Mining paste filling material magnetizing device and using method

A paste filling and magnetizing device technology, which is applied to liquid ingredient supply devices, unloading devices, chemical instruments and methods, etc., can solve the problems of easy blockage, low strength of paste filling body, and poor fluidity of filling slurry, etc. Achieve the effect of avoiding sinking, solving poor liquidity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

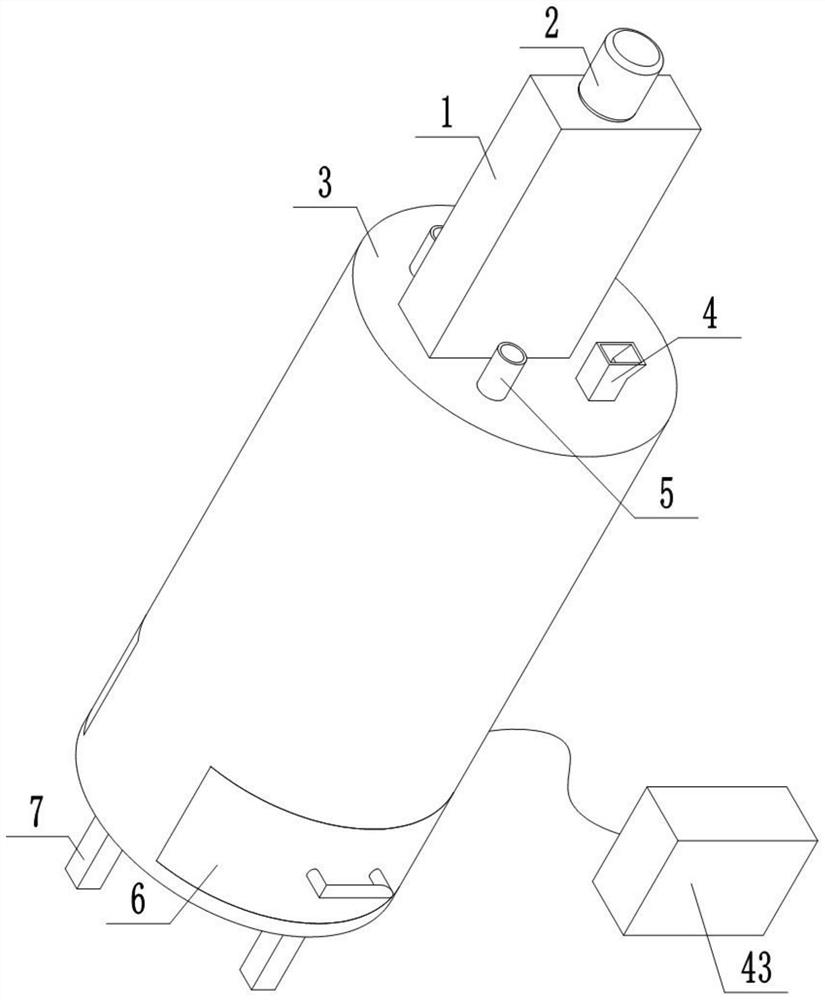

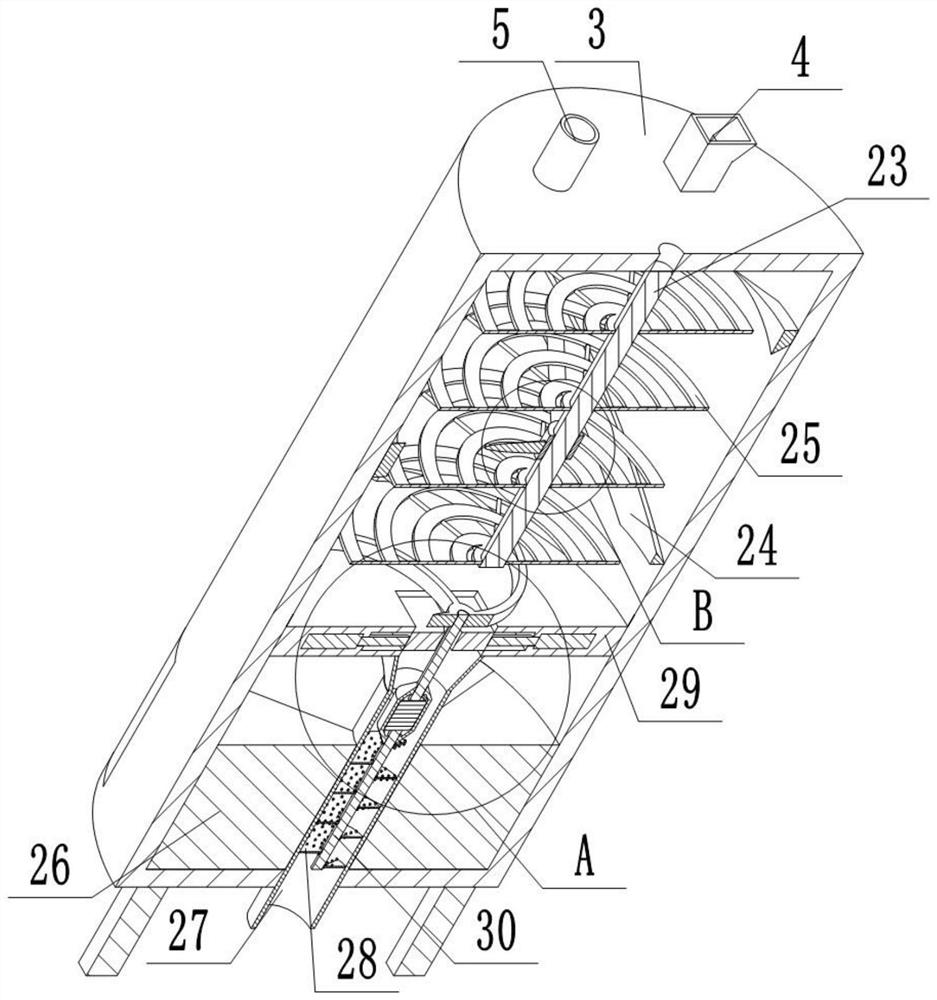

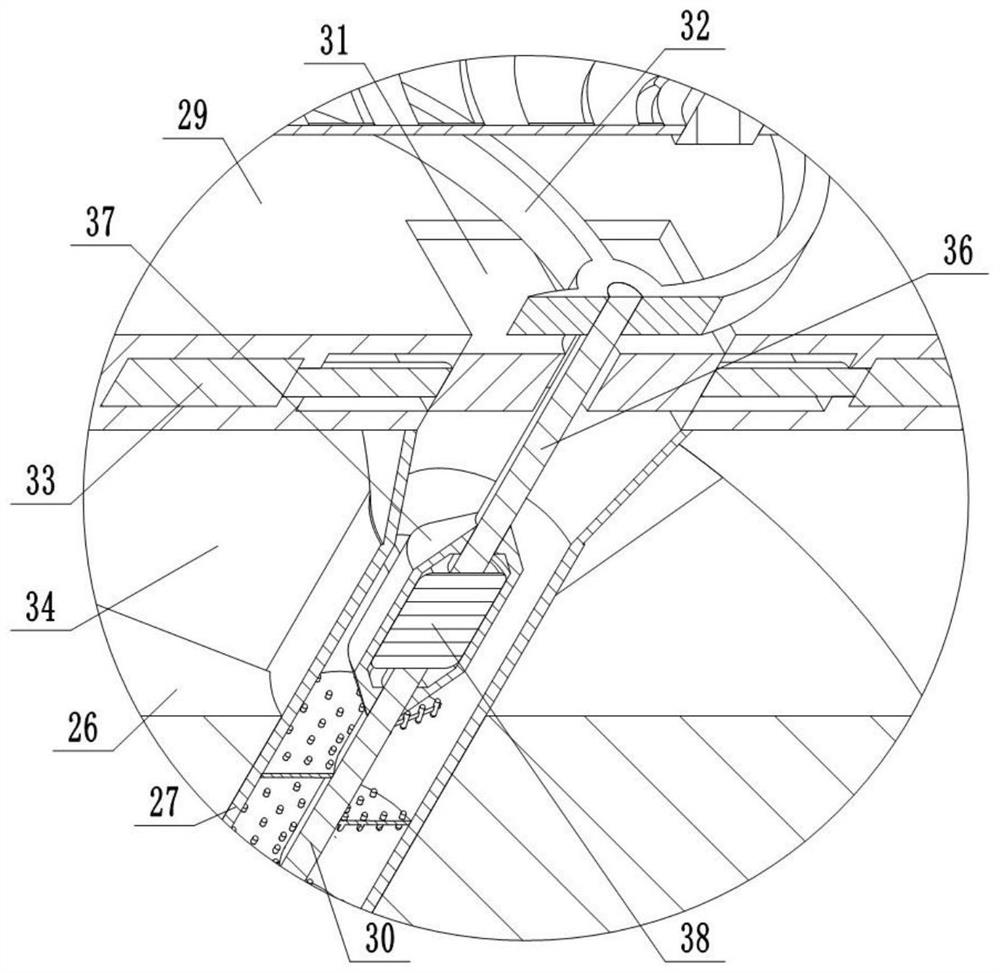

[0042] Reference Figure 1-3 , 5-9, the present invention provides a mineral paste filler magnetization device, comprising:

[0043] Cylinder 3, cylinder 3 is fixed with a partition 29, the partition 29 from top to bottom of the cylinder 3 is divided into a mixing chamber and a magnetization chamber, and the separator 29 is provided with a gate part; the top outer wall of the cylinder 3 is fixed with a number of inlet hoppers 4 and several inlet pipes 5, the feed hopper 4 and the inlet pipe 5 are connected with the mixing chamber;

[0044] Mixing mechanism, the mixing mechanism comprises a transmission part fixed at the top of the cylinder 3, the transmission part is fixed to the top of the drive motor 2, the drive motor 2 is connected to the transmission part, and the output end of the transmission part is extended into the mixing chamber and fixed with a number of stirring blades 25;

[0045]Magnetization mechanism, the magnetization mechanism comprises a discharge pipe 27 fixed ...

Embodiment 2

[0070] Reference Figure 2 、 4 10, 11, the difference between Example II and Example I is that the second hinge 23 is provided with a connecting cylinder 39, the outer wall of the connecting cylinder 39 is fixed to a number of connecting rods 40, the connecting rod 40 is fixed at the end of the first scraper 24, the outer wall of the first scraper 24 is in contact with the inner wall of the mixing chamber;

[0071] The first scraper 24 main view is shaped as a straight line with an oblique setting.

[0072]Working process: when driving the motor 2 to drive the second shaft 23, the second shaft 23 drives the first scraper 24 movement, the first scraper 24 is in contact with the mixing chamber wall, which can scrape the mixing chamber wall, effectively reduce the solid matter attached to the inner wall of the mixing barrel during the mixing process, ensure a better mixing effect, form a more uniform paste filler, and provide protection for better magnetization of the subsequent paste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com