A semi-solid friction brazing method for dissimilar metals based on high frequency assistance

A dissimilar metal, high-frequency assisted technology, used in metal processing equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of limited design range of stud head structure, thick intermetallic compound layer, affecting the overall performance of joints, etc. The effect of improving bending resistance and fatigue resistance, simple layout and high comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

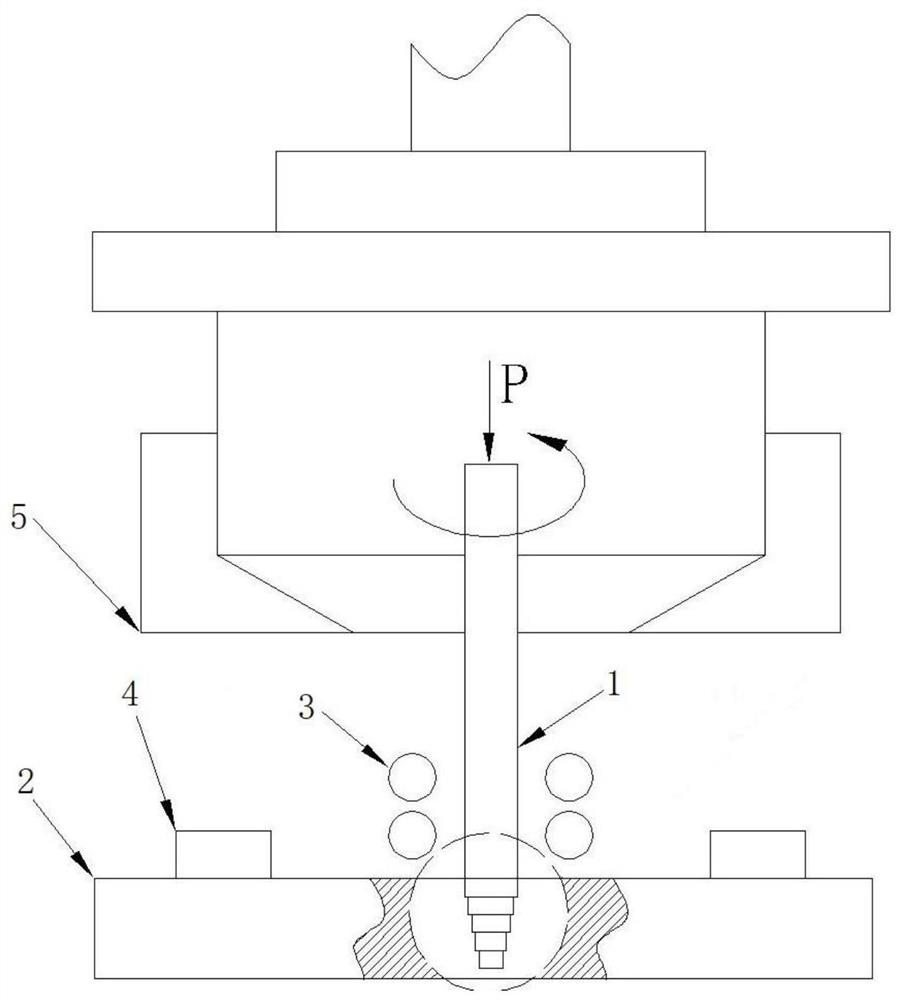

[0043] Embodiment 1, a method for semi-solid friction brazing of dissimilar metals based on high frequency assistance, which includes the following steps.

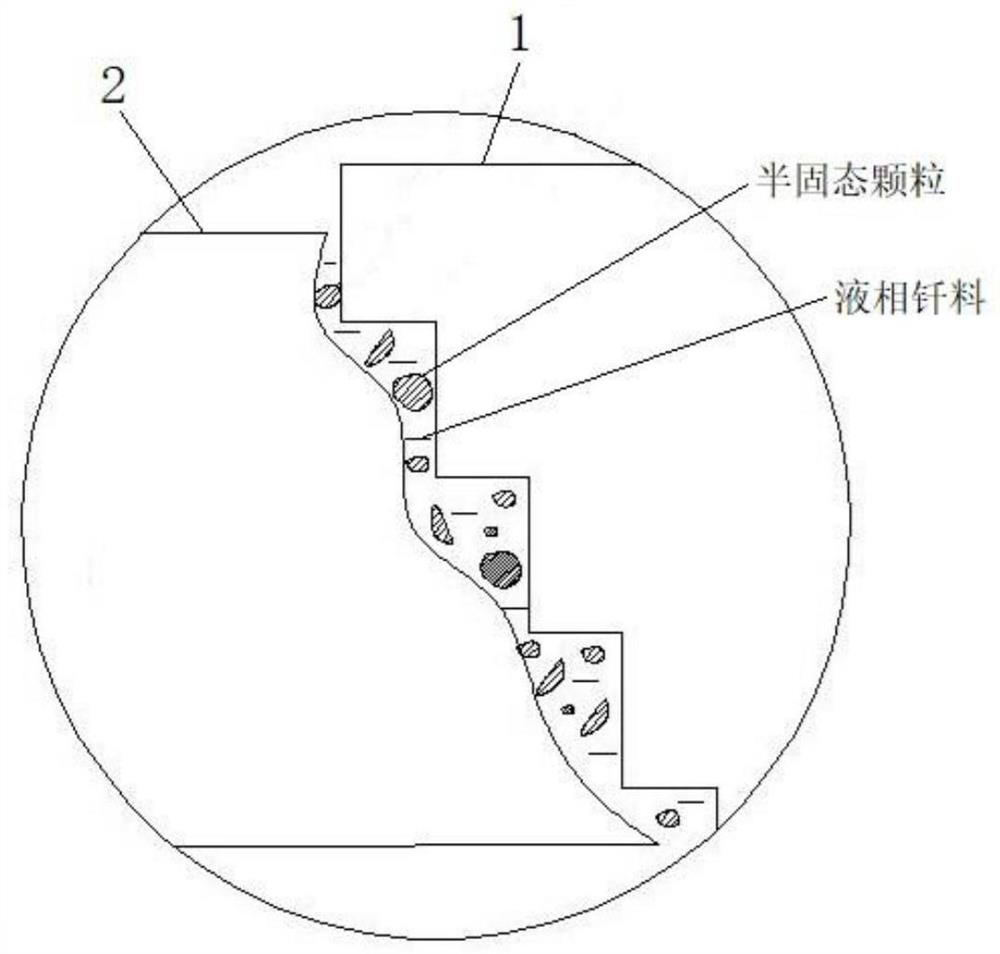

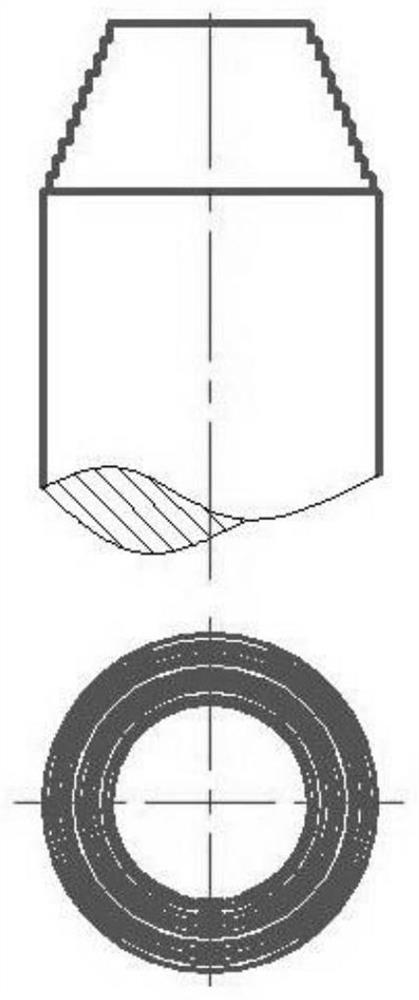

[0044] Step 1, prepare steel studs to be welded and aluminum alloy workpieces to be welded, see Figure 5 , the welding end of the stud to be welded is processed into a tapered step shape: the welding end is in the shape of a conical column with a taper angle of 10° as a whole, and 5 steps are respectively arranged in the direction of the stud to be welded from its end face, and the diameter of 5 steps is Decreases away from the shaft. The shape of the workpiece to be welded is a thick plate, and a preset hole is processed at the surface of the workpiece to be welded. The preset hole is in the shape of a truncated cone. The solder is placed on the inner wall of the preset hole of the workpiece to be welded. see Figure 9 , the inner wall ring of the preset hole of the workpiece to be welded is provided with two protrusi...

Embodiment 2

[0049] Embodiment 2, a method for semi-solid friction brazing of dissimilar metals based on high frequency assistance, which includes the following steps.

[0050] Step 1, prepare steel studs to be welded and copper workpieces to be welded, see Figure 7 , the welding end of the stud to be welded is processed into a tapered thread shape, and the welding end is in the shape of a conical column with a taper angle of 10° as a whole, and its outer peripheral surface is provided with a spirally arranged thread groove. mm, the pitch is 1.5mm. Preset holes are processed at the surface of the workpiece to be welded, the preset hole is in the shape of a truncated cone, and the angle of its generatrix is the same as the single taper of the welding end of the stud to be welded, and the Zn-Al15 solder is placed on the preset hole of the workpiece to be welded. inner wall of the hole. see Figure 10 , the Zn-Al15 solder is attached to the inner wall of the preset hole of the workpiece...

Embodiment 3

[0055] Embodiment 3, a method for semi-solid friction brazing of dissimilar metals based on high-frequency assistance, which includes the following steps:

[0056] Step 1, prepare copper studs to be welded and aluminum alloy workpieces to be welded, see image 3 , the welding end of the stud to be welded is processed into a tapered step thread shape, and the welding end is in the shape of a conical column with a taper angle of 10° as a whole. There are 10 steps from the end face to the direction of the stud to be welded. The 10 steps The diameter of the steps decreases from the direction away from the rod, and the outer peripheral surface of the welding end is processed with double helical grooves. The double helical grooves start from the second step near the root step, and the starting angles are 0° and 180° respectively. The depth is 1mm and the pitch is 1mm. Preset holes are processed at the surface of the workpiece to be welded, the preset hole is in the shape of a trunc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com