Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Realize shredding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

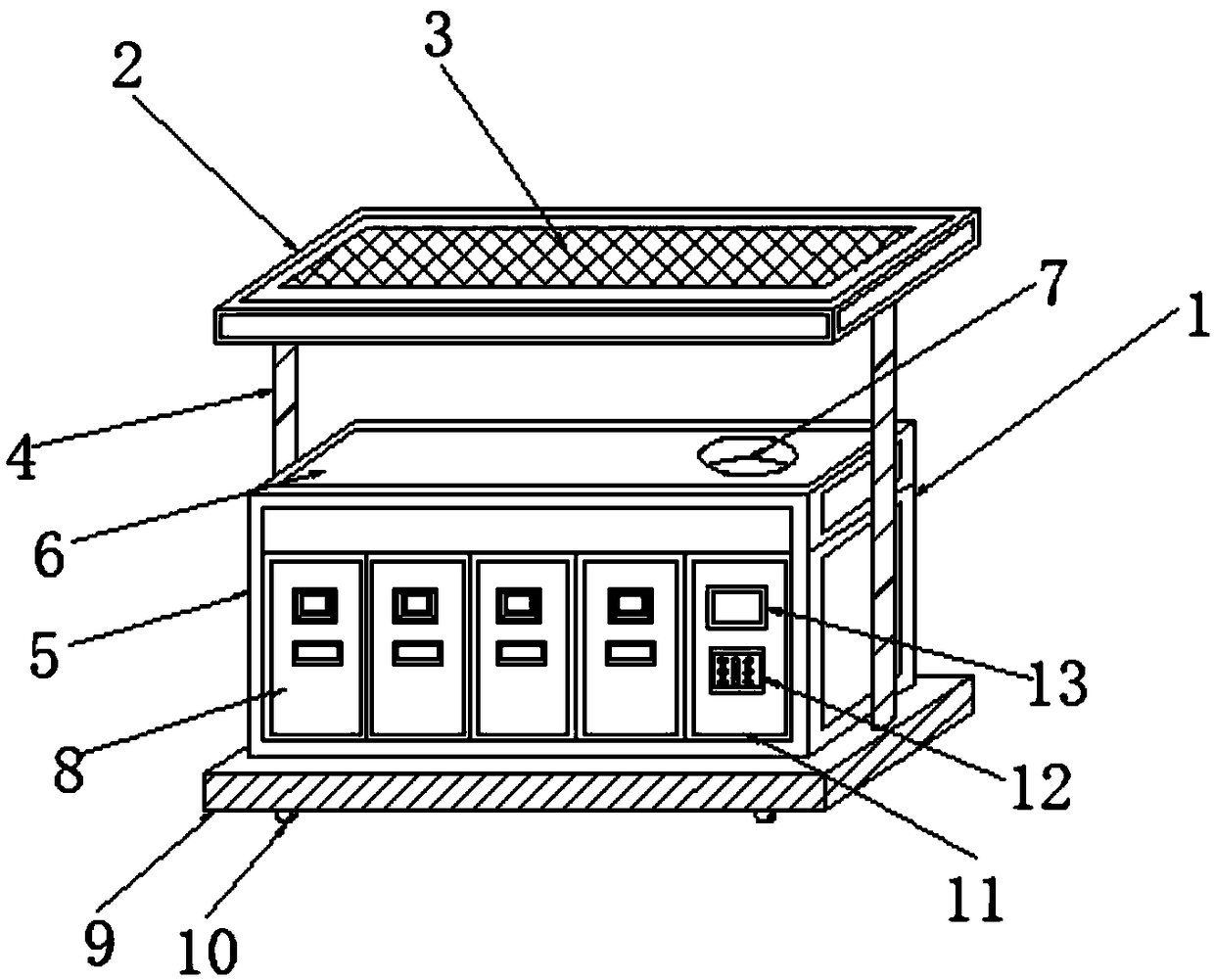

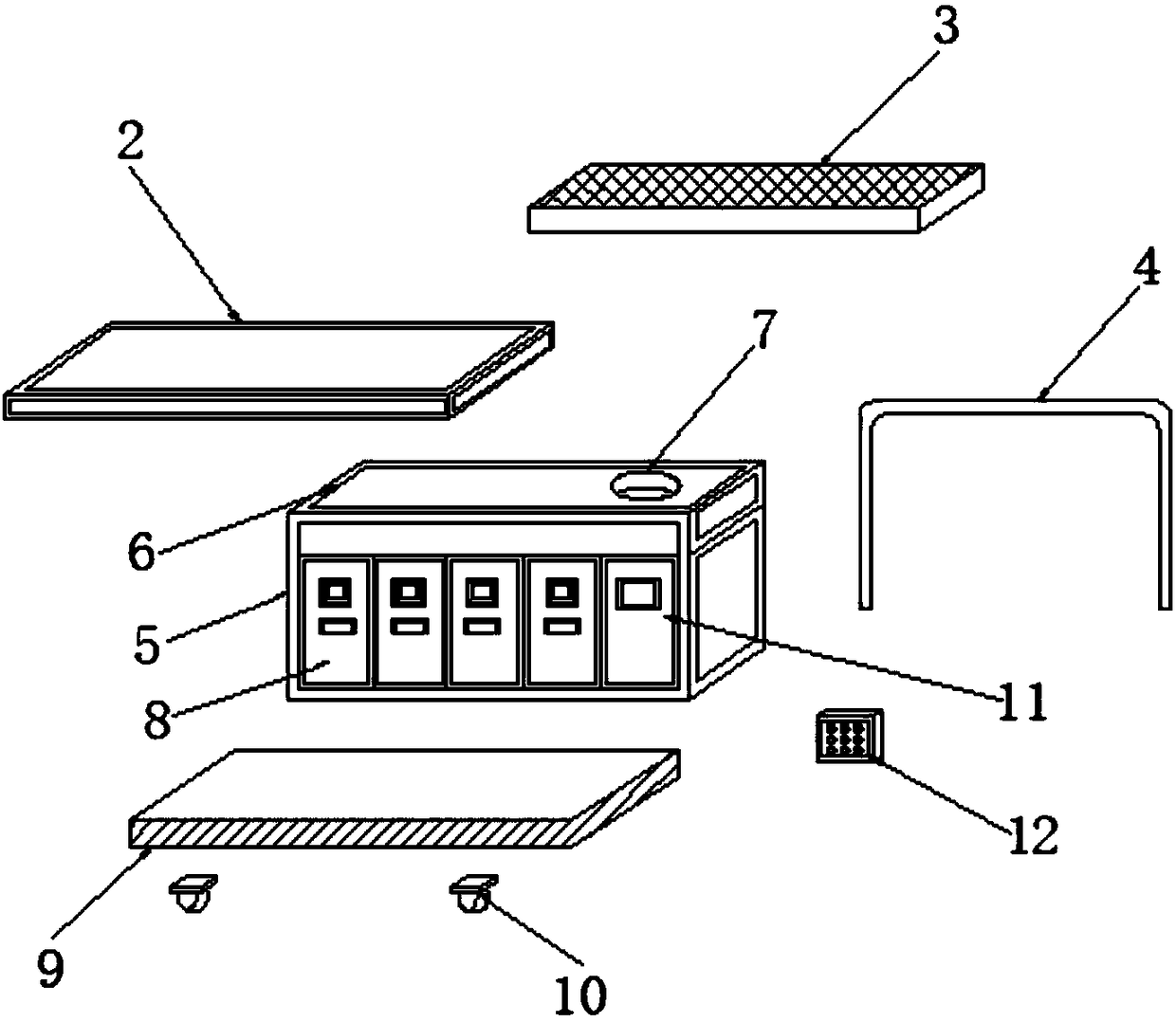

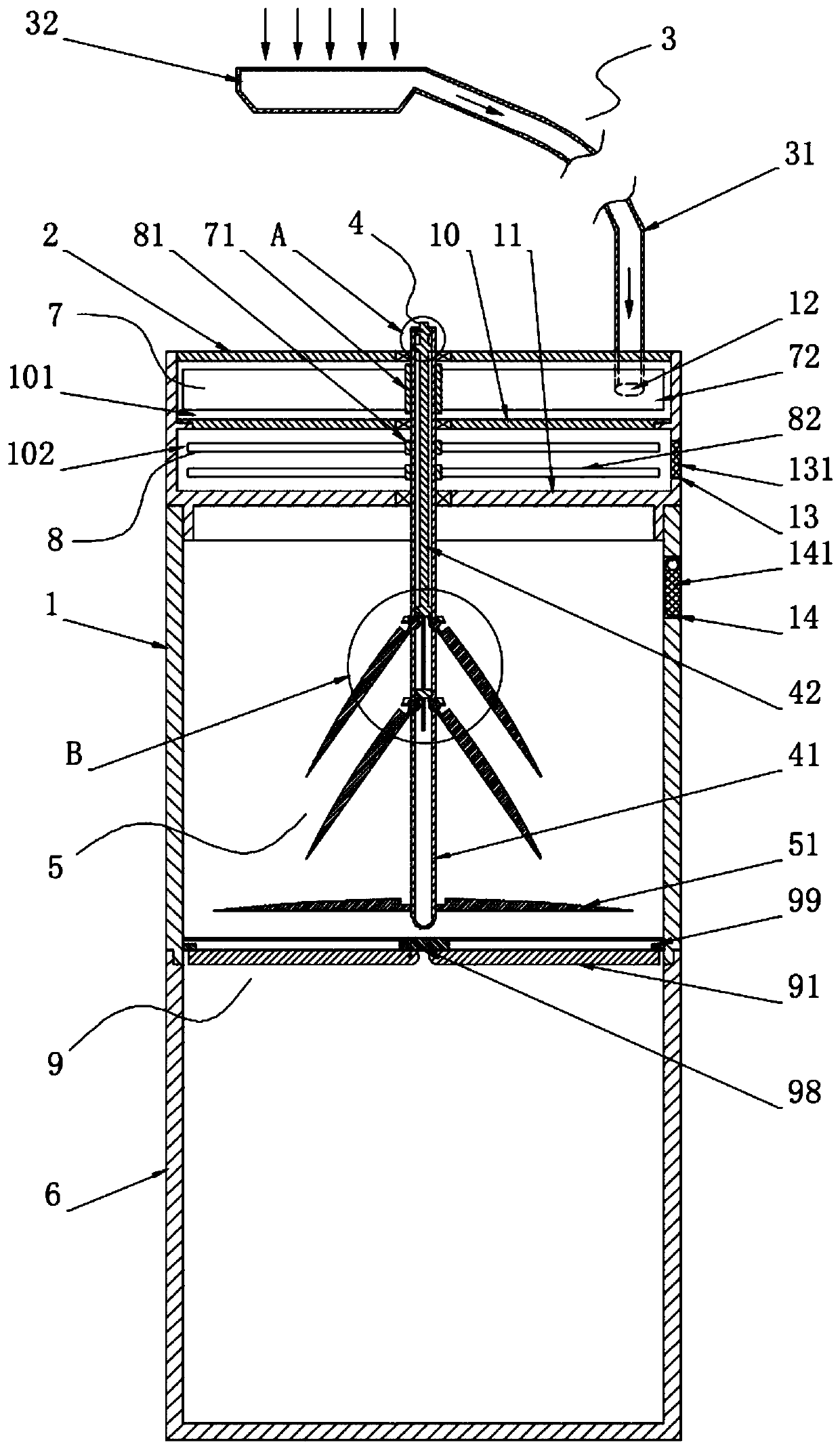

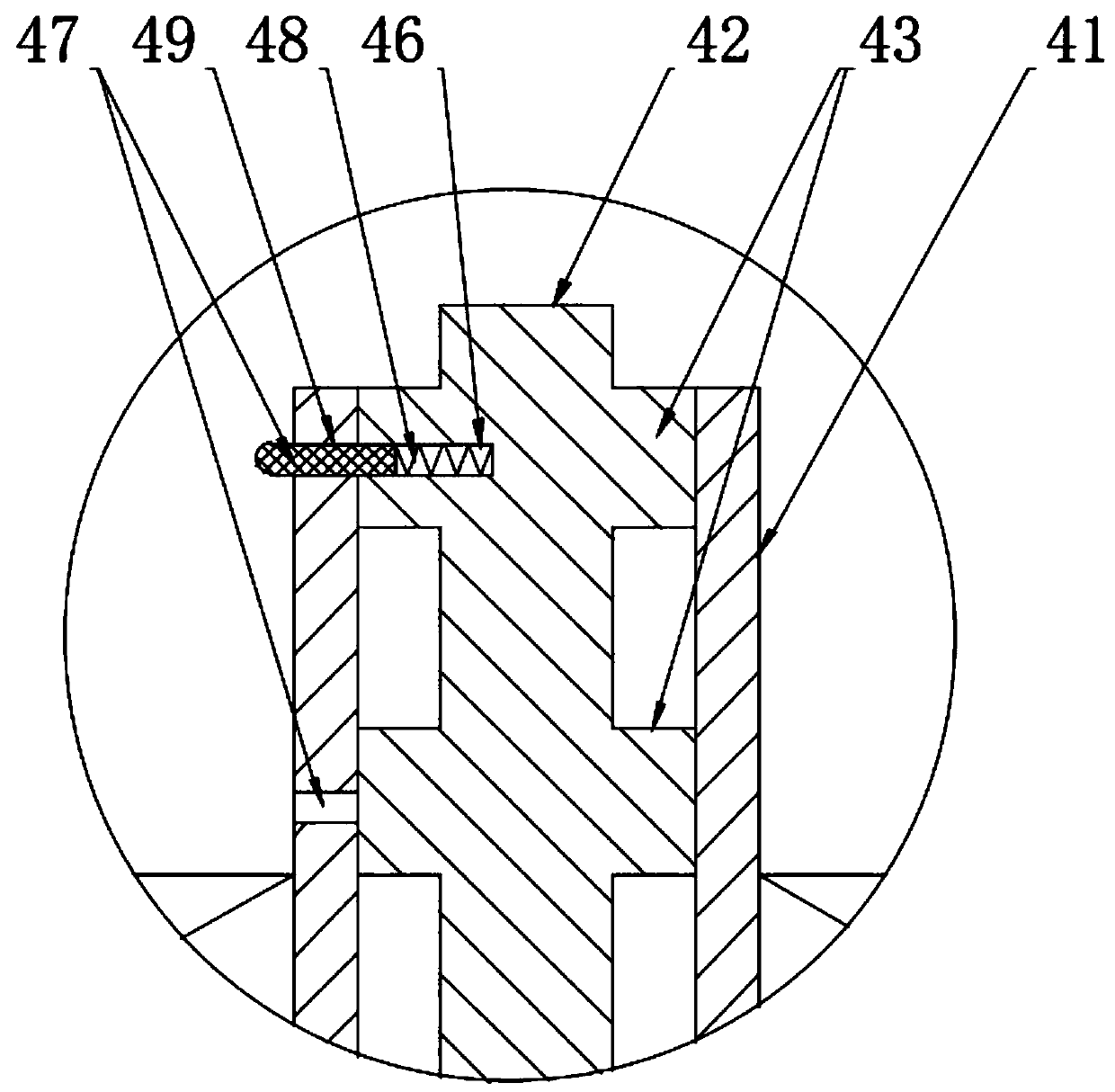

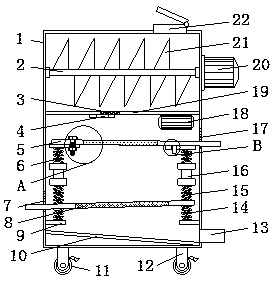

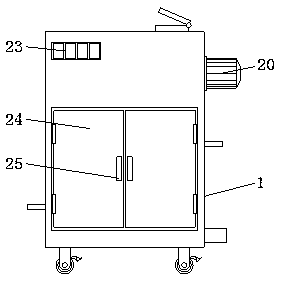

Environment-friendly garbage can

InactiveCN108545373ARealize integrated utilizationTo achieve the effect of energy saving and environmental protectionWaste collection and transferRefuse receptaclesAlternating currentSolar cell

The invention discloses an environment-friendly garbage can. The garbage can is capable of classifying various types of garbage, and comprises a garbage can body, wherein a top cover is arranged abovethe garbage can body, a fixing seat is arranged at the bottom end of the garbage can body, the outer side of the garbage can body is provided with a shell, an electric cabinet is arranged on the front side of the garbage can body, a solar cell panel is arranged at the top of the top cover, a supporting frame is arranged at the joint of the top cover and the fixing seat, and rolling wheels are arranged at the bottom end of the fixing seat. According to the environment-friendly garbage can, the structure is scientific and reasonable, the operation is convenient, the solar cell panel can be usedfor absorbing sunlight, solar radiation energy can be directly or indirectly converted into electric energy through the photoelectric effect or the photochemical effect to be stored in a storage battery, then the direct current of the storage battery is converted into alternating current through an inverter for use, so that the energy-saving and environment-friendly effects are achieved; and a crushing device can be used for crushing the garbage, and therefore convenience is provided for subsequent processing of the garbage.

Owner:CHENGDU FUYANG TECH DEV

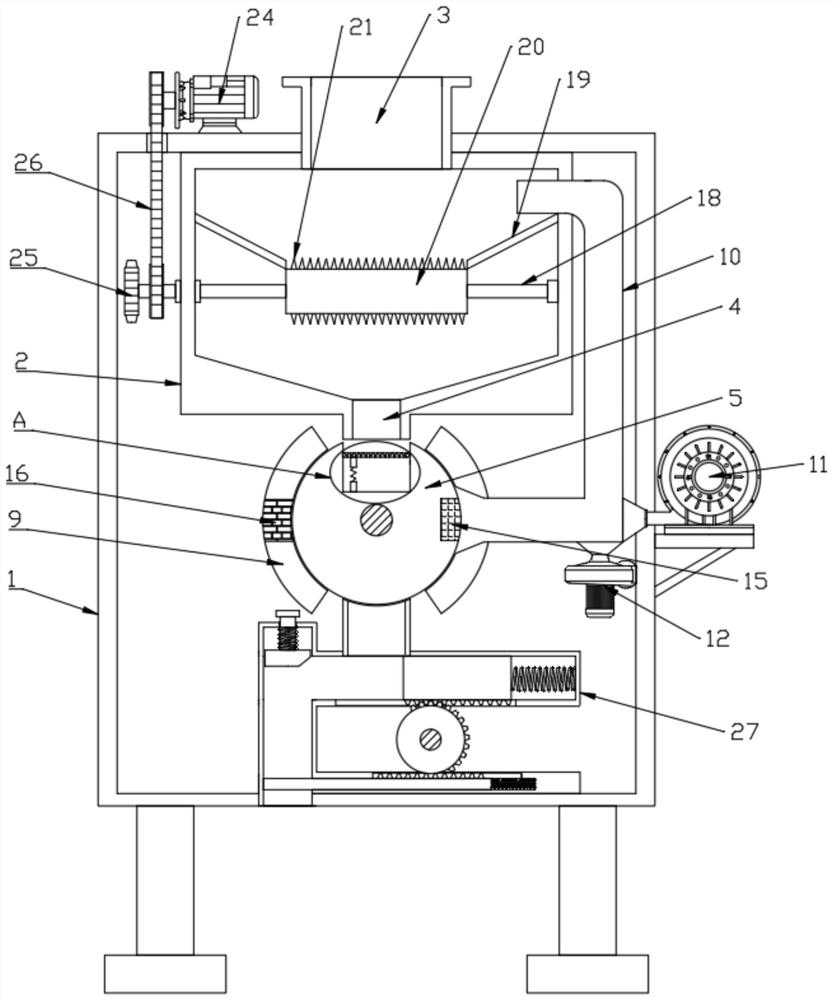

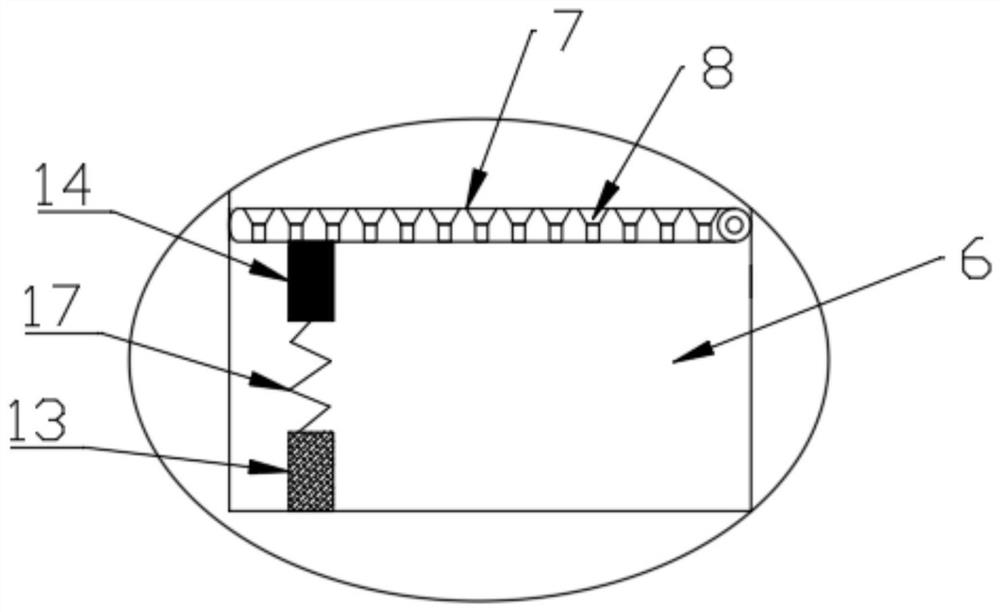

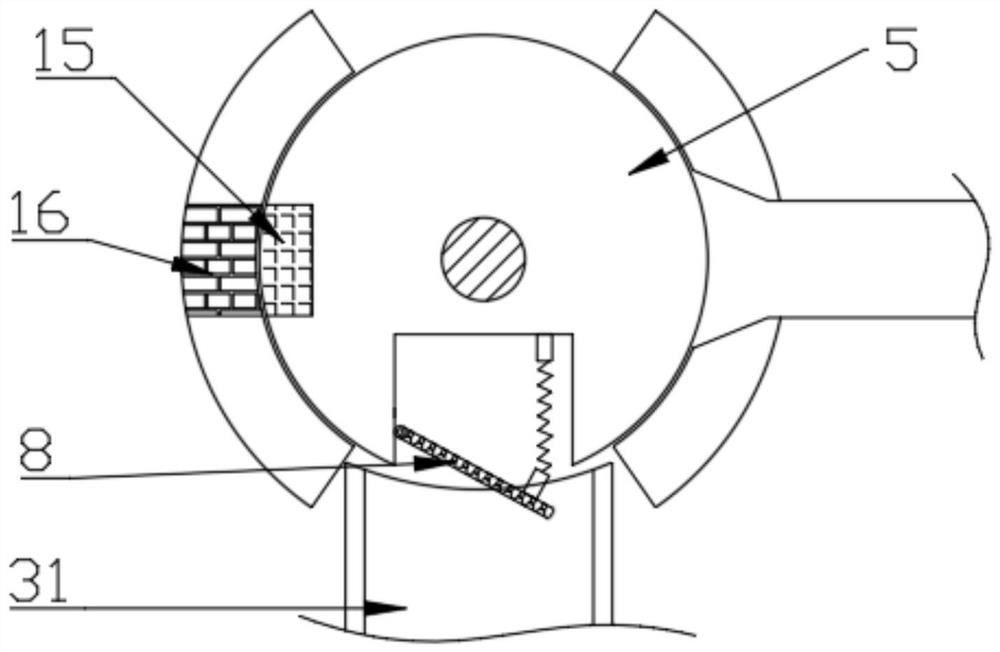

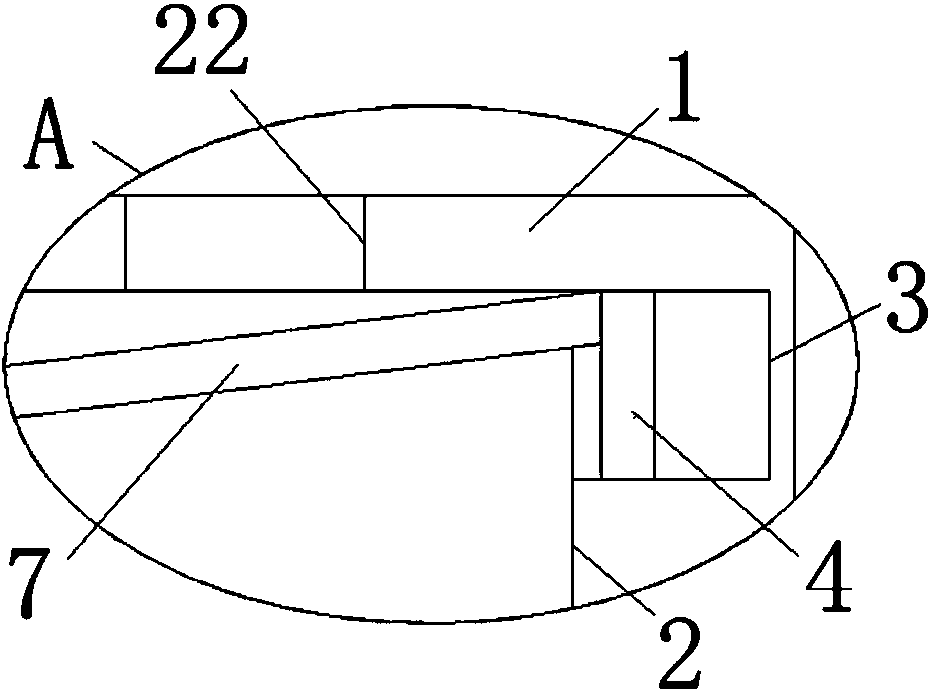

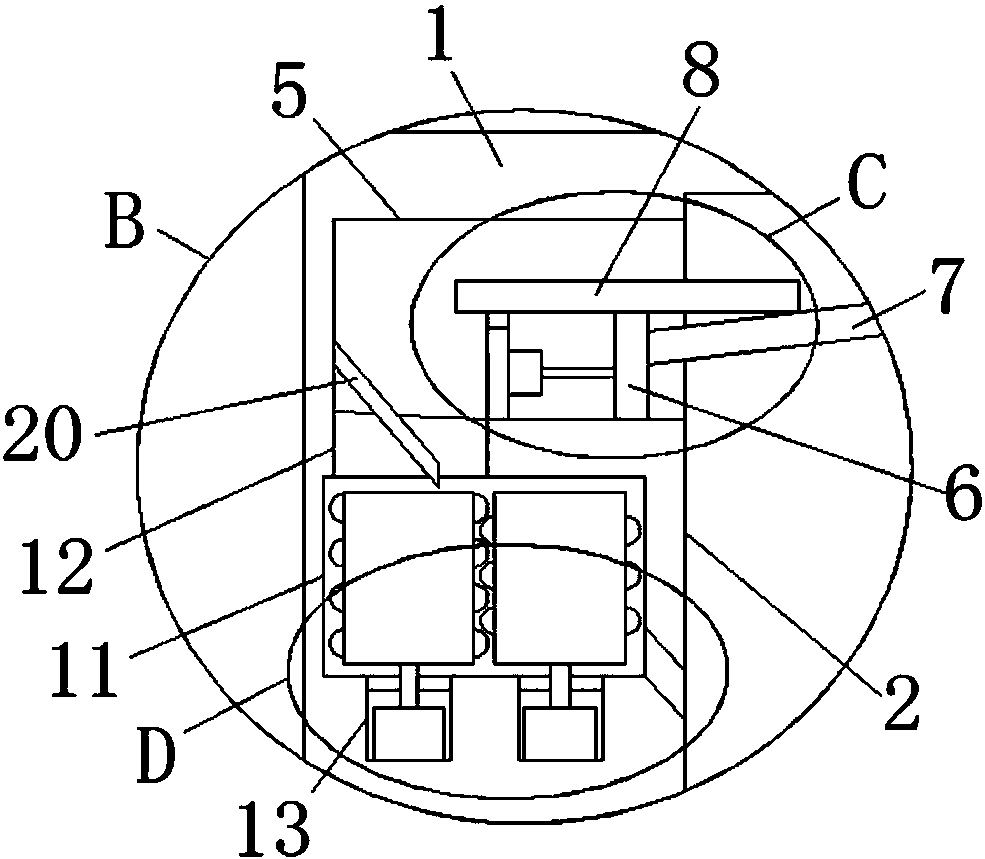

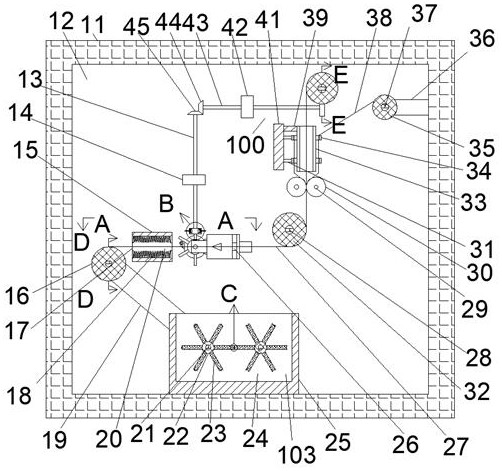

Vehicle-mounted garbage can

InactiveCN111547409ARealize shreddingAchieving stirringWaste collection and transferRefuse receptaclesActivated carbonIn vehicle

The invention discloses a vehicle-mounted garbage can, and relates to the field of environmental protection equipment. The vehicle-mounted garbage can comprises a can body, a can cover, an air inlet assembly, a rotating shaft assembly, a crushing mechanism and a collecting box. According to the vehicle-mounted garbage can, a common garbage collection and storage capacity is achieved, and in the running process of the automobile, a vehicle window is opened, so that the vehicle-mounted garbage can can drive a fan assembly to rotate by means of wind power generated in the running process of the automobile, and the rotating shaft assembly, a stirring assembly and a crushing mechanism are driven to rotate synchronously; on one hand, garbage in the can body is crushed, the space utilization rateof the can body is increased, and on the other hand, active carbon particles in a deodorization chamber can be stirred so that unpleasant odors in the can body can be fully absorbed by the active carbon particles; and in addition, the rotating shaft assembly does not need to be manually driven to rotate, so that the energy is saved, and the labor is saved.

Owner:芜湖杰瑞节能环保科技有限公司

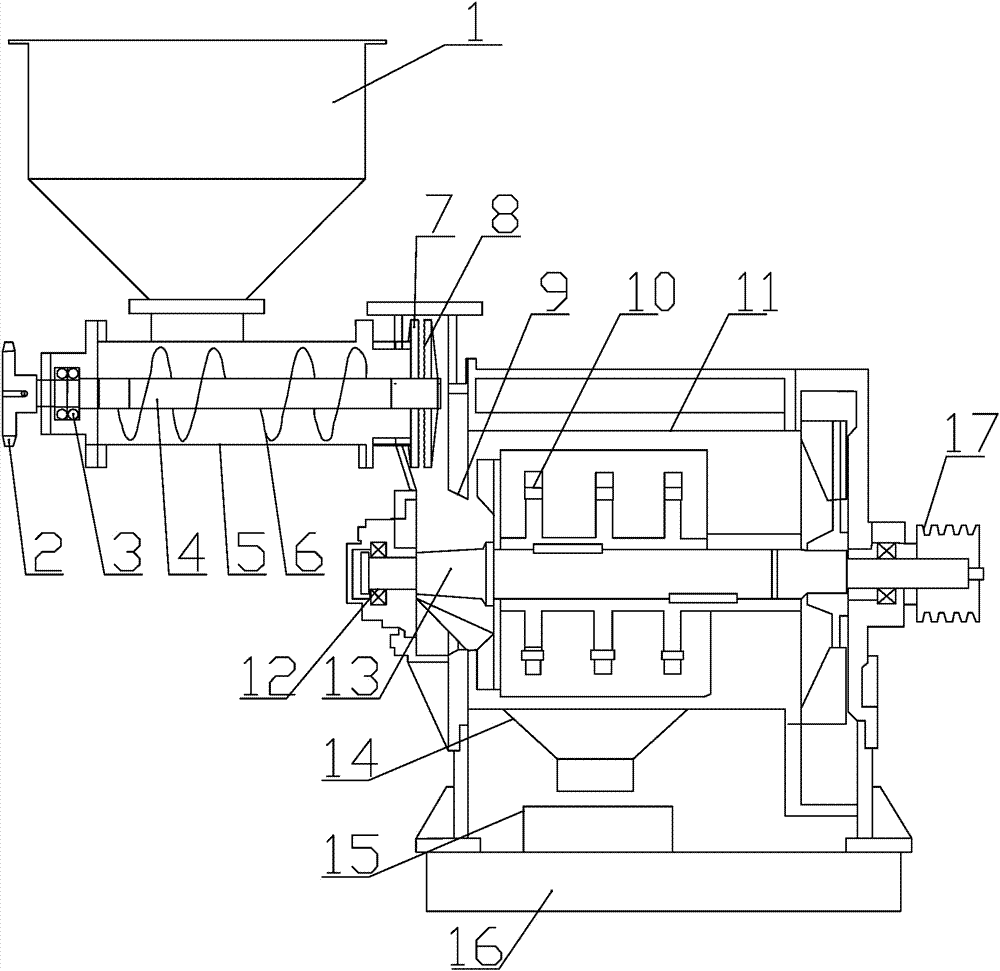

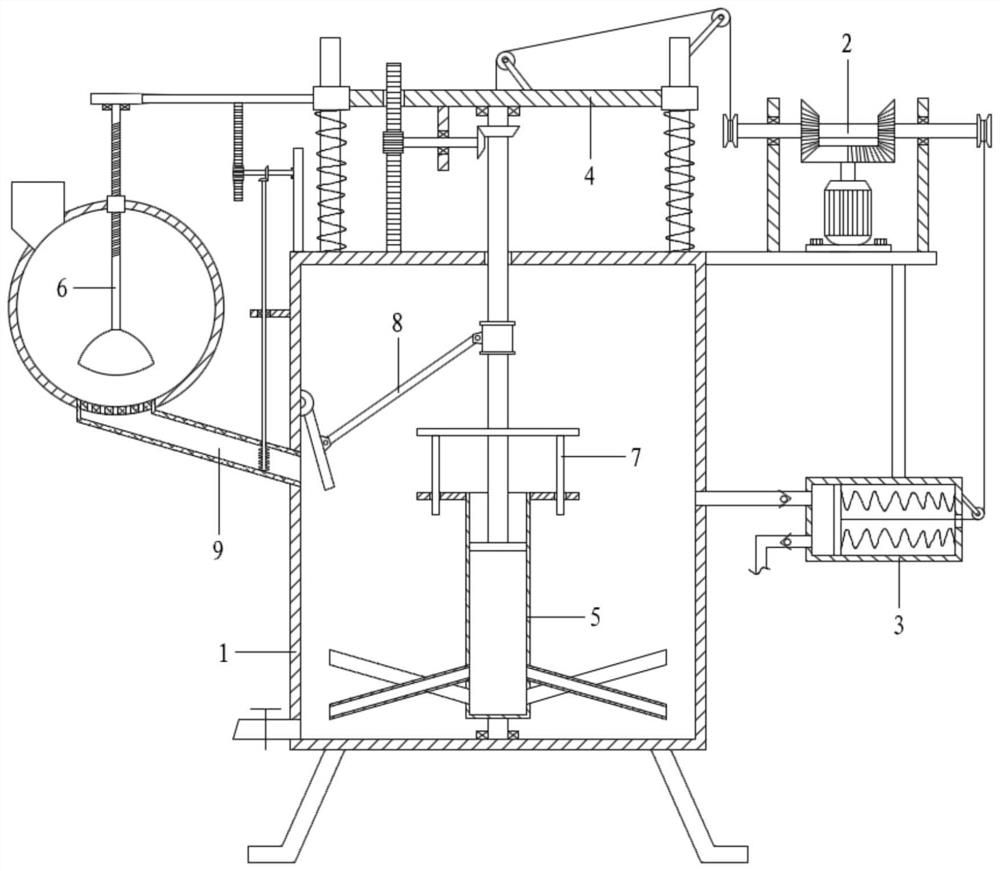

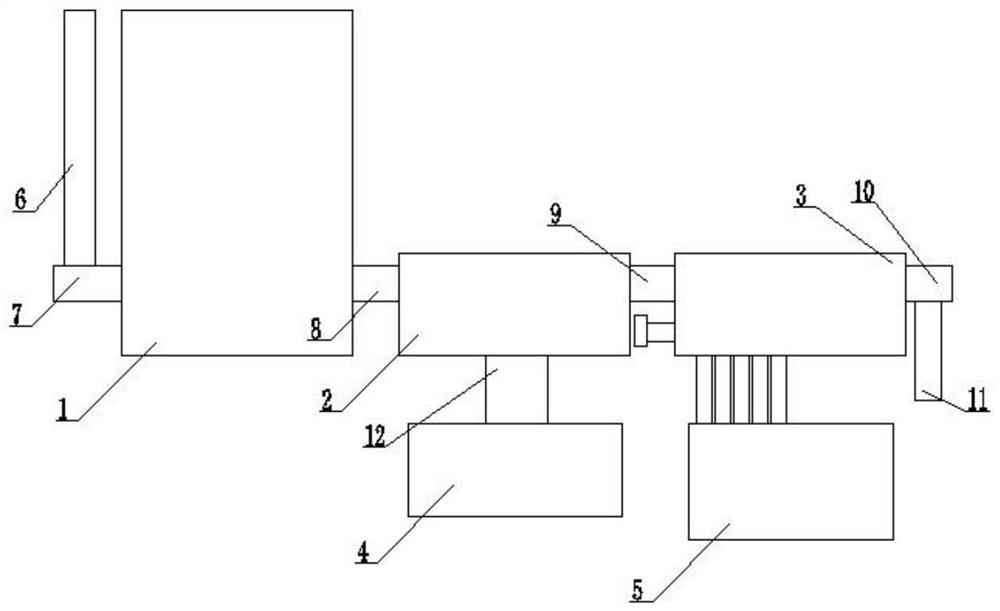

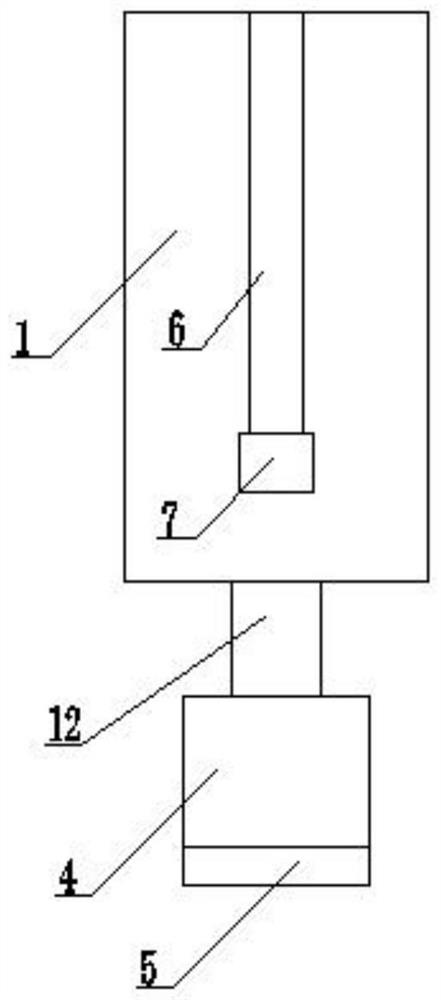

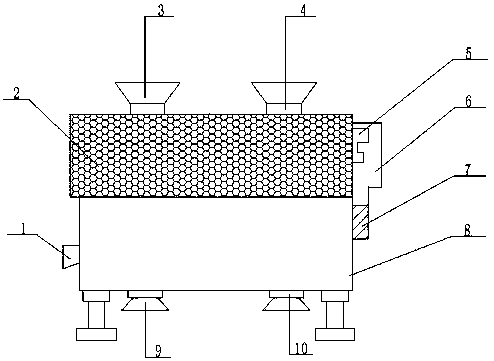

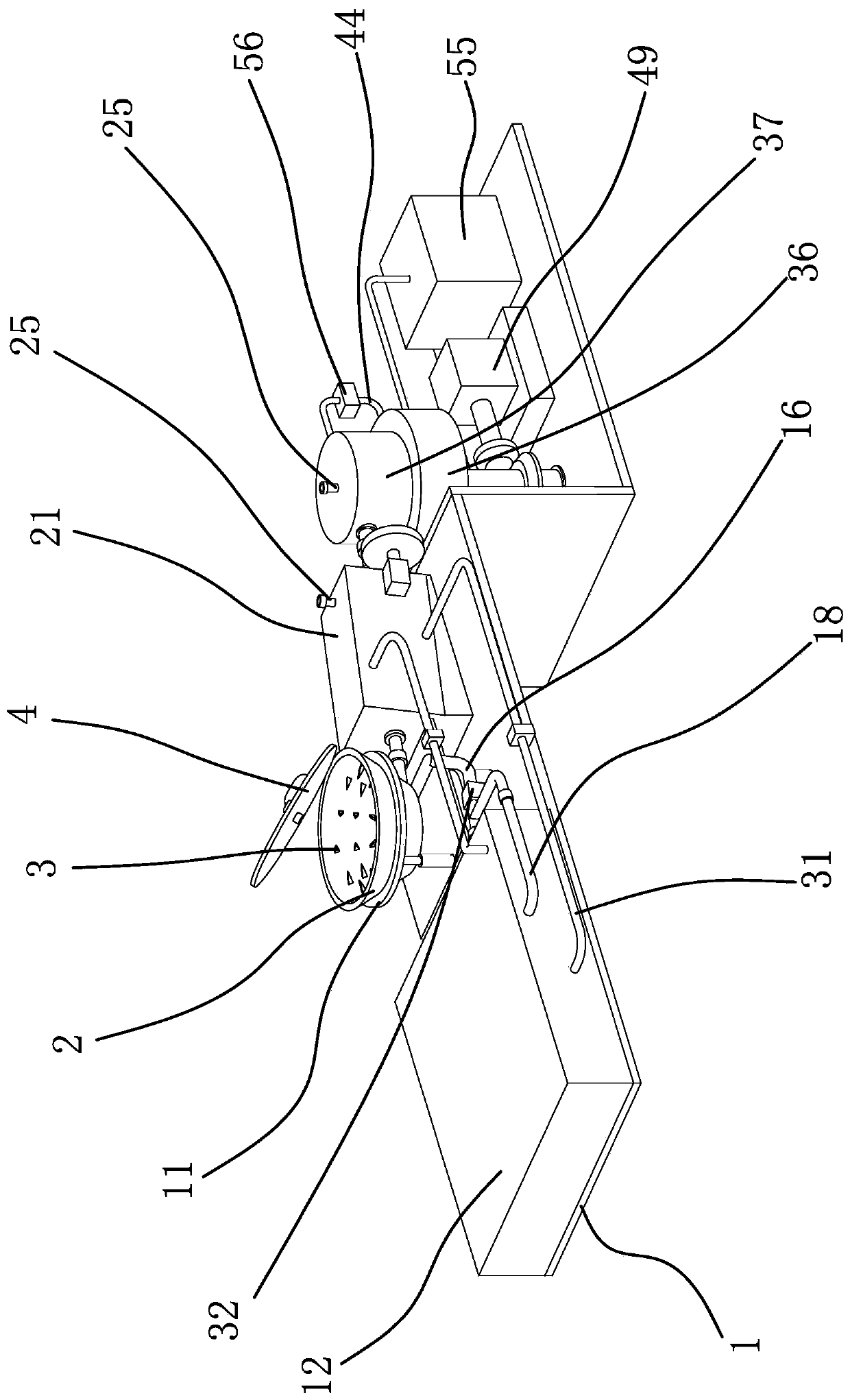

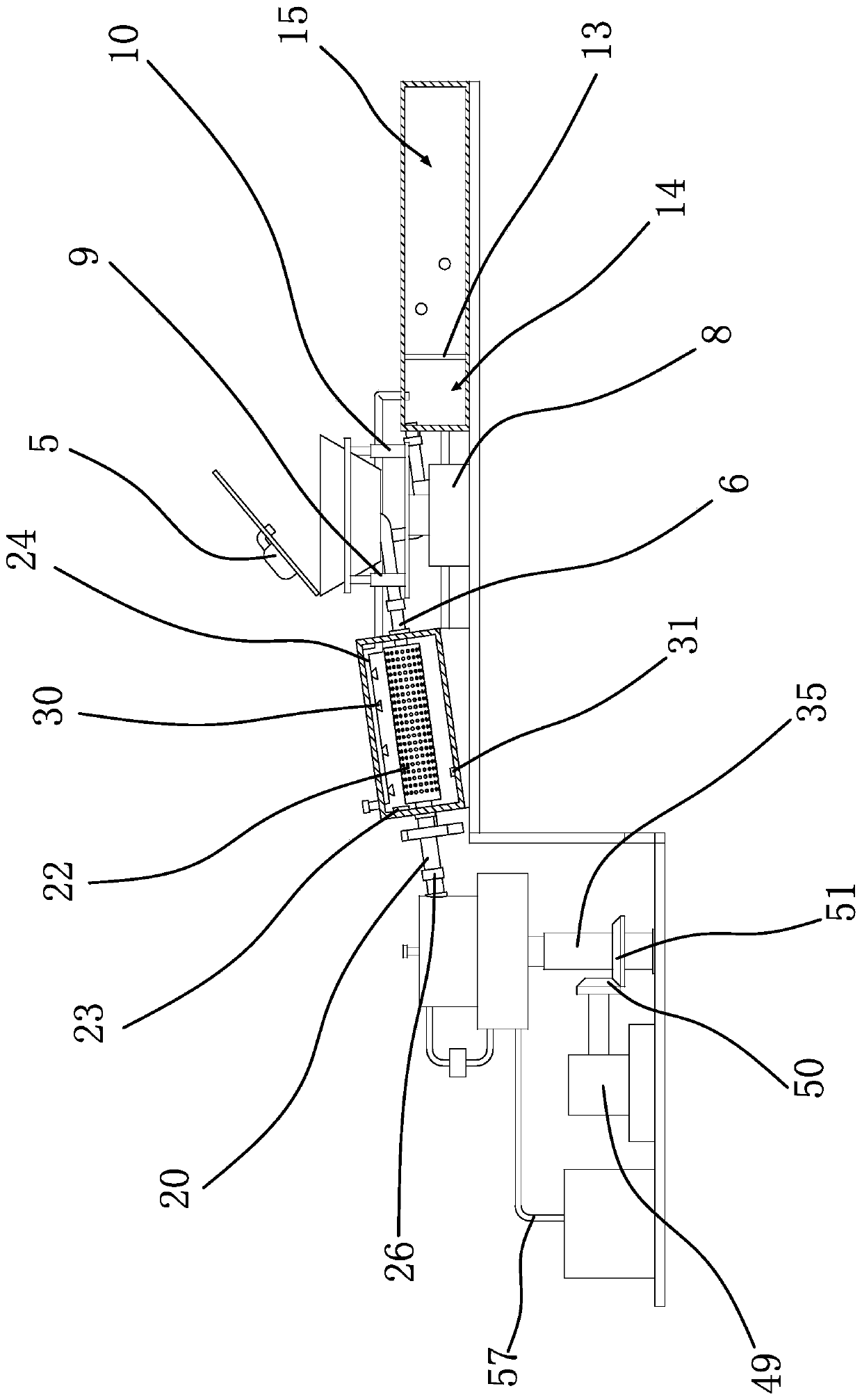

Minced fillet grinding stirrer

InactiveCN107302976ARealize shreddingGreat tasteRotary stirring mixersTransportation and packagingAdditive ingredientSprocket

The invention relates to a minced fillet grinding stirrer. The minced fillet grinding stirrer comprises a feeding hopper, wherein the feeding hopper is mounted on the top of a grinding device; the grinding device comprises a grinding box; a grinding spindle is mounted inside the grinding box; a thread plate is machined on the grinding spindle; the grinding spindle is supported and mounted on the grinding box through a bearing; a chain wheel is arranged at the left end of the grinding spindle, and a main grinding head is arranged at the right end of the grinding spindle; the main grinding head is matched with an auxiliary grinding head; the auxiliary grinding head is fixedly arranged at a main ingredient outlet of the grinding box; a discharging hopper is arranged just under the main grinding head and the auxiliary grinding head and stretches into the stirring box; and a stirring device is arranged inside the stirring box. According to the grinding stirrer, the production efficiency of minced fillet can be improved, the degree of automation is improved, the workload of an operator is reduced, the uniform mixing degree of the minced fillet is improved, and the quality of breaded fish sticks can be well ensured.

Owner:HUBEI QINJIE FOOD CO LTD

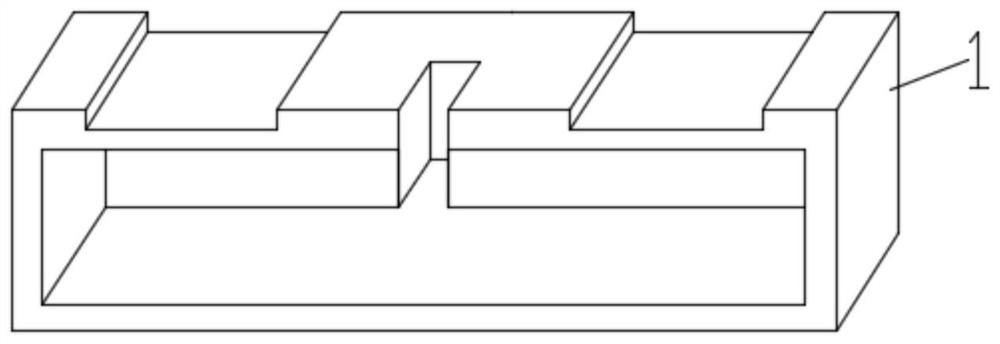

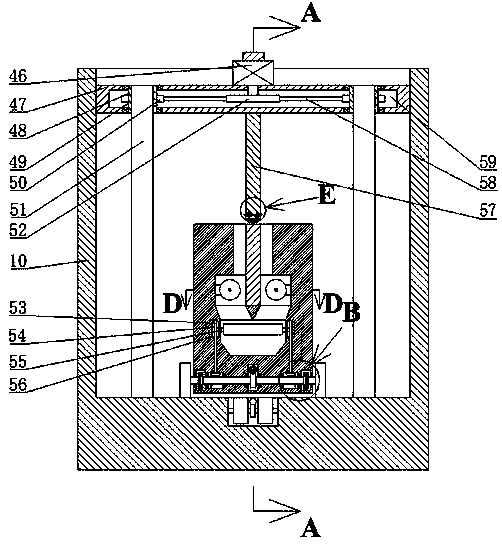

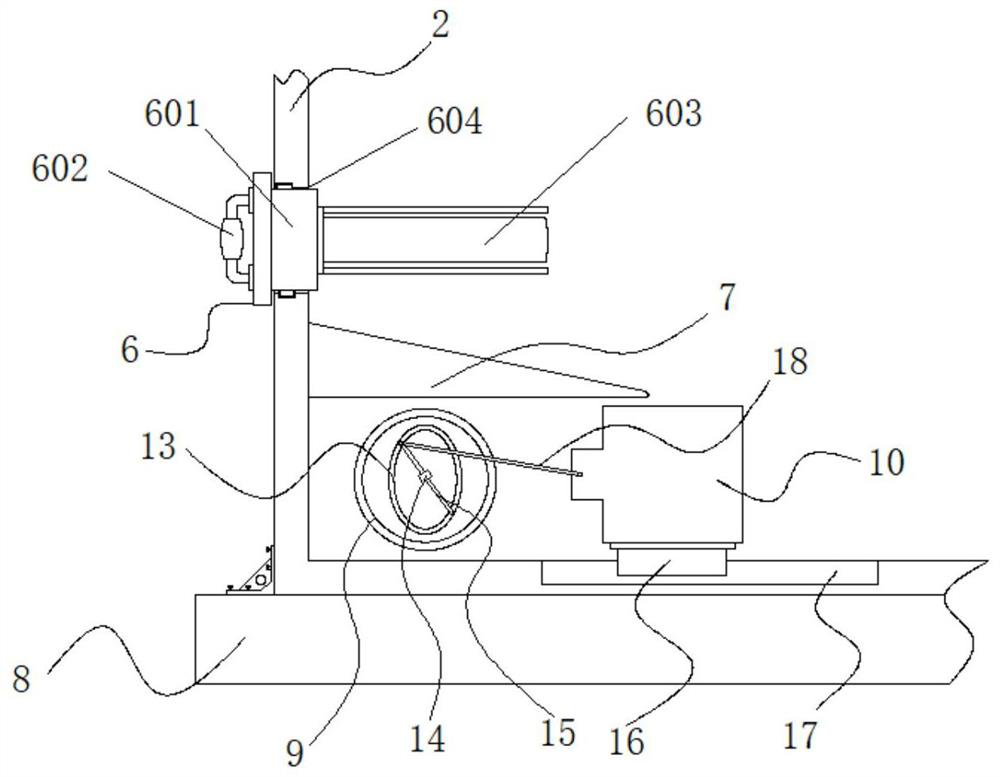

Anti-return feeding device for low-all-vanadium roasting of rotary kiln and using method of anti-return feeding device

InactiveCN113188328ARealize shreddingRealize anti-blocking treatmentRotary drum furnacesGrain treatmentsGear driveGear wheel

The invention discloses an anti-return feeding device for low-all-vanadium roasting of a rotary kiln and a using method of the anti-return feeding device. The anti-return feeding device comprises a bottom box, wherein a feeding box is arranged at the top of the bottom box; a No. 2 ventilation rod is rotationally connected to the interior of the feeding box; a rotating mechanism is arranged on one side of the feeding box, and connected with the No. 2 ventilation rod; a filtering mechanism is arranged at the top of the bottom box; the filtering mechanism is connected with the rotating mechanism; and a feeding mechanism is arranged in the bottom box. The anti-return feeding device has the beneficial effects that a No. 1 belt wheel and a No. 2 belt wheel are additionally arranged, so that simultaneous rotation of a half gear and a No. 2 gear is achieved; crushing rollers are additionally arranged, so that raw materials are crushed through the crushing rollers; a No. 4 ventilation rod and a No. 3 ventilation rod are additionally arranged, so that anti-blocking treatment on internal materials is achieved; the filtering mechanism is additionally arranged, so that filtering treatment on external air is achieved; and the half gear and a rack are additionally arranged, so that the half gear drives a connecting frame to move in a reciprocating mode through the rack.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

Waste paper crushing device for environmental protection

InactiveCN112871368ARealize shreddingImplement extrusion processingGrain treatmentsPress ramPaper dustEnvironmental engineering

Owner:胡晓

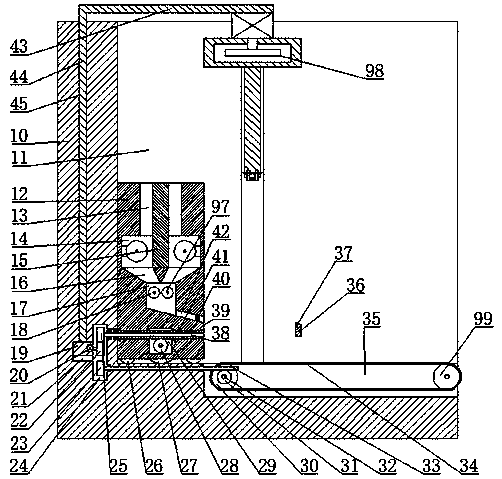

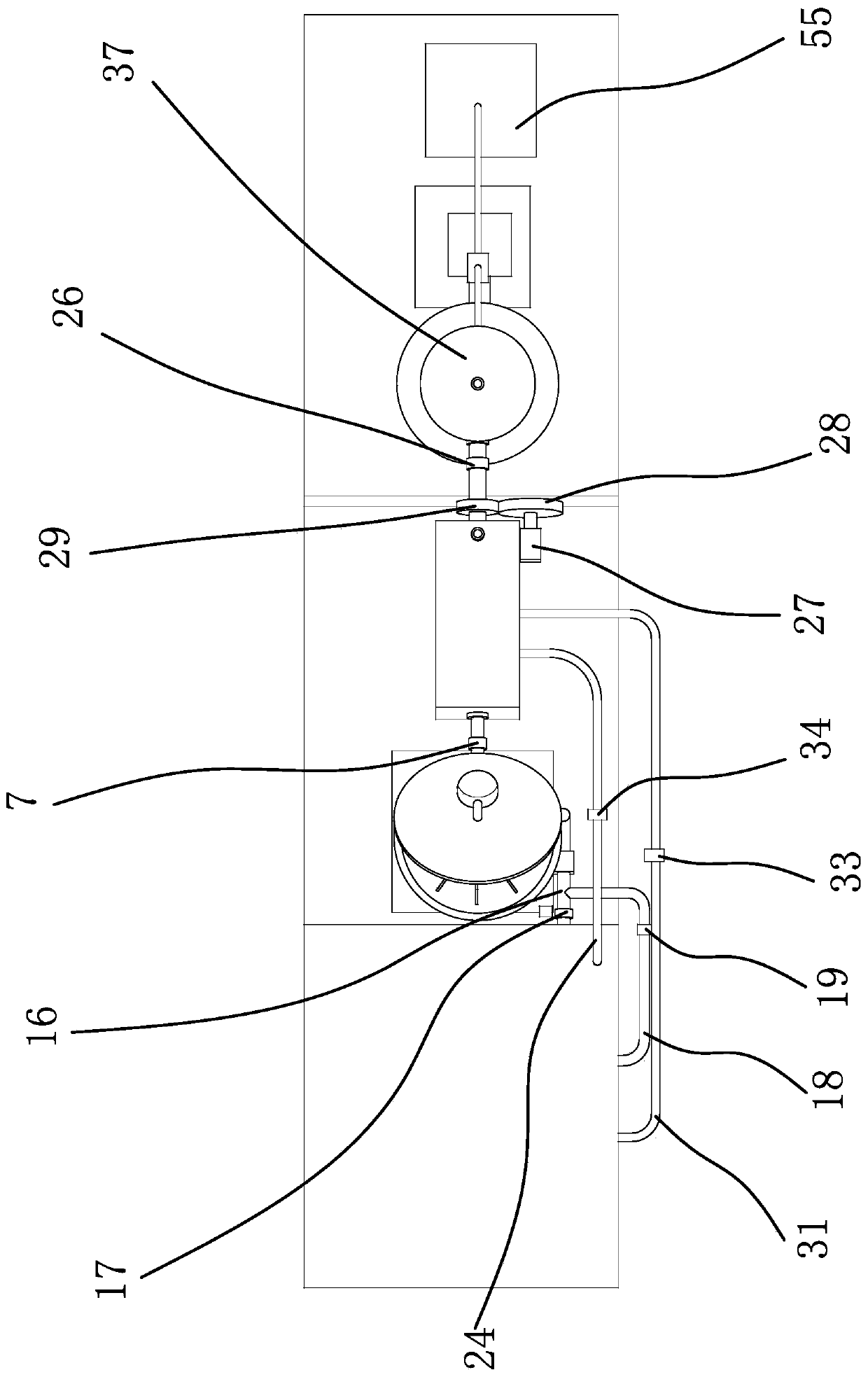

Biomass water fertilizer production machine for agricultural planting and production method thereof

InactiveCN111804222ARealize automatic water additionRealize shreddingTransportation and packagingMixer accessoriesAgricultural scienceGear wheel

The invention relates to the technical field of biomass water fertilizer production, and in particular, relates to a biomass water fertilizer production machine for agricultural planting and a production method thereof. A servo motor is adopted to drive an incomplete gear to rotate, and the incomplete gear is in intermittent fit with a driven gear to enable a first rotating shaft to periodically rotate forwards and backwards; a first winding wheel at the right end of the first rotating shaft synchronously rotates and winds and unwinds wires, and a first spring is matched to enable a first piston plate to move left and right in a first piston cylinder; due to the arrangement of two one-way valves, automatic water adding is achieved; a sliding sleeve moves up and down along with a lifting plate and drives a top plate to move synchronously through a first connecting rod, so that a pressing rod drives a crushing head to move up and down, the crushing head crushes biomass raw materials, andcrushing treatment on the biomass raw materials is achieved. The lifting rod drives a second piston plate to move up and down in a second piston cylinder, so that the second piston cylinder generatessuction and discharge, materials continuously enter and exit the second piston cylinder and generate surging, sedimentation is effectively avoided, and rapid dissolution and mixing are achieved.

Owner:安徽酷简全屋定制家具有限公司

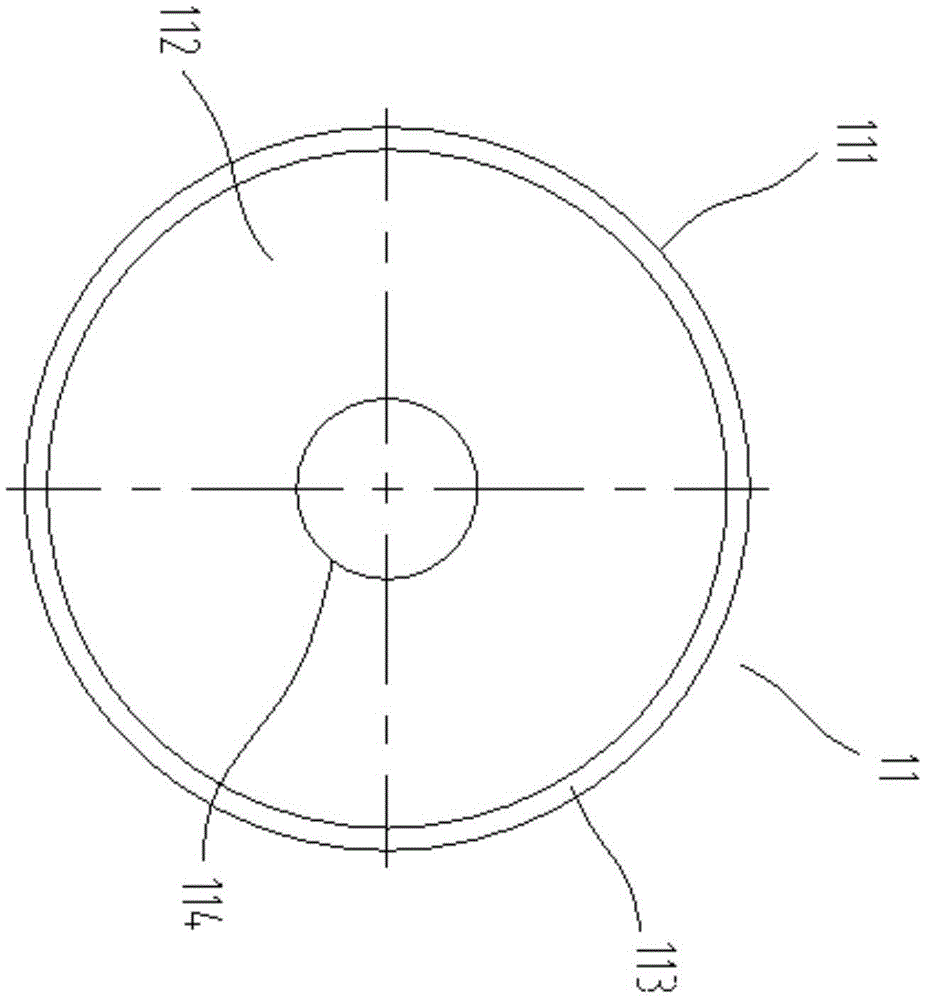

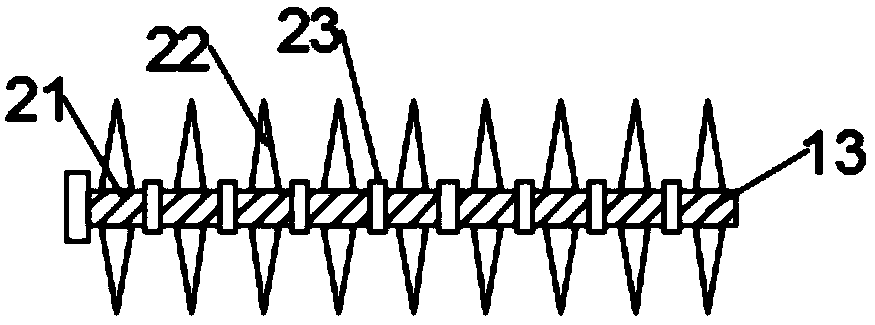

Hobbing cutter and cutter assembly for processing seaweed materials

The invention relates to a hobbing cutter and a cutter assembly for processing seaweed materials. A main body part of the hobbing cutter is driven by the power to rotate around a rotation axis, the main body part is provided with a peripheral wall, the peripheral wall is in a closed curve shape on a cross section perpendicular to the rotation axis, the peripheral wall is provided with a plurality of cutting edges which are in a closed curve shape, and each cutting edge which is in the closed curve shape defines a groove corresponding to the shape of the cutting edge. The cutter assembly comprises the hobbing cutter and an elastic fastener. The hobbing cutter is suitable for being pressed against the elastic fastener and rolls on the elastic fastener, so that the chopping operation of the seaweed materials can be realized; and meanwhile, foreign matters such as nylon threads in the seaweed materials can be prevented from being cut, and the original shape of the foreign matters can be kept, so that not only is the production efficiency increased, but also a condition is created for subsequently sorting the foreign matters.

Owner:连云港市赣榆区知识产权维权援助中心(连云港市赣榆区知识产权保护与服务中心)

Medical waste recycling and treating equipment with disinfection and sterilization functions

The invention relates to the related field of medical waste recycling equipment, in particular to medical waste recycling and treating equipment with disinfection and sterilization functions. The medical waste recycling and treating equipment comprises a box body and a first cavity fixedly formed in the box body, a waste inlet is fixedly formed in the end wall on the upper side of the box body, aninlet slide plate is fixedly installed on the end wall on the upper side of the first cavity in the left side of the waste inlet, and first belt wheel shafts are symmetrically left and right and rotationally mounted between the front end wall and the rear end wall of the first cavity in the lower side of the inlet slide plate. The invention provides the medical waste recycling and treating equipment with disinfection and sterilization functions, which can disinfect the medical waste first, and then sort and process the medical waste. Iron waste in the medical waste can be sorted by an electromagnet, and winnowing can be performed according to difference in weight, so that plastic bottles are separated from glass bottles, the glass bottles and the plastic bottles can be crushed, and crushed slag can be heated until melted.

Owner:LONGYOU KAYI ENVIRONMENTAL PROTECTION TECH CO LTD

Sugarcane peeling device

Owner:GUANGXI SUBTROPICAL CROPS RES INST GUANGXI SUBTROPICAL AGRI PROD PROCESSING RES INST

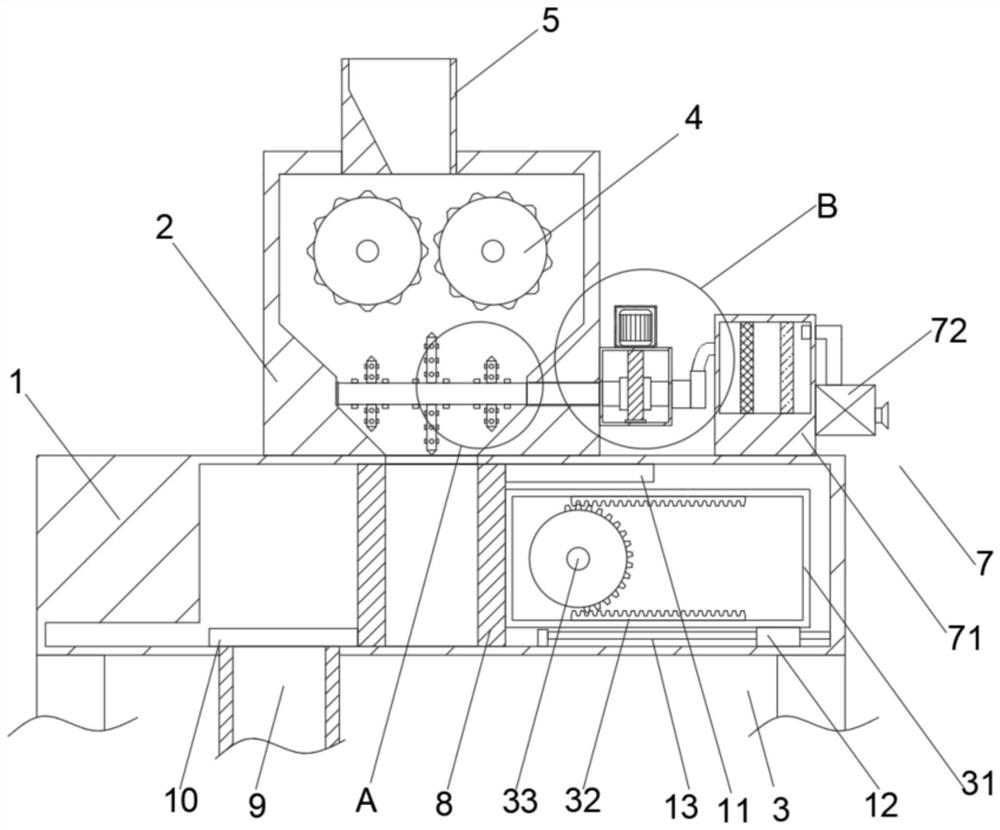

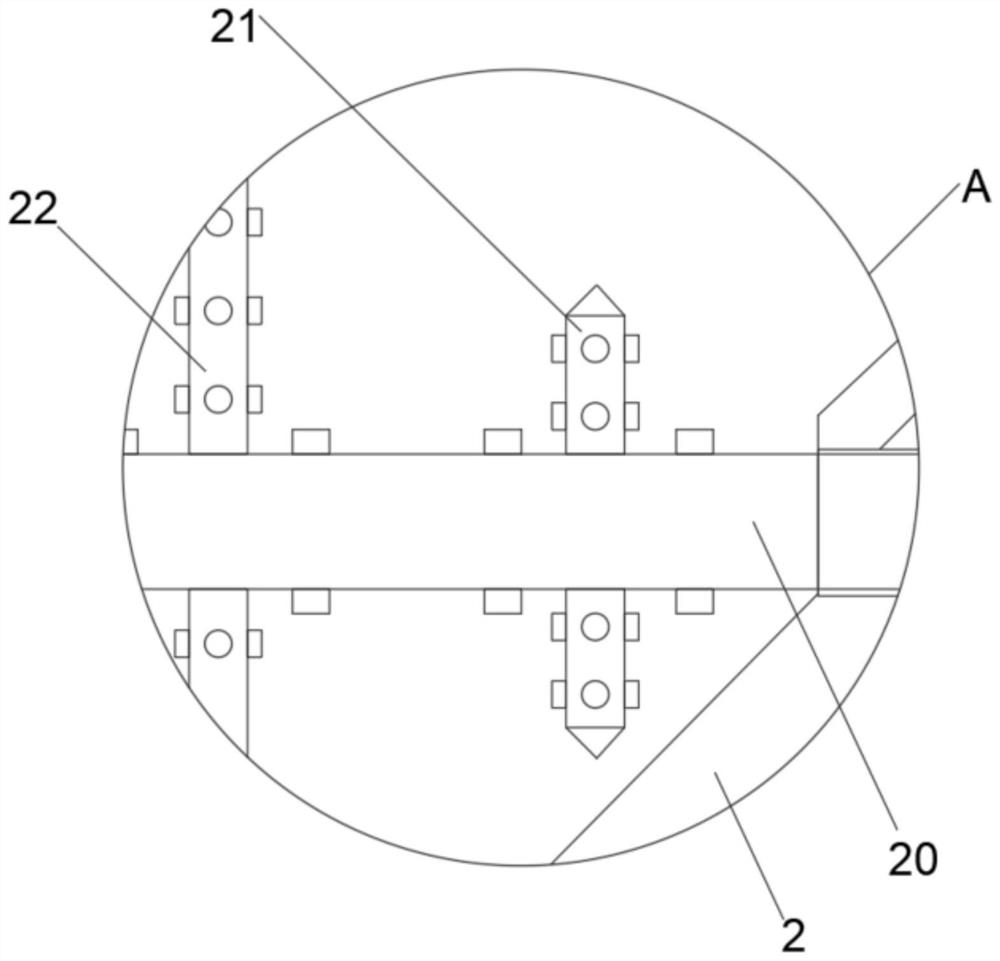

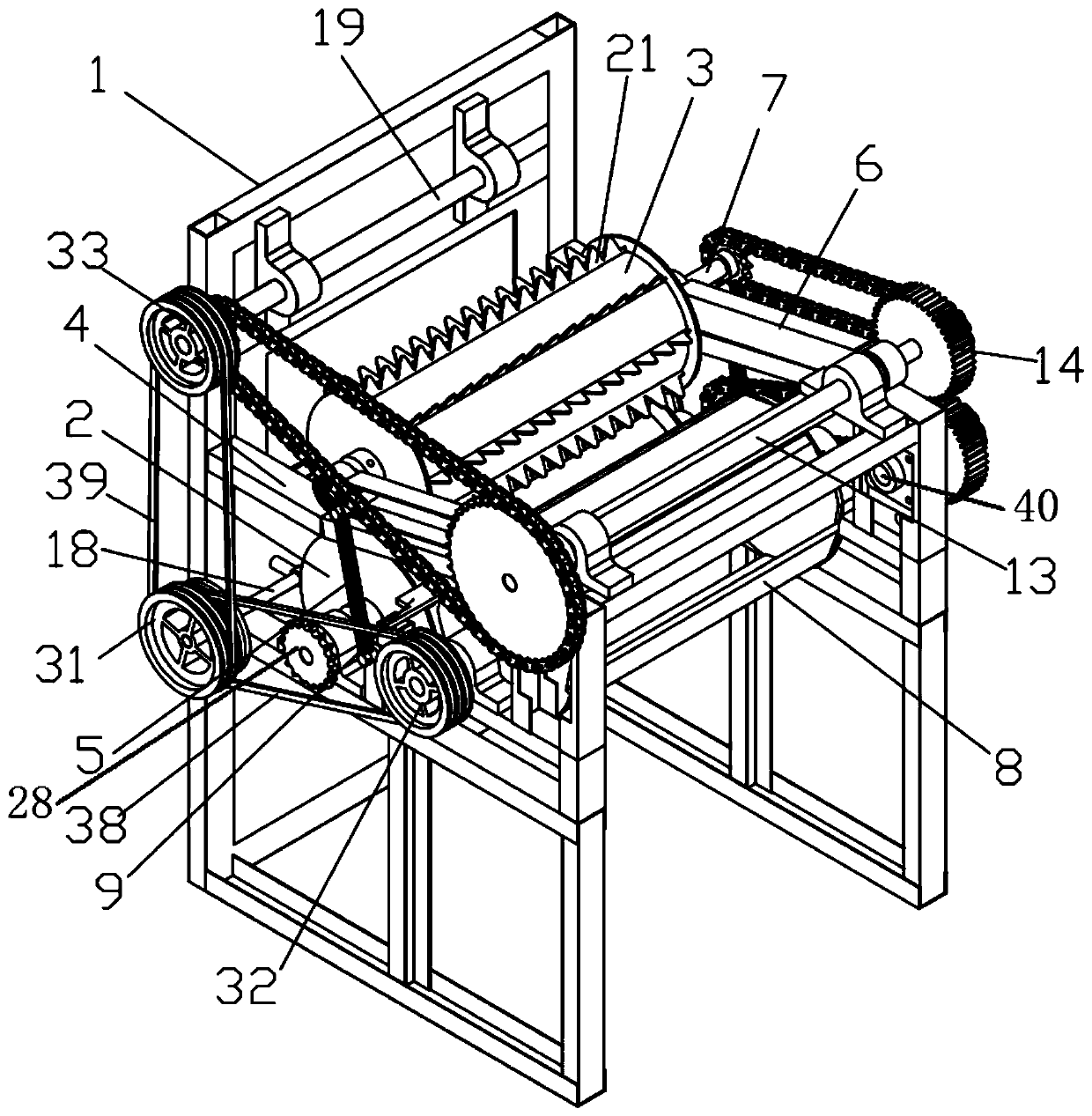

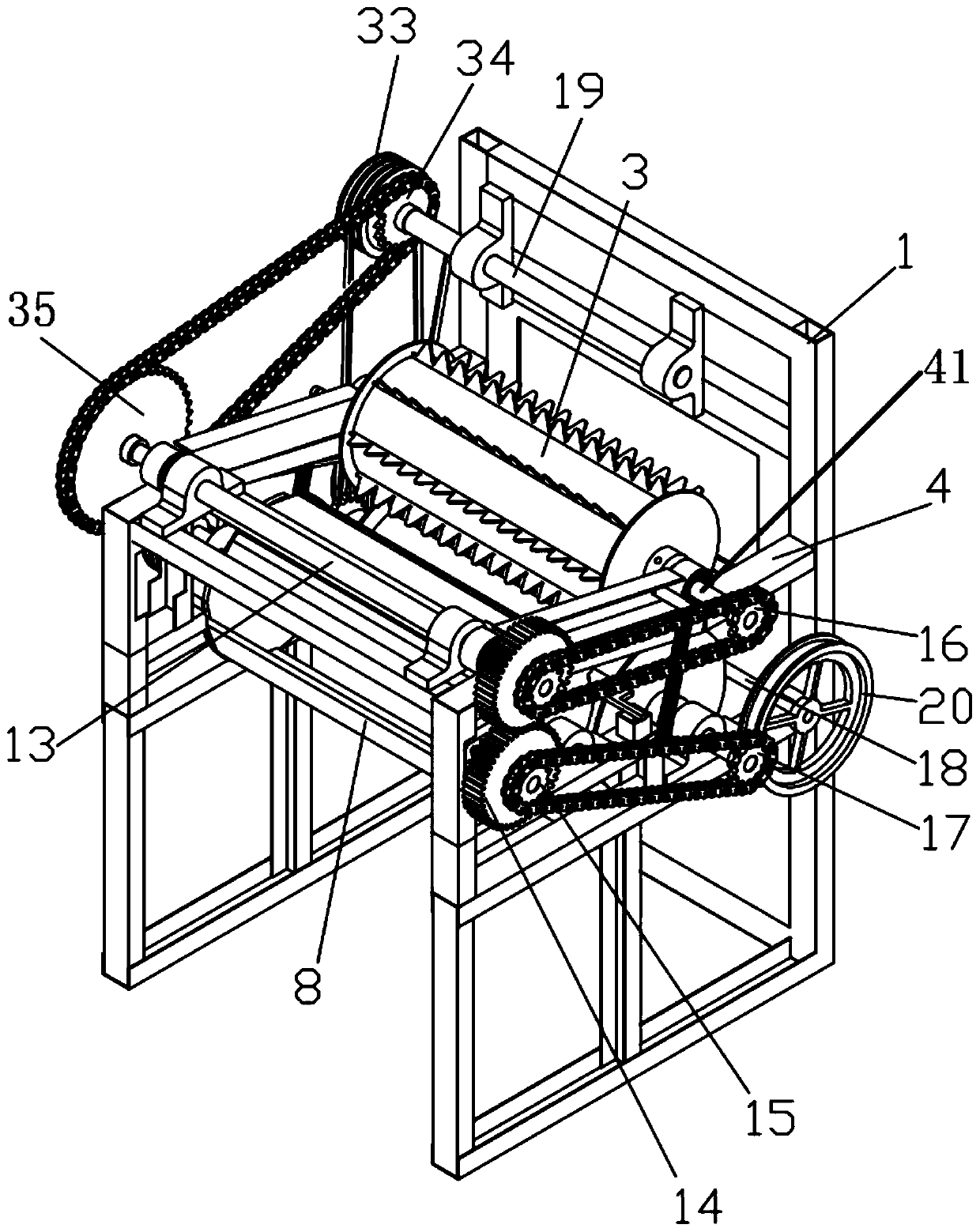

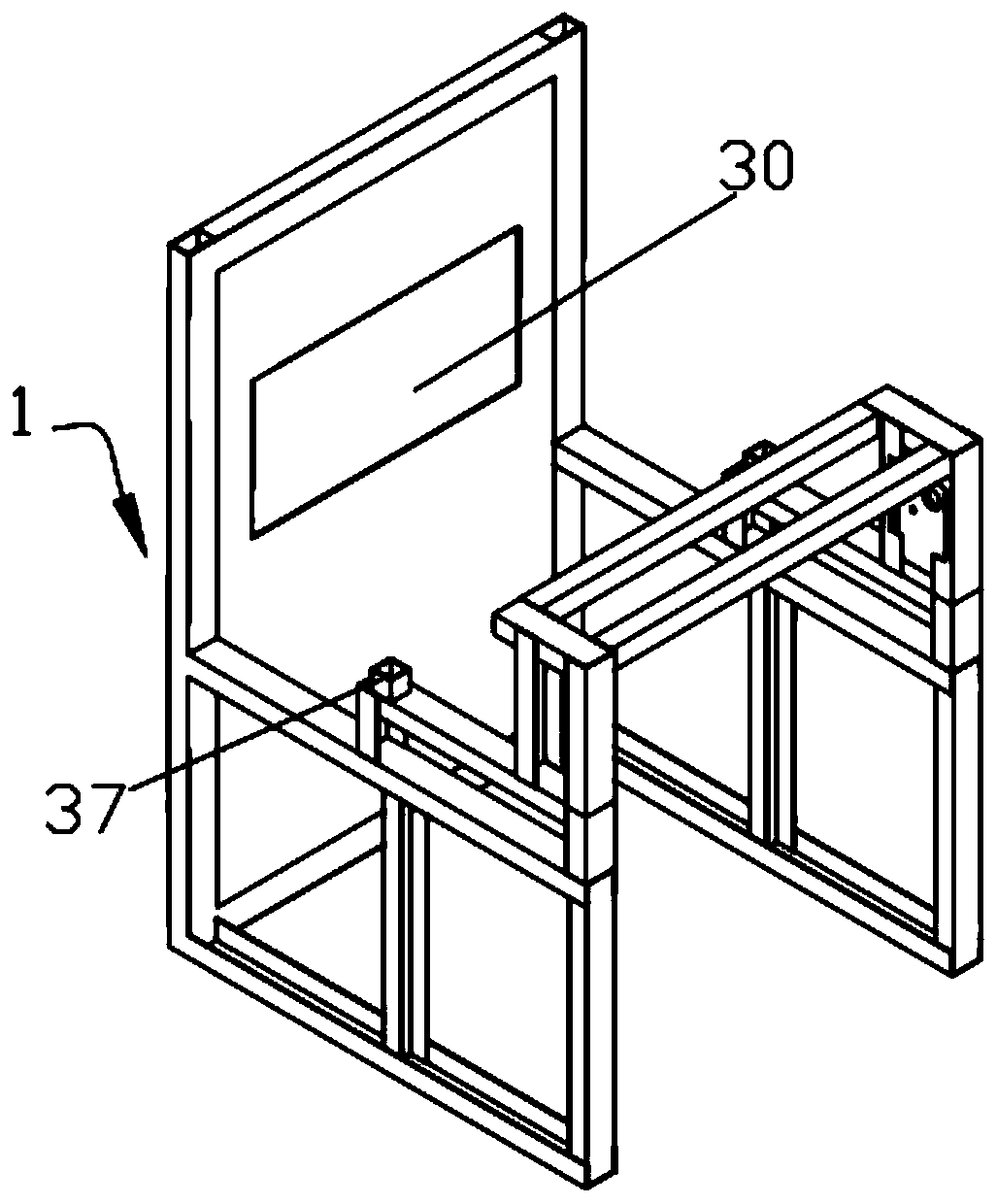

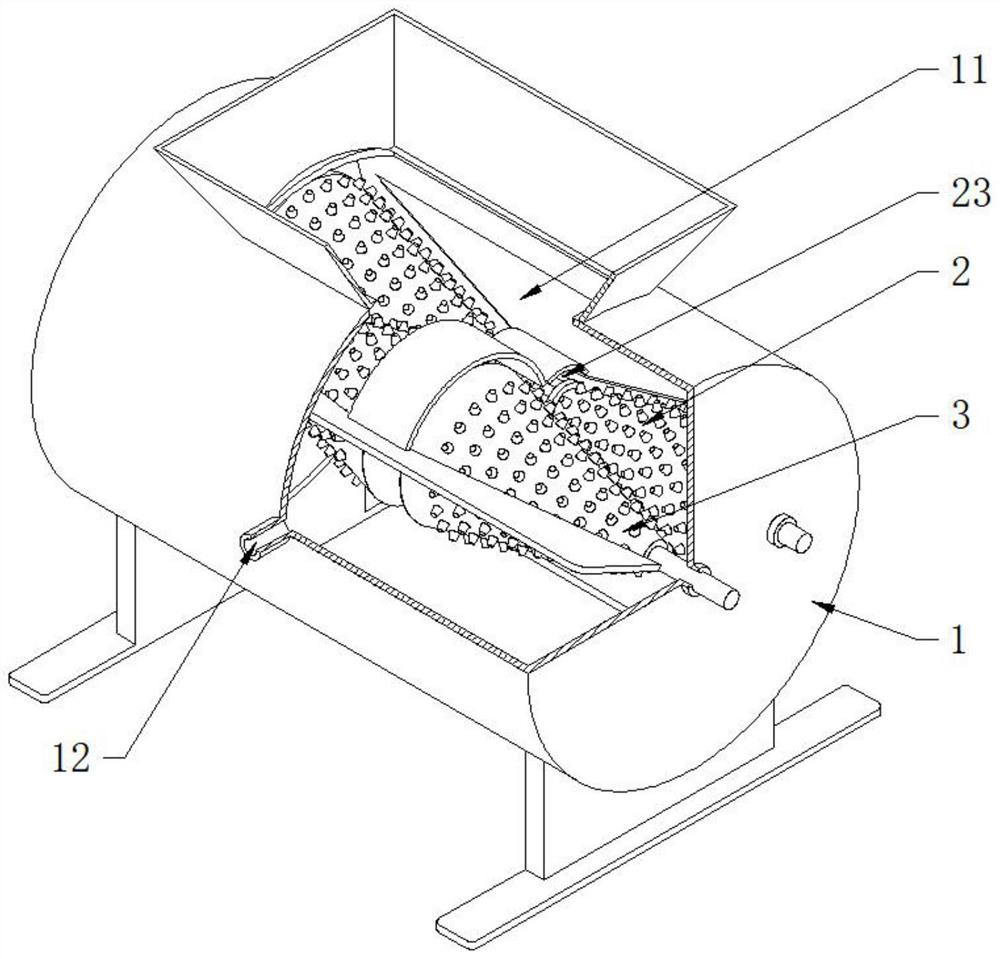

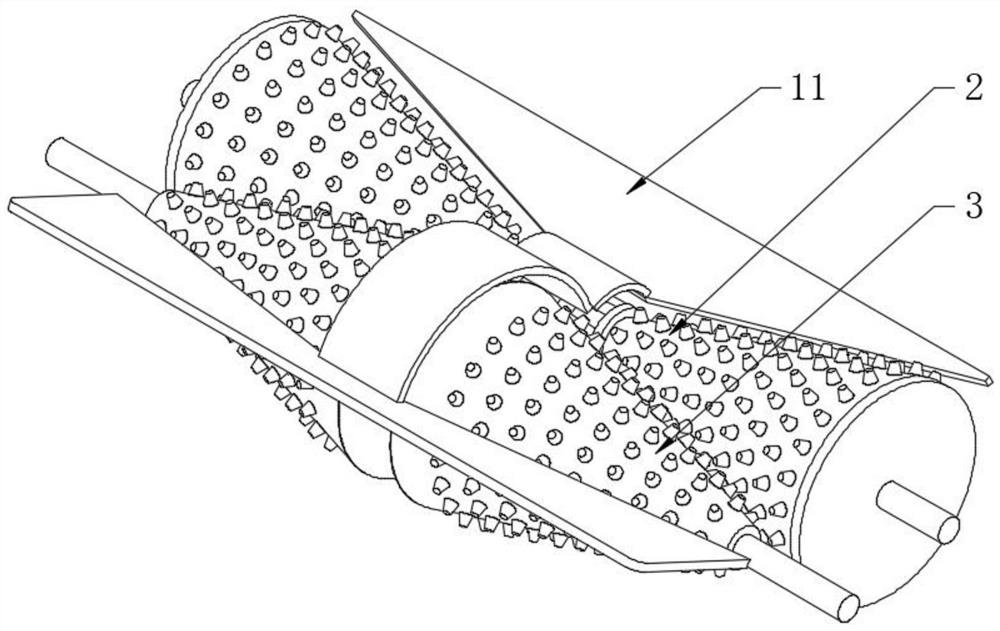

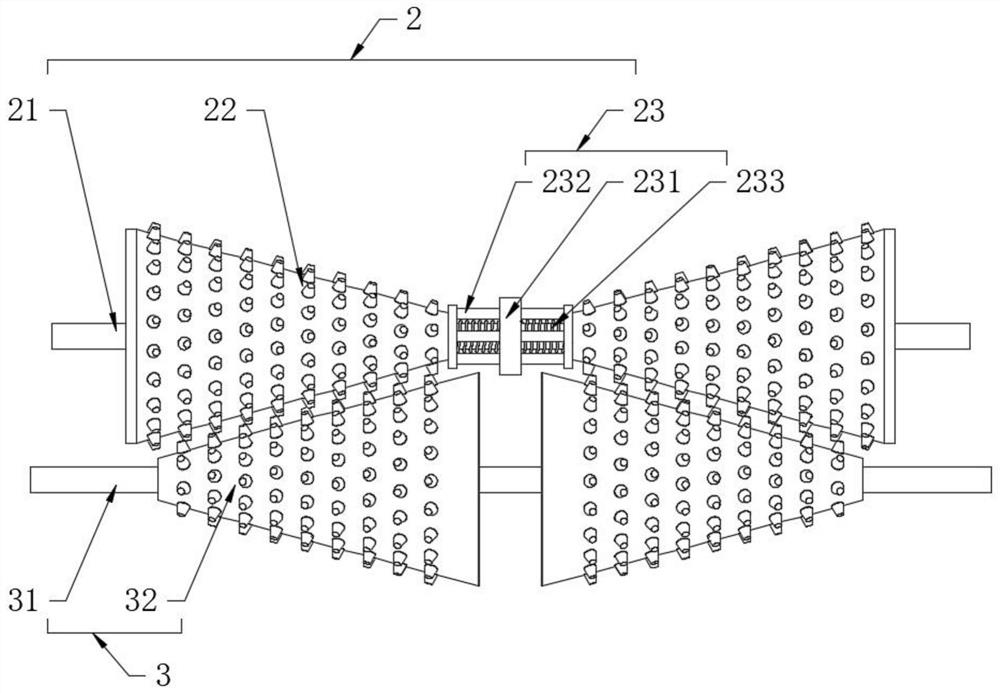

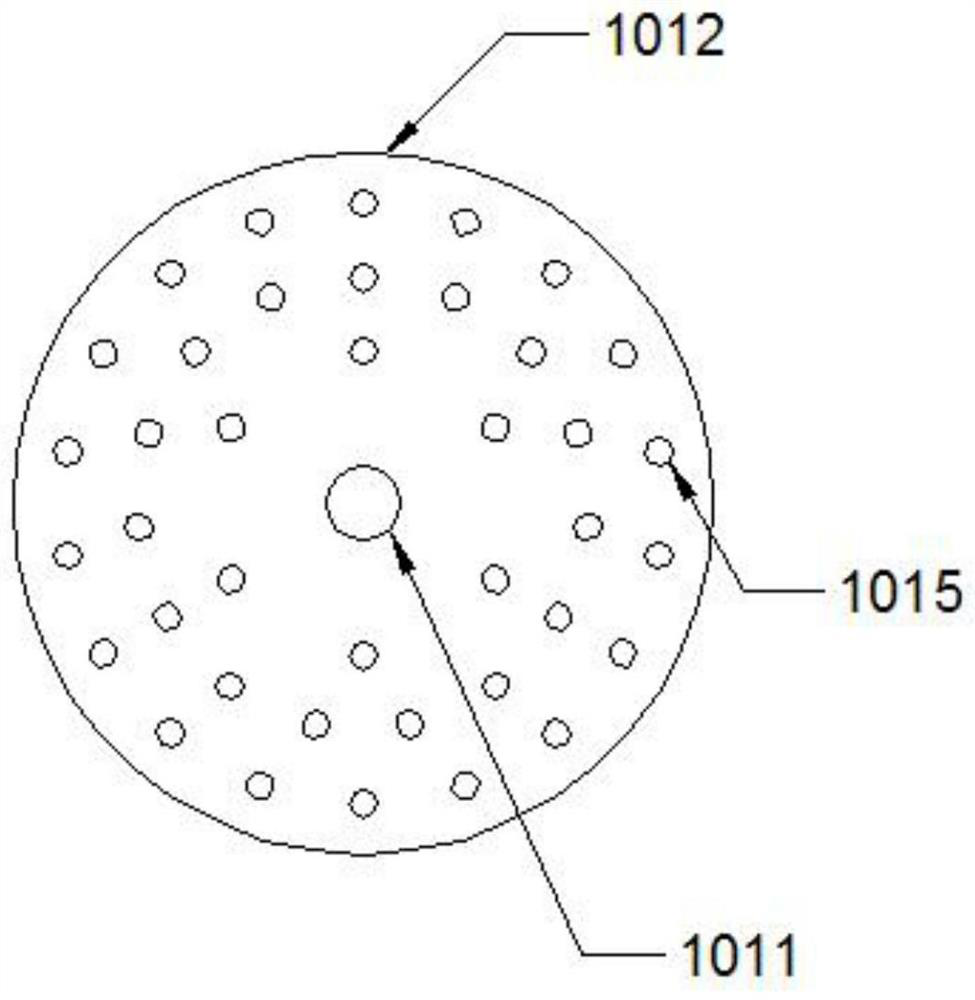

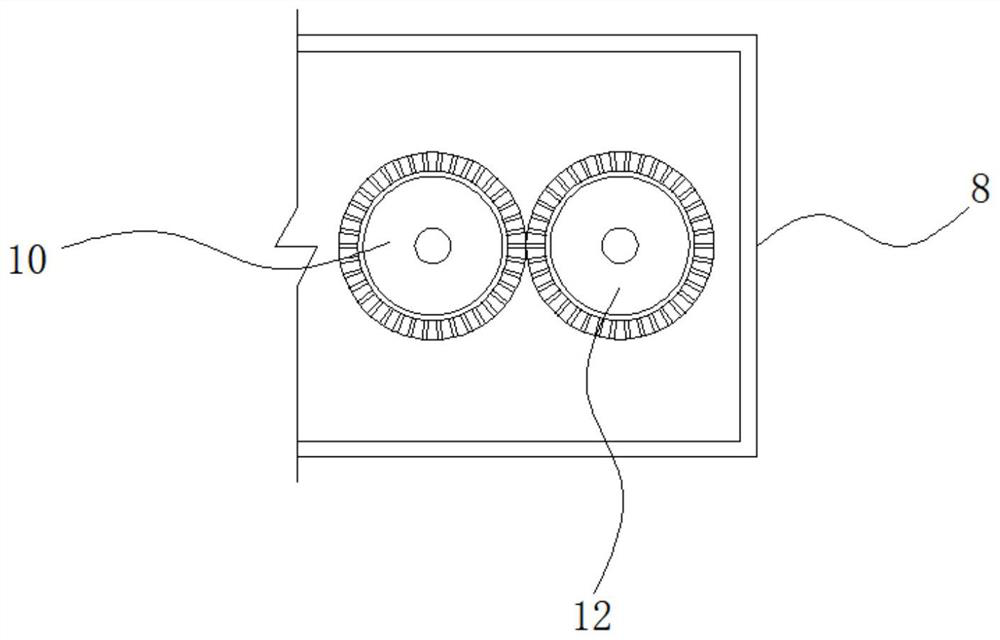

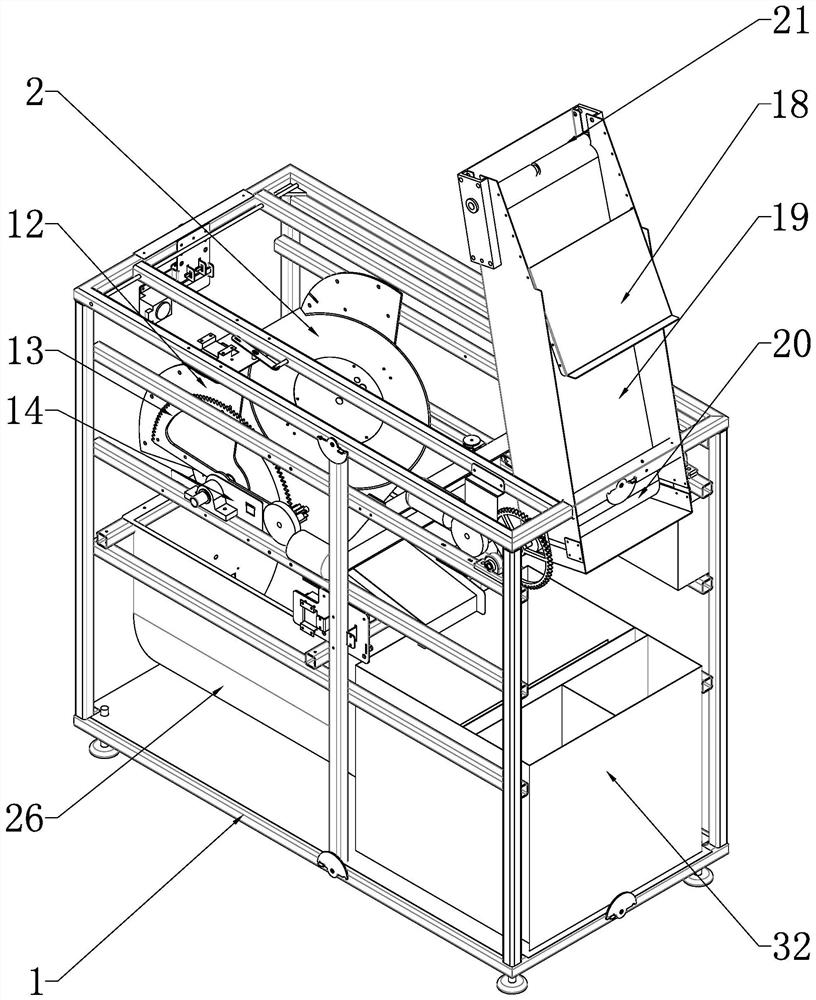

Roller-type feeding and shredding device

The invention discloses a roller-type feeding and shredding device. The roller-type feeding and shredding device includes a rack, a feeding mechanism and a shredding mechanism, wherein the feeding mechanism and the shredding mechanism are installed on the rack; a discharge hole of the feeding mechanism is aligned with a feeding hole of the shredding mechanism; the feeding mechanism comprises a lower pressing roller, an upper pressing roller, an upper pressing roller lower limit assembly, a tension spring and a swinging member, wherein the lower pressing roller and the upper pressing roller synchronously rotate in opposite directions, and the lower pressing roller is pivotally connected with the rack; one end of the swinging member is pivotally connected with the rack, the other end of theswinging member is pivotally connected with an upper pressing roller shaft, and the swinging member is supported on the upper pressing roller lower limit assembly together with the upper pressure roller; the upper end of the tension spring is connected with the end, close to the upper pressing roller shaft, of the swinging member, and the lower end of the tension spring is connected with the portion, located below the upper pressing roller lower limit assembly, of the upper pressing roller. The roller-type feeding and shredding device has the advantages of self-adaptive and adjustable materialfeeding gap, uniform and controllable shredding length, strong anti-winding performance, stable and reliable work and high work efficiency during operation.

Owner:HUNAN AGRICULTURAL UNIV

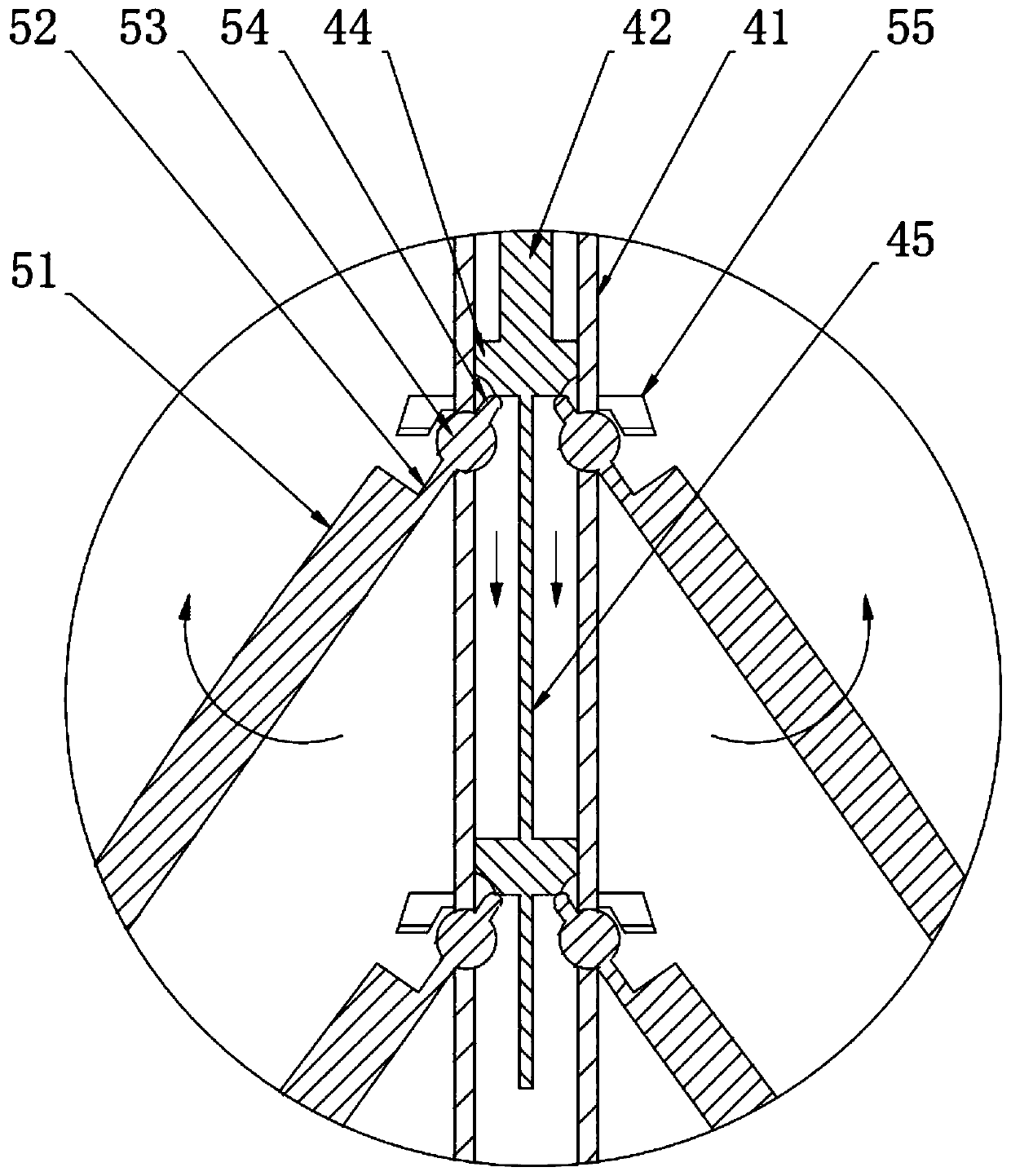

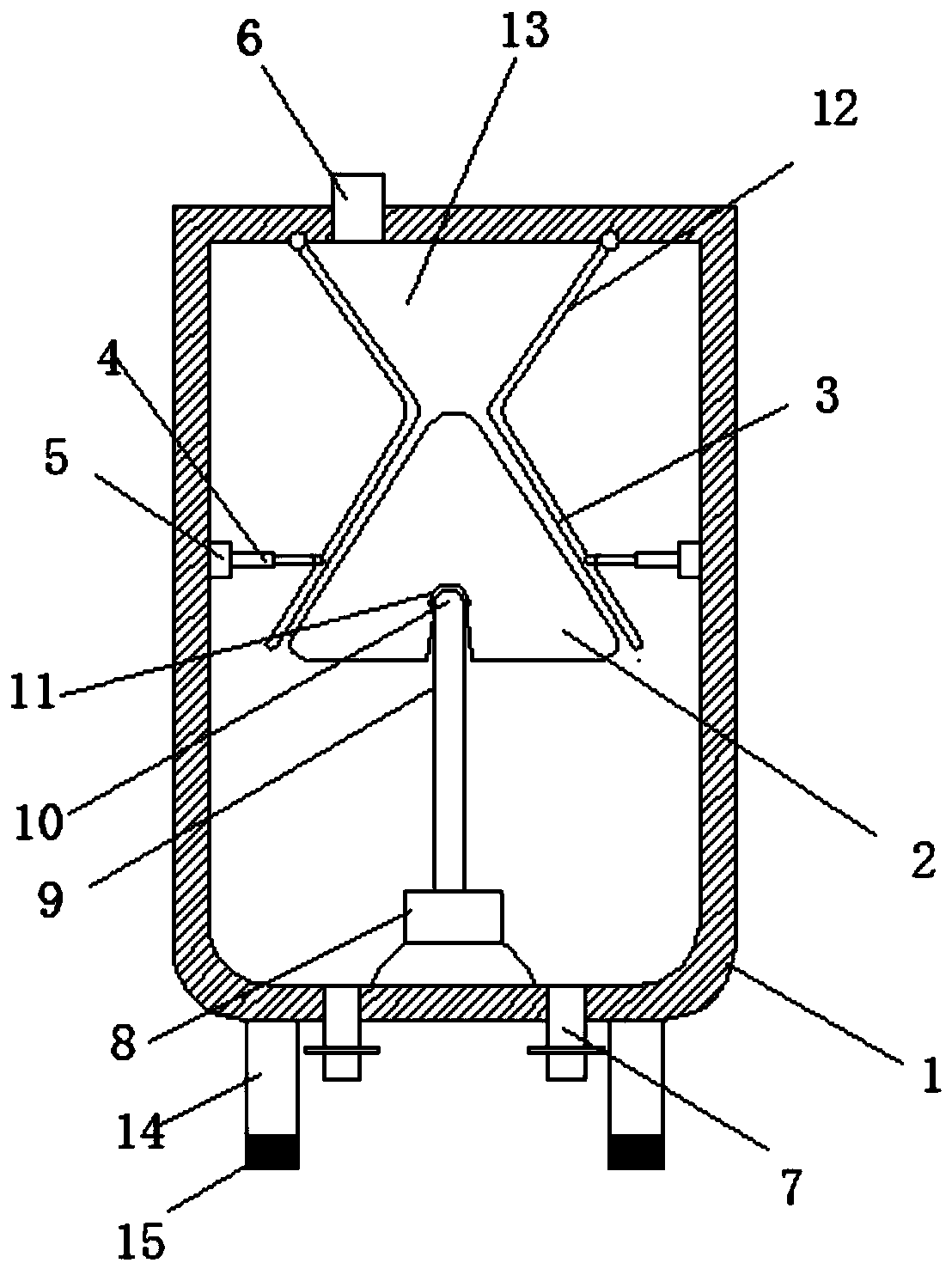

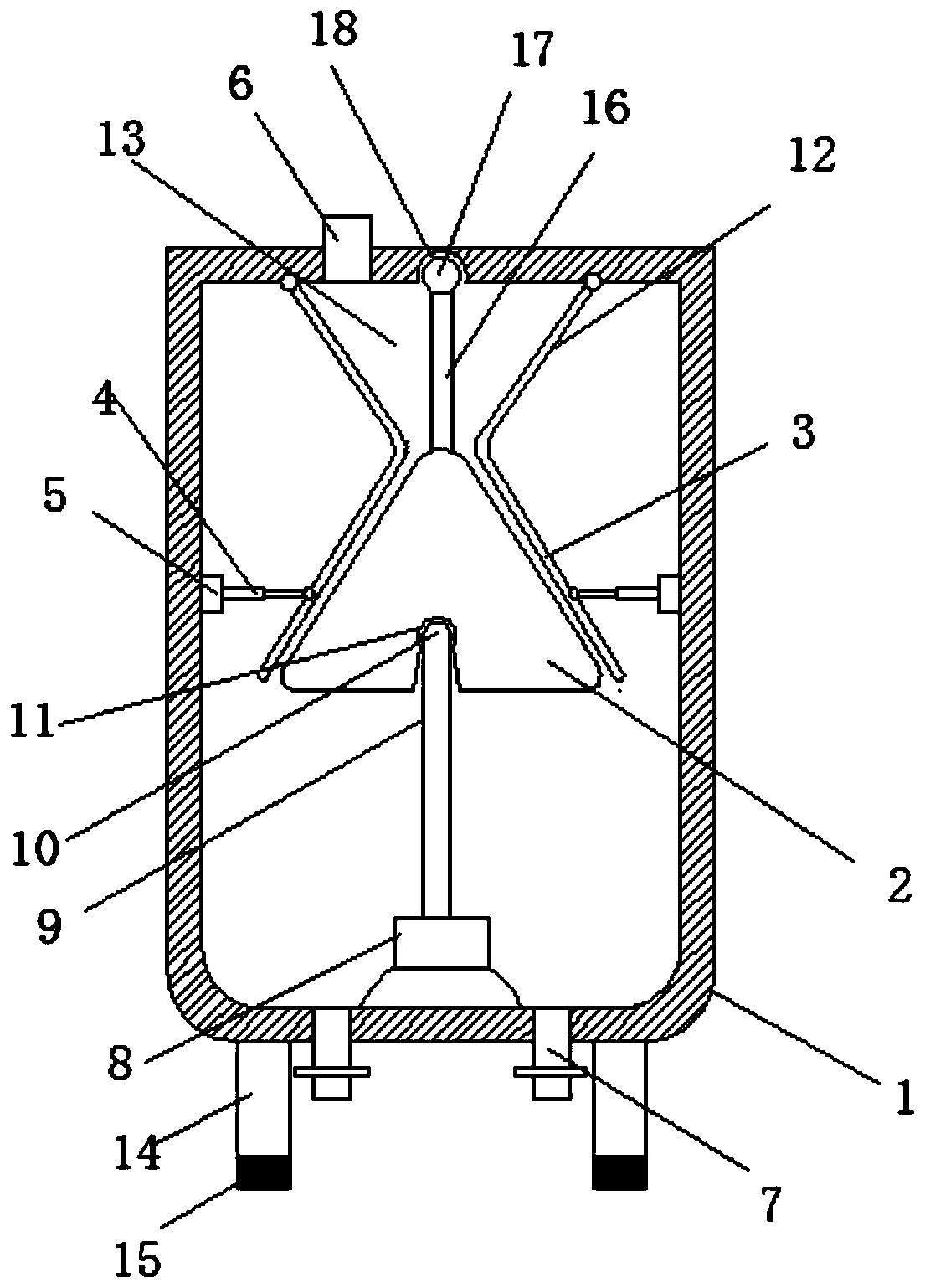

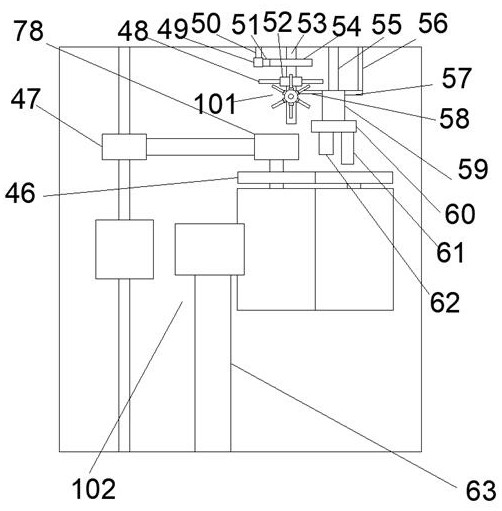

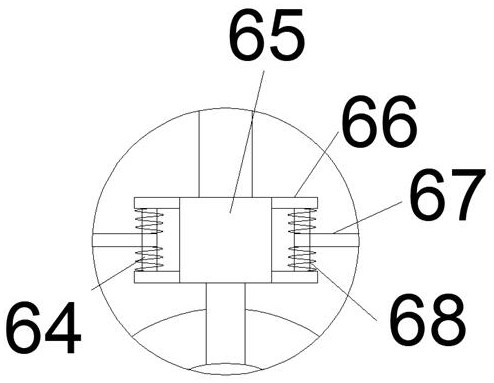

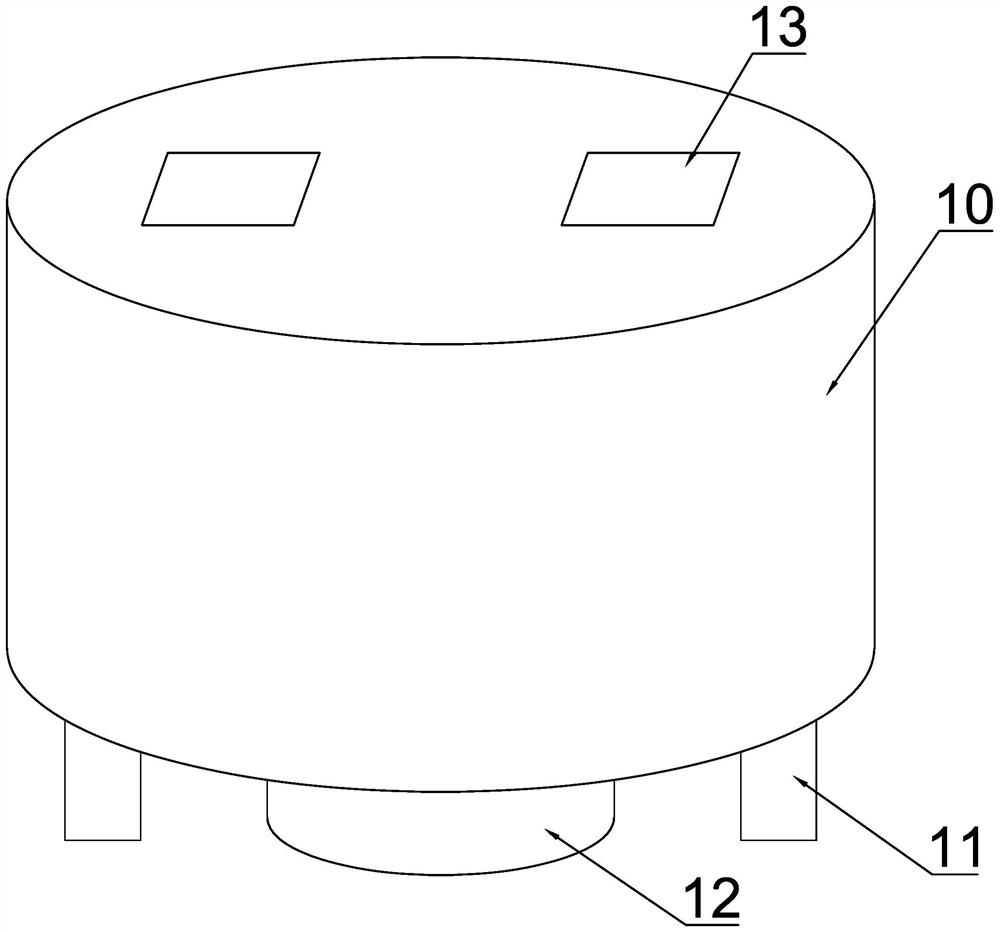

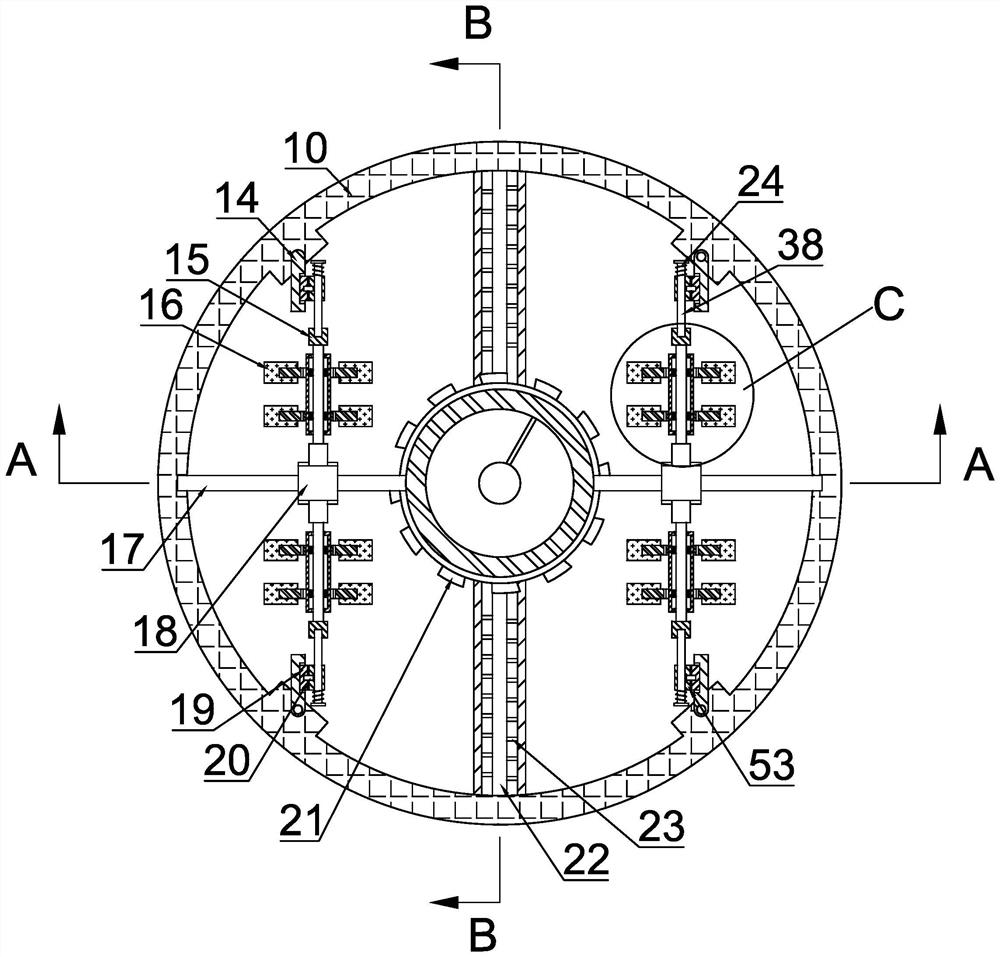

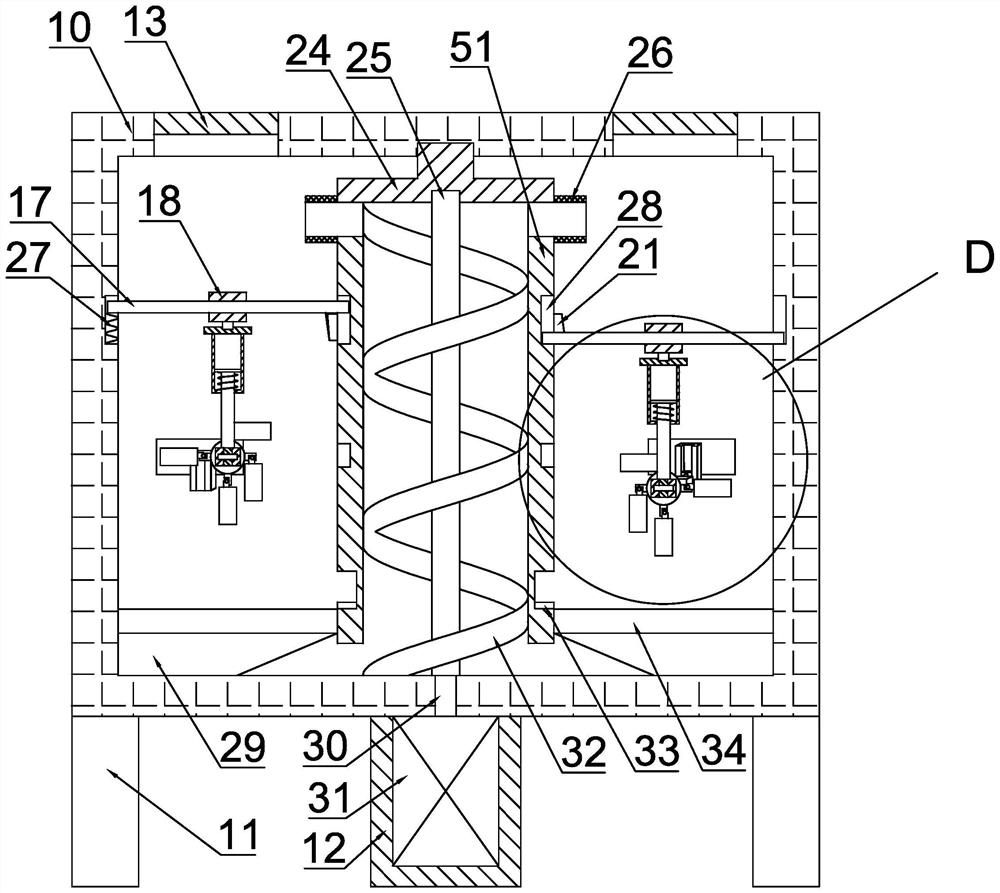

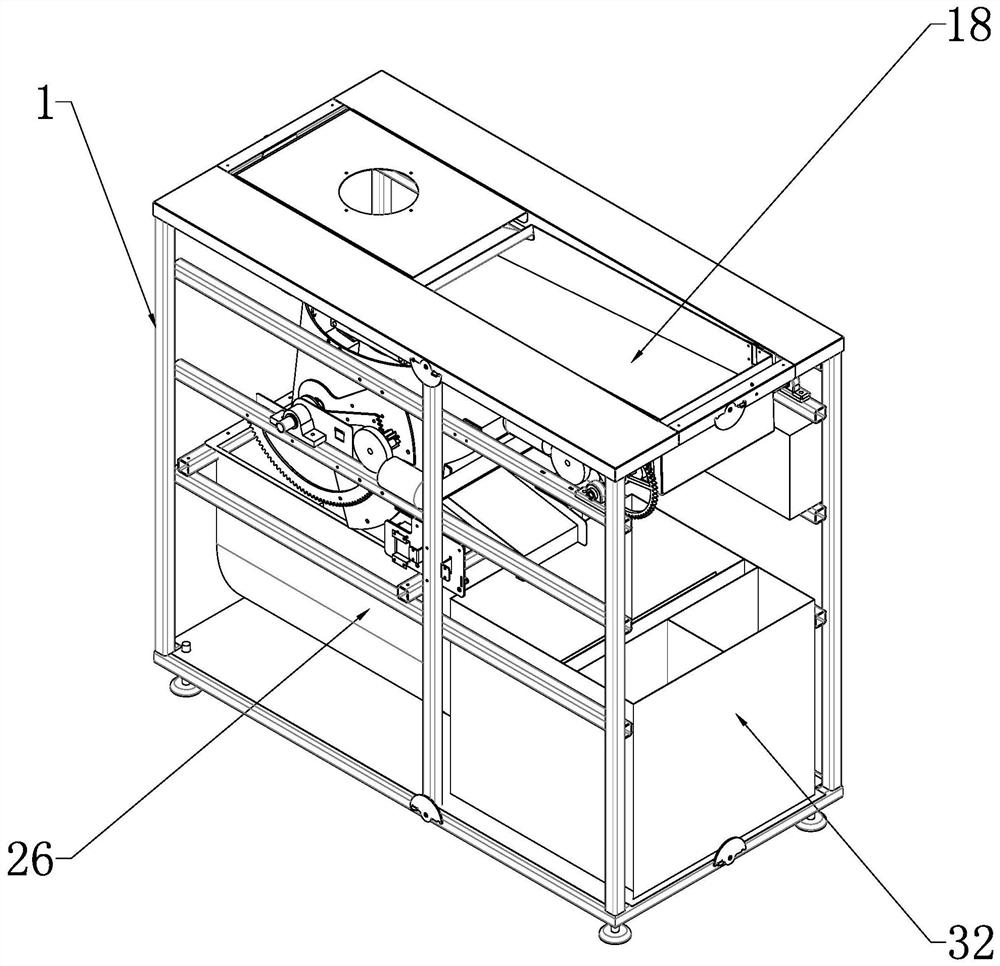

High-performance reaction kettle stirrer for chemical machinery

InactiveCN111790343AImplement buffer protectionRealize shreddingTransportation and packagingMixer accessoriesProcess engineeringMechanical engineering

The invention discloses a high-performance reaction kettle stirrer for chemical machinery, belongs to the technical field of chemical production, and solves the problem of non-uniform material mixingcaused by incapability of crushing caked raw materials by stirring blades in an existing device. The reaction kettle stirrer is technically characterized by comprising a kettle body and a feeding port, wherein the bottom of the kettle body is fixedly installed on a buffer base, a stirring cavity is formed in the kettle body, the feeding port is formed in the center of the upper surface of the kettle body, the feeding port communicates with the stirring cavity, a driving assembly is arranged in the stirring cavity and connected with a mixing assembly, and a crushing assembly is arranged below the mixing assembly. According to the embodiment of the invention, by arranging the buffer assembly, buffer protection of the mixing assembly is achieved, damage to the mixing assembly is avoided, andmixing and stirring of materials are facilitated; and the swing plate swings to smash the materials, and the arranging of the crushing assembly achieves the smashing treatment of raw materials, so that the uniformity of the particle size of the raw materials is guaranteed.

Owner:辛树成

Production device and method of graphite carbon block

The invention discloses a production device and method of a graphite carbon block. The production device of the graphite carbon block comprises a hopper, a cavity is formed in the hopper, and a firstsliding groove is formed in the inner wall of one side of the cavity; a first plate is slidably arranged in the first sliding groove, and a second sliding groove is formed in the inner wall of the other side of the cavity; a second plate is slidably arranged in the second sliding groove, and a sieve plate which is obliquely arranged is fixedly arranged on the sides, close to each other, of the first plate and the second plate; a baffle is fixedly arranged at the top of the second plate, and the baffle is in sliding connection with the second sliding groove; a mounting plate fixedly arranged onthe side wall of the second sliding groove is arranged on the side, away from the cavity, of the second plate. The device is high in practicability, simple in structure and convenient to operate, rawcoal can be conveniently screened, and large-particle raw coal can be further ground and crushed, so that the particles of the raw coal are smaller, the production quality of the graphite carbon block is improved, and people can conveniently use the graphite carbon block.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

A high-efficiency pulverizer for energy-saving building construction garbage

ActiveCN111841735BRealize shreddingImprove crushing efficiencyGrain treatmentsConstruction engineeringStructural engineering

The invention discloses a high-efficiency crushing processor for energy-saving building construction garbage, which comprises a crushing machine shell, a crushing roller one and a crushing roller two. In the present invention, the crushing roller 1 includes a support shaft 1, a crushing cylinder 1 and an axial guide combination, the number of the crushing cylinder 1 is two and is coaxially distributed and set on the support shaft 1, and the axial guide combination fixed sleeve It is arranged on the support shaft 1 and is located between the two crushing cylinders 1. The crushing roller 2 includes the support shaft 2 and the crushing cylinder 2 sleeved on the support shaft 2. The number of the crushing cylinders 2 is two and is conical. The big ends of the two crushing tubes are opposite to each other. The taper of the crushing tube 2 and the crushing tube 1 are the same. The crushing tube 2 and the crushing tube 1 form two crushing gaps. One crushing gap increases dynamically, and the other crushing gap decreases synchronously. One crushing gap is passively increased to crush large-volume garbage, and the other crushing gap is synchronously reduced to continue crushing small-volume garbage, achieving complete crushing of all kinds of garbage.

Owner:广东创晟控股集团有限公司

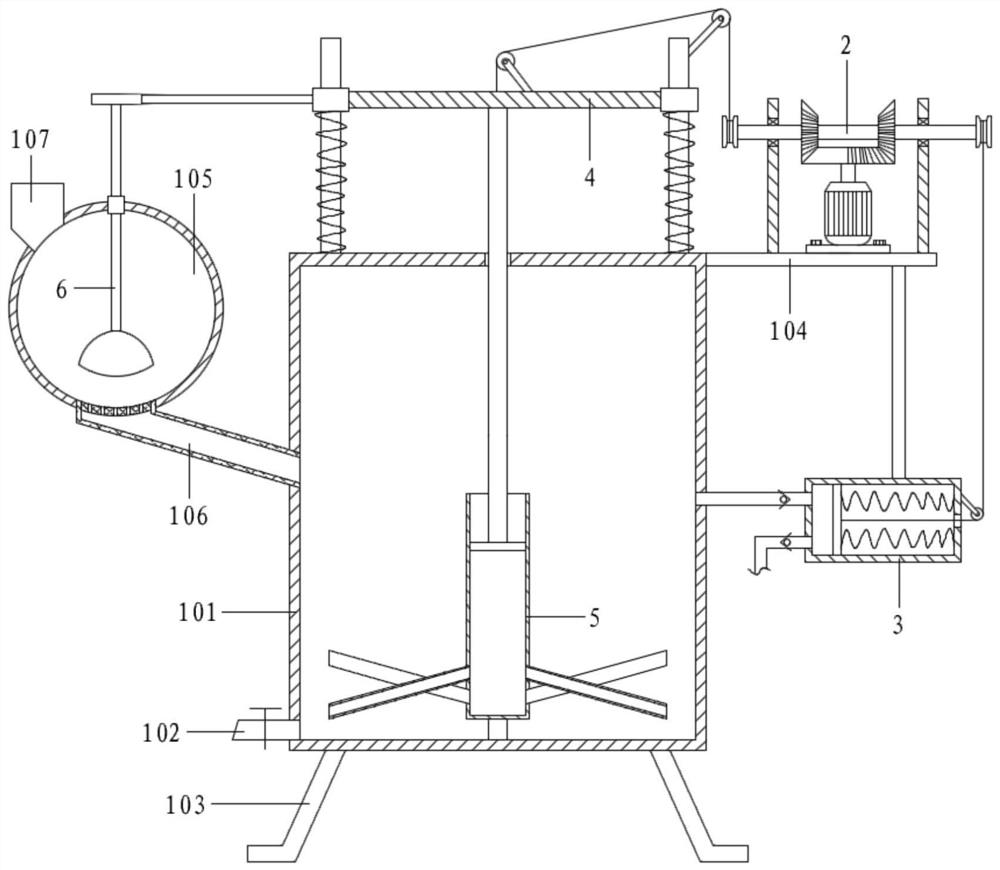

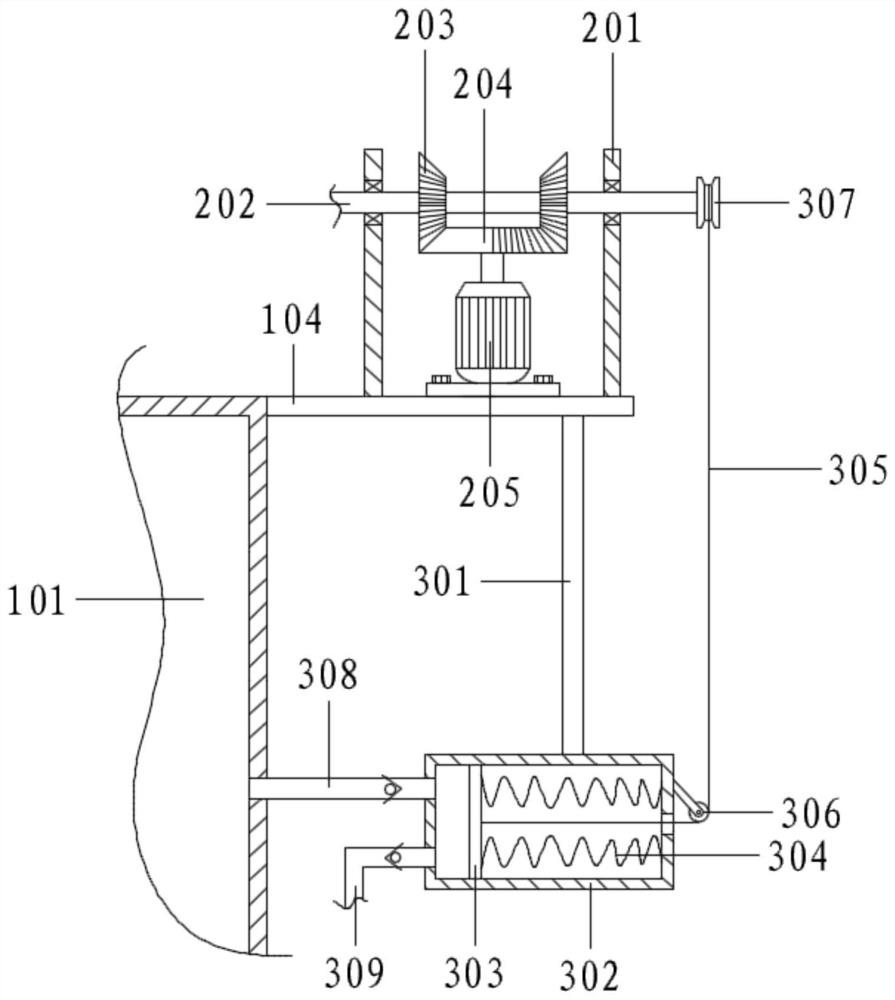

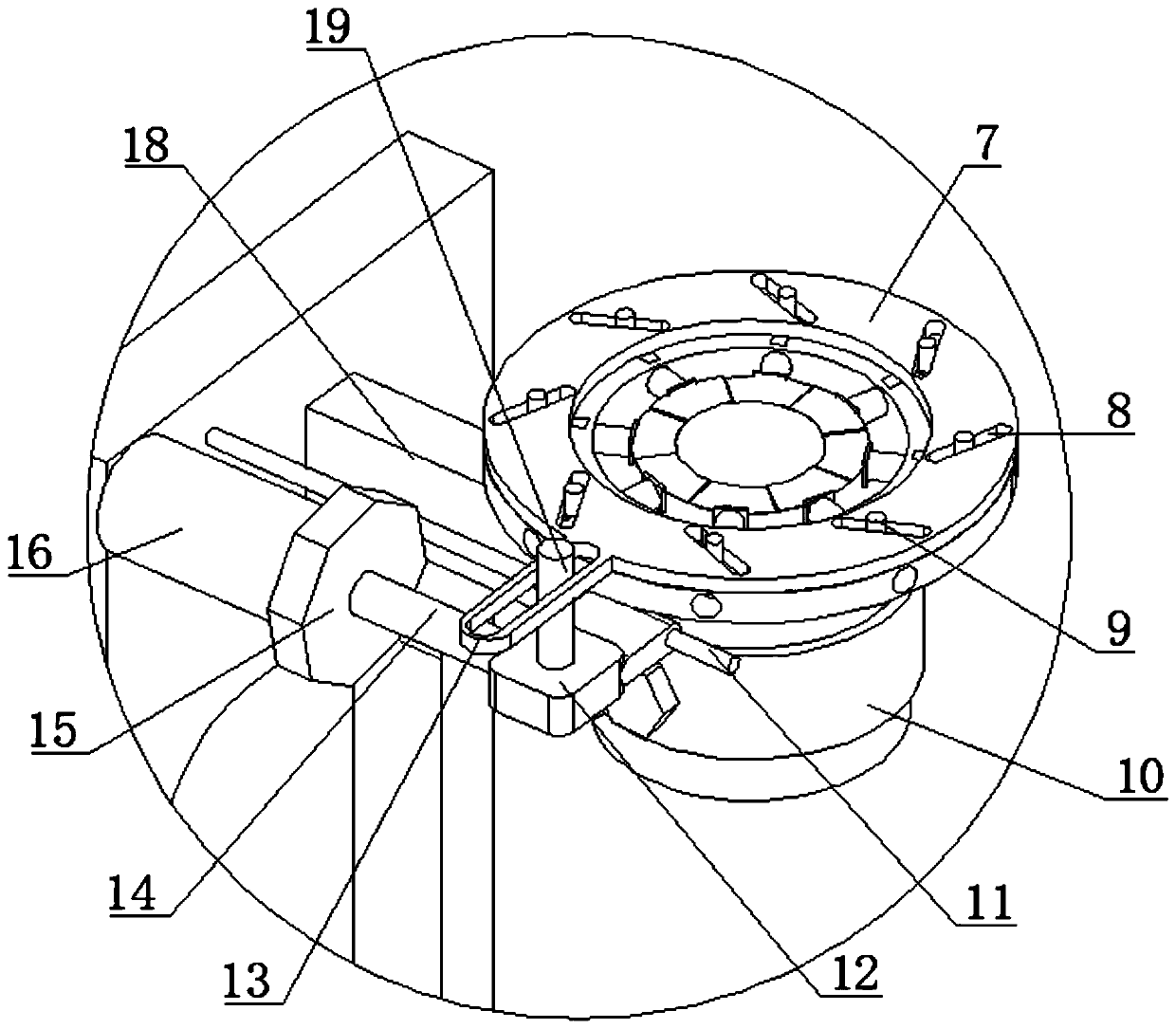

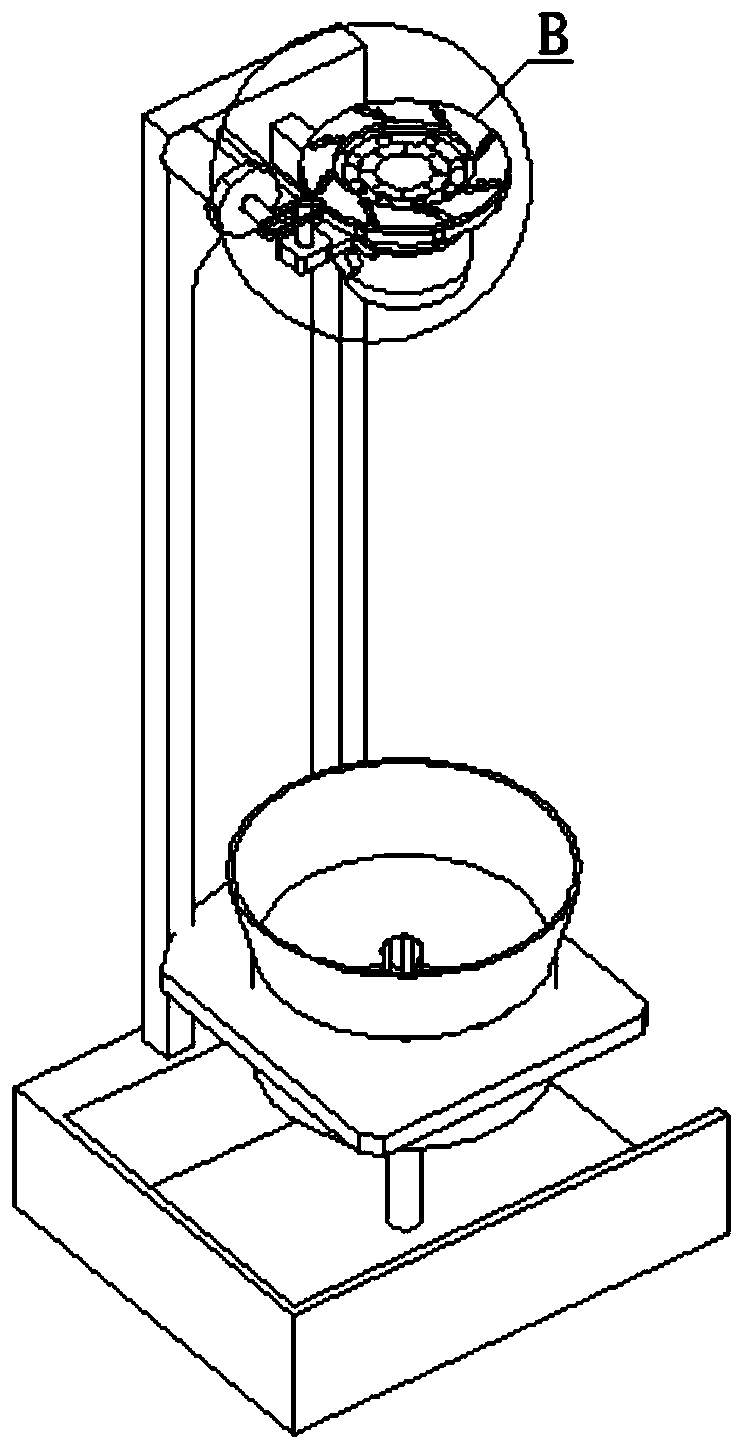

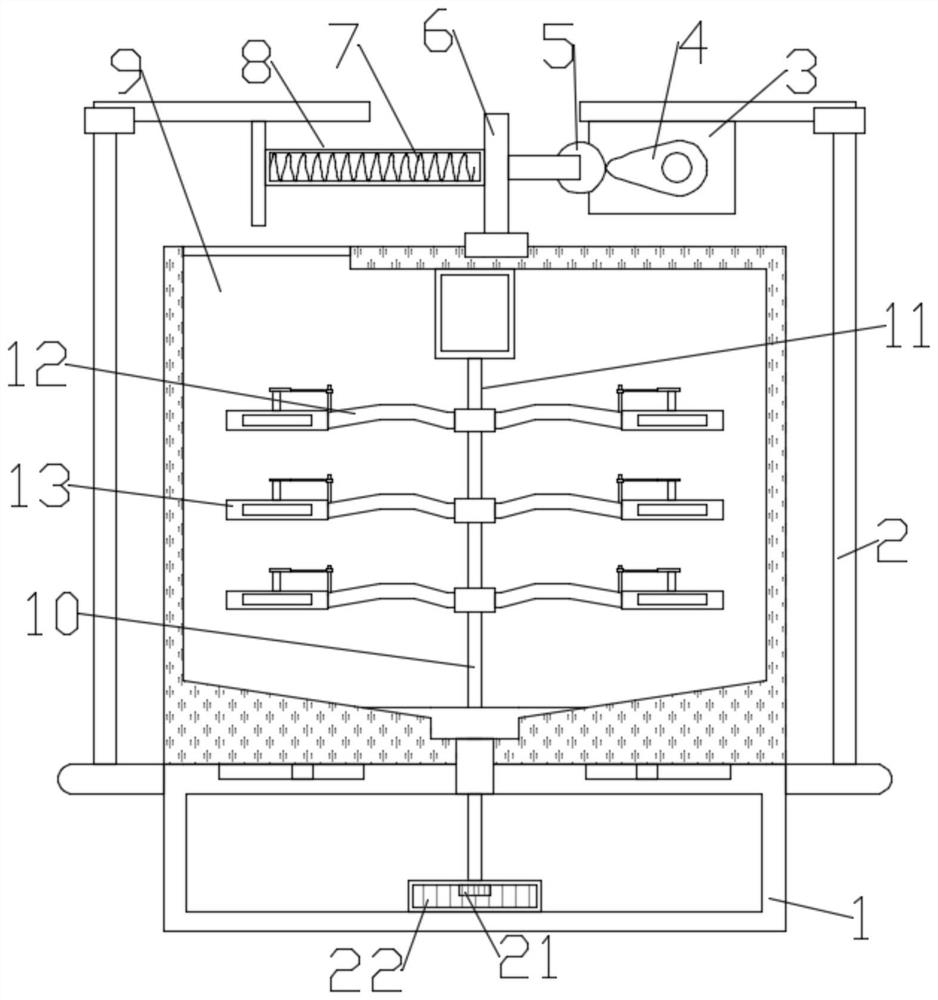

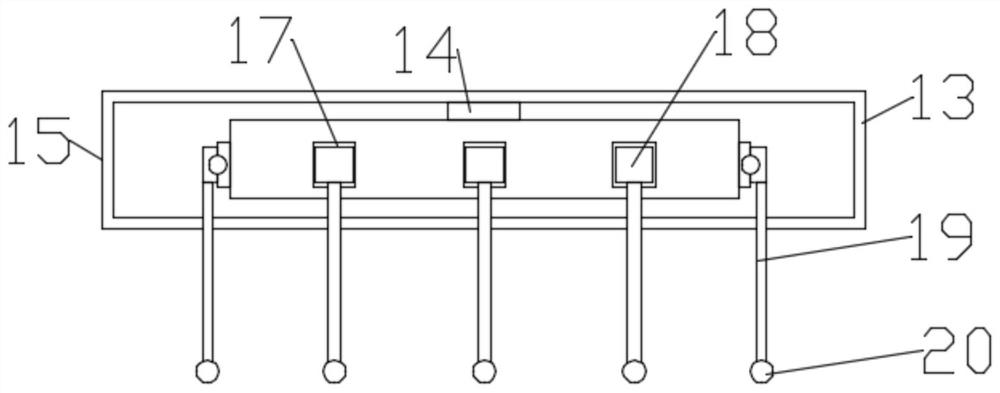

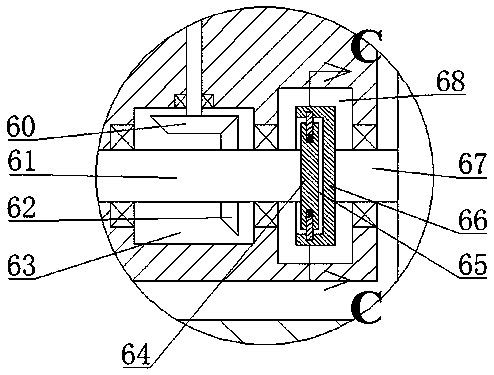

Raw material stirring device for highway bridge duct grouting

InactiveCN111805747ARealize shreddingAchieve protectionCement mixing apparatusGrain treatmentsElectric machineArchitectural engineering

The invention discloses a raw material stirring device for highway bridge duct grouting, and belongs to the technical field of bridge construction. The raw material stirring device for the highway bridge duct grouting solves the problem that an existing device cannot crush a blocky raw material and affects the stirring effect. The device is technically characterized by comprising a base, a supportand a stirring box, wherein the stirring box is arranged on the base, the support is arranged outside the stirring box, a stirring assembly is arranged inside the stirring box, a smashing assembly used for smashing the raw material is installed on the stirring assembly, a motor installation base is fixedly installed at the top of the support, and a servo motor is fixedly installed on the motor installation base. According to the embodiment of the invention, the smashing assembly is arranged, the smashing treatment on the blocky raw material in the stirring box is realized, the protection on aswinging rod and a striking block is realized through arrangement of an outer protection ring, and meanwhile, the striking block can be limited, so that the striking block is prevented from strikingthe side wall of the stirring box in a swinging process, and the service life of the stirring box is prolonged.

Owner:邓小军

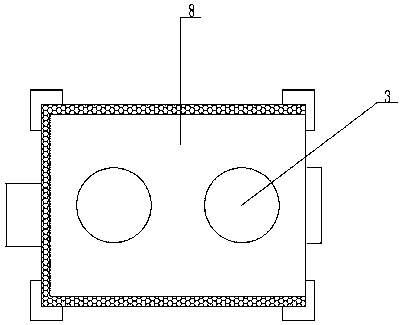

Secondary water supply device

InactiveCN111749305AReliable connectionEasy inspection and maintenanceService pipe systemsWater mainsPondageWater storage tank

The invention provides a secondary water supply device comprising a water storage tank, a filtering box and a pressurizing box. The left side face of the water storage tank is provided with a first transverse through pipe. The top of the first transverse through pipe is provided with a water inlet pipe. The right side face of the water storage pipe communicates with the left side face of the filtering tank through a second transverse through pipe. The bottom of the filtering box is provided with a smashing chamber. A power box is arranged at the bottom of the smashing chamber. The right side face of the filtering box communicates with the left side face of the pressurizing box through a third transverse through pipe. The right side face of the pressurizing box is provided with a fourth transverse through pipe. The bottom of the fourth transverse through pipe is provided with a water outlet pipe. A pressure transmitting box is arranged below the pressurizing box. The left side wall andthe right side wall in the water storage tank are provided with a first electric cylinder base plate and a second electric cylinder base plate correspondingly. The secondary water supply device can effectively solve the technical problems that in the prior art, the functions of automatically controlling the amount of stored water, filtering and smashing impurities, conducting classified pressurization and the like are not achieved, and the secondary water supply device is beneficial for application and popularization.

Owner:贺俊威

Efficient crushing device for quartz sand

PendingCN110124781AImprove grinding effectImprove grinding efficiencyNon-rotating vibration suppressionGrain treatmentsArchitectural engineeringDrive motor

The invention discloses an efficient crushing device for quartz sand. The efficient crushing device comprises a box. A feeding opening and discharging openings are formed in the top and the bottom ofthe box correspondingly. A movable cone and a fixed cone cooperating with the movable cone are further arranged in the box. The top of the fixed cone is hinged to the inner top wall of the box. The bottom of the fixed cone is connected with telescopic rods, and the other end of each telescopic rod is connected with an output shaft of a telescopic air cylinder fixed to the inner wall of the box. Adrive motor is fixed to the bottom wall of the box. A main shaft is connected to an output shaft of the drive motor. A spherical tile is arranged at the top of the main shaft. A spherical supporting portion is upwards arranged in the middle of the bottom of the movable cone. The movable cone is mounted on the spherical tile at the top of the main shaft through the supporting portion. The crushingdevice has the advantages of being good in crushing effect and high in crushing efficiency, the crushing clearance can be adjusted, and therefore the crushing requirements of different quartz sand rawmaterials are met.

Owner:新沂市引河石英材料有限公司

Device for extracting active ingredients in burdock

PendingCN114225471ARealize shreddingFully cleanedGas solvent extractionSolid solvent extractionDistillationProcess engineering

The invention discloses a device for extracting active ingredients in burdock. The device comprises a cleaning barrel internally provided with a material placing rack, a crushing rod is arranged in the crushing chamber; a feeding hole formed in the distillation chamber is hermetically communicated with a discharging hole formed in the bottom of the crushing chamber through a feeding pipeline; the condensation assembly comprises a condenser communicated with the distillation chamber through a breather pipe, a receiving bottle communicated with the breather pipe is arranged below the condenser, and the filter plate is located below the feed port and the breather pipe; the negative pressure pump is hermetically communicated with the distillation chamber through a gas delivery pipe; the steam generator is hermetically communicated with the distillation chamber through a steam conveying pipeline I; and the drying box is in sealed communication with the receiving bottle through a liquid conveying pipe, one end of the liquid conveying pipe extends into the drying box, and an atomizing nozzle is fixedly arranged at the end. According to the burdock cleaning device, damage-free cleaning of burdock for active ingredient extraction is achieved, full extraction of all active ingredients in the burdock is achieved, and the requirement for processing and utilizing all the active ingredients in the burdock is met.

Owner:XUZHOU UNIV OF TECH

Multilevel pulp pulverizer for papermaking

ActiveCN109082918ARealize shreddingAvoid adsorptionRaw material divisionPulp and paper industryPulverizer

The invention discloses a multilevel pulp pulverizer for papermaking. The pulverizer comprises a machine body, a feeding inlet, a crushing cavity, a discharge opening and a working motor; the machinebody is internally provided with the crushing cavity, and the feeding inlet is formed in the middle of the upper portion of the machine body; the pulverizer is characterized in that the feeding inletis communicated with the crushing cavity, the discharge opening is formed in the lower portion of the machine body, a discharge cavity is formed in the upper portion of the discharge opening, the upper portion of the discharge cavity is communicated with the crushing cavity, the working motor is arranged on the upper left of the machine body, and a sieve plate is movably arranged in the dischargecavity. Accordingly, multilevel pulp crushing can be achieved, particle uniformity of pulp is guaranteed, and then the produced products are higher in quality and suitable for popularization.

Owner:嘉兴市欧博特造纸设备科技有限公司

Storage and packaging facility capable of recycling cables

InactiveCN112009770AAutomate the packaging processRealize shreddingPackagingPower modeElectric machinery

The invention relates to the related field of cables, in particular to a storage and packaging facility capable of recycling the cables. The facility comprises a box body and a first cavity fixedly formed in the box body. Rotary drum shaft installation frames are fixedly installed on the right side end wall of the first cavity in a front-and-back symmetry manner, and a rotary drum shaft is rotationally installed between the tail ends of the left sides of the rotary drum shaft installation frames. A rotary drum is fixedly installed on the outer surface of the rotary drum shaft, and a packagingbelt for packaging the cables is installed on the outer surface of the rotary drum. A worm shaft is rotationally installed between the front end wall and the rear end wall of the first cavity and located on the left side of the rotary drum shaft and is connected with a main shaft of a first motor in a power mode. According to the storage and packaging facility capable of recycling the cables, automatic packaging of the cables can be achieved, the packaging quality and efficiency are high, automatic recycling of the cables can be achieved, packages on the surfaces of the cables are removed in the recycling process, and are completely removed, and the purpose that smashing treatment is conducted on the removed packaging belt and the like can be achieved.

Owner:GUANGZHOU FENGTIAN PACKAGING MATERIAL CO LTD

Mixing equipment for flame-retardant thermoplastic polyurethane elastomer

InactiveCN113601744ARealize heat treatmentRealize shreddingElectric machineThermoplastic polyurethane

The invention discloses mixing equipment for a flame-retardant thermoplastic polyurethane elastomer. The mixing equipment comprises an equipment main body, the bottom end of the equipment main body is fixedly connected with a top plate, the two sides of the bottom end of the top plate are fixedly connected with supporting rods, the bottom ends of the supporting rods are fixedly connected with a bottom plate, and a uniform discharging mechanism is arranged between the top plate and the bottom plate. A material guiding mechanism is arranged below a water inlet and comprises a third driving motor arranged on the outer wall of the equipment main body, the third driving motor is transversely arranged, a rotating shaft is arranged at the output end of the third driving motor, and the third driving motor, a cam, a spring and a discharging plate are connected in a matched mode. Materials crushed by a crushing mechanism and materials entering from the water inlet can fall on the surface of the discharging plate and fall near a mixing and crushing mechanism through the discharging plate, the material guiding effect is achieved, and the materials can be prevented from being concentrated at the corner of the equipment main body.

Owner:李宁

Waste rubber tire treatment device

InactiveCN110712322AImprove crushing efficiencyHigh degree of automationPlastic recyclingMechanical material recoveryWaste tiresProcess engineering

The invention relates to the field of waste tire treatment, and particularly relates to a waste rubber tire treatment device. The waste rubber tire treatment device comprises a machine body and an operation cavity formed in the machine body, wherein a conveying cavity with an upward opening is formed in the bottom wall of the operation cavity; a conveying device for driving waste tires to move isarranged in the conveying cavity; a supporting plate is arranged in the operation cavity in an up-down sliding manner; a lifting device for driving the supporting plate to move up and down is arrangedin the supporting plate; a sleeve rod extending downwards is fixedly arranged on the bottom wall of the supporting plate. According to the waste rubber tire treatment device, tire smashing treatmentcan be achieved, the equipment can cut the tires firstly and then smash the tires, and therefore the tire smashing efficiency is higher; and meanwhile, the equipment can effectively convey the tires,a tire conveying mechanism is used for conveying out cut tire rubber particles, and the automation degree is higher.

Owner:衢州林玉环保科技有限公司

Efficient and environment-friendly garbage treatment device

PendingCN108421819ASafety, environmental protection and battery lifeRealize shreddingWaste processingTransportation and packagingElectric energyMaterial storage

The invention discloses an efficient and environment-friendly garbage treatment device. The efficient and environment-friendly garbage treatment device comprises a treatment box and a melting box, wherein a feed inlet control valve is arranged at the upper end of the treatment box; a feed inlet is arranged at the upper end of the feed inlet control valve; a photovoltaic panel is arranged outside the treatment box; a secondary material outlet is mounted on one side of the treatment box; an operator is mounted on the other side of the treatment box; and an 80C51 controller and a storage batteryare arranged inside the operator. The efficient and environment-friendly garbage treatment device provided by the invention has the beneficial effects that the crushing treatment of the garbage that can be crushed can be realized through the arrangement of a first material storage barrel, the crushed garbage can be sieved by grading again through a screen, and subsequent treatment can be facilitated; fusible garbage can be classified and melted into a liquid state through the arrangement of the melting box, so that subsequent treatment can be facilitated; and through the arrangement of the photovoltaic panel, the sunlight can be used to supply electric energy to the device, and the garbage treatment device provided by the invention is safe and environment-friendly and has strong endurance.

Owner:江苏创凌非晶科技发展有限公司

Chemical fertilizer mixing device

PendingCN114100464ARealize shreddingAvoid damageTransportation and packagingMixer accessoriesSoil scienceAgricultural engineering

The invention belongs to chemical fertilizer mixing, and relates to a chemical fertilizer mixing device which comprises a shell, two feed inlet baffles are symmetrically arranged at the upper end of the shell, four supporting legs are fixedly arranged at the lower end of the shell, a chemical fertilizer separating and quantitative mixing device is arranged at the lower end in the shell, a chemical fertilizer spraying device is arranged in the shell, and the chemical fertilizer spraying device is arranged in the shell. Four protrusions are arranged in the shell in the circumferential direction, and a raw material caking smashing device is arranged between every two protrusions. According to the chemical fertilizer mixing device, two different chemical fertilizers can be repeatedly mixed in a small amount, caked chemical fertilizers in raw materials can be smashed and then mixed when the chemical fertilizers are mixed, the phenomenon of uneven mixing is effectively prevented through small amount of fertilizer mixing, the mixed chemical fertilizers are sprayed to a material cavity for secondary mixing, and through rotation of the device, the mixing efficiency is improved. And the raw material caking crushing device is driven to rotate irregularly, so that chemical fertilizer raw material caking crushing treatment is realized.

Owner:宁波欣元环保科技有限公司

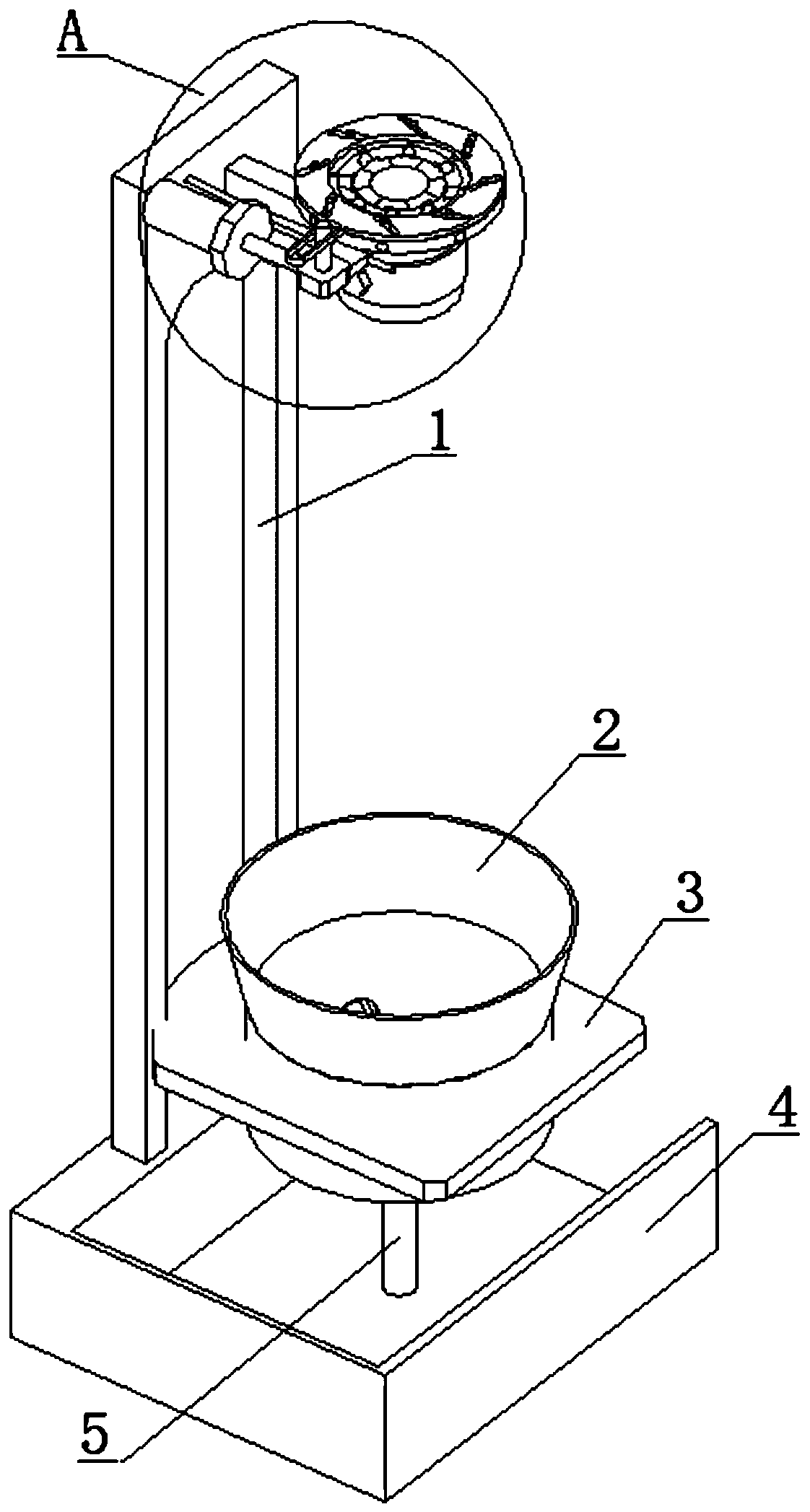

Waste processing mechanism in food waste processing device

PendingCN111792225ARealize shreddingAvoid the disadvantages of easily clogging the outlet holeWaste collection and transferRefuse receptaclesRefuse DisposalsKnife blades

The invention provides a waste processing mechanism in a food waste processing device and belongs to the technical field of environmental protection devices. The waste processing mechanism in the foodwaste processing device comprises an outer barrel with the upper portion provided with an opening and an inner barrel with the upper portion provided with an opening, and the inner barrel is locatedin the outer barrel. The center of the bottom of the outer barrel is provided with a drive mechanism capable of driving the inner barrel to rotate. The drive mechanism extends into the inner barrel tobe evenly provided with a plurality of moving blades. The inner side face of the outer barrel is evenly and fixedly provided with a plurality of fixed blades. The fixed blades extend into the inner barrel to form a waste smashing area with the moving blades. One side of the bottom of the outer barrel is provided with a water outlet. The side face and / or the bottom face of the inner barrel are / isprovided with a plurality of water outlet holes. A swinging mechanism capable of achieving dumping of the outer barrel is arranged between the outer barrel and a machine body. The waste processing mechanism in the food waste processing device can achieve smashing of food waste and separation of residues and liquid.

Owner:浙江德丽洁生物科技有限责任公司

Cosmetic powder screening machine

InactiveCN109261312ARealize shreddingRealize the three-level screening requirementsGrain treatmentsScreening effectEngineering

The invention discloses a cosmetic powder screening machine. The cosmetic powder screening machine comprises a casing, wherein a crushing shaft is movably arranged at the upper end of an inner cavityof the casing; the outer surface of the crushing shaft is fixedly connected with crushing teeth; the right side of the crushing shaft is fixedly connected with the output end of a crushing motor; thecrushing motor is fixedly arranged at the upper end of the right side of the casing; a separating plate is arranged in the inner cavity of the casing and is fixedly connected with the lower end of thecrushing shaft. The cosmetic powder screening machine has the advantages that by movably arranging the crushing shaft at the upper end of the inner cavity of the casing, a material can be crushed under the actions of the crushing teeth and the crushing motor, so as to avoid the influence to the screening effect due to caking of the material; under the actions of a support plate, a first spring, afixed screen net, a second spring, a vibration motor, a third spring, an installation plate, a movable screen net, a second material outlet, a third material outlet and a fourth material outlet, thethree-stage screening requirement of the material can be realized; the material screening effect is improved, and great convenience in use is realized for people.

Owner:章炯

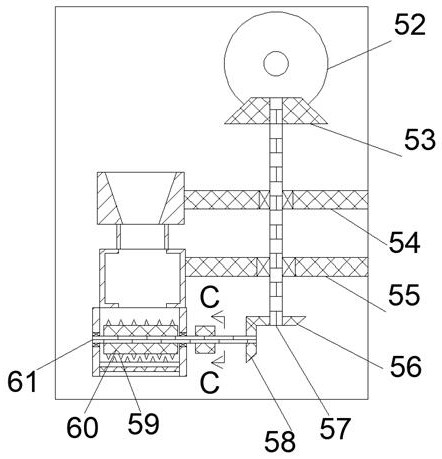

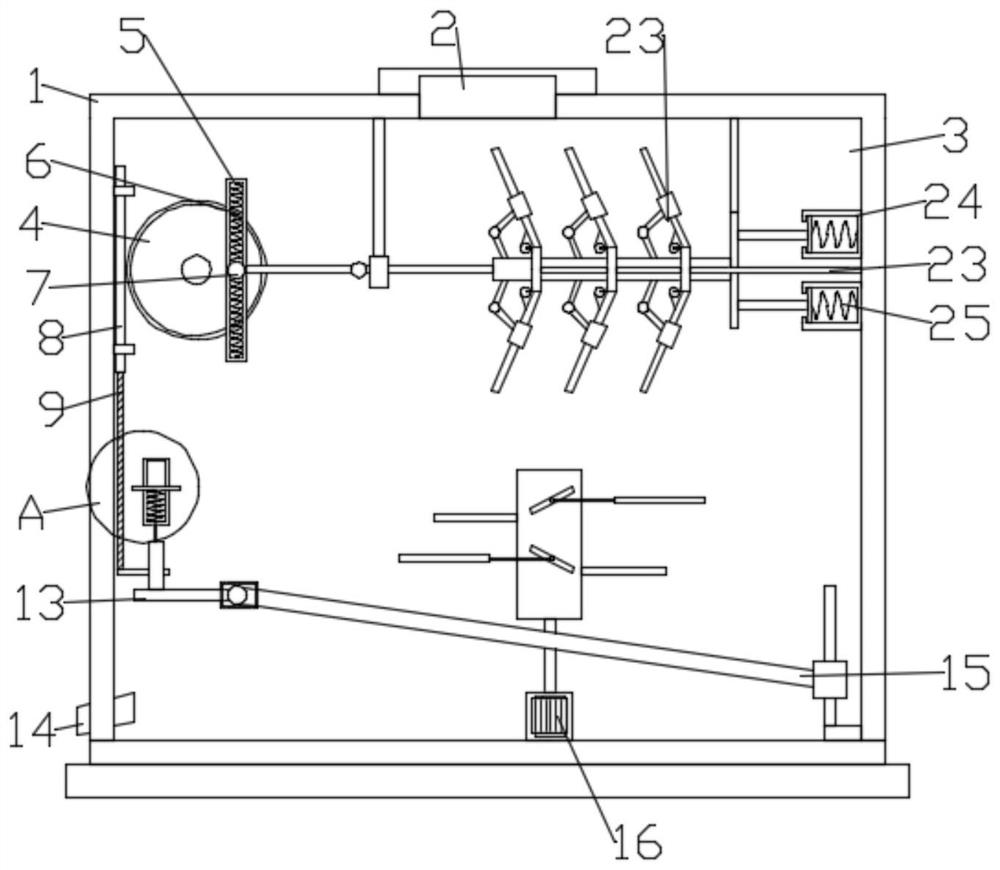

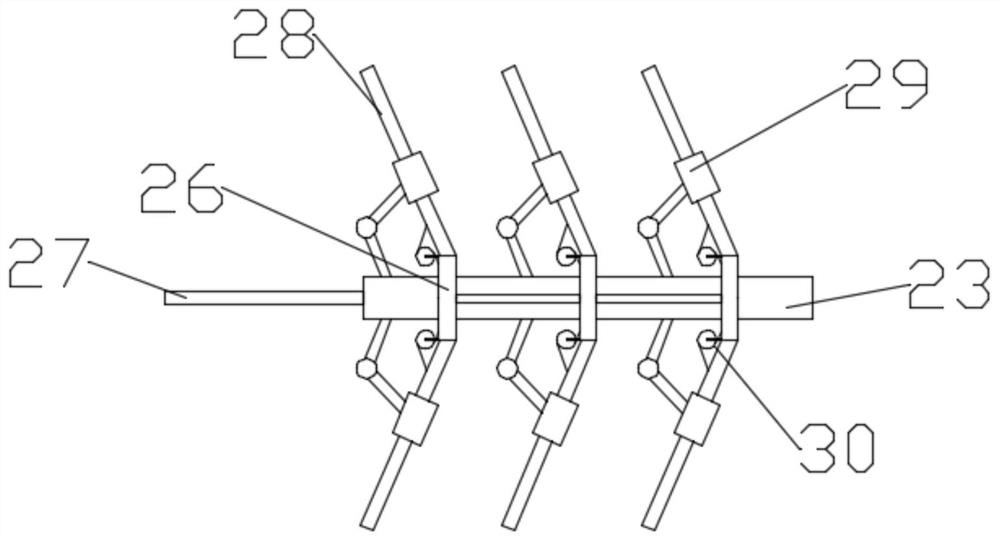

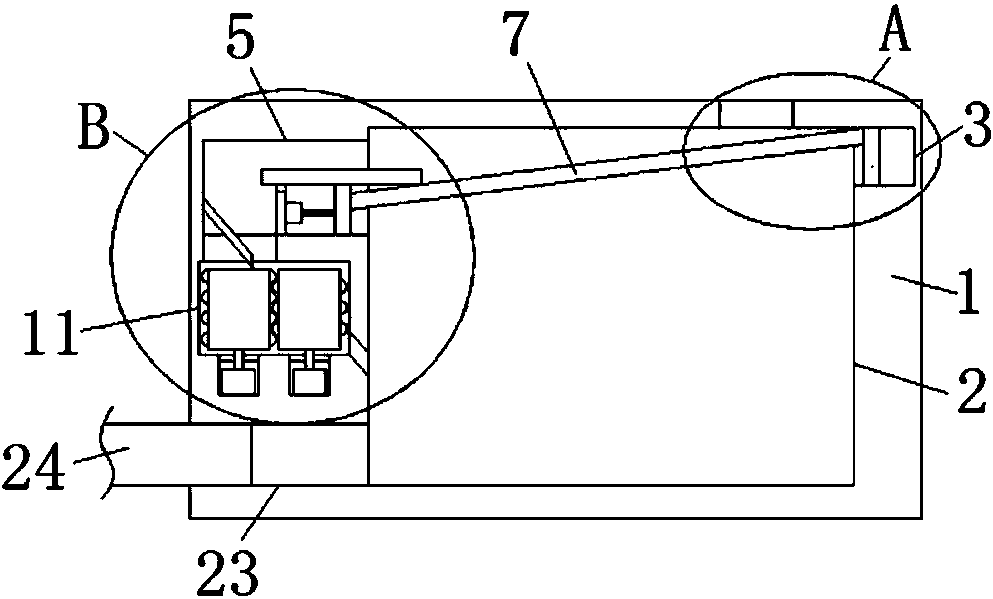

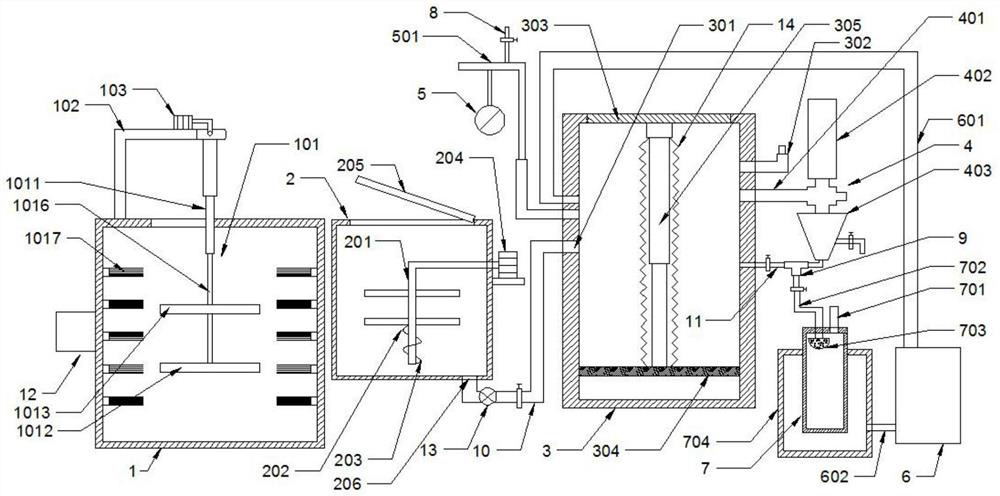

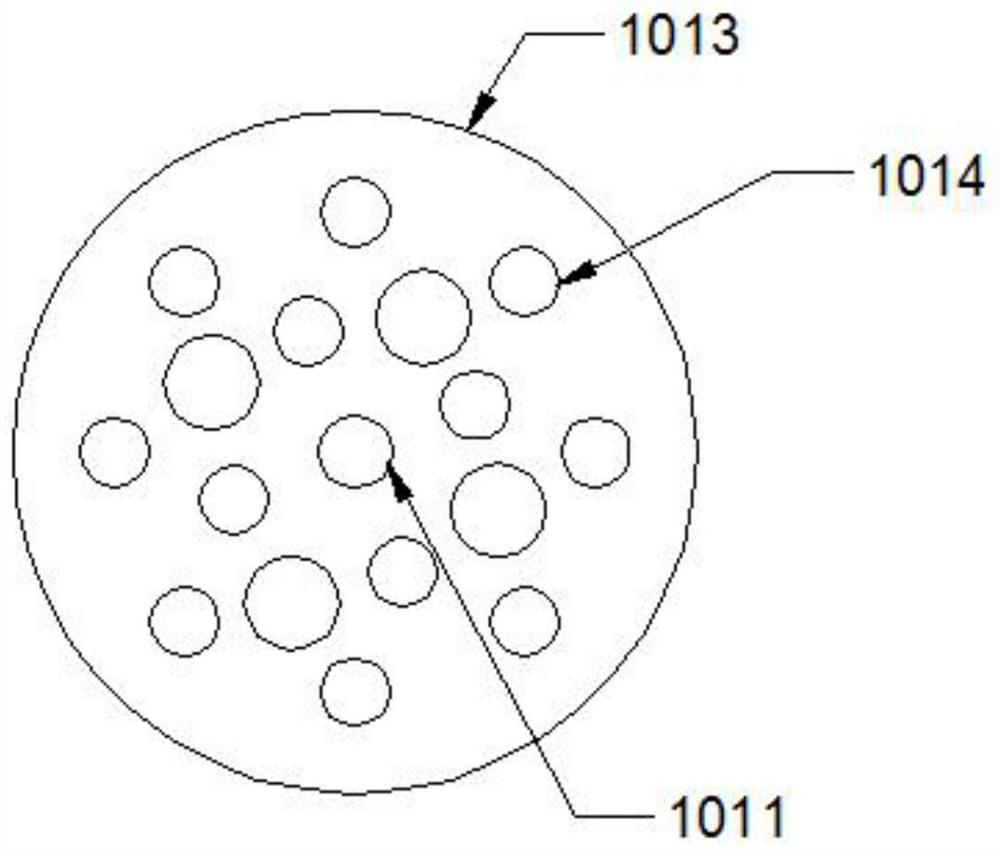

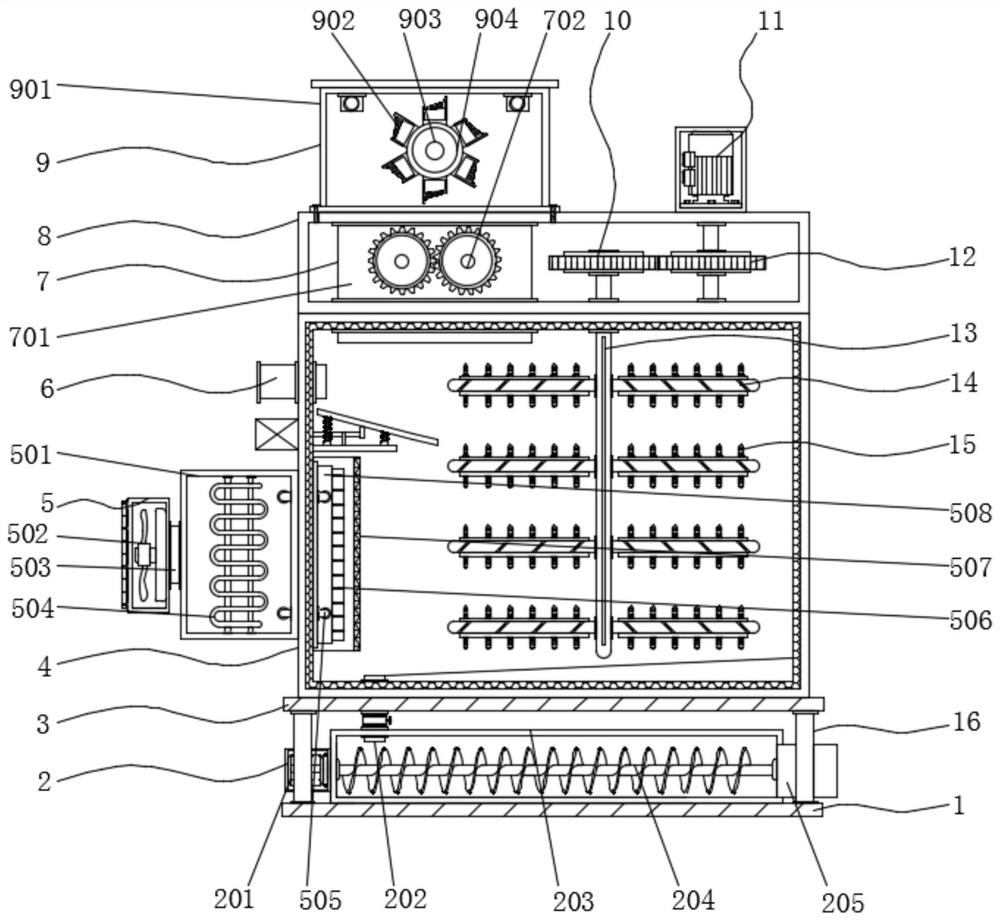

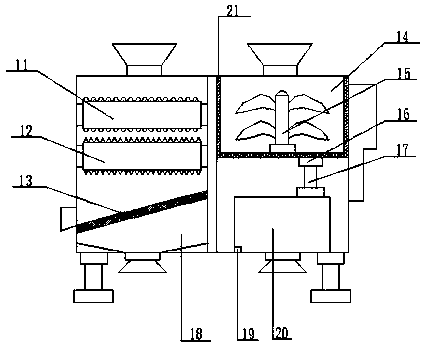

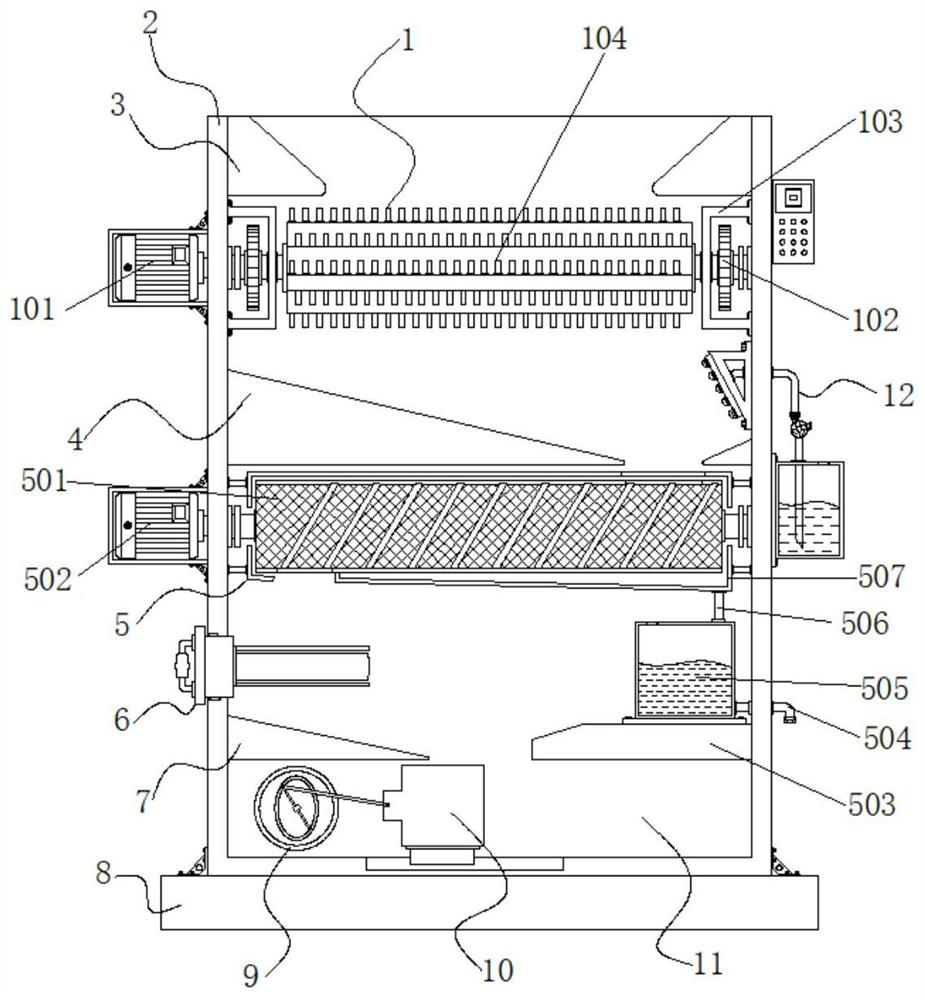

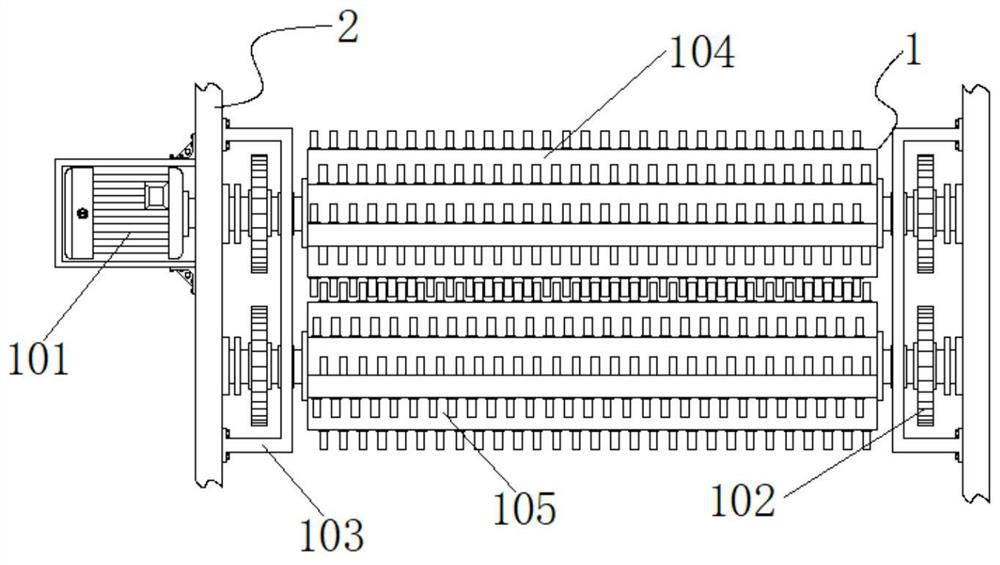

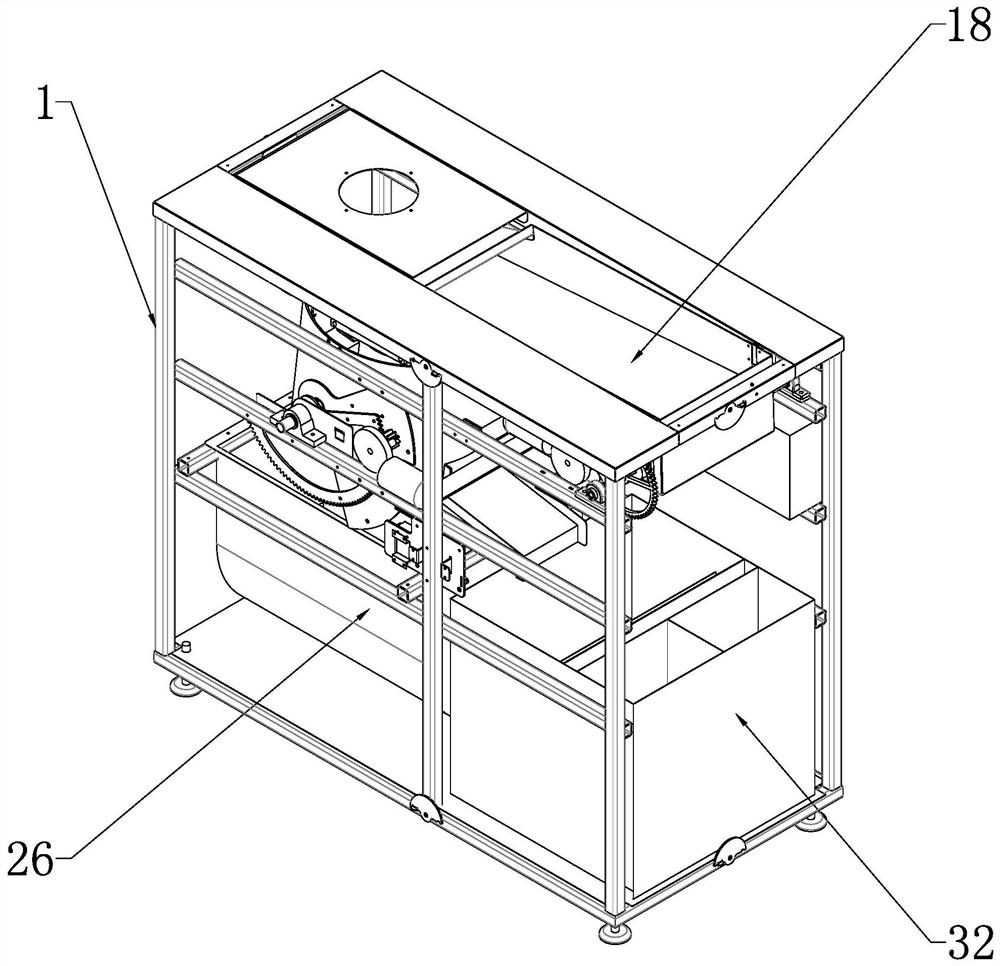

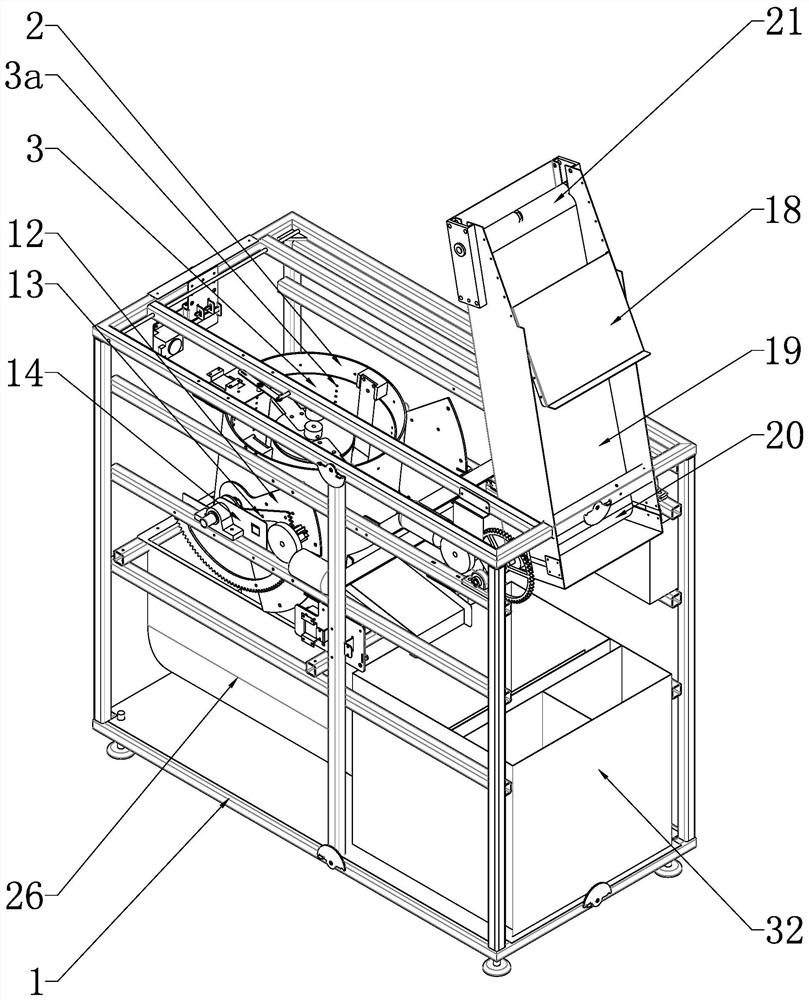

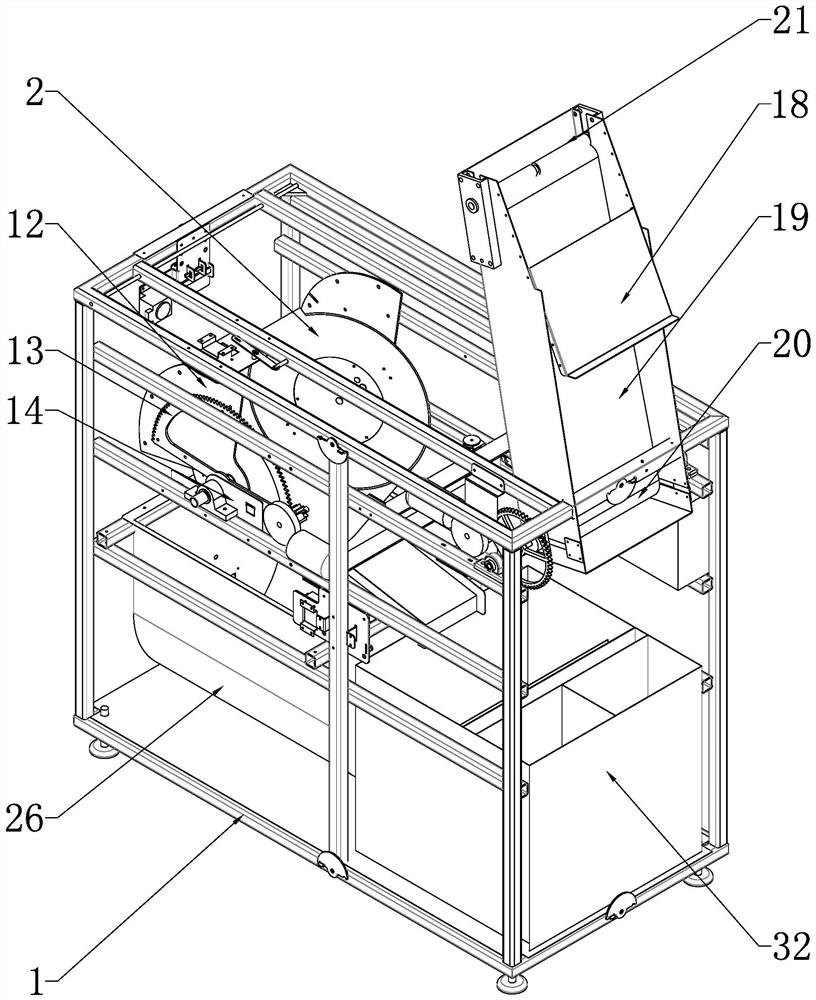

An all-in-one machine for preparing straw fine powder in comprehensive utilization of straw

ActiveCN108076866BRinse and stir wellEasy to crush laterCuttersCleaning using liquidsProcess engineeringMechanical engineering

The invention provides an integrated machine for producing straw fine powder in comprehensive utilization of straw, and belongs to the technical field of industrial production. The integrated machinefor producing the straw fine powder in comprehensive utilization of the straw includes a working table and a material collecting box, wherein a cleaning device, a drying device and a smashing device are sequentially arranged on the working table, the cleaning device includes a cleaning barrel, a stirring device is arranged on the working table, and the drying device includes a drying box and a drying drum; the smashing device includes a smashing drum and a storage box, a connecting plate is arranged in the chamber of the smashing drum, and a first smashing shaft and a second smashing shaft arefixed on both ends of the connecting plate vertically; smashing blades are fixed on outer walls of the first smashing shaft and second smashing shaft, and a drive structure which can drive the connecting plate to rotate is also arranged on the working table. Through the integrated machine, more energy-saving and convenient treatment of cleaning, drying and smashing of the straw can be achieved, so that the straw is powdered finely.

Owner:QUZHOU UNIV

A domestic waste disposal device

ActiveCN112090921BRealize the compaction processRealize shreddingSolid waste disposalTransportation and packagingElectric machineReciprocating motion

The invention discloses a domestic waste treatment device, specifically relates to the technical field of domestic waste treatment devices, comprising a base, the top of the base is fixedly connected with a frame, and the top inside of the frame is provided with a first guide material The top of both sides inside the frame is provided with a crushing mechanism, the inside of the bottom frame of the crushing mechanism is provided with a second material guide block, and the middle position inside the bottom frame of the second material guide block is provided with a dehydration mechanism. In the present invention, a compression mechanism is arranged at the bottom end inside the frame body, and the controller controls the operation of the third drive motor. The third drive motor drives the rotary block through the coupling, and the rotary block rotates through the first movable rod and the second movable rod. Drive the compression block to reciprocate, the slider and the chute guide the movement of the compression block, the garbage passing through the bar magnet falls to the top of the third material guide block and slides into the compression cavity, the compression block compresses the garbage Reduces the volume of litter particles.

Owner:池州市芯村里新材料科技有限公司

Food waste treatment device

PendingCN111957713ARealize shreddingAvoid the disadvantages of easily clogging the outlet holeSolid waste disposalCooling/ventillation arrangementWaste treatmentRefuse Disposals

The invention provides a food waste treatment device and belongs to the technical field of environmental protection equipment. The food waste treatment device comprises a machine body. A conveying mechanism capable of conveying waste into the machine body and a waste treatment mechanism capable of crushing and dehydrating conveyed waste are arranged on the upper portion of the interior of the machine body. A residue treatment mechanism and a residual liquid collection mechanism are arranged on the lower portion of the interior of the machine body. The waste treatment mechanism comprises an outer barrel with an upper opening and an inner barrel with an upper opening. The inner barrel is located inside the outer barrel. A driving mechanism capable of driving the inner barrel to rotate is arranged at the center of the bottom of the outer barrel. The driving mechanism extends into the inner barrel, and the inner barrel is internally provided with a plurality of movable blades. A pluralityof fixed blades are uniformly fixed to the inner side face of the outer barrel. The fixed blades extend into the inner barrel, and the fixed blades and the movable blades form a waste crushing area. The food waste treatment device can achieve crushing of food waste and separation of residual liquid.

Owner:浙江德丽洁生物科技有限责任公司

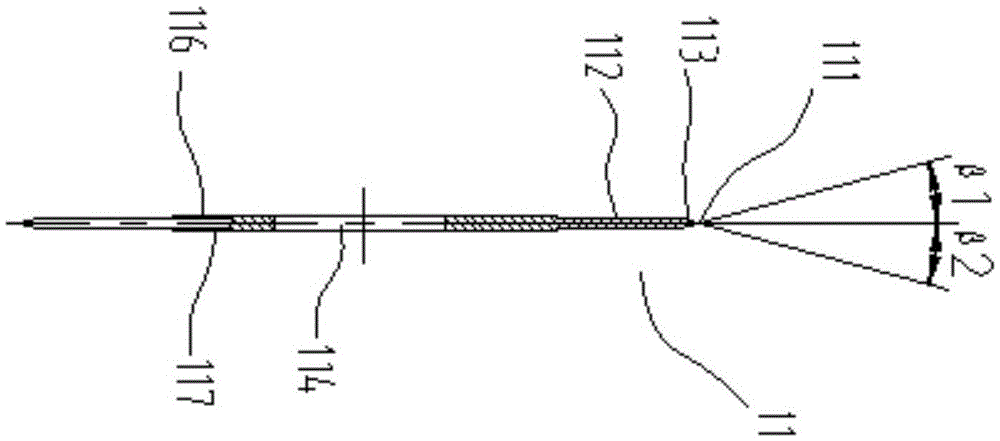

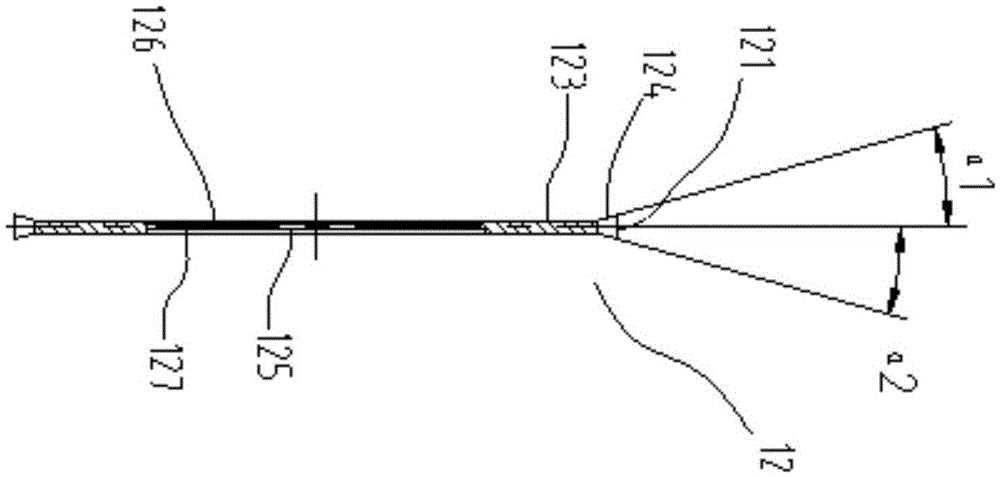

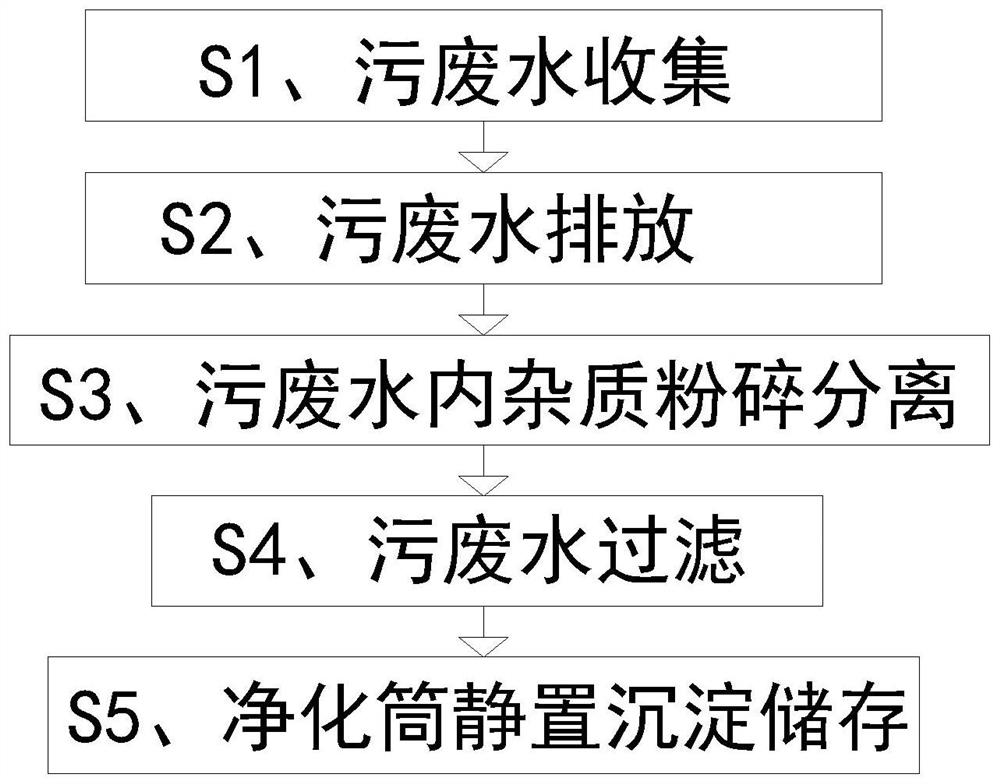

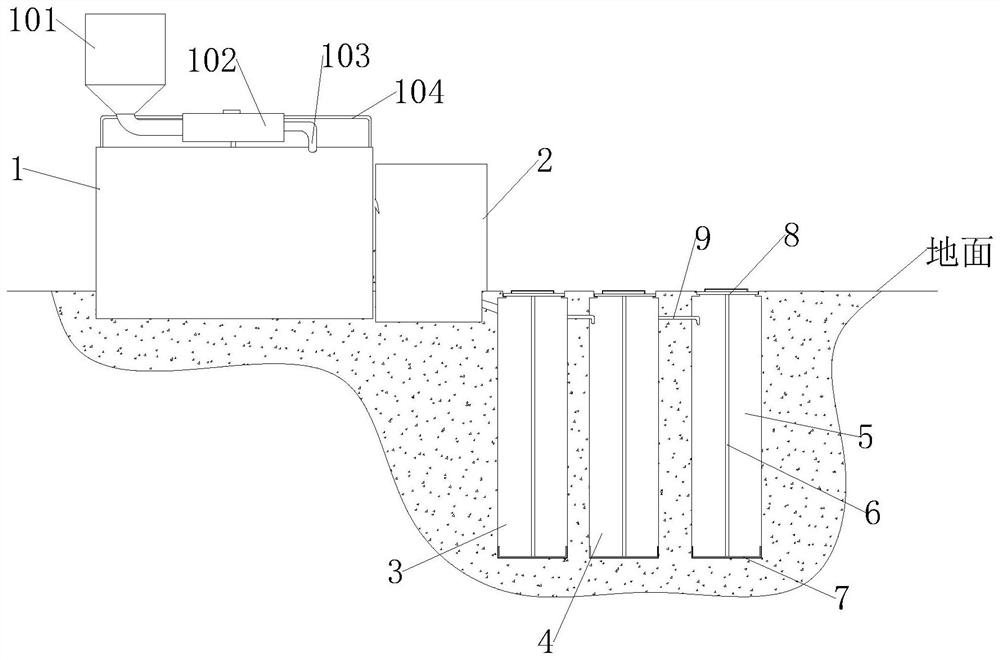

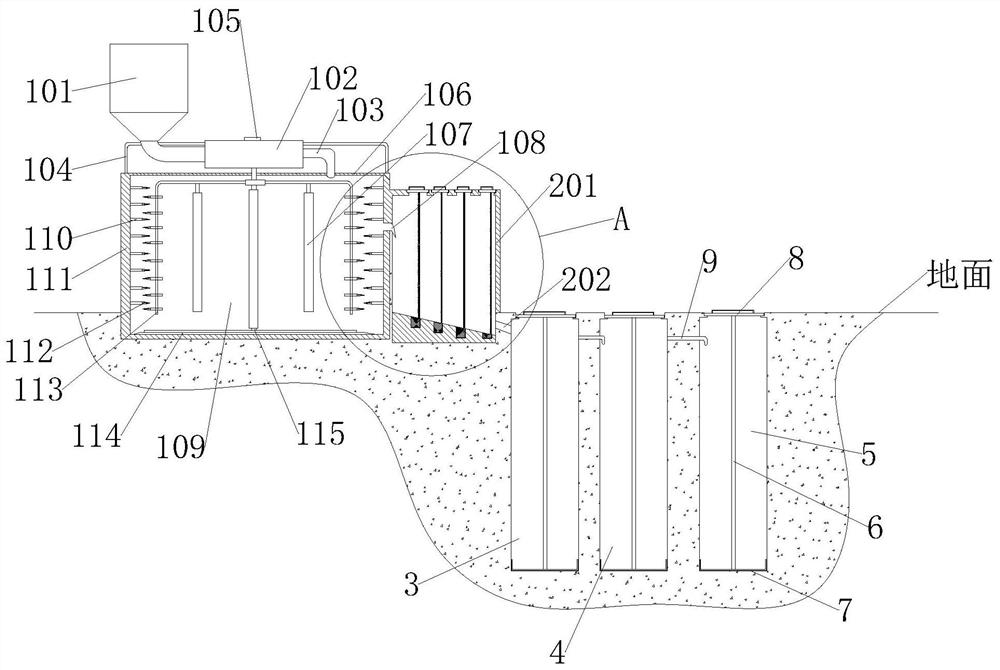

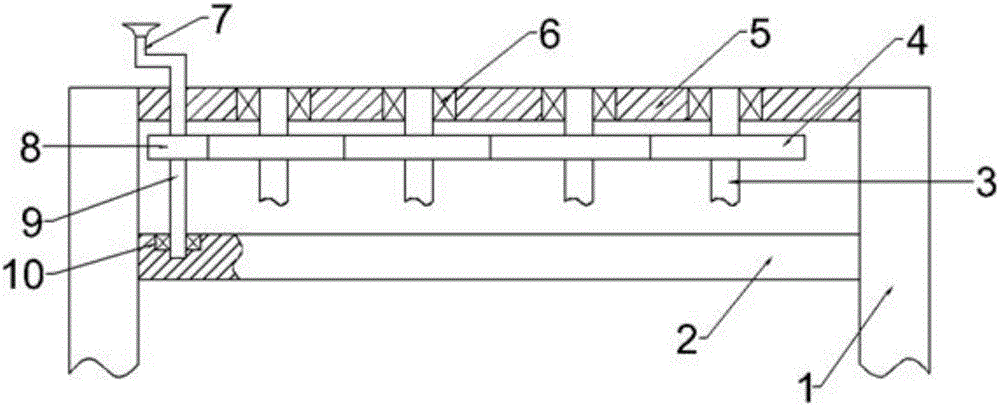

Zero-power-consumption medical equipment production sewage and wastewater treatment method

InactiveCN113620500AGuaranteed to workRealize zero power consumption workSpecific water treatment objectivesTreatment involving filtrationMedical equipmentMedical treatment

The invention provides a zero-power-consumption medical equipment production sewage and wastewater treatment method, and relates to the technical field of medical equipment production. The method comprises the following steps: S1, collecting sewage and wastewater: discharging and collecting sewage and wastewater generated during medical equipment production into a sewage and wastewater collecting barrel; and S2, discharging sewage and wastewater: uniformly discharging sewage and wastewater in the sewage and wastewater collecting barrel by utilizing a sewage discharge pipe for the sewage and wastewater collected in the step S1, and pushing impeller blades to rotate by utilizing potential energy generated in the sewage and wastewater discharge process in the sewage discharge pipe so as to drive a sewage crushing device to work. Through a movable shredding rod 106 and a plurality of inverted tooth hooks 1161 at the top end of a shredding rod 110, the relative displacement between the movable shredding rod 106 and the shredding rod 110 is utilized, and floating or suspending impurities in sewage and wastewater are hung through the plurality of inverted tooth hooks 1161, so that the floating or suspending impurities are crushed.

Owner:樊顺胜

Driving device for rapid detection equipment

InactiveCN106771069ARealize shreddingImprove processing efficiencyToothed gearingsEarth material testingEngineeringRapid detection

The invention relates to a driving device for rapid detection equipment. The driving device comprises two support frames, a plurality of first rotating rods and a plurality of driven gears, wherein a first mounting plate is fixed between the two support frames, and a second mounting plate is fixed between the two support frames above the first mounting plate; the driven gears are fixedly connected with the first rotating rods and are sequentially meshed one another; the top ends of the first rotating rods are rotatably connected with the second mounting plate; and a driving gear is meshed to the left side of the driven gear on the leftmost ride and is fixedly connected with a second rotating rod, and the bottom end of the second rotating rod is rotatably connected with the first mounting plate. The driving device has the beneficial effects that multiple samples can be simultaneously crushed, the processing efficiency is high, and human resources are effectively saved. The driving device has the advantages of reasonable structural design, convenience in use, high detection efficiency and the like and further has certain popularization and application values.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com