Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Affect the blending effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

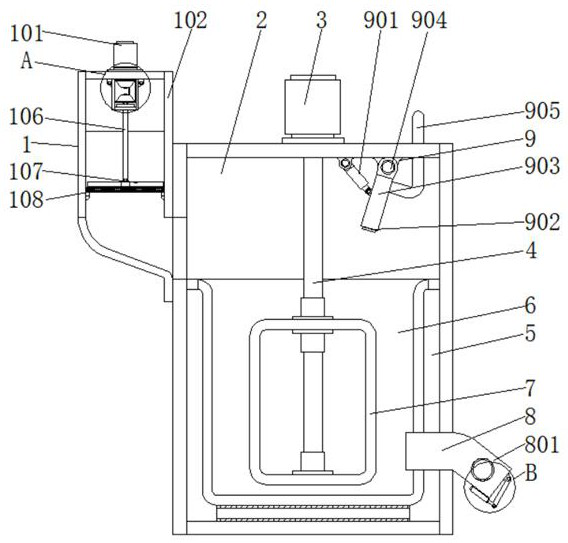

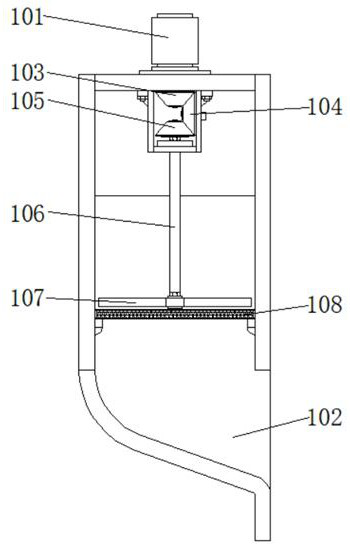

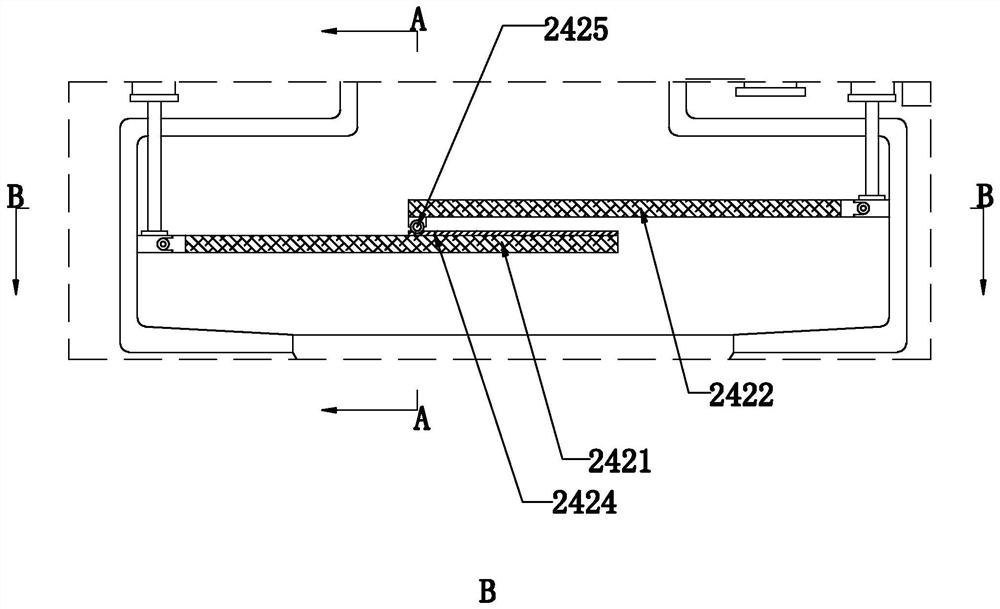

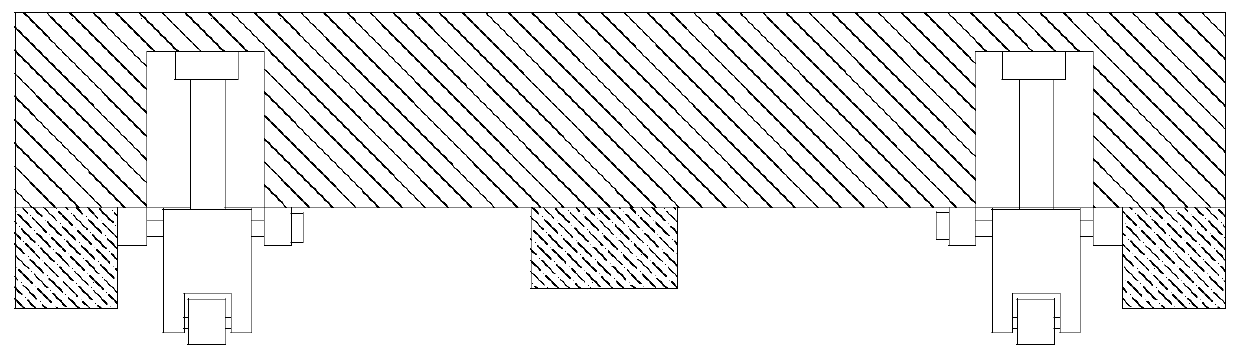

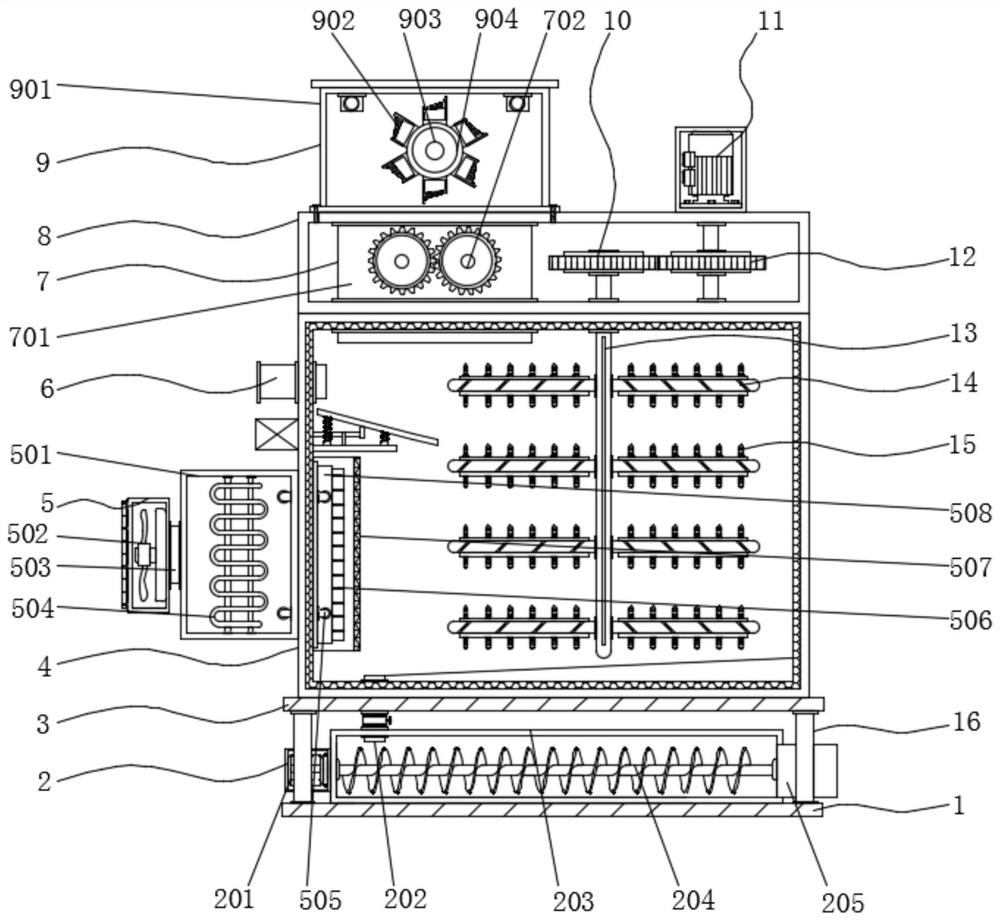

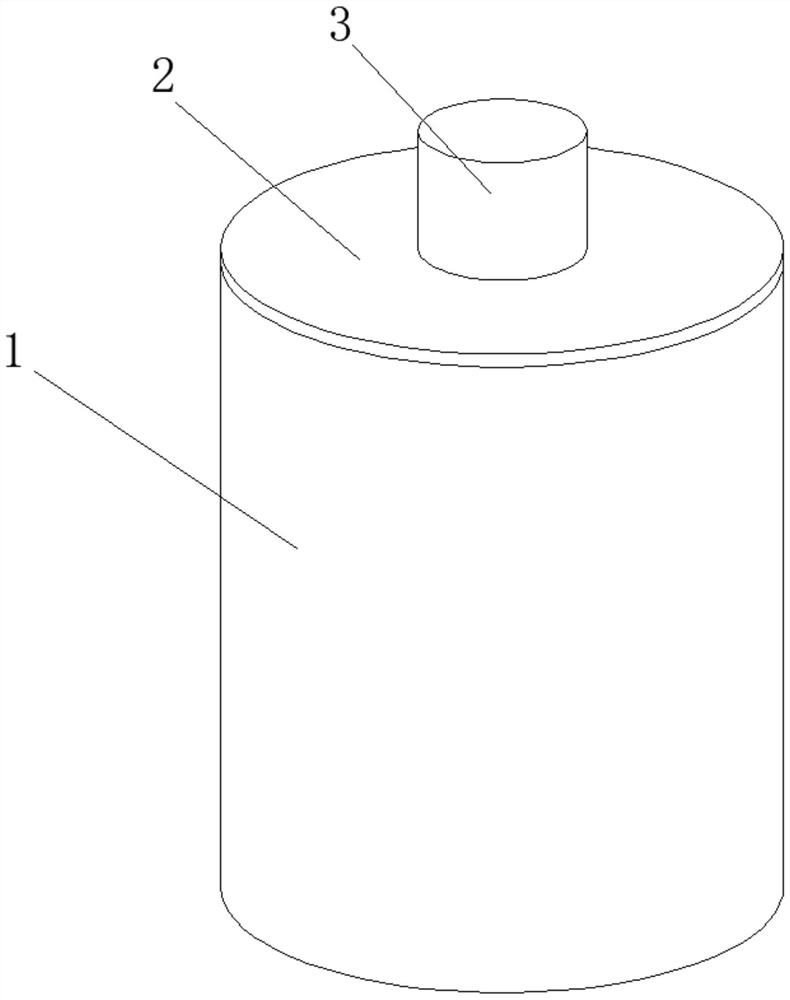

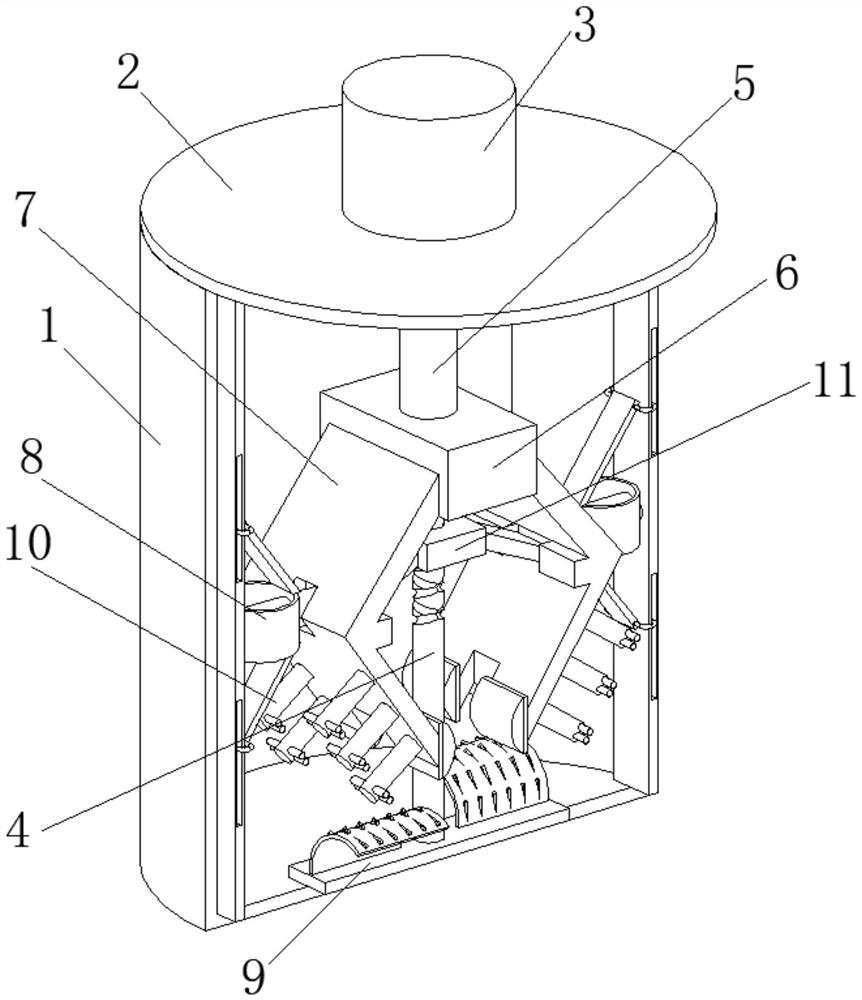

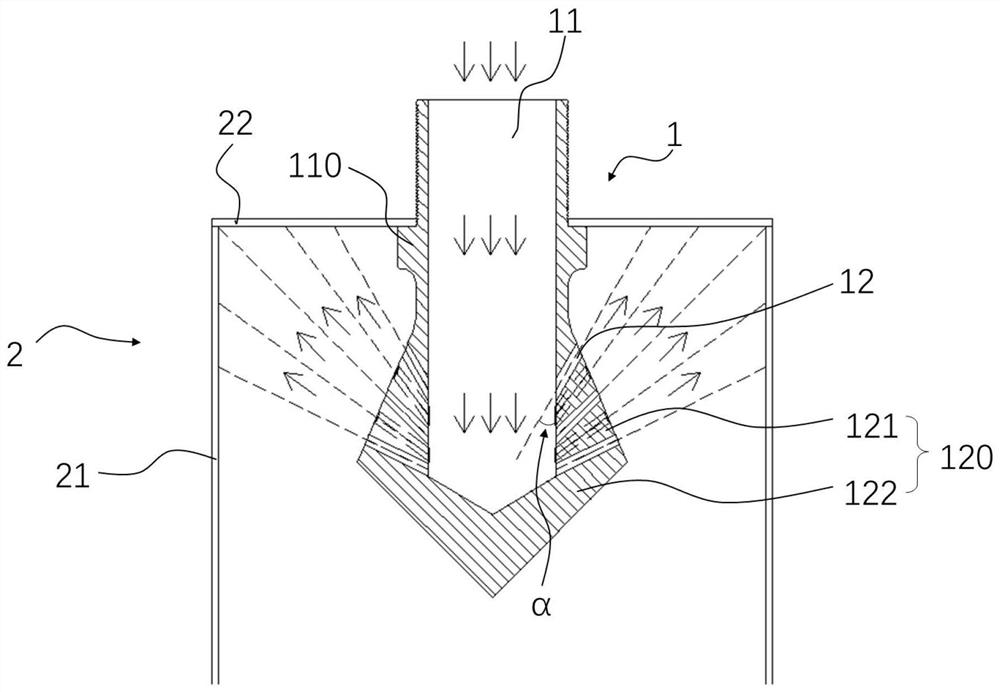

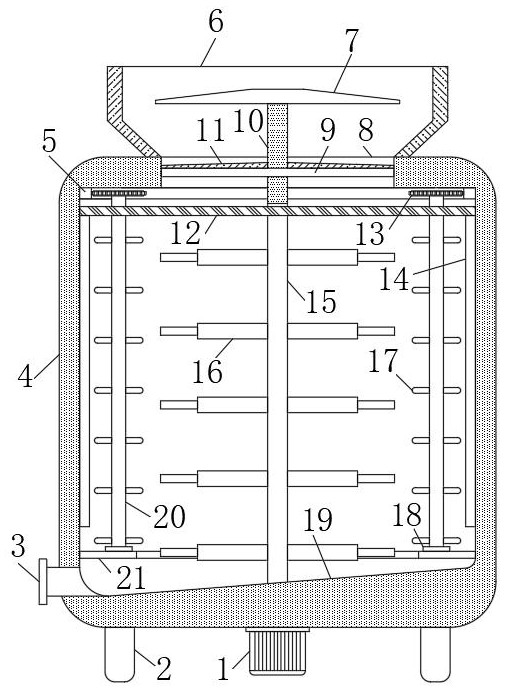

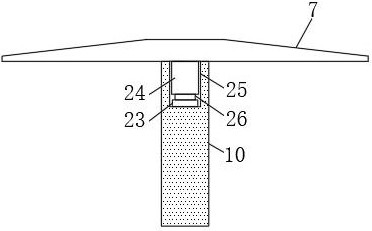

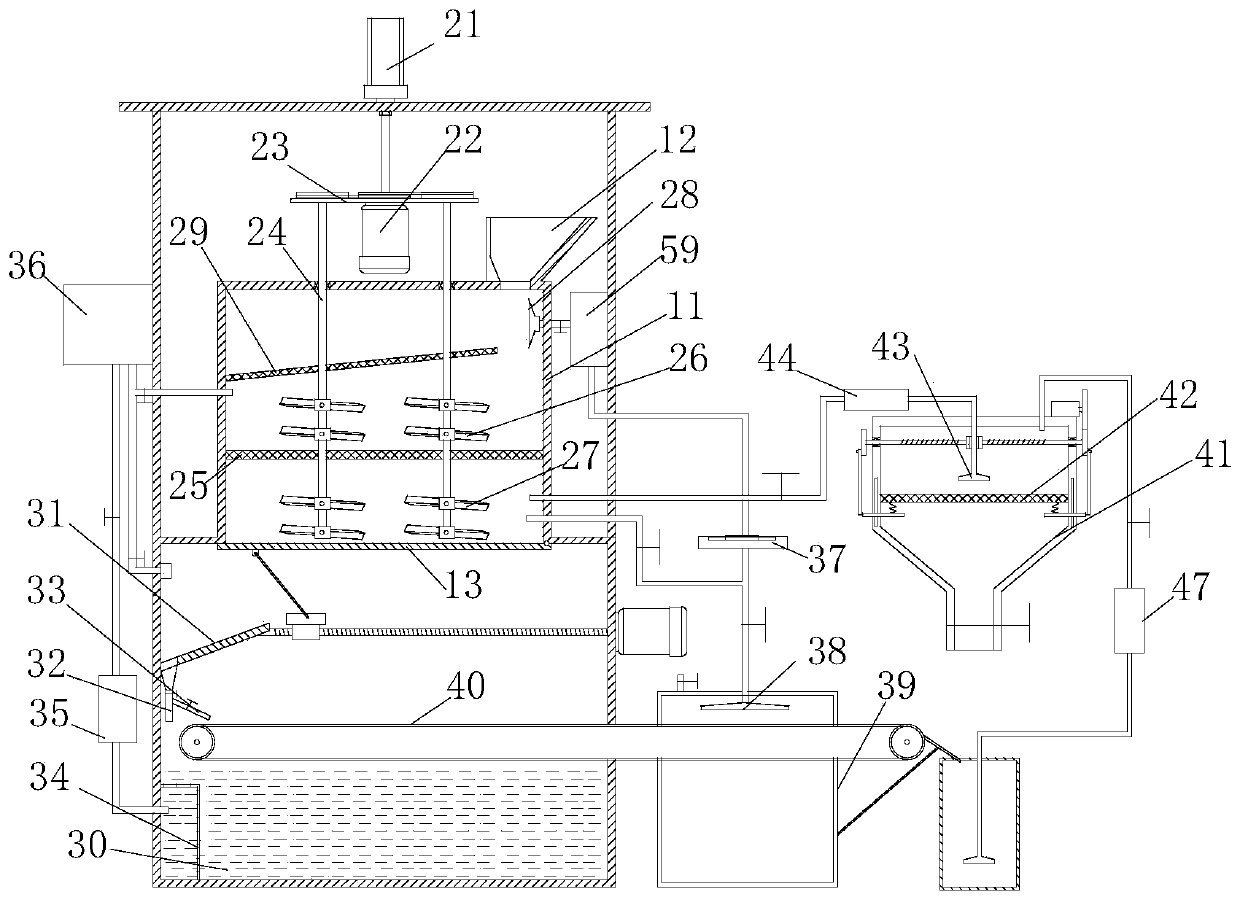

Material mixing device with multiple mixing chambers

ActiveCN108479611AAvoid cloggingWell mixedGas current separationTransportation and packagingSprayerCorn flour

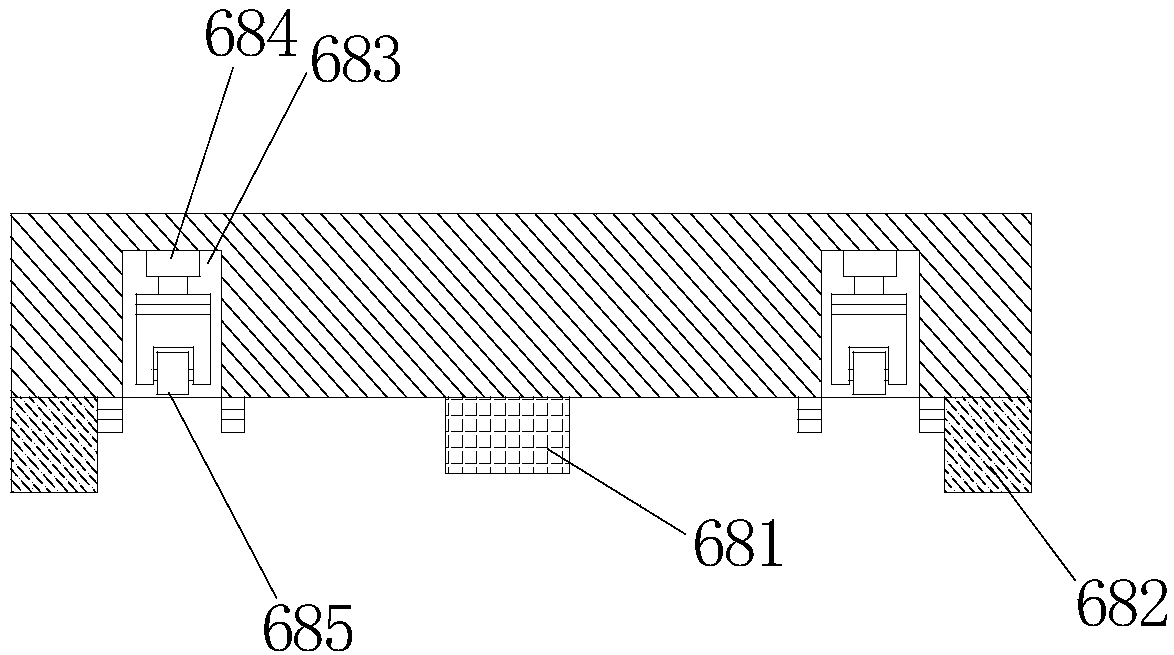

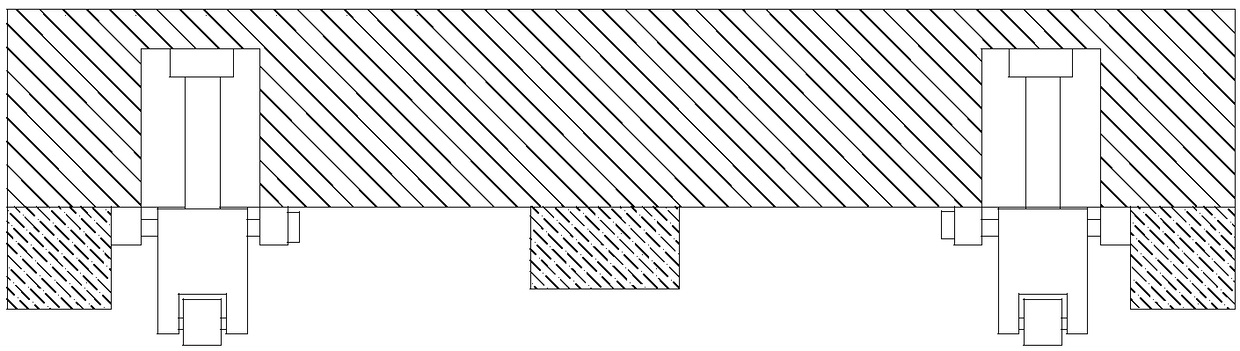

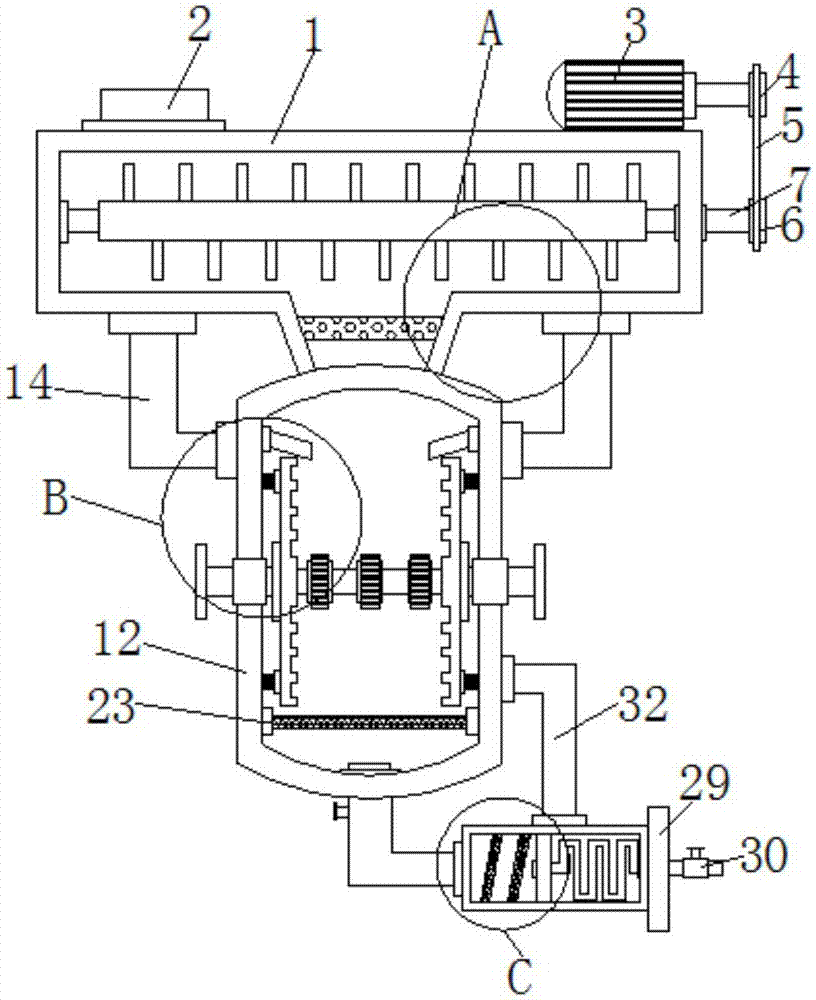

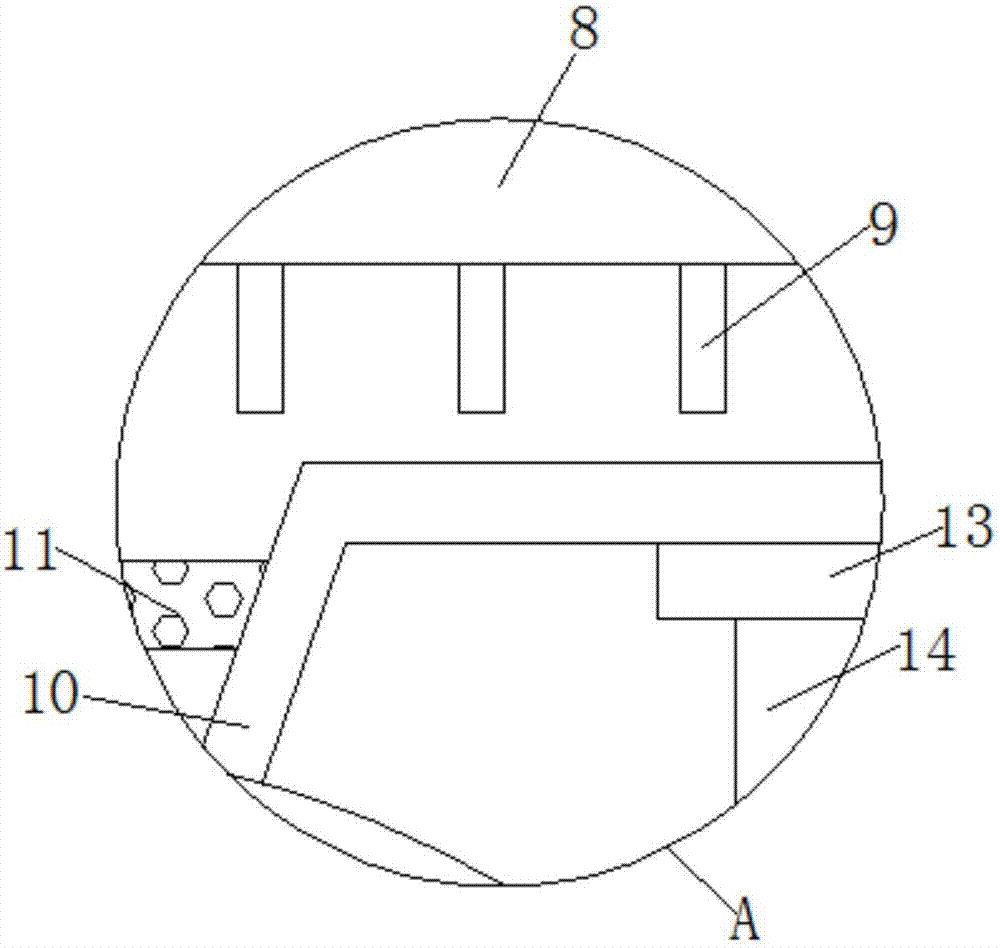

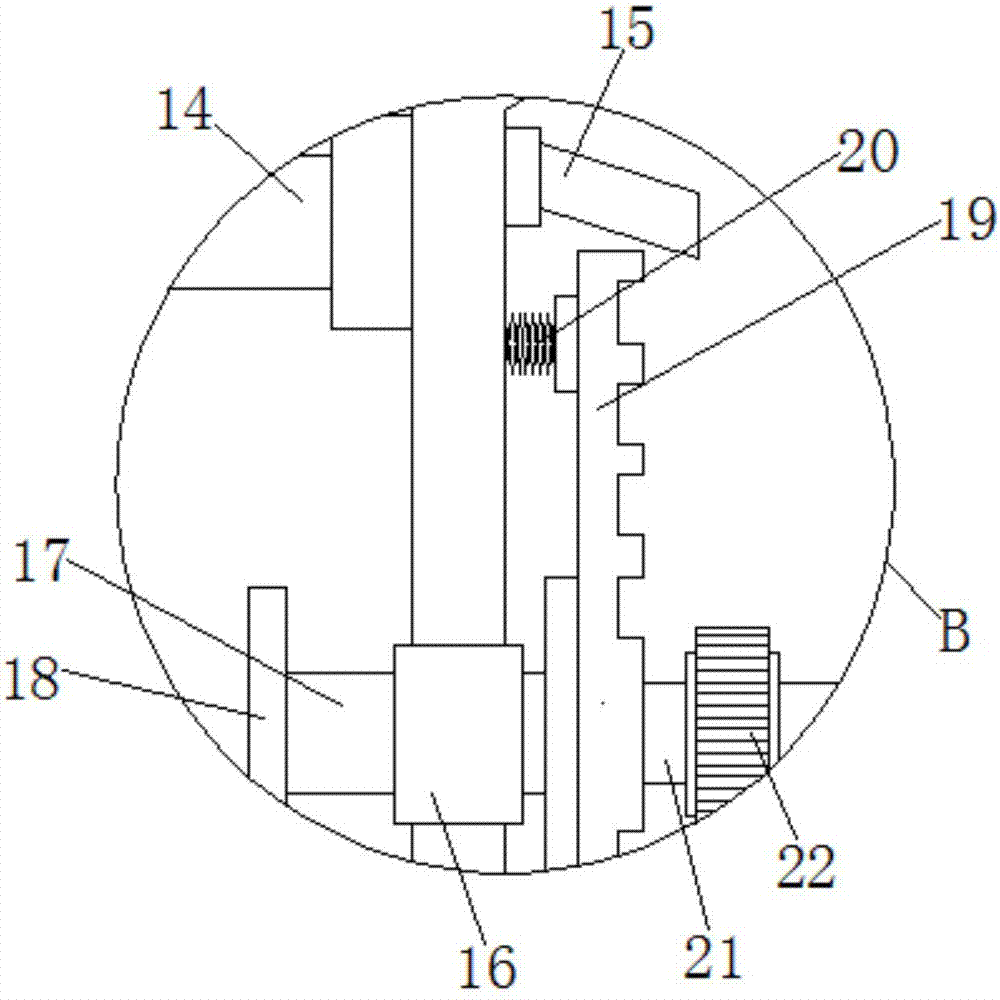

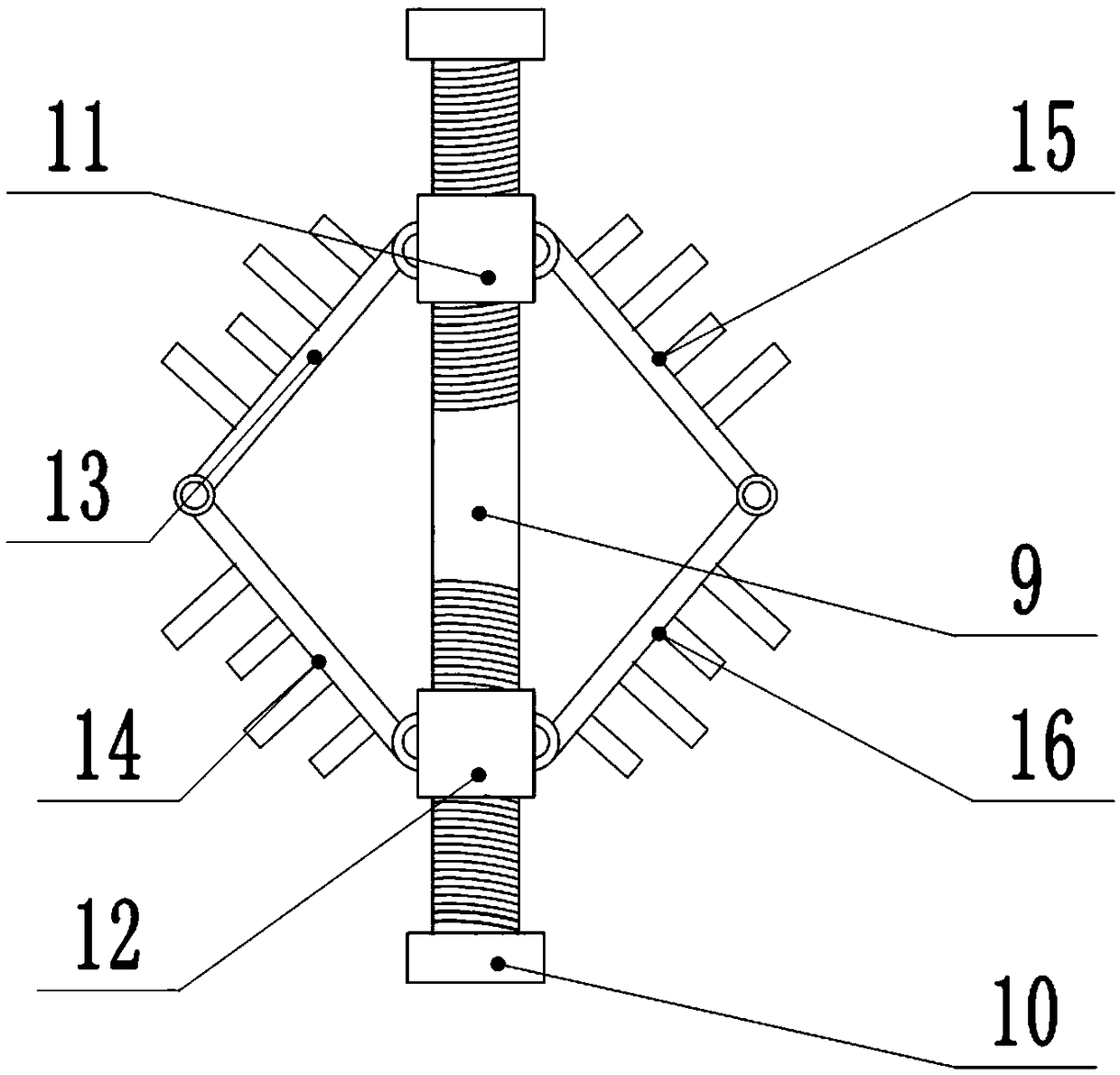

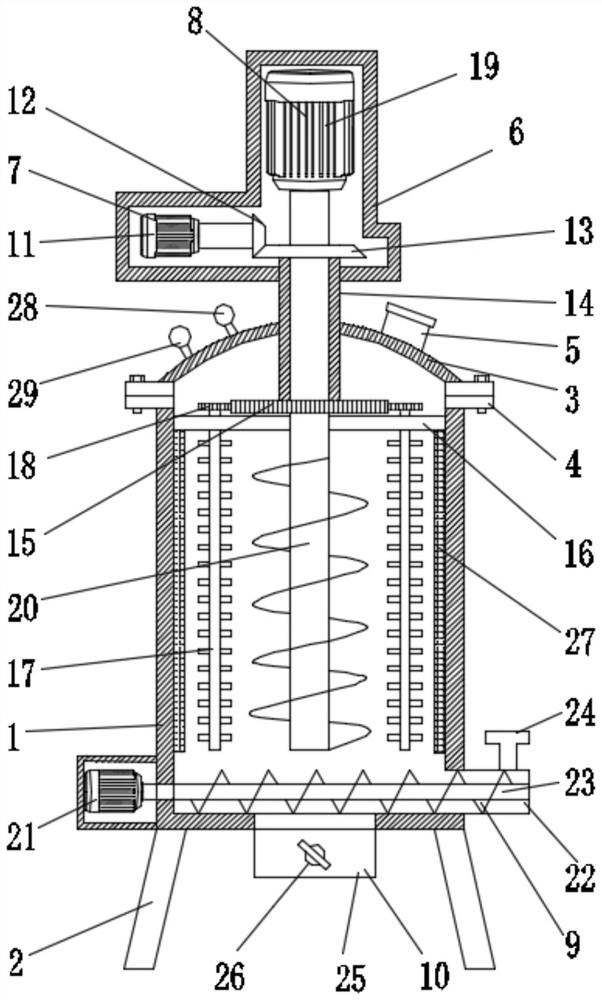

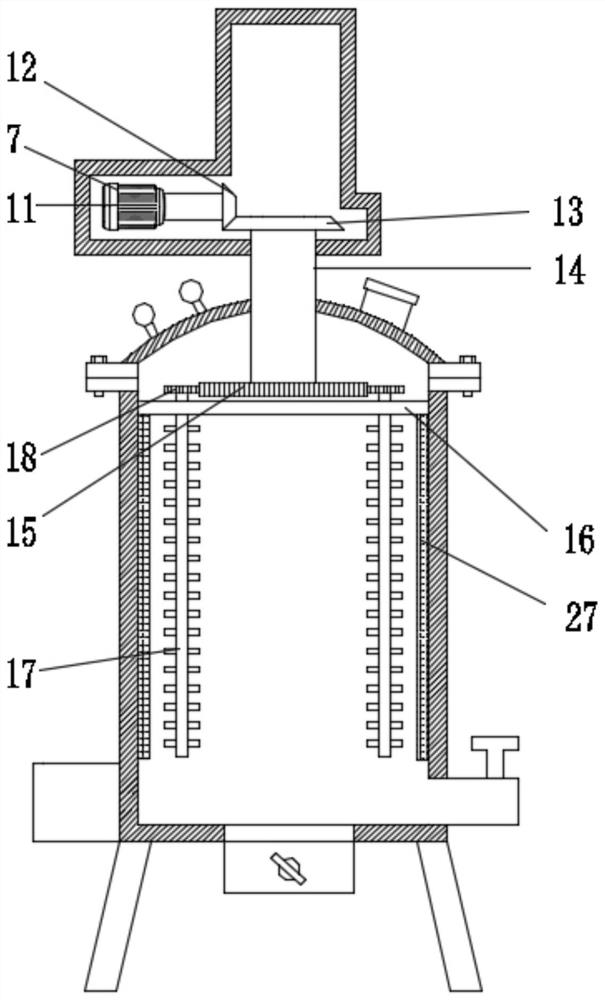

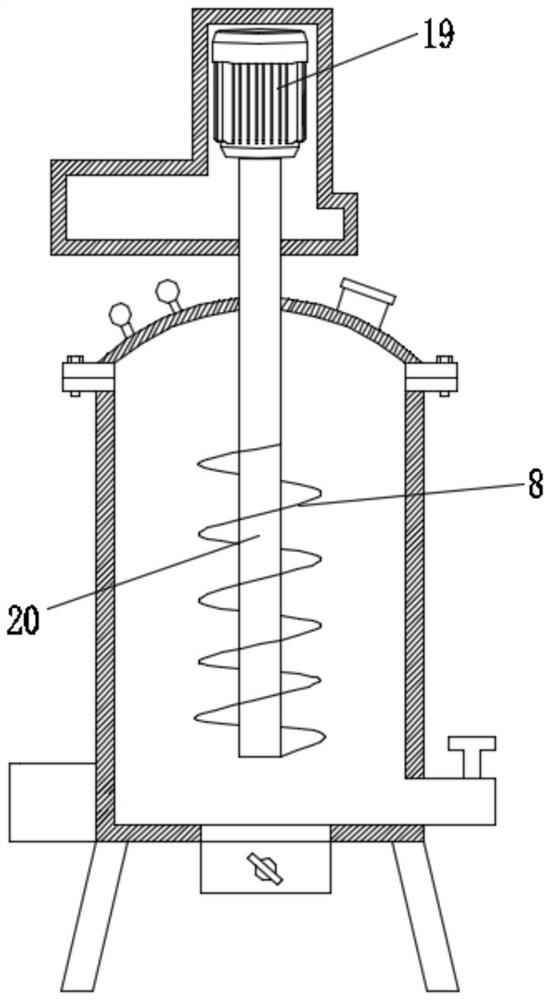

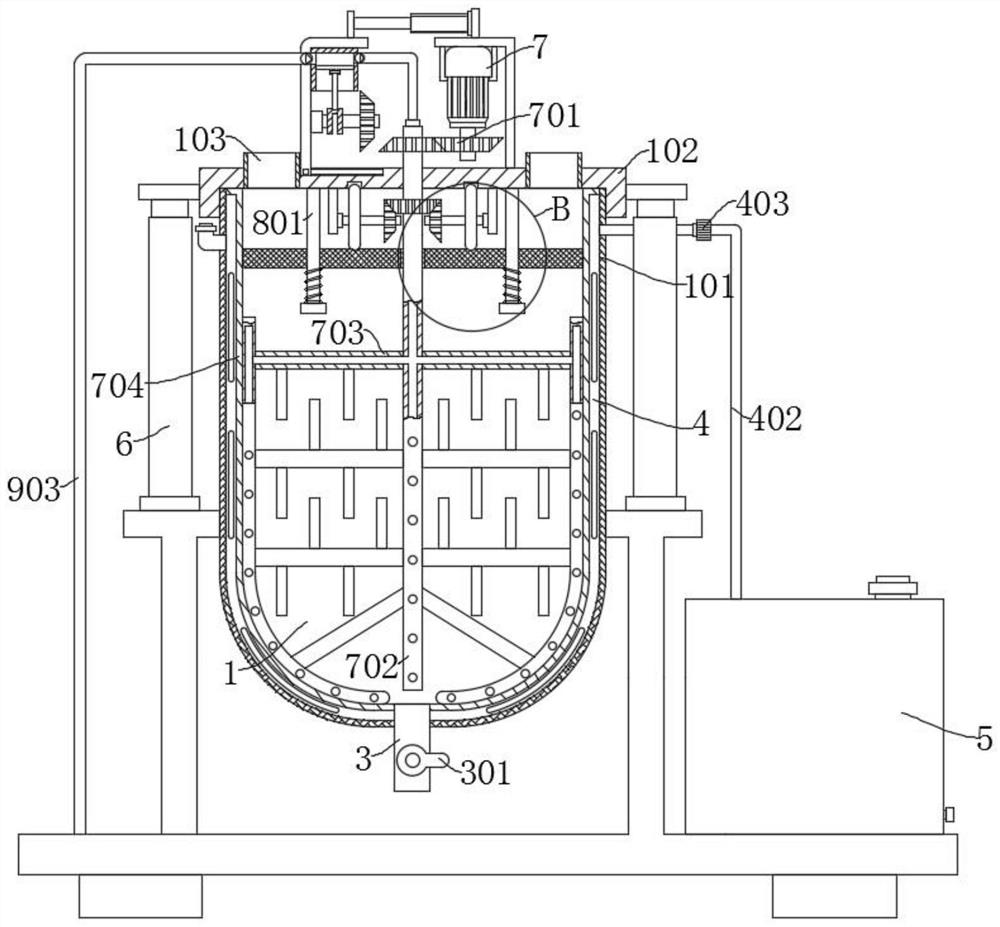

The invention discloses a material mixing device with multiple mixing chambers. The device comprises a mixing tank body and a mixing top cover covering the mixing tank body, and a first mixture sieving plate, a first mixing chamber, a second mixture sieving plate and a crushing / mixing integration chamber are sequentially arranged in the cavity of the mixing tank body from top to bottom. A screw feeding rod is mounted in a feeding chamber to prevent wheat flour and corn flour from obstructing the feeding chamber; and a first sprayer is mounted at the lower part of the feeding chamber, and can sprays a material to change a traditional discharging manner, so the material is smoothly discharged, the sprayed material is loose, and can be subsequently mixed easily, and the mixing efficiency is improved.

Owner:SHENGZHOU YIYUAN INVESTMENT MANAGEMENT

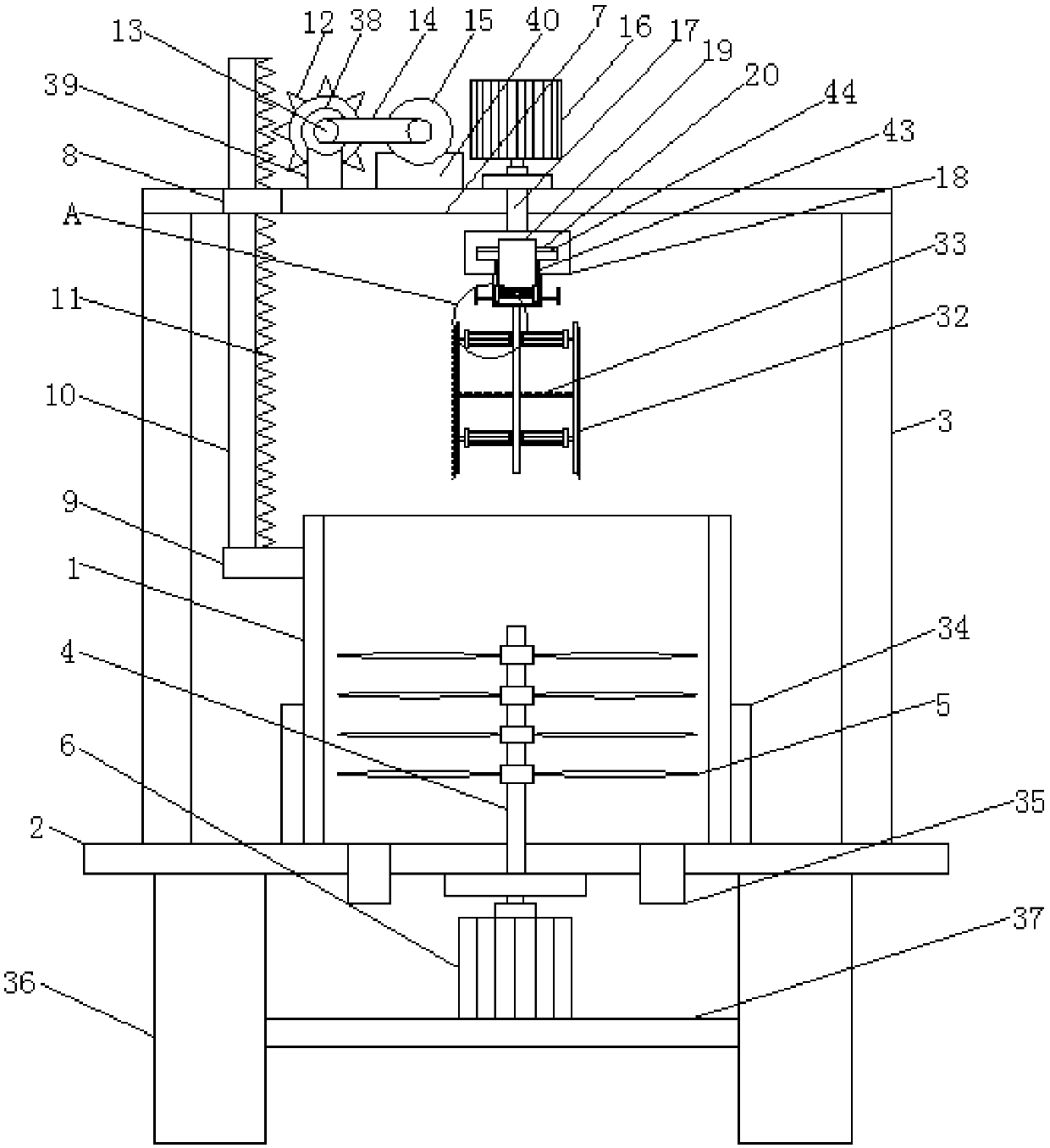

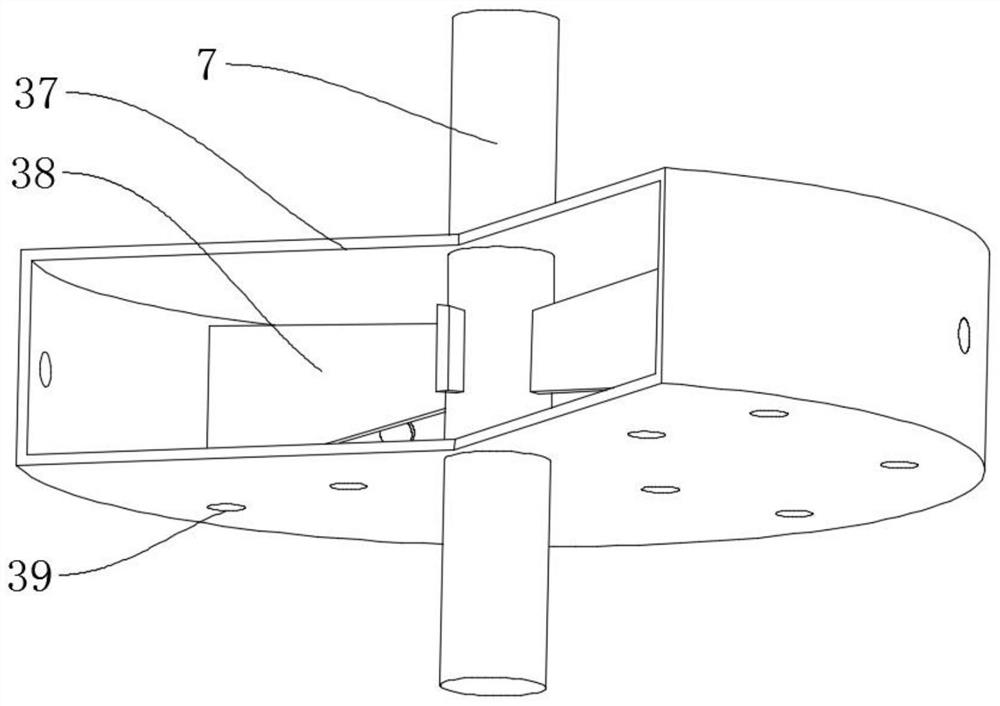

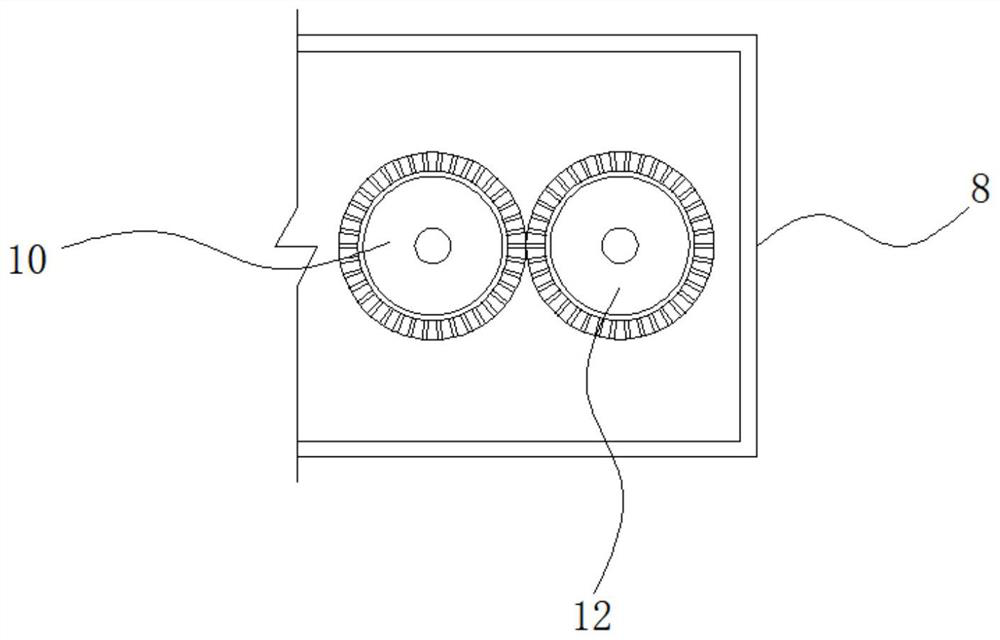

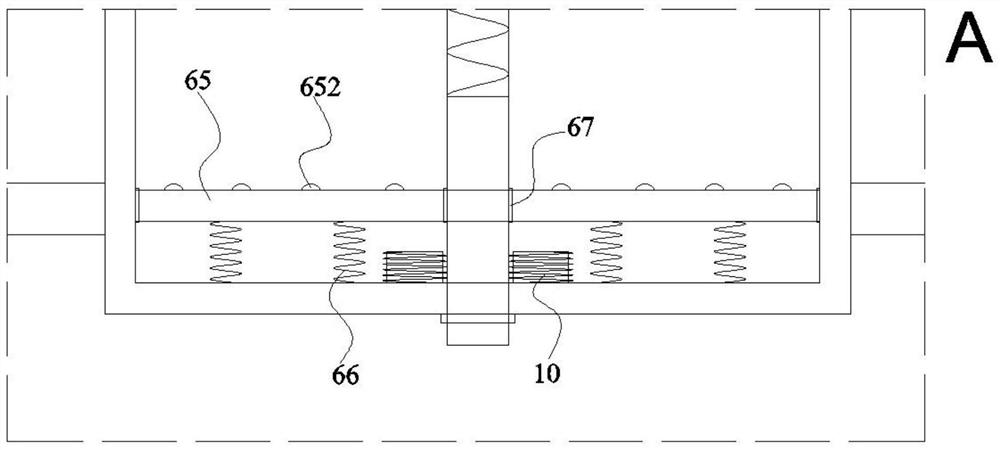

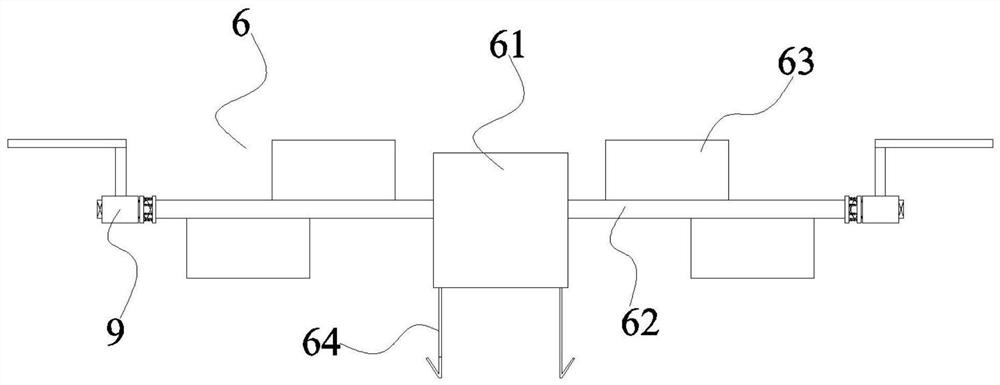

Full-automatic concrete mixing equipment capable of realizing proportioning

InactiveCN111702952AScientific and reasonable structureEasy to useMixing operation control apparatusPretreatment controlElectric machineGear wheel

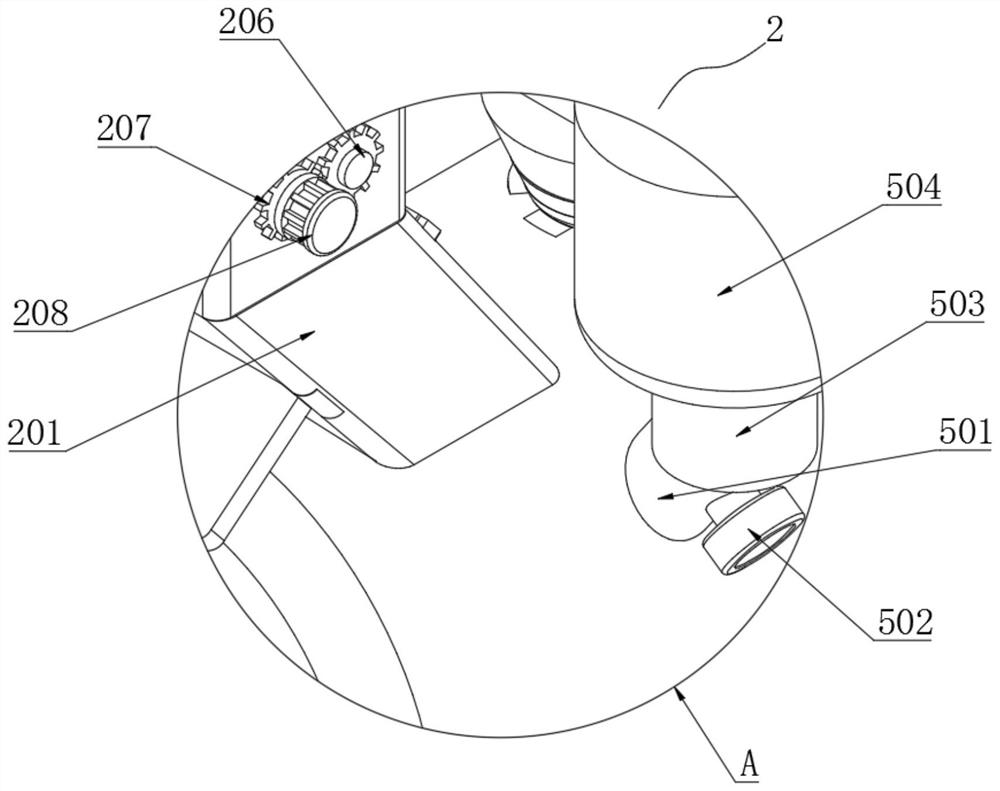

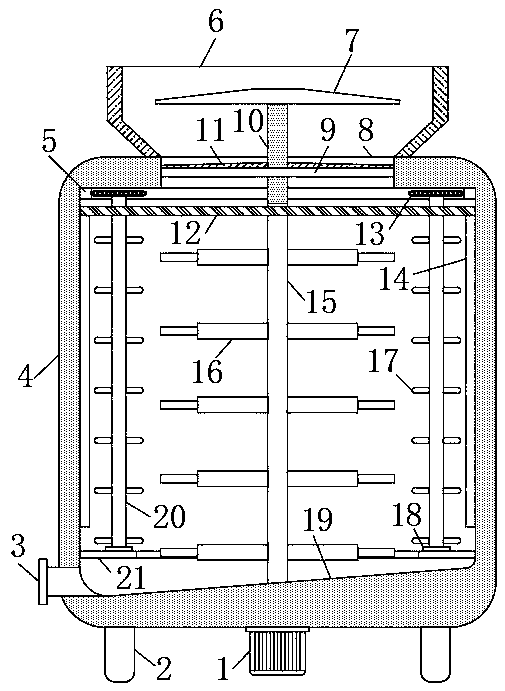

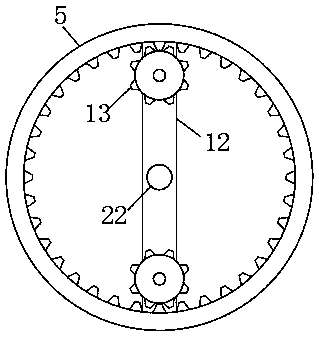

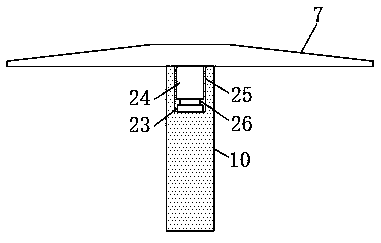

The invention discloses full-automatic concrete mixing equipment capable of realizing proportioning. The full-automatic concrete mixing equipment is characterized in that a bottom frame is fixedly connected to the bottom end of a mixing drum, a discharging opening is fixedly connected to the position, corresponding to the top of the bottom frame, of the outer end of the mixing drum, a gravel feeding mechanism is fixedly connected to one side of the top end of the mixing drum, the other side of the top end of the mixing drum is fixedly connected with a cement feeding mechanism, the side edge ofthe outer end of the mixing drum is fixedly connected with a water control mechanism, and a stirring mechanism is embedded inside the mixing drum. The equipment is scientific and reasonable in structure and safe and convenient to use; the gravel feeding mechanism is arranged, a rotating motor drives first rotating rods to rotate, and through cooperation of transmission gears, two first rotating rods drive two rough grinding rollers to rotate together to crush gravel, and meanwhile, through belt transmission, the two first rotating rods drive the two second rotating rods to rotate together, sothat the two fine grinding rollers are driven to rotate, and the gravel and cement mixing effect is improved.

Owner:李彦红

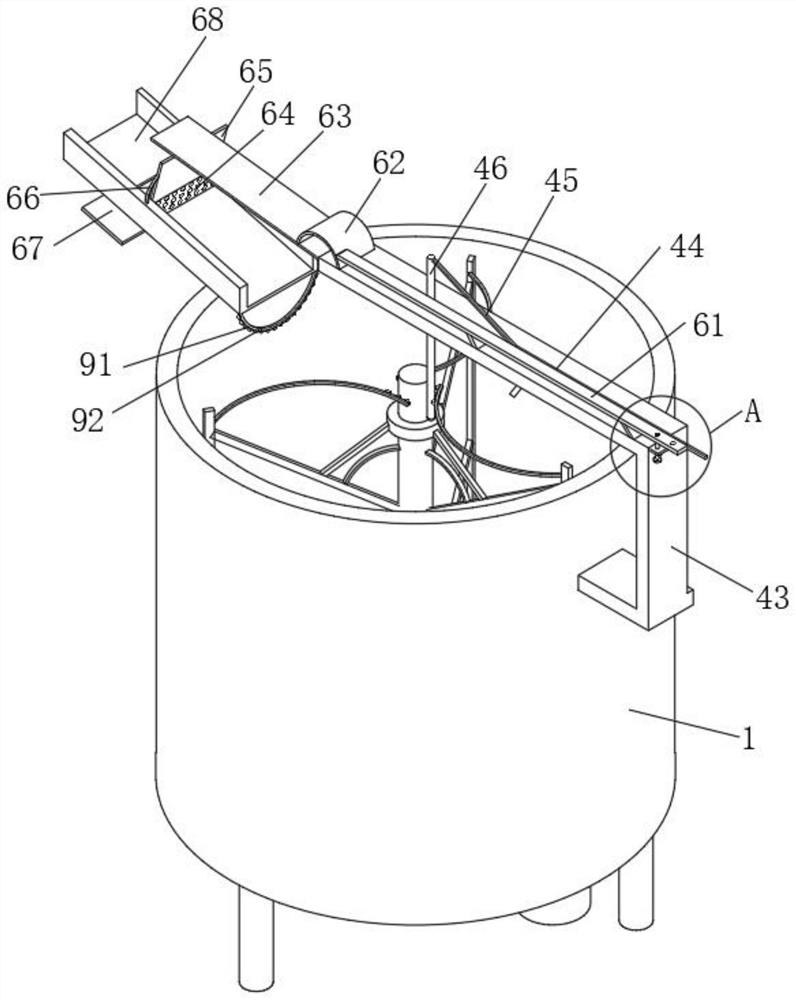

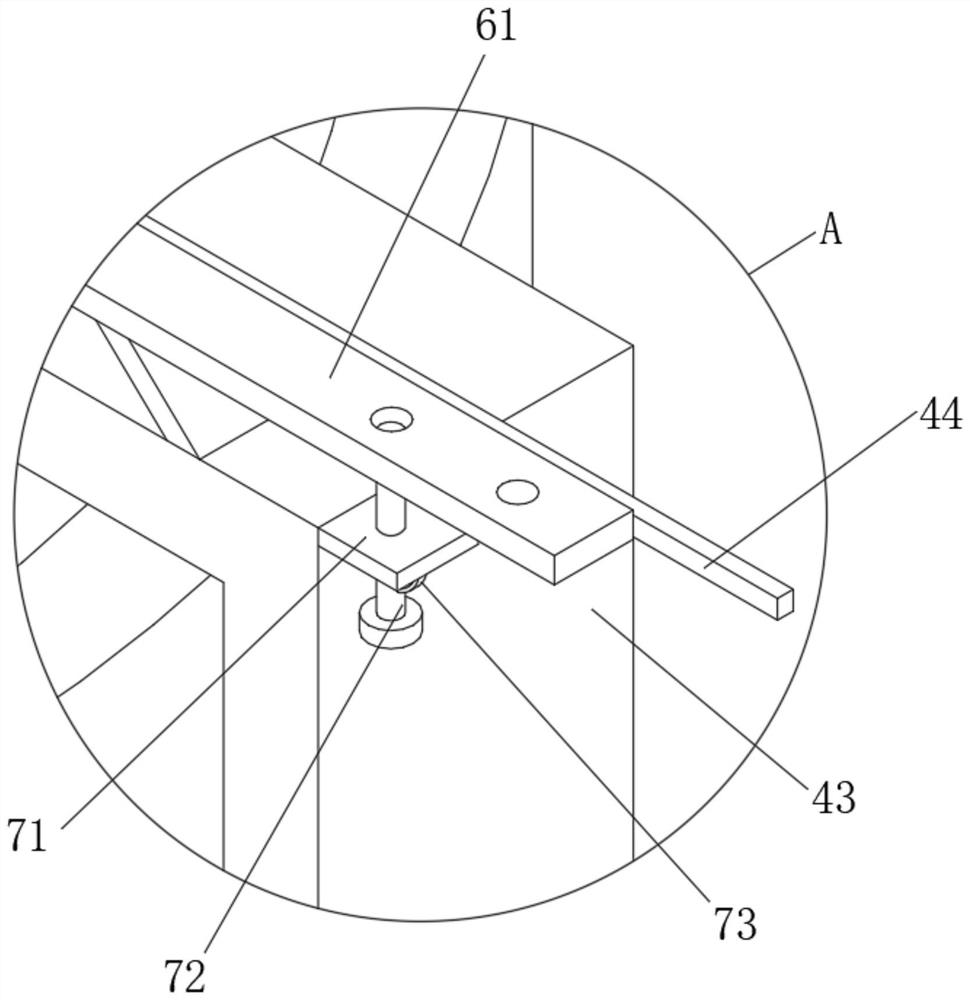

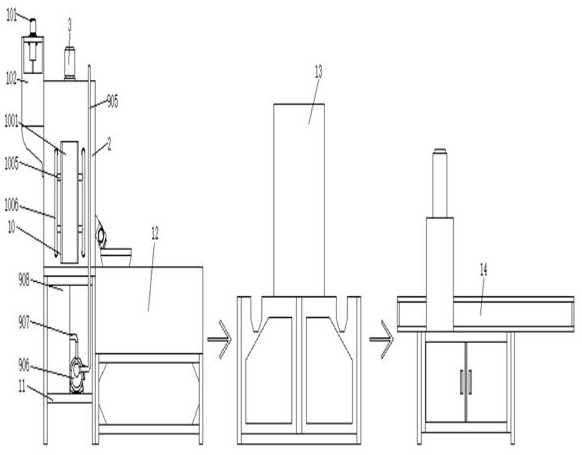

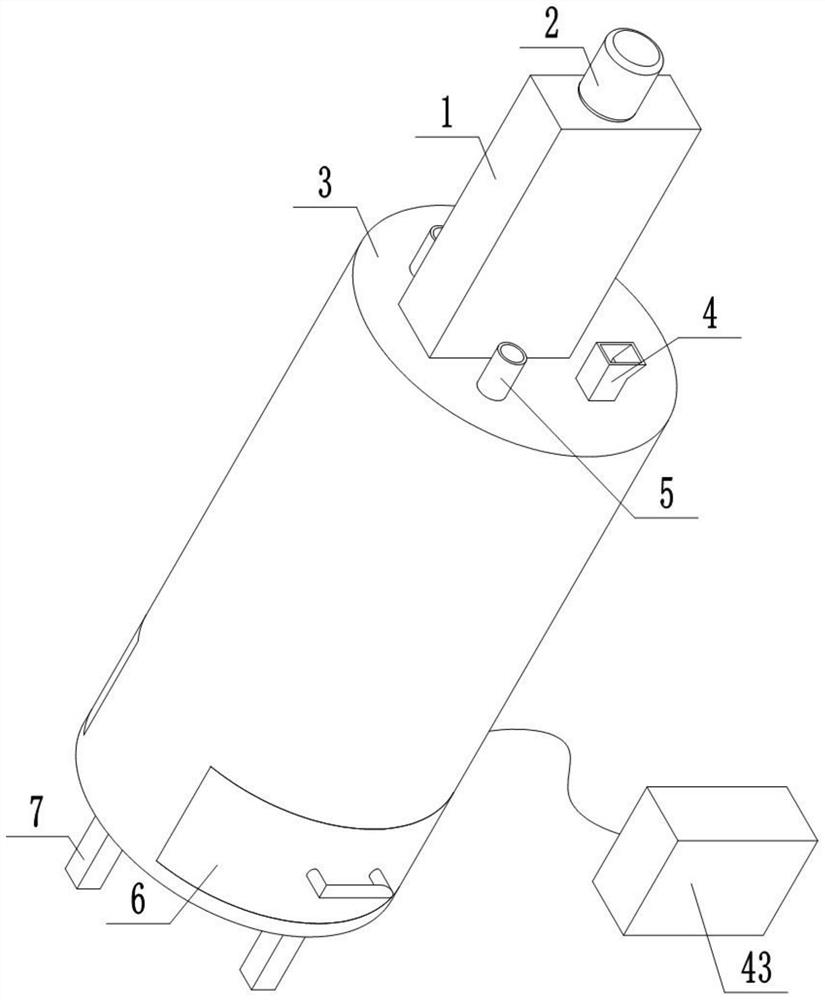

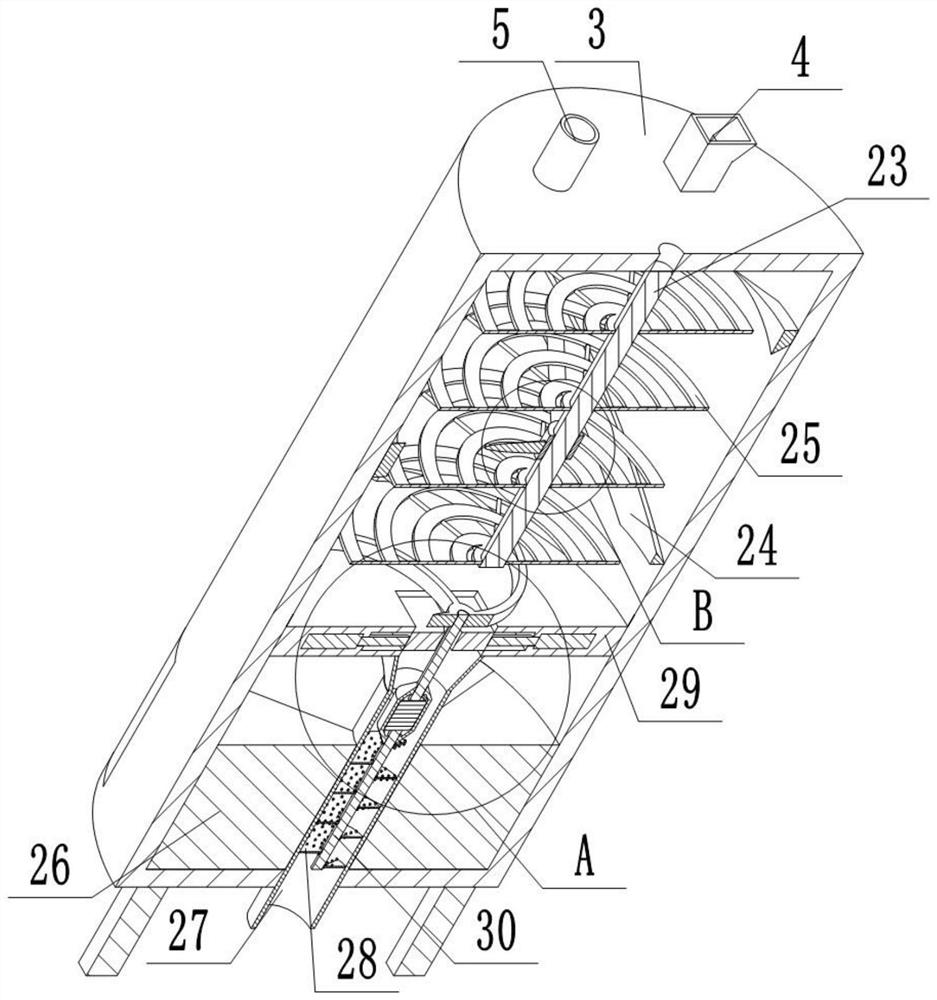

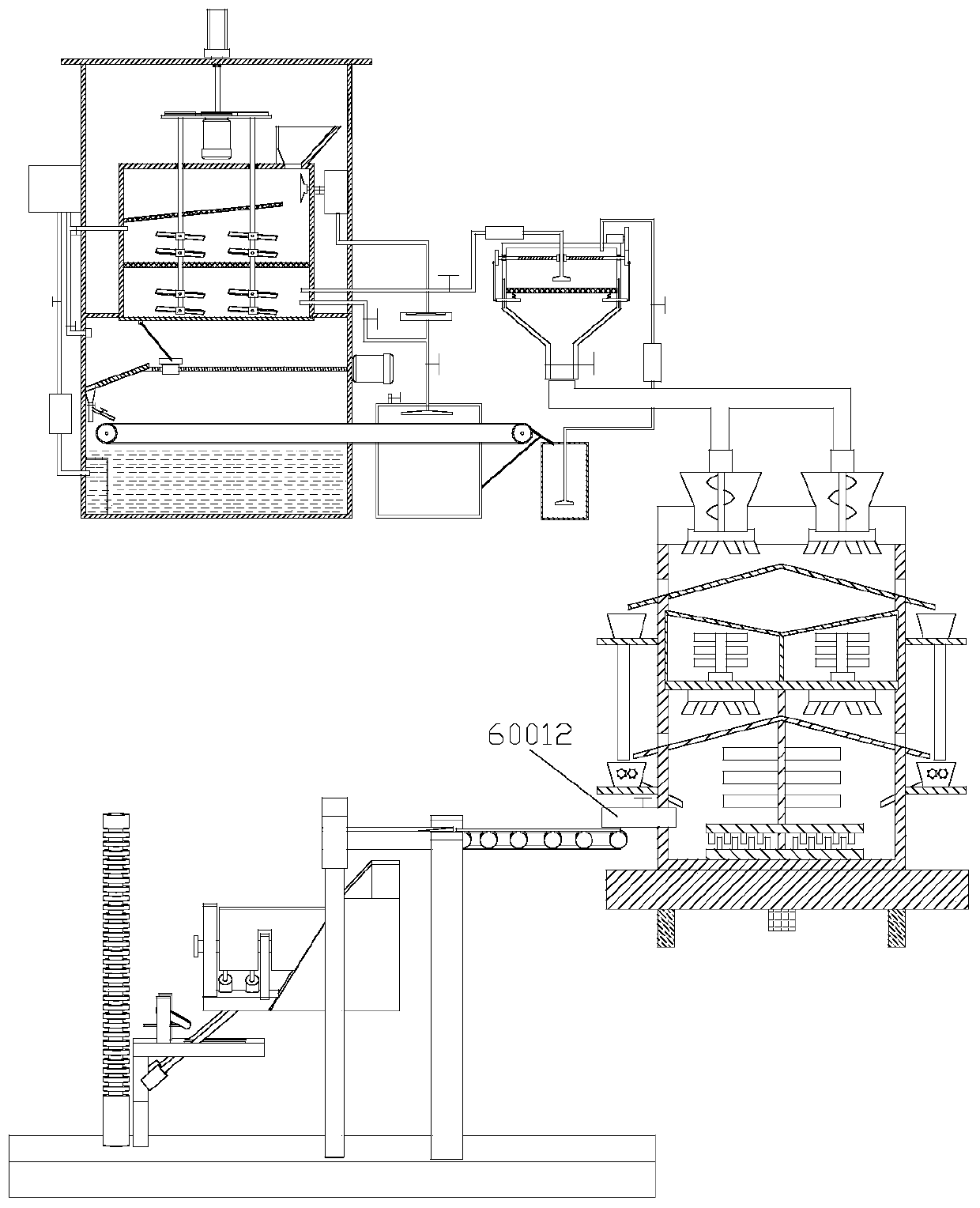

Corn flour production and processing mechanism based on multidirectional feeding

ActiveCN108654757AGuaranteed crushing efficiencyEnsure crushing efficiencySievingConveyorsCorn flourEngineering

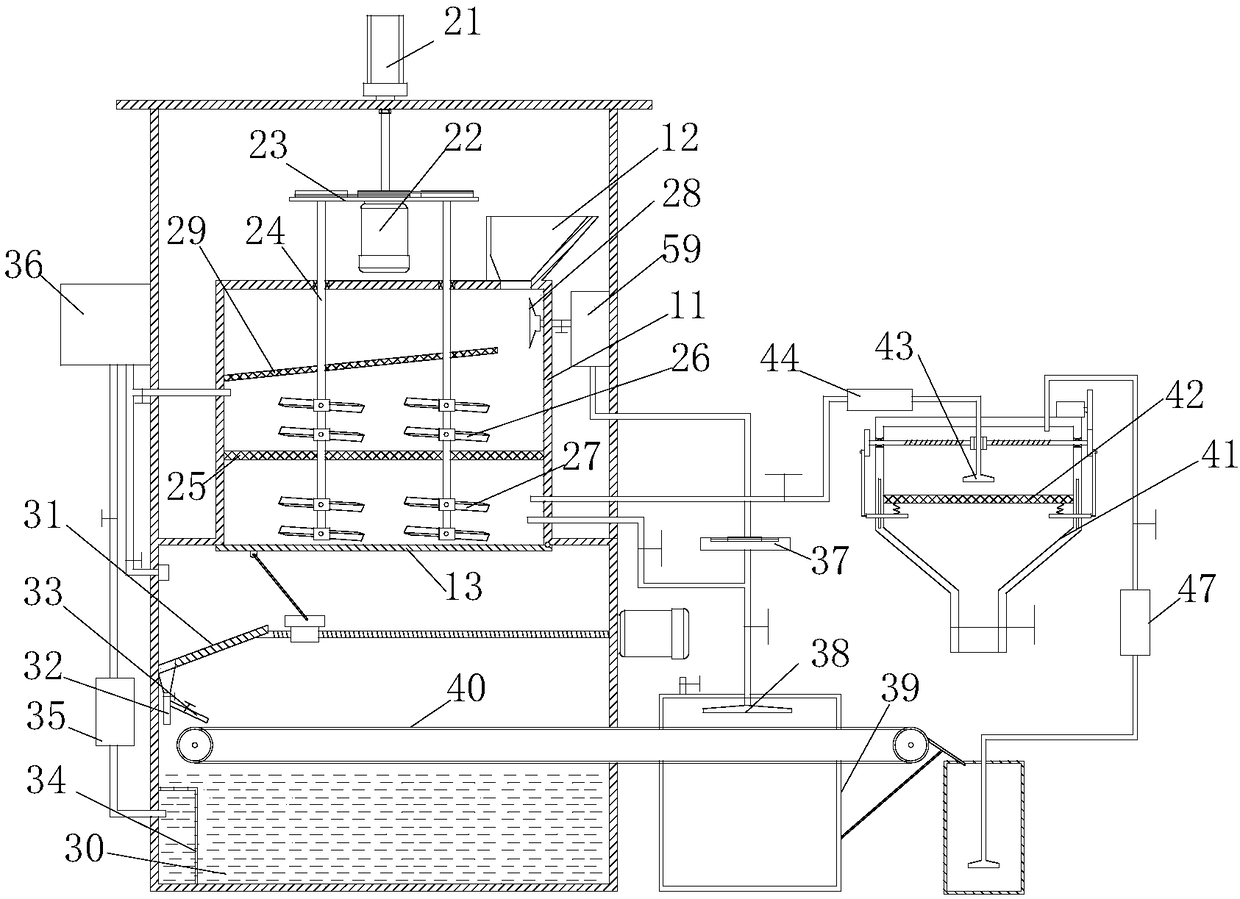

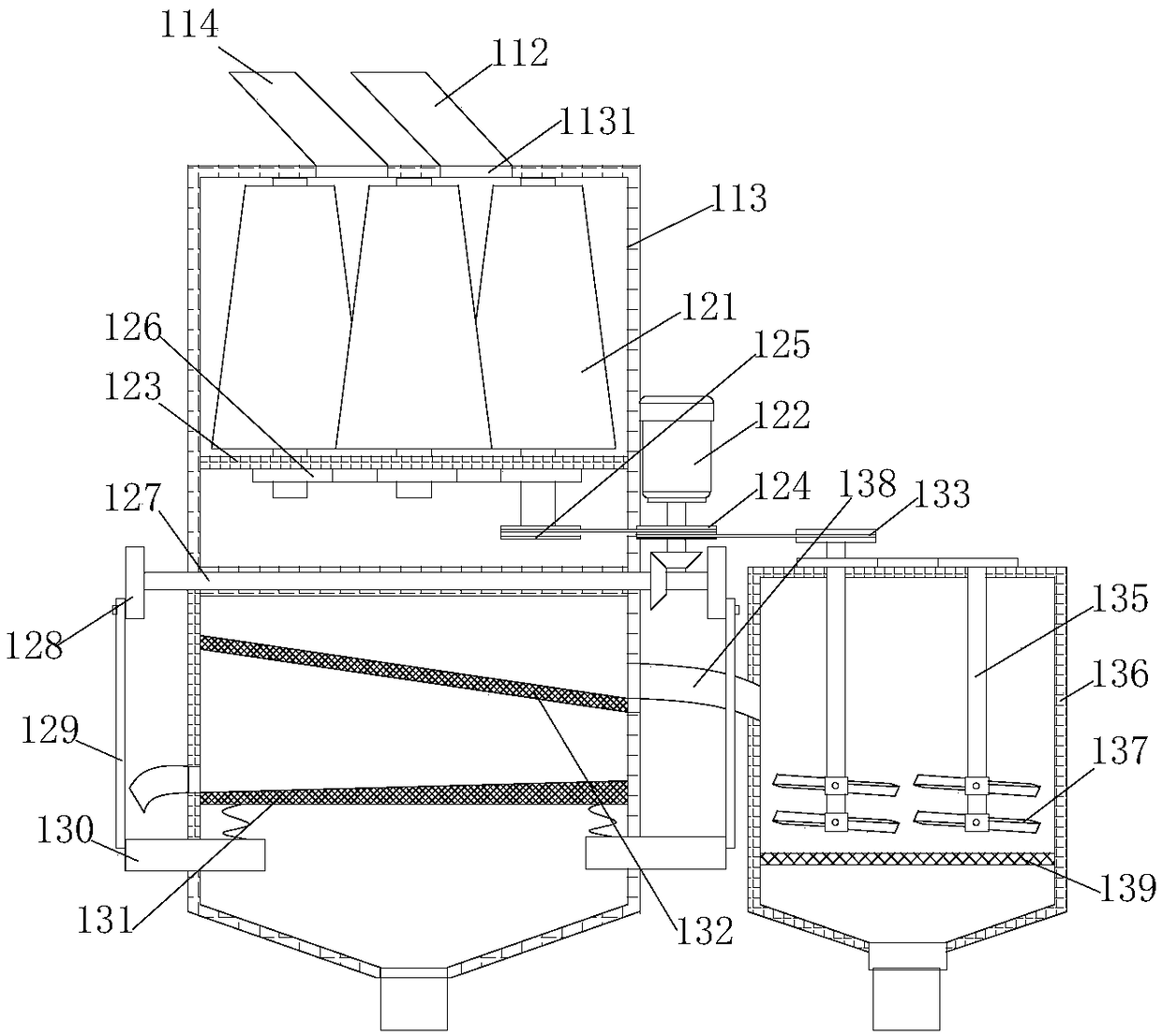

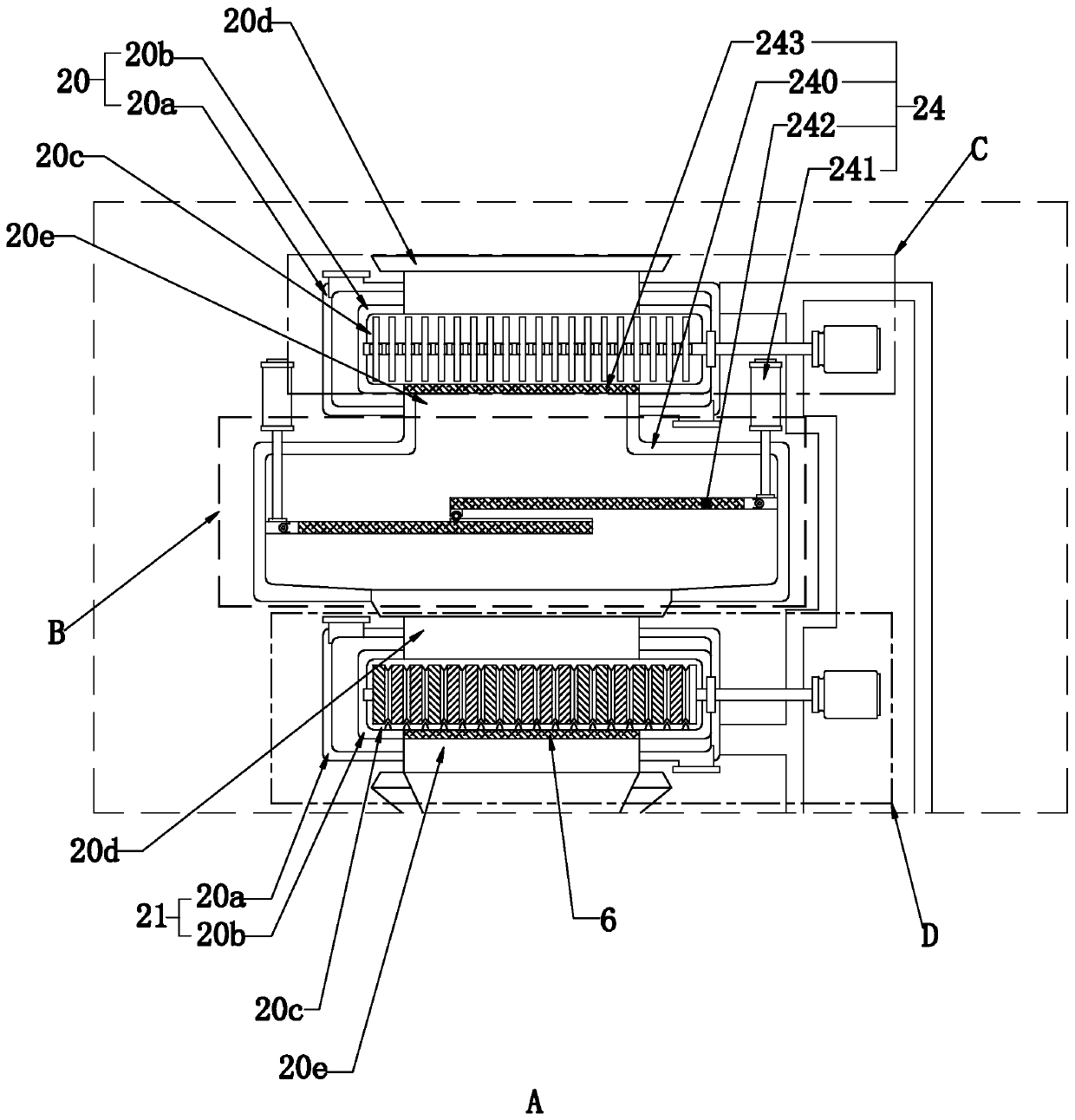

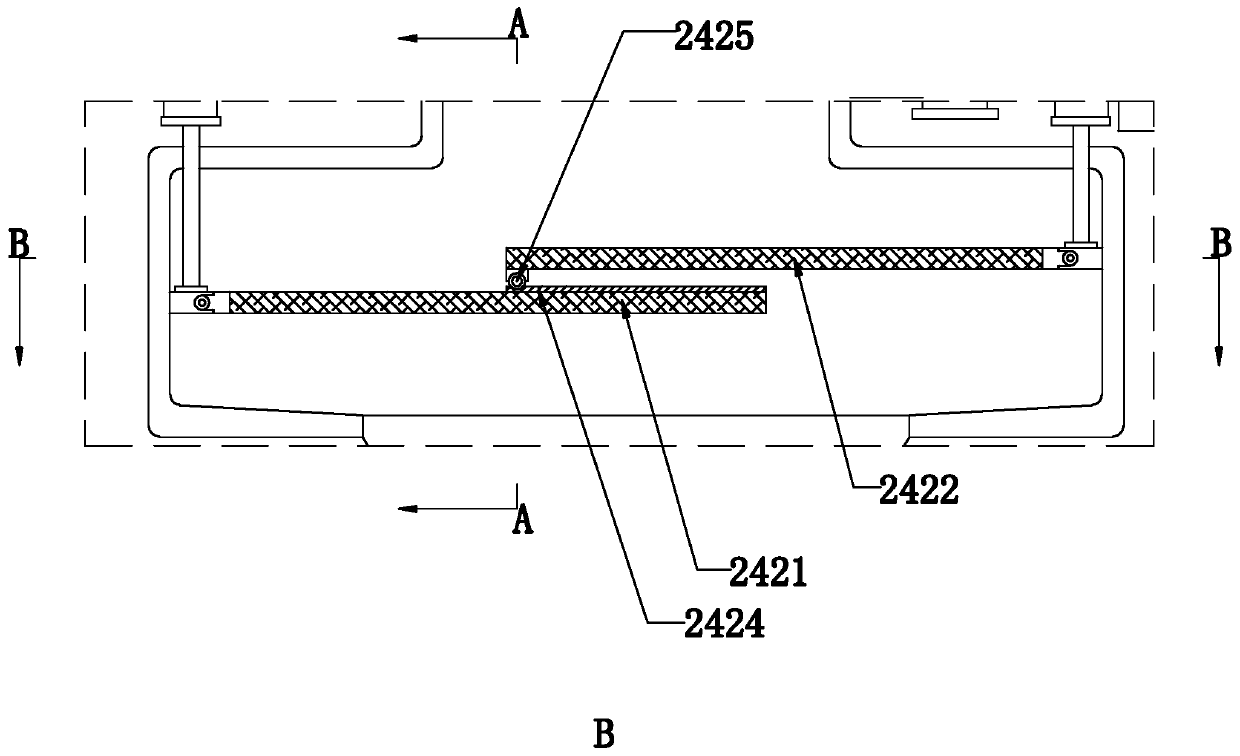

The invention discloses a corn flour production and processing mechanism based on multidirectional feeding. The corn flour production and processing mechanism comprises a corn grain crushing device, apowder mixing device and a powder transfer device according to the technological process from front to back. The corn grain crushing device comprises a crushing unit, a drying unit and a material return device according to the technological process in sequence. The powder mixing device comprises a material mixing tank and a material mixing upper cover covering the material mixing tank, and a cavity of the material mixing tank is internally provided with a first material mixing and screening plate, a first mixing chamber, a second material mixing and screening plate and a crushing / mixing integrated chamber from top to bottom in sequence. The powder transfer device comprises a transfer conveyor belt, a turnover discharging device, a transfer baffle, a conveyer bucket, a transfer elastic device and a transfer lifting base station from front to back in sequence. The corn flour production and processing mechanism has the advantages of quality guarantee of produced corn flour, good mixing effect of corn flour and flour, high continuity of operation, precise single feeding quantity and high working efficiency, and is not liable to caking or blockage.

Owner:安徽双全面粉有限公司

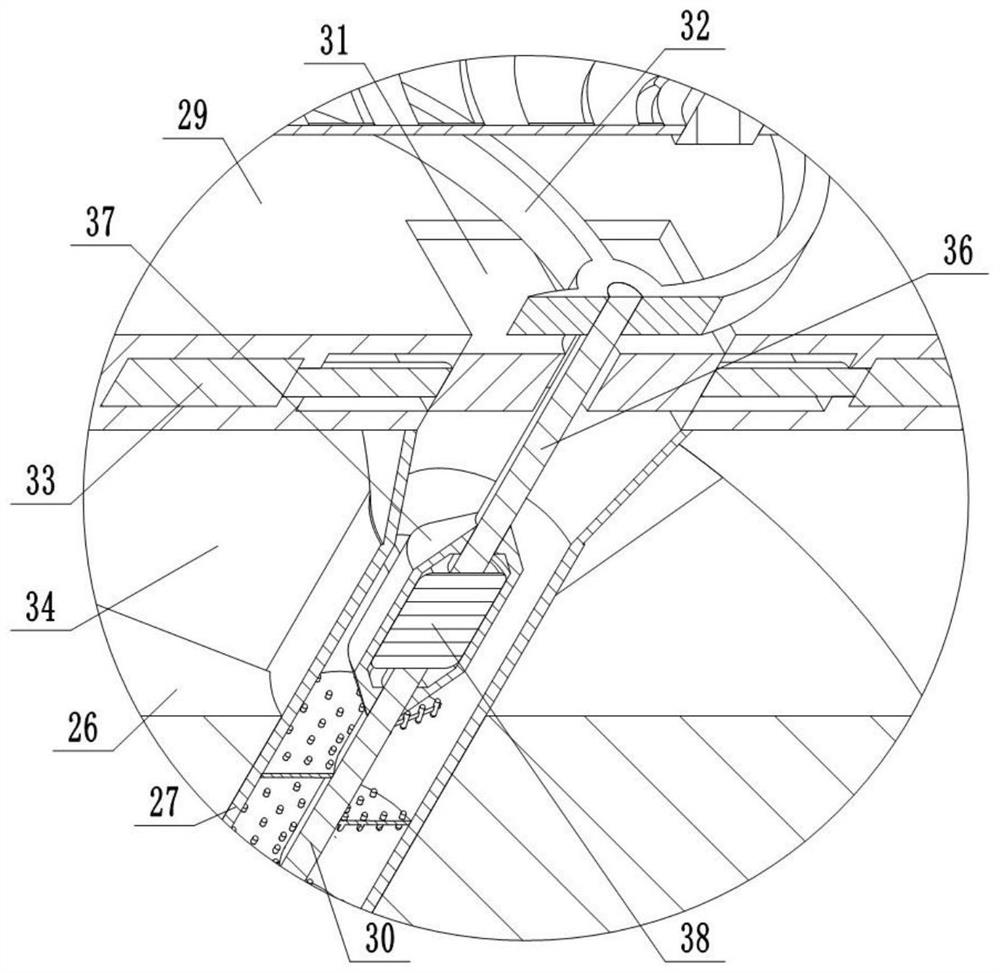

Solid state powder guide mechanism based on multi-mixing chamber

InactiveCN108554300AAvoid cloggingWell mixedGas current separationTransportation and packagingEngineeringMixing effect

The invention discloses a solid state powder guide mechanism based on a multi-mixing chamber. The solid state powder guide mechanism sequentially comprises a powder mixing device and a powder transferdevice according to a process flow from the front to rear, wherein the powder mixing device comprises a mixing tank and a mixing upper cover covering the mixing tank, wherein a first mixing and screening plate, a first mixing chamber, a second mixing and screening plate and a grinding / mixing integrated chamber are sequentially formed in a cavity of the mixing tank from top to bottom; the powder transfer device sequentially comprises a transfer conveyor belt, a turning type unloading device, a transfer baffle, a conveyer bucket, an elastic transfer device and a transfer lifting base from the front to rear; the solid state powder guide mechanism further comprises a transfer guide table. The solid state powder guide mechanism disclosed by the invention has the advantages of being excellent in mixing effect, difficult to agglomerate and block, high in operating continuity, accurate in single feed capacity and high in working efficiency.

Owner:芜湖拓云农业技术有限公司

High-efficiency lubricating oil production blending device

ActiveCN107413270AAvoid accumulationAvoid affecting the processing effectTransportation and packagingMixer accessoriesDrive wheelOil production

The invention discloses a high-efficiency lubricating oil production blending device. The high-efficiency lubricating oil production blending device comprises a stirring box, a blending box and a condensation box, wherein a material inlet is formed in one side of the top of the stirring box, the other side of the top of the stirring box is fixedly connected with a motor, one end of a motor output shaft is fixedly connected with a driving wheel, the outer surface of the driving wheel is connected with the outer surface of a driven wheel in a transmission manner by virtue of a belt, the axis of the driven wheel is sleeved with a rotating shaft, one end of the rotating shaft penetrates through the stirring box and is fixedly connected with one side of the inner wall of the stirring box, the rotating shaft disposed on the outer surface, disposed in of the inner cavity of the stirring box, of the rotating shaft is sleeved with a sleeve plate, and the outer surface of the sleeve plate is fixedly connected with a stirring rods. According to the high-efficiency lubricating oil production blending device, lubricating oil to be processed is arranged into the stirring box by virtue of the material inlet, and the driving wheel, the driven wheel and the rotating shaft are driven by the motor to rotate so as to drive the sleeve plate and the stirring rods to rotate and to stir and scatter the lubricating oil, so that the accumulation of impurities contained in the lubricating oil can be prevented, and the subsequent processing effect is not influenced.

Owner:统一石油化工有限公司

Waste sintered brick and tile environment-friendly lightweight concrete and preparation method thereof

ActiveCN111960782ALow thermal conductivityHigh compressive strengthSolid waste managementCompressive resistanceBrick

Owner:HANGZHOU WUYOU BUILDING MATERIALS CO LTD

Corn flour dry-mixing mechanism

InactiveCN108435090AImprove product qualityReduce wearTransportation and packagingMixersEngineeringMixing chamber

The invention discloses a corn flour dry-mixing mechanism, which comprises a corn kernel grinding device and a powder mixing device sequentially from front to back according to a technical process. The corn kernel grinding device comprises a grinding unit, a drying unit and a return unit sequentially according to a technical process. The grinding unit comprises a grinding tank, a rotating shaft, adecontaminating mechanism, an upper grinding mechanism and a lower grinding mechanism, and the decontaminating mechanism, the upper grinding mechanism and the lower grinding mechanism are arranged inthe grinding tank. The top of the grinding tank is provided with a feeding port and an upper insertion port allowing vertical insertion of the rotating shaft, and the bottom of the grinding tank is provided with a discharging port. The powder mixing device comprises a mixing tank and an upper mixing cover which covers the mixing tank, and a cavity of the mixing tank is provided with a first mixing screen plate, a first mixing chamber, a second mixing screen plate and a grinding / mixing integrated chamber sequentially from top to bottom. The corn flour dry-mixing mechanism has advantages of guarantee of produced corn flour quality, effectiveness in mixing of corn flour and wheat flour and less proneness to caking and blockage.

Owner:芜湖拓云农业技术有限公司

Agricultural machine for producing edible powder

InactiveCN108617277AReduced labor requirementsFree handsTransportation and packagingMixersAgricultural engineeringCorn flour

The invention discloses an agricultural machine for producing edible powder. The agricultural machine sequentially comprises a corn cob processing device, a corn grain crushing device, a powder mixingdevice and a powder operation device according to a process flow. The corn cob processing device comprises a feeding unit and a processing unit. The powder mixing device comprises a material mixing tank body and a material mixing upper cover which covers the material mixing tank body. A first material mixing and sieving plate, a first mixing chamber, a second material mixing and sieving plate, and a crushing / mixing integrated chamber are sequentially arranged in the cavity of the mixing tank body from top to bottom. The powder operation device comprises an operation conveying belt, a turnoverdischarging device, an operation baffle, a conveying hopper, an operation elastic device and an operation lifting base table. The agricultural machine provided by the invention has the advantages that the processing efficiency of corn cobs is improved, the quality of the produced corn flour is ensured, the mixing effect of the corn flour and the flour is good, the corn flour and the flour do notcake easily, blocking does not occur easily, the working continuity is strong, the feeding amount of a single time is accurate, and the working efficiency is high.

Owner:芜湖拓云农业技术有限公司

Nutrient solution mixing device for planting herbaceous plants

InactiveCN109046137AHigh purityAffect the blending effectShaking/oscillating/vibrating mixersTransportation and packagingInterference fitDrive motor

The invention discloses a nutrient solution mixing device for planting herbaceous plants. The nutrient solution mixing device comprises a base, guide posts, a mixing tank, a screw rod, a rack, a driving motor and a special-shaped gear, wherein mounting lugs are arranged on the guide posts in a sliding manner; the mixing tank is fixedly connected between the mounting lugs positioned on two sides; material splitting drums are in interference fit with a connecting shaft and are intermittently provided with material storage tanks; a driving motor is fixedly arranged on the guide post positioned onthe left side; an output shaft of the driving motor faces forward and is fixedly connected with the special-shaped gear. A first feeding opening and a second feeding opening are respectively providedwith filter screens, so that the purity of a nutrient solution is improved, and the influence of impurities contained in the nutrient solution on mixing effect is avoided; by controlling positive andnegative rotation of a material mixing motor, stirring range of stirring blades on connecting rods is changed, and stirring is more sufficient and efficient; by rotating the material splitting drums,the dosage of the nutrient solution can be determined according to the sizes of the material storage tanks, and simplicity and convenience are realized.

Owner:徐得强

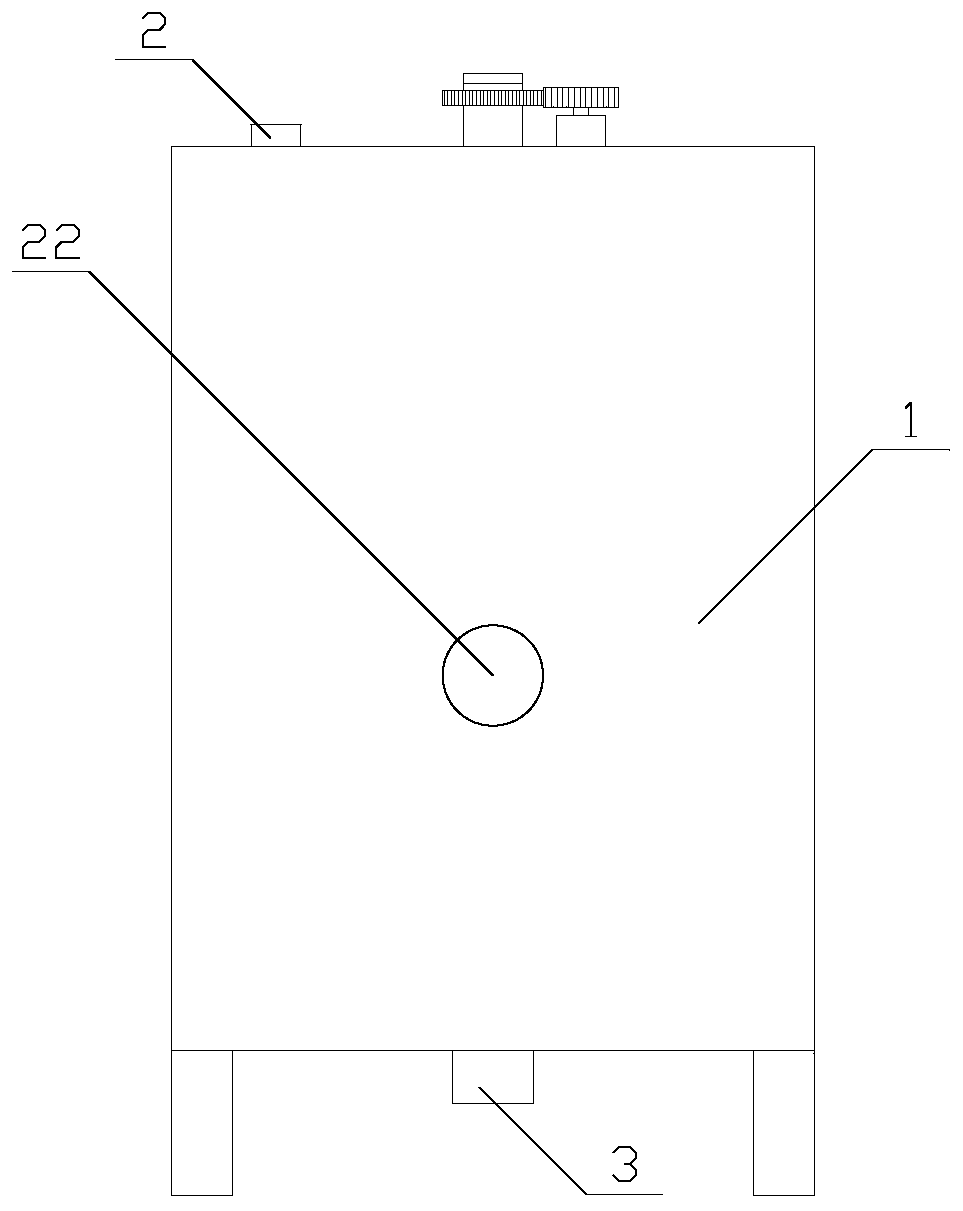

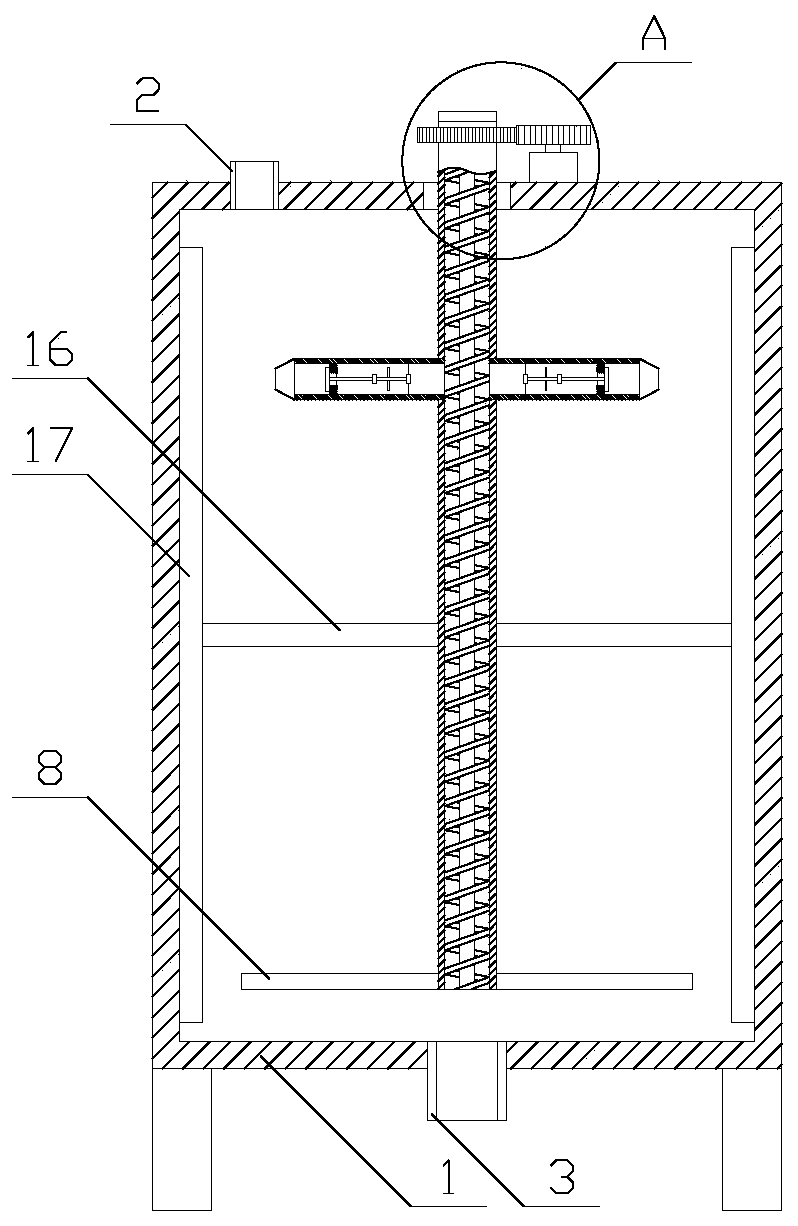

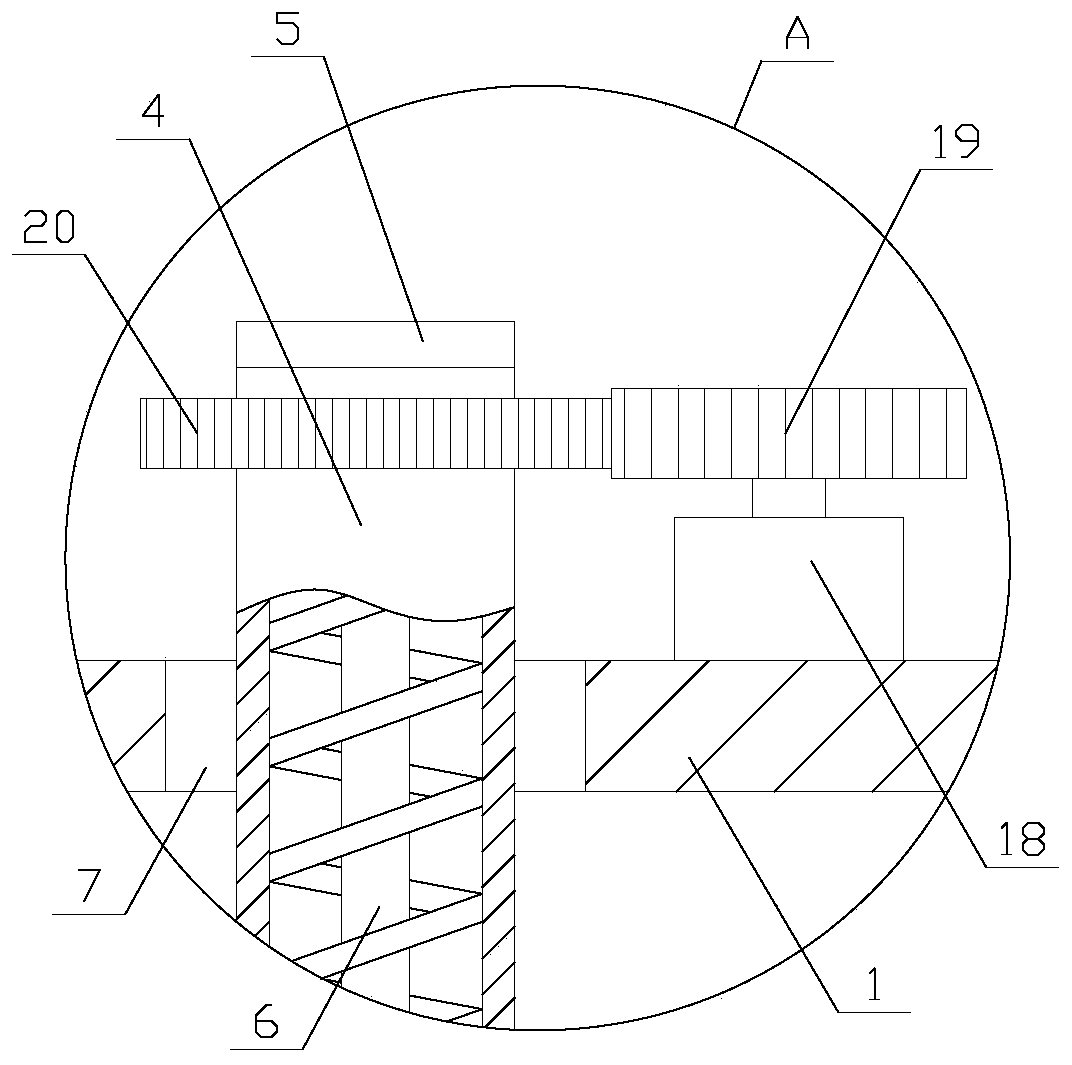

Energy-saving and environment-friendly pulping device for papermaking and printing

ActiveCN110552222AAffect the blending effectEasy to cleanRaw material divisionPapermakingElectric machinery

The invention discloses an energy-saving and environment-friendly pulping device for papermaking and printing. The pulping device comprises a box body, the lower end of the box body is fixedly connected with a plurality of supporting feet, a discharge port is arranged at the middle and lower position of the side wall of the box body, the middle part of the upper end of the box body is provided with a feed inlet, the upper end of the box body is fixedly connected with a feed hopper at a position corresponding to the feed port, the lower end of the box body is fixedly connected with a motor, theend of the output shaft of the motor penetrates through the lower end of the box body and is fixedly connected with a rotating rod, the output shaft of the motor is rotatably connected with the box body, a plurality of crushing knives are arranged at equal intervals along the axial direction on the outer side of the rotating rod, a rotating plate is sleeved on the rotating rod, and the two are fixedly connected. The invention has reasonable structural design, can disperse materials into the inside of the box body, is beneficial to improving the pulping effect, can fully mix the materials, andcan also prevent the materials from adhering to the inner wall of the box body.

Owner:温州市金龙纸业有限公司

Paint preparation process and preparation device

ActiveCN110628328AGuaranteed preparation efficiencyImprove efficiencyTransportation and packagingMixersEngineeringSolvent

The invention relates to a paint preparation process, which comprises the steps of raw material preparation, solid grinding, raw material mixing and remaining material adding. The preparation device comprises a rack, and a grinding apparatus, a solid feeding assembly and a dispersing apparatus that are respectively mounted on the rack from top to bottom. The invention has the beneficial effects that: the solvent and solute are respectively filtered and crushed before mixing so as to improve the subsequent paint preparation efficiency and effect.

Owner:浙江富思丽涂料有限公司

Mixing device for plastic woven bag production

The invention discloses a mixing device for plastic woven bag production. The mixing device comprises a mixing barrel, supporting legs, a barrel cover, a flange plate, a feeding port, a power box, a stirring device, an up-down mixing device, a discharging device and a constant-temperature heating device, the supporting legs are arranged on the lower portion of the mixing barrel, the barrel cover is connected with the mixing barrel through the flange plate, the feeding port is formed in the barrel cover, the power box is arranged above the barrel cover, the stirring device is arranged in the power box and penetrates through the barrel cover to be arranged in the mixing barrel, the up-down mixing device is arranged in the power box and penetrates through the stirring device to be arranged in the mixing barrel, the discharging device is arranged at the bottom end in the mixing barrel, and the constant-temperature heating device is arranged at the bottom of the mixing barrel. The invention belongs to the technical field of woven bag production. The mixing device for plastic woven bag production has the advantages of constant-temperature stirring, up-and-down stirring and uniform stirring.

Owner:徐州远大包装有限公司

Batching device with good stirring effect and for graphene production and processing

InactiveCN110404442AIngenious structurePracticalRotary stirring mixersTransportation and packagingBiochemical engineeringGraphene

The invention relates to a batching device with a good stirring effect and for graphene production processing. The device comprises a tank body, a material feeding tube and a material discharging tube, the tank body has a cylindrical shape, the material feeding tube is arranged at the top of the tank body, the material discharging tube is arranged at the bottom of the tank body, an auxiliary mechanism and a stirring mechanism are arranged in the tank body, the stirring mechanism comprises a rotating tube, a sealing plate, a screw, a first bearing, a driving assembly and at least two stirring assemblies, every stirring assembly comprises a stirring bar, a connecting tube and a nozzle, the auxiliary mechanism comprises at least two auxiliary assemblies, the auxiliary assemblies correspond tothe connecting tubes in a one-to-one manner, and the auxiliary assemblies are arranged in the connecting tubes. The batching device with the good stirring effect and for graphene production and processing realizes the function of removing agglomeration in raw materials through the auxiliary mechanisms in order to avoid the influences of agglomeration on the mixing effect of the raw materials, andalso realizes the function of stirring the raw materials through the stirring mechanism.

Owner:广州市鹭江远科技有限公司

Uniform mixing tank for industrial raw materials

InactiveCN107899452AAffect the blending effectEasy to cleanRotary stirring mixersTransportation and packagingEngineeringMixing effect

The invention relates to the technical field of industry, and discloses a uniform mixing tank for industrial raw materials. The uniform mixing tank comprises a tank body, wherein the top portion of aconnection seat is connected to a connection plate, the right side of the connection plate is connected to a tooth rail, the top portion of the right side of the tooth rail is engaged with a transmission gear, a rotation shaft is connected in the middle portion of the transmission gear in a penetrating manner, both sides of the inner wall of an installation groove are respectively provided with asnapping groove, an installation sleeve is overlapped on the bottom portion of an installation plate, the inner side of the installation sleeve is connected to a movement shaft, the top portion of a movement sleeve is connected to a connection rod, the top portion of the connection rod is connected to a snapping block, the piston side away from a rotating rod is connected to a stretching rod, thestretching rod side away from the piston is connected to a brush rod, and the brush rod side away from the stretching rod is connected to brush hair. According to the present invention, through the matched use of the installation pipe, the piston, the stretching rod, the brush rod, the brush hair and the electric motor, the brush hair on the brush rod cleans the industrial raw material adhered inthe mixing tank during the rotation, such that the influence of the adhered industrial raw material on the raw material mixing effect is prevented.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Ore pulp treatment device

InactiveCN112495221AImprove the mixing effectIncrease relative volatilityTransportation and packagingRotary stirring mixersPharmacy medicinePulp treatment

The invention discloses an ore pulp treatment device, and belongs to the field of ore pulp treatment. The ore pulp treatment device comprises a box body, a heating sleeve and a supporting plate, a stirring rod and an auxiliary rod are rotatably connected into the box body, stirring fan blades and auxiliary fan blades are fixedly connected to the stirring rod and the auxiliary rod respectively, anda top plate is fixedly connected to a fixing plate; and the output end of a motor is fixedly connected with a first transmission mechanism, a second transmission mechanism and the stirring rod, the fixing plate is connected with a piston cylinder and a rotating shaft, and the piston cylinder is connected with the heating sleeve through an air outlet pipe. Vortex generated by opposite rotation ofthe fan blades collides with each other, the mixing effect of ore pulp and medicine is improved, meanwhile, the ore pulp is heated, the mixing speed of the ore pulp and the medicine is further increased, the mixing time is shortened, the mixing efficiency is improved, meanwhile, the medicine is evenly sprayed to the ore pulp, medicine caking is reduced, the medicine mixing effect is prevented frombeing affected, and the drug volatilization effect is improved.

Owner:NANYANG INST OF TECH

Preparation process of nano thermal insulation coating

InactiveCN111607328AImprove insulation effectStrong insulationFireproof paintsAntimony oxides/hydroxides/oxyacidsThermal insulationPhysical chemistry

The invention discloses a preparation process of a nano thermal insulation coating. The method comprises the following steps: preparation of nano antimony pentoxide: adding 14-15 parts of antimonous oxide and 19-20 parts of deionized water into a stirring reaction kettle to be stirred, so that the antimonous oxide and the deionized water are fully mixed into a slurry; then heating the slurry to raise the temperature to 90-95 DEG C, after the heating is finished, adding inlet water into the kettle and stirring for 5 to 7 minutes; slowly dropwise adding 11-12 parts of hydrogen peroxide into a mixture after stirring; after hydrogen peroxide is added completely, continuing to stir for 2-4 minutes to fully mix a slurry with hydrogen peroxide; after mixing, heating and refluxing an obtained mixture for 43 to 48 minutes to prepare a white thick paste, slightly cooling the white thick paste, filtering the white thick paste to remove aggregates or block particles in the white thick paste, and drying the obtained white thick paste in an oven at 80-90 DEG C to obtain the nano antimony pentoxide.

Owner:JIANGSU BAOPING ANTI THEFT TECH CO LTD

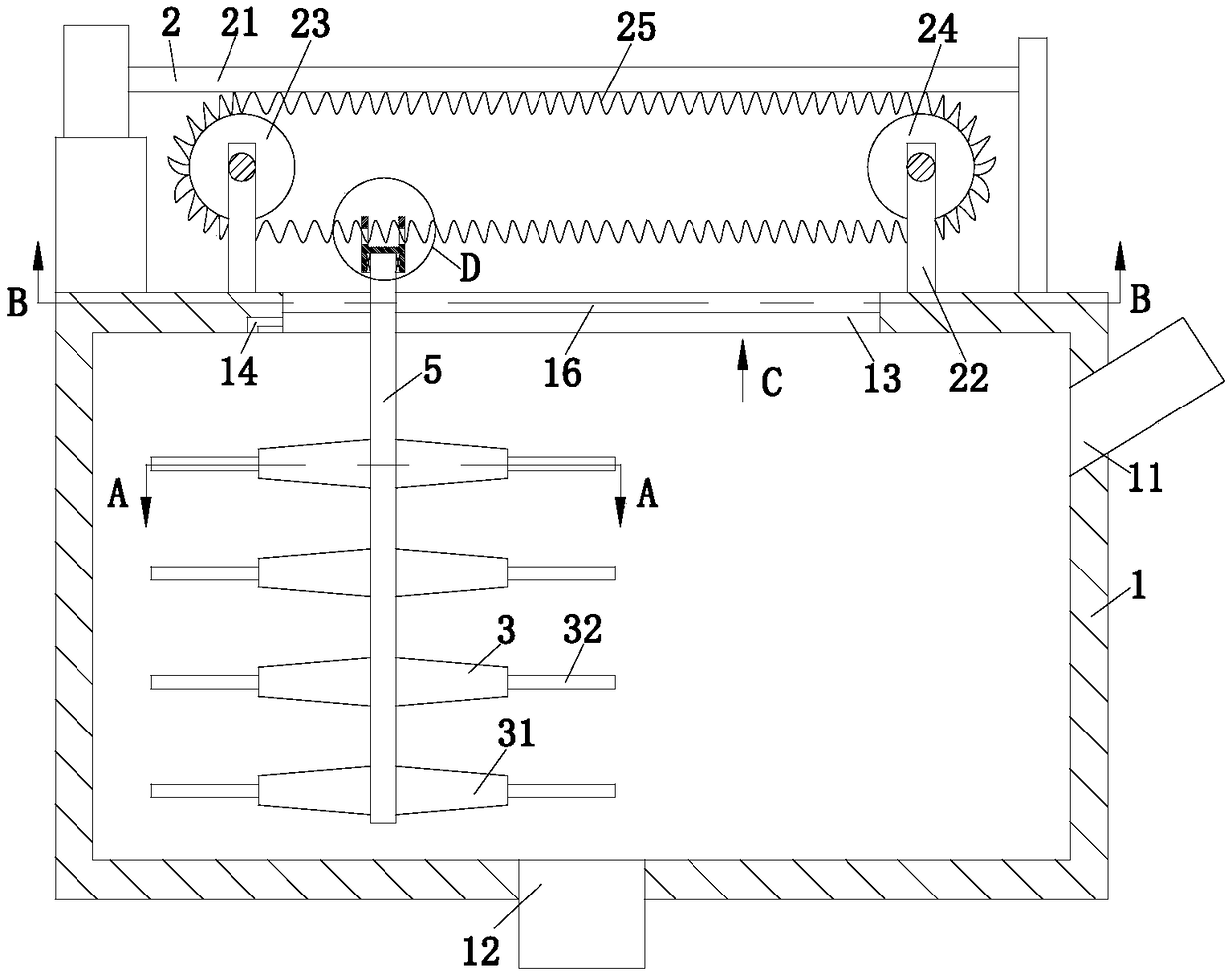

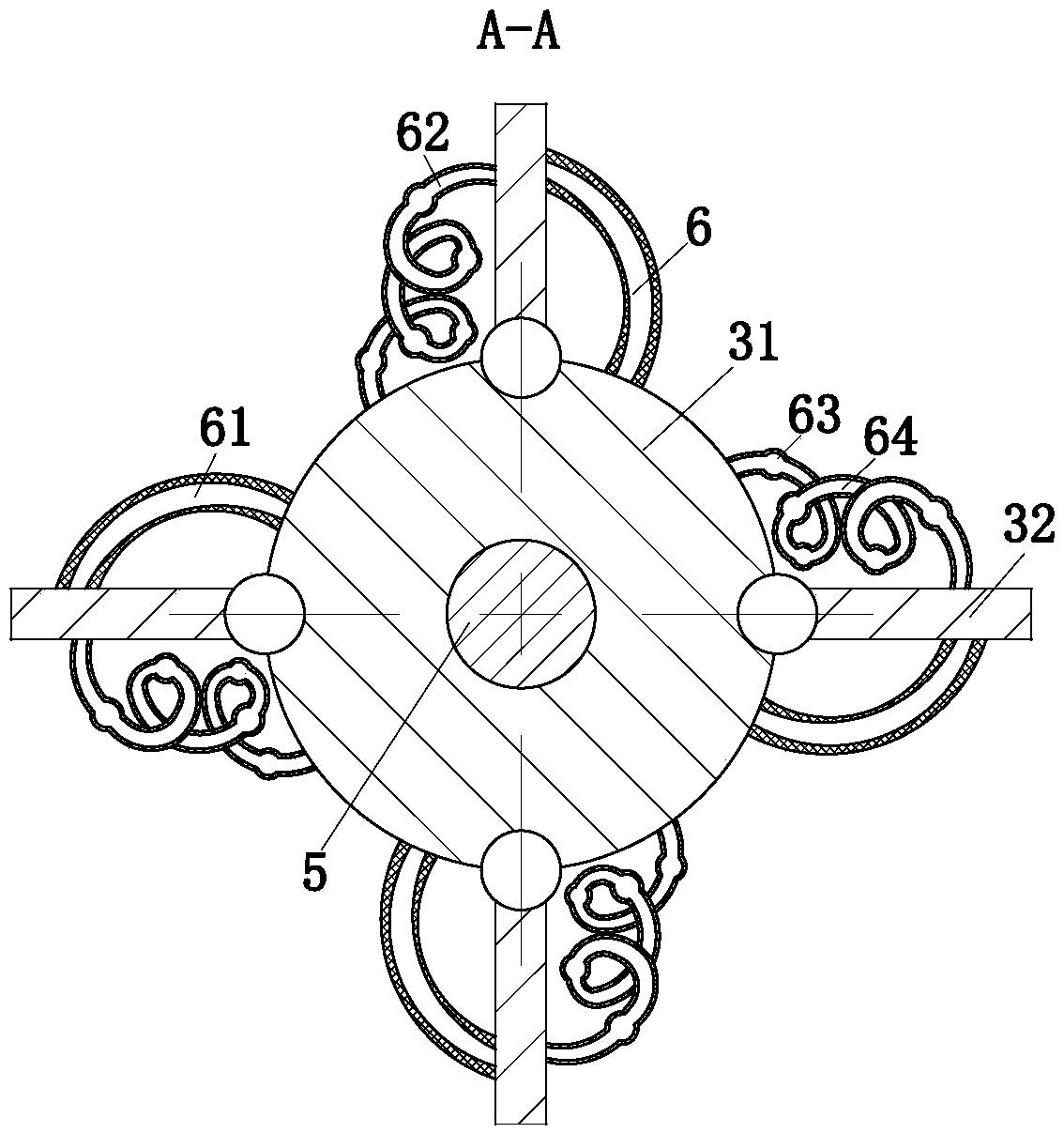

Reciprocating type building material powder mixing machine

InactiveCN109261000AAffect the blending effectImprove the mixing effectTransportation and packagingRotary stirring mixersReciprocating motionEngineering

The invention relates to the technical field of mixing machines and specifically relates to a reciprocating type building material powder mixing machine which comprises a box body and further comprises a driving unit, four or more mixing units, a lantern ring, a first shaft and a controller, wherein the driving unit comprises a motor, a worm rod, an installation plate, a support, a first wheel, asecond wheel and a first spring; each mixing unit is arranged on an outer ring of the first shaft, the four or more mixing units are used for evenly mixing the building material powder, and each mixing unit comprises a rotating disk and a stirring rod. The reciprocating type building material powder mixing machine is provided with the driving unit, the mixing units, the lantern ring, the first shaft and the controller; the driving unit is used for driving the mixing units to do reciprocating motion in the box body; meanwhile, under the action of a semicircular gear block, the first shaft and the lantern ring, the mixing units can rotate, the mixing units can stir and mix the building material powder in the box body in a mode without dead corners; thus, a building material powder mixing effect is improved.

Owner:高继平

Coating mixing device for water pump production line and mixing method thereof

InactiveCN114345182AAffect qualityAffect the blending effectRotary stirring mixersTransportation and packagingWater storage tankThermal water

The invention discloses a coating mixing device for a water pump production line and a mixing method thereof, and belongs to the technical field of water pump production. The paint mixing device for the water pump production line comprises a supporting seat, a mixing tank is arranged on the supporting seat, and the paint mixing device further comprises a mixing assembly arranged in the mixing tank and used for mixing paint; according to the paint mixing device, water in the first sealing cavity is heated, so that the heated water can heat paint in the mixing tank, and the situation that the viscosity of the paint is high in the stirring process in cold weather, and the mixing effect of the paint is affected is prevented; water vapor is generated in the water heating process and enters a second sealing cavity through a pipeline to heat water in a water storage tank, so that when hot water cleans the inner wall of the mixing tank subsequently, the activity of molecules in a coating is improved, and then the cleaning effect on the inner wall of the mixing tank is improved; and the coating is screened through the screen before being mixed, so that the quality of the mixed coating is improved.

Owner:闫文所

Concrete stirring device for building construction

InactiveCN114833942AAvoid cleanup effectAffect the blending effectUsing liquid separation agentMixing operation control apparatusArchitectural engineeringBuilding construction

The invention discloses a concrete stirring device for building construction, and relates to the technical field of concrete stirring. The concrete stirring device for building construction comprises a device body, a driving device is fixedly installed at the bottom of the device body, a rotating shaft is fixedly installed at the output end of the driving device, a stirring rod is rotatably installed on the surface of the rotating shaft, and a scraping plate is hinged to the end, away from the rotating shaft, of the stirring rod. According to the concrete stirring device for building construction, a stirring plate and a scraping plate can be driven to rotate through a rotating shaft, a pushing rod can be driven to move through a sliding rod, the pushing rod can push a sliding block to move downwards, and the sliding block can push a stirring rod to rotate through transmission of a linkage rod; the stirring rod can drive the scraping plate to be attached to the interior of the device body, the stirring rod drives the scraping plate to rotate so that the scraping plate can clean the inner wall of the device body, and it is avoided that concrete remains on the device body.

Owner:徐吉良

Preparation process of antibacterial fresh-keeping bag

PendingCN111941886AEffective filteringAffect the blending effectChemical industryHollow article cleaningProcess engineeringThermal treatment

The invention discloses a preparation process of an antibacterial fresh-keeping bag, and relates to the technical field of bacteriostatic fresh-keeping bag preparation, in particular to a preparationprocess of the antibacterial fresh-keeping bag. The preparation process of the antibacterial fresh-keeping bag comprises a feeding mechanism and a supporting frame, a stirrer tank is installed on oneside of the feeding mechanism, a stirring motor is connected to the upper portion of the stirrer tank, a main shaft is arranged in the stirrer tank, a heating inner cavity is formed in the lower portion of the main shaft, an inner cleaning mechanism is installed on one side of the upper portion of the main shaft, an inner shell is arranged in the heating inner cavity, and a stirring arm is arranged in the inner shell. According to the preparation process of the bacteriostatic fresh-keeping bag, a heating mechanism is arranged, a fan can effectively guide high-temperature gas generated by a heating wire in a heating inner chamber into a guide pipe along a short pipe, the high-temperature gas is guided into the heating inner cavity through a nozzle, and high-temperature gas in the heating inner cavity can effectively provide heating treatment for the inner shell, so that the inner shell can effectively provide efficient heating for materials.

Owner:西安海宏保鲜科技有限责任公司

A kind of preparation technology of coating and preparation device thereof

ActiveCN110628328BGuaranteed preparation efficiencyImprove efficiencyTransportation and packagingMixersMetallurgySolvent

The invention relates to a coating preparation process, including raw material preparation, solid grinding, raw material mixing and additional addition of remaining materials; the preparation device includes a machine frame, a grinding device installed on the frame from top to bottom, a solid material Feeding assembly and dispersing device; the beneficial effect of the present invention is that the "solvent" and "solute" are filtered and pulverized before mixing, thereby improving the efficiency and effect of subsequent coating preparation.

Owner:浙江富思丽涂料有限公司

A material mixing device with multiple mixing chambers

ActiveCN108479611BAvoid cloggingWell mixedGas current separationTransportation and packagingEngineering

The invention discloses a material mixing device with multiple mixing chambers, which comprises a mixing tank body and a mixing upper cover covered on the mixing tank body, and the cavities of the mixing tank body are sequentially A first mixing sieve plate, a first mixing chamber, a second mixing sieve plate, and a crushing / mixing integrated chamber are provided. Because the screw feeding rod is installed in the feeding bin, it can prevent the flour and corn flour from being blocked in the feeding bin; because the first spraying device is installed in the lower part of the feeding bin, the material is sprayed out through the first spraying device, changing the traditional The advanced feeding method not only makes the discharge smoother, but also makes the sprayed materials looser, which facilitates subsequent material mixing and improves mixing efficiency.

Owner:SHENGZHOU YIYUAN INVESTMENT MANAGEMENT

Mixing equipment for flame-retardant thermoplastic polyurethane elastomer

InactiveCN113601744ARealize heat treatmentRealize shreddingElectric machineThermoplastic polyurethane

The invention discloses mixing equipment for a flame-retardant thermoplastic polyurethane elastomer. The mixing equipment comprises an equipment main body, the bottom end of the equipment main body is fixedly connected with a top plate, the two sides of the bottom end of the top plate are fixedly connected with supporting rods, the bottom ends of the supporting rods are fixedly connected with a bottom plate, and a uniform discharging mechanism is arranged between the top plate and the bottom plate. A material guiding mechanism is arranged below a water inlet and comprises a third driving motor arranged on the outer wall of the equipment main body, the third driving motor is transversely arranged, a rotating shaft is arranged at the output end of the third driving motor, and the third driving motor, a cam, a spring and a discharging plate are connected in a matched mode. Materials crushed by a crushing mechanism and materials entering from the water inlet can fall on the surface of the discharging plate and fall near a mixing and crushing mechanism through the discharging plate, the material guiding effect is achieved, and the materials can be prevented from being concentrated at the corner of the equipment main body.

Owner:李宁

Low-vibration epoxy floor paint stirring device for indoor construction

ActiveCN112808114AAvoid accumulationWell mixedShaking/oscillating/vibrating mixersTransportation and packagingElectric machineStructural engineering

The invention discloses a low-vibration epoxy floor paint stirring device for indoor construction. The low-vibration epoxy floor paint stirring device for indoor construction comprises a device body, a support, a forward or reverse motor, a feed port, a main shaft, a stirring blade mechanism, a scraping mechanism and a discharge port, wherein the device body is fixedly connected with the upper end of the support; the bottom end of the support is in contact with the ground; the forward or reverse motor is arranged at the top end of the device body; the feed port is located in one side of the forward or reverse motor; the main shaft penetrates through the interior of the device body in a vertical direction; one end of the main shaft penetrates through the side wall of the device body and is connected with the acting end of the forward or reverse motor; the main shaft and the device body are connected in a sealed mode through a bearing; the scraping mechanism and the stirring blade mechanism sequentially penetrate through and are arranged on the main shaft; the scraping mechanism is located above the stirring blade mechanism; one end of the scraping mechanism is movably connected with the main shaft, and the other end of the scraping mechanism is fixedly connected with the stirring blade mechanism; the scraping mechanism is transversely attached to the inner side wall of the device body; and the discharge port is formed in one side of the device body.

Owner:乐清市路航电气有限公司

A kind of waste sintered brick and tile environment-friendly lightweight concrete and its preparation method

ActiveCN111960782BLow thermal conductivityHigh compressive strengthSolid waste managementCompressive resistanceBrick

The application relates to an environmentally friendly lightweight concrete of waste fired bricks and tiles and a preparation method thereof, which belongs to the technical field of concrete. The raw materials of lightweight concrete include cement, water, waste fired bricks and tiles, fly ash, slag, silica fume, polymer Acrylonitrile fiber, plastic steel fiber, polystyrene particles, ceramic powder, silica powder, polycarboxylate high-efficiency water reducer, phenolic resin, and through the synergistic effect between raw materials, under the condition of ensuring low thermal conductivity of lightweight concrete , so that the lightweight concrete has good compressive strength and flexural strength, and also makes the lightweight concrete have good frost resistance. In the preparation method of environmentally friendly lightweight concrete, the waste sintered bricks and tiles are pre-mixed with soaking water, and the fly ash and adsorption water are pre-mixed to reduce the mixing effect of waste sintered bricks, tiles and fly ash due to the adsorption of water. , so that the mixing of raw materials is uniform and stable.

Owner:HANGZHOU WUYOU BUILDING MATERIALS CO LTD

Probiotic mixing device and method

InactiveCN114082352AAvoid cakingBreak up fullyTransportation and packagingMixer accessoriesElectric machineryControl theory

The invention relates to the technical field of probiotics, and discloses a probiotic mixing device. The device comprises a tank body, a top cover is mounted at the top of the tank body, a motor is fixedly connected to the bottom of the top cover, a screw rod is fixedly connected to the output end of the motor, a shaft sleeve is rotatably connected to the surface of the screw rod, the bottom end of the shaft sleeve is rotatably connected with a fixing block, the inner wall of the fixing block is rotatably connected with a rotating plate, the front portion of the rotating plate is provided with a cleaning device, the bottom end of the screw rod is provided with a stirring device, the surface of the screw rod is movably connected with a sliding block through a clamping block, the inner wall of the sliding block is rotatably connected with a transmission plate, and a clamping plate is fixedly connected to one side, away from the stirring rod, of the rotating plate. The screw rod drives the sliding block to move, the sliding block drives the transmission plate to move, the transmission plate can open the rotating plate and then close the rotating plate, the rotating plate drives the clamping plate to close and close in a reciprocating mode, and then caked probiotics can be crushed.

Owner:农少文

Mining paste filling material magnetizing device and using method

PendingCN114523568AChange the viscosityChange surface tensionSolid waste managementDischarging apparatusElectric machineryEngineering

The invention discloses a mining paste filling material magnetizing device, which comprises a cylinder, a partition plate is fixedly connected in the cylinder, the partition plate divides the cylinder into a material mixing chamber and a magnetizing chamber from top to bottom, and a gate part is arranged on the partition plate; a plurality of feed hoppers and a plurality of water inlet pipes are fixedly connected to the outer wall of the top end of the barrel and are communicated with the mixing chamber; the stirring mechanism comprises a transmission part fixedly connected to the top end of the barrel, a driving motor is fixedly connected to the top end of the transmission part and is in transmission connection with the transmission part, and the output end of the transmission part extends into the mixing chamber and is fixedly connected with a stirring part; the magnetizing mechanism comprises a discharging pipe fixedly connected to the inner wall of the top end of the magnetizing chamber, the tail end of the discharging pipe extends out of the cylinder, and the mixing chamber is communicated with the discharging pipe through a gate part; an auxiliary discharging part is installed in the discharging pipe, permanent magnets are symmetrically arranged on the two sides of the discharging pipe, and the two permanent magnets are detachably connected into the magnetizing chamber. The magnetization of the paste can be realized, and the flowability of the paste is enhanced.

Owner:ANHUI UNIV OF SCI & TECH

Rectification container

PendingCN112098276AImprove uniformityShort tripParticle size analysisParticle suspension analysisEngineeringMechanical engineering

The invention discloses a rectification container which comprises a main body arranged in an aerosol mixing pipe, a containing cavity is formed in the main body, the main body is further provided witha plurality of rectification holes penetrating through the side wall of the containing cavity, the multiple rectification holes are all located below a top plate of the aerosol mixing pipe, the containing cavity communicates with an aerosol air inlet pipe, the containing cavity is communicated with the aerosol mixing pipe through the rectification holes, the opening direction of the rectificationholes is arranged upwards, the included angle between the rectification holes and the vertical direction ranges from 30 degrees to 65 degrees, and thus aerosol flowing out of the rectification holescan collide with the pipe wall or the top plate. According to the scheme, the mixing uniformity of aerosol is greatly improved.

Owner:吴江市华宇净化设备有限公司

An energy-saving and environment-friendly pulping equipment for papermaking and printing

ActiveCN110552222BAffect the blending effectEasy to cleanRaw material divisionPapermakingElectric machinery

The invention discloses an energy-saving and environment-friendly pulping device for papermaking and printing. The pulping device comprises a box body, the lower end of the box body is fixedly connected with a plurality of supporting feet, a discharge port is arranged at the middle and lower position of the side wall of the box body, the middle part of the upper end of the box body is provided with a feed inlet, the upper end of the box body is fixedly connected with a feed hopper at a position corresponding to the feed port, the lower end of the box body is fixedly connected with a motor, theend of the output shaft of the motor penetrates through the lower end of the box body and is fixedly connected with a rotating rod, the output shaft of the motor is rotatably connected with the box body, a plurality of crushing knives are arranged at equal intervals along the axial direction on the outer side of the rotating rod, a rotating plate is sleeved on the rotating rod, and the two are fixedly connected. The invention has reasonable structural design, can disperse materials into the inside of the box body, is beneficial to improving the pulping effect, can fully mix the materials, andcan also prevent the materials from adhering to the inner wall of the box body.

Owner:温州市金龙纸业有限公司

A cornmeal production and processing mechanism based on multi-directional feeding

ActiveCN108654757BGuaranteed crushing efficiencyEnsure crushing efficiencySievingConveyorsAgricultural engineeringCorn flour

The invention discloses a cornmeal production and processing mechanism based on multi-directional feeding, which comprises a corn grain crushing device, a powder material mixing device and a powder material running device in sequence from front to back according to the technological process. The corn grain crushing device includes a crushing unit, a drying unit and a recycling unit in sequence according to the process flow. The powder mixing device includes a mixing tank body and a mixing upper cover covered on the mixing tank body. The cavity of the mixing tank body is sequentially provided with a first mixing sieve plate, a first mixing Chamber, second mixing sieve plate, crushing / mixing integrated chamber. The powder running device includes a running conveyor belt, a flip-type unloading device, a running baffle, a hopper, a running elastic device, and a running lifting base that are arranged in sequence from front to back. The invention has the advantages of ensuring the quality of the produced corn flour, good mixing effect of corn flour and flour, no agglomeration, no clogging, strong work continuity, accurate single feeding amount and high work efficiency.

Owner:安徽双全面粉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com