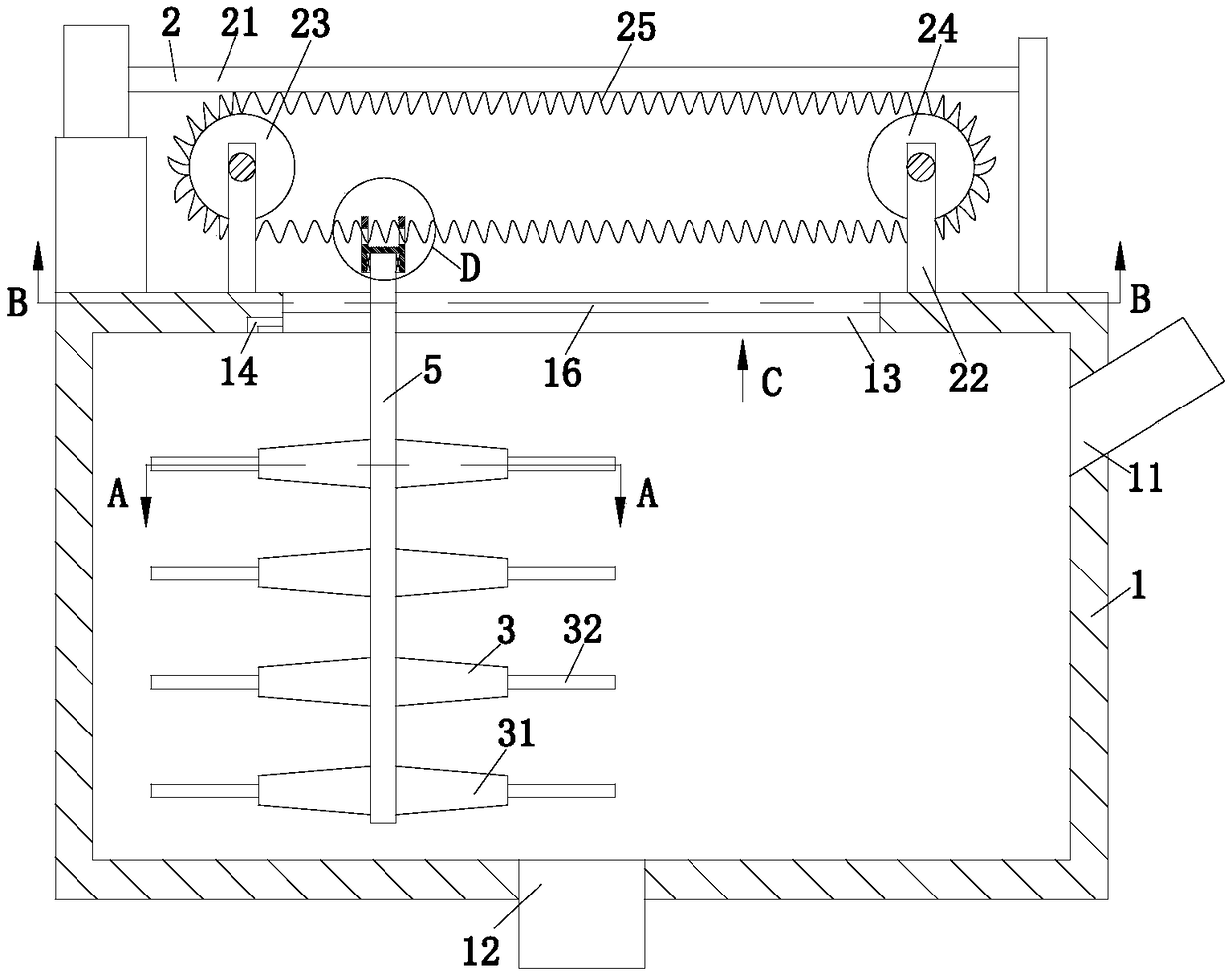

Reciprocating type building material powder mixing machine

A technology for building material powder and mixers, which is applied to mixers, mixers with rotating stirring devices, and dissolution, etc. It can solve the problems that building material powders cannot be fully stirred and mixed, and achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

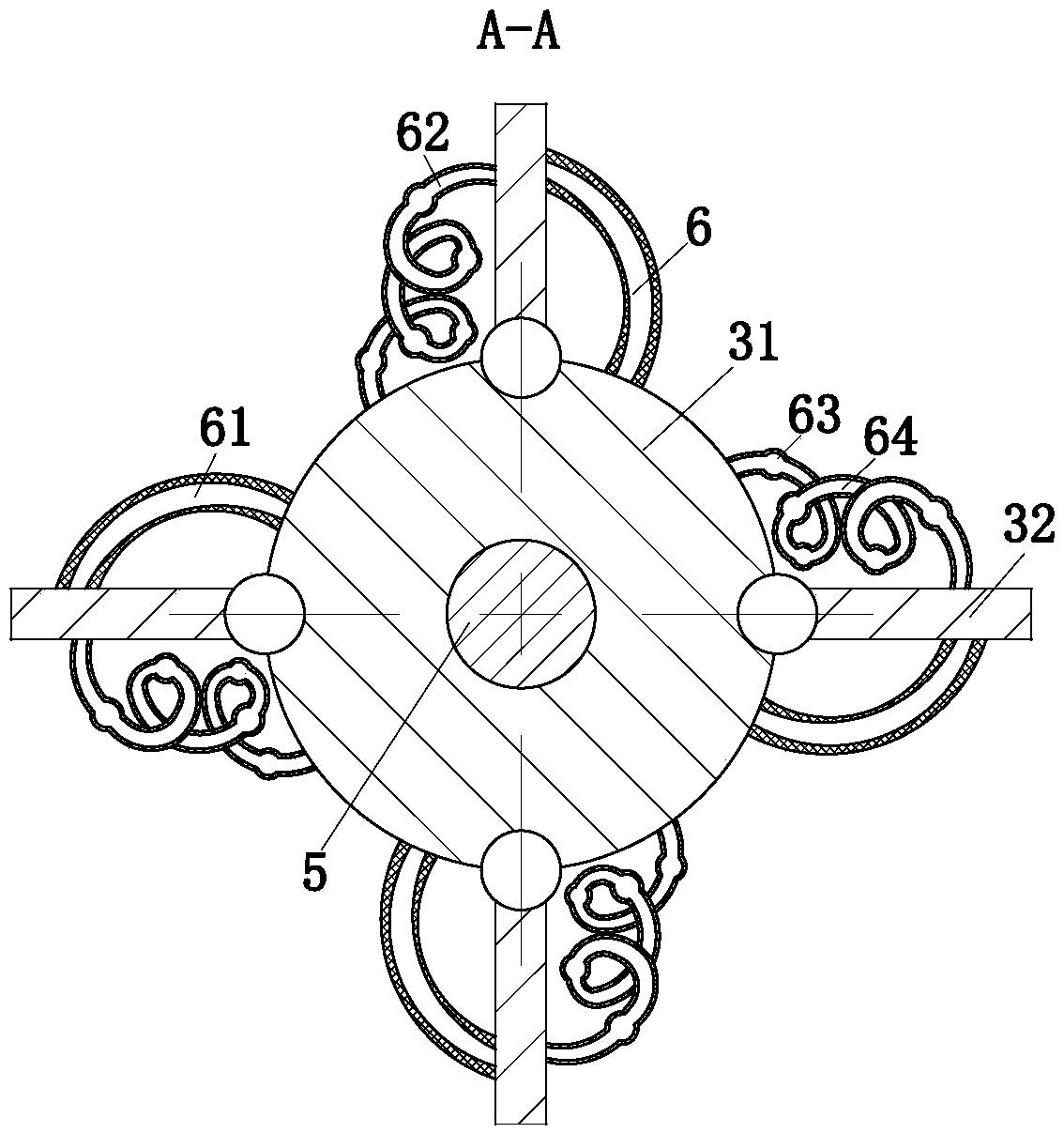

[0033] As an embodiment of the present invention, the cross section of the No. 1 spring 25 steel wire is composed of No. 1 arc 251, No. 2 arc 252 and No. 3 arc 253; the No. 1 arc 251 and No. 2 arc 252 are arranged oppositely, And the arc length of the first arc 251 is less than the arc length of the second arc 252; the number of the third arc 253 is two, and the third arc 253 is mutually symmetrical, and one end of the third arc 253 is fixedly connected with the first arc 251, The other end of the third arc 253 is fixedly connected with the second arc 252 . When the No. 1 spring 25 in the prior art was subjected to gravity, the No. 1 spring 25 was easily deformed, thereby affecting the service life of the No. 1 spring 25; Arc 252 and No. 3 arc 253 are formed. On the one hand, this cross-section increases the bearing force of No. 1 spring 25. At the same time, when the two sides of No. 1 arc 251 are squeezed, this cross-section faces the squeeze force received. Decomposition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com