Powder packaging bag crusher screen

A technology of packaging bags and screening machines, which is applied in the direction of solid separation, sieves, grilles, etc., can solve the problems of easy pollution of the environment, high risk, and low work efficiency, and achieve high material recovery rate, high safety performance, and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

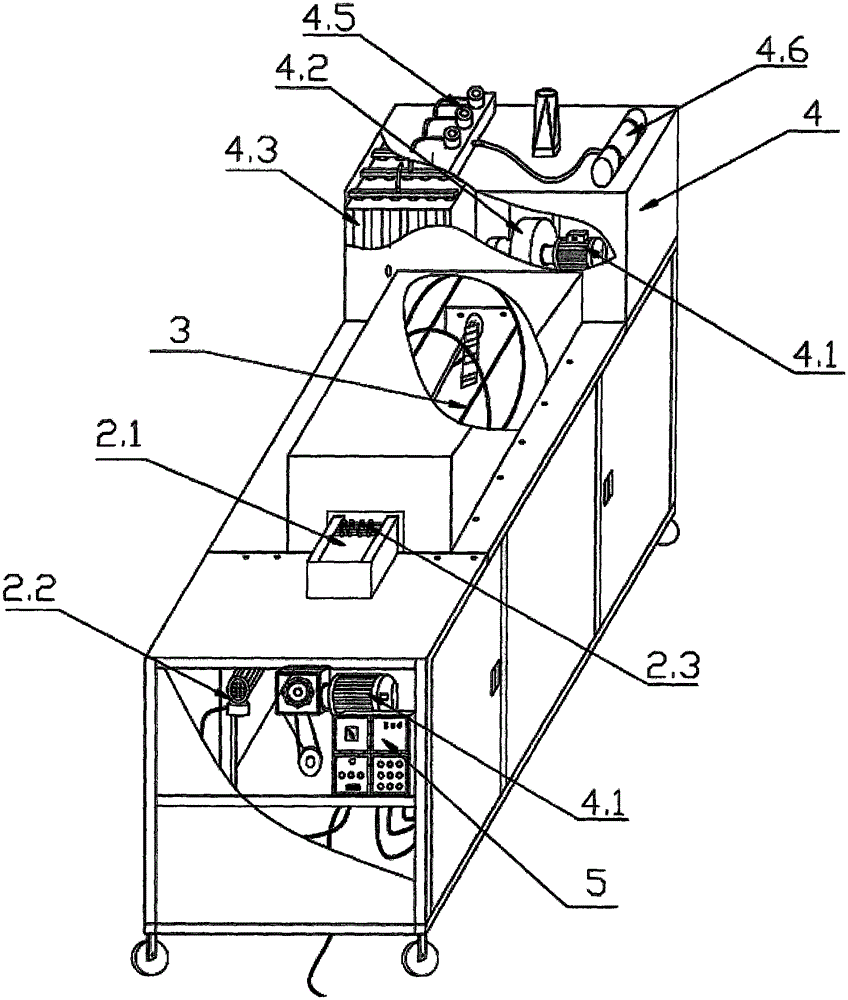

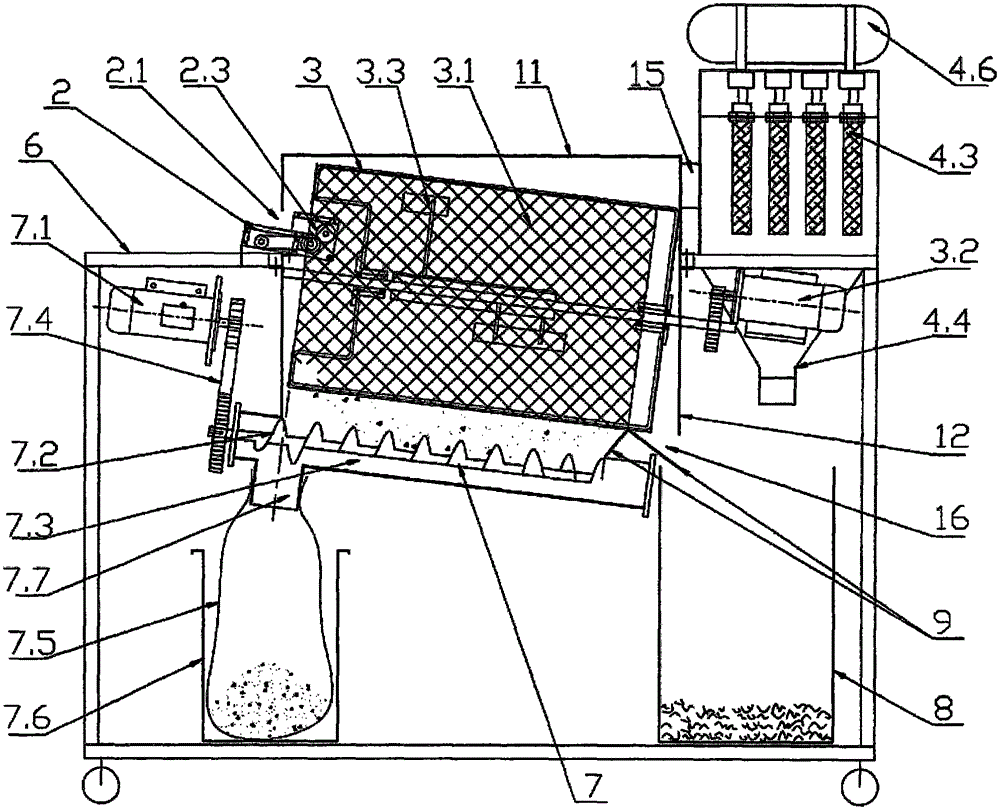

[0022] In conjunction with the accompanying drawings, a powder packaging bag crushing and screening machine includes a frame 1, a crushing mechanism 2, a screening mechanism 3, a material collection device, a fan filter 4 and an explosion-proof control box 5, and the screening mechanism 3 It includes a screen cage 3.1 installed obliquely on the frame 1 and a first motor 3.2 that drives the screen cage 3.1 to rotate. The higher end of the screen cage 3.1 is provided with a workbench 6, and the crushing mechanism 2 is arranged on the screen Between the cage 3.1 and the workbench 6, the material collection device includes a powder collection device 7 arranged under the screen cage 3.1 and a debris collection device 8 arranged at the lower end of the screen cage 3.1, and the fan filter The device 5 is arranged at the end of the screen cage 3.1 away from the crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com