Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about "Hydroxy-anthraquinone dyes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

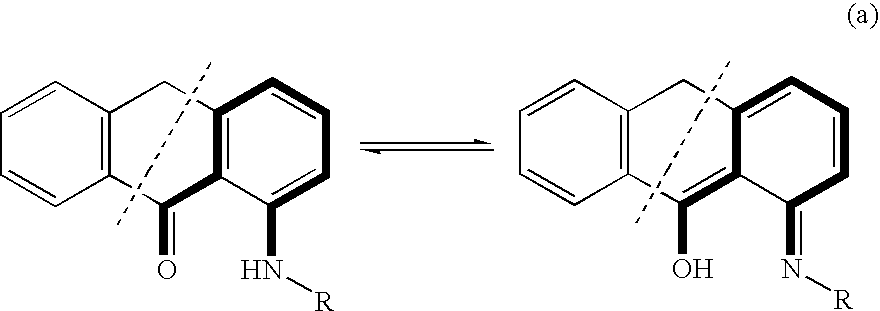

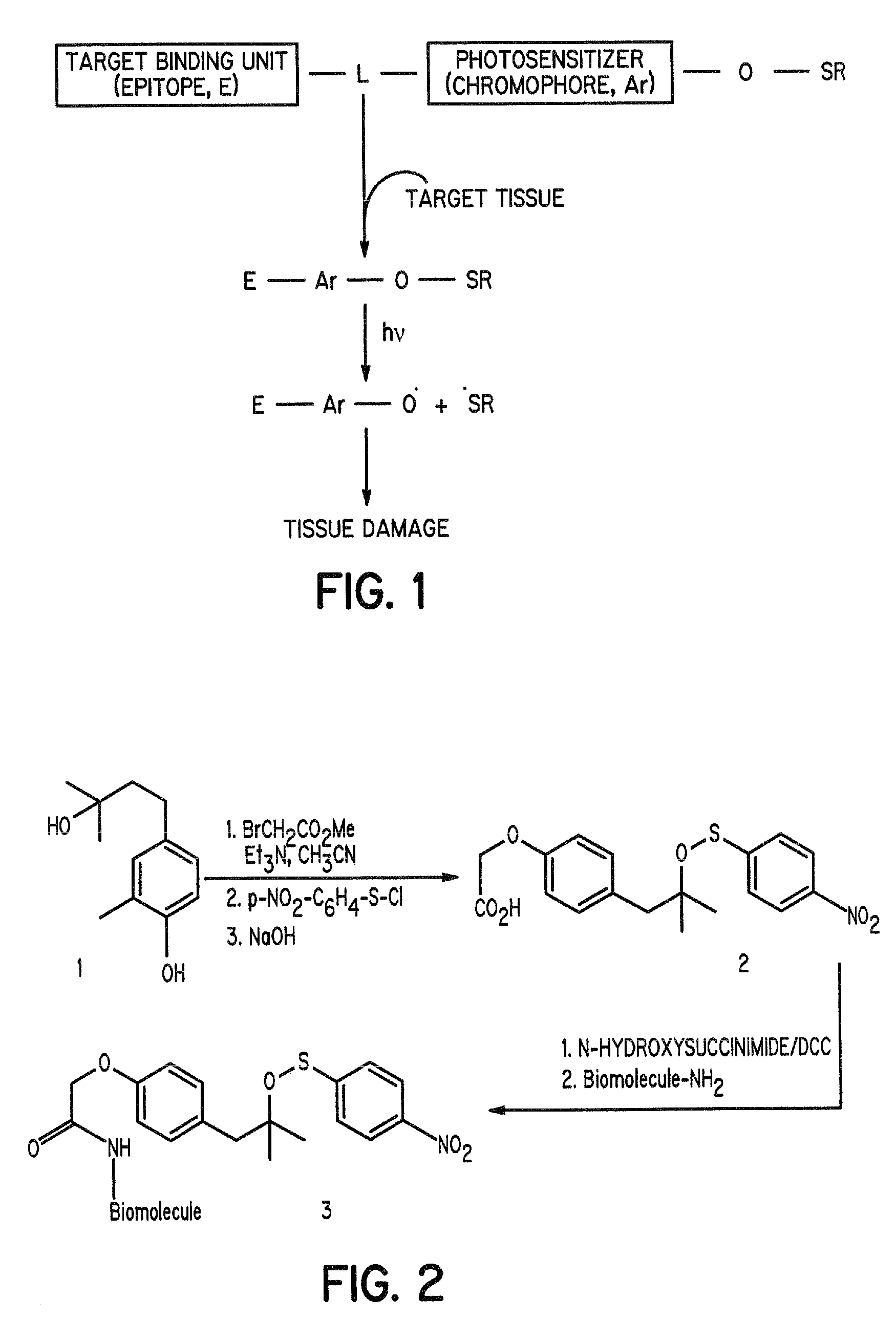

Aromatic sulfenates for type I phototherapy

InactiveUS7235685B2Sufficient fluenceSufficient powerOrganic active ingredientsElectrotherapyAbnormal tissue growthLight treatment

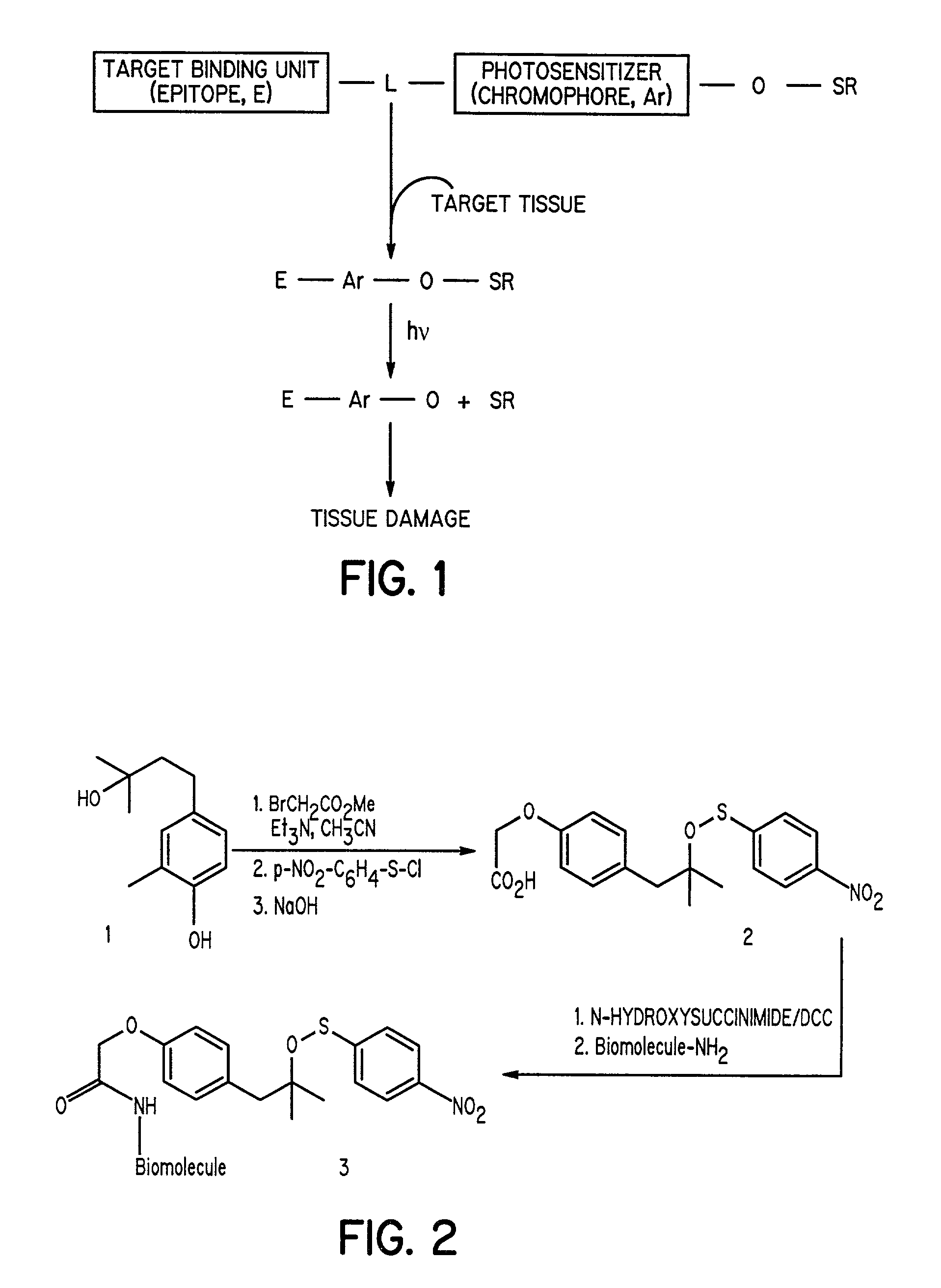

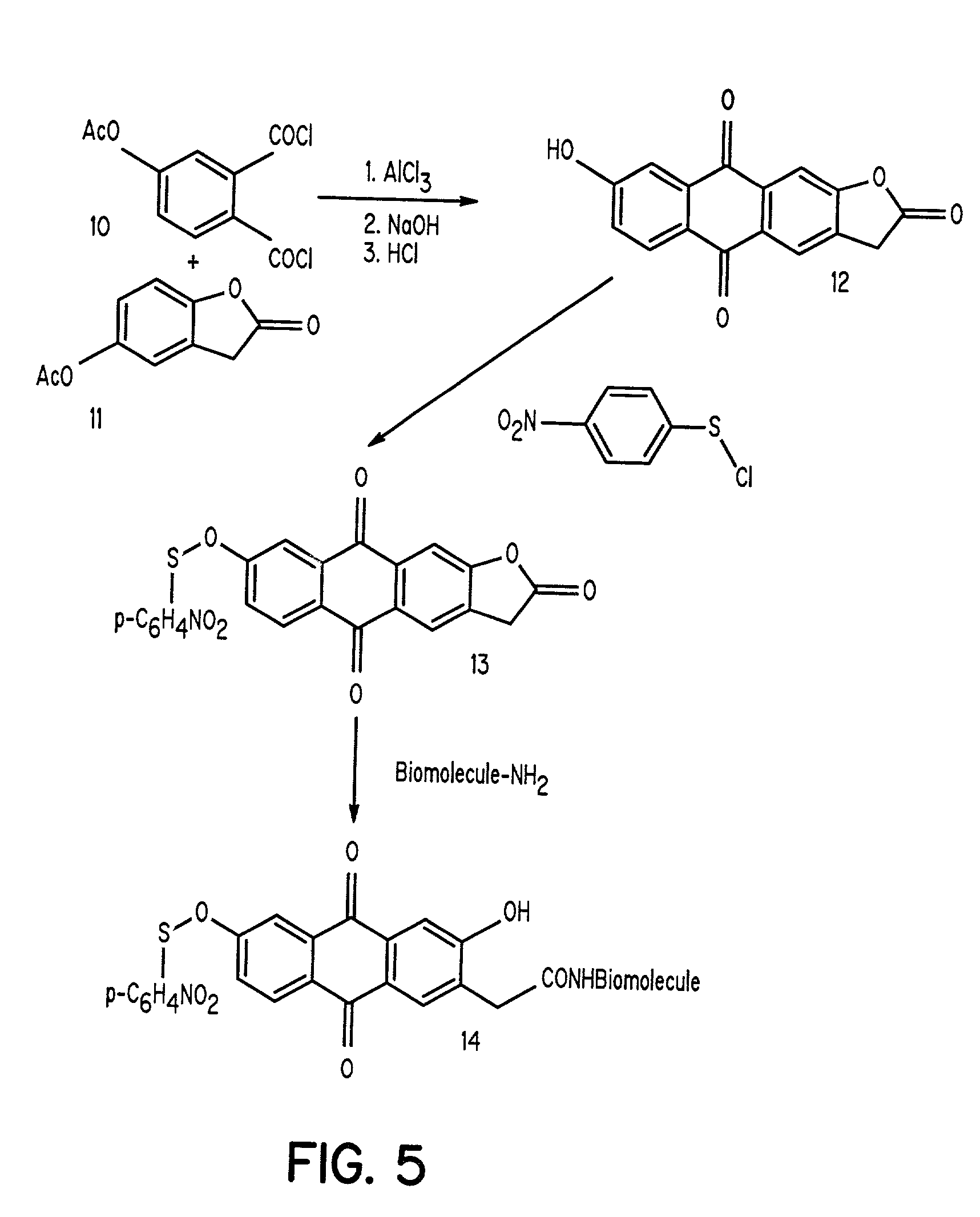

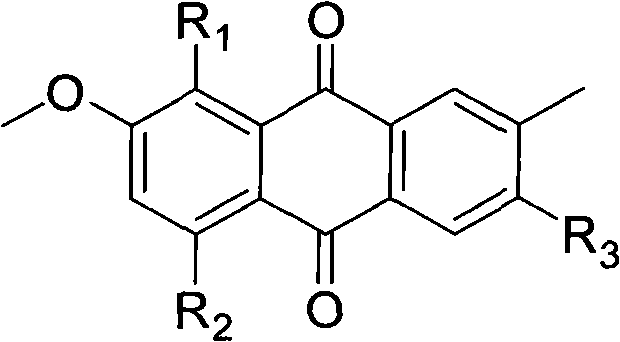

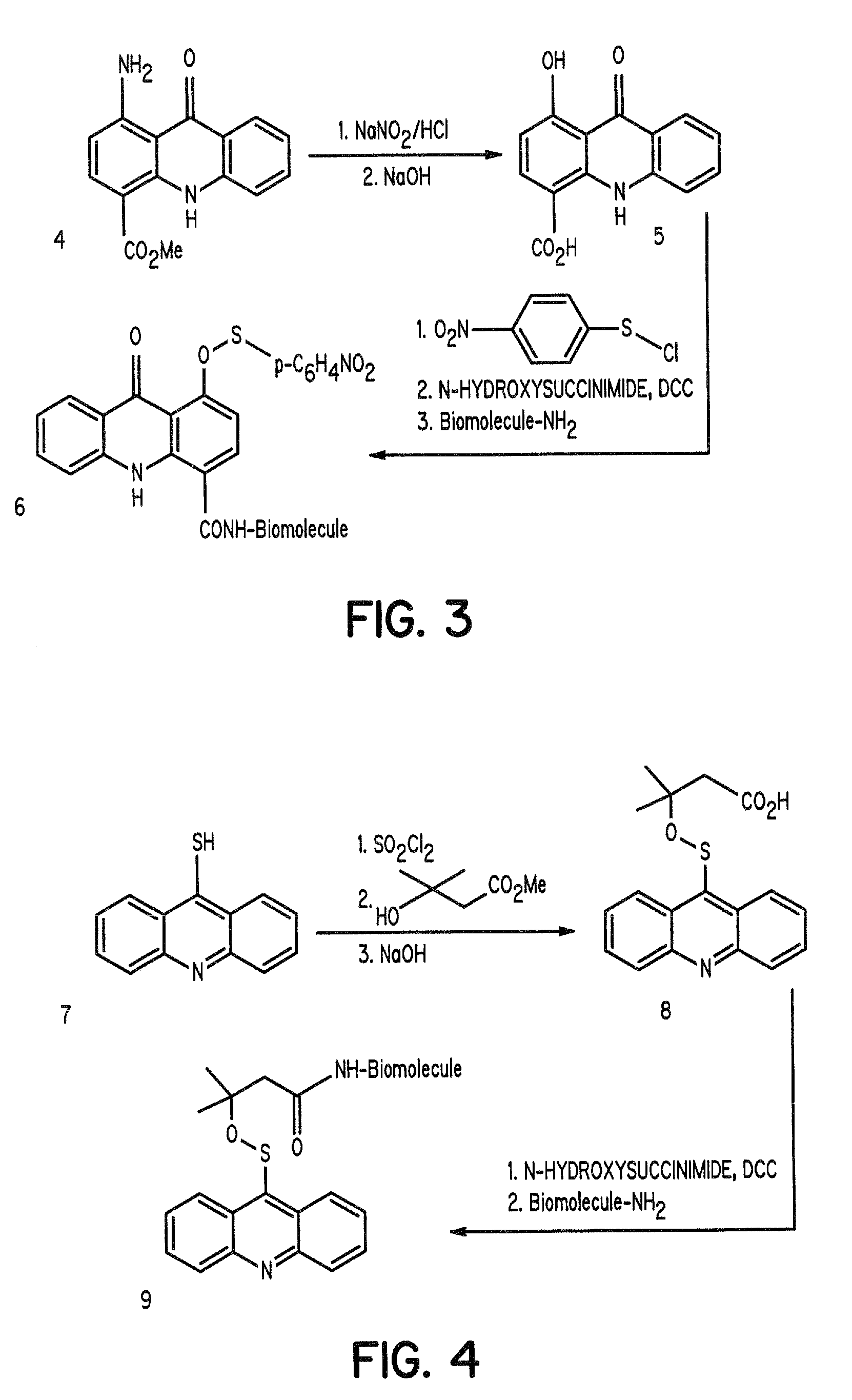

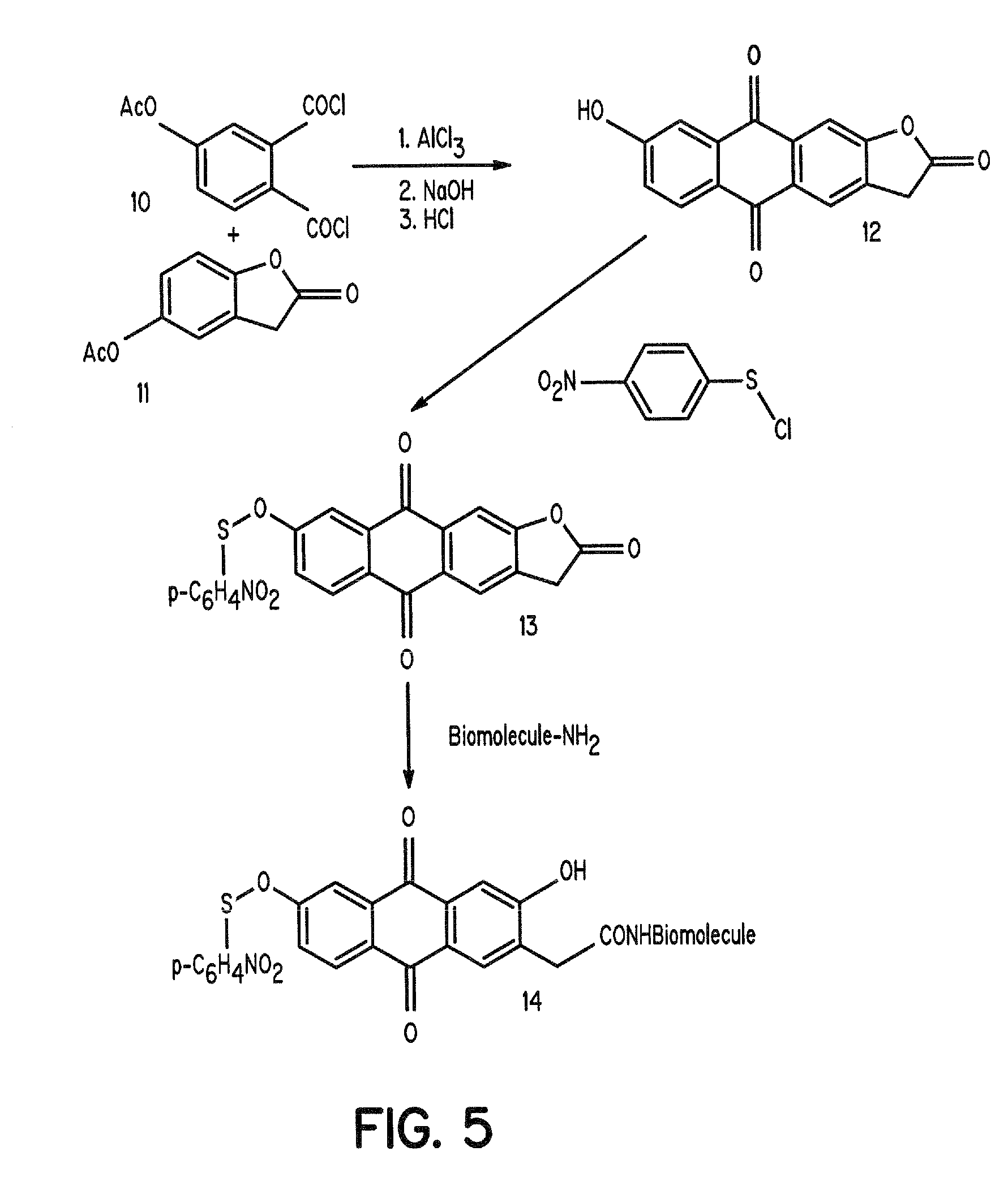

The present invention discloses novel sulfenate derivatives and their bioconjugates for phototherapy of tumors and other lesions. The sulfenates of the present invention are designed to absorb low-energy ultraviolet, visible, or near-infrared (NIR) region of the electromagnetic spectrum. The phototherapeutic effect is caused by direct interaction of free radicals, the reactive intermediate produced upon photofragmentation of the sulfenate moiety, with the tissue of interest.

Owner:MALLINCKRODT INC

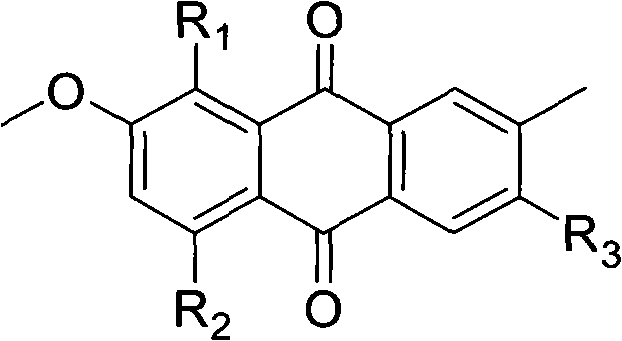

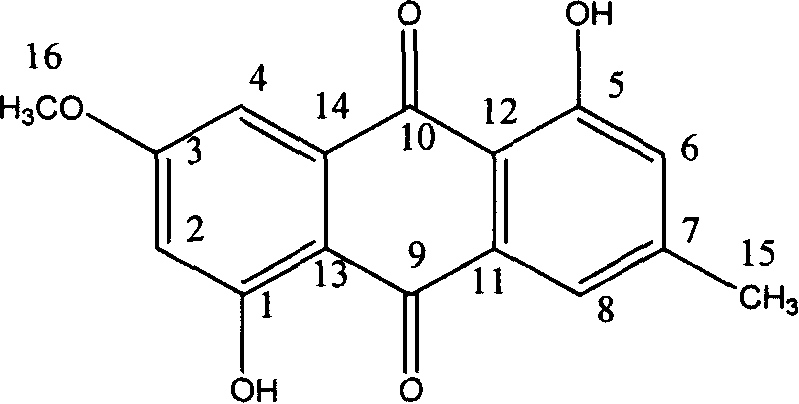

Anthraquinone derivative, as well as preparation method and application of anthraquinone derivative serving as antibacterial agent

InactiveCN102603525AHas selective inhibitory activityAntibacterial agentsOrganic active ingredientsEscherichia coliBacillus cereus

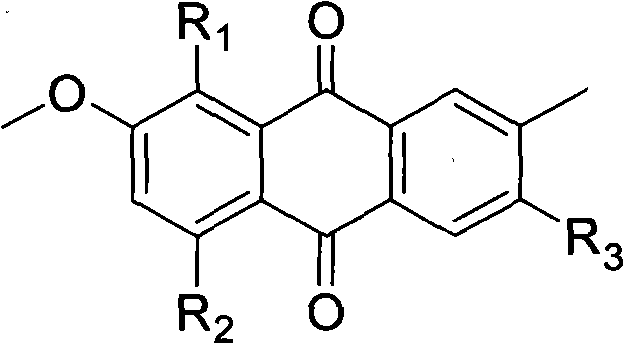

The invention provides an anthraquinone derivative, as well as a preparation method and application of the anthraquinone derivative serving as an antibacterial agent. The preparation method comprises the following steps: culturing a strain of Nigrospora sp. (HM565952) in a strain culture medium; fermenting the nigrospora sp. in a fermentation culture medium; filtering the fermentation broth, removing thallus, and extracting the fermentation broth with ethyl acetate; concentrating the extract, and performing chromatographic separation, and concentrating the eluent to obtain two types of yellow powder, namely 3,5,8-Trihydroxy-7-methoxy-2-methylanthracene-9,10-dione and austrocortirubin; and adding an acetic anhydride reagent in a solution dissolved with the compound, and reacting to obtain the anthraquinone derivative. The anthraquinone derivative obtained from the Nigrospora sp. (HM565952) has selective inhibitory activity to Bacillus subtilis, Bacillus cereus, Micrococcus tetragenus, Micrococcus lutea, Escherichia coli, Staphylococcus aureus, Staphylococcus albus, Vibrio parahaemolyticus and Vibrio anguillarum, and can be used for developing selective bacteriostatic agents; and the raw materials can be produced on a large scale, and not limited by resources. Therefore, the anthraquinone derivative has the advantage of wide application prospect.

Owner:OCEAN UNIV OF CHINA

Red anthraquinone dispersion dye

InactiveCN1597788ANovel structureGood fastness to sublimationHydroxy-anthraquinone dyesDisperse dyeSolvent

The invention is a type of red dispersive dye containing two anthraquinone rings, using 1-amino-2-bromo-4- hydroxyl (or alkoxy) anthraquinone as raw material to make condensation reaction with diphenol A, quinol, diphenol S, etc, respectively, in a high-boiling point inert solvent so as to make it. It has not only simple synthetic process and fewer steps but also better sublimating fastness and higher molar extinction coefficient.

Owner:DALIAN UNIV OF TECH

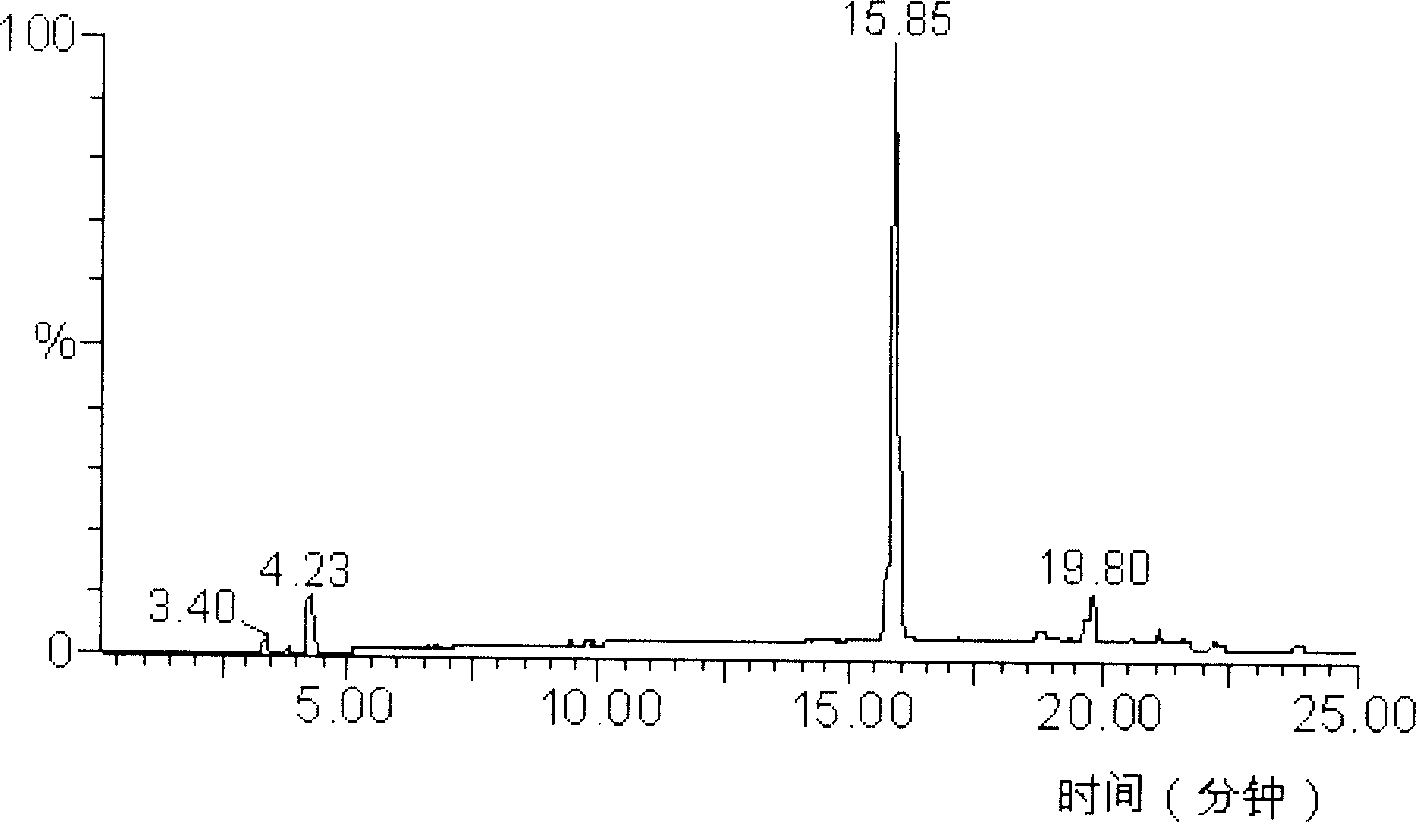

Novel process for producing 1,4-dihydroxy anthraquinone

InactiveCN103664567AHigh yieldReduce manufacturing costOrganic compound preparationHydroxy-anthraquinone dyesSolventHydrolysis

The invention discloses a novel process for producing 1,4-dihydroxy anthraquinone, and relates to the technical field of chemical production. The technological process is as follows: firstly, co-heating and dehydrating fuming sulphuric acid and boric acid for 30-60 minutes, adding phthalic anhydride, heating up to 130 DEG C, adding parachlorophenol into the reaction system for multiple times in batches, heating up to 200-205 DEG C after adding the parachlorophenol, continuously reacting for 5-10 hours, slowly putting a reactant in 8 times by volume of water for hydrolysis after the reaction is finished, controlling the hydrolysis temperature at 100-130 DEG C, extracting the product to an organic phase by use of a solvent after hydrolysis, discharging the lower-layer waste acid, washing the upper-layer extracting solution by use of hot water, distilling the solvent for cycle use, and carrying out high-vacuum distillation and sublimation to obtain high-quality 1,4-dihydroxy anthraquinone. The novel process disclosed by the invention is used for improving the product yield and reducing the production cost by regulating process conditions such as raw material feeding ratio, feeding method, feeding temperature and the like on the premise of ensuring the product yield and the product quality.

Owner:PENGZE XINGDA CHEM

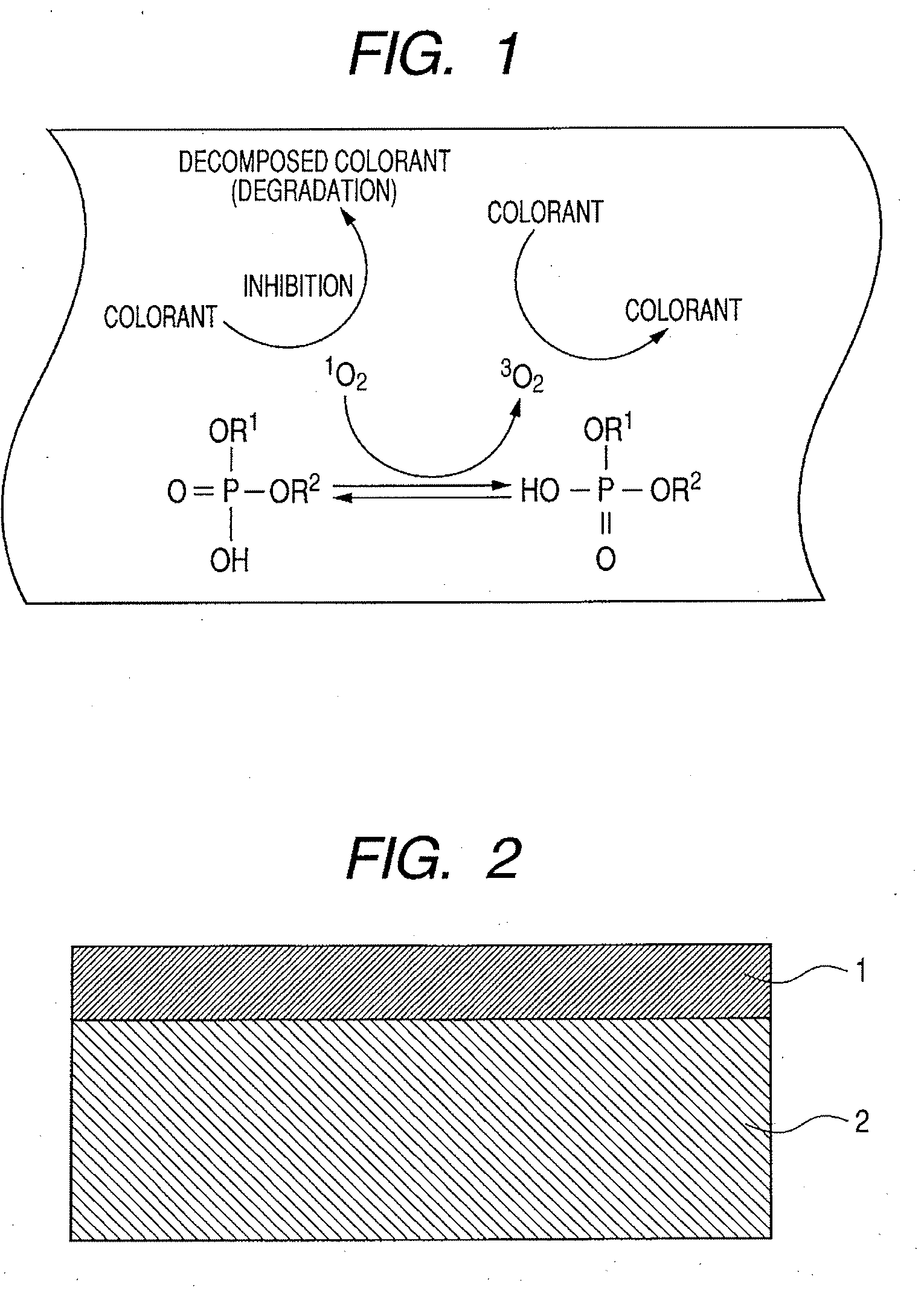

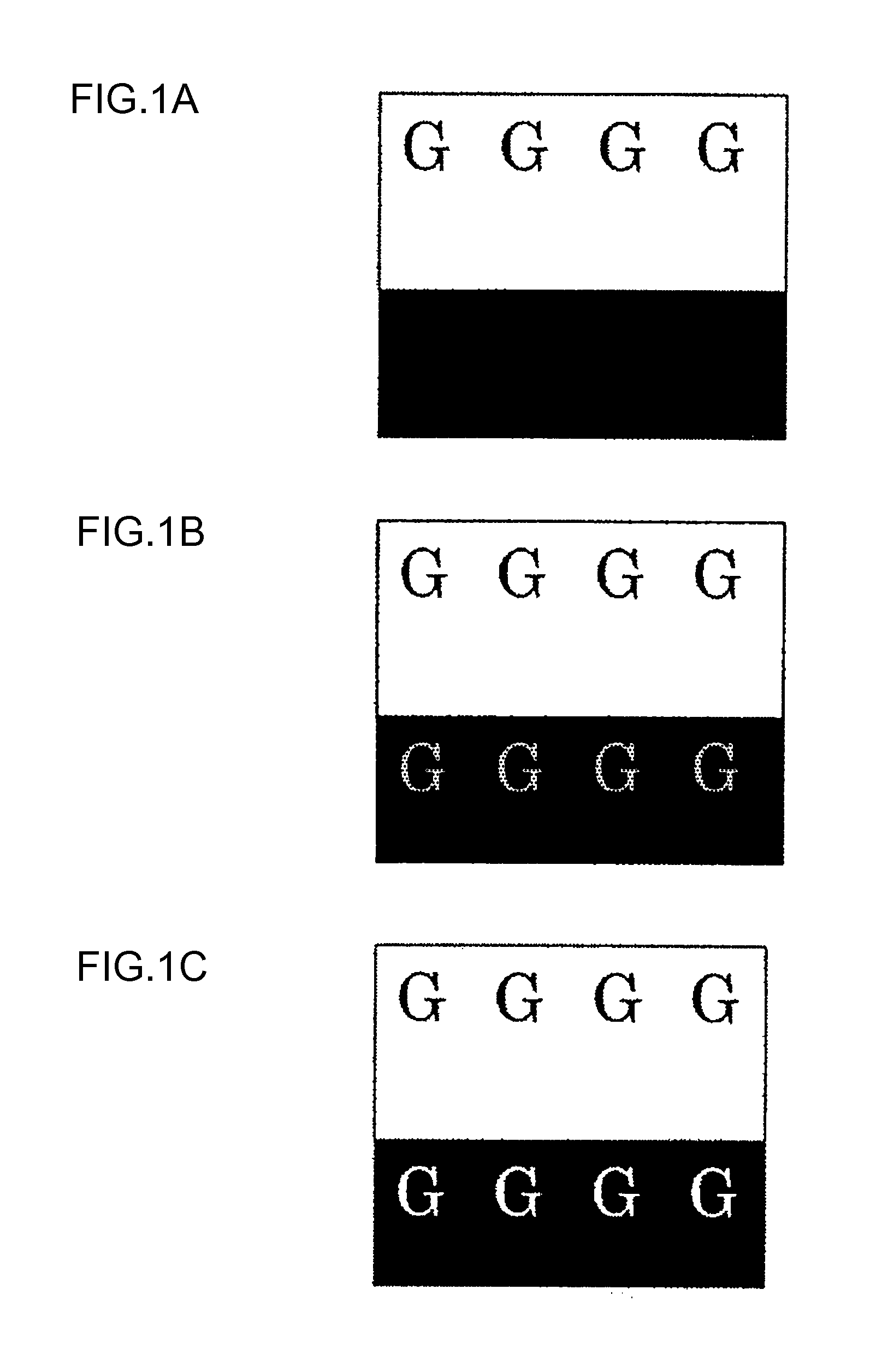

Image fading preventing agent, image forming element, recording medium, image forming method and image

InactiveUS20070093386A1Maintain stabilityPreventing of image formedHydroxy-anthraquinone dyesInksImaging qualityImage formation

Owner:CANON KK

Aromatic sulfenates for type 1 phototherapy

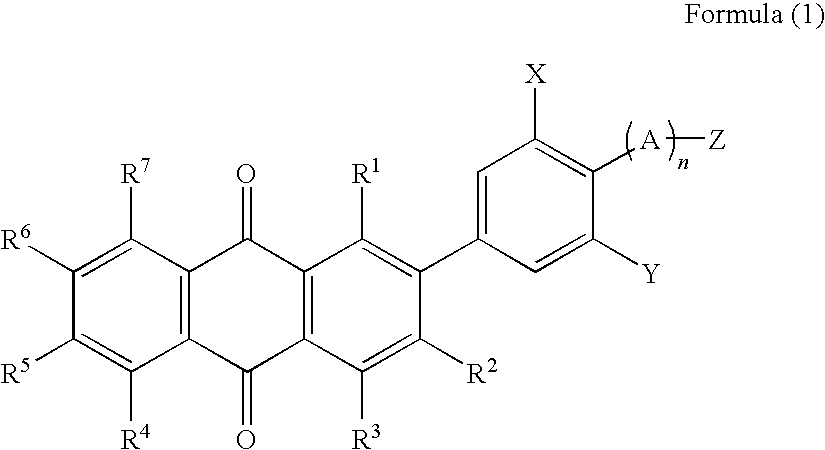

InactiveUS7427657B1Sufficient fluenceSufficient powerElectrotherapyPeptide/protein ingredientsLight treatmentUltraviolet

The present invention discloses novel sulfenate derivatives and their bioconjugates for phototherapy of tumors and other lesions. The sulfenates of the present invention are designed to absorb low-energy ultraviolet, visible, or near-infrared (NIR) region of the electromagnetic spectrum. The phototherapeutic effect is caused by direct interaction of free radicals, the reactive intermediate produced upon photofragmentation of the sulfenate moiety, with the tissue of interest.

Owner:MALLINCKRODT INC

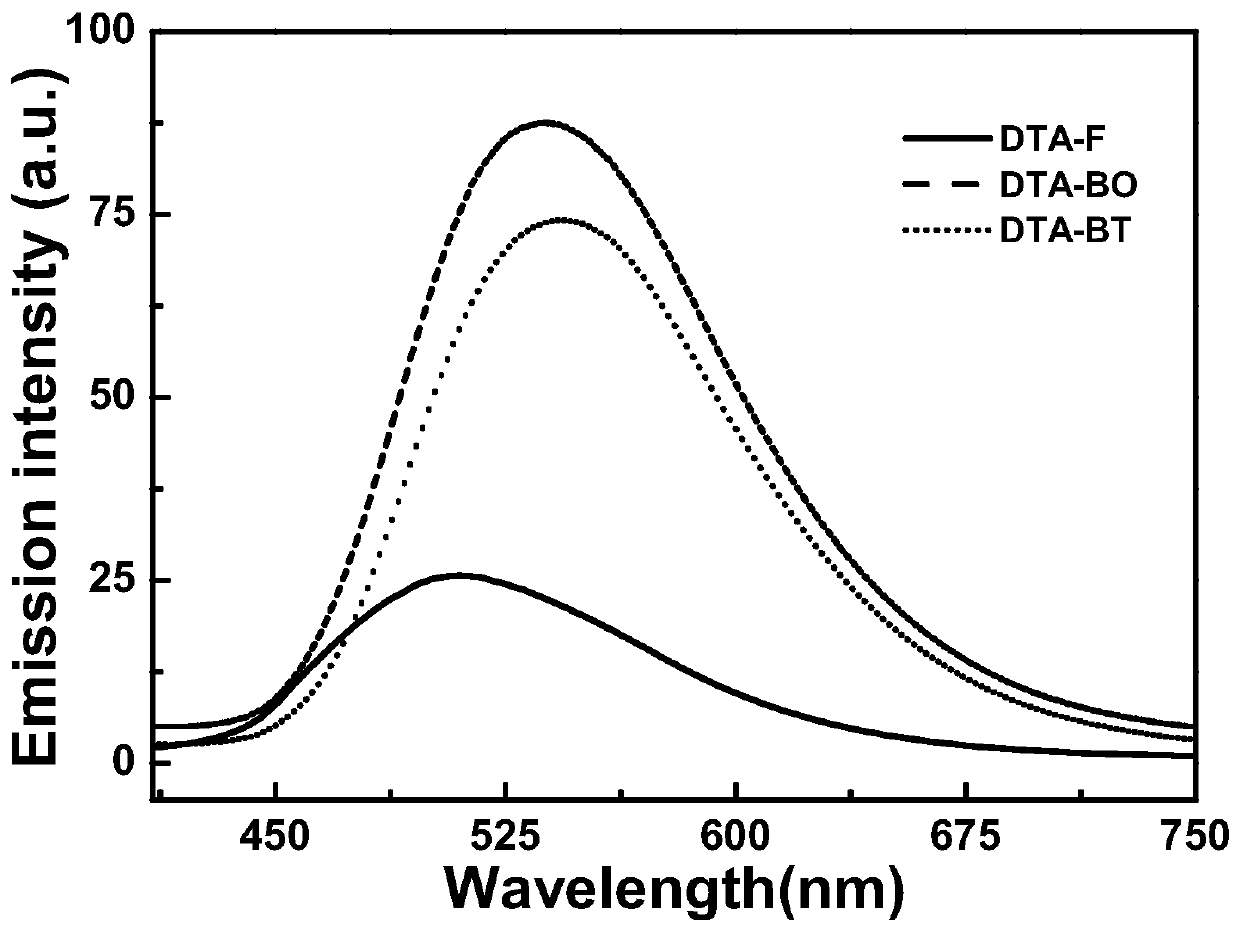

Asymmetric 9,10-dithienylanthracene fluorescence compound, and preparation method and application thereof

ActiveCN110156749AReduce manufacturing costThe synthesis method is simpleOrganic chemistryHydroxy-anthraquinone dyesAnthracenePhotoluminescence

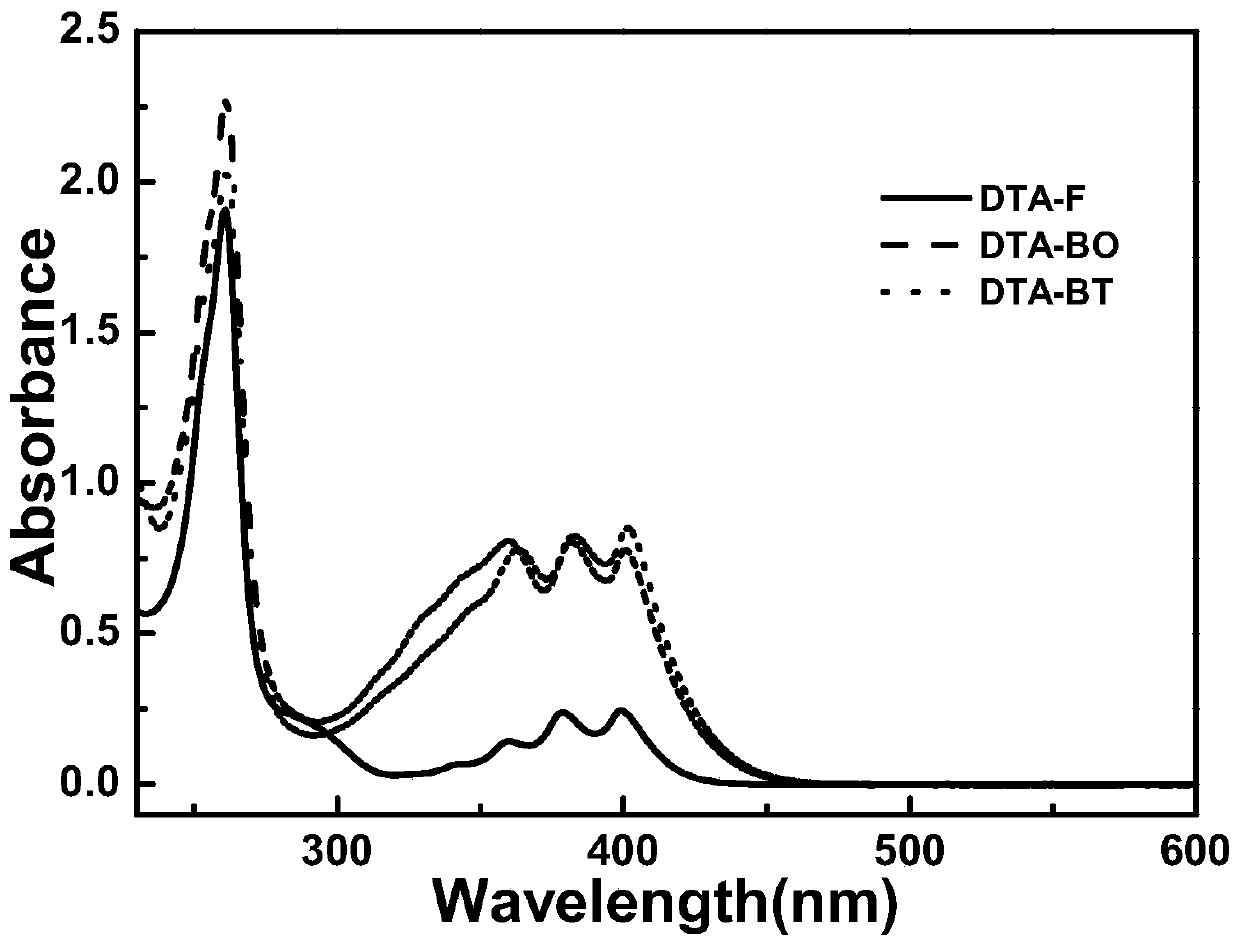

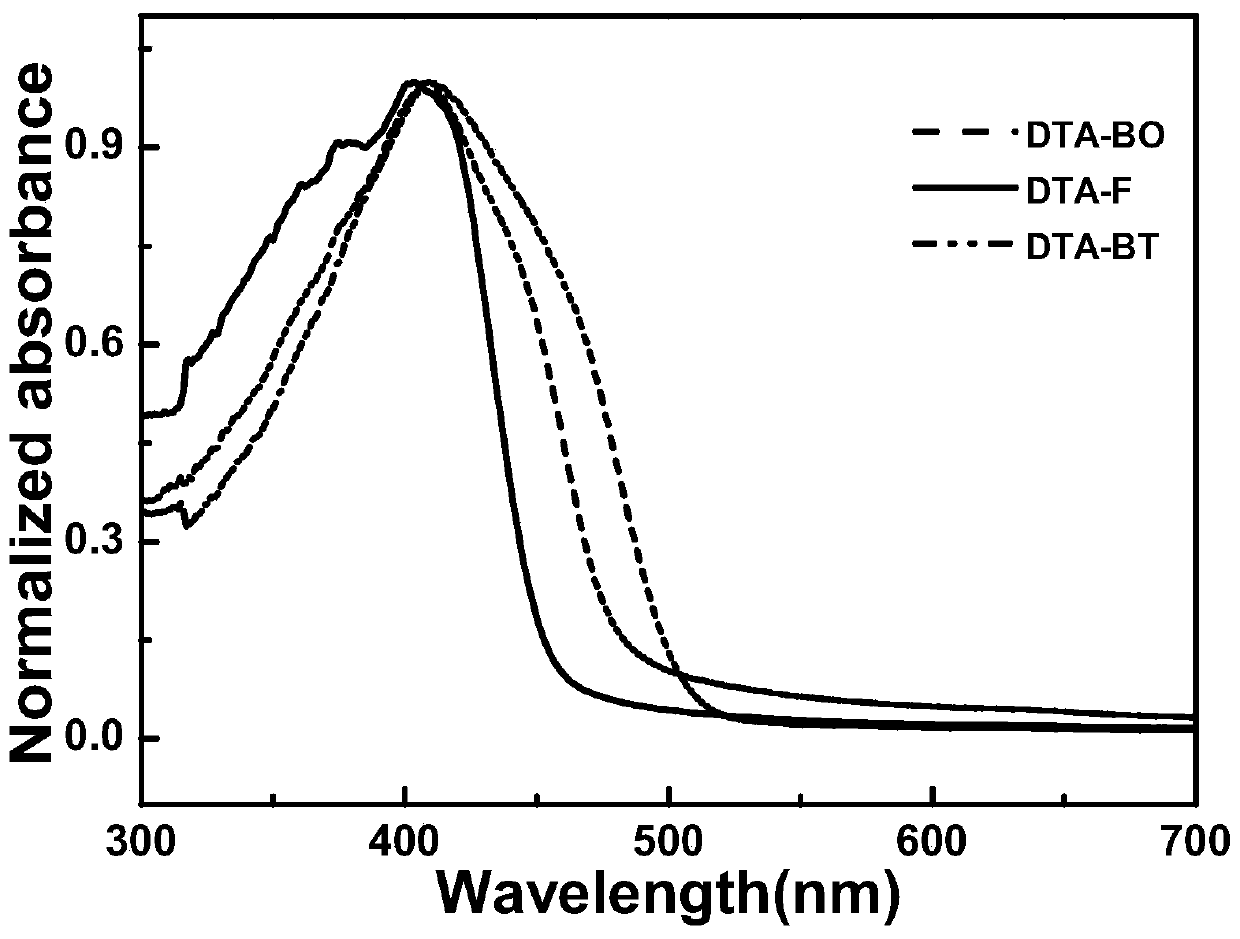

The invention relates to the technical field of aggregation-induced luminescent materials, and provides an asymmetric 9,10-dithienylanthracene fluorescence compound. [9-thienyl,10-(5-vinylbenzothiazolyl)-2-thienyl]anthracene (DAT-BT) and [9-thienyl, 10-(5-vinylbenzoxazolyl)-2-thienyl]anthracene (DAT-BO) have significant AIE characteristics and a significant mechanical grinding discoloration characteristic. The invention also provides a preparation method of the compound. The preparation method provided by the invention has the advantages of simple steps, low cost, mild preparation conditions,suitableness for industrial production, and great application prospect. The invention further provides applications of the asymmetric 9,10-dithienylanthracene fluorescence compound in cell fluorescence imaging, organic photoluminescence materials and mechanical photochromic materials.

Owner:豫章师范学院

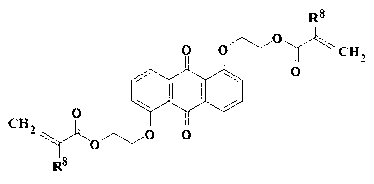

Dyestuff with polymerizable group and preparation of microspheres containing dyestuff

ActiveCN103319909AOvercoming incompatibilitiesEliminate colorless particlesMethine/polymethine dyesHydroxy-anthraquinone dyesPolymer scienceMembrane emulsification

The invention discloses dyestuff with a polymerizable group and the preparation of microspheres containing dyestuff. Dyestuff molecule covalence is bound into resin, and is compatible with other dewatering systems of resin, paraffin and the like, and the problem that pigment particles are can not be compatible in a scattering system easily is overcome; dyestuff exists in colourment in a molecule state, colorless particles can be completely eliminated, and the product quality can be improved. According to the dyestuff, emulsion is formed by a membrane emulsion method, and is polymerized again so as to obtain polymeric microspheres which are good in size, shape and uniformity, and have narrow particle diameter distribution, and the microsphere particles are regular in shape, are fresh in color, and have glossiness.

Owner:SPECIAL CHEM CO LTD DALIAN FIRSTAR

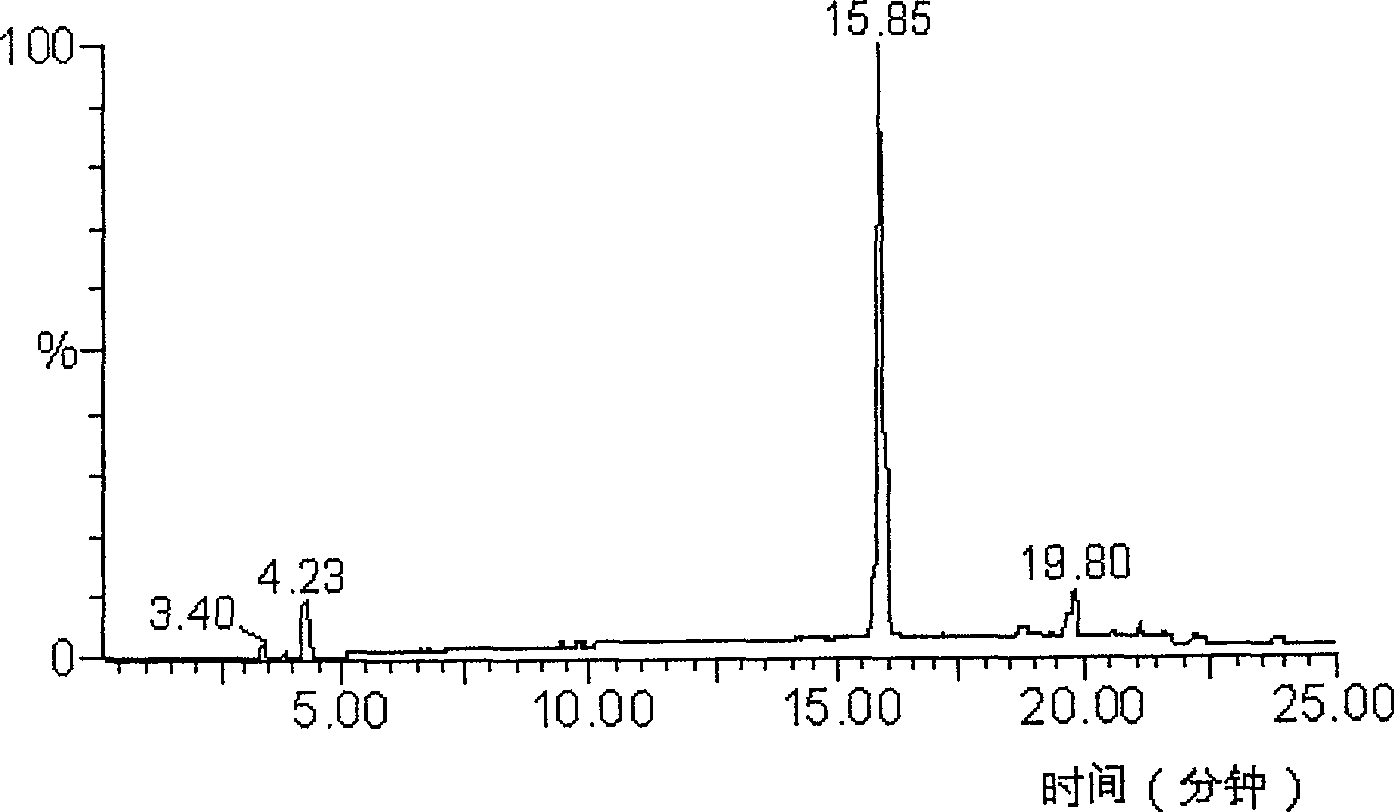

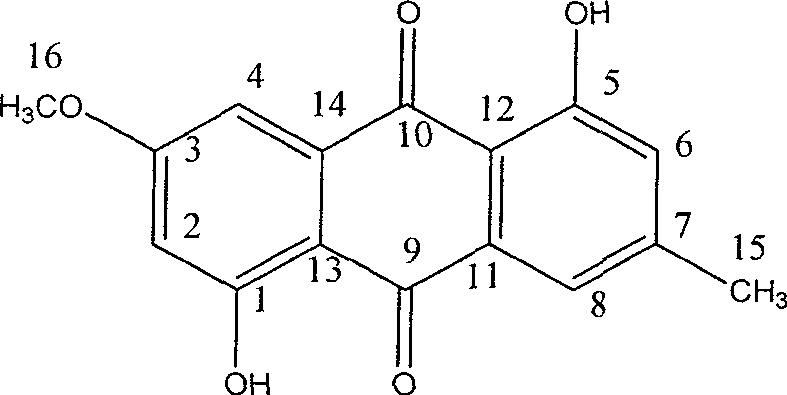

Method for preparing natural anthraquinone pigments using bamboo parasitic fungus fermentation

The invention relates the method for making anthraquinone pigments with bamboo yellow bacterium submerged cultuse, submerged cultuse liquid and anthraquinone pigments 1, 5- dihydroxy-3- methoxy-7- methyl-anthraquinonyl. The method comprises the following steps: using bamboo yellow bacterium as strain, carrying out fluid culture, fluid enlargement culture, one-level seed culture and submerged cultuse culture, separating the fermentation liquor, purifying, and getting the products. The invention first produces the anthraquinone pigments (I), which is brown solid. The products can be used as food additives, and have oxidation resistance and bacteriostasis.

Owner:JIANGNAN UNIV

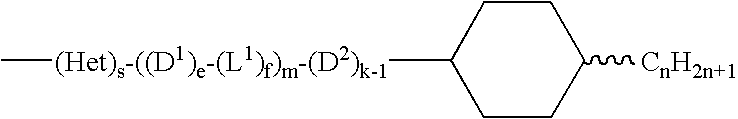

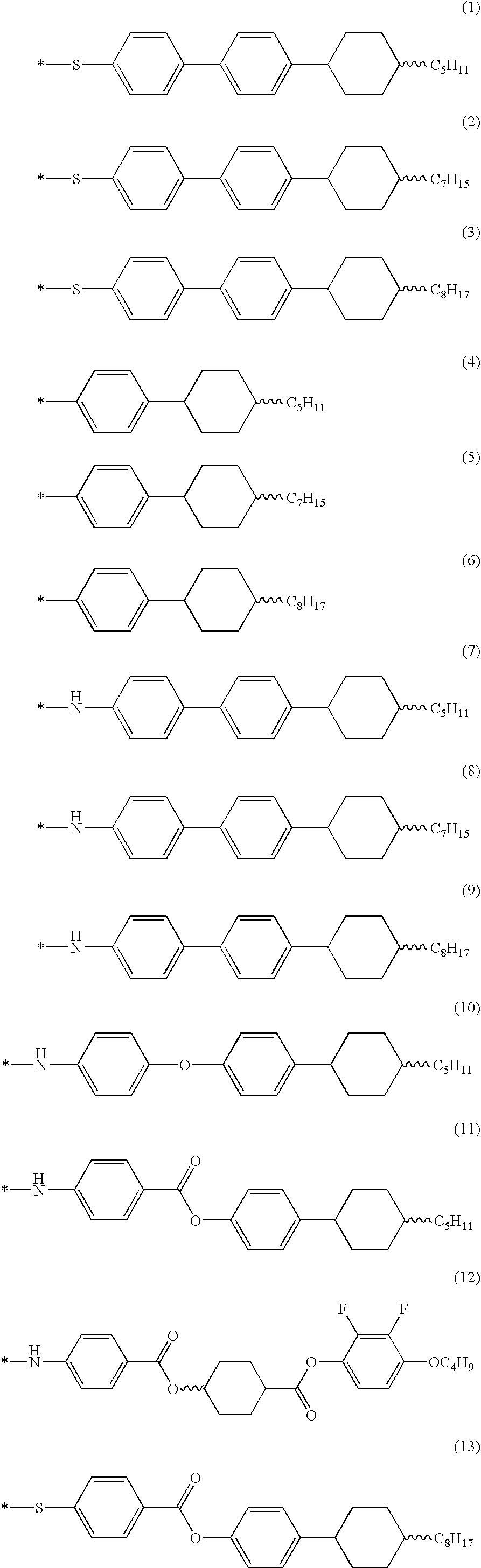

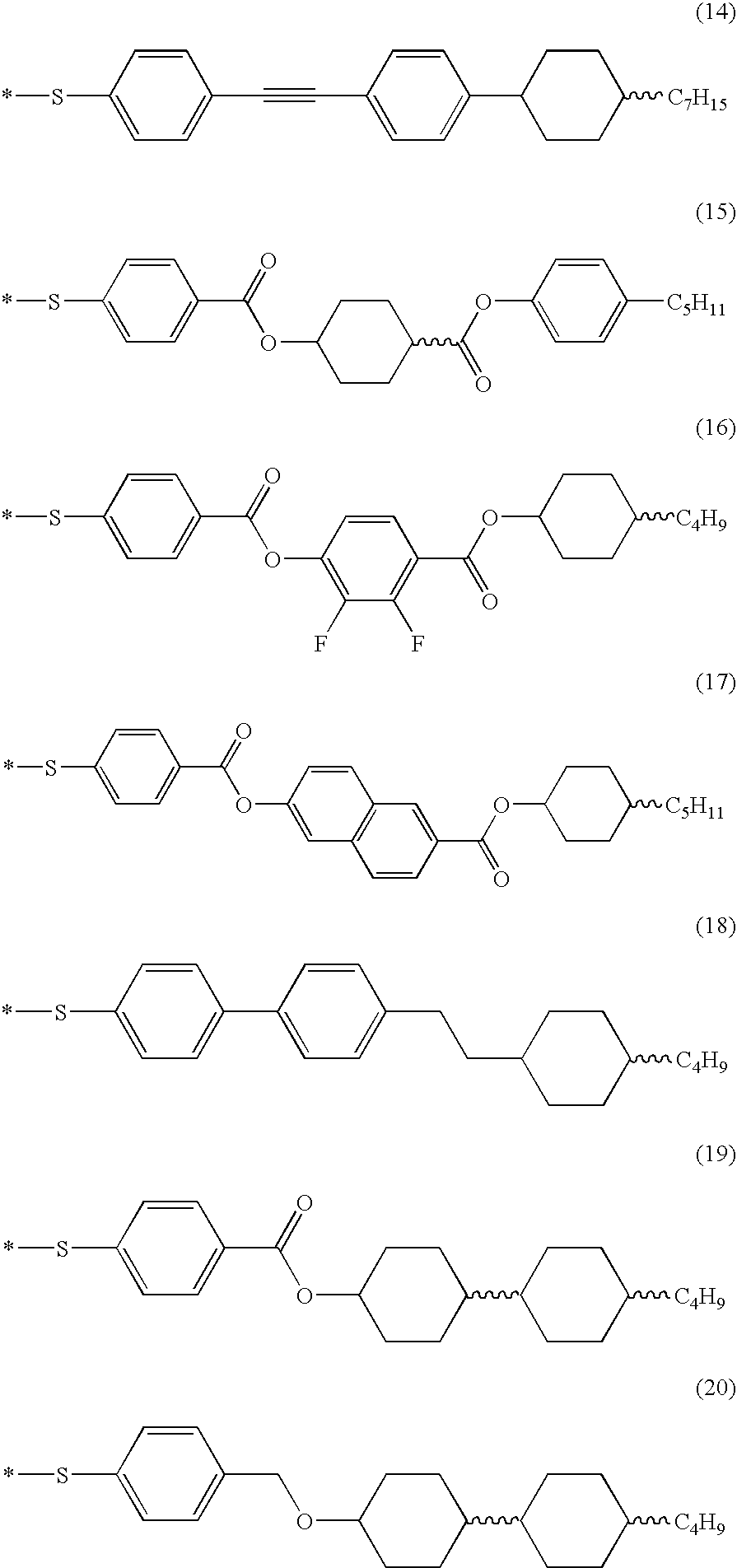

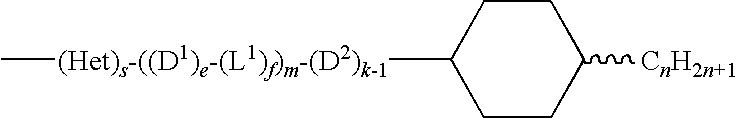

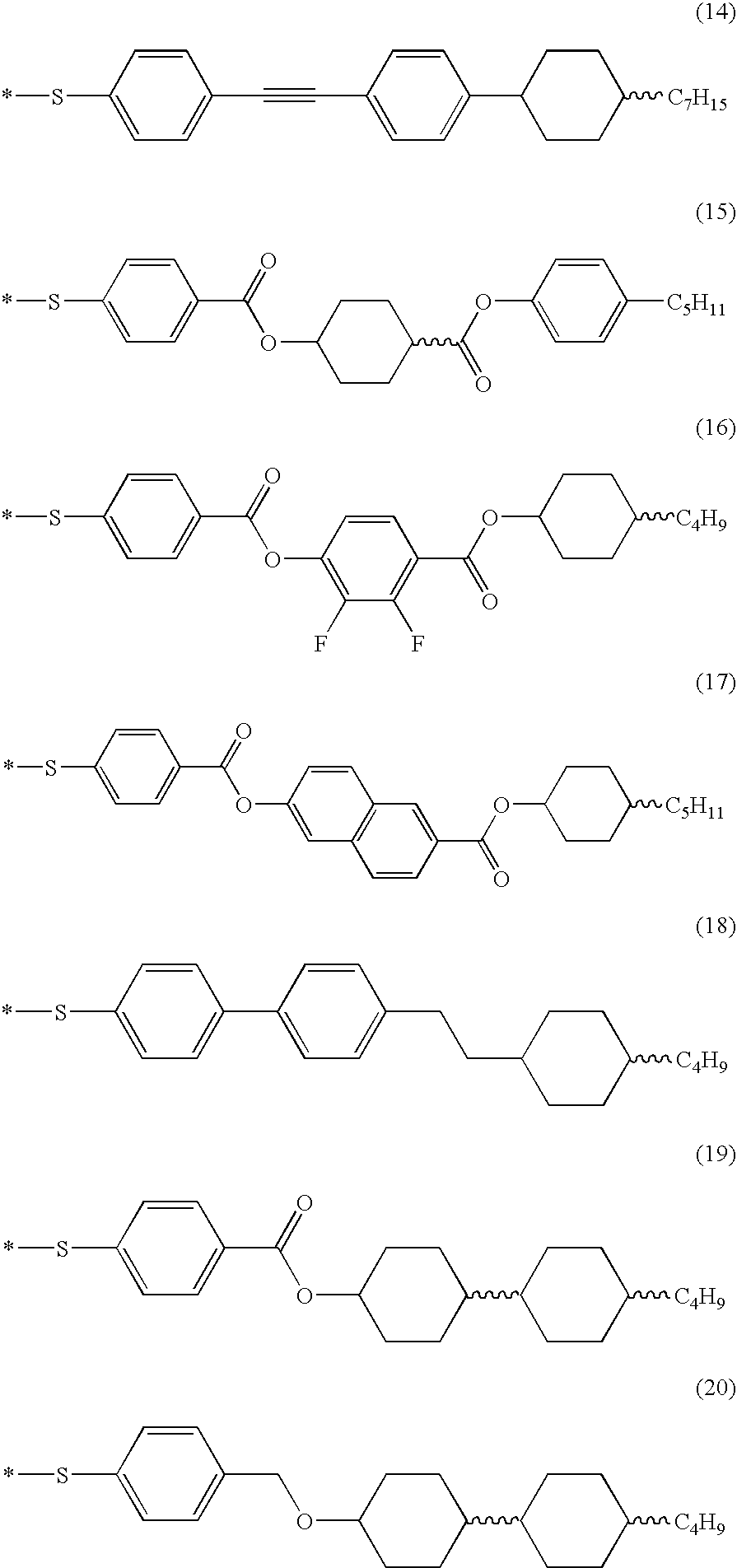

Dichroic dye, and liquid crystal composition and liquid crystal device using the same

The present invention provides one or more dichroic dyes which exhibit high solubility in liquid crystal and a high order parameter. The dichroic dyes each have a first substituent having at least one cis-cyclohexane ring and / or a second substituent having at least one trans-cyclohexane ring. The dichroic dye(s) may be provided as a mixture including at least a first dichroic dye having at least the first substituent and a second dichroic dye having at least the second substituent. The dichroic dye(s) may also be provided as a plurality of dichroic dyes, each of the molecules of which has at least the first substituent and the second substituent. The present invention also provides a liquid crystal composition and a liquid crystal element including the one or more dichroic dyes.

Owner:FUJIFILM CORP

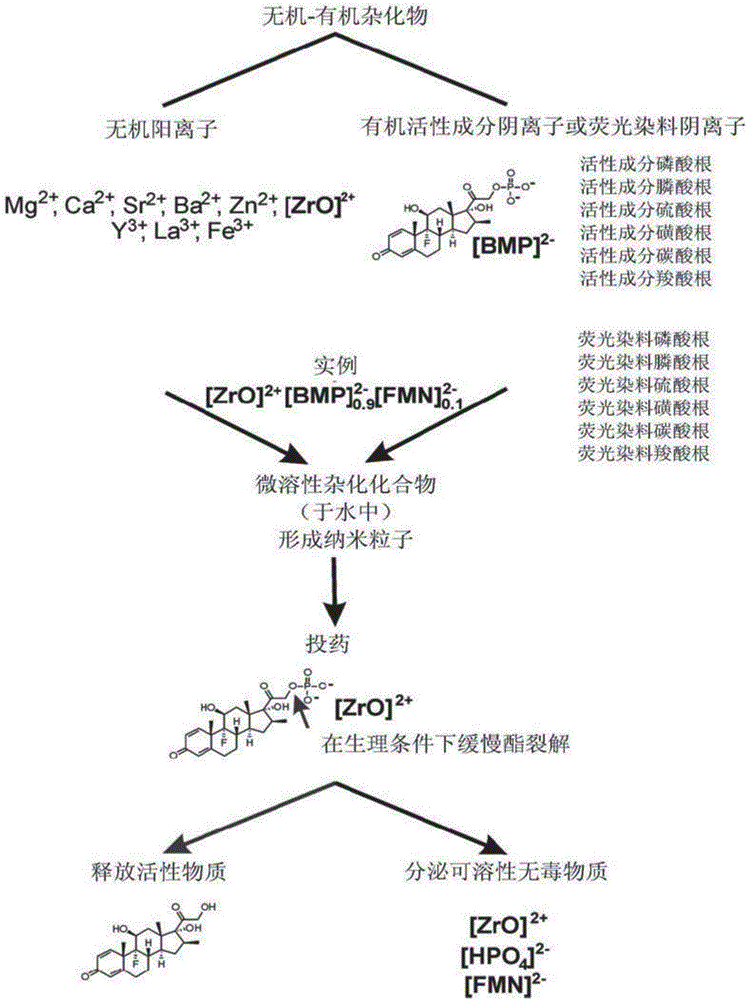

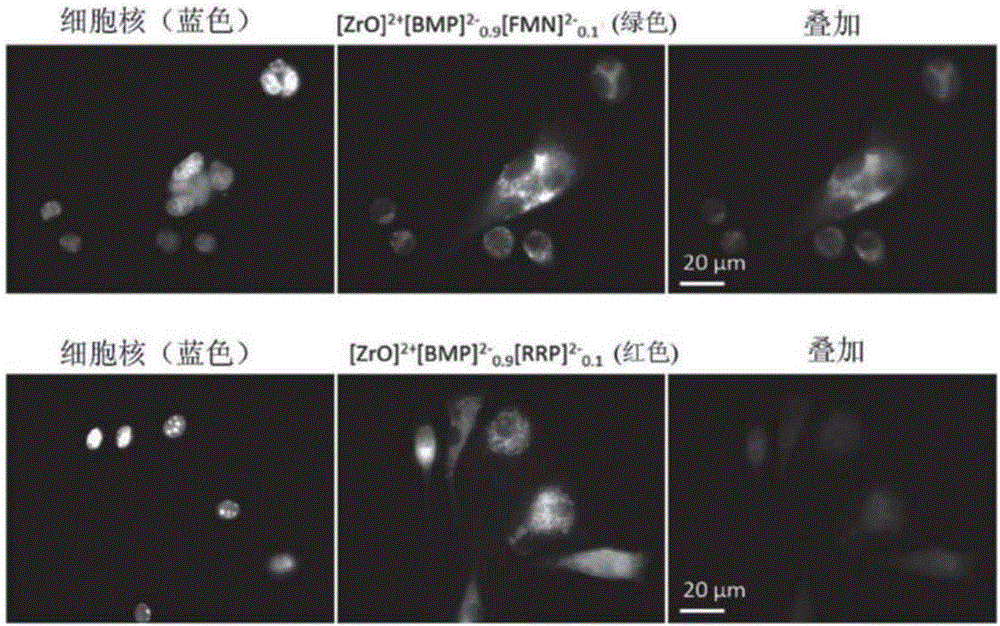

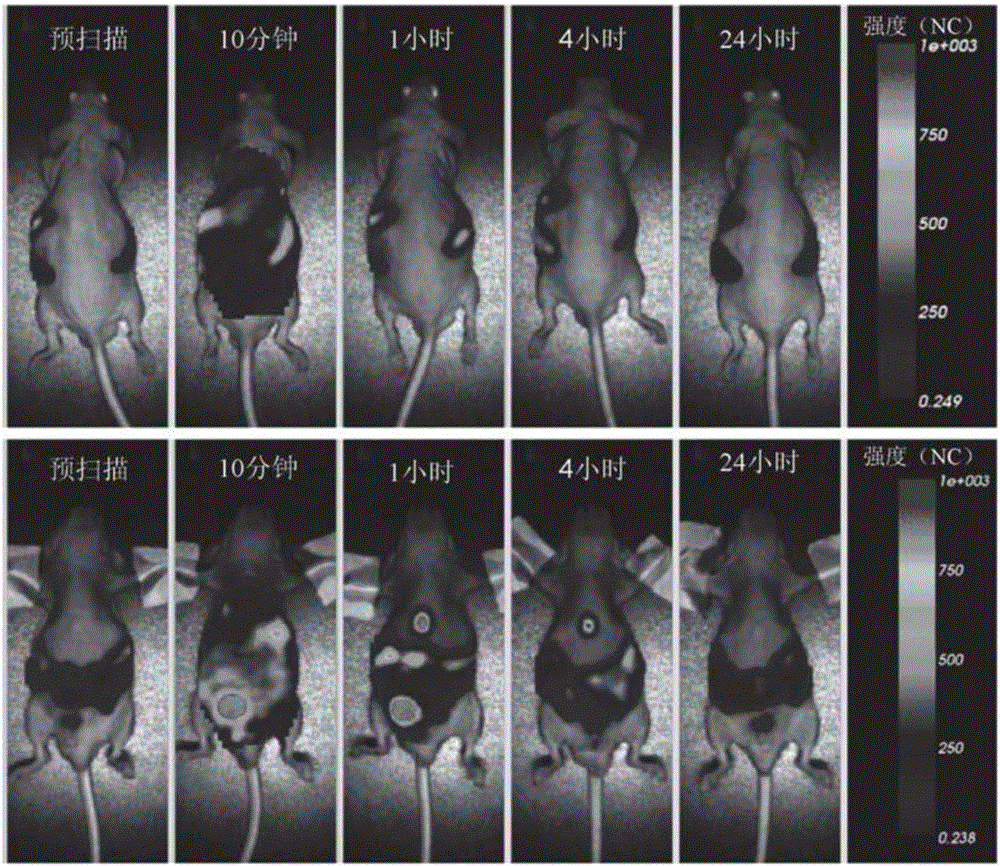

Inorganic-organic hybrid compound

InactiveCN106660944AChange ratioEasy to synthesizeAntibacterial agentsOrganic active ingredientsFluorescenceHybrid compound

The invention relates to an inorganic-organic hybrid compound as an ion compound, composed of an inorganic cation and an organic anion active substance and optionally, an organic anion fluorescent dye.

Owner:KARLSRUHER INST FUR TECH +1

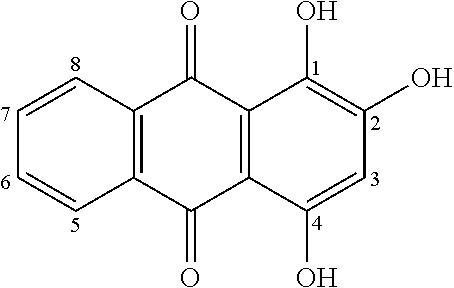

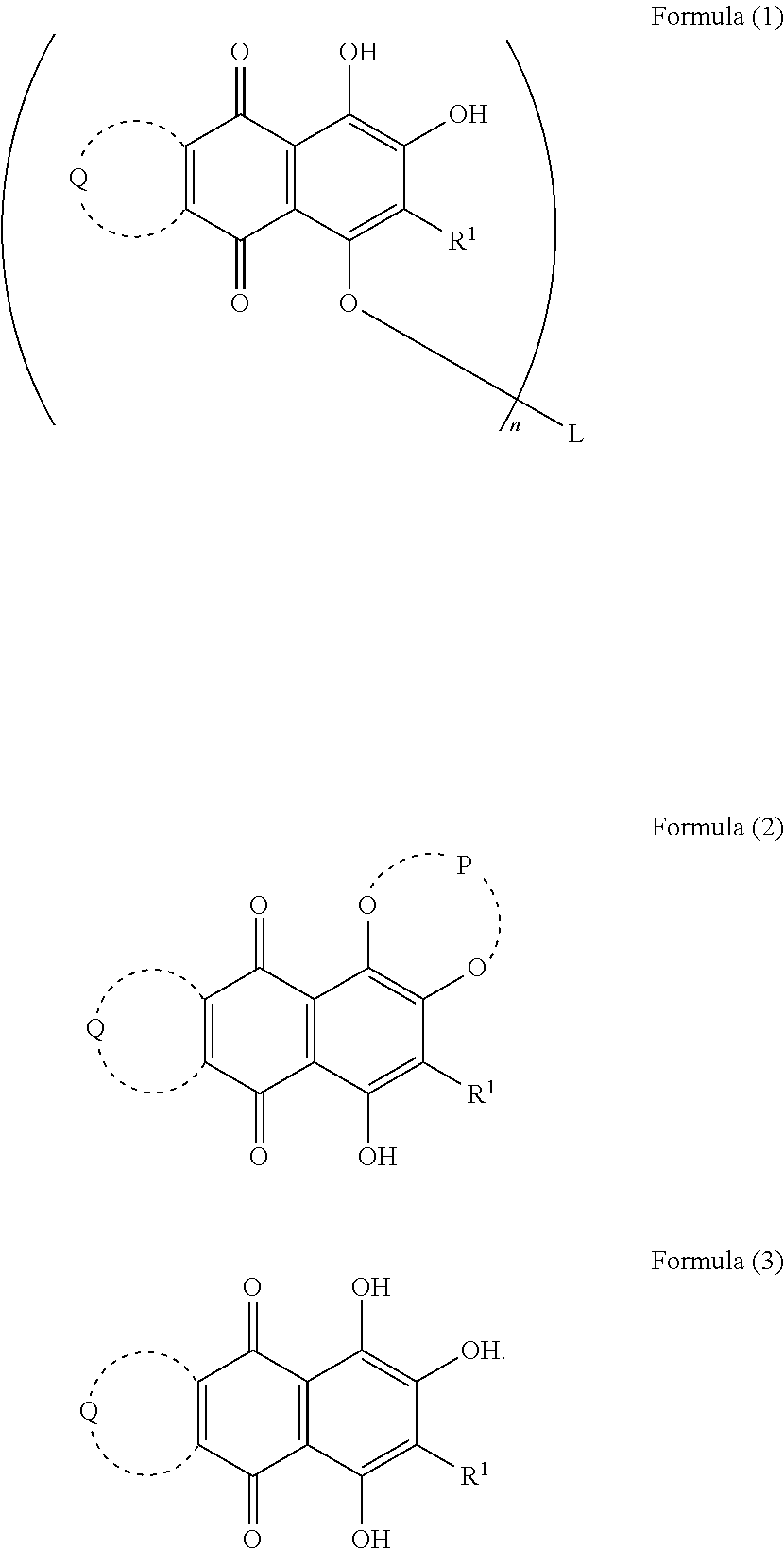

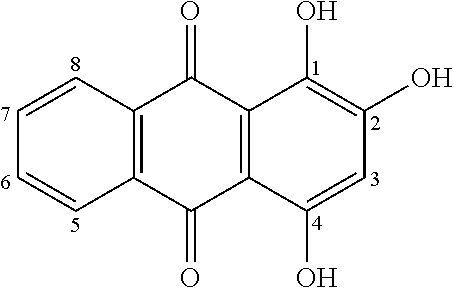

Method for preparing alizarin derivative compound, novel alizarin derivative compound, surface modification method, photoelectric conversion film, photoelectric conversion element, and electrophotographic photoreceptor

ActiveUS20120244462A1Simplified and low methodSimplified and low cost methodSilicon organic compoundsOrganic compound preparationHydrogen atomAlizarin

The present invention provides a novel alizarin derivative compound and a simplified and low cost method for preparing an alizarin derivative compound including: obtaining a compound represented by Formula (2) using a compound represented by Formula (3); and obtaining an alizarin derivative compound represented by Formula (1) using the compound represented by Formula (2); in Formulae (1) to (3), R1 represents a hydrogen atom or a substituent; n represents an integer of 1 to 3, L represents a specific alkyl group; Q represents an atomic group needed to form an aromatic ring or a heteroaromatic ring with adjacent carbon atoms; and P represents an atomic group which includes an atom(s) selected from a hydrogen atom, a carbon atom, an oxygen atom, a sulfur atom, a silicon atom and a boron atom, and which is needed to form a ring structure group with adjacent two oxygen atoms and two carbon atoms;

Owner:FUJIFILM CORP

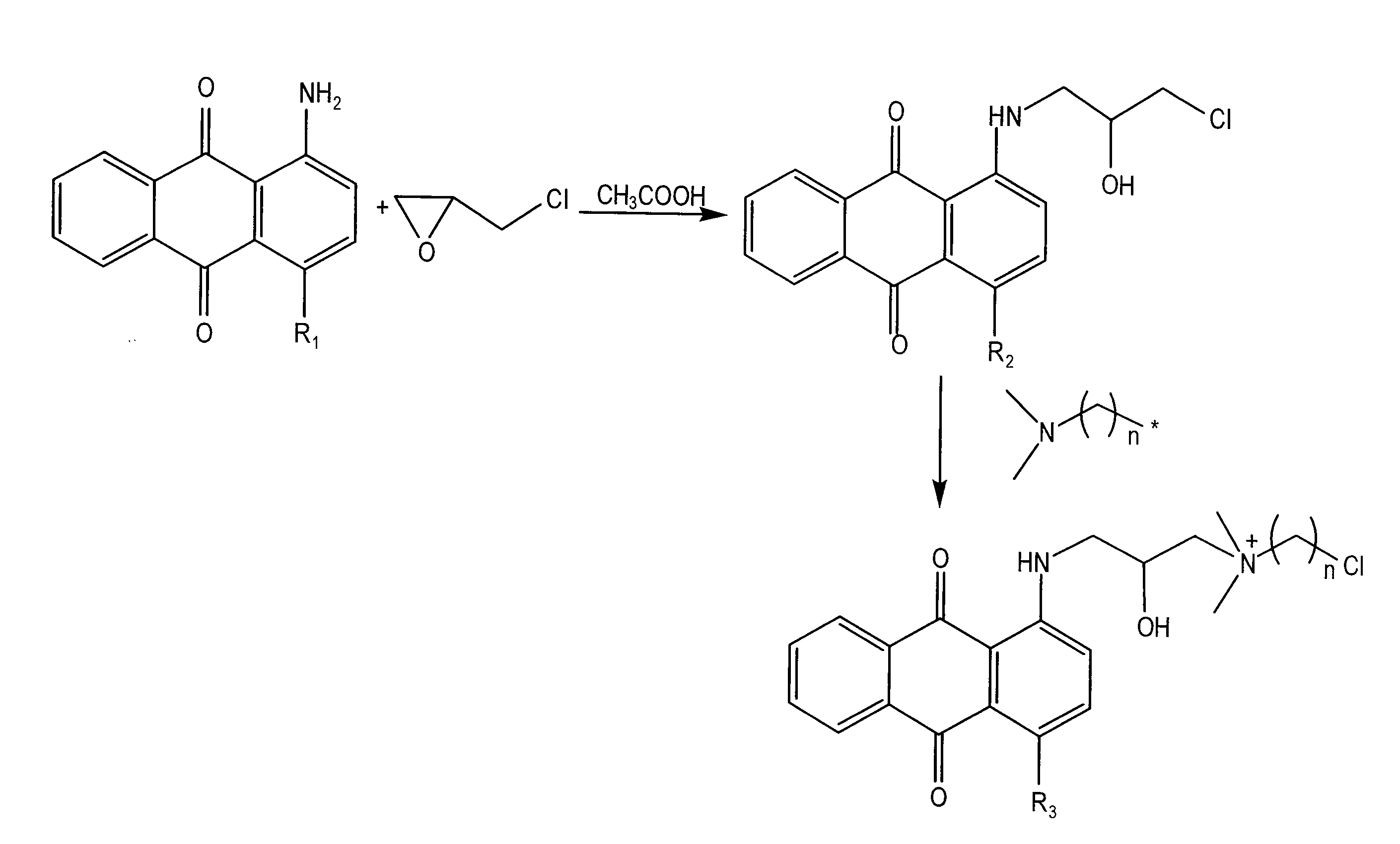

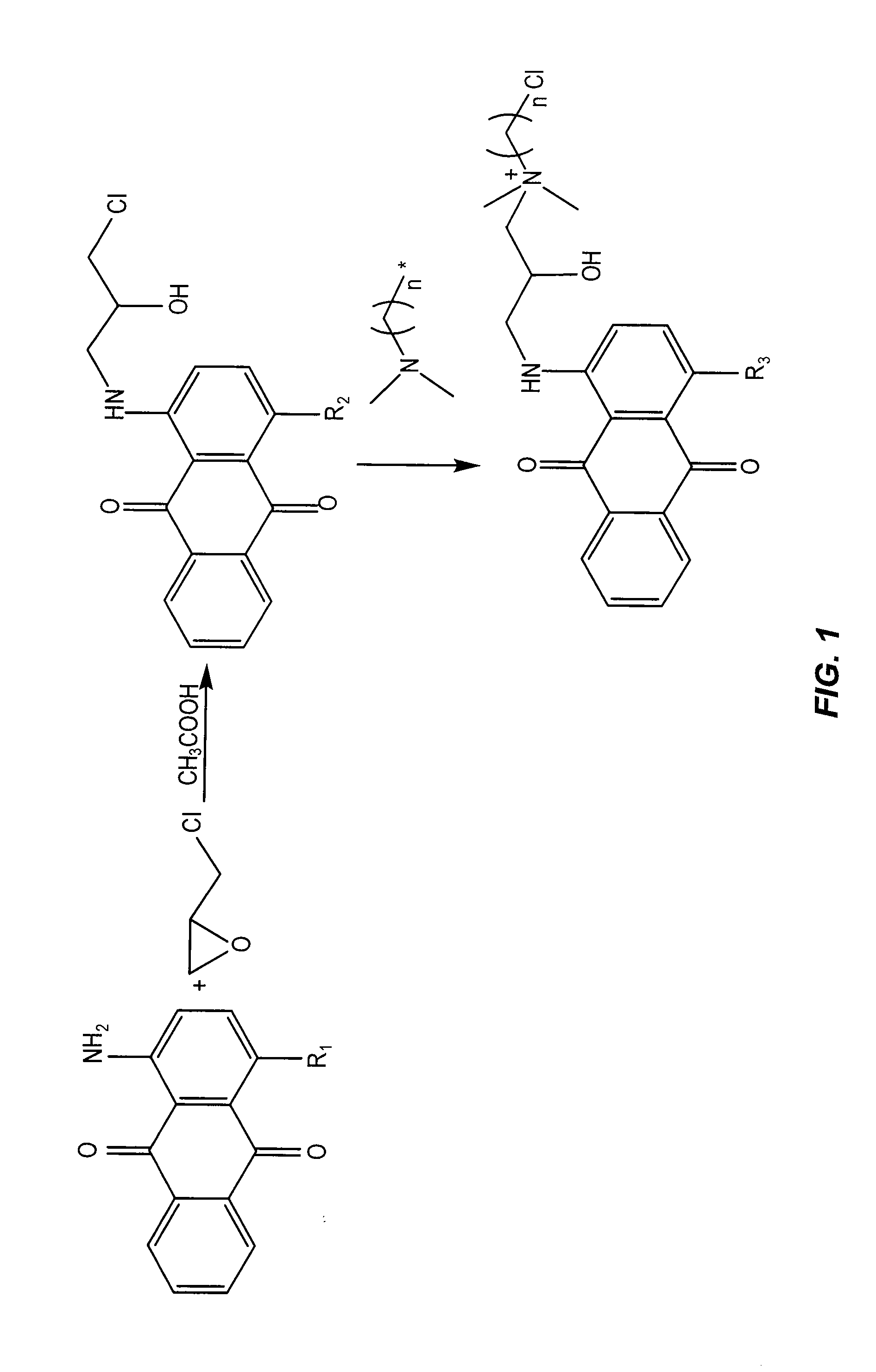

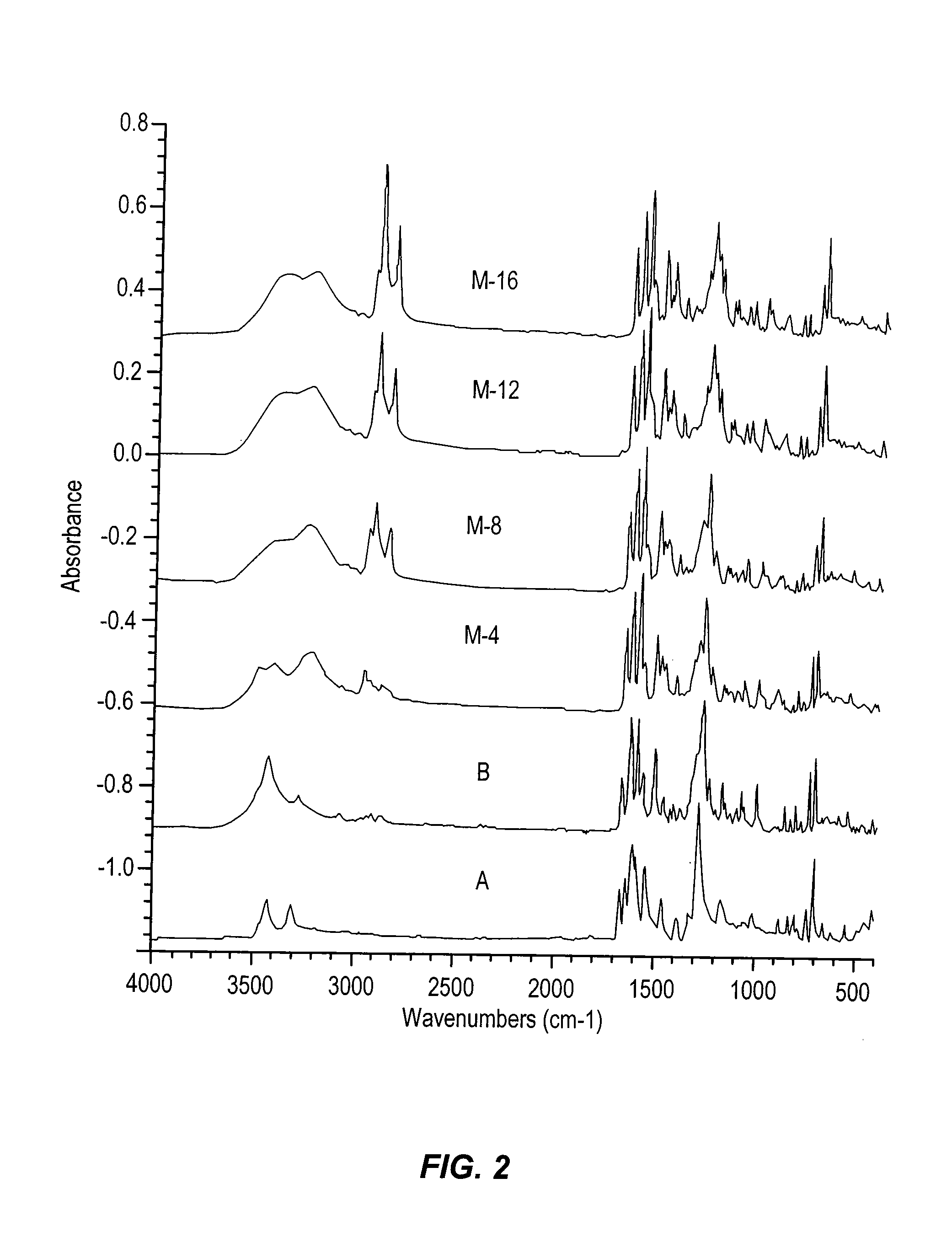

Antimicrobial colorants

InactiveUS20080201871A1Avoid pollutionEasy to wearBiocideOrganic chemistryMinimum inhibitory concentrationNuclear chemistry

Quaternary ammonium salts were incorporated into anthraquinone dyes via a stable linkage. The structure of the antimicrobial colorants were characterized by Fourier Transform Infrared (FTIR), Nuclear Magnetic Resonance (NMR) and UV-vis spectrometry. The dyes demonstrated excellent antimicrobial ability against both gram-negative and gram-positive bacteria in aqueous solution, as indicated by very low minimum inhibitory concentration (MIC). The colorants showed excellent stability in water under light, continuous heating as well as acidic and alkaline conditions.

Owner:RGT UNIV OF CALIFORNIA

Subcutaneous alizarin red S marking method for sepiella maindroni and special marking reagent thereof

InactiveCN101743918AEasy to operateReduce harmClimate change adaptationHydroxy-anthraquinone dyesComputer scienceALIZARIN RED

The invention discloses a subcutaneous alizarin red S marking method for sepiella maindroni. The method comprises the following steps: firstly, anesthesia step: selecting sepiella maindroni to be marked into MS-222 anesthetic solution with a concentration of 40ppm to 70ppm for 0.5 to 4 minutes; secondly, marking step: injecting dyeing liquor into the inner shell of the sepiella maindroni treated in step one with an injector. Because the MS-222 anesthetic solution is used for performing anesthesia processing to the sepiella maindroni, the sepiella maindroni basically has no stress when being injected with dyeing liquor, thereby being convenient for operation and reducing the hurt to the sepiella maindroni. The special marking reagent for the subcutaneous alizarin red S marking method for sepiella maindroni comprises 1 part of alizarin red S powder and 4-8 parts of yoghourt according to part by weight, marks can be formed in relatively concentrated subcutaneous areas and are more highly identifiable than the ordinary dyeing marks. In addition, by using the method, after being resuscitated, the sepiella maindroni is not required to be raised temporarily to remove the floating color but can be freed immediately.

Owner:ZHEJIANG OCEAN UNIV

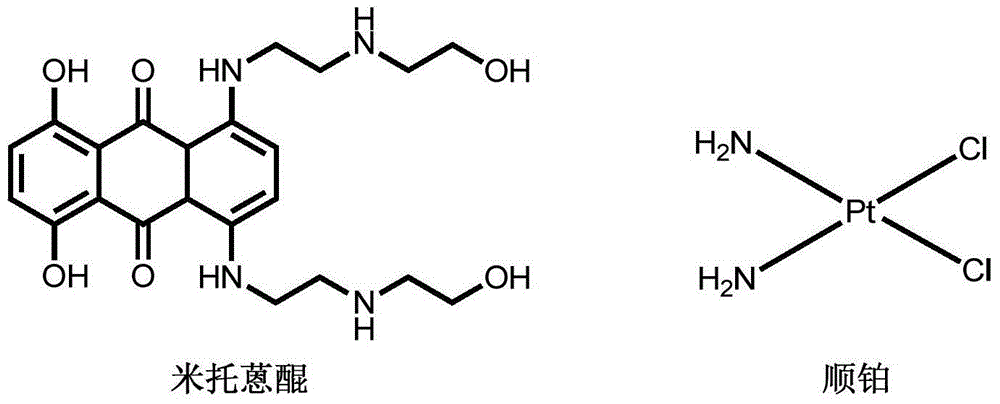

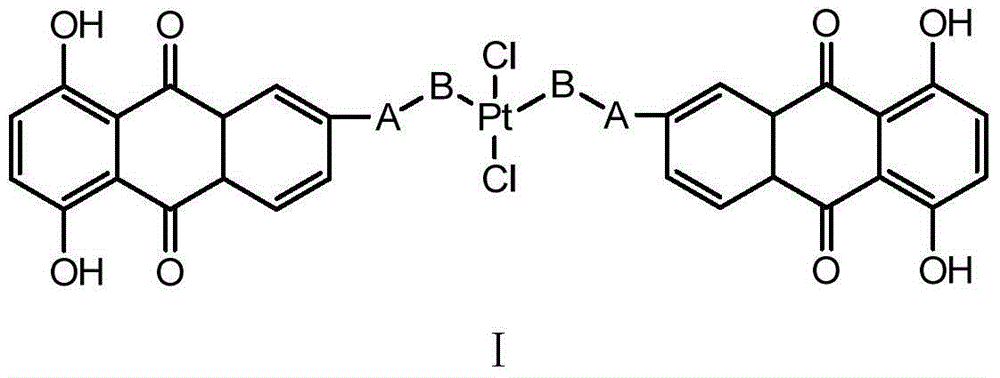

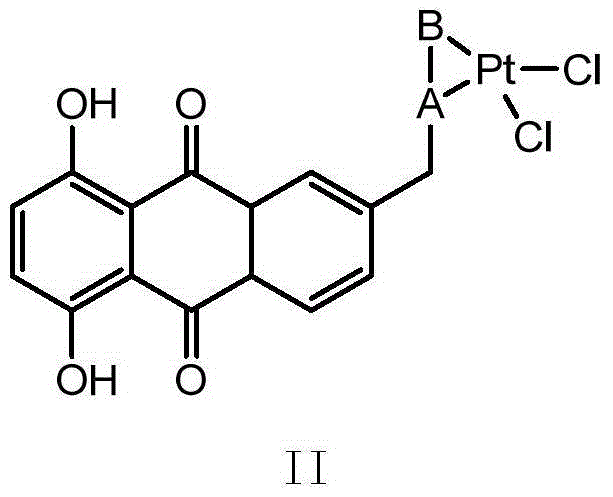

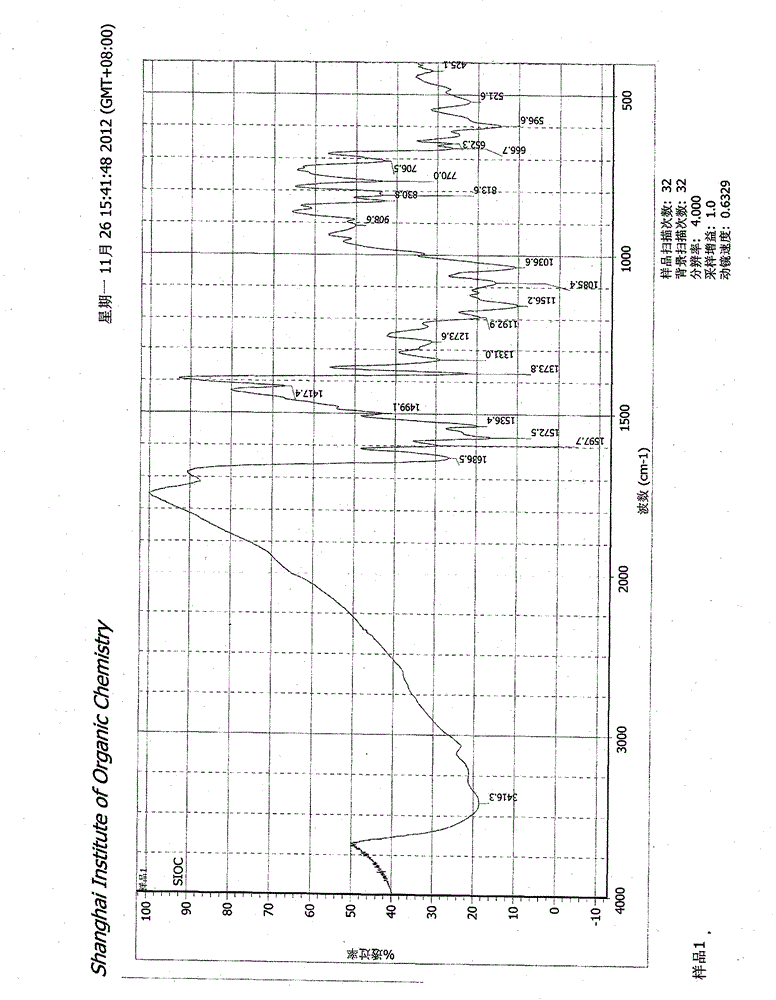

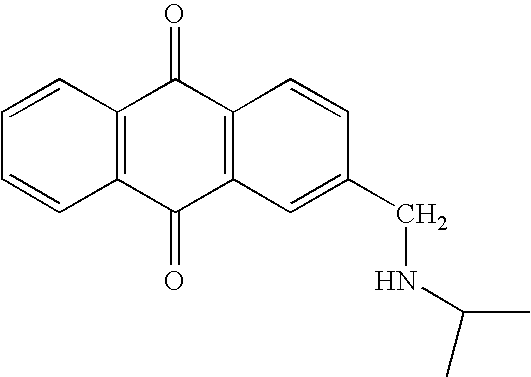

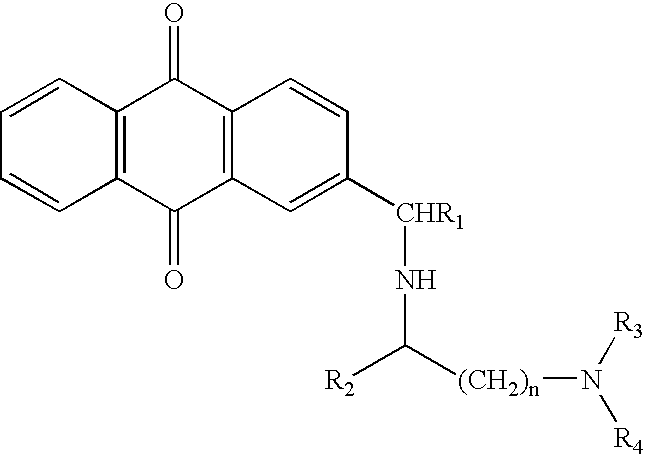

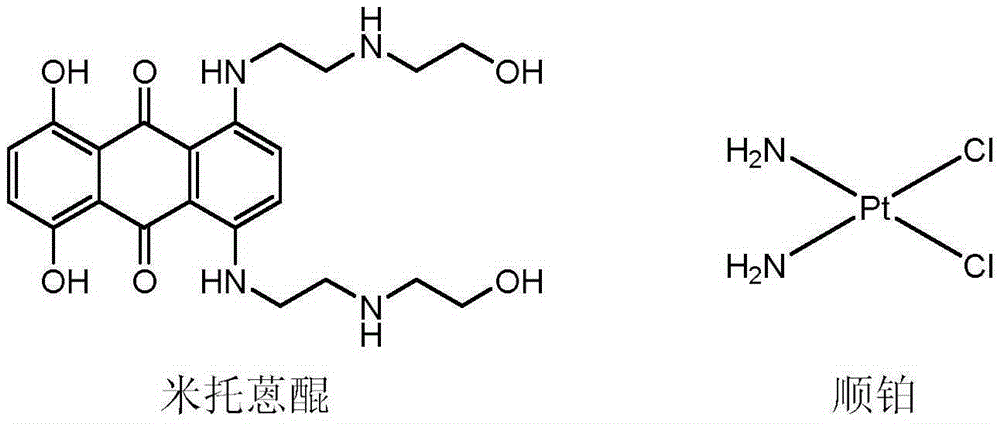

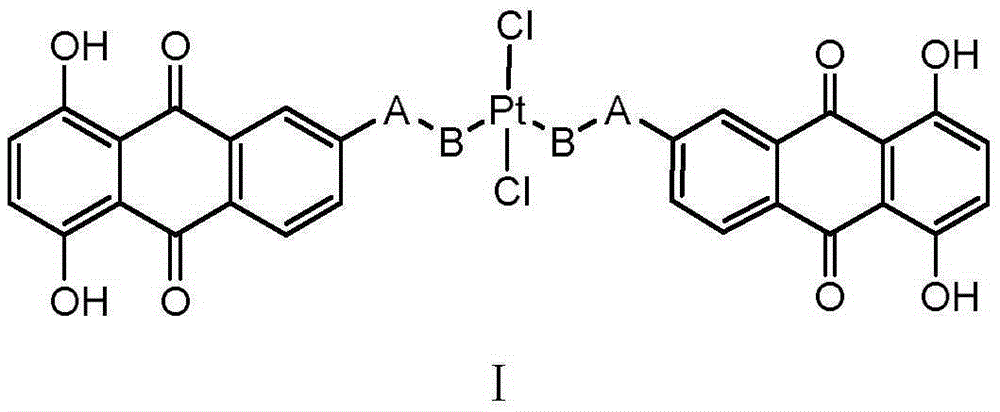

6-(azacyclo-substitute) anthraquinone platinous chloride complex as well as preparation method and application thereof

ActiveCN103554188AGood antitumor activityImprove securityOrganic active ingredientsHydroxy-anthraquinone dyesMedicineChloride

The invention discloses a 6-(azacyclo-substitute) anthraquinone platinous chloride complex as well as a preparation method and an application thereof. The 6-(azacyclo-substitute) anthraquinone platinous chloride complex disclosed by the invention has the structure of a formula I. The complex disclosed by the invention has good anti-tumor activity and security, and has great application values in treating lung cancer, liver cancer, leukemia, colon cancer and ovarian cancer in the medicine field.

Owner:LIAONING UNIVERSITY

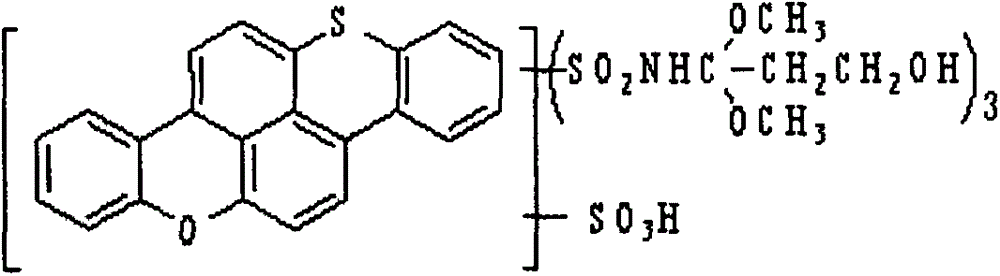

Modified anthraquinone coloring agent

The invention discloses a modified anthraquinone coloring agent, which is prepared by introducing amino groups / substituted amino groups / piperidyl groups and water-soluble sulfonic groups into the molecular structure of a water-insoluble anthraquinone dye taken as the basic material through modification. The modified anthraquinone coloring agent has a structural formula (1) which is represented in the description, and has the characteristics of bright color, strong coloring performance, high coloring rate, good cooperation among each component, no layering, no deposition, and low color degree, high solubility, and good stability of sewage after the paper pulp coloring process,. The using amount of color-fixing agent used in the conventional printing and dyeing process is reduced, so the pollution to the environment is reduced. Moreover the modified anthraquinone coloring agent can be easily applied to industrial production, so the costs for papermaking and paper printing and dyeing are greatly reduced.

Owner:上海汇友精密化学品有限公司

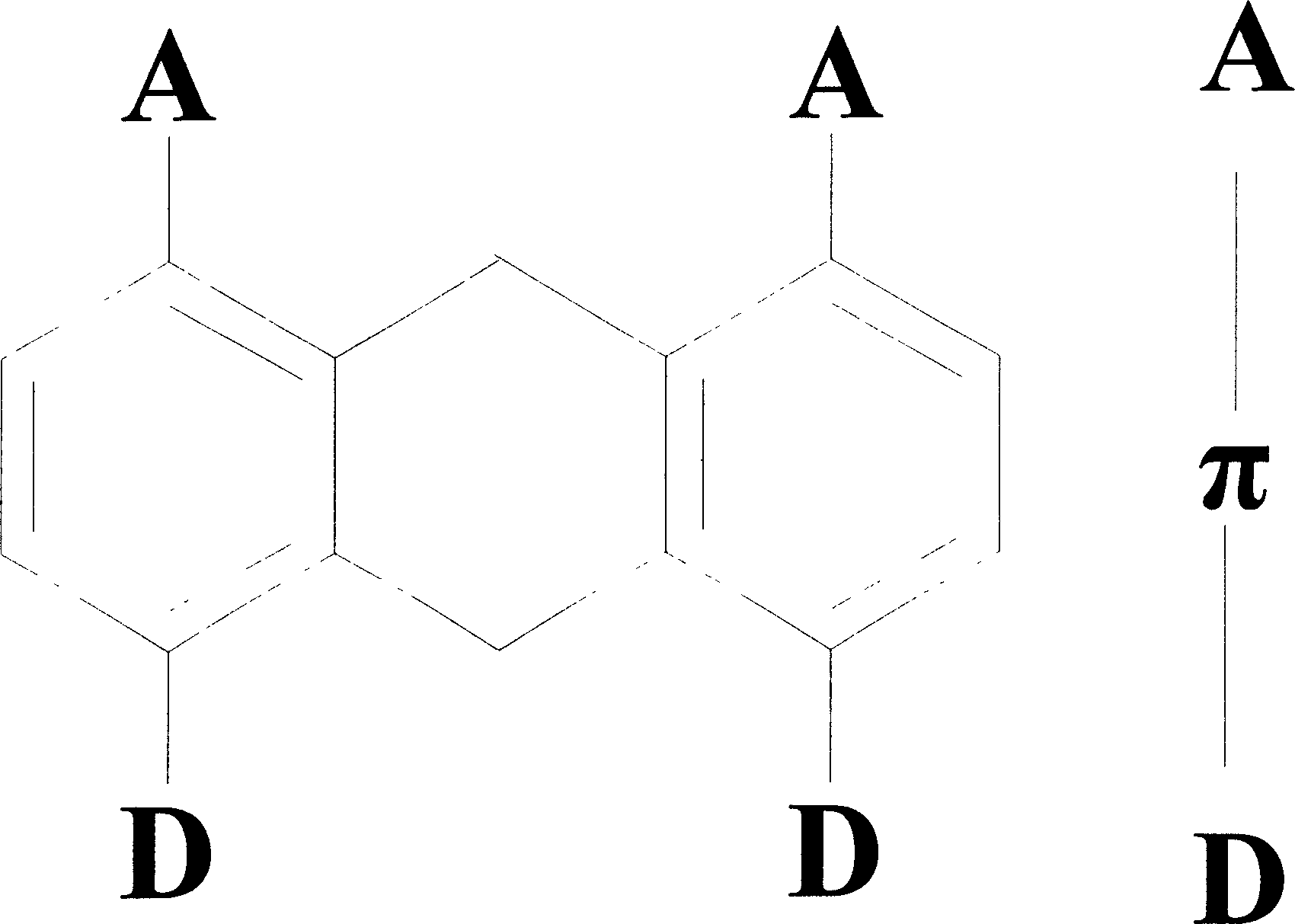

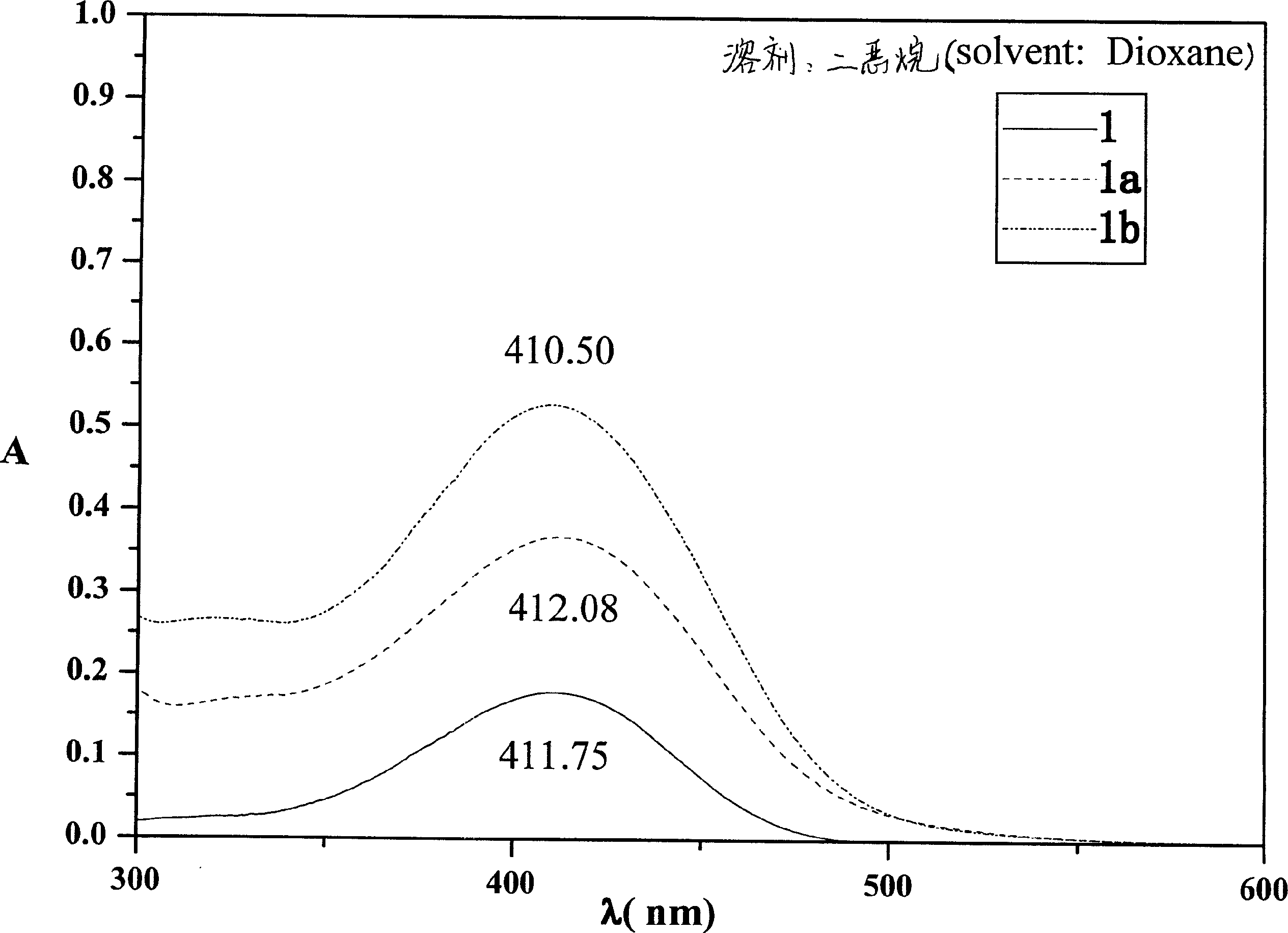

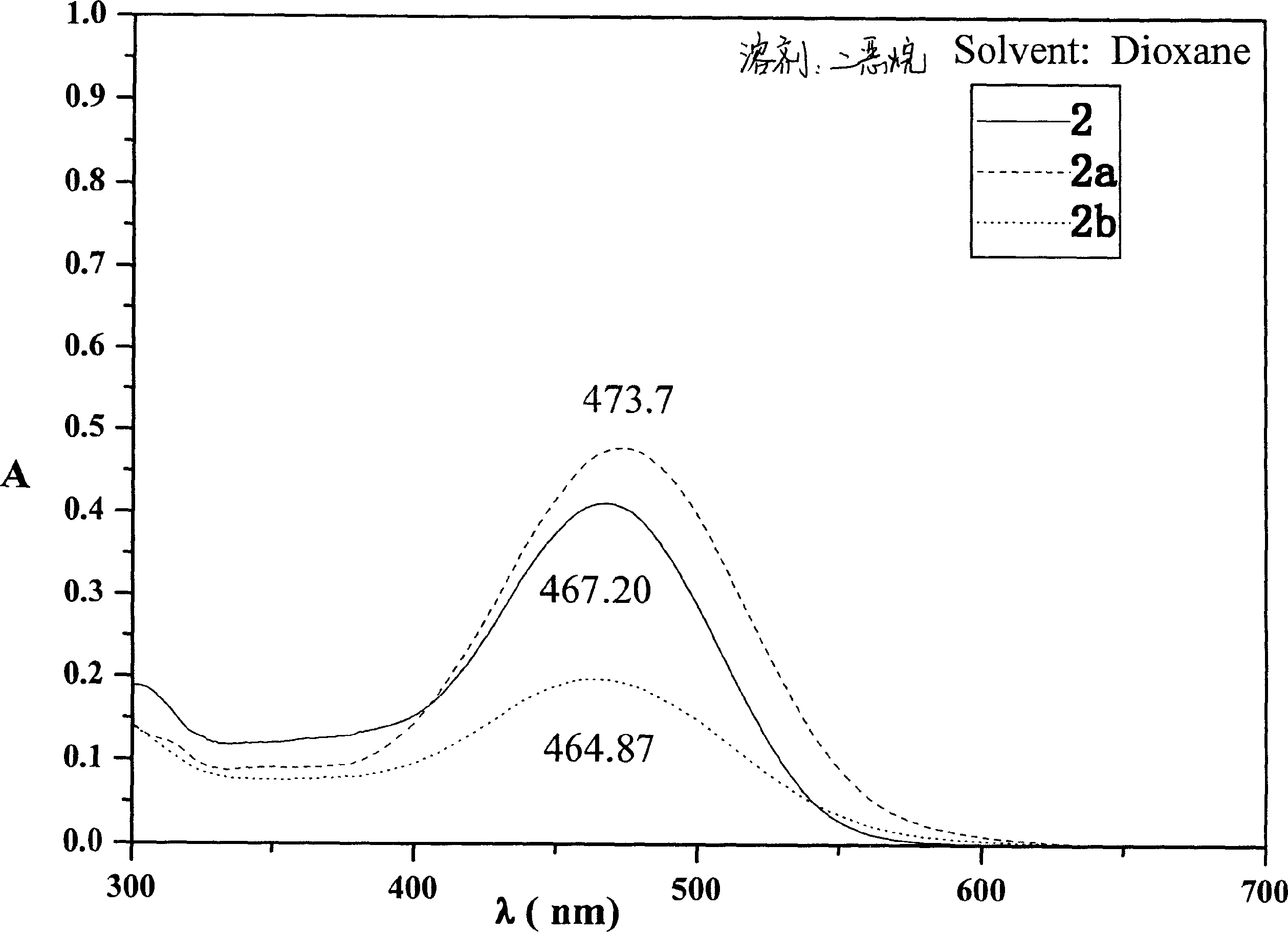

9, 10-dihydroanthracene chromophore compound and its preparing process

InactiveCN1621452ALarge second order nonlinear coefficientGood light transmissionHydroxy-anthraquinone dyesHexahydropyridineDichloromethyl ether

The present invention relates to relates to 9, 10-dihydro anthracene chromophore compound and its preparation. The preparation process includes the following steps: introducing two formyls with 1, 1-dichloromethyl ether as formylation reagent to the methoxyl para position of the material 1, 8-dimethoxyl-9, 10-dihydro anthracene under the catalysis of Lewis acid and titanium tetrachloride to obtain 4, 5-dimethoxyl-1, 8-diformyl-9, 10-dihydro anthracene; and the reflux reaction between 4, 5-dimethoxyl-1, 8-diformyl-9, 10-dihydro anthracene and isophorone -malononitrile condensate or isophorone -barbituric acid condensate in absolute alcohol as solvent in the catalysis of hexahydropyridine and acetic acid to obtain the organic compound. The compound of the present invention has high second-order non-linear coefficient and excellent transmittancy and may be used as second-order non-linear optical material, especially laser frequency doubling material.

Owner:NANJING UNIV

Method for preparing alizarin derivative compound, novel alizarin derivative compound, surface modification method, photoelectric conversion film, photoelectric conversion element, and electrophotographic photoreceptor

ActiveUS8741513B2Simplified and low methodLow costOrganic compound preparationHydroxy-anthraquinone dyesHydrogen atomAlizarin

The present invention provides a novel alizarin derivative compound and a simplified and low cost method for preparing an alizarin derivative compound including: obtaining a compound represented by Formula (2) using a compound represented by Formula (3); and obtaining an alizarin derivative compound represented by Formula (1) using the compound represented by Formula (2); in Formulae (1) to (3), R1 represents a hydrogen atom or a substituent; n represents an integer of 1 to 3, L represents a specific alkyl group; Q represents an atomic group needed to form an aromatic ring or a heteroaromatic ring with adjacent carbon atoms; and P represents an atomic group which includes an atom(s) selected from a hydrogen atom, a carbon atom, an oxygen atom, a sulfur atom, a silicon atom and a boron atom, and which is needed to form a ring structure group with adjacent two oxygen atoms and two carbon atoms;

Owner:FUJIFILM CORP

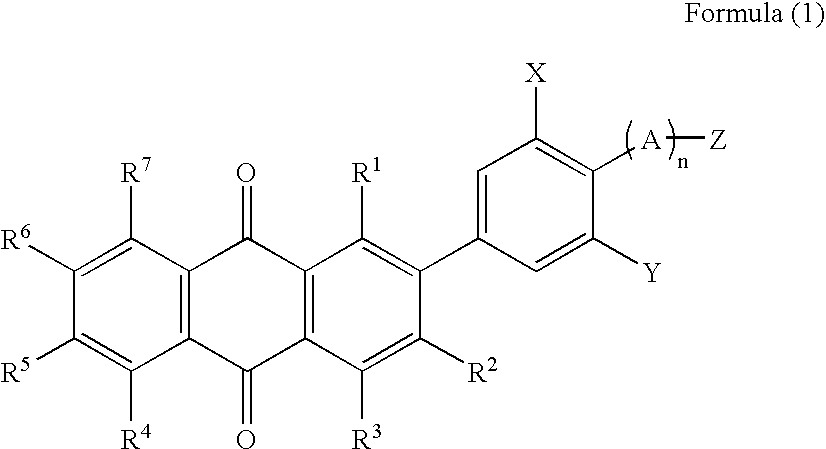

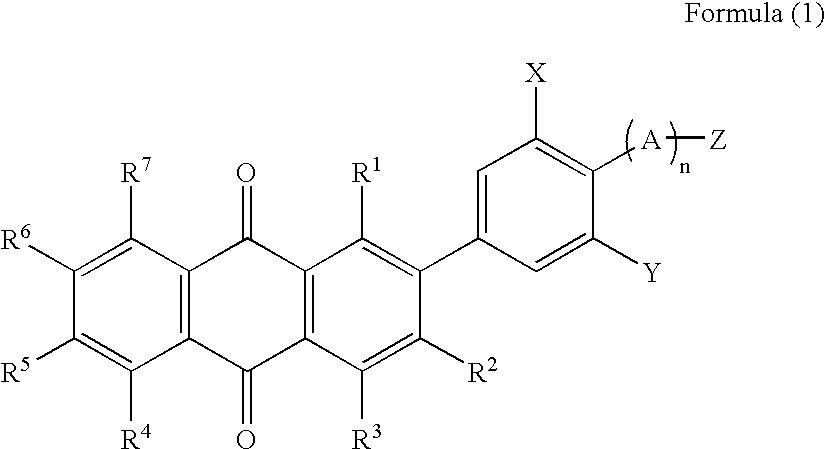

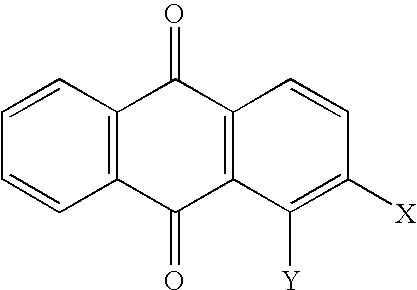

Liquid crystal composition, liquid crystal device, reflection display material, light modulating material, and anthraquinone compound

ActiveUS20090074991A1Liquid crystal compositionsOrganic compound preparationLiquid crystallineAcyl group

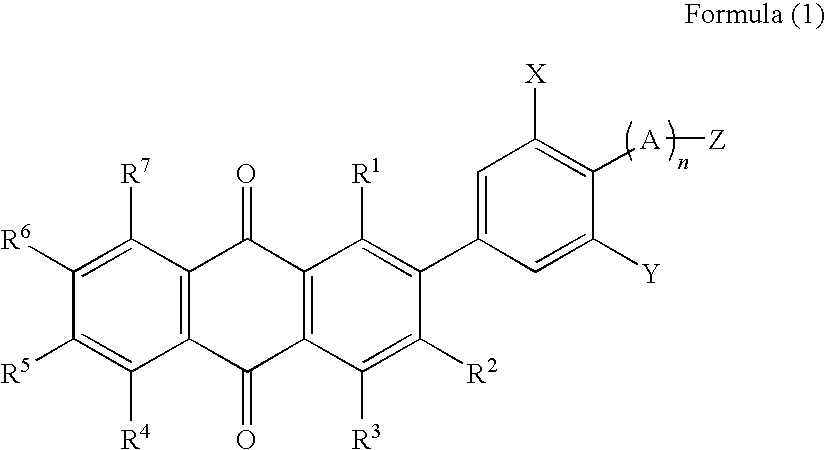

The liquid crystal composition of the present invention contains a compound represented by the following Formula (1) and a liquid crystal. In Formula (1), at least one among R1 to R7 is a liquid crystalline substituent, and those among R1 to R7 that are not a liquid crystalline substituent each independently represent a hydrogen atom or a substituent. X and Y each independently represent an alkyl group, a halogen atom, an alkoxy group, or an alkylthio group. Z represents an alkyl group having 3 or more carbon atoms, an acyl group, or an aryl group. A represents an oxygen atom, a sulfur atom, or a nitrogen atom. n represents 0 or 1. The liquid crystal device, reflection display material, and light modulating material of the invention contain the liquid crystal composition.

Owner:FUJIFILM CORP

Method for preparing natural anthraquinone pigments using bamboo parasitic fungus fermentation

The present invention relates to the field of biological fermentation, in particular the present invention relates to a method for preparing anthraquinone pigments by submerged fermentation of bamboo yellow bacteria, and the submerged fermentation liquid obtained by the method and the anthraquinone pigment 1,5-di Hydroxy-3-methoxy-7-methylanthraquinone. The method comprises the steps of carrying out liquid shake flask culture, liquid shake flask expanded culture, primary seed culture and submerged fermentation culture with bamboo yellow fungus as the starting strain, and separating and purifying the obtained fermented liquid. The present invention realizes for the first time the production of anthraquinone pigments of formula (I) through bamboo yellow fungus submerged fermentation technology, and the compound is a brown-red solid. The fermented liquid and anthraquinone pigments obtained by the method of the invention can be used as pigments as food additives, and the pigments of the invention also have anti-oxidation and / or antibacterial effects.

Owner:JIANGNAN UNIV

Liquid crystal composition, liquid crystal device, reflection display material, light modulating material, and anthraquinone compound

ActiveUS7722784B2Liquid crystal compositionsOrganic compound preparationLiquid crystallineAcyl group

The liquid crystal composition of the present invention contains a compound represented by the following Formula (1) and a liquid crystal. In Formula (1), at least one among R1 to R7 is a liquid crystalline substituent, and those among R1 to R7 that are not a liquid crystalline substituent each independently represent a hydrogen atom or a substituent. X and Y each independently represent an alkyl group, a halogen atom, an alkoxy group, or an alkylthio group. Z represents an alkyl group having 3 or more carbon atoms, an acyl group, or an aryl group. A represents an oxygen atom, a sulfur atom, or a nitrogen atom. n represents 0 or 1. The liquid crystal device, reflection display material, and light modulating material of the invention contain the liquid crystal composition.

Owner:FUJIFILM CORP

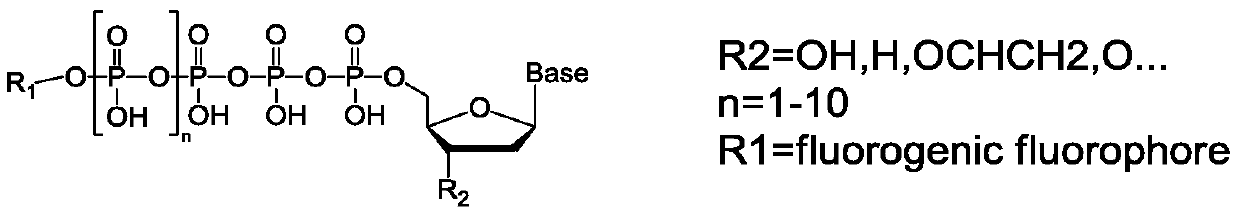

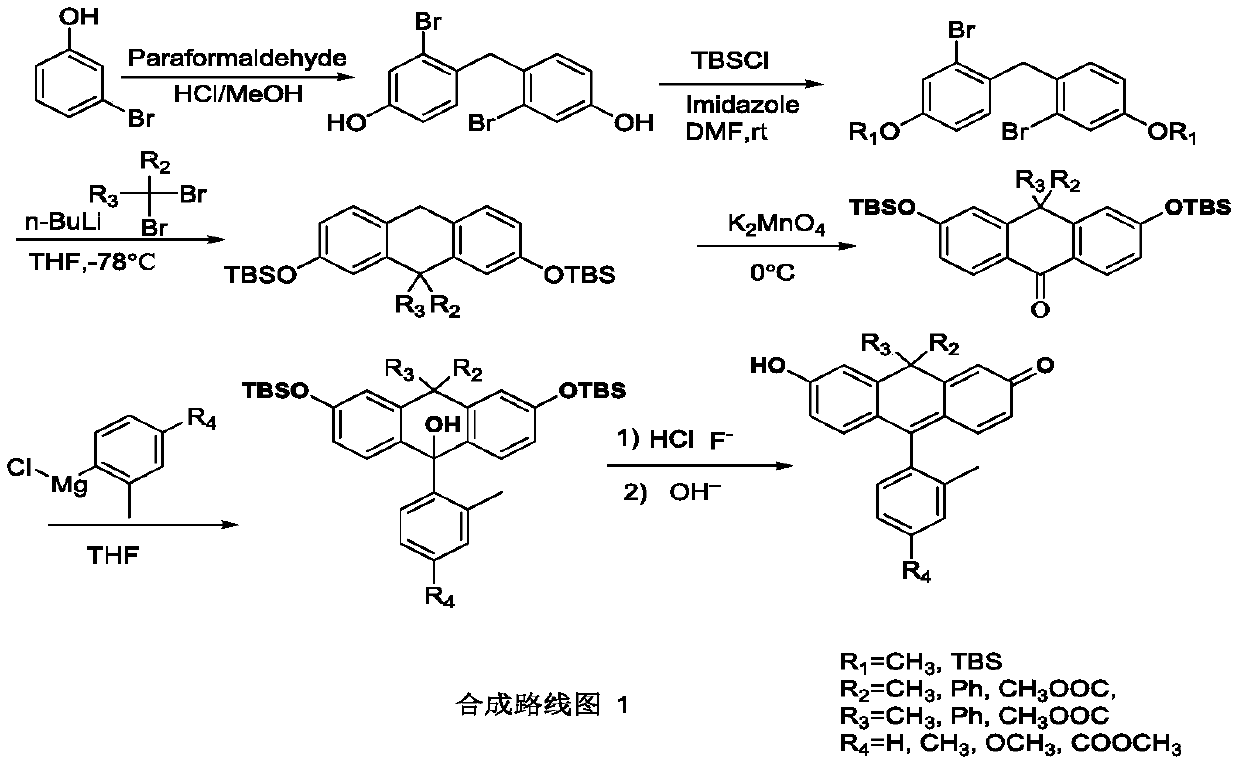

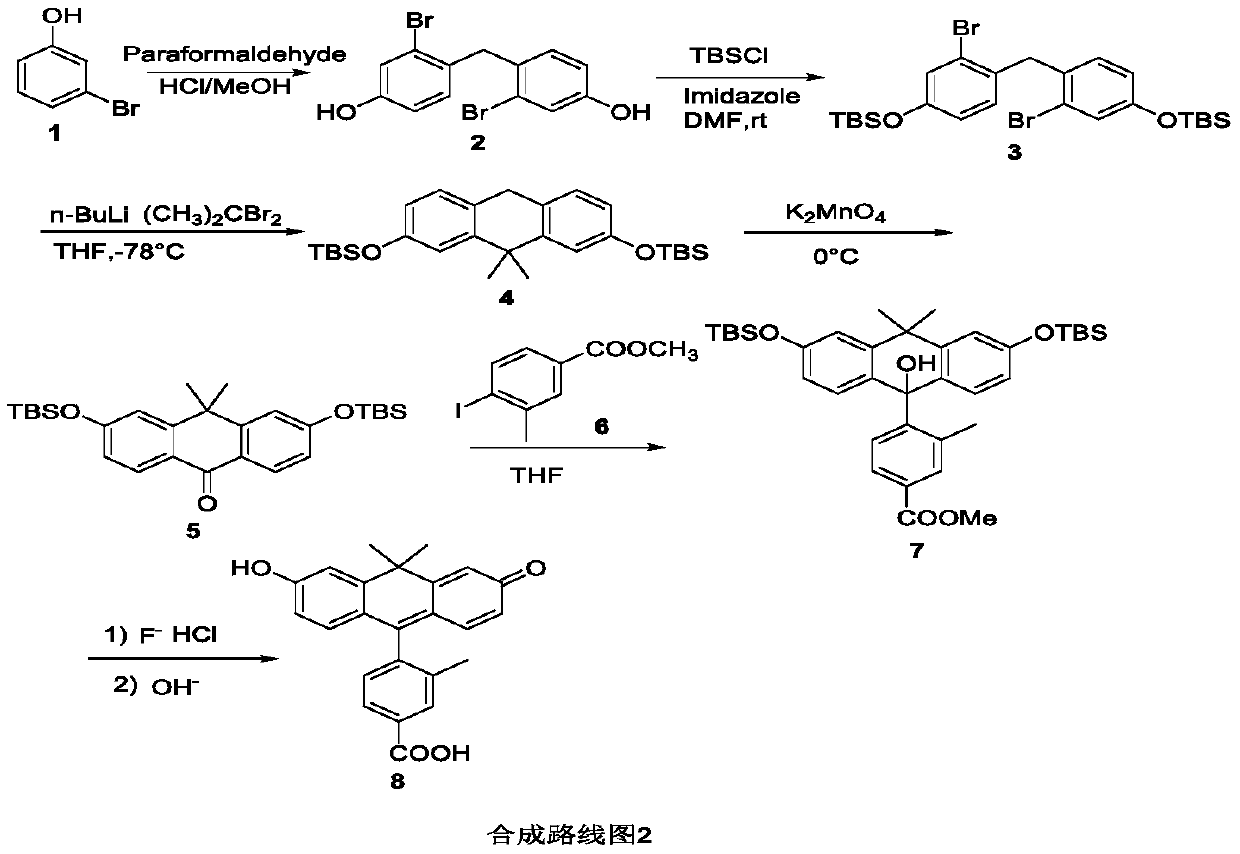

Method for synthesizing anthracene fluorescent dye

InactiveCN111205669ARaw materials are cheap and easy to getEasy to makeHydroxy-anthraquinone dyesGrignard reagentPhenol

The invention provides a method for synthesizing an anthracene fluorescent dye, which is used for solving the problems of difficult preparation of a key intermediate and low yield when the anthracenefluorescent dye is synthesized. The method has the advantages of easily available raw materials, mild reaction conditions and reduced operation risk. The synthesis method mainly comprises the following six steps: reacting m-halogenated phenol or substituted m-halogenated phenol with formaldehyde in an acidic solution, and purifying to obtain a diphenylmethane derivative, namely a first intermediate product; converting the phenolic hydroxyl group of the first intermediate product into methyl ether or silyl ether to obtain a diphenylmethane derivative with phenolic hydroxyl group protecting groups, namely a second intermediate product; converting the second intermediate product into an organic lithium salt, and reacting the organic lithium salt with a dihalogenated compound to generate an anthracene derivative, namely a third intermediate product; oxidizing the third intermediate product to obtain an anthrone compound, namely a fourth intermediate product; reacting the fourth intermediate product with a Grignard reagent to obtain a fifth intermediate product; and removing the phenolic hydroxyl protecting groups to obtain the fluorescent dye.

Owner:CYGNUS BIOSCI BEIJING CO LTD

Leuco compounds

Owner:MILLIKEN & CO

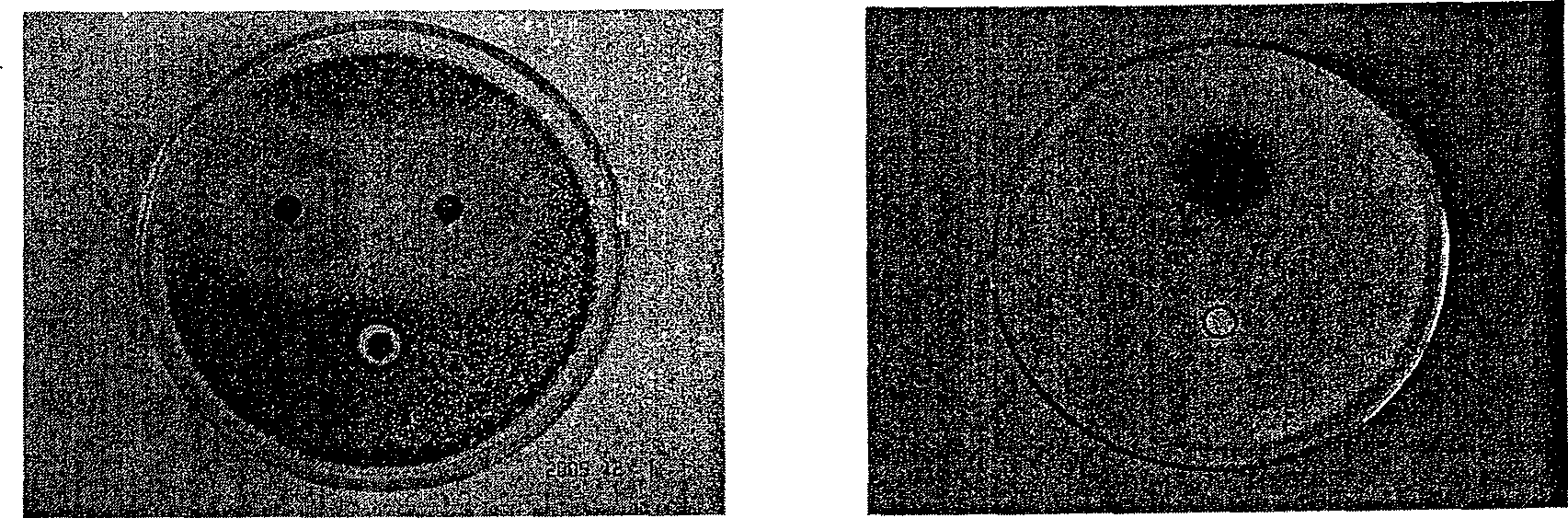

Selective algaecides for control of cyanochloronta

We have now discovered that certain 9,10-anthraquinone derivatives we developed possess potent activity against O. perornata while possessing a sufficiently high level of solubility in water to make their activity against O. perornata viable. These compounds possess a high level of activity against O. perornata yet are relatively non-toxic to green algae and fishes. The compounds also possess a relatively short half-life. The compounds represent a new means to providing compounds possessing a high degree of selective activity against blue-green algae while being physiologically tolerated by catfish and green algae. The compounds provide a means for controlling blue-green algae in managed bodies of water that are destined for public use or consumption.

Owner:UNIVERSITY OF MISSISSIPPI +1

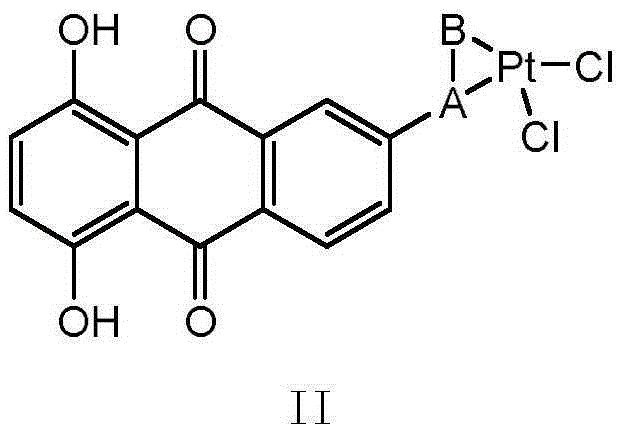

Mono6-(azabicyclo-substitution) anthraquinone platinous chloride compound and preparation method and application thereof

ActiveCN105254679AGood antitumor activityImprove securityOrganic active ingredientsHydroxy-anthraquinone dyesAnthraquinonesChemical compound

Owner:LIAONING UNIVERSITY

Color-protecting agent and method for improving thermal stability of cochineal dye

ActiveCN110157217AImprove stabilityImprove thermal stabilityHydroxy-anthraquinone dyesNatural dyesGlucomannanSolvent

Owner:上海统益生物科技有限公司

Disperse dye and method for dyeing hydrophobic fiber material using same

InactiveCN103228740AImprove light fastnessGood repeatabilityPerinonesMonoazo dyesDisperse dyePhotochemistry

The present invention relates to a disperse dye composition containing a disperse dye and the like represented by formulas (1) through (4), and a method for dyeing a hydrophobic fiber material using the same. The present invention provides a disperse dye composition and a mixed disperse dye composition that not only have strong light fastness of each color, but also well-balanced light fastness between the three primary colors, and uniform dye properties during dyeing. The present invention also provides a method for dyeing using the disperse dye composition and the mixed disperse dye composition.

Owner:NIPPON KAYAKU CO LTD

Dichroic dye, and liquid crystal composition and liquid crystal device using the same

The present invention provides one or more dichroic dyes which exhibit high solubility in liquid crystal and a high order parameter. The dichroic dyes each have a first substituent having at least one cis-cyclohexane ring and / or a second substituent having at least one trans-cyclohexane ring. The dichroic dye(s) may be provided as a mixture including at least a first dichroic dye having at least the first substituent and a second dichroic dye having at least the second substituent. The dichroic dye(s) may also be provided as a plurality of dichroic dyes, each of the molecules of which has at least the first substituent and the second substituent. The present invention also provides a liquid crystal composition and a liquid crystal element including the one or more dichroic dyes.

Owner:FUJIFILM CORP

Novel combinations for use as toners in polyesters

InactiveUS20030209698A1Reduce extractionImprove anti-yellowing effectHydroxy-anthraquinone dyesSynthetic resin layered productsPolyesterUltraviolet

Combinations of individual colorant compounds that provide effective toning (or bluing) to combat yellowing within polyester articles (such as bottles, containers, and the like) are provided. Such a novel toner combination permits effective neutralization of yellowness while also providing highly desirable low haze and increased brightness due to a sharp absorption peak within the needed range of wavelengths (e.g., from about 565 to 590 nm) and a narrow half-height band width. Furthermore, such a combination of compounds is preferably liquid in nature and may thus be incorporated within an added ultraviolet absorber solution or shelf-stable dispersion to facilitate addition within target polyesters at various stages of production. The particular UV absorbers desired as additives within target polyesters also tend to exhibit certain yellowing effects that require attention as well. The inventive combination bluing agent thus also accords effective neutralization of such UV absorber yellowing as well. Methods of production and liquid UV absorber / individual bluing agent formulations are also encompassed within this invention.

Owner:MILLIKEN & CO

Method for preparing cochineal aluminum-free lake pigment by using protein, product and application of cochineal aluminum-free lake pigment

ActiveCN111454588AEasy to operateAvoid security concernsHydroxy-anthraquinone dyesDye lakesCochineal redFree protein

The invention discloses a method for preparing a cochineal aluminum-free lake pigment by using protein, a product and application of the cochineal aluminum-free lake pigment. The method comprises thefollowing steps: adding axinic acid into a buffer solution with a pH value of 3 to prepare a pigment solution, adding metal ions, and carrying out full stirring to obtain an axinic acid pigment solution; adding protein into the axinic acid solution, carrying out full and uniform mixing, adding polyphenol, carrying out uniform stirring, conducting centrifuging, taking a precipitate, freeze-drying the precipitate, and carrying out grinding to obtain the cochineal aluminum-free lake pigment. The method for preparing the cochineal aluminum-free lake pigment by using the protein is simple and convenient to operate; and the product does not contain aluminum, so the safety of the product is prevented from being doubted. According to the cochineal aluminum-free protein lake provided by the invention, the lake has a relatively good color generation effect in an alkaline dilute iron solution and an alkaline calcium solution, and shows a relatively good dyeing effect on dough, minced fillet and single cream.

Owner:JIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com