Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153results about How to "Break up fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slurry-homogenizing process for positive electrode slurry of lithium ion battery, positive electrode plate and lithium ion battery

ActiveCN106654166AImprove uniformity and stabilityReduce evaporationSecondary cellsNon-aqueous electrolyte accumulator electrodesCurrent collectorLithium electrode

The invention discloses a slurry-homogenizing process for positive electrode slurry of a lithium ion battery, a positive electrode plate and the lithium ion battery, and belongs to the technical field of manufacturing of the lithium ion battery. The slurry-homogenizing process for the positive electrode slurry of the lithium ion battery comprises the steps of preparing an adhesive solution, stirring by a V-shaped stirrer, performing pre-mixing and stirring, performing high-speed stirring, performing viscosity adjustment, performing vacuum defoaming and the like; the positive electrode plate of the lithium ion battery comprises a positive electrode current collector and the positive electrode slurry for coating the positive electrode current collector; the positive electrode current collector adopts an aluminum foil; the positive electrode slurry is prepared by the slurry-homogenizing process for the positive electrode slurry of the lithium ion battery; and the lithium ion battery adopts the positive electrode plate of the lithium ion battery prepared by the method. By adoption of the slurry-homogenizing process, the solid content of the slurry is increased, so that solid granule friction in stirring can be improved, and the uniformity and the stability of the slurry can be improved; and by lowering a baking temperature in a drying oven in coating and drying, gaps formed between active material granules, conducive carbon granules and a binder can be reduced, thereby enhancing an adhesive effect and improving the performance of the lithium ion battery.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

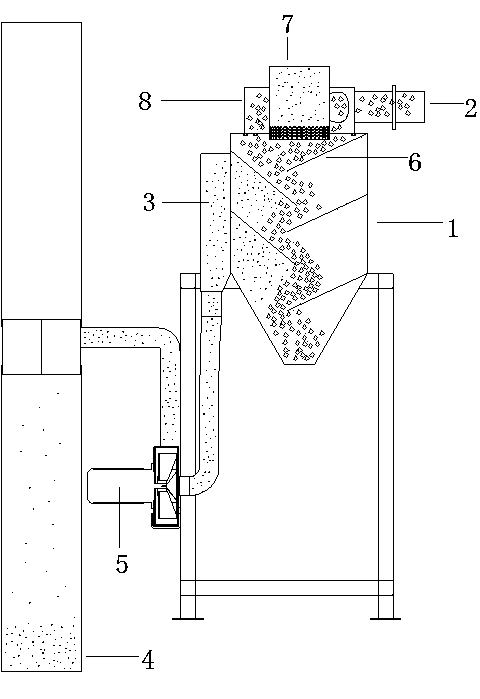

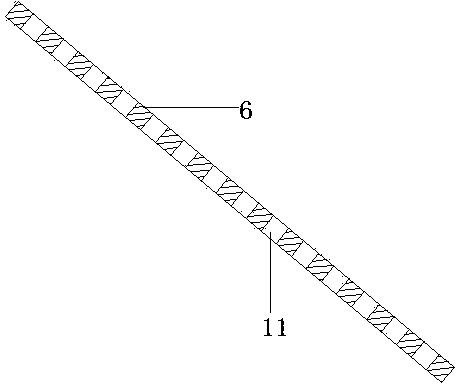

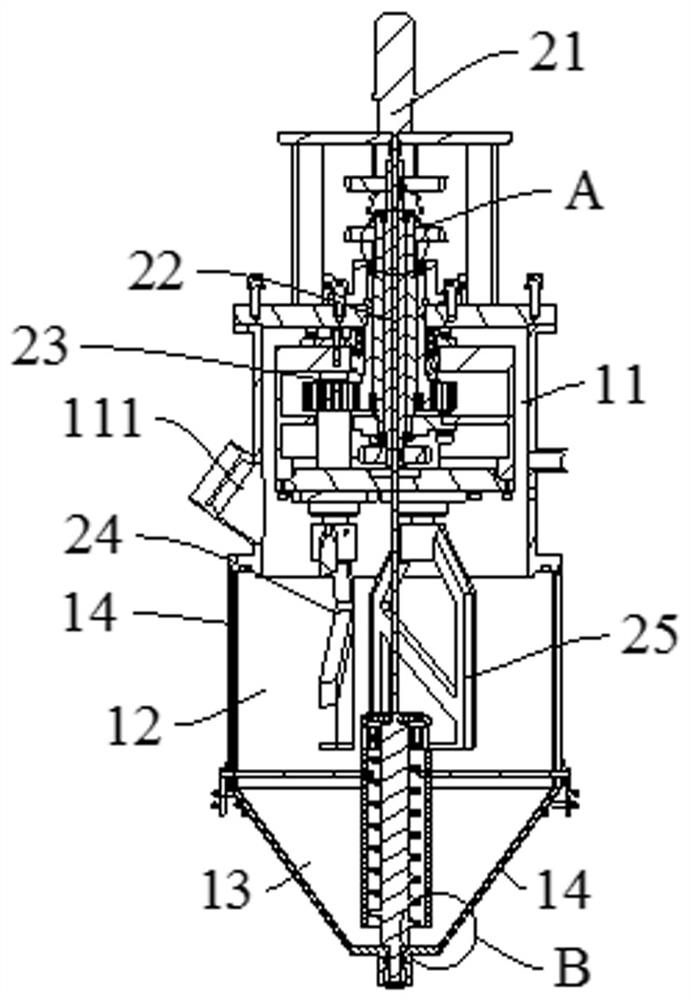

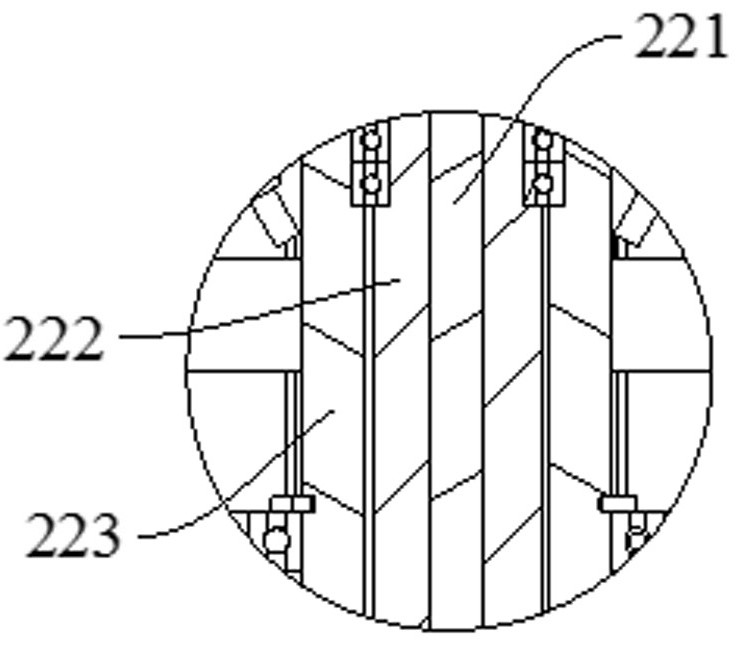

Dust separation and collection device

ActiveCN103522451ANot easy to reboundClear quicklyGas current separationPlastic recyclingFrequency conversionEngineering

The invention discloses a dust separation and collection device which is good in separation effect, can sufficiently and thoroughly separate and recycle dust and solves the deficiencies that partial plastic is separated along with the dust, and the dust is easy to rebound, mix and adhere again in a separation process of a plastic dust separation device in the prior art. A plastic dust frequency-conversion separation device comprises a main dust removing cylinder and a feeding hole, wherein the main dust removing cylinder is connected with a dust collection bag through an air guiding pipe, an air guiding and dust collection fan is arranged on the air guiding pipe, a plurality of material-guiding inclined plates are arranged in the main dust removing cylinder, and a discharging hole is formed in the lower end of the main dust removing cylinder; a cyclone cylinder is arranged on the main dust removing cylinder, dust collection meshes are formed in the side wall of the cyclone cylinder, and a pre-dedusting cylinder is arranged outside the cyclone cylinder and is connected with the feeding hole. The dust separation and collection device is suitable for applicative occasions of existing plastic dust separation devices and has the characteristics of capability of complete scattering and separation of plastic particles, good dust removing effect, high separation efficiency and the like.

Owner:宁波斯曼尔电器有限公司

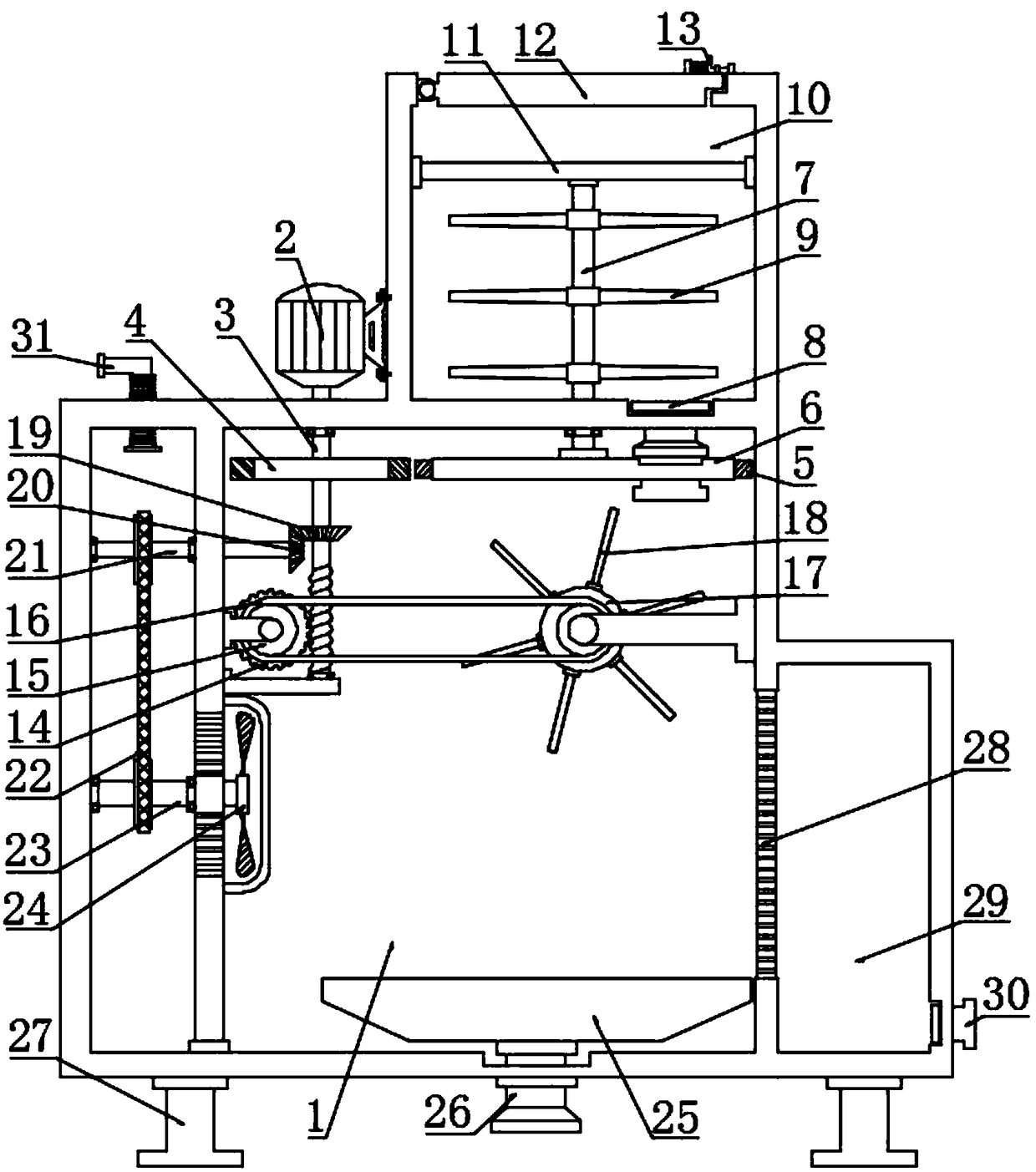

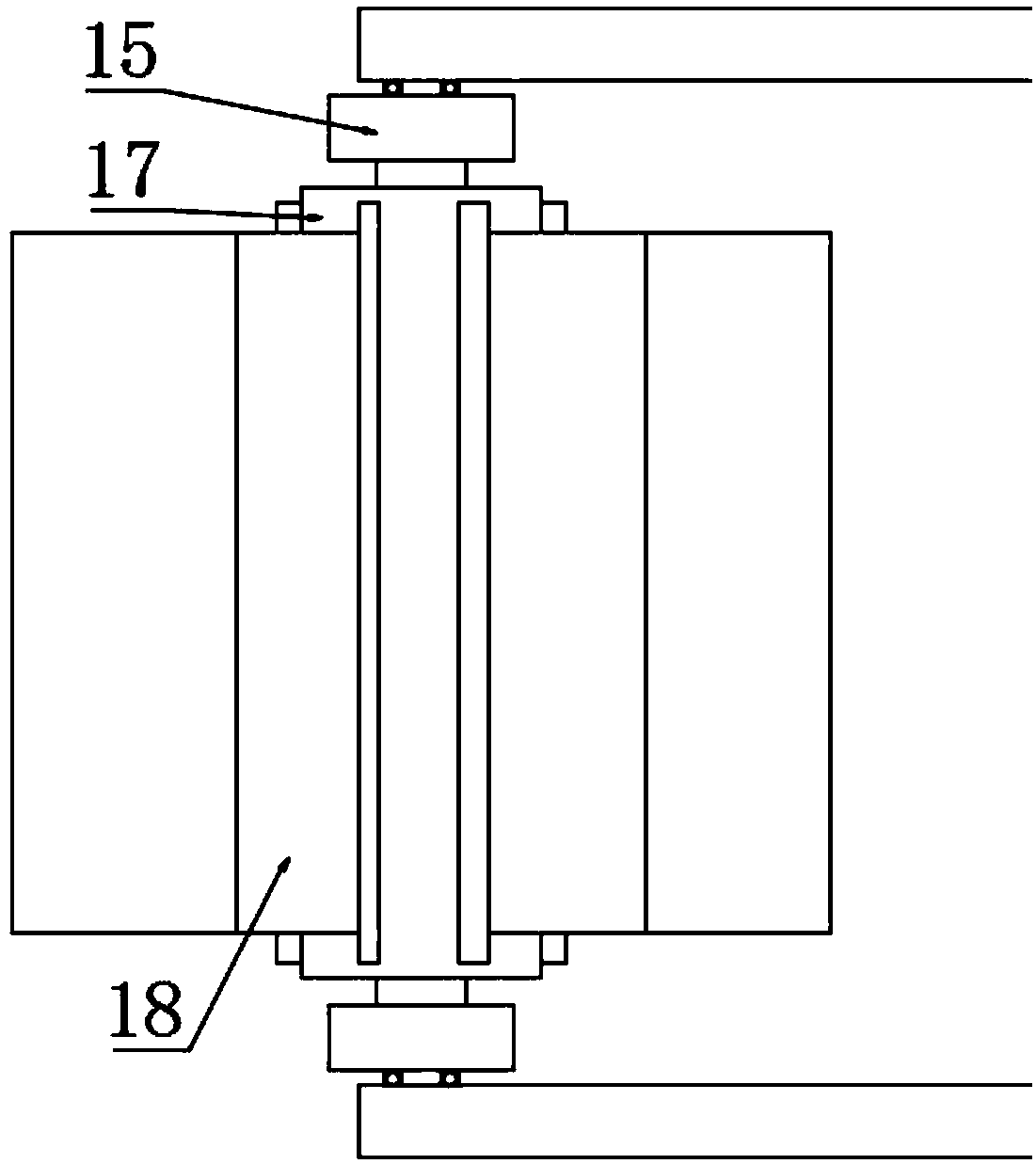

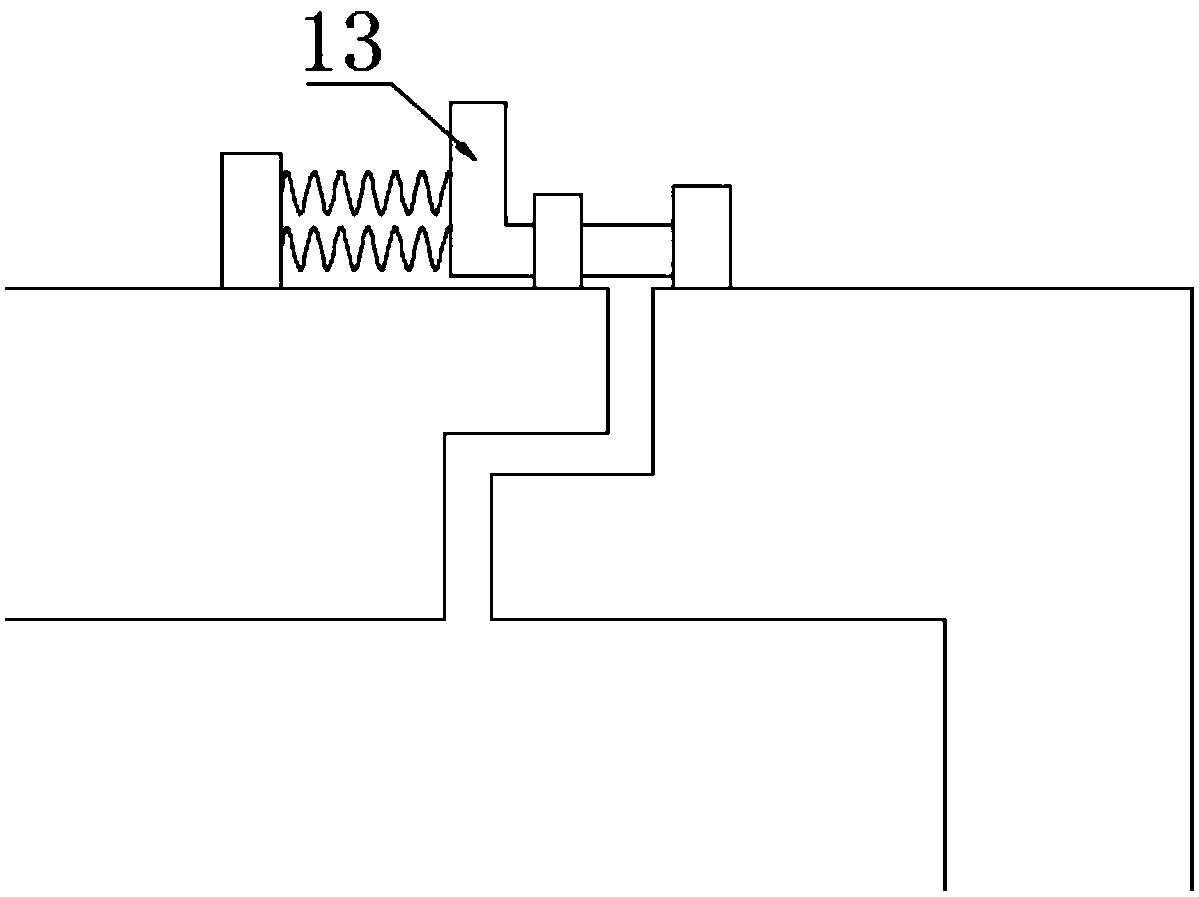

Agricultural efficient overturning winnowing device

PendingCN108057620APrevent unityBreak up fullyGas current separationGear wheelAgricultural engineering

The invention discloses an agricultural efficient overturning winnowing device. A worm is rotationally connected to the upper end of a device body through a bearing, and the lower end of the worm is rotationally connected with a transverse plate. The transverse plate is fixedly connected with the device body. The upper portion of the worm is fixedly connected with a gear. The gear is engaged withan annular rack. The annular rack is fixedly connected with a rotation disc. The middle portion of the rotation disc is fixedly connected with the lower end of a stirring shaft. The lower portion of the stirring shaft is rotationally connected with the bottom of a storage box through a bearing, and the upper end of the stirring shaft is rotationally connected with a retainer. The retainer is fixedly connected with the side wall of the storage box. The middle portion of the stirring shaft is fixedly connected with a stirring bar. According to the device, the rotation disc is used for driving athrough hole in the circumferential direction of the rotation disc to communicate with an unloading pipe in a reciprocating manner for achieving intermittent discharging, the rotating stirring bar stirs grain in the storage box, and the situation that the grain is caked and is not discharged is prevented. A roller drives an overturning plate to rotate to scatter grain falling down from the throughhole in the surface of the rotation disc, and the grain is sufficiently scattered in air. The device is reasonable and applicable in structure design, the dust removing effect in the winnowing process is greatly improved, the automation degree is high, and labor is saved.

Owner:刘翠玲

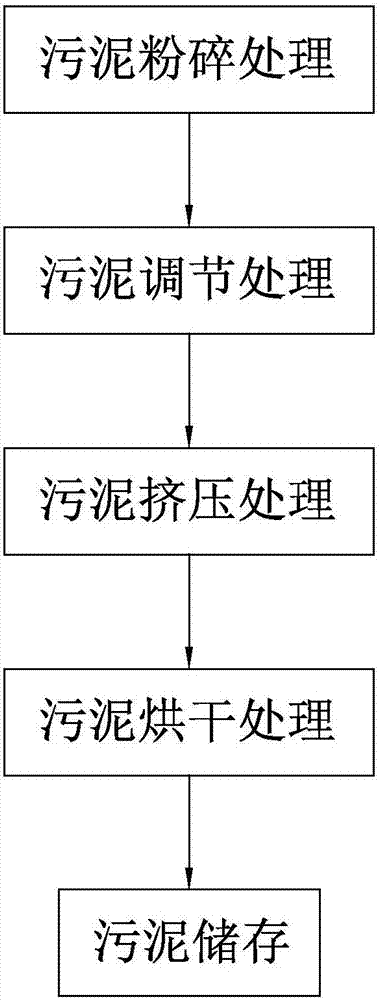

Sludge concentration and dewatering treatment method

ActiveCN107129127AEasy to dehydrateReduce moisture contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMultiple treatmentsCapillary water

The invention discloses a sludge concentration and dewatering treatment method. The method comprises the following steps: (1) sludge pulverizing treatment; (2) sludge conditioning treatment; (3) sludge extrusion treatment; (4) sludge drying treatment; and (5) sludge storage. The method disclosed by the invention is simple in structure, high in practicality, convenient to use and remarkable in the sludge dewatering effect; through the multiple treatments of a pulverizing cavity, a conditioning tank and a dewatering cavity, void water, adsorbed water and capillary water in sludge are all separated out, so that the dewatering rate of the sludge is effectively improved, and the volume of the sludge is reduced, thereby facilitating subsequent recycling of the sludge; and the overall structure design is more reasonable and scientific.

Owner:浙江金华德朗水务有限公司

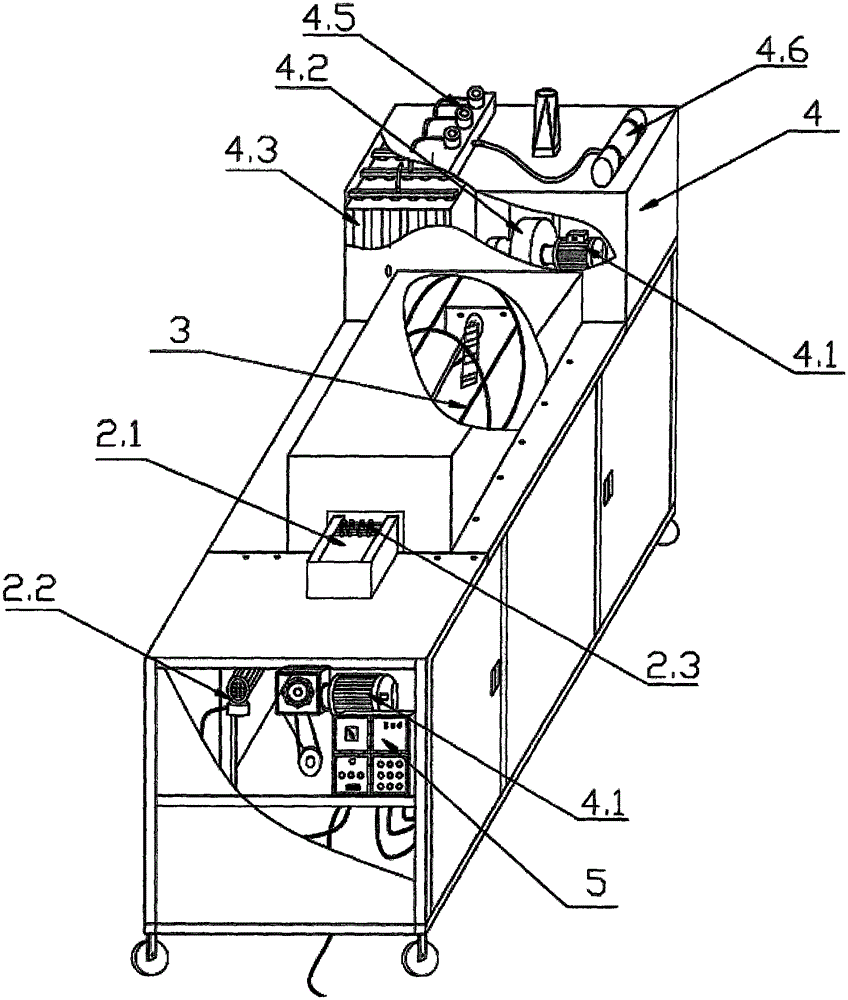

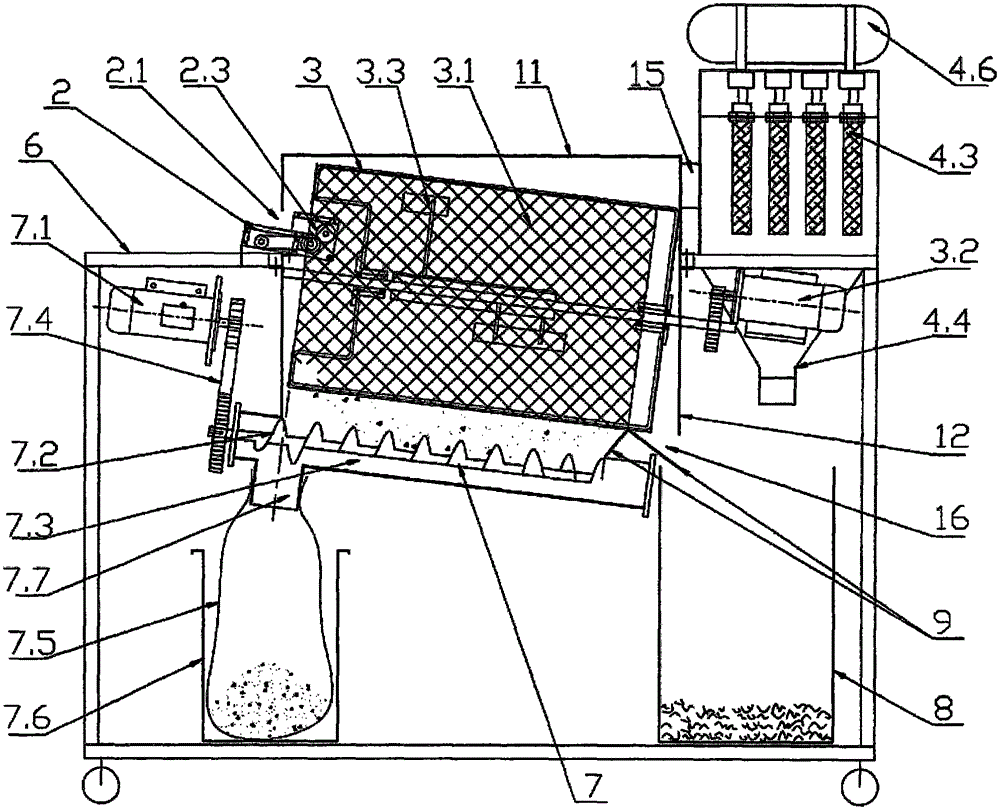

Powder packaging bag crusher screen

The invention discloses a powder packaging bag crusher screen which is characterized by comprising a rack (1), a crushing mechanism (2), a screening mechanism (3), a material collecting device, a fan filter (4) and an anti-explosion control box (5), wherein the screening mechanism (3) comprises a screen cage (3.1) obliquely arranged on the rack (1), a workbench (6) is arranged at the relatively high end part of the screen cage (3.1), the crushing mechanism (2) is arranged between the screen cage (3.1) and the workbench (6), and the fan filter (4) is arranged at the end part, far away from the crushing mechanism (2), of the screen cage (3.1). When the powder packaging bag crusher screen is used, a packaging bag just needs to be arranged at a bag feeding hole directly, materials can be shaken out from a shredded bag sufficiently due to the arrangement of the screen cage, and a negative pressure state is kept in the screen cage all the time due to the arrangement of the fan filter, so that harmful dust cannot diffuse to the working environment, and therefore, material recovery rate is high and safety performance is high.

Owner:安徽万秀园生态农业集团有限公司

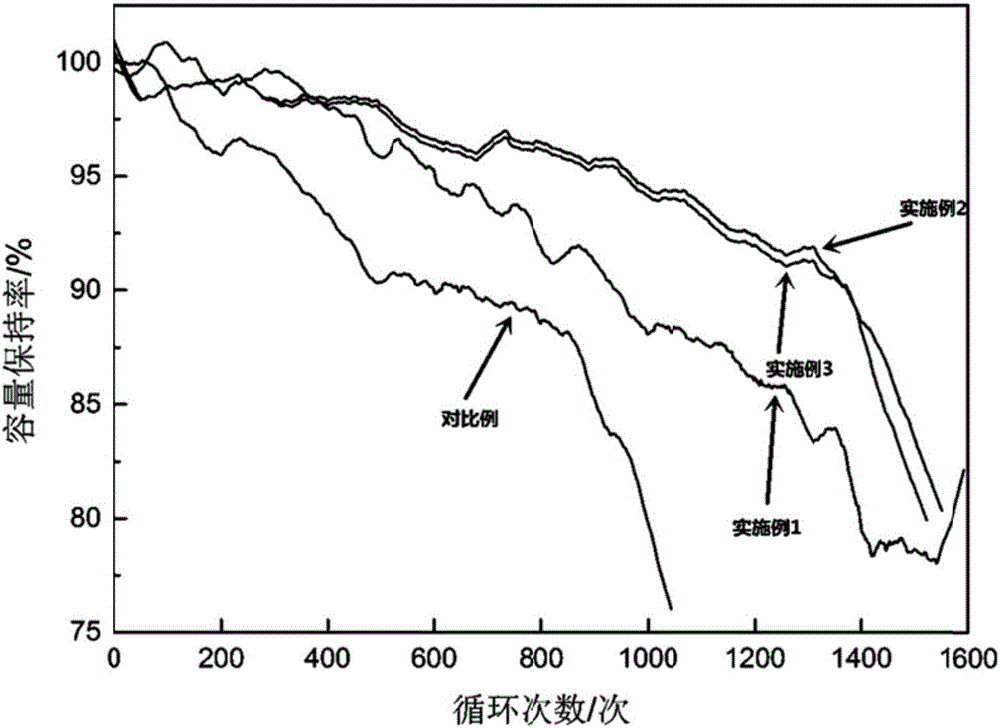

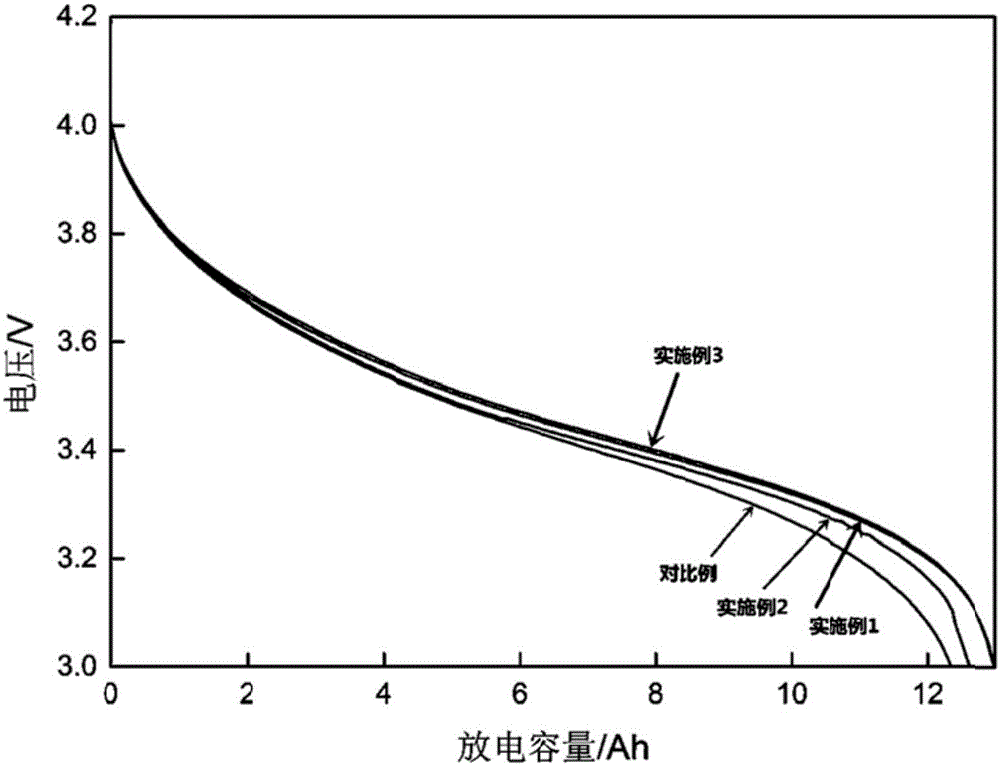

Tantalum doped nickel-cobalt-manganese lithium iron battery positive material

InactiveCN107819114ABreak up fullyHigh mechanical strengthCell electrodesSecondary cellsLithiumTantalum compound

The invention discloses a tantalum doped nickel-cobalt-manganese lithium iron battery positive material and a preparation method thereof. The chemical expression of the tantalum doped nickel-cobalt-manganese-lithium iron battery positive material is LiaNixCoyMnzTabO2, wherein a is more than or equal to 1 and less than or equal to 1.2, x is more than or equal to 0.3 and less than or equal to 0.98,y is more than or equal to 0.01 and less than or equal to 0.6, z is more than or equal to 0.001 and less than or equal to 0.6, b equals to 4 / 5-a / 5-3x / 5-3y / 5-3z / 5, and b is more than or equal to 0.00001 and less than or equal to 0.2. According to the invention, a single crystal nickel-cobalt-manganese compound precursor and a tantalum compound are premixed at a superhigh speed, and the mixture of the single crystal nickel-cobalt-manganese compound precursor and the tantalum compound are mixed with a common poly-crystal nickel-cobalt-manganese precursor, so as to improve the mixing effect; sincea single crystal compound precursor is high in mechanical strength, superhigh-speed mixing can be adopted instead of breaking, and the single crystal compound precursor can play a role of a collisionmedium, so as to sufficiently scatter the tantalum compound and sufficiently mix doped elements and main elements.

Owner:JINGMEN GEM NEW MATERIAL

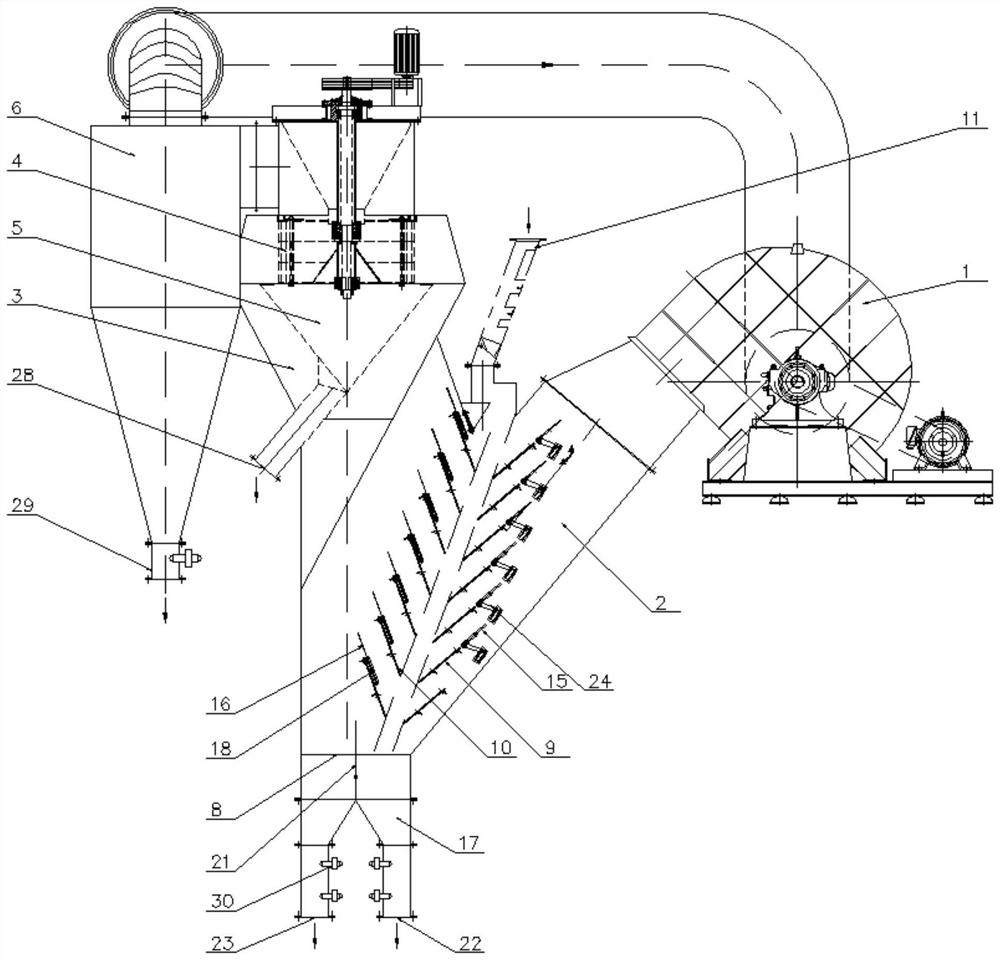

Composite sandstone powder concentrator

PendingCN112387592ALarge amount of processingImprove sorting efficiency and effectGas current separationVortex flow apparatusPhysicsEngineering

The invention relates to a composite sandstone powder concentrator. The composite sandstone powder concentrator comprises a fan, a V-shaped separation device, a medium sand conical hopper, a cage rotor, a fine sand conical hopper and a cyclone separator, wherein a feeding port of the V-shaped separation device is obliquely communicated with a distribution device; multiple stages of scattering blocks with the number of the scattering blocks being increased stage by stage are arranged on one side of the interior of the distribution device; deflection blades capable of being adjusted in a deflection mode are arranged at the ends of first fixed scattering blades of the V-shaped separation device; telescopic blades capable of being adjusted in a parallel front-back displacement mode are arranged on the side portions of second fixed scattering blades of the V-shaped separation device; and a discharging port is communicated with the bottom of the medium sand conical hopper and provided with amaterial segregation device. Coarse sand, medium sand, fine sand and powder in sandstone are separated and collected in an environment-friendly manner by adopting composite powder separation, the distribution device scatters materials to form a uniform material curtain, and sand molds with different particle sizes and specified gradings in machine-made sand are accurately separated out by adjusting and controlling the movement time and stroke of the materials in the powder concentrator, so that accurate grading meeting specified requirements is achieved, the treatment capacity can be remarkably increased, and the separation efficiency and effect of a composite sandstone separator are improved.

Owner:盐城市盐富环保设备有限公司

Mixing apparatus for making of spirits

ActiveCN107418823ABreak up fullyBreak up evenlyAlcoholic beverage preparationClamp connectionMechanical engineering

The invention relates to the field of processing of spirits, in particular to a mixing apparatus for making of spirits. The mixing apparatus comprises a first mixing chamber and a second mixing chamber which are in rotational connection. A hollow-inside slide rod and a vertical rod are arranged in the first mixing chamber; the top of the first mixing chamber is connected with the slide rod; a plurality of flaps are movably connected onto the slide rod and are in helical distribution thereon; an extensible rod is connected among the flaps; an ejecting rod is arranged inside the slide rod, and a clamp plate is arranged at the bottom of the ejecting rod, and is in clamped connection with the bottom flap of the slide rod; the vertical rod is connected to the top of the second mixing chamber. Elastic fabric is arranged on the top of the first mixing chamber and connected with a pulling mechanism; a vibrating plate is arranged on the top of the second mixing chamber, balls are arranged in the second mixing chamber, the balls and the vibrating plate are connected through elastic ropes, and a rotation mechanism is connected onto the second mixing chamber. In application of the mixing apparatus, fermented grains and hulls are both scattered secondly before being mixed, and thus the fermented grains and the hulls are mixed more uniformly.

Owner:贵州古酿坊酒业(集团)有限公司

Stir-fry machine and porridge cooking control method thereof

ActiveCN111084537AFull heat absorptionBreak up fullyBoiling over preventionWarming devicesProcess engineeringFood material

The invention discloses a stir-fry machine and a porridge cooking control method thereof. The stir-fry machine comprises a heating assembly, a cooking cavity and a stirring shovel extending into the cooking cavity, wherein the stirring shovel is used for turning over cooking food materials that are placed in the cooking cavity up and down. The porridge cooking control method comprises the steps: agradient type temperature rising stage: controlling the heating power of the heating assembly to heat in a gradient descending mode, and controlling the stirring shovel to turn over the cooking foodmaterials in a first rotating mode; and a boiling porridge cooking stage: controlling the heating power of the heating assembly to heat in an intermittent heating mode, and turning over the cooking food materials up and down by the stirring shovel in a second rotating mode until the cooking is finished. According to the invention, in the stirring process, the food is gelatinized, the viscosity ismoderate, the taste of a user is good, and the pot overflowing phenomenon in the porridge cooking process can be avoided by combining segmented and stepped heating with stirring.

Owner:JOYOUNG CO LTD

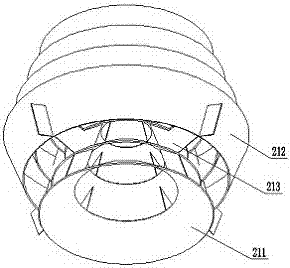

Sorting grid and powder selecting machine for sorting by sorting grid

PendingCN106975609ACompact structureIngenious designGas current separationEngineeringMechanical engineering

The invention discloses a sorting grid. The sorting grid comprises multiple inverted frustum type outer grid plates, multiple forward frustum type inner grid plates, and a sorting grid consisting of multiple grid plates; the outer grid plates and the inner grid plates are coaxially sleeved along the center axis of the sorting grid; and multiple outer and inner grid plates inserted one by one are connected as a whole from top to bottom through the grid plates arranged in the radial direction to form wind ways for enabling wind to pass through and scattering and sorting channels for enabling materials to fall step by step. The invention further discloses a powder selecting machine for sorting by the sorting grid; and the powder selecting machine includes a shell provided with a material sorting cavity inside, a sorting grid mounted in the material sorting cavity, a feed mechanism and a discharge mechanism. The sorting grid is used for enabling the materials to collide by multiple times for full scattering in the natural falling process under the effect of self weight in limited space; and a sorting machine once sorts the materials in the gradual scattering process to effectively improve the sorting efficiency and the sorting rate.

Owner:MIANYANG LANAO HEAVY MACHINERY MFG

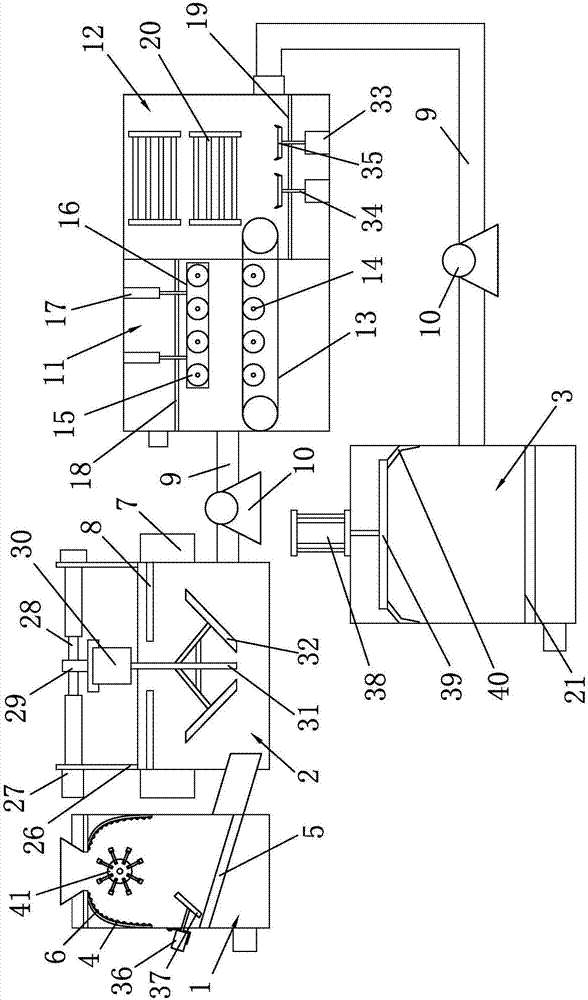

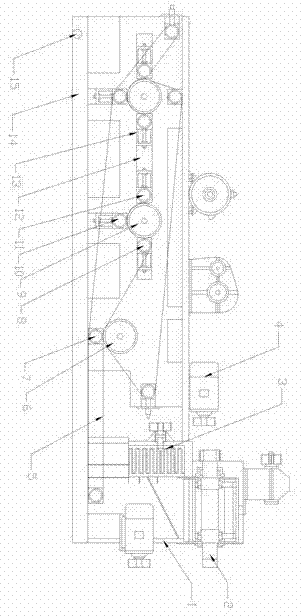

Silage processing equipment

InactiveCN104509956AControl moisture contentMoisture content is easy to controlFeeding-stuffEngineeringFodder

The invention provides silage processing equipment. The silage processing equipment comprises a rack, a conveyor belt, and a cutting device and a dispersing device which are connected in sequence, and further comprises a grinding device, wherein the grinding device comprises three compression roller wheel sets which are connected in sequence; the first compression roller wheel set is composed of an upper compression roller and a second compression roller; each of the second compression roller wheel set and the third compression roller wheel set is composed of one driving roller and three driven compression rollers, namely the driving roller driven by a motor, and the first driven compression roller, the second driven compression roller and the third driven compression roller which are located on the left and right sides and under the driving roller; the conveyor belt penetrates through a gap between the upper and lower compression rollers of the first compression roller wheel set and gaps among driving rollers of the second and third wheel sets and the driven compression rollers. The grinding device is reasonably designed and the moisture content of materials is controlled; the materials are prevented from going moldy and going bad due to bad weather; meanwhile, drying equipment is not used so that the energy consumption is reduced and the expenditure is saved. The silage processing equipment is suitable for crushing and machining silages including banana stems and leaves and the like.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

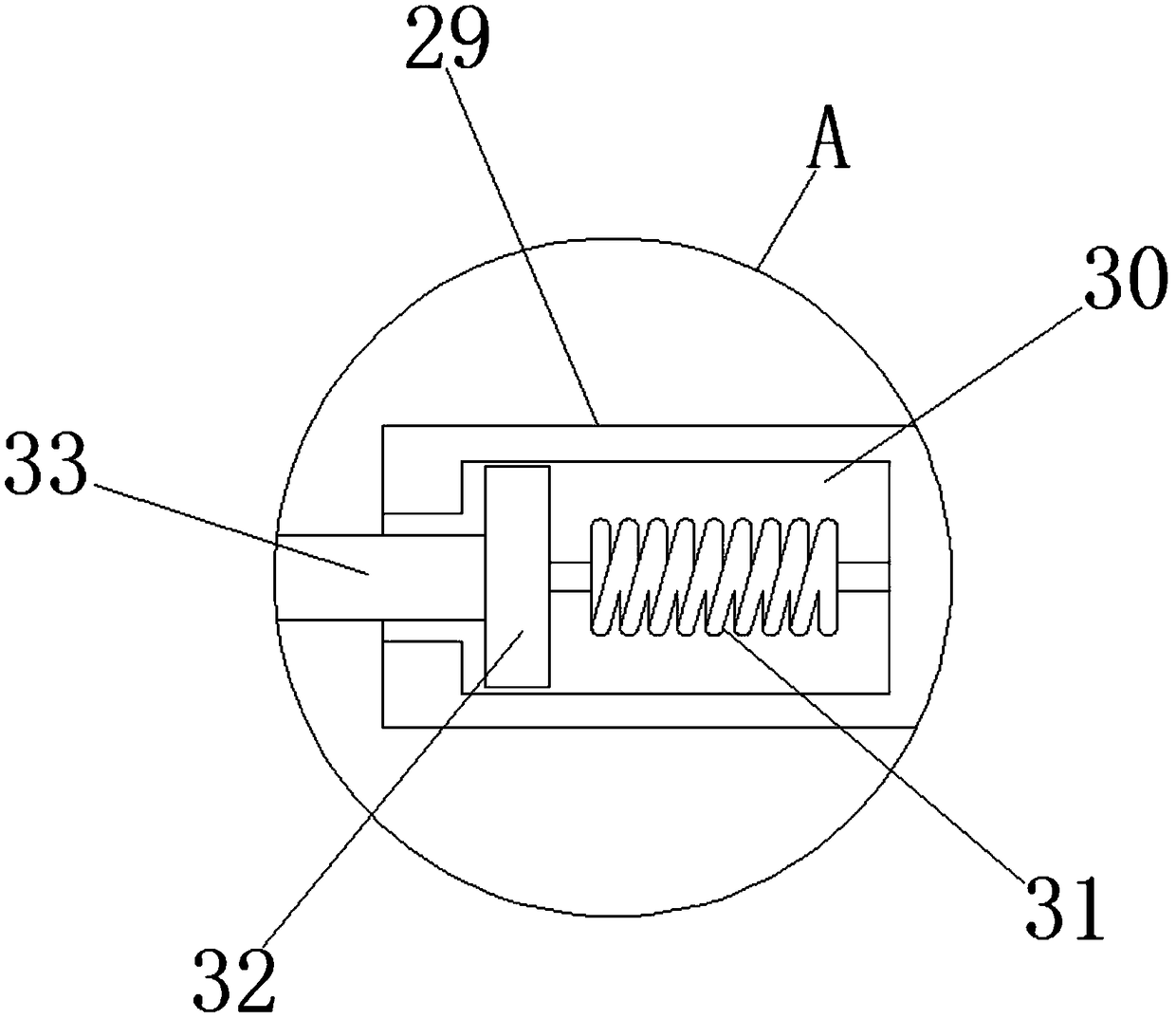

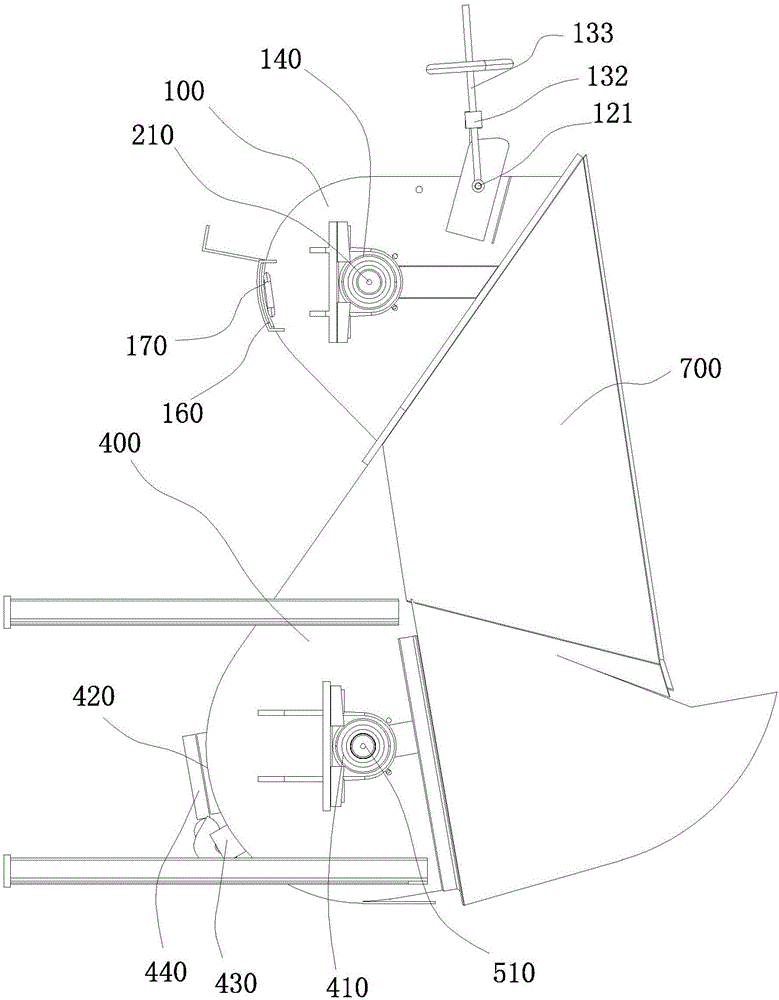

Ton bag extruder

PendingCN108688903ASolve production problems that are difficult to feedIncrease productivityPackagingGrain treatmentsEngineeringMechanical engineering

The invention relates to a ton bag extruder. The ton bag extruder comprises a base, a loading platform, an extruding component, a first driving device and a second driving device, wherein the loadingplatform is arranged on the upper part of the base in a manner of being capable of rotating on a plane relative to the base; the loading platform is used for loading ton bags; the extruding componentis hinged to the base; and the first driving device is fixedly arranged on the base, is connected with the loading platform, and is used for driving the extruding component to extrude the ton bags loaded on the loading platform. By adopting the ton bag extruder provided by the invention, caked ton bag materials can be primarily extruded and then rotated for secondary extrusion, so that the caked materials are thoroughly broken; the production problem that the caked ton bag materials are difficult to charge is effectively solved; and manual breaking is replaced by the ton bag extruder, so thatproduction efficiency is improved.

Owner:无锡市永春科技有限公司

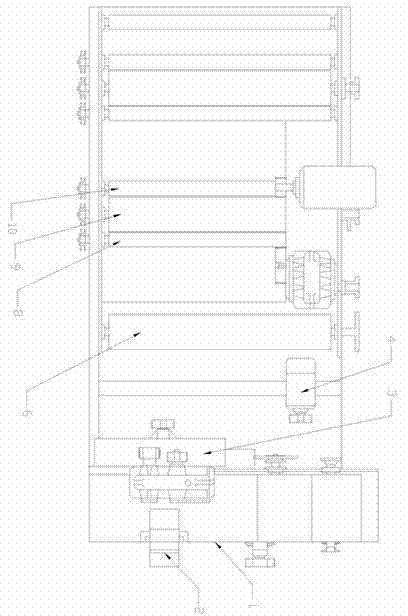

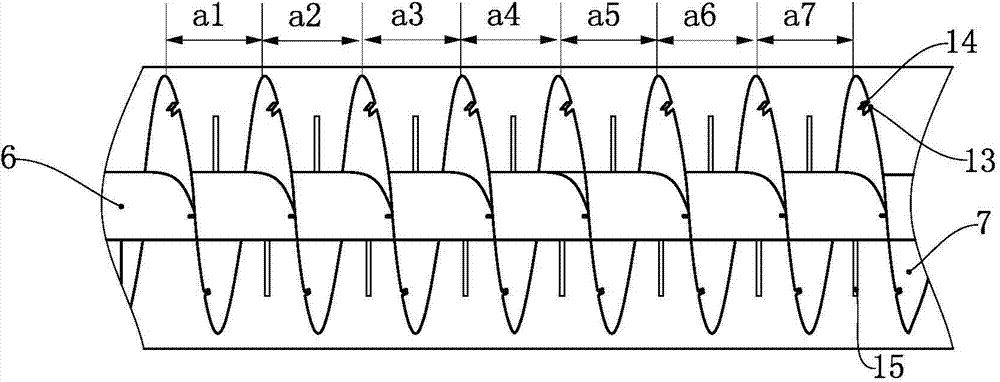

Diluting spiral for conveying straw papermaking slurry

ActiveCN104492535AEffective dilutionMeet the needs of dilutionPackagingGrain treatmentsSpiral bladePapermaking

The invention discloses a diluting spiral for conveying straw papermaking slurry; the diluting spiral disclosed by the invention comprises a conveying groove; a feeding hole and a discharging hole are formed in the conveying groove; a feeding groove body is formed in the feeding hole; two tooth type crushing rollers are rotatably installed in the feeding groove body; the two tooth type crushing rollers are arranged in parallel; a rotating shaft is installed in the conveying groove; spiral blades are arranged on the rotating shaft; the spaces among the front sections of the spiral blades of the rotating shaft are gradually increased; the spaces among the rear sections of the spiral blades of the rotating shaft are equal; a cover plate is arranged at the upper part of the conveying groove; a water spraying pipe is installed on the cover plate; the diluting spiral further comprises driving equipment; and the driving equipment is in power connection with the tooth type crushing rollers and the rotating shaft respectively. According to the diluting spiral, the requirement of conveying the slurry while diluting in the straw papermaking process is satisfied; and furthermore, the problem of being poor in quality caused by that the slurry is aggregated and enters the subsequent steps in the straw papermaking process is avoided.

Owner:昌邑润德生态纤维有限公司

Particle shaping equipment

ActiveCN102755857APrevent adhesion formationBreak up fullyGranulation in stationary drums/troughsEngineeringSilicon

The invention discloses particle shaping equipment, which is arranged between particle forming equipment and cooling equipment and comprises a trough and a stirring device, wherein the trough is used for receiving a solid material led out by the particle forming equipment and is provided with a feed port and a discharge port; and the stirring device is used for scattering the solid material and conveying the solid material to the discharge port, is arranged in the trough and comprises at least two helical stirring paddles which are arranged in the trough in parallel. According to the particle shaping equipment, the solid material can be effectively prevented from being adhered into large blocks due to rapid cooling, cooling and subsequent sieving and crushing are easy, and the particle quality of inorganic silicon is improved.

Owner:山东龙港硅业科技有限公司

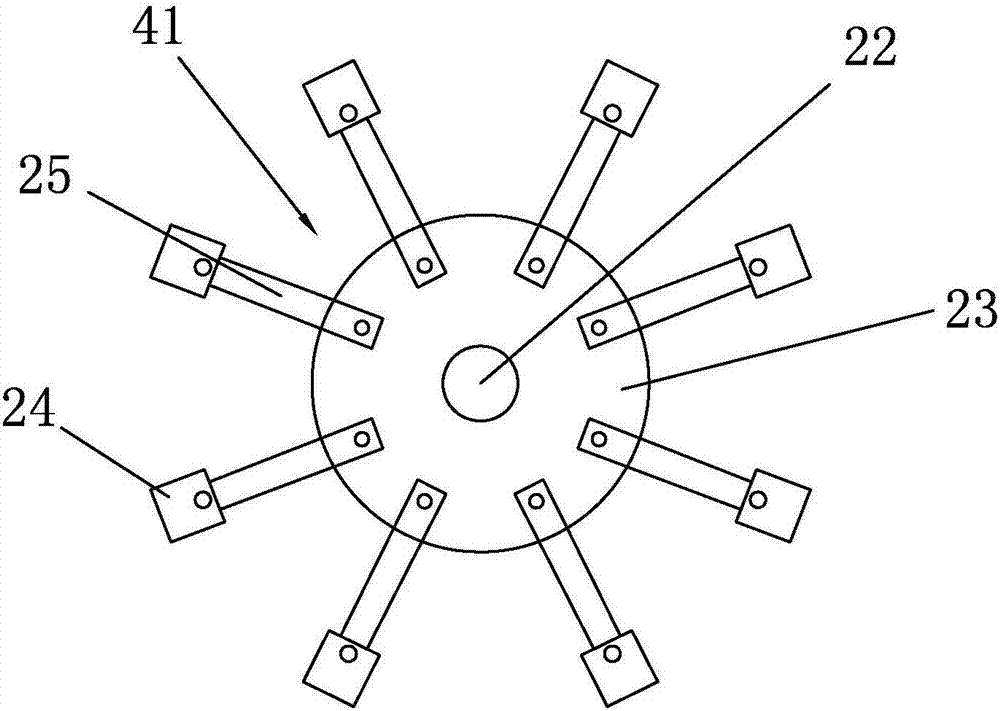

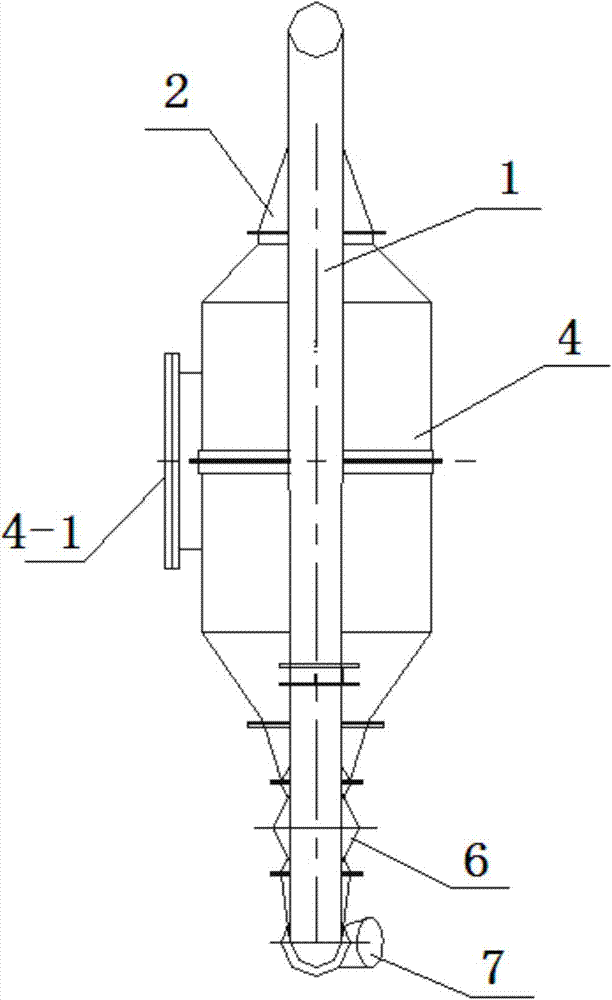

Centrifugal sewage treatment device and operation method thereof

InactiveCN109422324AAvoid cloggingBreak up fullyWater/sewage treatment by centrifugal separationSpecific water treatment objectivesSludgeArchitectural engineering

The invention provides a centrifugal sewage treatment device, comprising a stirring tank and a centrifuging tank. A fixed base is fixedly connected to the top of the left wall of the inner cavity of the stirring tank. The right end of the fixed base is fixedly connected to the top of the right wall of the inner cavity of the stirring tank. The bottom of the fixed base is provided with a movable slot the left inner wall of which is embedded with a sliding bar. The right end of the sliding bar is embedded in the right inner wall of the movable slot, and sliding blocks are movably mounted on thesurface of the sliding bar. According to the device and the method, through arrangement of a motor case, a first motor, a stirring cylinder and breaking blocks, the first motor is turned on when sewage water in the stirring cylinder is pumped into the inner cavity of the centrifuging tank through a water discharging pipe by a water pump, and an output end of the first motor rotates to drive a stirring shaft to rotate, and therefore, sludge settled in the stirring tank is broken by the breaking blocks and is mixed with sewage, and blockage of the water discharging pipe during water pump pumpingis effectively avoided.

Owner:江苏佳鑫环保工程有限公司

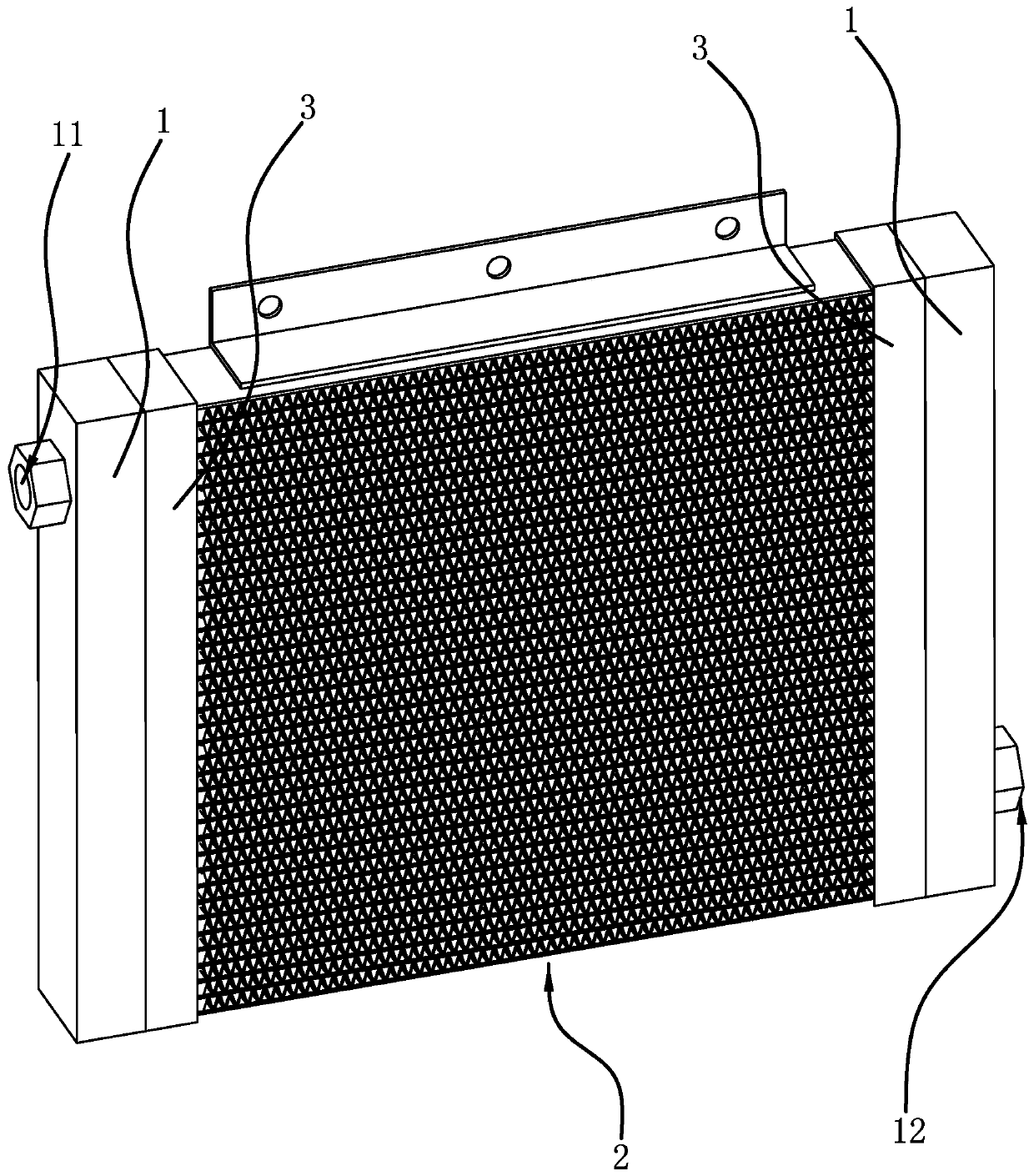

Universal cooler for efficiently removing oily water

ActiveCN109813144ABreak up fullySufficient heat exchangeStationary conduit assembliesHeat exchanger casingsEngineeringRefrigeration

The invention provides a universal cooler for efficiently removing oily water, and belongs to the technical field of refrigeration equipment. The problems that an existing cooler is poor in cooling performance and pressure resistance are solved. The universal cooler for efficiently removing oily water comprises two oil chambers and a core body located between the two oil chambers, the core body comprises a plurality of cooling pipes, two long strip-shaped cooling fins are arranged between ever two adjacent cooling pipes, the cooling fins comprise a plurality of inclined sections and bent portions, the inclined sections are crossed, clamped and positioned, the two opposite side faces of the cooling pipes are provided with a plurality of first positioning grooves, the bent portions of the cooling fins are concaved inwards to form a plurality of flat and straight heat exchange portions, a positioning portion is formed between every two adjacent heat exchange portions, the positioning portions are embedded into the first positioning grooves and welded and fixedly connected to the inner walls of the first positioning grooves, and the outer side faces of the heat exchange portions are infit with the side faces of the cooling pipes in a pressing mode. The universal cooler for efficiently removing oily water has high cooling performance and pressure resistance.

Owner:山东宏阳型材科技股份有限公司

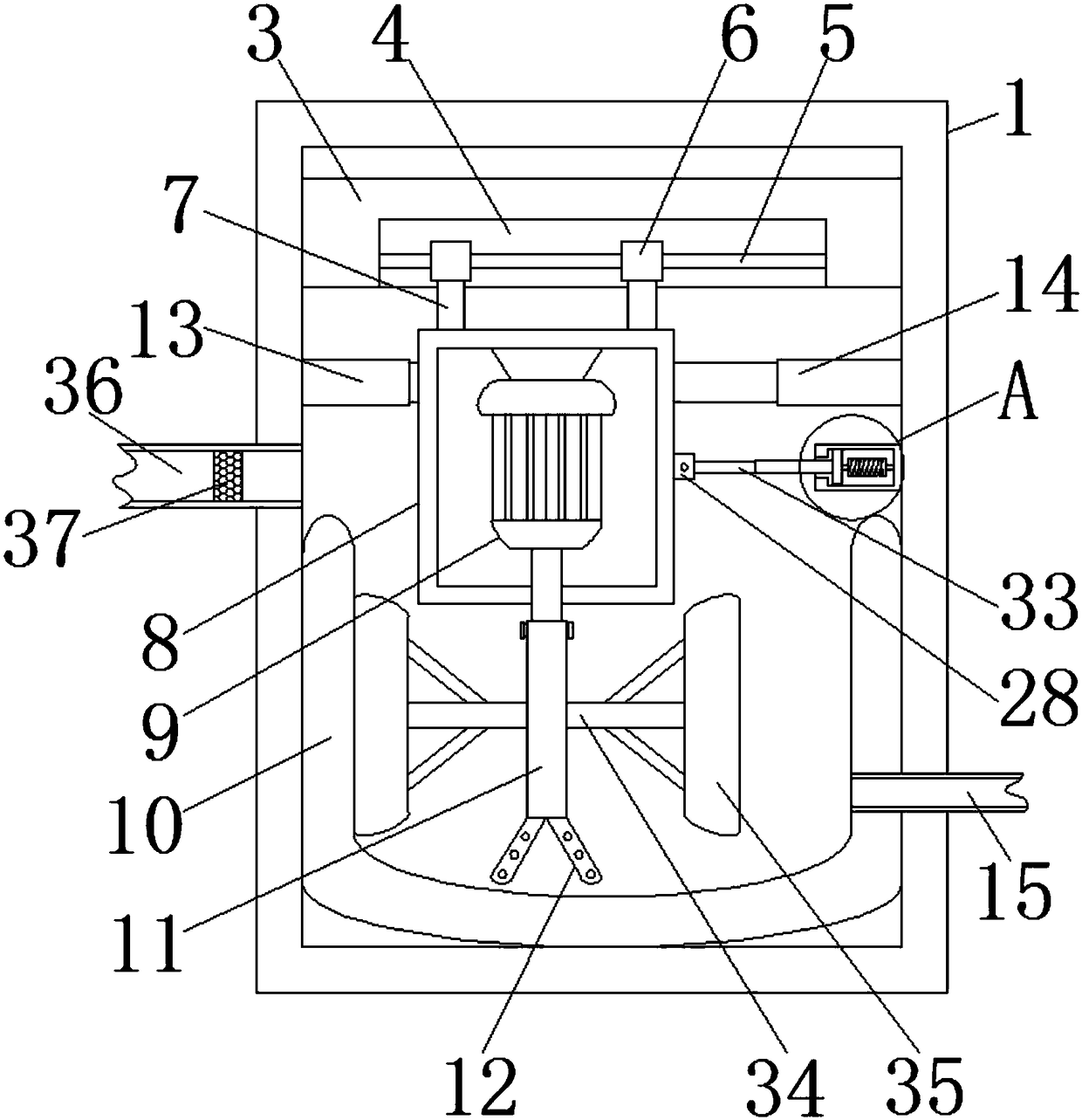

Multifunctional reaction kettle

InactiveCN106311113AImprove dispersion effectImprove efficiencyChemical/physical/physico-chemical stationary reactorsGas generation devicesElectric machineryGear transmission

A multifunctional reaction kettle includes a kettle body. A rotary shaft is arranged therein and is connected to a speed reducer on the top of the kettle body. The speed reducer is connected to a motor. A stirring apparatus is connected to the lower part of the rotary shaft and comprises a positioning disk that passes through and is fixedly connected to the rotary shaft. A gear box body is connected to the positioning disk. A large bevel gear is mounted in the gear box body and is connected to a hydraulic motor. The hydraulic motor is connected to a first rotary shaft that is fixedly connected to the gear box body. An anti-deposit hairbrush is connected to the end of a second rotary shaft. The reaction kettle has the following advantages: with the gear transmission, when a first impeller revolves around the central line of the gear box body, the first impeller also auto-rotates around the axis of the bevel gear, thereby improving dispersion effect. In addition, by means of a side-wall cleaning hairbrush and the anti-deposit hairbrush, agglomerated substances on the bottom and the side wall of the kettle body can be broken fully, thus improving reaction efficiency.

Owner:汪超

Powder drying device for pea protein production

ActiveCN113483541AIncrease the areaImprove heating efficiencyDrying gas arrangementsDrying chambers/containersPea proteinStructural engineering

The invention discloses a powder drying device for pea protein production, and relates to the technical field of pea protein production. The powder drying device comprises a damping support, a hot air blowing fan is fixedly installed on the inner wall of the damping support, an air supply pipe is fixedly installed on the side face of the damping support, one end of an air outlet of the hot air blowing fan communicates with the air supply pipe, a vibration base is fixedly installed on the top face of the damping support, and a set of vibration motors distributed regularly are fixedly installed on the top face of the vibration base; and a shell is fixedly installed on the inner wall of the vibration base, a servo motor is fixedly installed on the top of the shell, a drying mechanism is installed on the inner wall of the shell, and one end of an output shaft of the servo motor is in transmission connection with the drying mechanism through a bevel gear. Through the design of the drying mechanism and a drying module, the device can efficiently complete drying operation of pea protein powder in an automatic mode, and during drying operation of the device, a stacking type drying structure of a traditional powder drying device is changed into a multi-station dispersed flow type drying structure.

Owner:优承生物科技(烟台)有限公司

Device and method for regulating potassium feldspar powder size distribution

ActiveCN103495471AIncreased production flexibilityProduct quality is easy to guaranteeGrain treatmentsAir volumePotassium

The invention discloses a device and a method for regulating potassium feldspar powder size distribution. The device comprises an air regulation system arranged on a discharge hole of a ball mill, wherein the air regulation system comprises a material bin, a main air pipe and a side direction air inlet pipe; the middle in the side direction of the material bin is connected to the discharge hole of the ball mill, one end of the main air pipe is connected to the upper end of the material bin, the other end of the main air pipe downward extends and is bent so as to form a confluence section passing through the lower part of the material bin, and the lower end of the material bin is connected to the confluence section; the side direction air inlet pipe is arranged on the confluence section and is internally provided with an air regulation switch, and a rotating baiting valve is arranged between the lower end of the material bin and the confluence section. The device and the method provided by the invention have the advantages that the air volume of the side direction air inlet pipe is flexibly adjusted in real time in a production process according to the size distribution requirement of the potassium feldspar powder, thus the size distribution of the potassium feldspar powder is adjusted, the production flexibility is greatly improved, and the product quality is easy to guarantee.

Owner:广东奥胜新材料有限公司

Skin making mud based on large honeycomb ceramic carrier for skin making

ActiveCN103396103AReduce the difference in expansion coefficientStrong water resistanceFiberAdhesive

The invention discloses a skin making mud based on a large honeycomb ceramic carrier for skin making. The skin making mud comprises the following ingredients in parts by weight: 10-30 parts of 325-mesh cordierite fine powder with the average particle size of 10-12 microns, 30-80 parts of 150-mesh cordierite coarse powder with the average particle size of 45-50 microns, 5-20 parts of greater than 200 meshes of washed kaolin powder, 5-10 parts of inorganic fibres, and 5-20 parts of an inorganic adhesive. The skin making mud disclosed by the invention is high in breaking strength, good in thermal shock resistance, strong in water resistance, free from dry cracks, and free from the need of heating-drying; cordierite powders with different particle sizes are used as aggregates, thus reducing the expansion coefficient difference between the skin making mud and the large honeycomb ceramic carrier, and enhancing the matching property; the thixotropy, flowability and settleability of the skin making mud are regulated by kaolin; silica sol is used as a mud adhesive, and meanwhile, ceramic polycrystalline fibres or glass fibres are added in the mud to achieve anti-cracking and reinforcing effects.

Owner:JIAN JITAI ENERGY SAVING ENVIRONMENTAL PROTECTION MATERIAL

High-efficiency oil-removing washing detergent

InactiveCN105400624AGood emulsifying effectImprove solubilitySurface-active non-soap compounds and soap mixture detergentsAmpholytes/electroneutral surface-active compoundsAlcoholEther

The invention provides a high-efficiency oil-removing washing detergent. The high-efficiency oil-removing washing detergent comprises, by weight, 8 to 16 parts of sodium alcohol ether sulphate, 12 to 22 parts of a soap base, 3 to 4 parts of an amino acid humectant, 4 to 8 parts of absolute ethyl alcohol, 1 to 3 parts of a solubilizer, 0.05 to 0.5 part of an edible essence, 3 to 8 parts of citric acid, and the balance deionized water. Adding of the solubilizer and the amino acid humectant is capable of improving dissolving capacity of sodium alcohol ether sulphate and the soap base in a solution, improving emulsifying effect of the high-efficiency oil-removing washing detergent on oil, realizing full dispersion of oil molecules, and improving oil removing capability.

Owner:谭海涛

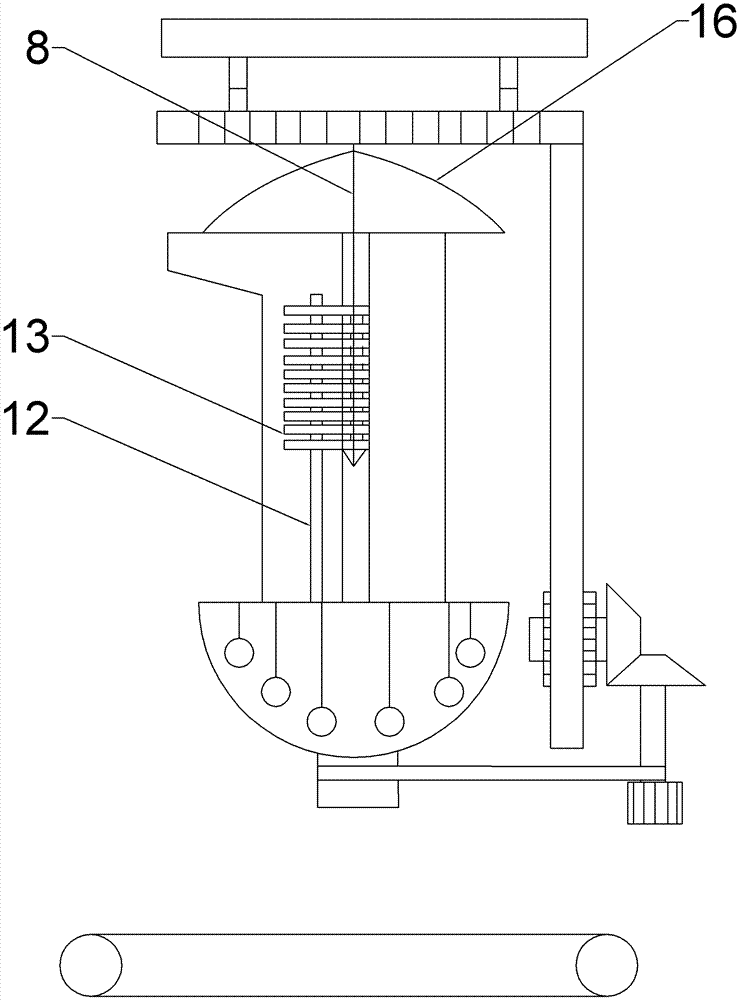

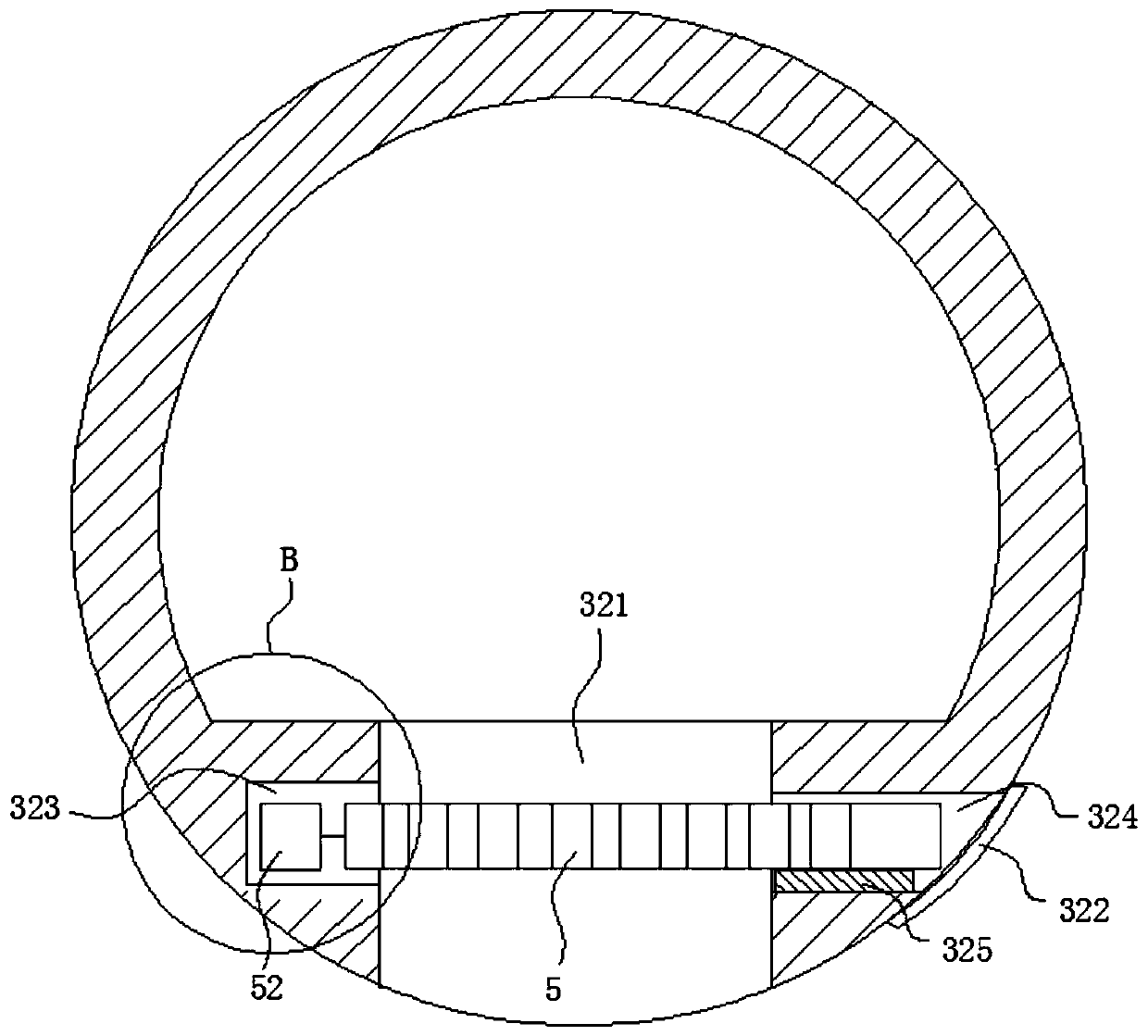

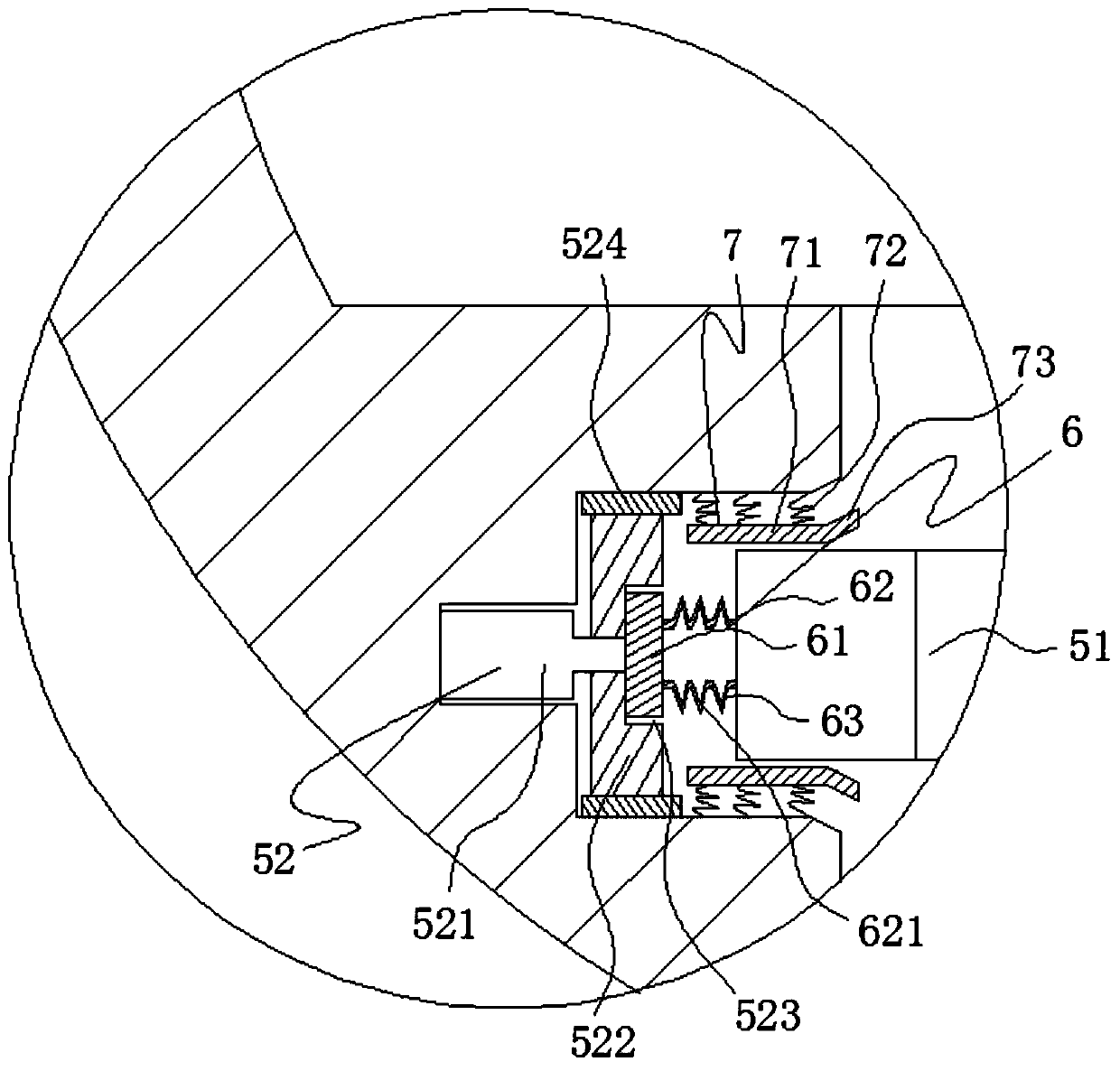

Sludge scattering and crushing device

InactiveCN104069915AEasily brokenBreak up fullySludge treatment by de-watering/drying/thickeningGrain treatmentsMesh gridMechanical engineering

The invention discloses a sludge scattering and crushing device which comprises a rack, a feeding hopper groove, a rotary shaft sleeve, two or more scattering and crushing devices and a discharging and conveying belt machine, wherein the discharging and conveying belt machine is fixedly mounted at the lower end of the rack, and the feeding hopper groove is formed in the upper end of the rack; the rotary shaft sleeve is arranged at the center of the feeding hopper groove, and a rotating motor and a rotary shaft device are arranged in the rotary shaft sleeve, and the scattering and crushing devices are mounted on the rotary shaft device; scattering paddles are fixedly mounted on the scattering and crushing devices, and crushing mesh holes are formed in the scattering paddles; the two scattering and crushing devices comprise a first scattering and crushing device and a second scattering and crushing device, and the first scattering and crushing device is arranged at the upper end of the second scattering and crushing device; the scattering paddles with the crushing mesh holes are arranged on both the first scattering and crushing device and the second scattering and crushing device. Therefore, the sludge scattering and crushing device can fully scatter sludge and is simple and compact in structure and reasonable in design.

Owner:WUXI CAIYUN MACHINERY & EQUIP

Processing technology for preparing high-strength concrete

InactiveCN110540390ATake advantage ofReduce processing costsSievingScreeningHigh strength concreteFiber

The invention discloses a processing technology for preparing high-strength concrete. The processing technology comprises the following steps: (1) raw material preparation: taking cement, sand, water,a water reducing agent, phenolic fiber and montmorillonite, wherein the sand is obtained by crushing construction waste by a crushing apparatus; (2) dry mixing: putting the cement, the sand, the water reducing agent, the phenolic fiber and the montmorillonite into a material mixing machine for dry material pre-mixing to obtain a mixture A after uniform mixing; and (3) wet mixing: putting the mixture A into a stirrer, adding water and a fine aggregate into the stirrer, and then performing uniform stirring to obtain the slurry-like concrete. According to the processing technology, the dry mixing operation is first performed before the wet mixing, so that a mixing uniformity degree of the dry powder materials is relatively high during mixing, and the processing technology ensures that various materials are all mixed together.

Owner:鄱阳县恒基建材有限公司

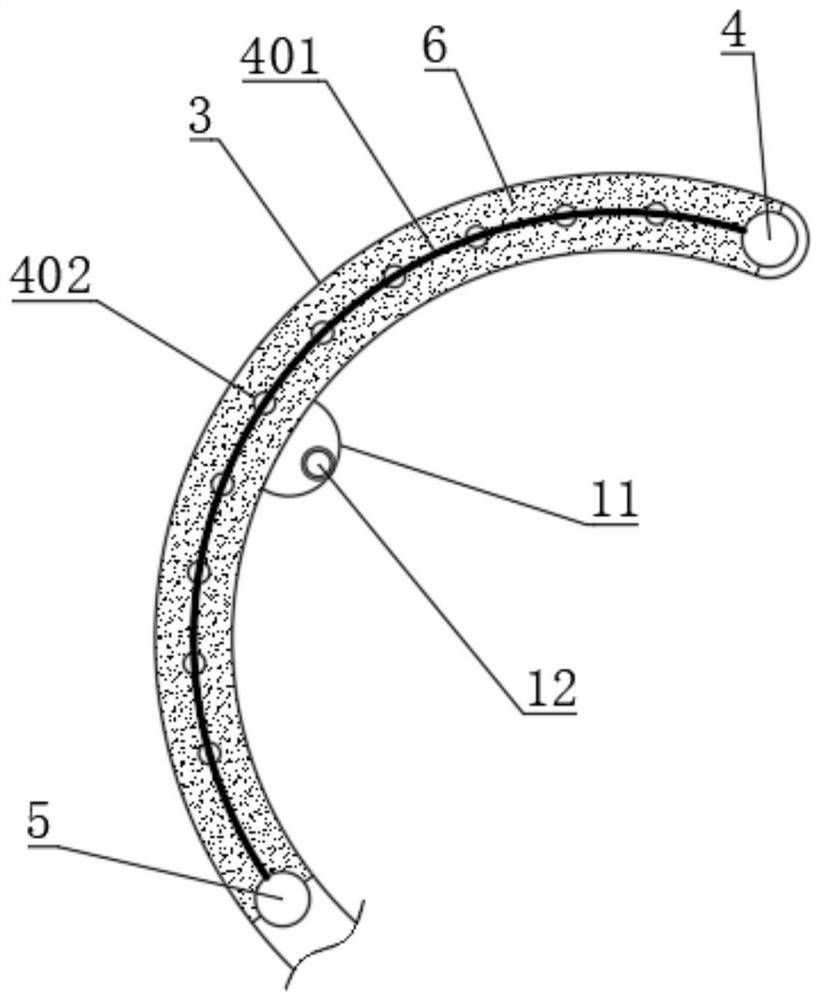

Phase-change thermal radiation absorption and storage type outdoor cable

InactiveCN112037977AIncrease air pressureExtended service lifeClimate change adaptationInsulated cablesLight reflectionEngineering

The invention discloses a phase-change thermal radiation absorption and storage type outdoor cable, belongs to the technical field of cables, and aims to promote ammonium chloride powder in an arc-shaped shading bag sheet to be heated and decomposed through irradiation of sunlight on the arc-shaped shading bag sheet, so that the air pressure in the arc-shaped shading bag sheet is increased, and the arc-shaped shading bag sheet extends outwards to wrap the surface of the cable. On one hand, the contact area between light and the surfaces of the wires and the cables can be reduced, and on the other hand, the ammonium chloride powder in the arc-shaped shading bag pieces can be used for replacing the wires and the cables to absorb heat radiation by means of the heat absorption effect of the ammonium chloride powder, further, the possibility of premature aging of the wire and cable is reduced, the service life of the wire and cable is prolonged, the high-temperature phase state of the wireand cable is recovered after the temperature of the traction metal rope rises, a light reflection ball in a spherical storage groove is driven to be exposed, and the heat radiation quantity received by the wire and cable can be reduced by means of the reflection effect of the light reflection ball on light.

Owner:闫山

Pneumatic fluidized coating device and lithium ion battery cathode material coating process

ActiveCN106602045AImprove electrochemical performanceImprove the first charge and discharge efficiencyCell electrodesSecondary cellsProcess engineeringControl valves

The invention discloses a pneumatic fluidized coating device, which comprises a mixing bin, wherein two material inlets are arranged in the mixing bin and feed valves are both arranged on feed pipelines respectively connected to the two feed inlets; an airflow inlet and an airflow outlet are respectively arranged in the mixing bin, an induced draft fan is arranged between the airflow inlet and the airflow outlet, the airflow outlet is connected to an inlet of the induced draft fan through a pipeline, and the airflow inlet is connected to an outlet of the induced draft fan through a pipeline; the pipeline between the outlet of the induced draft fan and the airflow inlet is connected to a discharge pipe, and a discharge valve is arranged on the discharge pipe; and a control valve is arranged on a pipeline between the discharge pipe and the airflow inlet, a pipeline between the control valve and the airflow inlet is connected to a bypass line, and a bypass valve is arranged on the bypass line. The invention also discloses a lithium ion battery cathode material coating process. The pneumatic fluidized coating device and the lithium ion battery cathode material coating process have good coating effect and cannot pollute the environment.

Owner:WEIFANG ZHENGYUAN POWDER ENG EQUIP

Vanadium-doped Ni-Co-Mn lithium ion battery positive electrode material

InactiveCN107799739ABreak up fullyHigh mechanical strengthMaterial nanotechnologyCell electrodesVanadium dopingManganese

The invention discloses a vanadium-doped Ni-Co-Mn lithium ion battery positive electrode material and a preparation method thereof. The molecular formula of the vanadium-doped Ni-Co-Mn lithium ion battery positive electrode material is LiNi<x>Co<y>Mn<z>VO<2>, wherein a is more than or equal to 1 but less than or equal to 1.2, x is more than or equal to 0.3 but less than or equal to 0.98, y is more than or equal to 0.01 but less than or equal to 0.6, z is more than or equal to 0.001 but less than or equal to 0.6, b is equal to 4 / 5-a / 5-3x / 5-3y / 5-3z / 5, and b is more than or equal to 0.00001but less than or equal to 0.2. A single-crystal Ni-Co-Mn composite precursor and a vanadium compound are mixed in advance at an ultrahigh speed, a mixture of the single-crystal Ni-Co-Mn precursor andthe vanadium compound and a conventional poly-silicon Ni-Co-Mn precursor are mixed at a high speed, so that a mixing effect is improved; and since the single-crystal composite precursor is high in mechanical strength, can be mixed at an ultrahigh speed and cannot be broken, meanwhile, the single-crystal composite precursor simultaneously can have an effect of touching a medium, the vanadium compound is fully dispersed, and a doping element and a main element are fully mixed.

Owner:JINGMEN GEM NEW MATERIAL

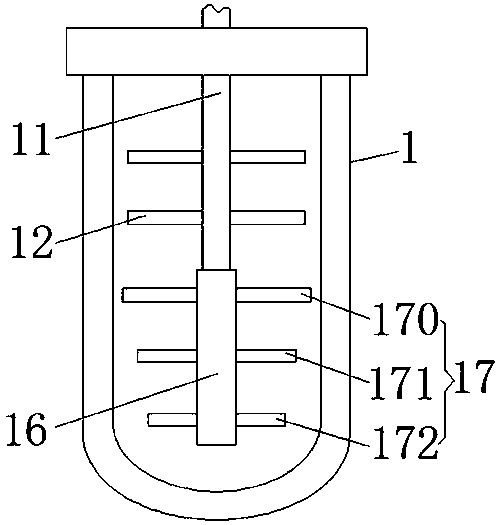

Microbial solid fermenting tank

PendingCN107760588AIncrease contact areaBreak up fullyBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention provides a microbial solid fermenting tank. The microbial solid fermenting tank comprises a fermenting tank body and a bottom plate, wherein the top part of the bottom plate is fixedly connected with fixed rods; the number of the fixed rods is two; the top parts of mutually adjacent sides of the two fixed rods are fixedly connected through a cross plate; the bottom parts of the mutually adjacent sides of the two fixed rods are fixedly connected through a baffle plate. According to the microbial solid fermenting tank provided by the invention, by arranging an electric telescopic rod, upright posts, sliding blocks, connecting rods, a smashing shaft, a smashing rod, a first smashing rod, a second smashing rod and a third smashing rod, a stirring shaft is driven to rotate throughrotation of the output end of a motor, the stirring shaft drives the smashing shaft and the smashing rod to rotate, scattering treatment can be carried out on materials by cross shafts, the first smashing rod, the second smashing rod and the third smashing rod, the electric telescopic rod is started to stretch and contract, and the electric telescopic rod drives the fermenting tank body to move up and down, so that an effect of more sufficient scattering can be achieved, and the contact area between a gas and the materials can be enlarged.

Owner:江苏棉海园林工程有限公司

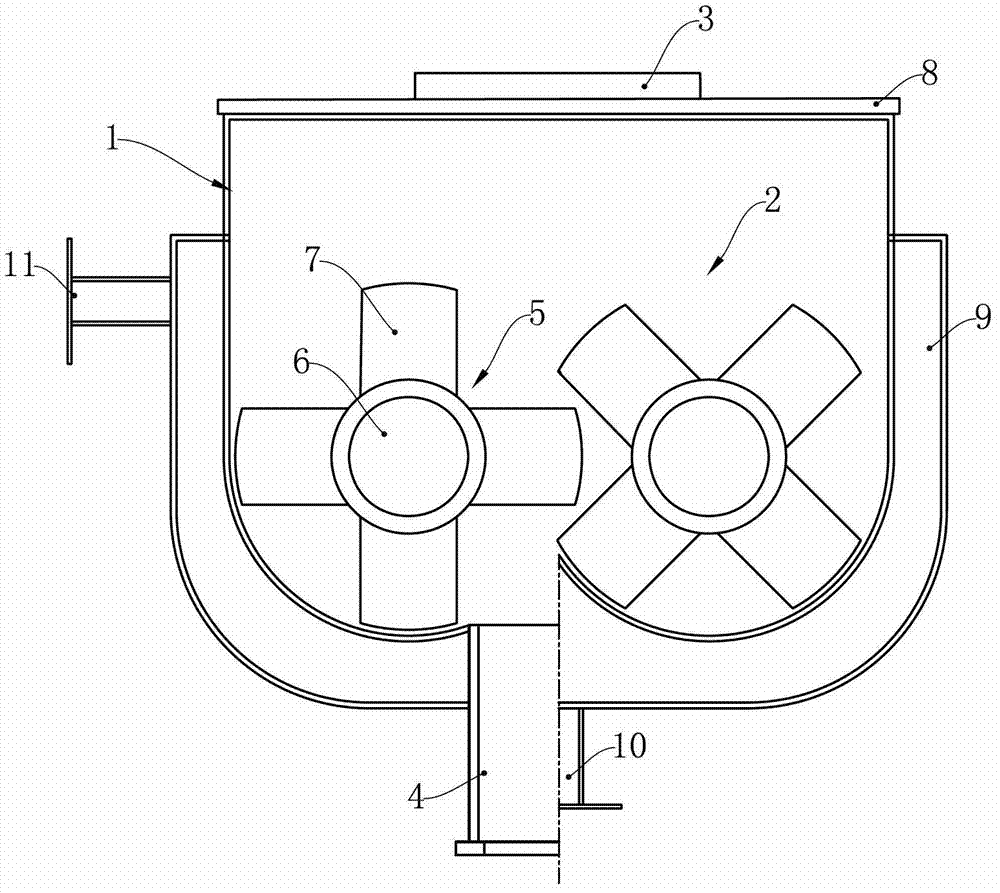

Dual-roller sand turnover box

ActiveCN106424544ABreak up fullySimple structureMould handling/dressing devicesEngineeringFunnel shape

The invention provides a dual-roller sand turnover box. The dual-roller sand turnover box comprises a funnel-shaped first box body and a funnel-shaped second box body. A first roller capable of rotating around the axis of the first roller is arranged in the first box body and provided with a plurality of first sanding bowls, and the two ends of the first roller are arranged on the two sides of the first box body in a penetrating manner. The first box body and the second box body are connected to be used for bearing sand turned out from the first box body, a second roller capable of rotating around the axis of the second roller is arranged in the second box body and provided with a plurality of second sanding bowls, and the two ends of the second roller are arranged on the two sides of the second box body in a penetrating manner. The dual-roller sand turnover box has the beneficial effects that the structure is simple, the actual use effect is obvious, and sand lumps can be scattered thoroughly.

Owner:宁波创二代机械科技有限公司

Raw material mixing device for producing cyclopropyl acetylene

InactiveCN113019297AControl the rate of circulationStir wellHydrocarbonsChemical/physical/physico-chemical stationary reactorsBLENDER/MIXERProcess engineering

The invention provides a raw material mixing device for producing cyclopropyl acetylene, and relates to the technical field of chemical equipment. The raw material mixing device comprises: a reaction kettle, wherein the reaction kettle is provided with a first kettle body, a second kettle body and a third kettle body from top to bottom, the first kettle body is provided with a feed port, the third kettle body is provided with a discharge port, the first kettle body is communicated with the second kettle body, the output end of the second kettle body is communicated with the input end of the third kettle body, and the output end of the third kettle body extends into the second kettle body and is communicated with the second kettle body; a stirring mechanism which is positioned at the side part of the reaction kettle and is used for stirring and dispersing raw materials which are fed into the reaction kettle and are used for producing cyclopropyl acetylene; and a flow control mechanism arranged at the boundary of the second kettle body and the third kettle body and used for controlling the flowing speed of the raw materials in the second kettle body to the third kettle body. Cyclopropyl acetylene meeting the industrial requirement can be obtained.

Owner:江西粤秀医疗科技有限公司 +1

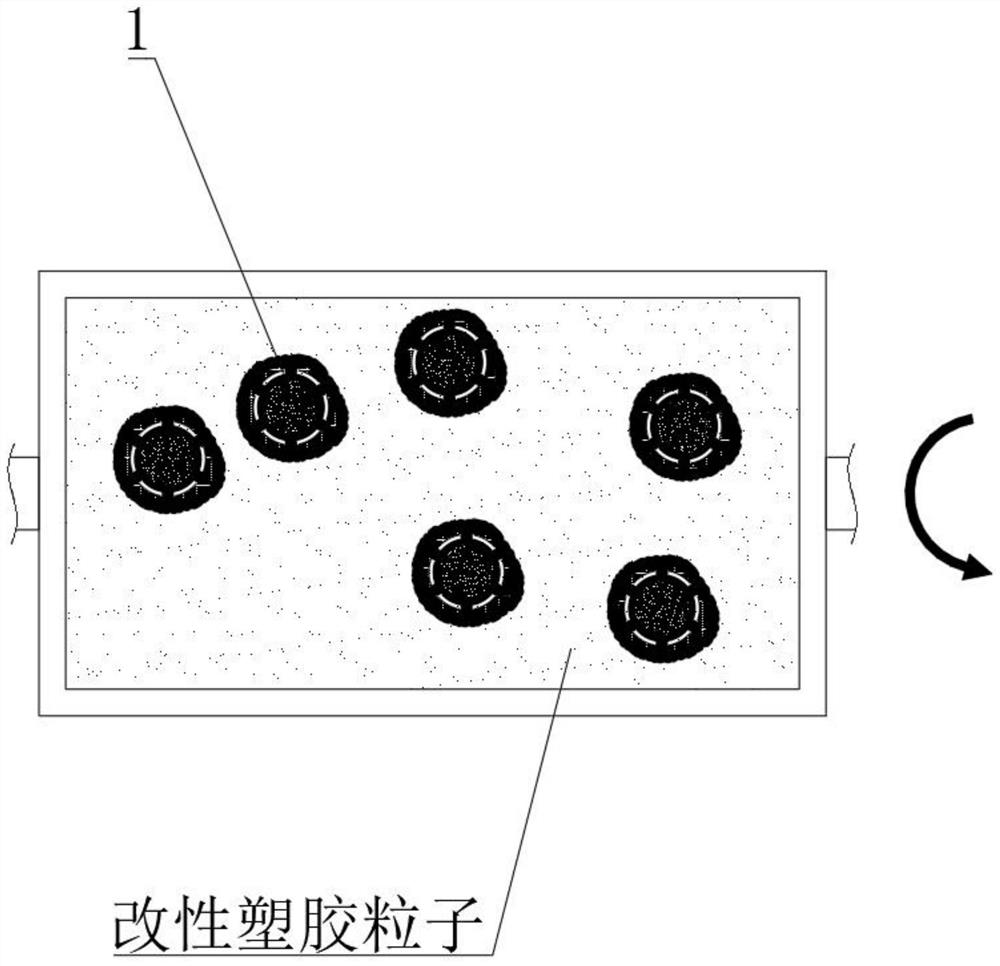

Preparation process of modified plastic particles

The invention discloses a preparation process of modified plastic particles, and belongs to the technical field of plastic production. According to the scheme, the preparation process of the modifiedplastic particles that potassium permanganate powder in a built-in storage bag can be promoted to be heated and gradually decomposed by continuously heating the modified plastic particles and auxiliary drying balls in a drying box, a large amount of oxygen is generated, so that the expansion of a convex capsule sleeve is realized, the oxygen ejects a rubber sealing sheet and then is diffused fromrelease through holes to promote a protective film to be opened, so that the contact efficiency of the protective film and moisture in the modified plastic particles is improved, after the protectivefilm is dissolved, on one hand, by means of release of oxygen, the plastic particles in a drying cylinder can be scattered, and the drying efficiency of the plastic particles is improved, and on the other hand, a large amount of heat can be generated by means of the reaction of oxygen and the reductive iron powder in the protective film, so that the drying effect on the modified plastic particlesis further improved.

Owner:南通瑞诚高分子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com