUS QUARZGLAS +1

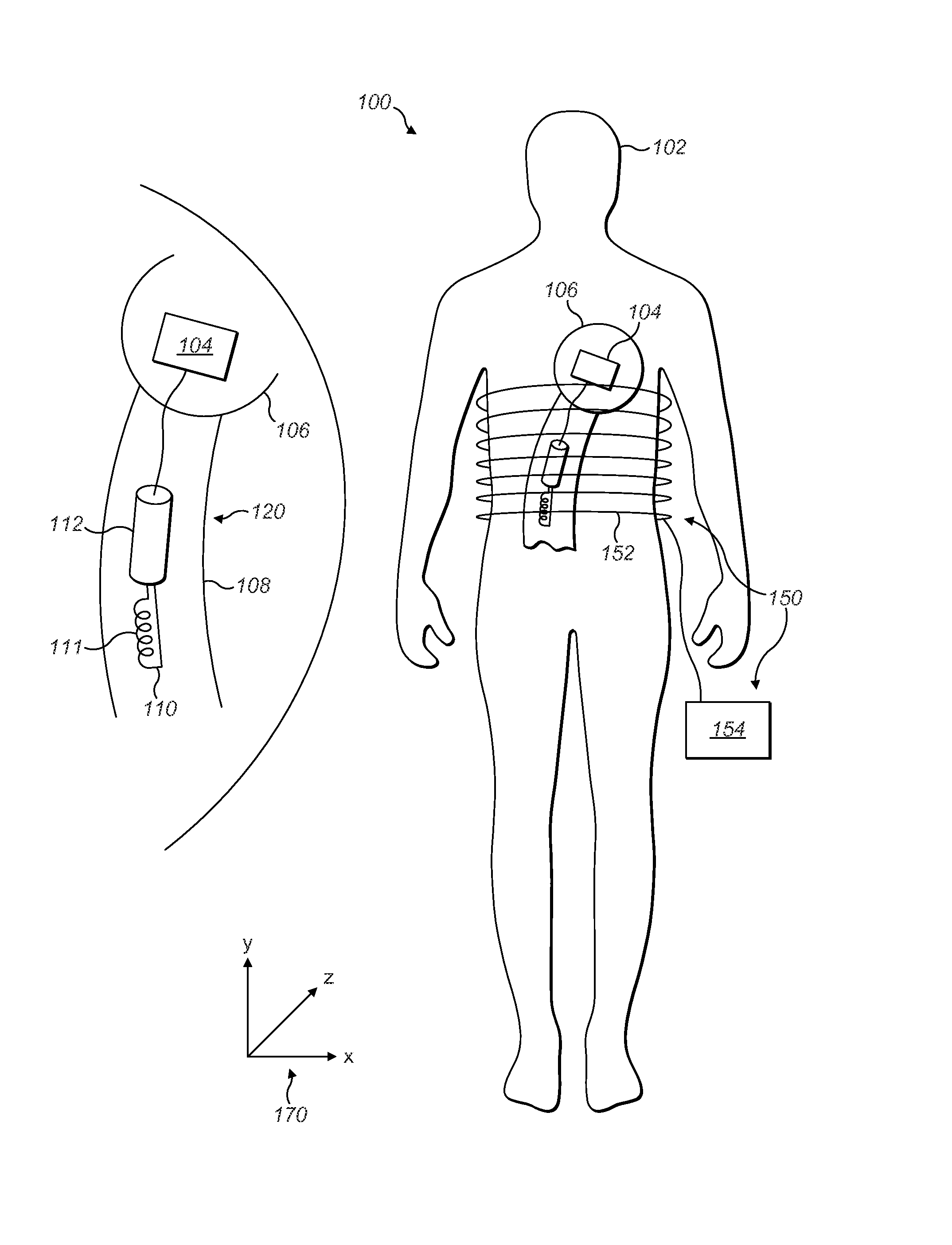

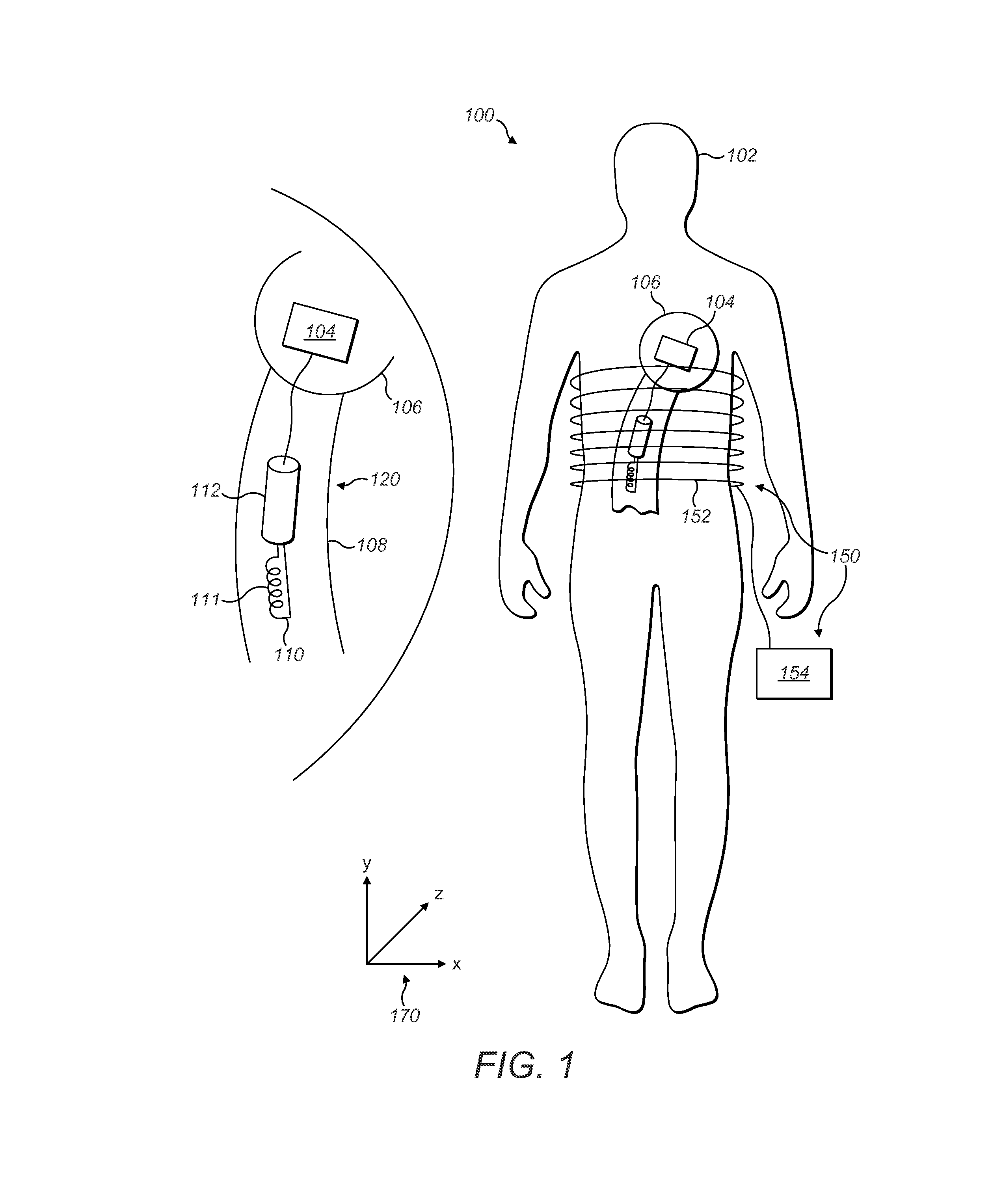

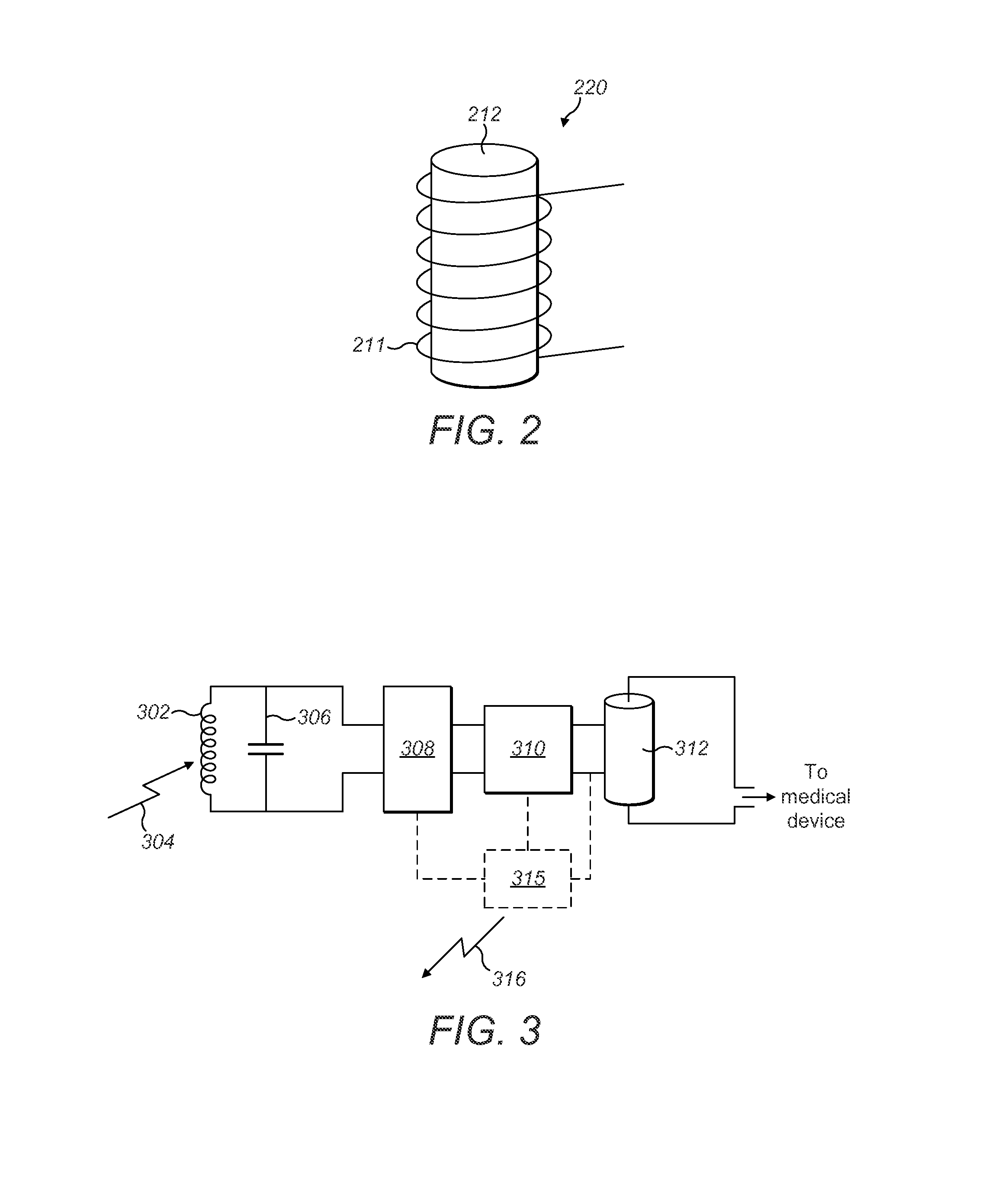

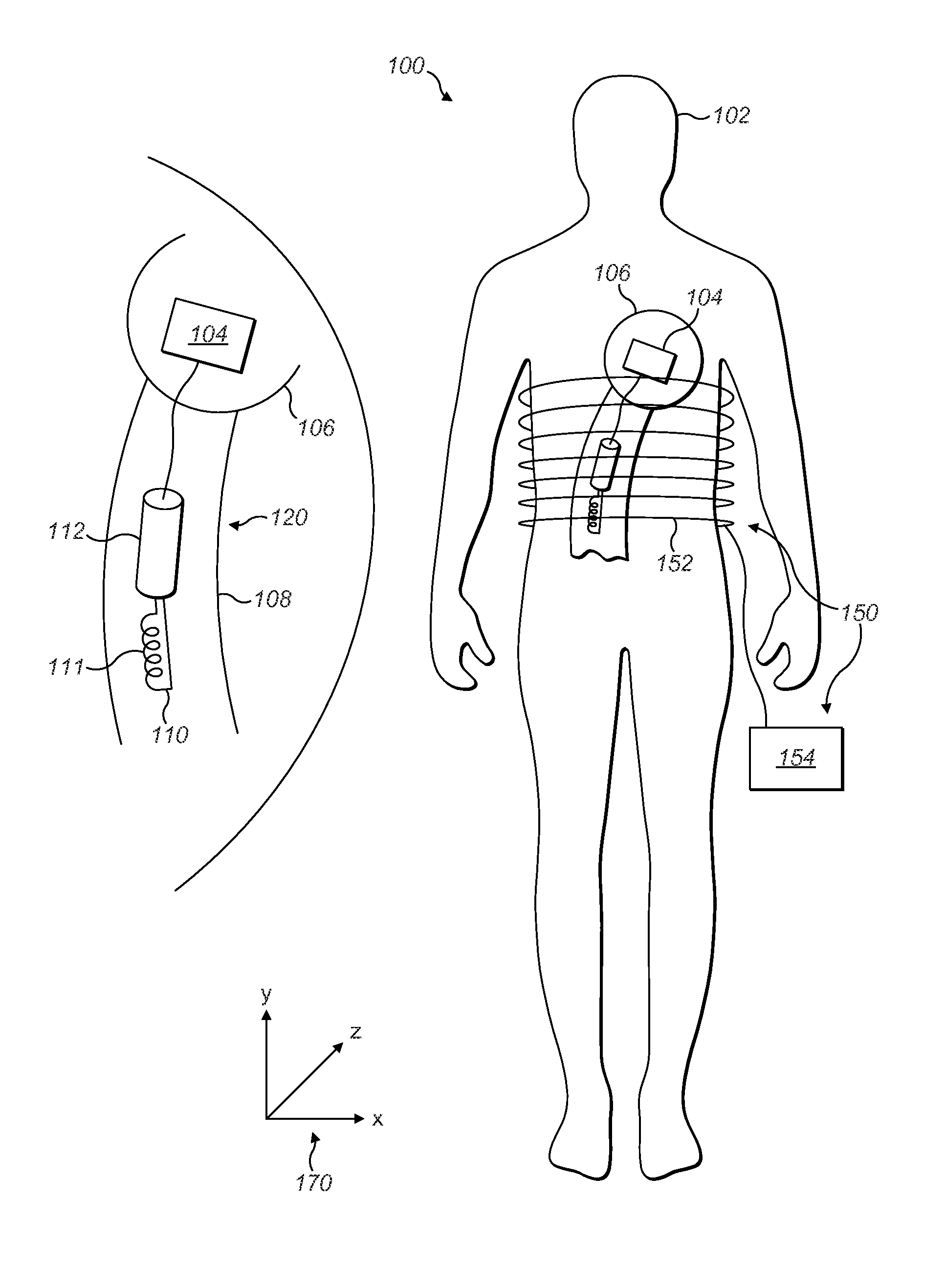

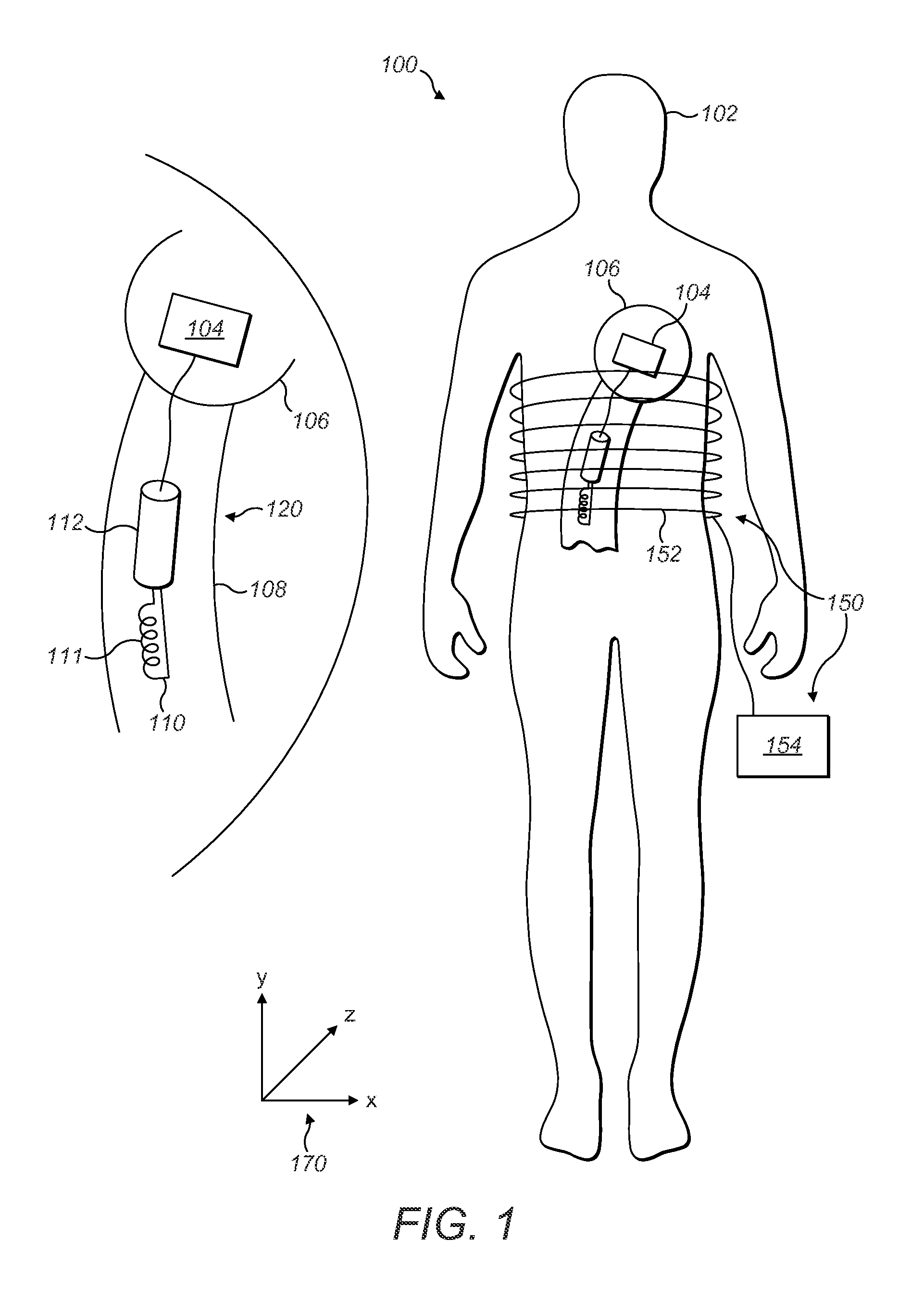

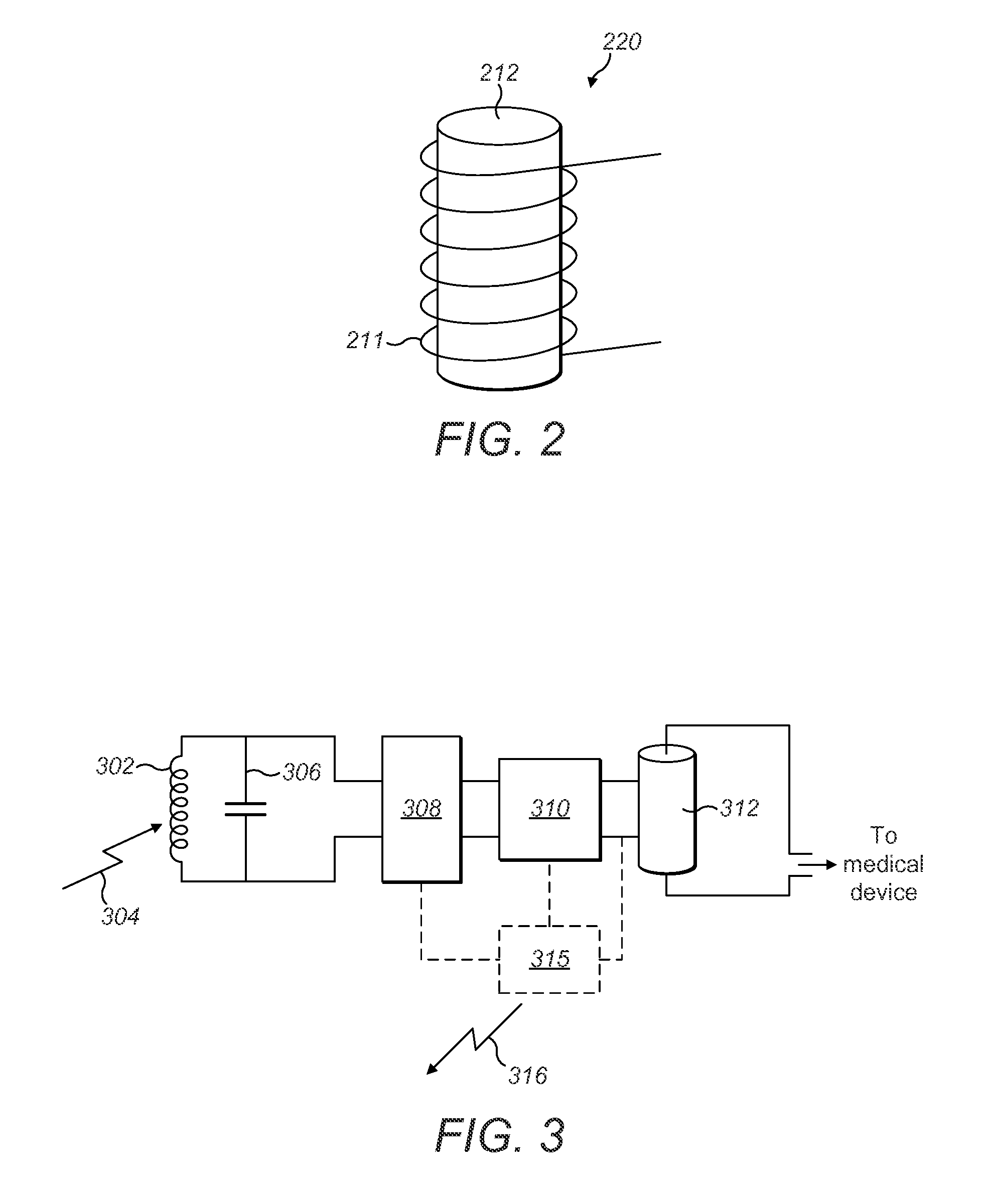

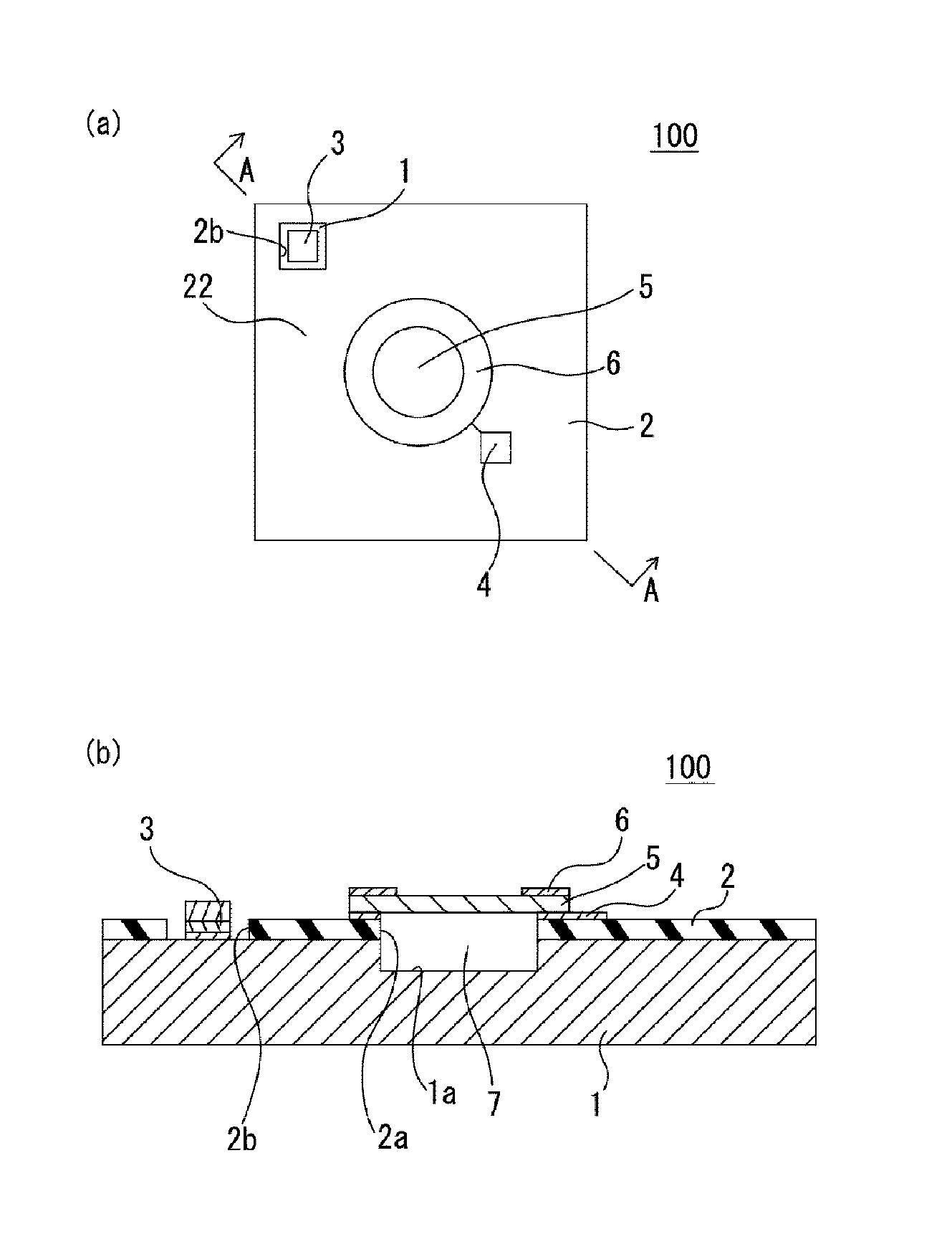

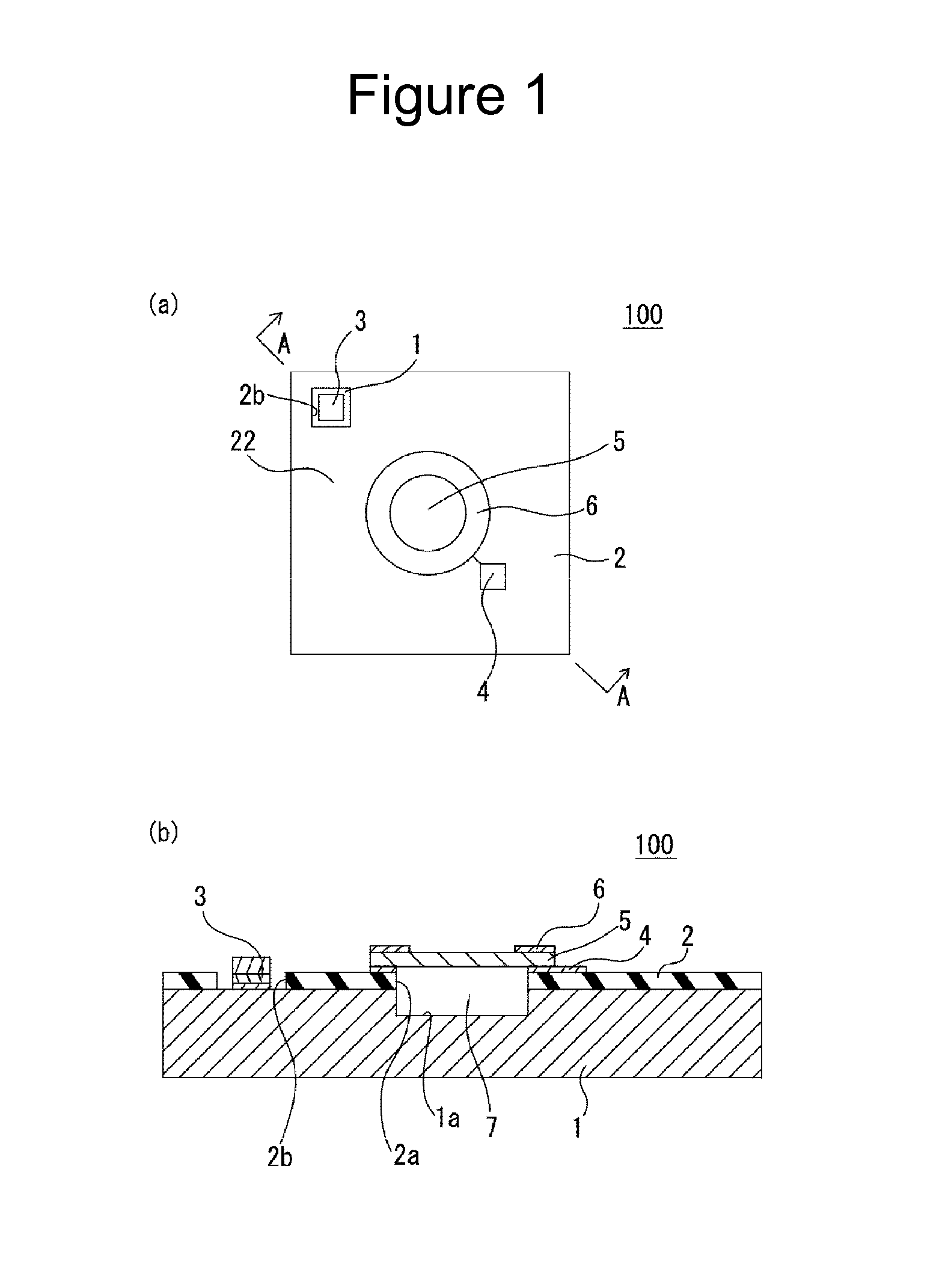

Apparatus for contactless power transfer in implantable devices

InactiveUS20170047762A1Large power storageReduce power levelElectrotherapyIntravenous devicesElectric power transmissionTransmitted power

In the field of contactless power transfer for medical devices, more specifically, to contactless power transfer for intra-corporeal medical devices, a rechargeable power supply for an intra-corporeal medical device comprises an implantable power receiving means for wirelessly receiving power, and implantable power storage means. The implantable power receiving means is arranged and configured to receive power from an extra-corporeal power transmitting means for wirelessly transmitting power. The apparatus is particularly useful in the context of minimally invasive procedures.

Owner:NUHEART

System and method for contactless power transfer in implantable devices

InactiveUS20170043077A1Reduce decreaseLarge power storageElectrotherapyBatteries circuit arrangementsElectric power transmissionTransmitted power

In the field of contactless power transfer for medical devices, more specifically, to contactless power transfer for intra-corporeal medical devices, a system and method for transmitting power to a rechargeable power supply are provided, the rechargeable power supply comprising implantable power receiving means, and an implantable power storage means. The system comprises an extra corporeal power transmitting means arranged and configured to supply power to the rechargeable power supply by wirelessly transmitting power to the implantable power receiving means. The system and method are particularly useful in the context of minimally invasive procedures.

Owner:NUHEART

Support member assembly for conductive contactor

InactiveUS20050001637A1Simple processEnsure positioning accuracySemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsPlastic materialsThermal deformation

Provided is a support member assembly suitable for use in a contact probe head comprising a support member formed with a plurality of holder holes for supporting conductive contact members in a mutually parallel relationship, and a reinforcing member integrally formed with the support member and extending in a part of the support member devoid of any holder holes. The reinforcing member increases the overall mechanical strength of the support member assembly, and prevents the thermal deformation of the support member. Because the holder holes are formed in the support member made of material suitable for forming holes, such as plastic material, the holder holes can be formed at high precision and at low cost.

Owner:NHK SPRING CO LTD

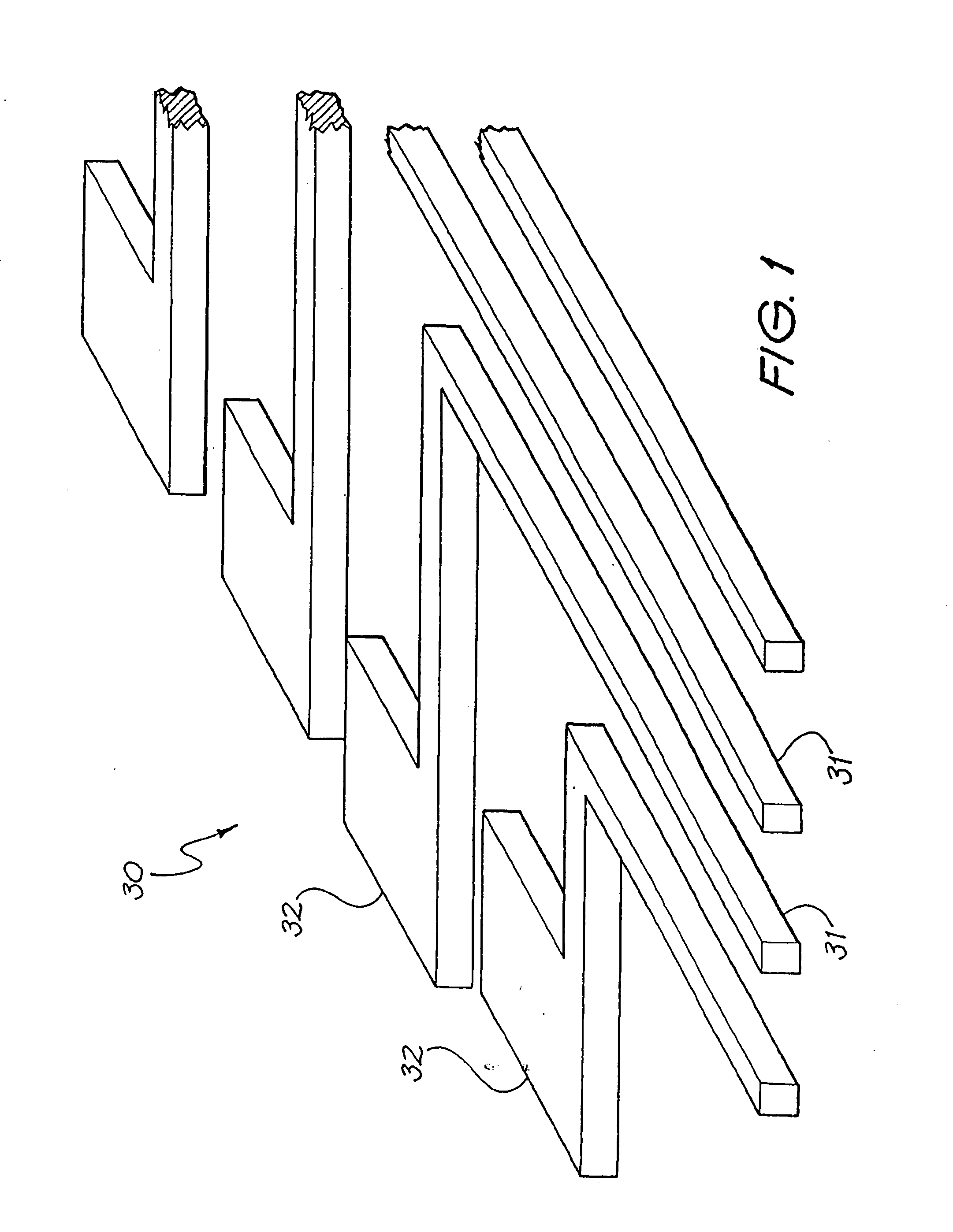

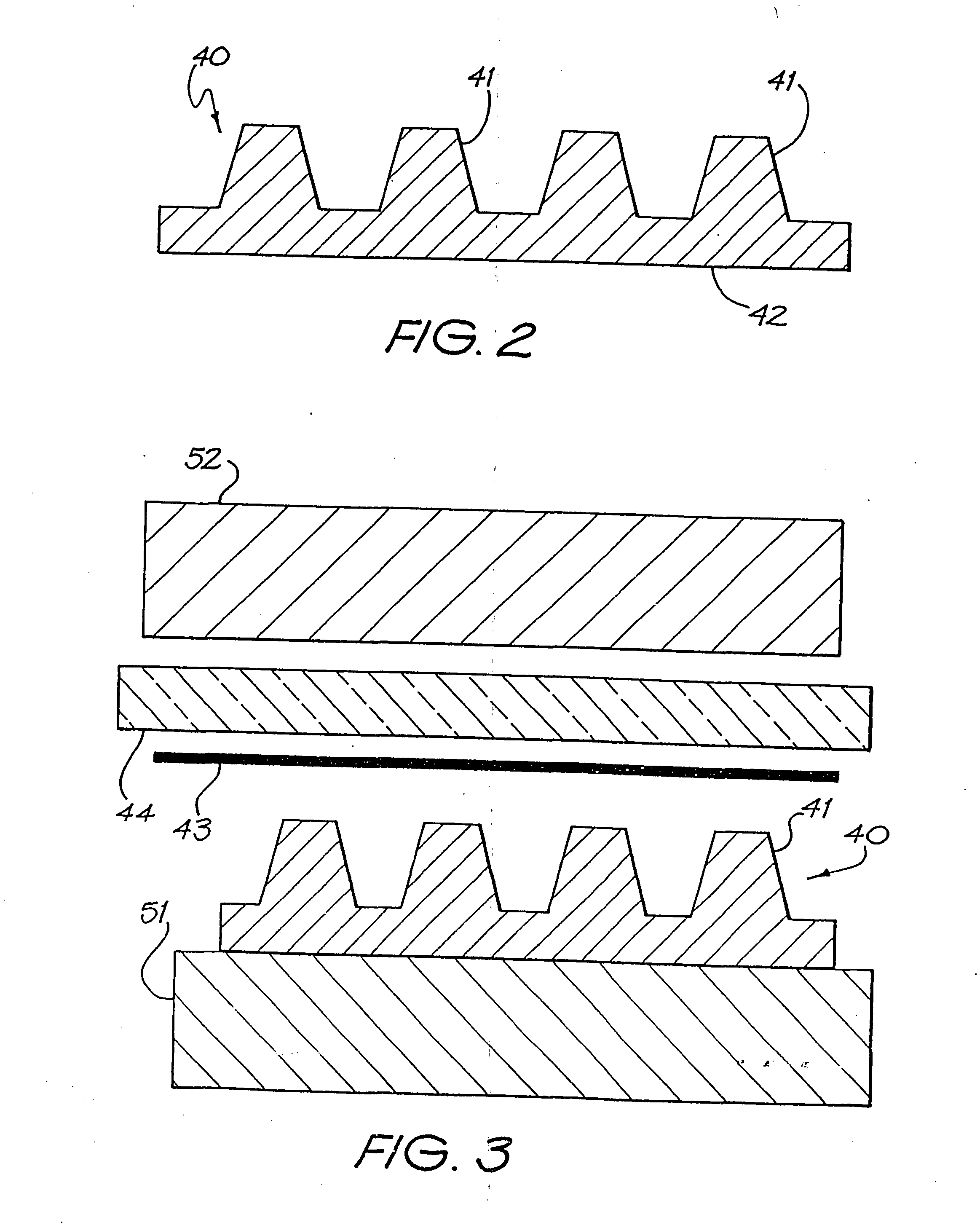

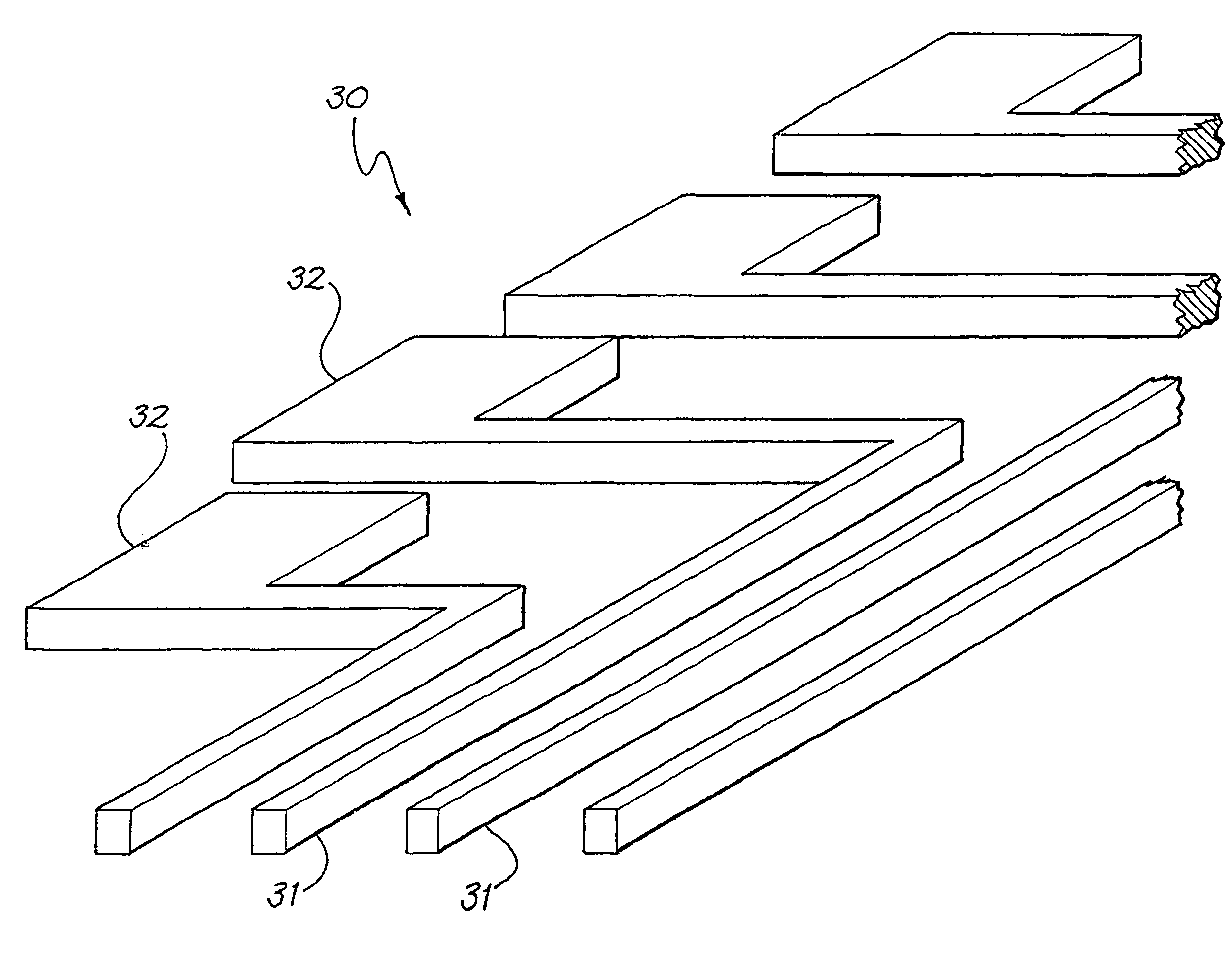

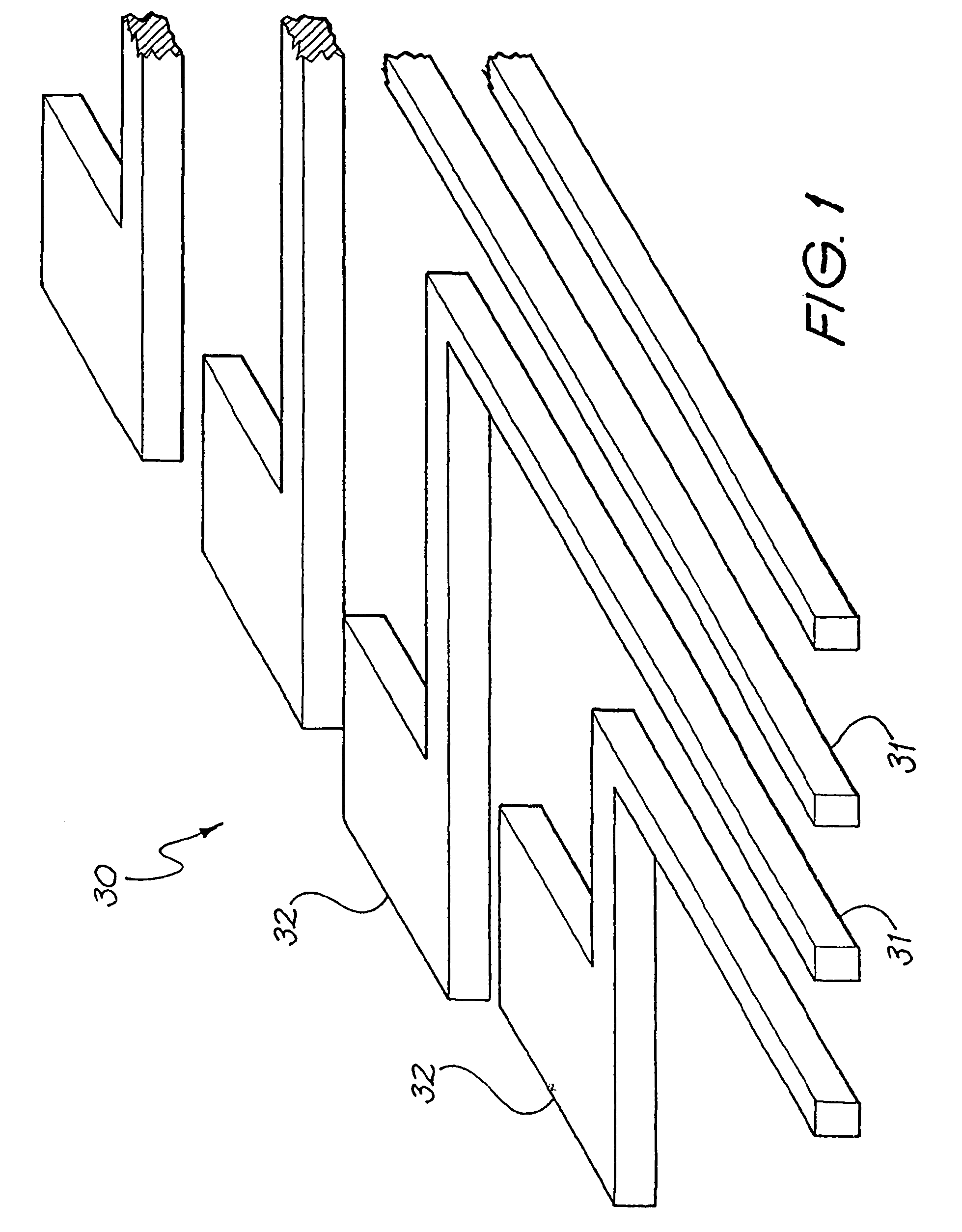

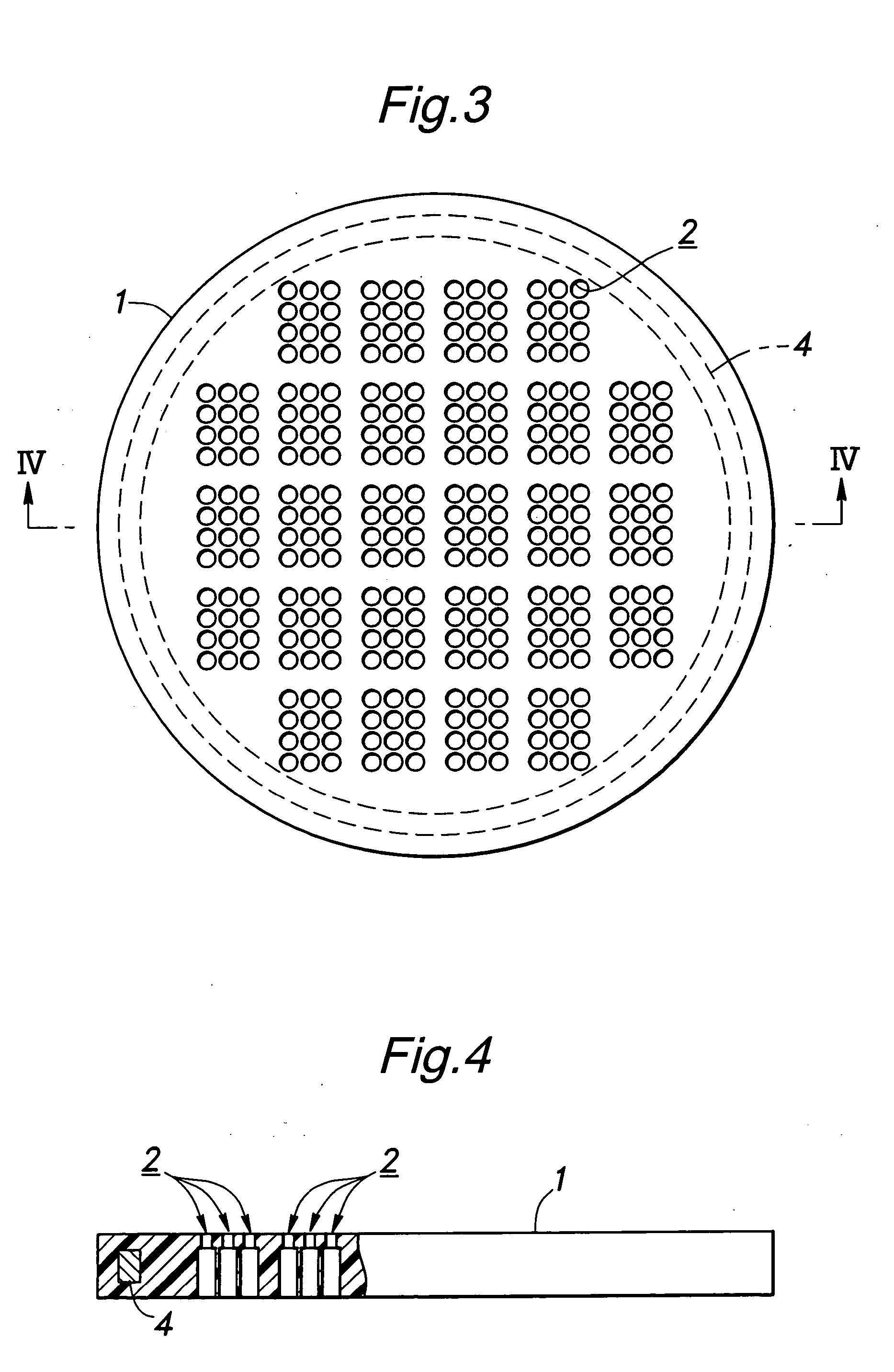

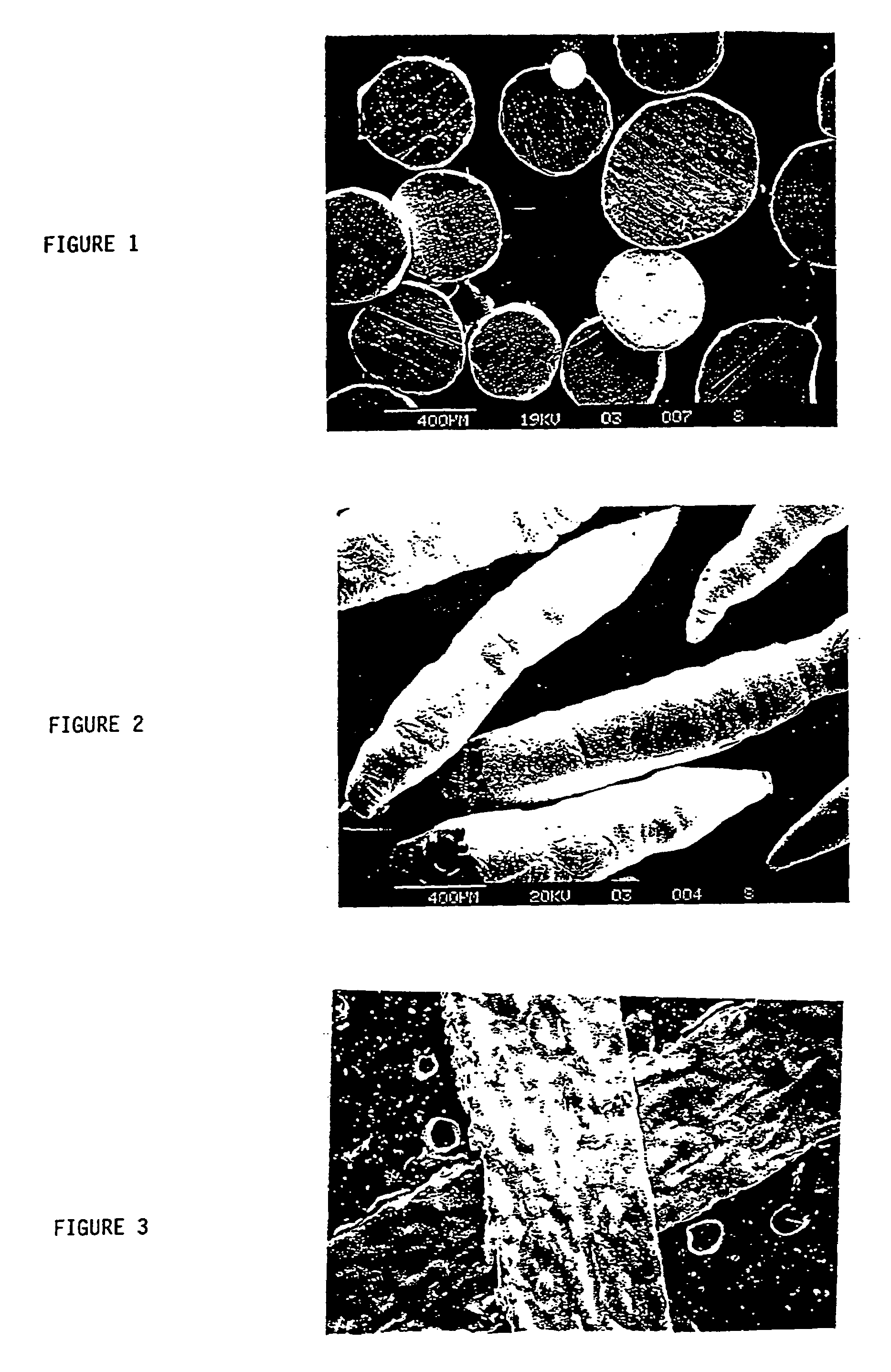

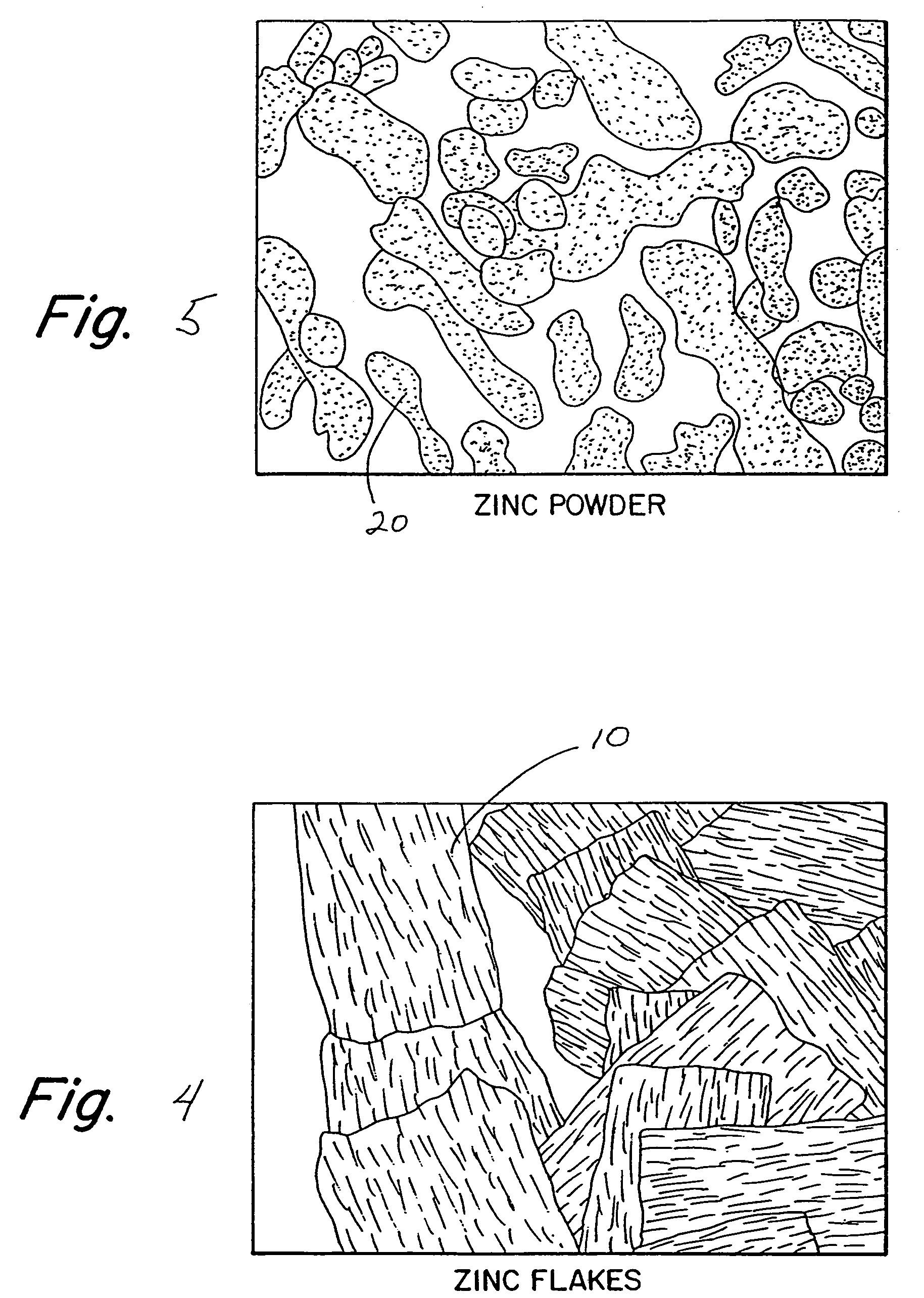

Zinc shapes for anodes of electrochemical cells

InactiveUS7045253B2Improve performanceEasy maintenancePrimary cell electrodesNon-aqueous electrolyte accumulator electrodesOptoelectronicsZinc

An electrochemical cell 30 which contains both a cathode 32 and an anode 34. The anode contains a mixture of uniformly shaped particles 10 and electrolyte. The anode can also contain a zinc powder comprising non-uniform shaped, which can be mixed with the uniformly shaped particles of the present invention.

Owner:ENERGIZER BRANDS

Cell-penetrating peptides and uses thereof

The present invention relates to the identification and functional characterization of human cell-penetrating peptides (CPPs) and their use; in particular as transfection vehicles.

Owner:F HOFFMANN LA ROCHE INC

Method for producing quartz glass crucible for use in pulling silicon single crystal and quartz glass crucible produced by said method

InactiveUS7587912B2Reduce heat resistance requirementsReduce pressurePolycrystalline material growthBy pulling from meltCrucibleSingle crystal

Owner:HERAEUS QUARZGLAS +1

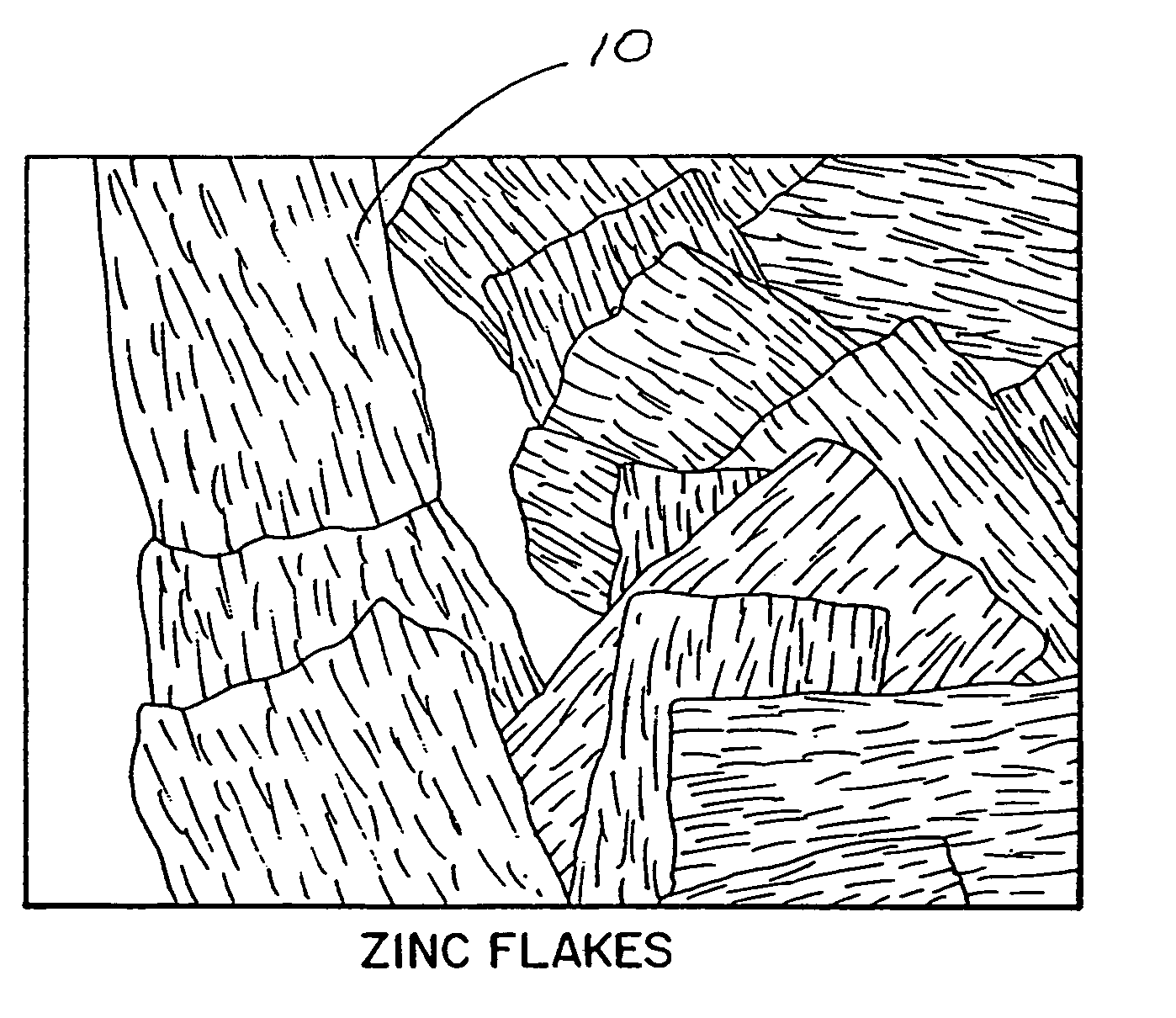

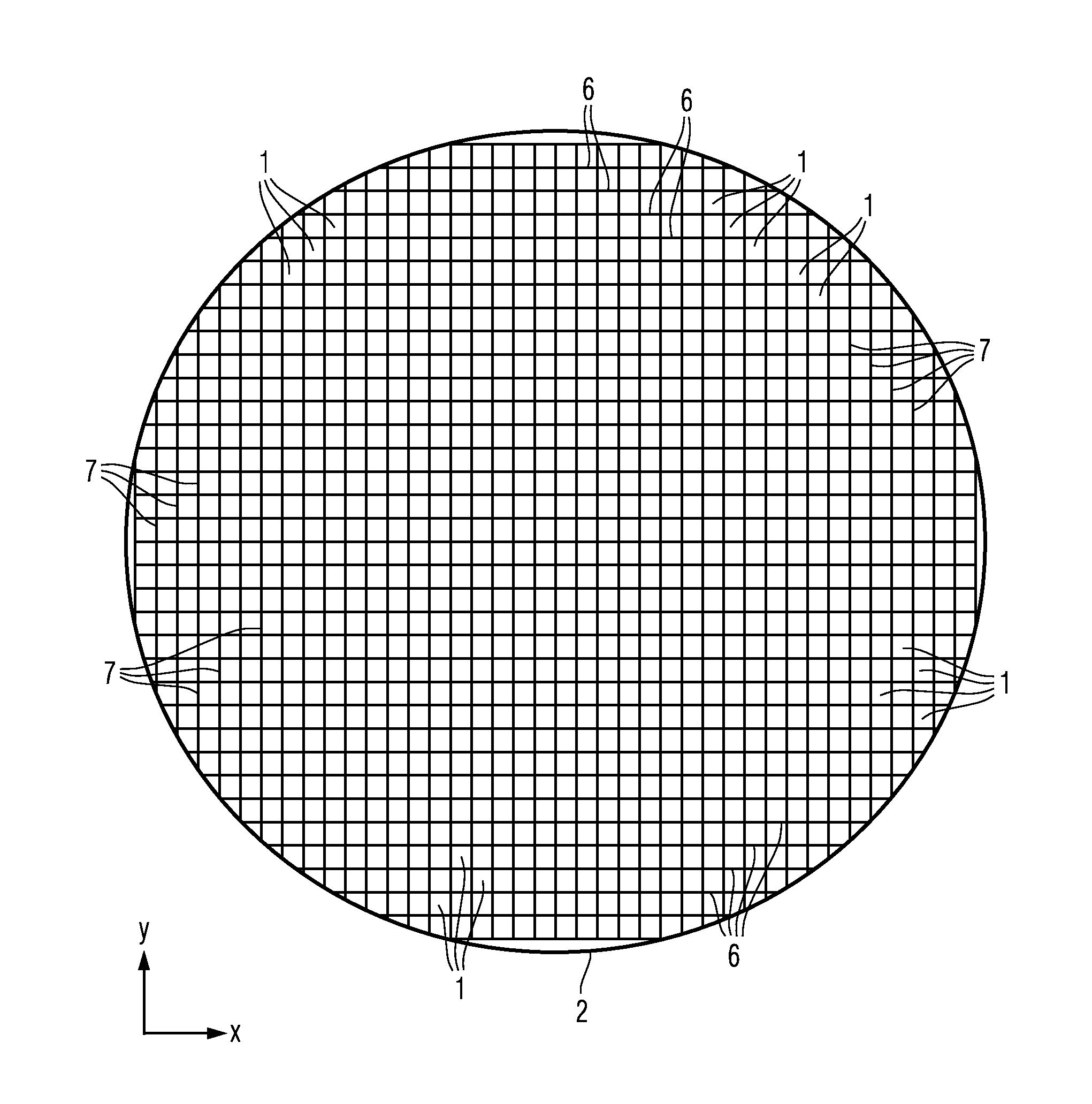

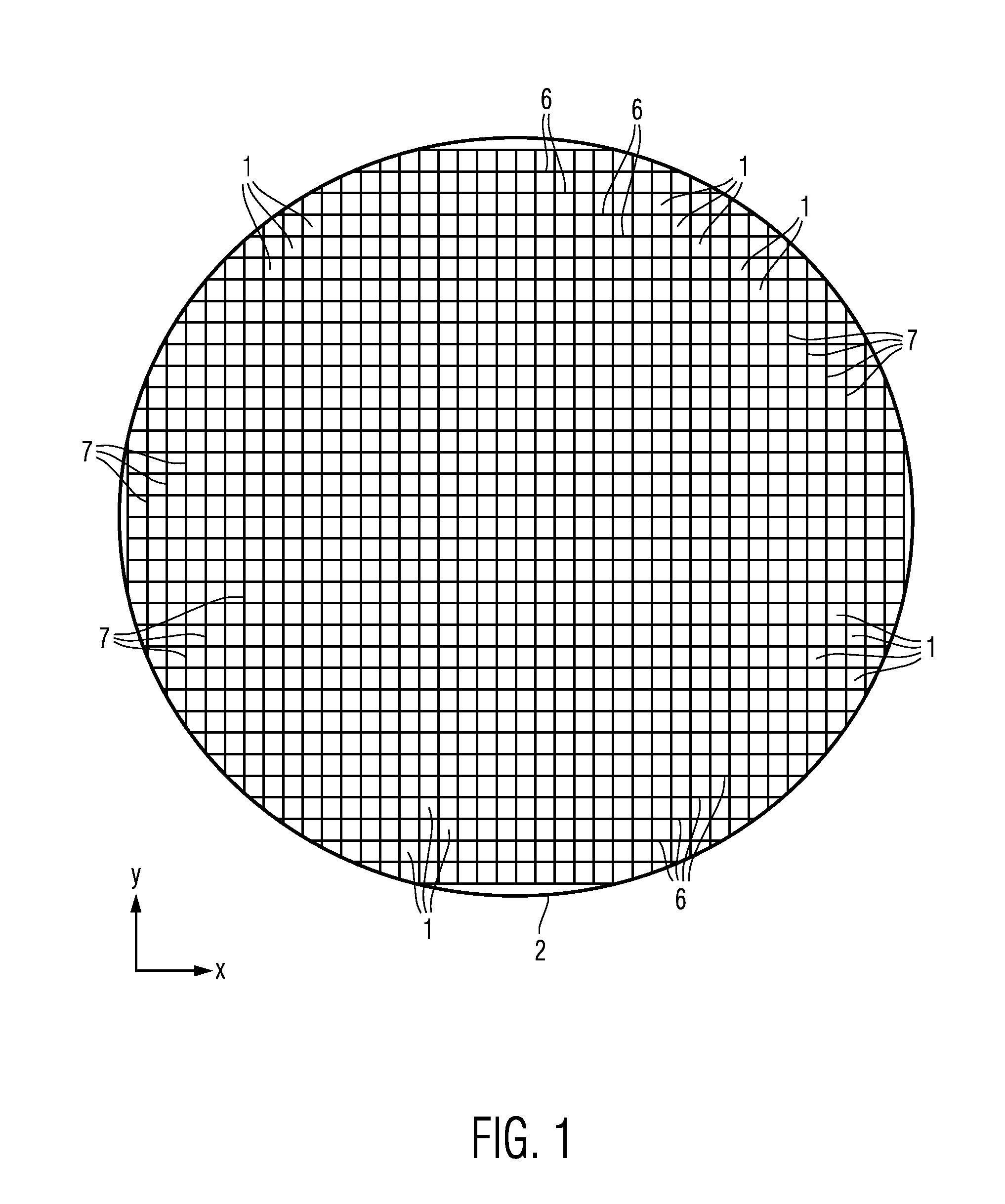

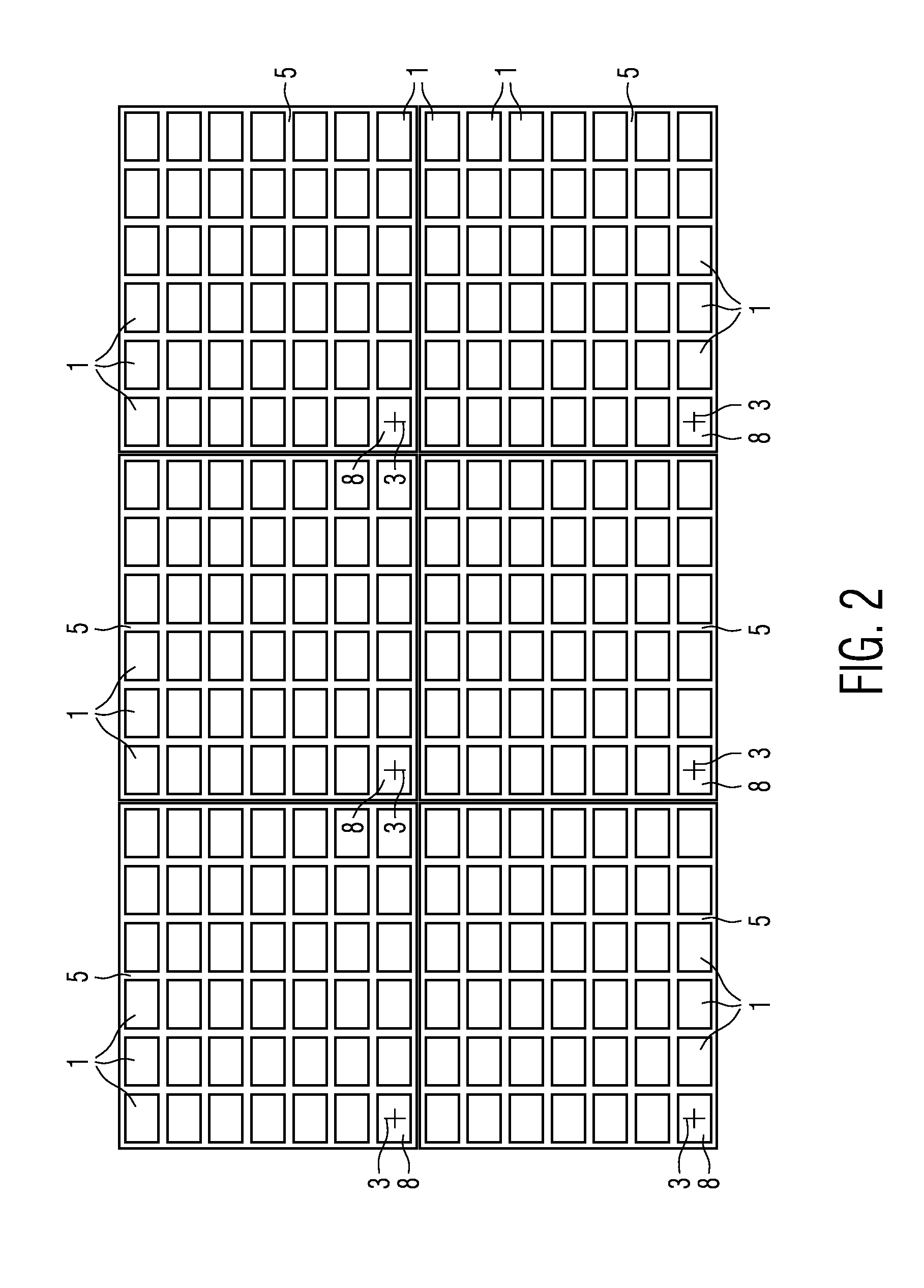

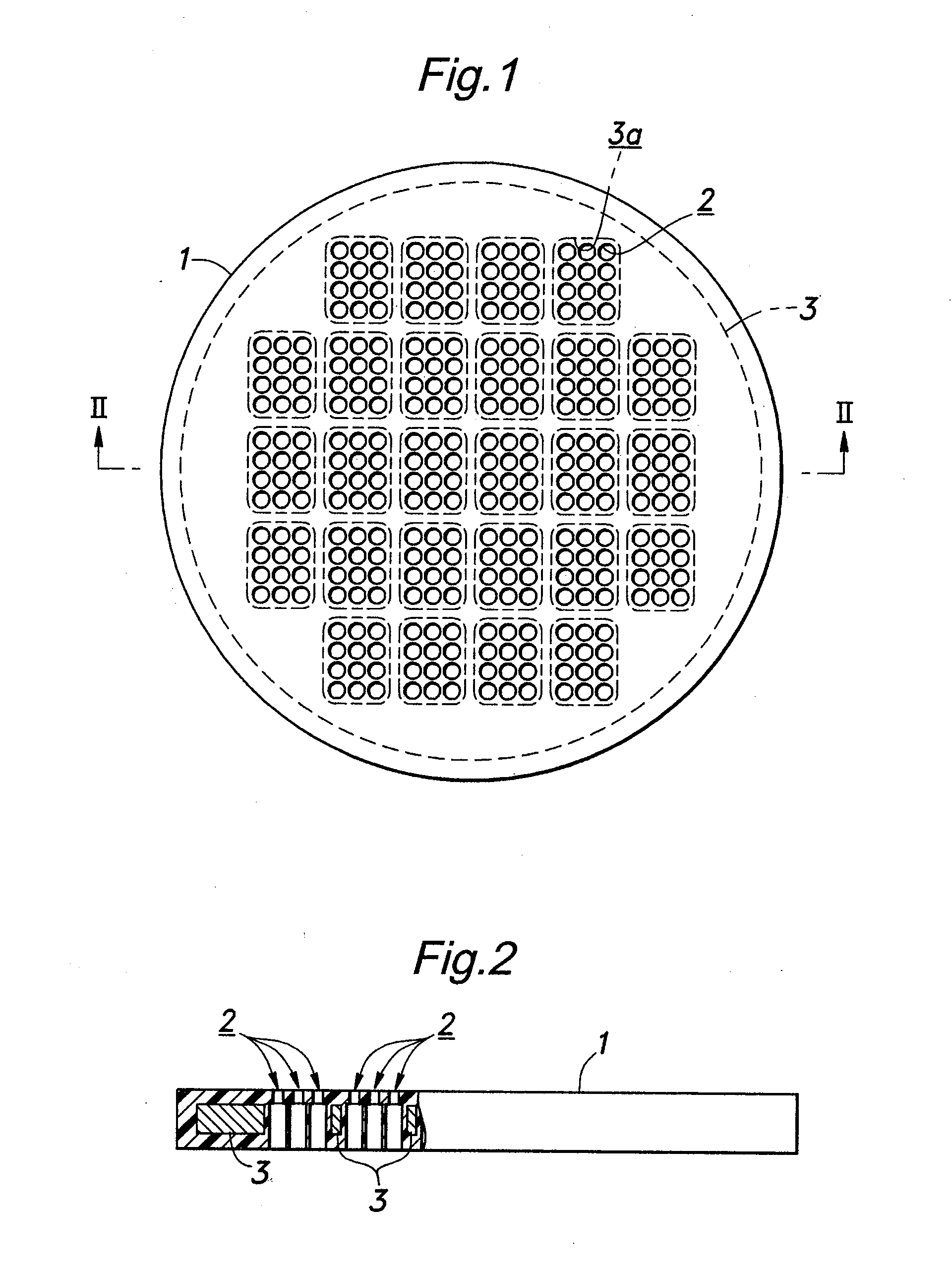

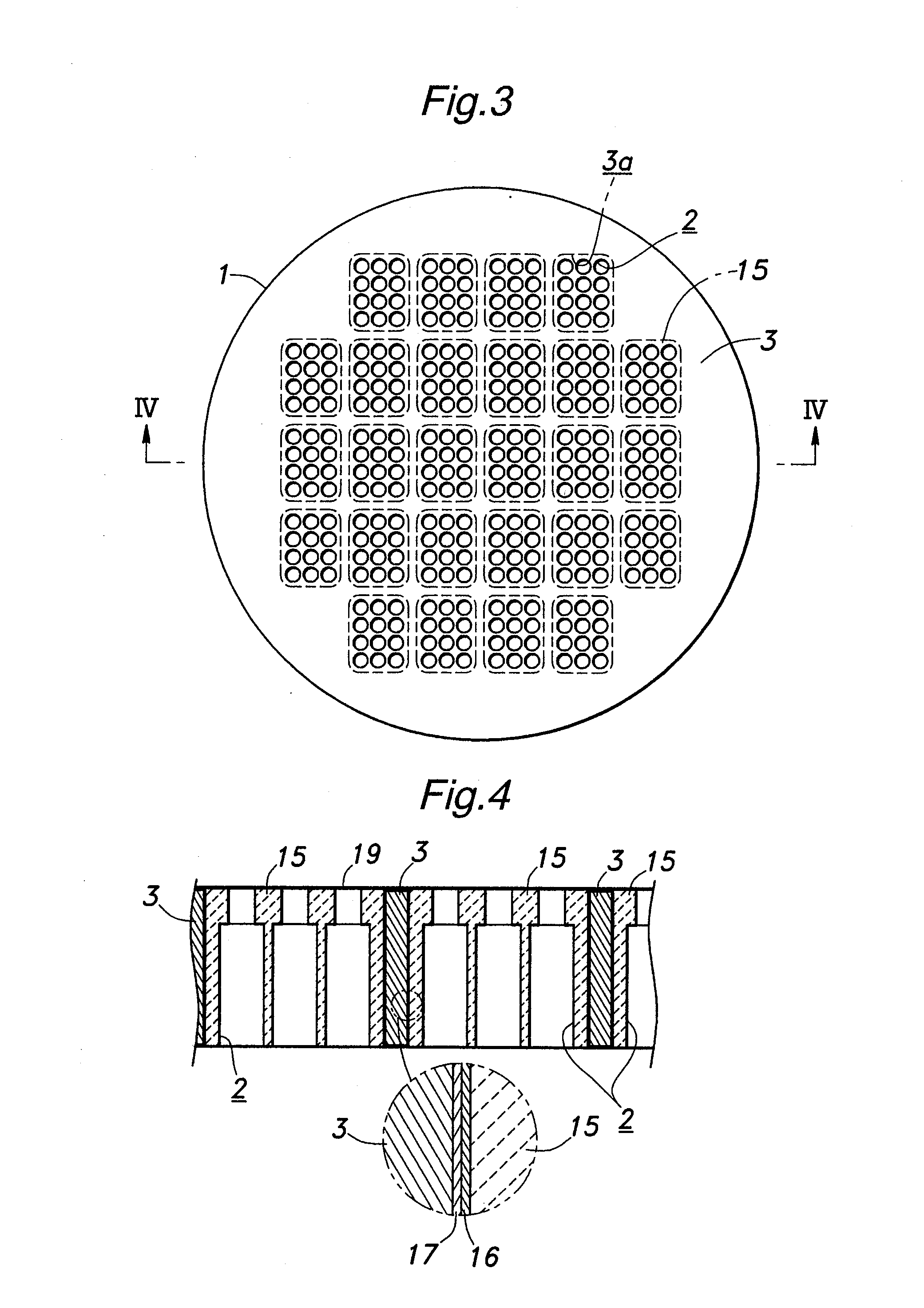

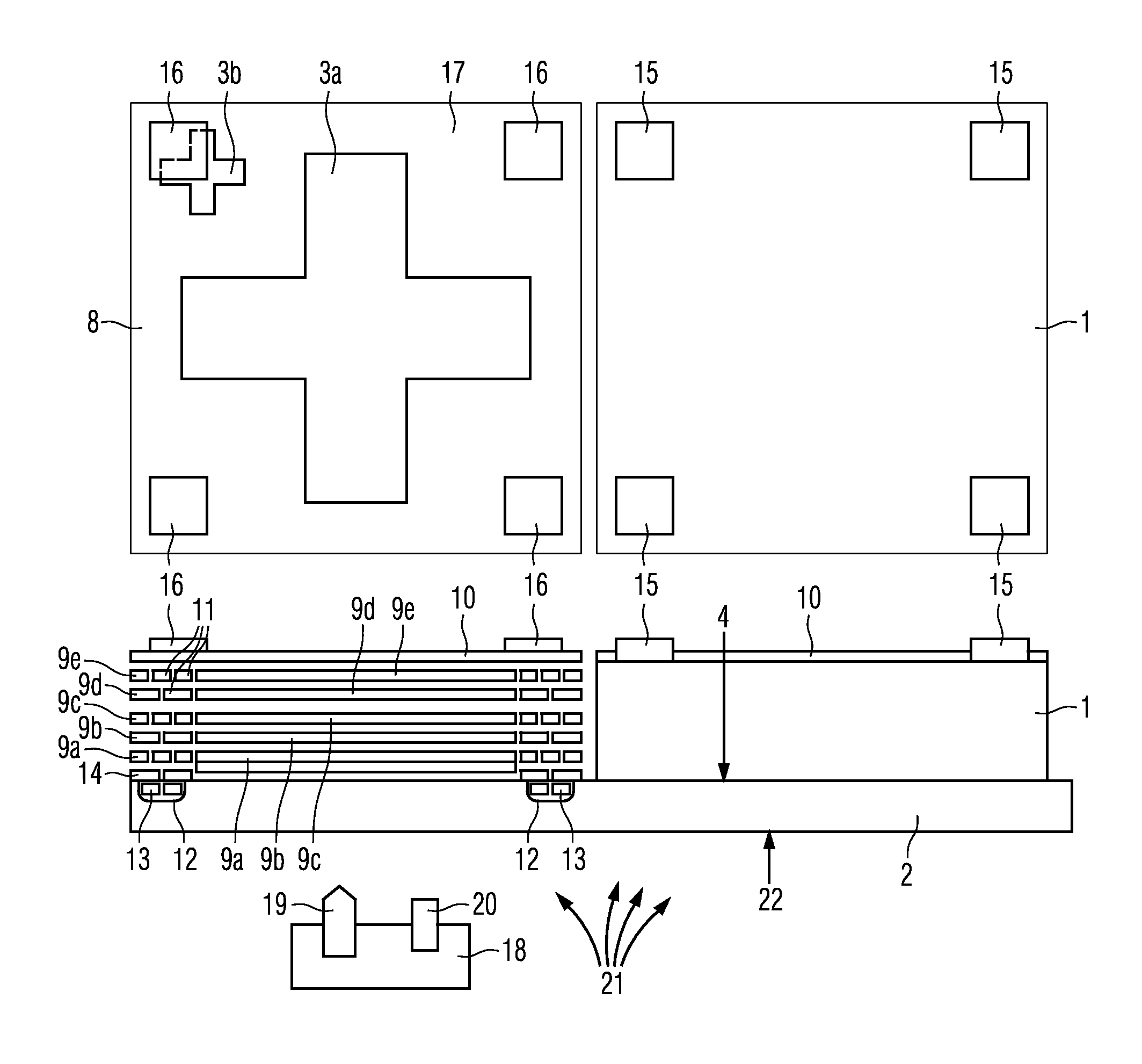

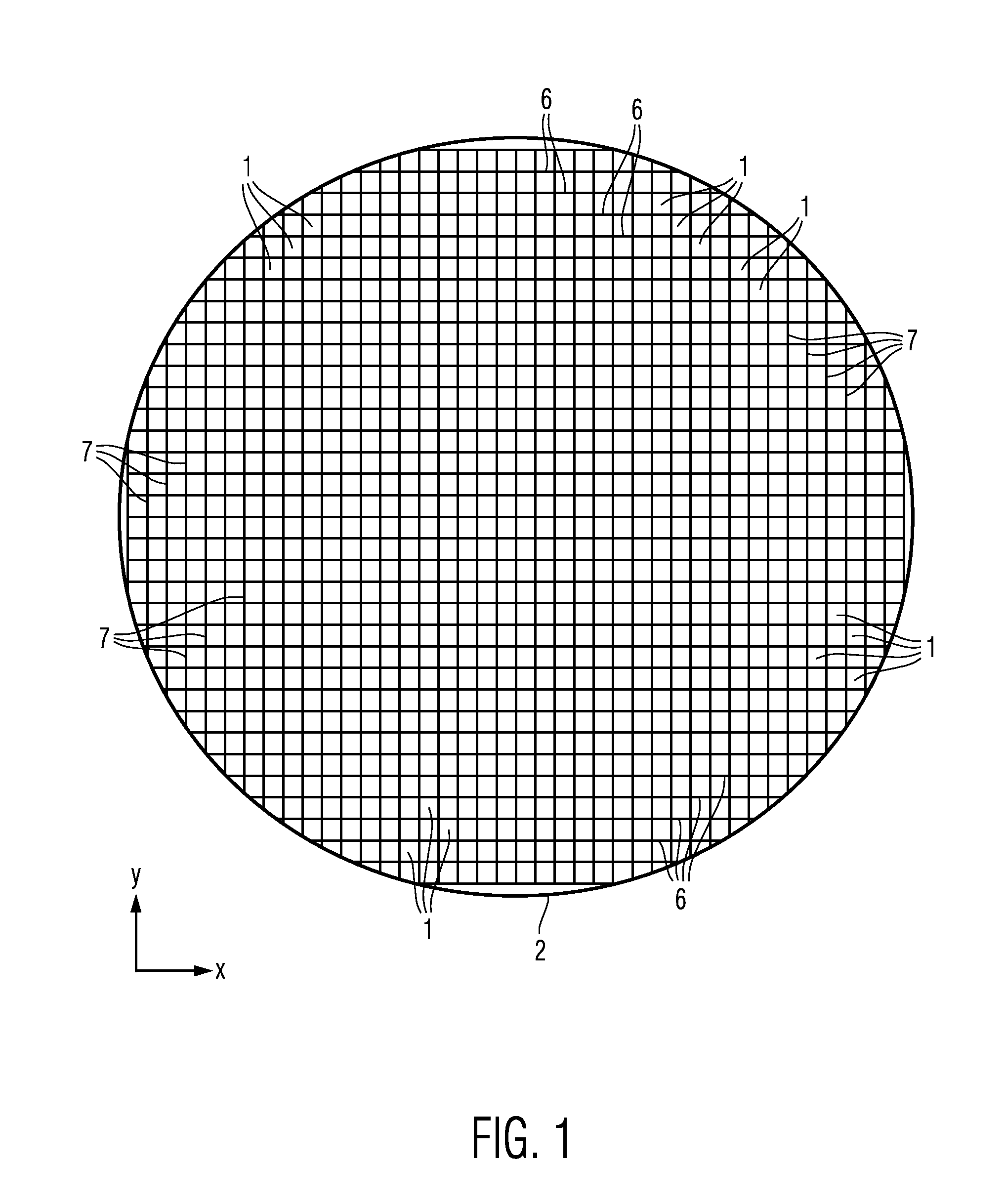

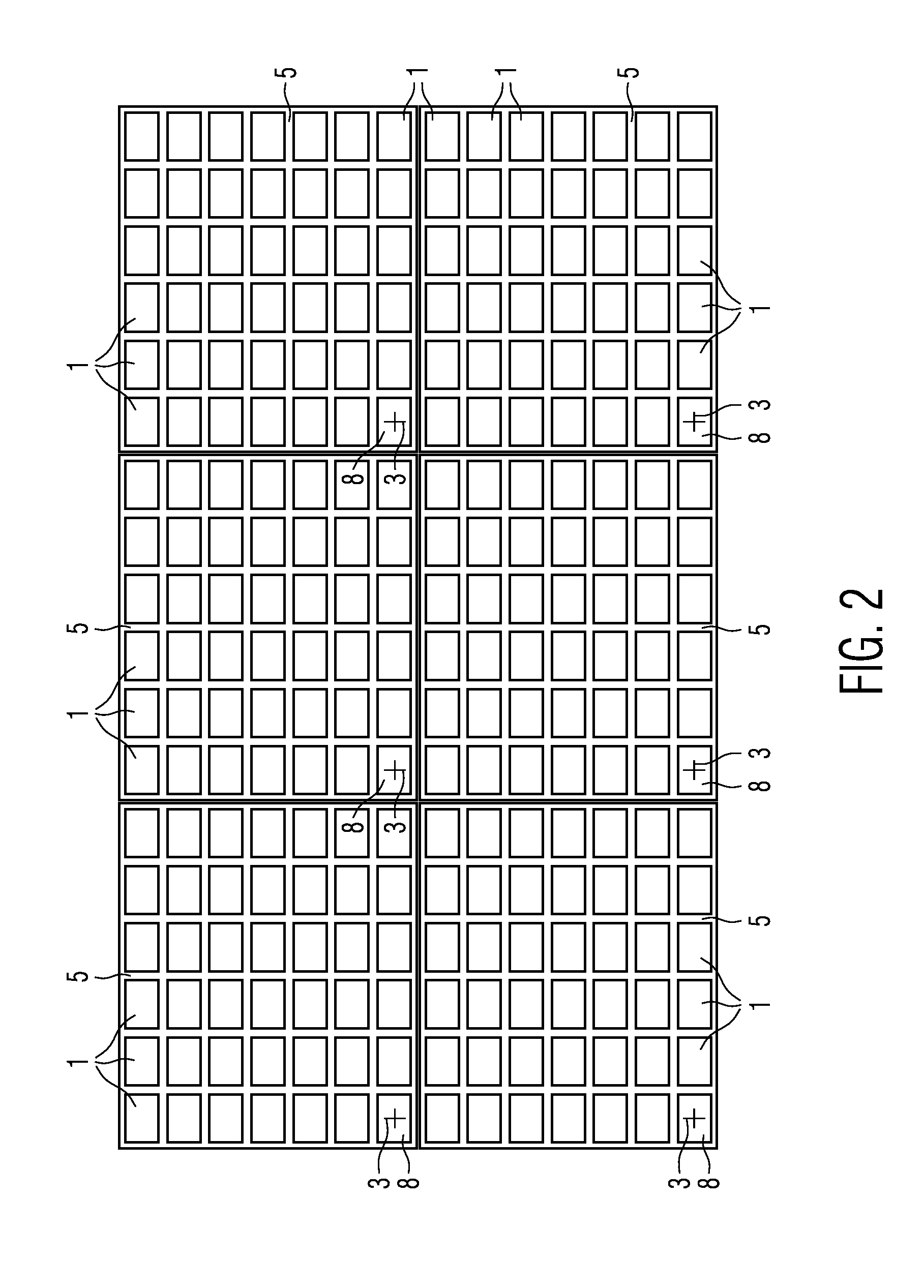

Integrated Circuits On A Wafer and Method For Separating Integrated Circuits On A Wafer

ActiveUS20100270655A1Reliable formingReliable separationSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitSeparation process

Integrated circuits (1) on a wafer comprise a wafer substrate (2) and a structure applied on a surface (4) of the wafer substrate (2). The structure forms a plurality of integrated circuits (1) formed on the wafer substrate (2) and the integrated circuits (1) are separated by saw lines (6, 7). The structure comprises a plurality of superposed layers (9a-9e) formed on the wafer substrate (2) and a top layer (10) formed on the superposed layers (9a-9e). The integrated circuit (1) on the wafer further comprise a plurality of alignment marks (3) intended for aligning a separating device (18) for separating the integrated circuits (1) on the wafer into individual integrated circuits (1) during a separation process, wherein the alignment marks (3) are formed from at least one of the superposed layers (9a-9e).

Owner:NXP BV

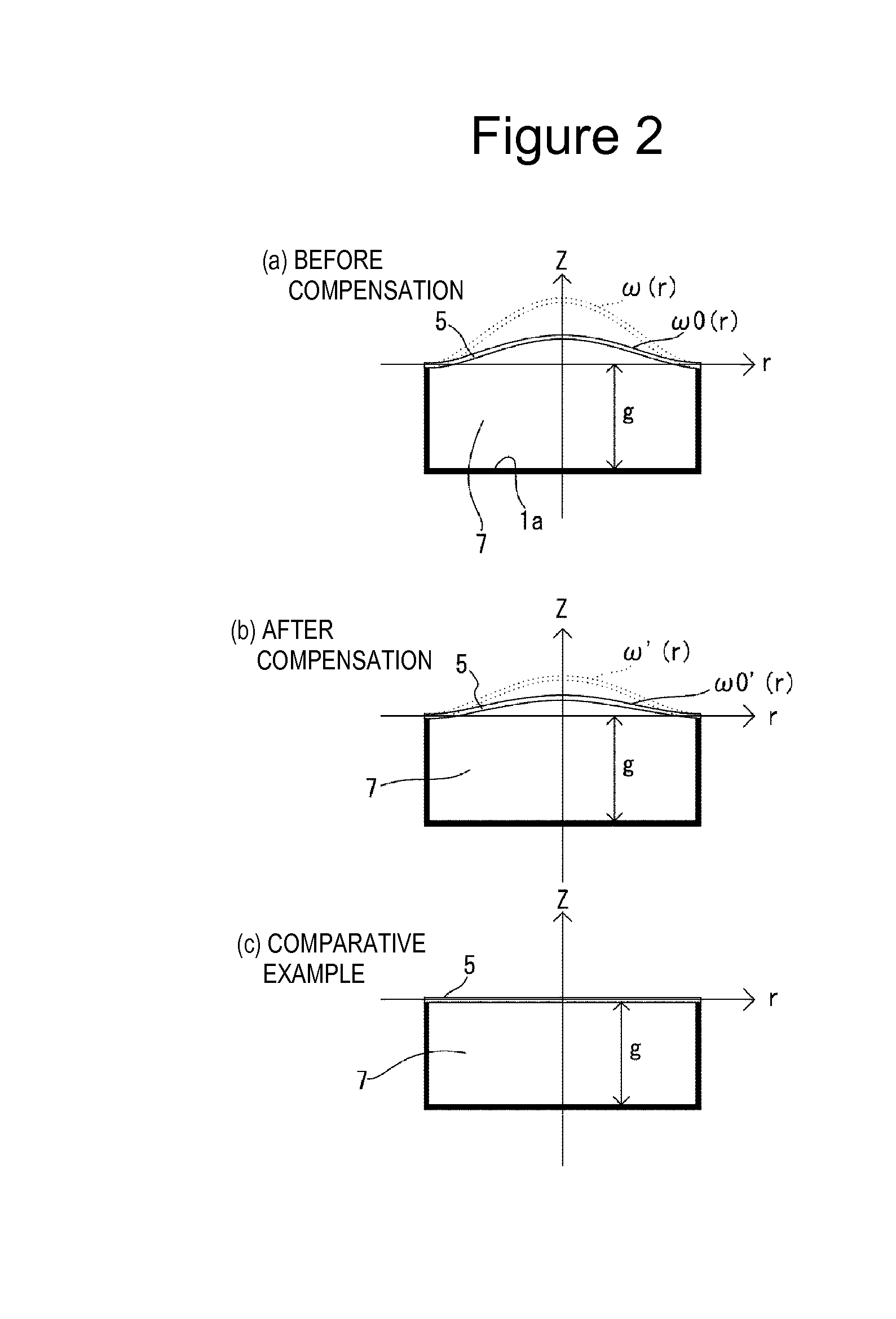

Method for temperature compensation in sensor, computation program for method for temperature compensation, computation processing device, and sensor

InactiveUS20140088890A1Reduce resistanceAllow for any formFlow propertiesFluid pressure measurement by mechanical elementsCapacitanceEngineering

Temperature compensation is performed using a computation program for temperature compensation, a computation processing, and a sensor. Deformation in a diaphragm caused by a pressure change due to the temperature of the gas in a cavity is cancelled out, and deformation of the diaphragm is minimized within the target temperature range, thereby allowing an optimum temperature compensation to be performed. The temperature compensation in a capacitance-type sensor executes calculation steps which include including a calculation step (S17) of acquiring the amount of change ΔC′ in capacitance. A parameter ΔC′ is obtained, through which it is possible to determine the degree of compensation for the deformation in the diaphragm section caused by a pressure change due to the temperature changes of the gas in the hermetically sealed space.

Owner:JAPAN SCI & TECH CORP

Support Member Assembly for Conductive Contact Members

InactiveUS20080224720A1High densityImprove accuracySemiconductor/solid-state device testing/measurementElectronic circuit testingGeneral assemblyPlastic materials

Provided is a support member assembly suitable for use in a contact probe head comprising a support member formed with a plurality of holder holes for supporting conductive contact members in a mutually parallel relationship, and a reinforcing member integrally formed with the support member and extending in a part of the support member devoid of any holder holes. The reinforcing member increases the overall mechanical strength of the support member assembly, and prevents the thermal deformation of the support member. Because the holder holes are formed in the support member made of material suitable for forming holes, such as plastic material and ceramic material, the holder holes can be formed at high precision and at low cost.

Owner:NHK SPRING CO LTD

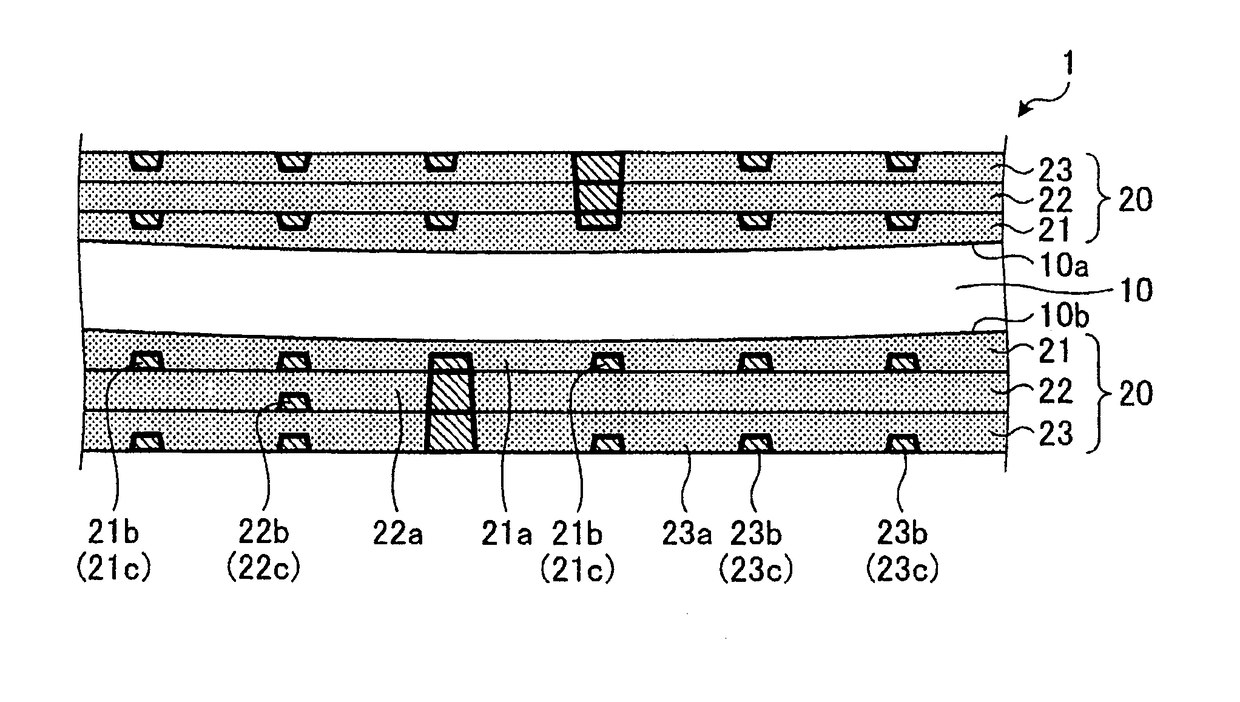

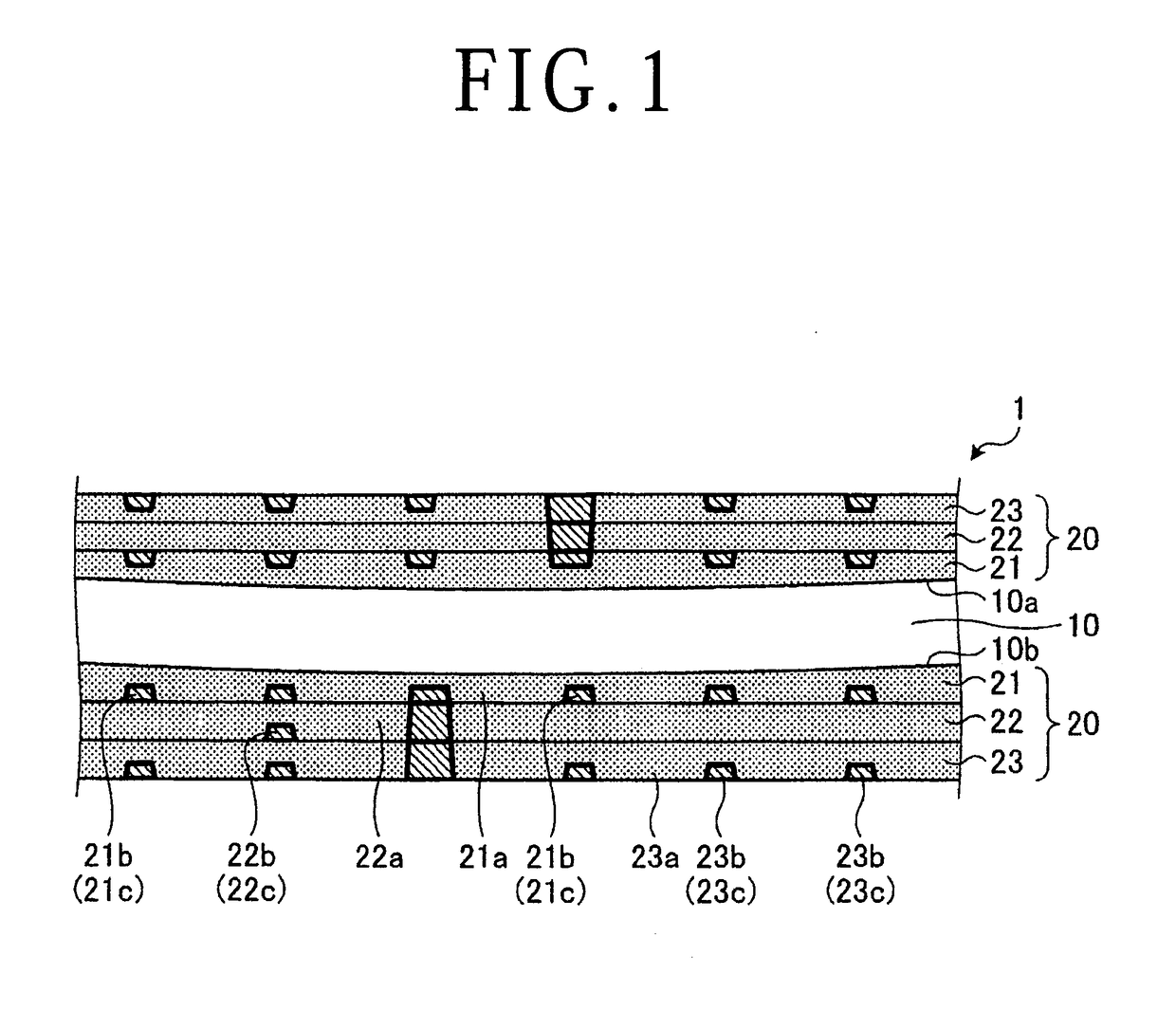

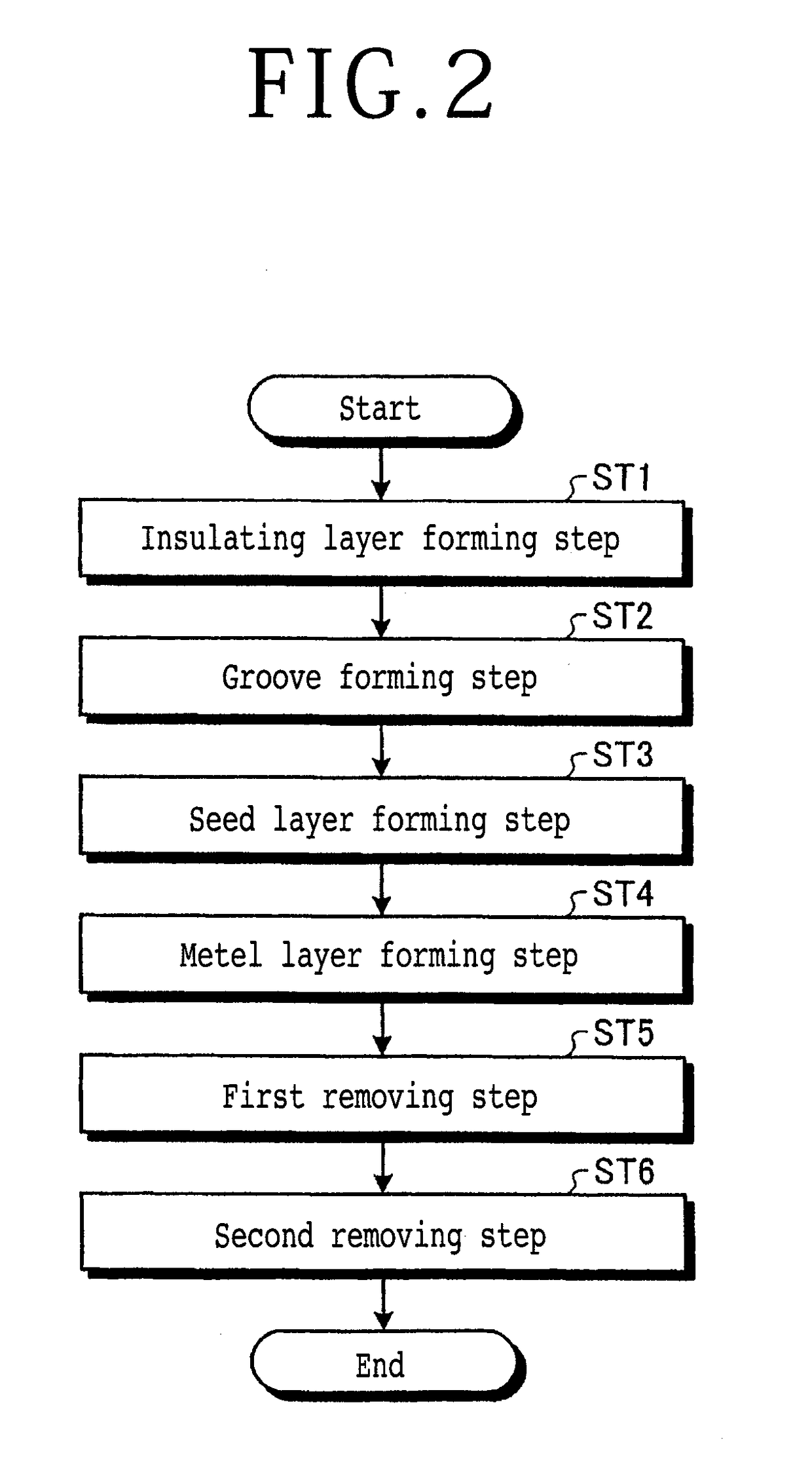

Manufacturing method for wiring board

ActiveUS20180103547A1InhibitionAllow for any formSemiconductor/solid-state device detailsSolid-state devicesMachiningElectroplating

A method for manufacturing a wiring board that has a rewiring layer on a surface thereof includes forming an insulating layer on a core substrate, forming a groove, in which a wiring layer of a circuit pattern is to be provided, on the insulating layer, forming a metal seed layer on an exposed face of the insulating layer on which the groove is formed, electrodepositing metal, which is to form the wiring layer, by plating to fill the groove with the metal to form a metal layer on the seed layer, machining the metal layer by a cutting tool to remove the metal layer up to a position not reaching the top of the insulating layer, and performing etching or a CMP process to expose the top of the insulating layer thereby to form the wiring layer in the groove and flatten an exposed face of the wiring layer.

Owner:DISCO CORP

Housing Part for a Measurement Device Having a Microwave-Permeable Glass or Ceramic Window

ActiveUS20170164494A1Simple and cost-effectiveSimple configurationWave based measurement systemsMetal casingsElectricityMicrowave

A housing part for a measurement device includes a single metal body having an outer circumferential side wall with an upper end and a lower end and an inner disc-shaped base wall located between the upper and lower ends, wherein the side wall and the base wall define two partially enclosed areas, where the base wall comprises a central hole into which a microwave-permeable glass or ceramic window is fused, microwave guides and dielectric matching elements are provided on both sides of the microwave-permeable or ceramic window to propagate microwaves between the desired points such as a radar antenna and radar electronics, and where the matching elements not only adjust the impedance of the microwave window to the impedances of the microwave guides but also put additional compression stress on the surfaces of the fused window, which are preferably ground flat to be flush with those of the center portion.

Owner:SIEMENS AG

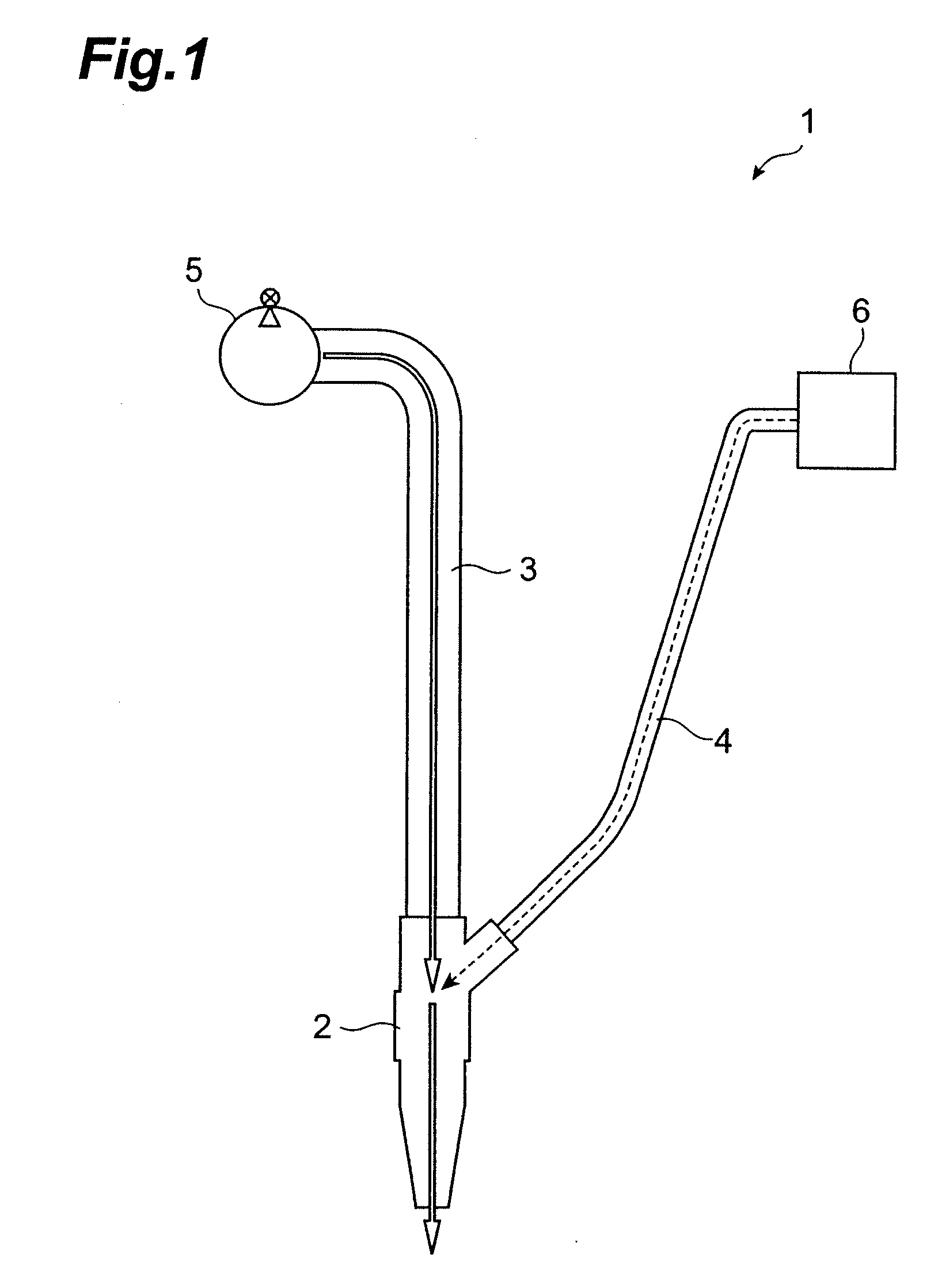

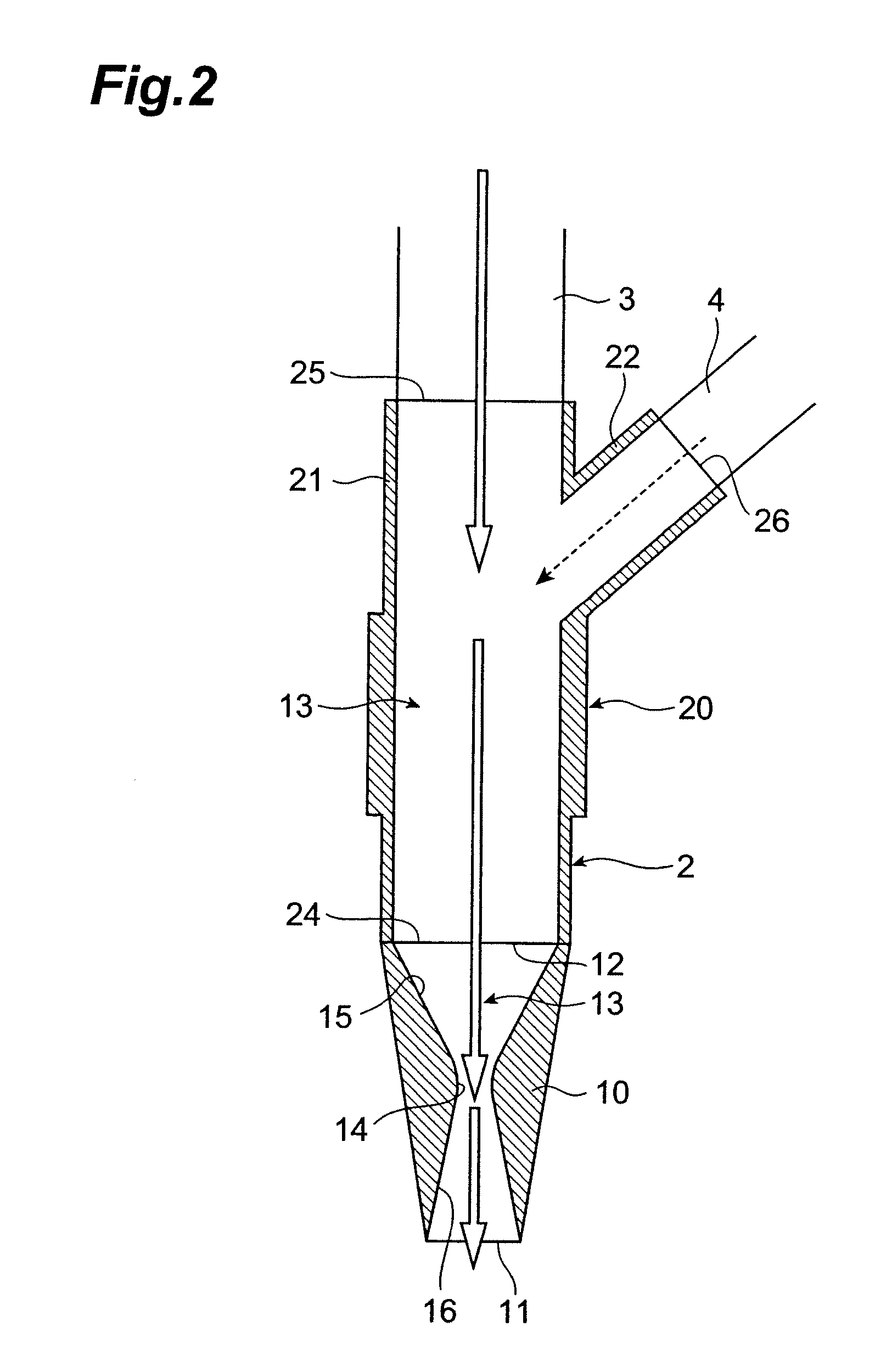

Method of spray application, and spray apparatus, for bentonite material

ActiveUS20090252881A1Increase dry densityReduce water contentFlow mixersTransportation and packagingSodium BentoniteEngineering

Owner:KAJIMA CORP

Core board comprising nickel layer, multilayer board and manufacturing method thereof

InactiveUS20070201214A1High bonding strengthAllow for any formStuffed mattressesSpring mattressesInsulation layerMaterials science

The present invention provides a core board and a manufacturing method thereof, in which the core board includes a nickel layer as a seed layer to improve the binding strength between an insulation layer and a conductive layer, so that it allows forming fine inner circuits by the semi-additive method.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Integrated circuits on a wafer and method for separating integrated circuits on a wafer

ActiveUS8415769B2Allow for any formReliable separationSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitSeparation process

Integrated circuits (1) on a wafer comprise a wafer substrate (2) and a structure applied on a surface (4) of the wafer substrate (2). The structure forms a plurality of integrated circuits (1) formed on the wafer substrate (2) and the integrated circuits (1) are separated by saw lines (6, 7). The structure comprises a plurality of superposed layers (9a-9e) formed on the wafer substrate (2) and a top layer (10) formed on the superposed layers (9a-9e). The integrated circuit (1) on the wafer further comprise a plurality of alignment marks (3) intended for aligning a separating device (18) for separating the integrated circuits (1) on the wafer into individual integrated circuits (1) during a separation process, wherein the alignment marks (3) are formed from at least one of the superposed layers (9a-9e).

Owner:NXP BV

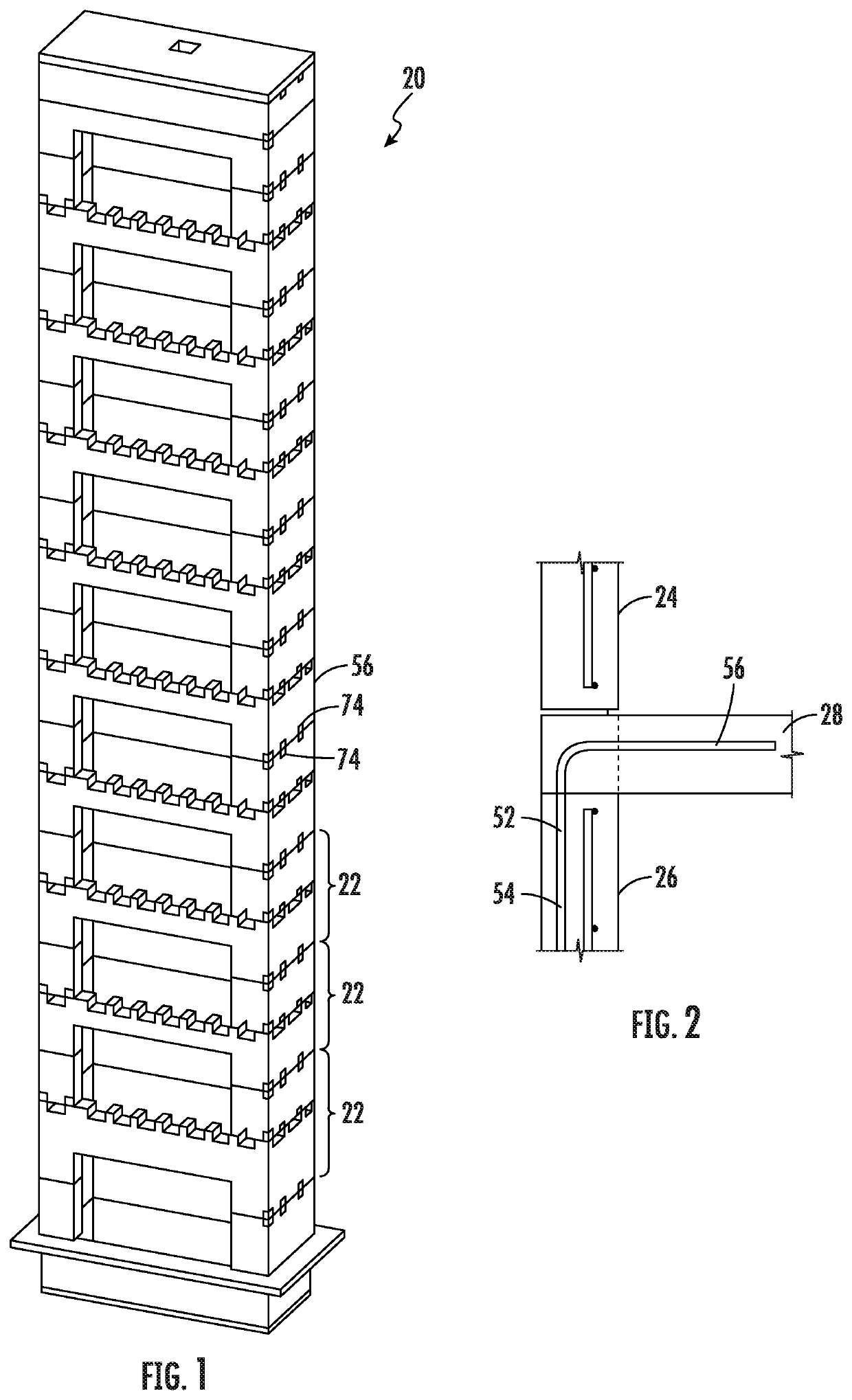

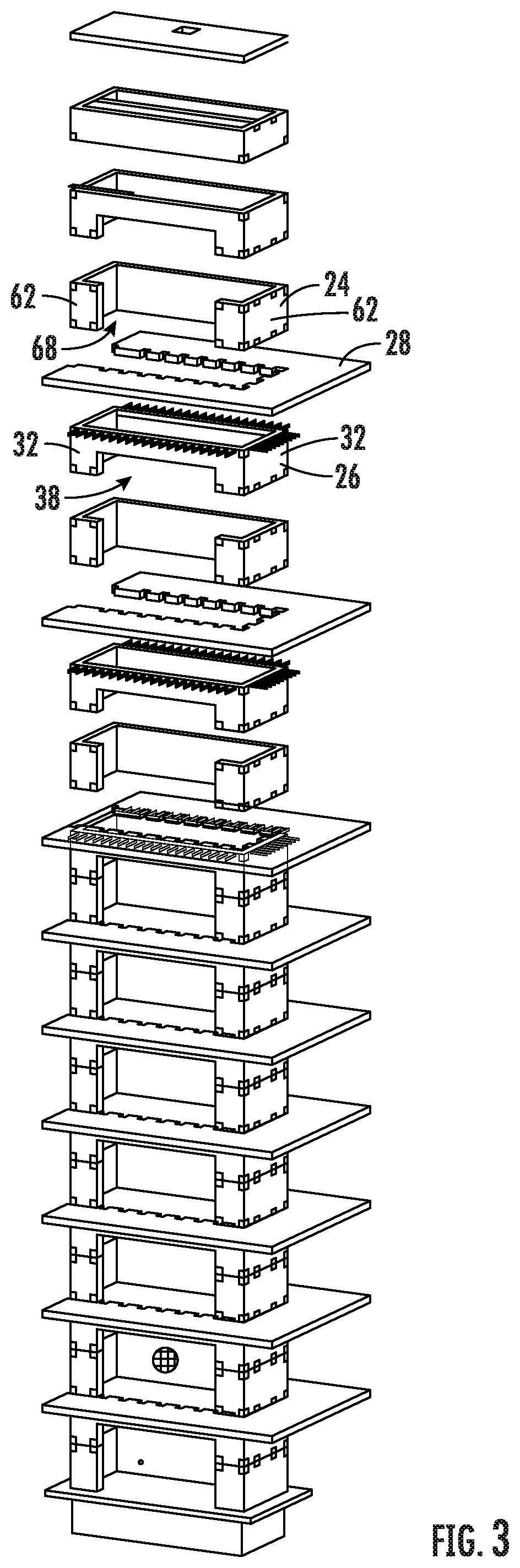

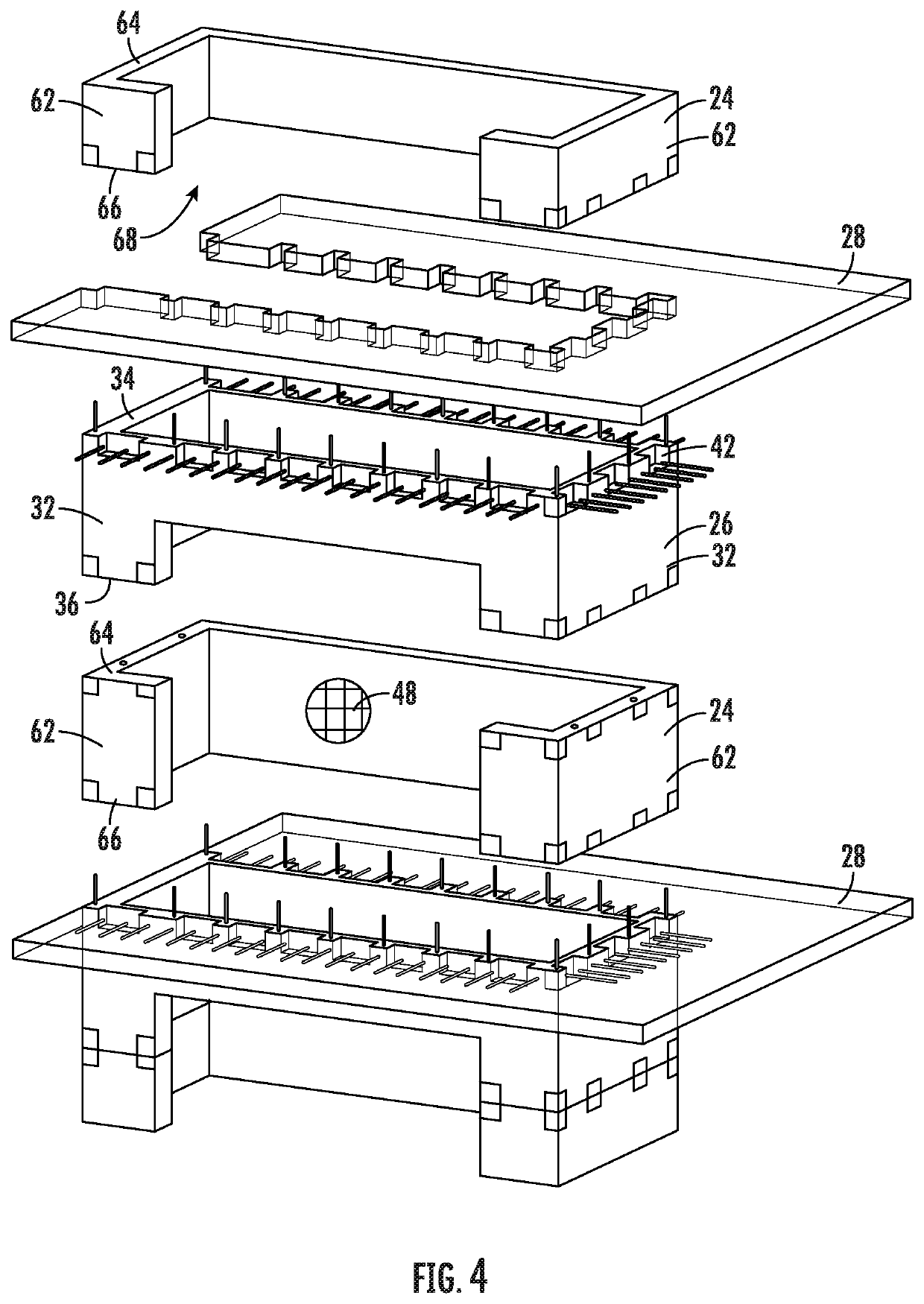

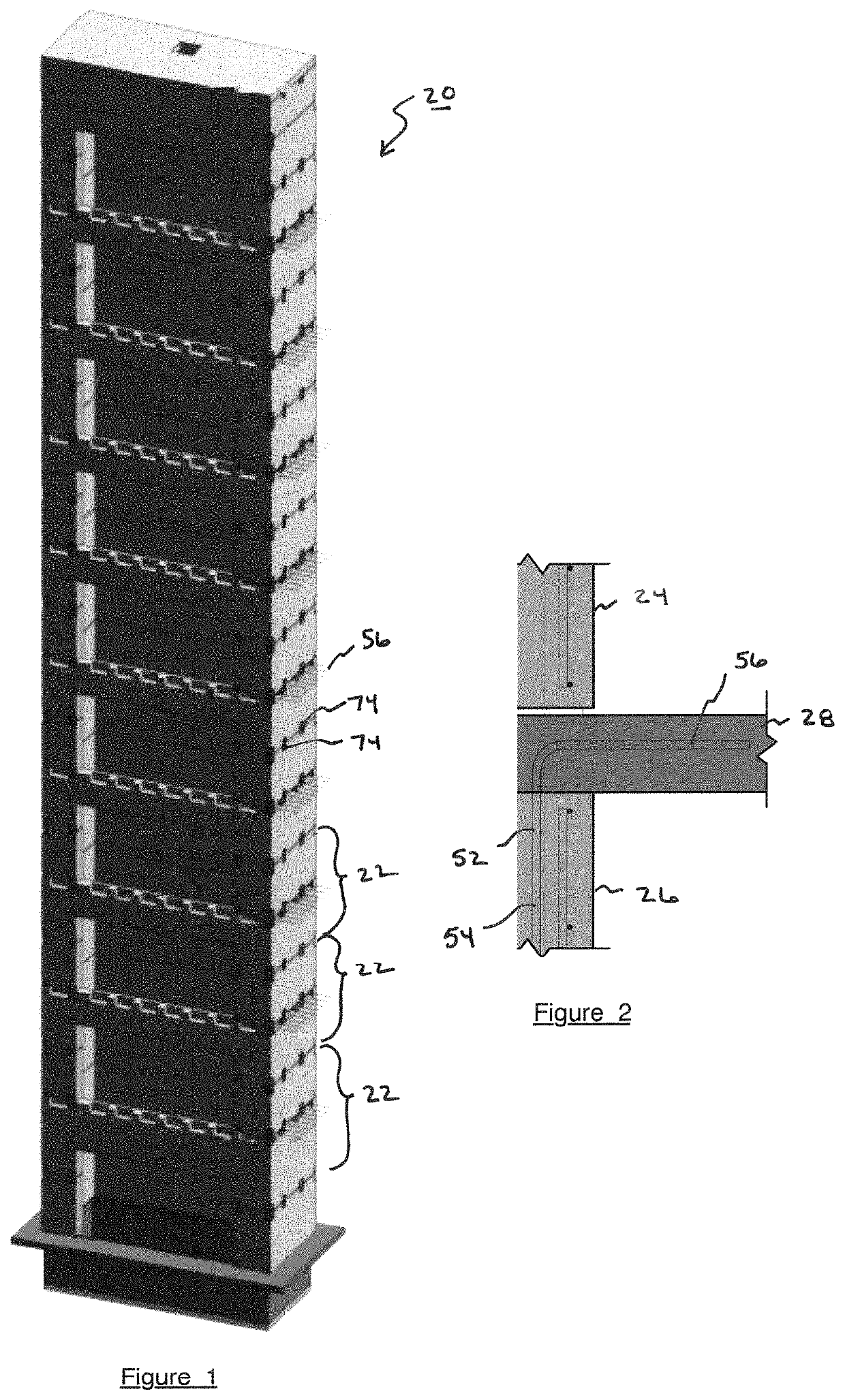

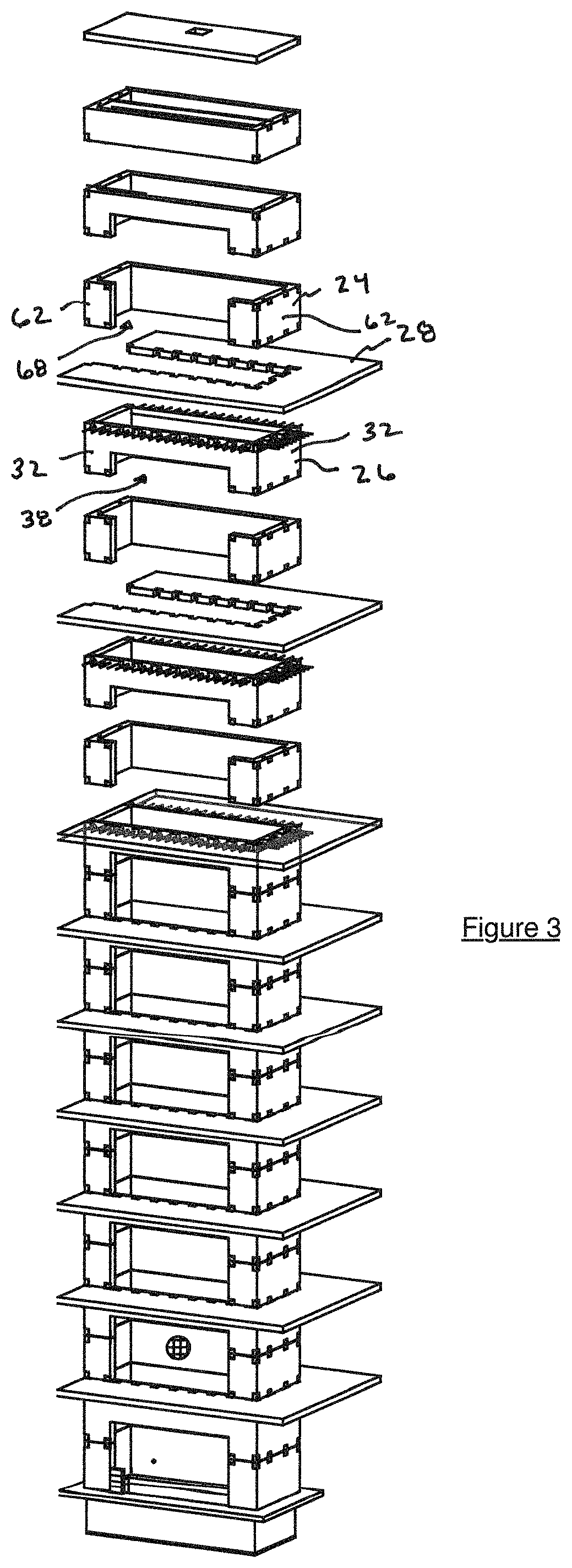

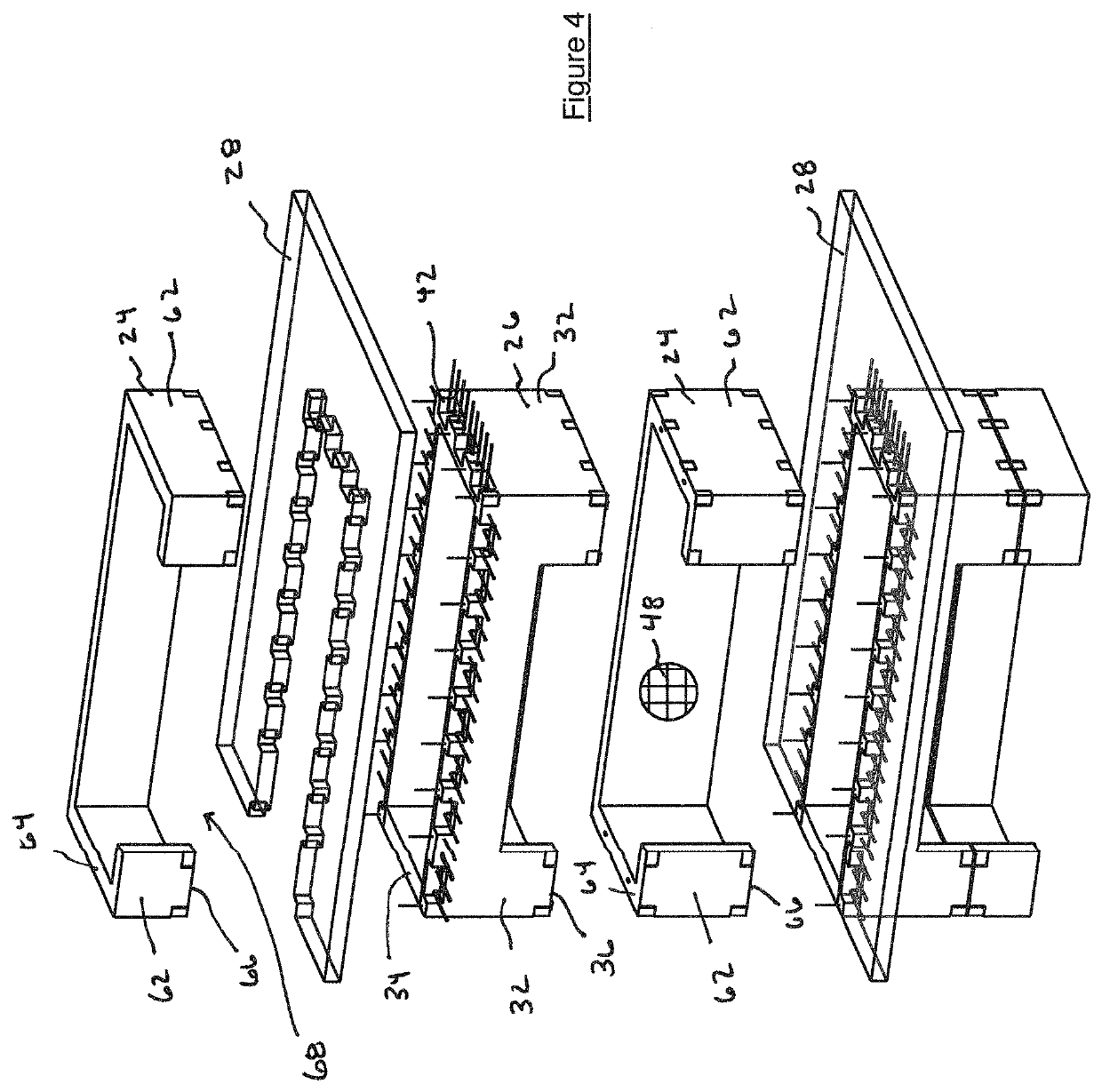

Structures for Use in Erecting Multistory Buildings and Methods for Making Such Structures

ActiveUS20210332585A1Quick assemblyAllow for any formMouldsPretreatment controlFloor slabArchitectural engineering

Disclosed are various construction techniques for erecting a multistory building with an elevator shaft. In accordance with the method, upper and lower shaft components are formed at an offsite facility. These shaft components are then joined together to form a segment of the larger elevator shaft. Once constructed, the segment is transported to a jobsite and erected. Once an individual segment is installed, a floor slab can be formed about the segment. Using pre-cast elevator segments simplifies and expedites the construction process. In one embodiment, each segment includes a serrated edge that facilitates a connection between the floor slab and the shaft segment. Rebar and reinforcing dowels can also be used to improve the connection. Associated shaft constructions are also disclosed.

Owner:RANDALL ENGINEERED WALL SYST INC

Structures for use in erecting multistory buildings and methods for making such structures

ActiveUS11230837B2Quick assemblyAllow for any formMouldsPretreatment controlFloor slabArchitectural engineering

Disclosed are various construction techniques for erecting a multistory building with an elevator shaft. In accordance with the method, upper and lower shaft components are formed at an offsite facility. These shaft components are then joined together to form a segment of the larger elevator shaft. Once constructed, the segment is transported to a jobsite and erected. Once an individual segment is installed, a floor slab can be formed about the segment. Using pre-cast elevator segments simplifies and expedites the construction process. In one embodiment, each segment includes a serrated edge that facilitates a connection between the floor slab and the shaft segment. Rebar and reinforcing dowels can also be used to improve the connection. Associated shaft constructions are also disclosed.

Owner:RANDALL ENGINEERED WALL SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com