Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Polyvinyl alcohol foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

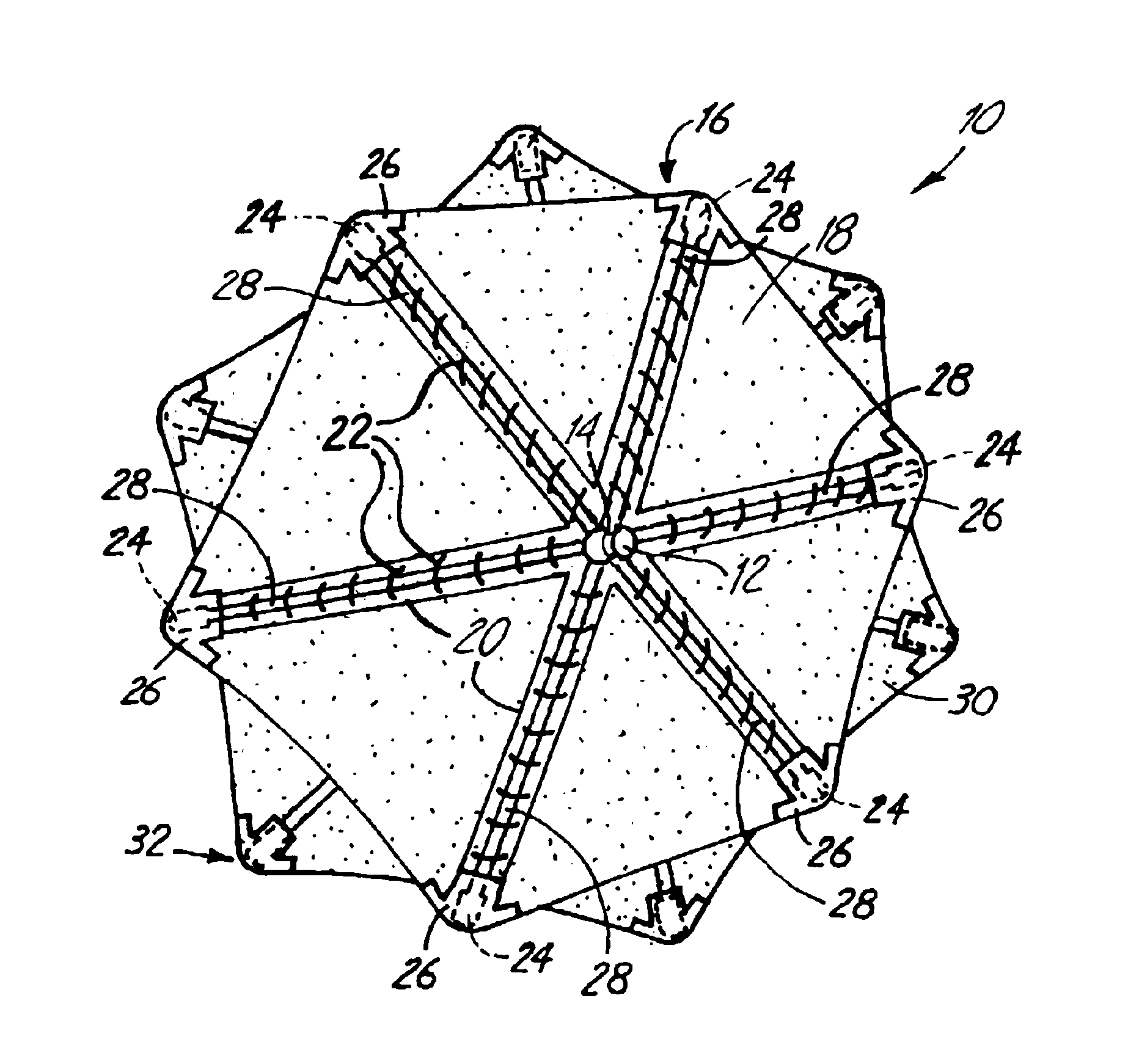

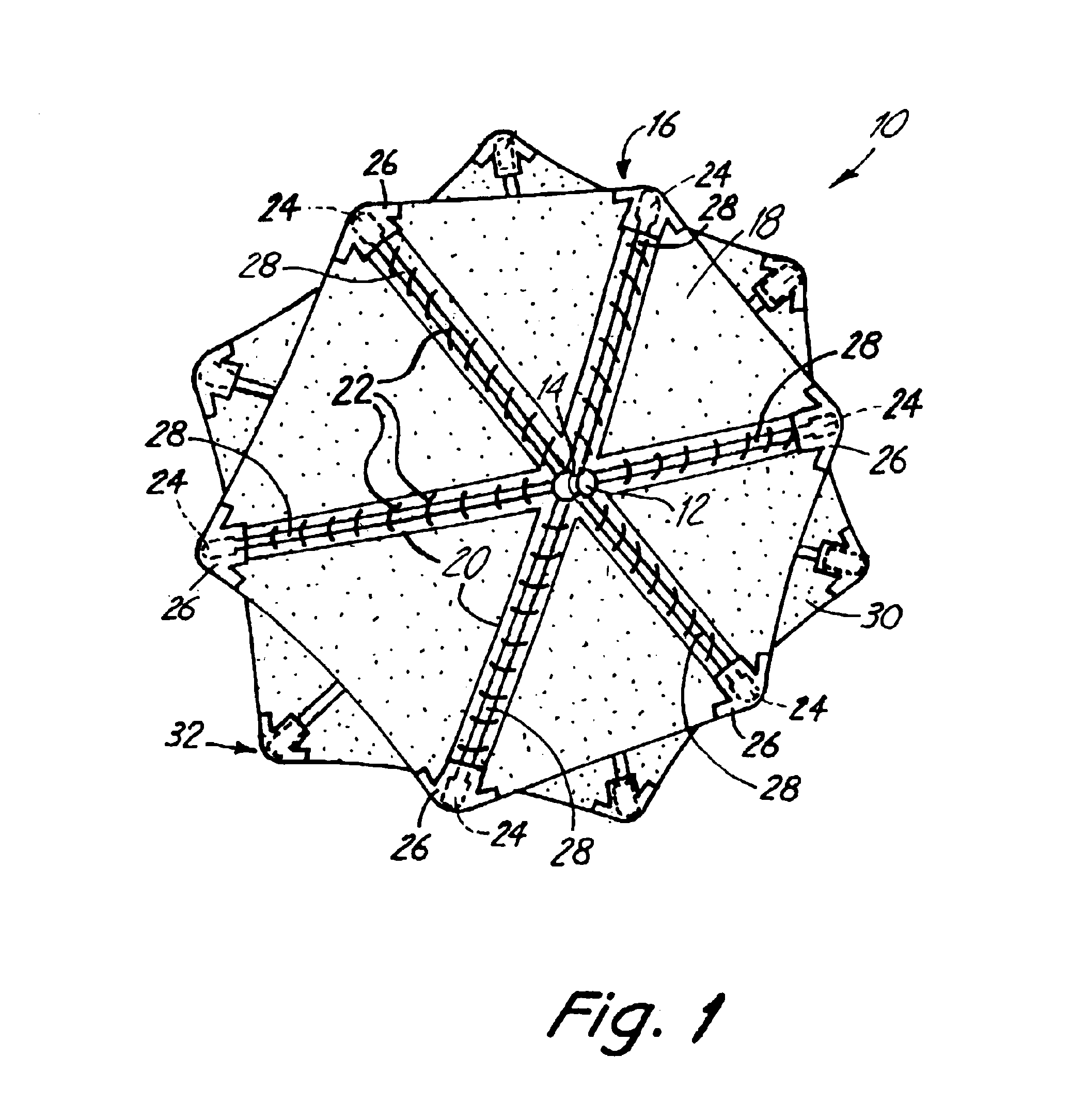

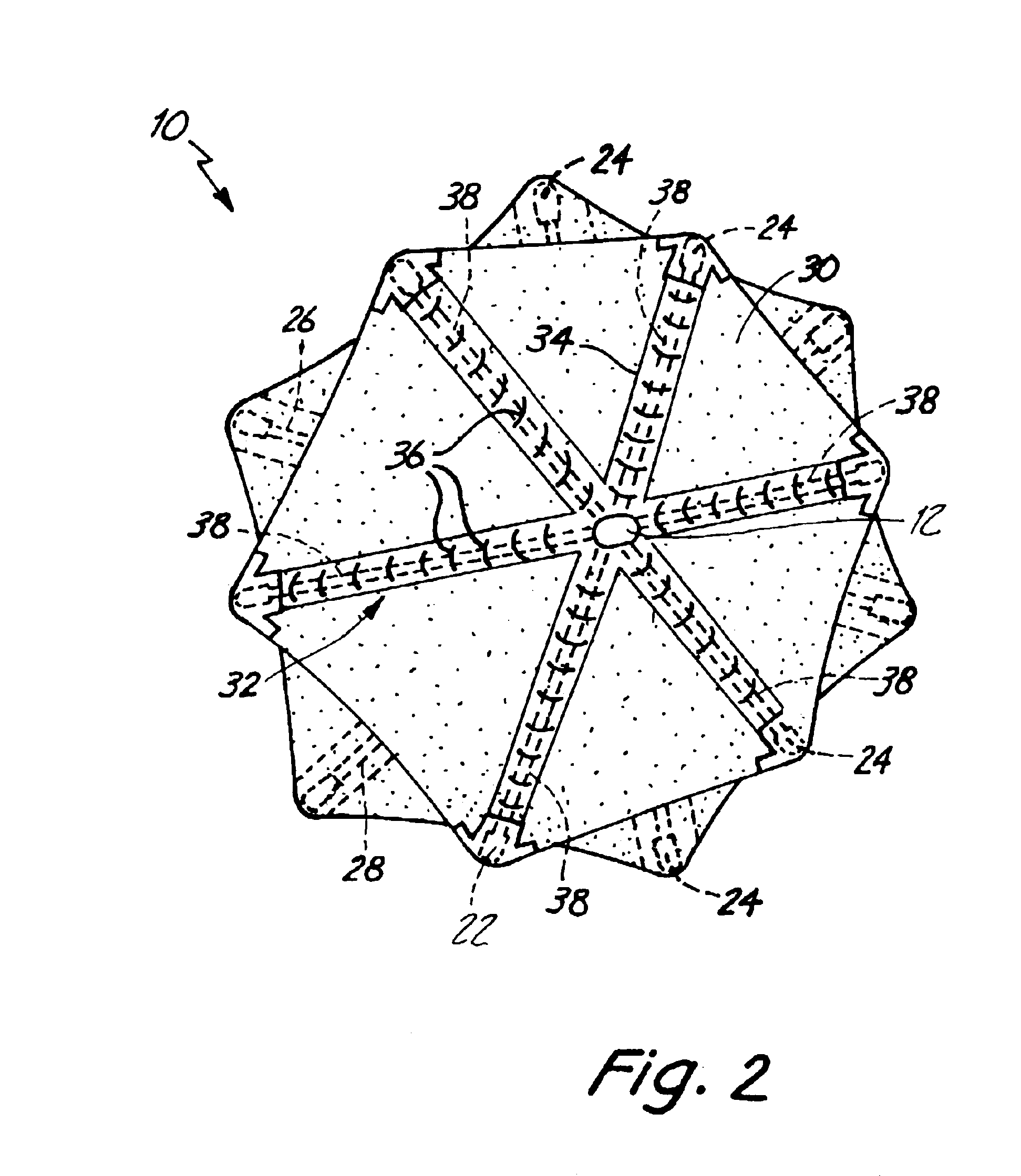

Laminated sheets for use in a fully retrievable occlusion device

An occlusion device having laminated polyvinyl alcohol sheets for occluding a defect. The laminated polyvinyl alcohol sheets provide an increased tear strength to the sheets that allows the device to be fully retrievable through the same catheter used to deploy it. The laminated sheets are created by obtaining thin sheets of polyvinyl alcohol foam, arranging the sheets on one another, and applying heat and pressure to laminate the sheets together.

Owner:CARDIA INC

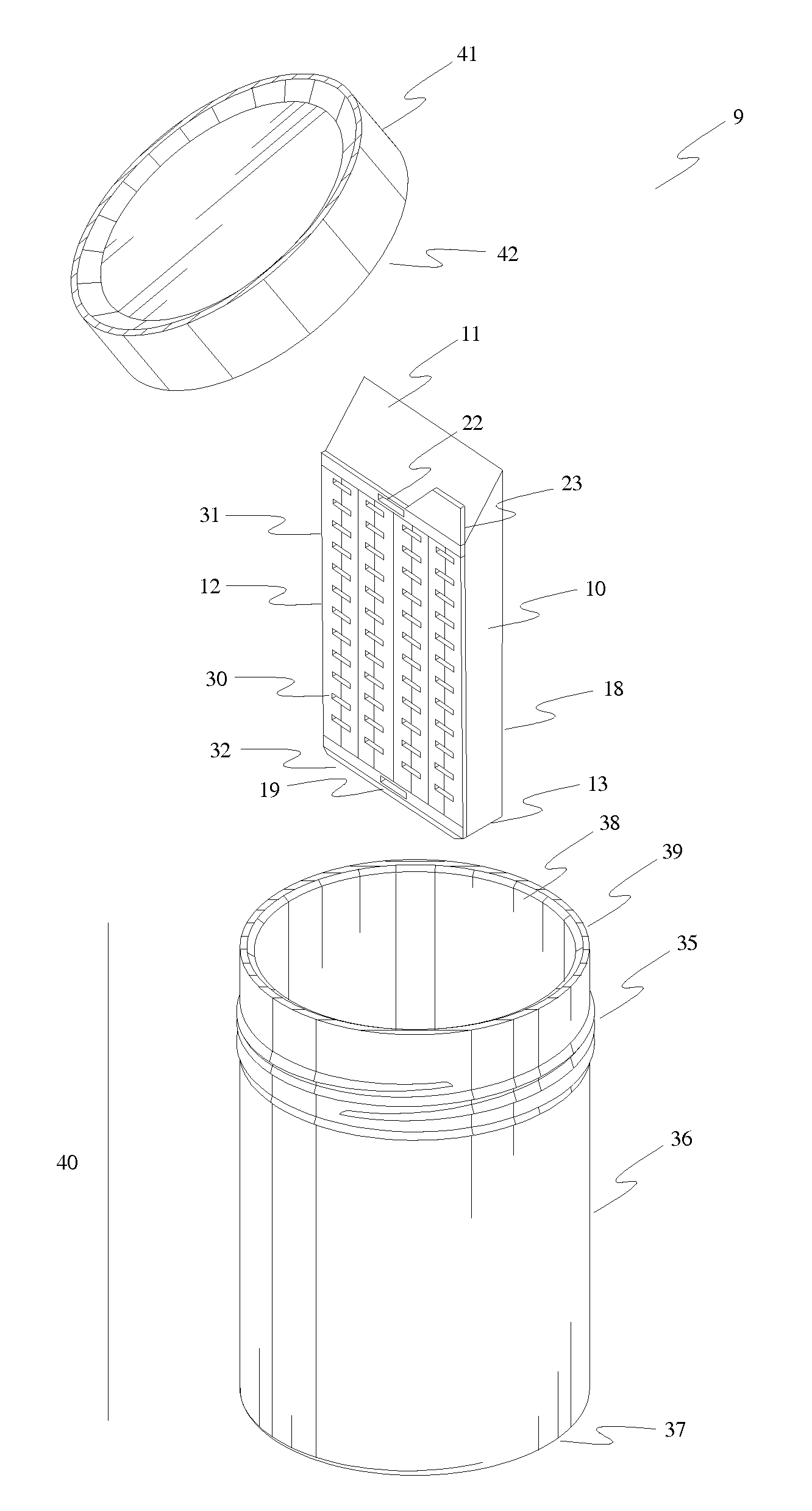

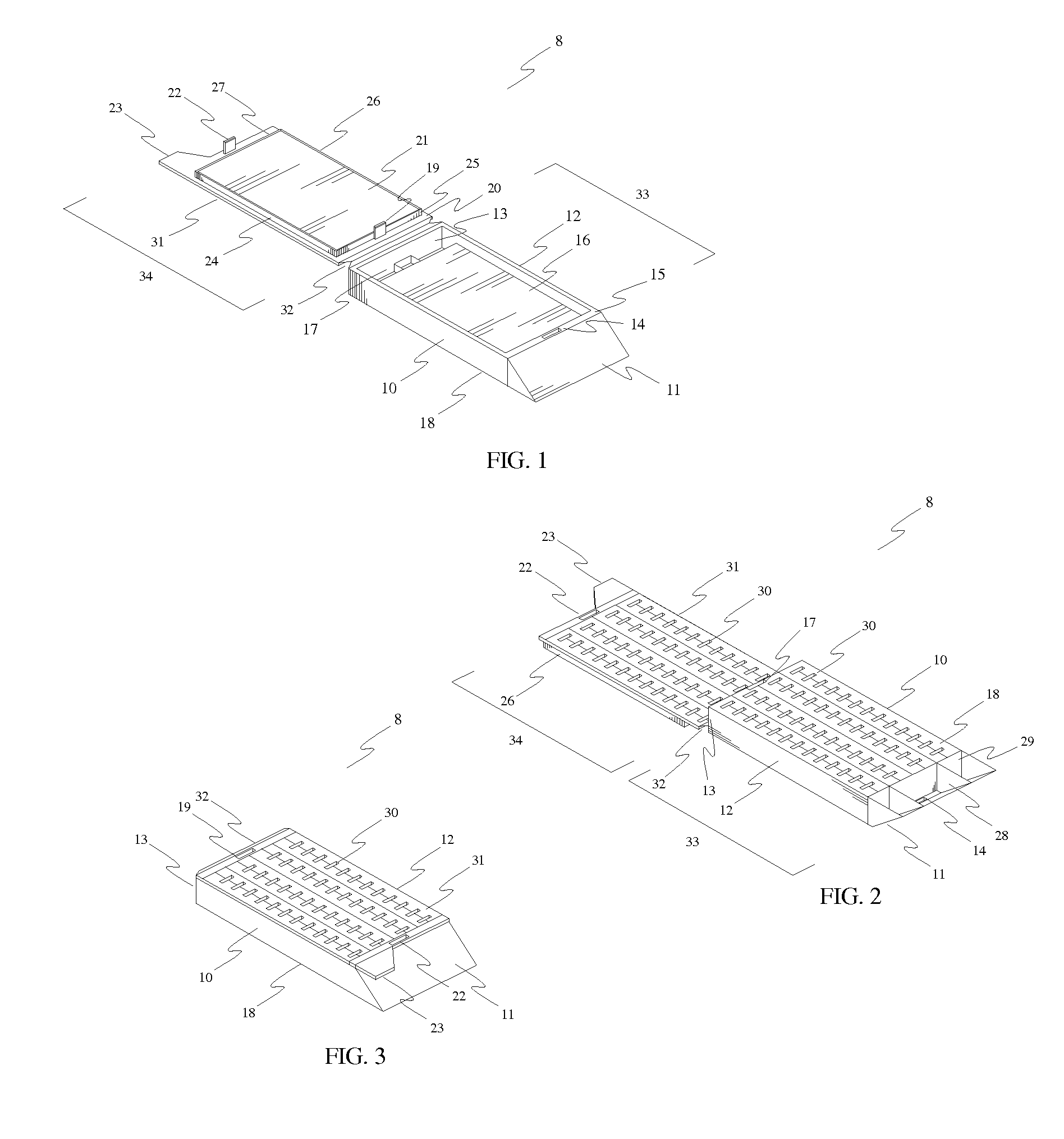

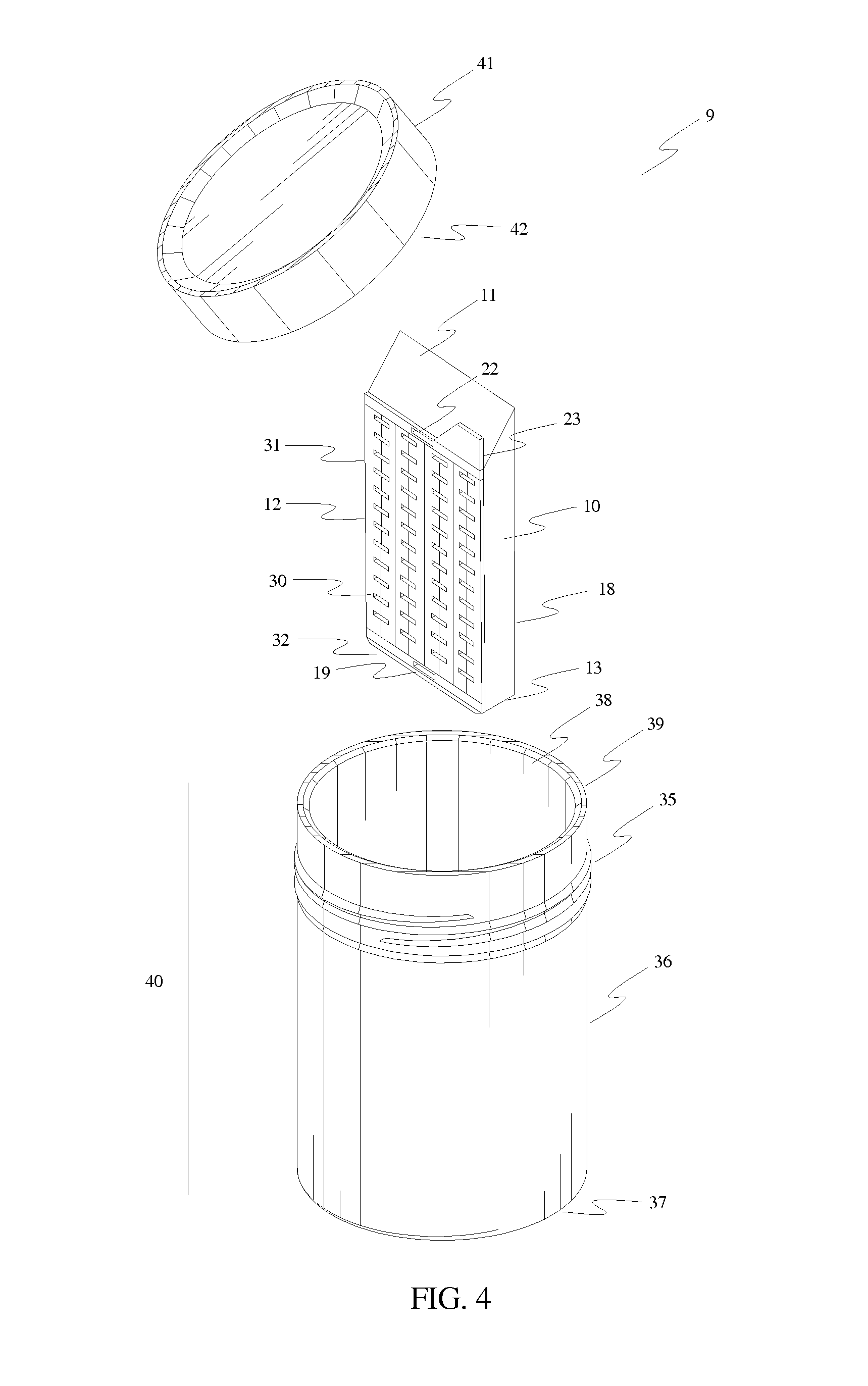

Reusable Tissue Biopsy Kit with Padded Cassette

InactiveUS20100075410A1Promote resultsBig errorBioreactor/fermenter combinationsAnalysis using chemical indicatorsTissue biopsySample integrity

An improved biopsy kit for the collection, storage, transportation, and processing of biopsy tissue samples is disclosed. The disclosed biopsy kit consists of a typical specimen container and an improved tissue cassette with adhesively attached polyvinyl alcohol foam pads on both the base and lid portions. An excised tissue sample is sandwiched between the pads upon cassette closure, simultaneously isolating and securing the sample in its original orientation. Superior wicking, absorbency, and moisture retention rate of these polyvinyl alcohol pads allows maximum tissue fixation as well as maintains sample integrity. Once the tissue is placed by the physician at the patient's side, it remains there until the tissue is ready to be processed. This eliminates transfer errors as well as tissue loss.

Owner:DESAI VIRENDRA +1

Polyvinyl alcohol foaming material and manufacture method thereof

The invention provides a polyvinyl alcohol foaming material and a manufacture method thereof. The polyvinyl alcohol foaming material comprises the composition comprising the following components: 48-95 parts by weight of polyvinyl alcohol powder (preferably 67-95 parts by weight), 5-40 parts by weight of plasticizing agent (preferably 5-25 parts by weight), 0.05-5 parts by weight of nucleating agent (preferably 0.1-3 parts by weight), 0.1-2 parts by weight of heat stabilizer (preferably 0.2-0.8 part by weight), 0.02-5 parts by weight of cross linking agent (preferably 0.02-4 parts by weight) and the balance of chemical foaming agent or physical foaming agent. The manufacture method disclosed by the invention can be a chemical foaming method or a physical foaming method. The chemical foaming method has simple technology, does not have rigorous requirements on equipment and only needs a common single screw extruder used for foaming. The physical foaming method disclosed by the invention can use same foaming equipment, does not pollute environment and is a foaming method which is highly prized at present.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

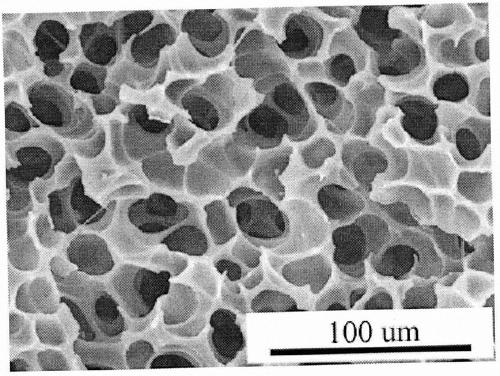

Macroporous reticular polyvinyl alcohol foam and preparation thereof

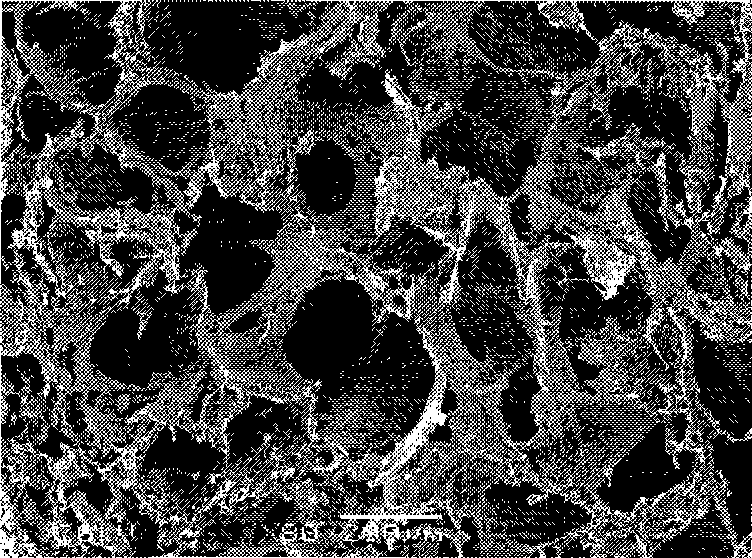

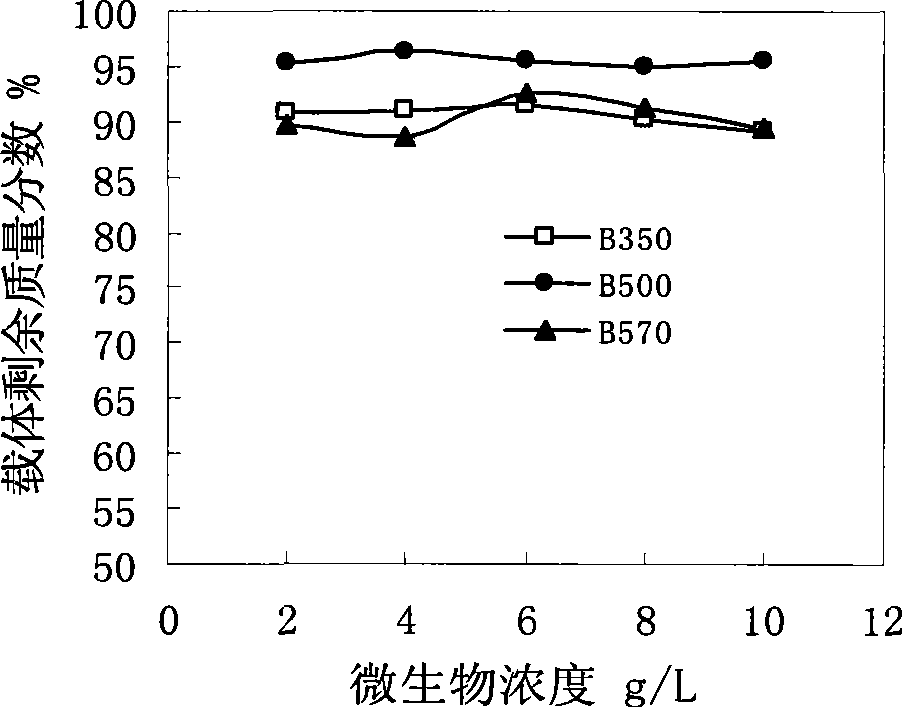

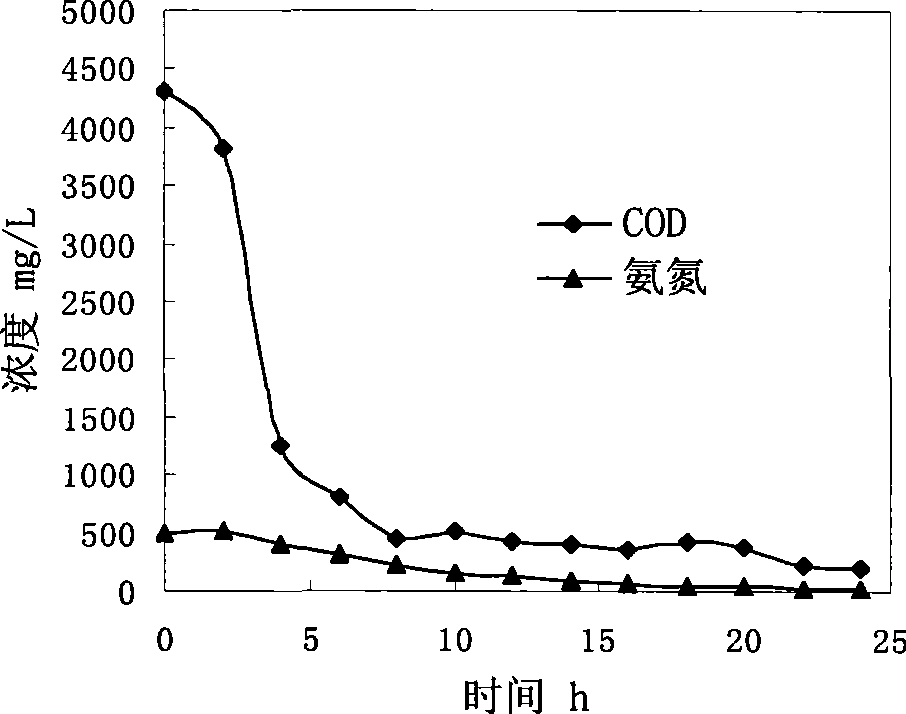

The invention provides a method for preparing a macroreticular polyvinyl alcohol foam carrier, which comprises the steps: polyvinyl alcohol, limestone and water are mixed and stirred to lead the polyvinyl alcohol to be fully and evenly dissolved; the mixture is added with dilute hydrochloric acid for acidification and is frothed to have foramen; by adopting the circulation of freezing-unfreezing, and refreezing-unfreezing again, macroreticular polyvinyl alcohol gel foam is formed; then, the polyvinyl alcohol gel foam is cut into pieces and is dipped into the dilute hydrochloric acid with the mass concentration of 0.5-1% until no bubble is generated; the polyvinyl alcohol is caused to form more stable cross-linked structure by chemical crosslinking reaction; after that, the polyvinyl alcohol is soaked in water to be washed to be neutrality, so that the white macroreticular polyvinyl alcohol foam carrier is obtained. The macroreticular polyvinyl alcohol foam carrier prepared by the invention has stable macroreticular structure, takes on good hydrophilicity, physical and chemical durability as well as biological degradability resistance, is applicable to immobilized enzyme and microorganism to form a bioreactor with multiple bed types, and can be used in the fields of modern biological engineering such as sewage disposal, etc.

Owner:LANZHOU UNIVERSITY

Polyvinyl alcohol foaming material for treating sewage

InactiveCN101186720AUnique adsorptionStrong water absorptionWater/sewage treatmentPolyethylene glycolCarbon nanotube

A polyvinyl alcohol foaming material for processing sewage uses polyvinyl alcohol, formaldehyde and amidon as raw material, sulfuric acid as catalyst, calcium sulfate as foaming agent for preparing soft foam plastic, which is characterized in that the charged carbon nanometer pipe and polyethylene glycol are foamed together to make the foaming material have large-aperture porous structure, and the aperture ranges from 0.05mm to 1.0mm. The water-absorbing quantity is 4-6 times as itself weight, which is especially provided with peculiar adsorption property for adsorbing particle and stain suspended in the sewage and stripping peculiar smell and decolouration effect, further processing sewage, not only processing living sewage, but also processing industrial sewage.

Owner:ANHUI UNIVERSITY

Method for preparing nano-crystalline cellulose enhanced polyvinyl alcohol foam material with oriented porous structure

The invention discloses a method for preparing nano-crystalline cellulose enhanced polyvinyl alcohol foam material with an oriented porous structure. The method comprises the following steps: A, preparation of suspension mixed liquid: performing acidolysis on plant paper pulp to prepare nanometer crystal whisker suspension liquid, and adding the nanometer crystal whisker suspension liquid into polyvinyl alcohol aqueous solution; B, oriented freezing: pouring the mixed liquid into a container and soaking into liquid nitrogen at the speed less than 0.2mm / s; C, low-temperature vacuum drying: after the growth of ice crystals in the mixed liquid is finished, instantly placing the container filled with the mixed liquid and taken out of the liquid nitrogen, into a vacuum freezing dryer, and taking out the container after the ice crystals are completely sublimated. The method only refers to physical phase change in a foaming process, any chemical medicaments are not used and any chemical reaction is avoided, the pollution to the environment in the foaming process is avoided, and the energy consumption is low. The prepared nano-crystalline cellulose enhanced polyvinyl alcohol foam material with the oriented porous structure has the micropore diameter range of 15-35 micrometers, and the compression strength is increased by 1.6-2 times in comparison with the compression strength of polyvinyl alcohol foam without the oriented structure.

Owner:NANJING FORESTRY UNIV

Halogen-free flame-retardant polyvinyl alcohol foam material and preparation method thereof

The invention discloses a halogen-free flame-retardant polyvinyl alcohol foam material and a preparation method of the halogen-free flame-retardant polyvinyl alcohol foam material. The preparation method comprises the steps of preparing composite powder by uniformly mixing 100 parts of polyvinyl alcohol, 20-35 parts of nitrogen-phosphorus halogen-free flame retardant, 0.1-10 parts of catalyst and 0.1-10 parts of nucleating agent, adding the composite powder into mixed solution formed by 0.1-10 parts of surface active agent, 0.1-10 parts of cross-linking agent and 30-40 parts of plasticizing foaming agent, and swelling sufficiently at the temperature of 60 DEG C-80 DEG C, and then continuously extruding and foaming to obtain the halogen-free flame-retardant polyvinyl alcohol foam material at the temperature of 140 DEG C-180 DEG C and with the pressure 8-10MPa. According to the halogen-free flame-retardant polyvinyl alcohol foam material provided by the invention, the limit oxygen index reaches 36%, the vertical burning reaches L94-V0 level and the material can extinguish automatically without fire, the halogen-free flame-retardant property is good, the hole density of the foaming material can be improved, and the halogen-free flame-retardant polyvinyl alcohol foam material can be widely applied to the fields of heat insulation, sound isolation, shock absorption, packaging, sport equipment, clothes and back cushions, soles, sofa, cushions and the like. In addition, the foam is extruded continuously by melting, so that the preparation process is simple, low in cost and environment-friendly, and the halogen-free flame-retardant polyvinyl alcohol foam material is suitable for large-scale industrial production.

Owner:SICHUAN UNIV

Preparation method of graphene oxide and quinone compound co-modified hydroxyl-containing macroporous foam carrier

InactiveCN106830311AStable decompositionPromote conversionWater contaminantsTreatment with anaerobic digestion processesSulfonyl chloridePollution

The invention relates to a preparation method of a graphene oxide and quinone compound co-modified hydroxyl-containing macroporous foam carrier and belongs to the technical field of water treatment in environmental engineering. The preparation method comprises the following steps: preparing a graphene oxide modified polyurethane foam composite material from a hydroxyl-containing macroporous foam material at the room temperature by virtue of a physical adsorption method, and aminating the composite material until graphene oxide and polyurethane foam contain a certain amount of primary amine; and reacting by virtue of an anthraquinone compound containing sulfonyl chloride groups with primary amine, so as to fix a quinone compound, wherein the hydroxyl-containing macroporous foam material can be polyvinyl alcohol foam or polyvinyl alcohol doped polyurethane foam and the like. According to the preparation method, the quinone compound and graphene oxide are simultaneously fixed to the surface of the macroporous foam material, so that the contact among a redox mediator, graphene and microorganisms is facilitated; and the technical bottlenecks that graphene and the water soluble quinone compound in a water treatment system are difficult to be recycled and flow out along with water to cause secondary pollution are solved.

Owner:DALIAN UNIV OF TECH

Polyvinyl alcohol foam oxygen insulation material and preparation method and application thereof

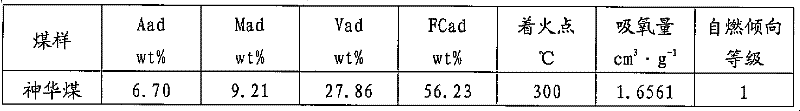

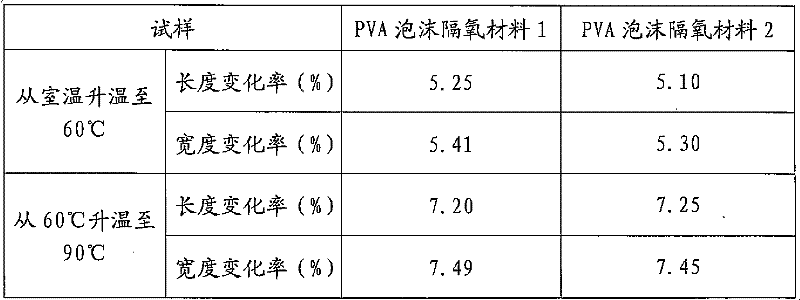

ActiveCN102336994AGood oxygen barrier effectSmall oxygen permeability coefficientDust removalFire preventionFoaming agentAlcohol

The invention discloses a polyvinyl alcohol foam oxygen insulation material, which comprises a component (A) and a component (B), wherein the component (A) comprises a solvent, and 3-8 percent by weight of polyvinyl alcohol, 0.5-1.5 percent by weight of linear hydrocarbon organic alcohol or ester and 0.04-0.10 percent by weight of foaming agent based on the total amount of the solvents contained in the component (A) and the component (B); the component (B) comprises 0.1-0.3 percent by weight of borate based on the total amount of solvents contained in the component (A) and the component (B); and the mass ratio of the solvent contained in the component (A) to the solvent contained in the component (B) is (5-9):1. A method for preparing the polyvinyl alcohol foam oxygen insulation material comprises the following steps of: dissolving polyvinyl alcohol into the solvent at constant temperature 70-95 DEG C, performing return flow agitation for 30-60 minutes, cooling to room temperature, and adding the linear hydrocarbon organic alcohol or ester and the foaming agent to obtain the component (A); adding borate into the solvent to obtain the component (B); and foaming the component (A), spraying onto a coal surface and spraying the component (B) to form a foam gel oxygen insulation material layer which plays a good role in sealing and insulating oxygen on the coal surface.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Polyvinyl alcohol water-soluble foamed plastic as well as preparation method and application thereof

The invention discloses a polyvinyl alcohol water-soluble foamed plastic and a preparation method thereof. The method comprises the following steps: polyvinyl alcohol powder with a polymerization degree of 500-2400 and an alcoholysis degree of 85-99% and water are used as main raw materials, under the condition of avoiding to use an acetalating agent or a crosslinking agent, a production process is improved, firstly, swelling is performed by using hot water of specific temperature, then extrusion processing is performed to form a foamable particle material, and finally the polyvinyl alcohol foamed material is prepared by a rapid heating method or an instantaneous decompression method. The method disclosed by the invention makes the product kept very good water solubility, and has a relatively simple process and low costs; and the prepared polyvinyl alcohol water-soluble foamed plastic has very good water solubility, can be widely used in the fields such as disposable medicines, packaging and pharmacy, and has the characteristics of easy degradation.

Owner:HUAIHUA UNIV

Polyvinyl-alcohol-based porous adsorption material and preparing method thereof

The invention relates to the technical field of polymer synthesis, in particular to a polyvinyl-alcohol-based porous adsorption material and a preparing method thereof. The preparing method comprisesthe steps of A) under the effect of a catalyst, carrying out a reaction between a polymer foam material containing hydroxyl groups and a functionalized modifier in a solvent to obtain a modified polymer foam material, wherein the polymer foam material containing the hydroxyl groups comprises one or more of a polyvinyl-alcohol-based foam material containing carboxyl groups, a polyvinyl-alcohol-based foam material containing sulfonic groups and a polyvinyl alcohol foam material, and the functionalized modifier comprises chloroacetyl chloride, bromobutyryl bromide, chloropropionyl chloride, chlorobutyryl chloride or epoxy chloropropane; B) carrying out a reaction between the modified polymer foam material and a solution of a macromolecular substance containing amino groups to obtain the polyvinyl-alcohol-based porous adsorption material. The prepared polyvinyl-alcohol-based porous adsorption material has excellent adsorption performance on heavy metal ions, and meanwhile, the preparing technology is simple.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Synthesis method of chitosan/polyvinyl alcohol foam

InactiveCN102146168ANo antibacterial effectEnhanced antimicrobial strengthSurgeryFoaming agentSynthesis methods

The invention belongs to field of medical materials and discloses a synthesis method of chitosan / polyvinyl alcohol foam. The synthesis method comprises the following steps: dissolving polyvinyl alcohol to prepare a solution, and adding a chitosan solution into the solution; adding a foaming agent, namely 1-2ml / 10g of polyvinyl alcohol, and stirring to ensure that the solution foams freely until the volume is 2.0-2.5 times of the original volume; adding sulfuric acid, stirring for 20-40 minutes continuously, then adding formaldehyde while keeping the temperature not more than 40 DEG C, and stirring for 15-30 minutes; and injecting foams in a mould, curing and forming at 55-60 DEG C, and then washing to ensure that the product is neutral and no foam is generated, thus obtaining the chitosan / polyvinyl alcohol composite foam material. The pure polyvinyl alcohol foam material has no bactriostasis; and the foam material combined with chitosan has obvious antibacterial property, and the antibacterial intensity of the material increases along with the increase of the chitosan content.

Owner:WUHAN UNIV

Preparation method of polyvinyl alcohol foamed plastics

The invention relates to the manufacturing of a material, and particularly to a preparation method of polyvinyl alcohol foamed plastics. The preparation method comprises the following steps: A, dissolving a given amount of polyvinyl alcohol; B, adding a dispersed framework material; C, stirring until uniformly mixed; D, adding additives; E, stirring and foaming; F, pouring into a mould, and drying. The polyvinyl alcohol foamed plastics prepared in the method adopt natural fibers as a framework raw material, the mechanical performance and degradation performance of foams can be improved; meanwhile, the source of straws and grass is wide, the cost is low, the starch used as a hole-forming agent is avoided, the grain resource is saved, reagents harmful to the human body such as formaldehyde are not used in the preparation process of the material, the environment-friendly preparation requirement can be met, the material foaming rate is relatively high, is 2 to 4 times and can be controlled by virtue of the content of the foaming agent and the stirring time, the softness adjusting rate of the material is high and can be adjusted by controlling the content of the plasticizer, and various buffer packaging materials meeting different requirements can be prepared.

Owner:SHENZHEN POLYTECHNIC

Flame-retardant polyvinyl alcohol foam material

The invention discloses a flame-retardant polyvinyl alcohol foam material. The flame-retardant polyvinyl alcohol foam material is prepared from, by mass, 100 parts of polyvinyl alcohol, 40-80 parts of an inorganic flame retardant, 30-50 parts of deionized water and 1-5 parts of a cross-linking agent, wherein the preparation process is that the polyvinyl alcohol and the deionized water are prepared into thermoplastic processed polyvinyl alcohol particles by adopting a molecular composite plastifying technology; the polyvinyl alcohol particles, the inorganic flame retardant and the cross-linking agent are fully mixed in a high-speed mixer to obtain blended particles, then the blended particles are put into a single screw extruder, and thermoplastic extrusion and foaming are performed to obtain the foam material with uniform foam holes, wherein the processing temperature of a mouth mold of the single screw extruder is 120-135 DEG C, and the screw speed is 15-45 rpm. The foam material with uniform foam holes is prepared through thermoplastic extrusion and foaming by using few components, has excellent comprehensive properties and has the advantages of being low in cost, simple in preparation and the like.

Owner:李谚华

Chitosan-iodine composite biological medical film and preparation method thereof

ActiveCN103386143APromote healingImprove antibacterial stabilityAbsorbent padsBandagesCompound aMicrowave

A chitosan-iodine composite biological medical film and a preparation method thereof are disclosed. The chitosan-iodine composite biological medical film is formed by compounding a chitosan-iodine polyvinyl-alcohol layer, a polyvinyl alcohol layer, a chitosan polyvinyl-alcohol foam layer and a hydrophilic polyglutamic acid net-shaped gel layer , and the chitosan polyvinyl-alcohol foam layer is compounded between the polyvinyl alcohol layer and the hydrophilic polyglutamic acid net-shaped gel layer . The four layers have different effects: the chitosan-iodine polyvinyl-alcohol layer has the effects of killing bacteria, moisturizing and promoting healing; the polyvinyl alcohol layer has the effects of moisturizing and promoting healing; the chitosan polyvinyl-alcohol foam layer has the effects of dewatering, absorbing seepage and moisturizing; and the hydrophilic polyglutamic acid net-shaped gel layer has the effects of stopping bleeding, adsorbing the wound and converting the adsorbed seepage to the chitosan polyvinyl-alcohol foam layer. According to the chitosan-iodine composite biological medical film, the chitosan-iodine polyvinyl-alcohol layer and the polyvinyl alcohol layer are heated in a microwave mode, so that a polar medium can be rapidly heated, the reaction temperature is rapidly reached, and the reaction time is shortened; and the chitosan polyvinyl-alcohol foam layer is dried by a vacuum freeze-drying method.

Owner:ZHEJIANG SANCHUANG BIOTECHNOLOGY CO LTD

Wound dressing

InactiveUS20160058621A1Reduce the risk of infectionShorten healing timeNon-adhesive dressingsBaby linensWound dressingBiomedical engineering

A wound dressing including a sheet body made of a compressed polyvinyl alcohol foam material. The sheet body includes a liquid absorption and locking layer in the form of a three-dimensional intercommunicating network, two liquid-permeable layers disposed at two sides of the liquid absorption and locking layer, respectively, and a plurality of liquid absorption holes running through the sheet body. The liquid-permeable layers are a one-way permeable membrane for preventing fluid loss.

Owner:GUANGDONG MEIJI BIOTECH

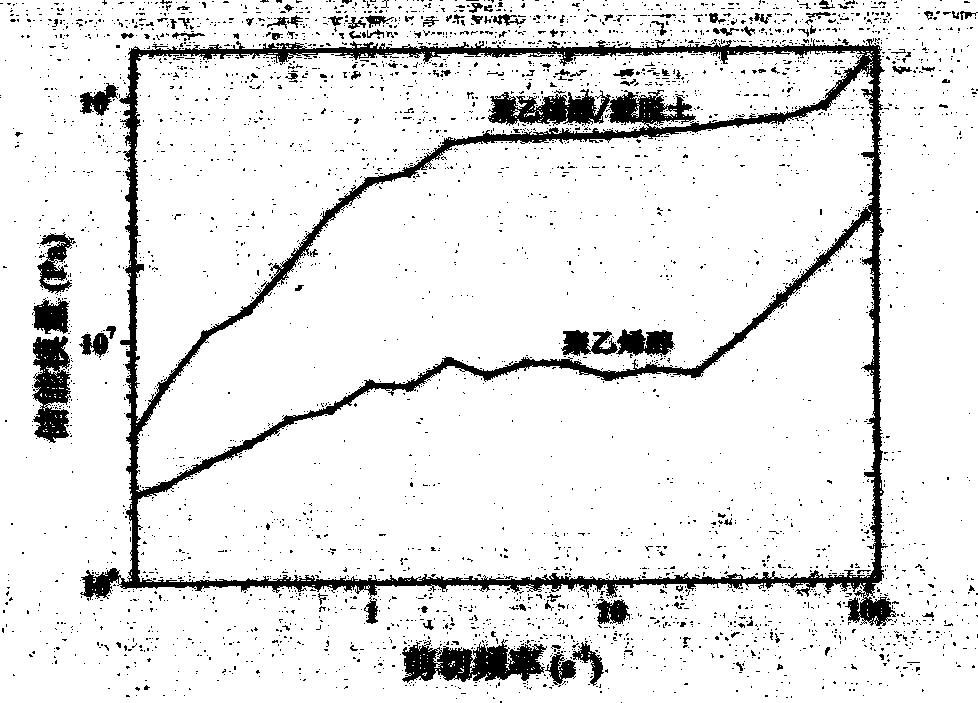

Polyvinyl alcohol/graphene composition microporous foaming material

InactiveCN109401153AReduce the free energy barrierIncrease the nucleation rateFree energiesPlasticizer

The invention relates to a polyvinyl alcohol / graphene composition microporous foaming material which has good cell stability and is not prone to collapse. The foaming material is prepared from a polyvinyl alcohol / graphene composition by a supercritical fluid foaming technique, wherein the composition comprises polyvinyl alcohol, isocyanate-based graphene and plasticizer. Preferably, the composition comprises, by mass, 100 parts of polyvinyl alcohol, 0.1 to 5.0 parts of isocyanate-based graphene, and 5 to 30 parts of plasticizer. Compared with a pure polyvinyl alcohol foaming material, the polyvinyl alcohol / graphene composition microporous foaming material has the following advantages: the isocyanate-based graphene can reduce the free energy barrier of cell nucleation, provide a heterogeneous nucleation site for the foaming of polyvinyl alcohol, and increase the cell nucleation rate, cells are not prone to collapse during the foaming process, and the mechanical properties are superior than those of pure polyvinyl alcohol foam.

Owner:宁波致微新材料科技有限公司

Preparation method of polyvinyl alcohol/silicon dioxide microporous foaming material

InactiveCN109370128AReduce the free energy barrierIncrease the nucleation rateFree energiesPolymer science

The invention relates to a preparation method of a polyvinyl alcohol / silicon dioxide microporous foaming material with cells good in stability and not easy to collapse. The preparation method comprises the three steps: (1) preparing silicon dioxide containing a polar group; (2) preparing a polyvinyl alcohol composition, wherein the polyvinyl alcohol composition contains polyvinyl alcohol, silicondioxide containing the polar group in the step (1) and a plasticizer; and (3) placing the polyvinyl alcohol composition into a high-pressure die, and preparing a polyvinyl alcohol microporous foamingmaterial by using a specific process. The method disclosed by the invention has the following advantages that silicon dioxide containing the polar group is capable of reducing free energy barriers ofcell nucleation and providing heterogeneous nucleation loci for polyvinyl alcohol foaming, so that the cell nucleation rate is increased, cells are not easy to collapse in a foaming process, and the polyvinyl alcohol / silicon dioxide microporous foaming material has better mechanical properties than pure polyvinyl alcohol foam.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Multifunctional medical materials and preparing method thereof

PendingCN110152052AAvoid defectsGood biocompatibilityPharmaceutical delivery mechanismAbsorbent padsWound healingBiocompatibility Testing

The invention belongs to the field of development of medical materials, and particularly relates to multifunctional medical materials and preparing methods thereof. The multifunctional medical materials are applied to a medical vacuum sealing drainage system and formed by compounding quaternary ammonium chitin / quaternary ammonium salted chitosan with polyvinyl alcohol, and the multifunctional medical materials are provided in three forms, namely (a) the polyvinyl alcohol-quaternary ammonium chitin / quaternary ammonium salted chitosan mixed foam material, (b) the medical material formed by polyvinyl alcohol foam and a quaternary ammonium chitin / quaternary ammonium salted chitosan non-woven fabric, and (c) the dual-layer medical foam material formed by polyvinyl alcohol foam and quaternary ammonium chitin / quaternary ammonium salted chitosan foam; meanwhile, the preparing methods of the multifunctional materials are provided. The prepared multifunctional medical materials have good biocompatibility and have good infection resistance, hemostasis performance and wound healing promotion performance compared with single liquid absorption functions of traditional medical foam materials.

Owner:WUHAN UNIV

Method for preparing polyvinyl alcohol foam material using modified graphene as filler

ActiveCN105385081AGood compatibilityImprove mechanical propertiesUltrasonic dispersionPolymer chemistry

The present invention discloses a method for preparing a polyvinyl alcohol foam material using modified graphene as a filler, and belongs to the field of porous materials. According to the method, graphene oxide is first prepared, a stable colloidal suspension is formed by ultrasonic dispersion of the graphene oxide in alkaline water, the stable colloidal suspension is mixed with gelatin, dextrin and a crosslinking agent, and then added into polyvinyl alcohol, graphene and polyvinyl alcohol show good compatibility, hydrogen bonding interactions between the graphene and the polyvinyl alcohol can be produced, polyvinyl alcohol molecular chains form physical crosslinking points, mechanical strength and toughness of the polyvinyl alcohol polymer can be greatly improved, excellent performance of the graphene can be played, and the thermodynamic properties of the polyvinyl alcohol material can be improved.

Owner:东莞市恒彩塑胶颜料有限公司

Polyvinyl alcohol/ silicon dioxide composition microcellular foaming material

InactiveCN109467734AReduce the free energy barrierIncrease the nucleation rateFree energiesPlasticizer

The invention relates to a polyvinyl alcohol / silicon dioxide composition microcellular foaming material which is good in cell stability and is unlikely to collapse. The foaming material is prepared from a polyvinyl alcohol / silicon dioxide composition through a supercritical fluid foaming technology. The composition comprises polyvinyl alcohol, isocyanate silicon dioxide and a plasticizer, when the polyvinyl alcohol in the composition accounts for 100 parts by mass, the isocyanate silicon dioxide accounts for 0.1-5.0 parts by mass, and the plasticizer accounts for 5-30 parts by mass. Comparedwith a pure polyvinyl alcohol foaming material, the polyvinyl alcohol / silicon dioxide composition microcellular foaming material has the advantages that by the isocyanate silicon dioxide, free energy barrier of cell nucleation can be relieved, heterogeneous nucleation sites are provided for foaming of the polyvinyl alcohol, the cell nucleation rate is increased, cells are unlikely to collapse ina foaming process, and compared with pure polyvinyl alcohol foam, the polyvinyl alcohol / silicon dioxide composition microcellular foaming material has more excellent mechanical property.

Owner:NINGBO UNIV

Polyvinyl alcohol polarity sponge plastics and method of producing the same

ActiveCN101153089BImprove adsorption capacityAdsorption is easy to decomposeProcedure AgentsFiltration

Owner:SICHUAN UNIV

Magnetic porous composite material and preparing method thereof

InactiveCN101692363AImprove efficiencyLarge specific surface areaMagnetic materialsAir atmosphereWater baths

The invention relates to a magnetic porous composite material and a preparing method thereof. The invention is characterized by comprising porous calcium sulphate serving as a matrix and magnetic ferric oxide component, and ferric oxide is tightly combined with calcium sulphate in the mode of nano-particles. The preparing method of the magnetic porous composite material comprises the following steps: (1) mixing polyvinyl alcohol with polyethylene glycol in a boiling water bath for swelling, then adding uniform mixture composed of starch, calcium carbonate and molysite or ferreous compound, and mechanically bubbling in the mode of violently stirring; and (2) adding formaldehyde and sulfuric acid to fix a macromolecule skeleton under acetalation reaction; finally performing heat treatment to prepared polyvinyl alcohol foam in air atmosphere at the temperature of 500 DEG C for 3 hours; then, ball milling for 4 hours at the rotating speed of 300r / min to obtain magnetic porous calcium sulphate / ferric oxide composite material. The invention has low preparing cost and simple preparing procedure and is easy to realize volume production.

Owner:ANHUI UNIVERSITY

Polyvinyl alcohol/montmorillonite nano-alloy foam material and preparation method thereof

InactiveCN103351561AImprove melt strengthSuitable for foam molding processingFoaming agentPlasticizer

The invention provides a polyvinyl alcohol / montmorillonite nano-alloy foam material and a preparation method thereof. The alloy foam material is prepared through using 55-95 parts by weight of polyvinyl alcohol powder, 5-40 parts by weight of a plasticizer, 0.01-5 parts by weight of montmorillonite and 0.25-5 parts by weight of a chemical foaming agent, wherein the consumption of the chemical foaming agent is calculated on the basis of using the dosage of polyvinyl alcohol as 100 parts by weight. Montmorillonite has the effects of a melt reinforcing agent, optimizes the foaming molding process of polyvinyl alcohol, and makes the foam material more suitable for the fusion extrusion foaming processing. Compared with polyvinyl alcohol foam materials without montmorillonite, the alloy foam material has the advantages of uniform cellular dimension, reduced blow hole and combined hole phenomena, and obviously decreased foam density.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Preparation method of maleic anhydride polypropylene micro-nano fiber/polyvinyl alcohol foamed material

The invention belongs to the technical field of composite material or high molecular foamed material, and especially relates to a preparation method of a maleic anhydride polypropylene micro-nano fiber / polyvinyl alcohol foamed material. The preparation method is capable of solving a problem in the prior art that the mechanical strength of conventional polyvinyl alcohol foamed material is low. According to the preparation method, PP-g-MAH micro-nano fiber and polyvinyl alcohol are taken as the main components, a foaming agent and a crosslinking agent are added to prepare the maleic anhydride polypropylene micro-nano fiber / polyvinyl alcohol foamed material. The mechanical performance of the foamed material is improved effectively through the cooperative effect of the components of the composite material.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Preparation method of polyvinyl alcohol/carbon nanotube microporous foaming material

InactiveCN109294137AReduce the free energy barrierIncrease the nucleation rateFree energiesPolymer science

The invention relates to a preparation method of a polyvinyl alcohol / carbon nanotube microporous foaming material which is good in bubble pore stability and not easy to collapse. The preparation method comprises three steps: (1) preparing carbon nanotubes containing polar groups; (2) preparing a polyvinyl alcohol composition, wherein the polyvinyl alcohol composition includes polyvinyl alcohol, the carbon nanotubes containing the polar groups and prepared in the step 1, and a plasticizer; and (3) placing the polyvinyl alcohol composition in a high-pressure mould and preparing the polyvinyl alcohol microporous foaming material by specific processes. The method has the following advantages: the carbon nanotube containing the polar groups can reduce the free energy barrier of nucleation of bubble pores, provides heterogeneous nucleation sites for polyvinyl alcohol foaming, increases the nucleation rate of the bubble pores, and has the bubble pores not easy to collapse during foaming process, and has superior mechanical properties than pure polyvinyl alcohol foams.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Polyvinyl alcohol foaming material for treating sewage

InactiveCN101186720BStrong water absorptionRealize purification and decontaminationWater/sewage treatmentCarbon nanotubePolyethylene glycol

A polyvinyl alcohol foaming material for processing sewage uses polyvinyl alcohol, formaldehyde and amidon as raw materials, sulfuric acid as catalyst, calcium sulfate as foaming agent to prepare softfoam plastic, which is characterized in that the charged carbon nanometer pipe and polyethylene glycol are foamed together to make the foaming material have large-aperture porous structure, and the aperture ranges from 0.05mm to 1.0mm. The water-absorbing quantity is 4-6 times as itself weight, which is especially provided with peculiar adsorption property for adsorbing particle and stain suspended in the sewage and stripping peculiar smell and decolouration effect, further processing sewage, not only processing living sewage, but also processing industrial sewage.

Owner:ANHUI UNIVERSITY

Preparation method of polyvinyl alcohol/graphene microcellular foam material

The invention relates to a preparation method of a polyvinyl alcohol / graphene microcellular foam material which has good foam pore stability and cannot collapse. The preparation method comprises the three steps as follows: (1) preparing graphene containing polar groups; (2) preparing polyvinyl alcohol composition comprising polyvinyl alcohol, the graphene containing the polar groups and prepared in the step 1 and a plasticizer; (3) placing the polyvinyl alcohol composition in a high-pressure mold and preparing the polyvinyl alcohol microcellular foam material with a specific process. The method has the advantages as follows: the graphene containing the polar groups can reduce free energy barrier for foam pore nucleation, provide heterogeneous nucleation sites for polyvinyl alcohol foamingand increase the foam pore nucleation rate, foam pores cannot collapse easily during foaming, and the mechanical performance is excellent than that of pure polyvinyl alcohol foam.

Owner:NINGBO UNIV

Polyvinyl alcohol/smectite composite nano foamed material and preparation method thereof

The invention relates to a polyvinyl alcohol / smectite compound nano foamed material which is prepared by compounding technology and chemical foaming technology. The foamed material contains 3-5 wt% of nano smectite, so that the mechanical strength and thermal stability of the foamed material are enhanced; and the inside of the polyvinyl alcohol foamed material has a crosslinked network structure and also has compact pores with uniform sizes, so the material has the advantages of large specific area, high adsorption capacity and low cost, has favorable functions of adsorption, filtration and separation, can be easily used repeatedly, and is hopeful to become a filtering / separating / adsorbing material which has wide popularization prospects in the fields of filtration, separation and adsorption. Therefore, by utilizing the characteristics of high mechanical strength and high thermal stability, the polyvinyl alcohol / smectite compound nano foamed material can be used in the fields of beverages, food, brewage, pharmacy, chemical engineering, sewage treatment, environmental protection and the like, and satisfies the requirements of higher technical conditions in a purification / solid-liquid separation / filtration recovery system.

Owner:李景峰 +1

Water soluble polyvinyl alcohol foam and preparation method thereof

The invention discloses a water soluble polyvinyl alcohol foam and a preparation method thereof. The water soluble polyvinyl alcohol foam comprises relative low molecular weight polyvinyl alcohol with a polymerization degree of 1300-1700 and relative high molecular weight polyvinyl alcohol with a polymerization degree of 3500-6500; and the weight ratio of the two components is determined by a formula: (DPH / DPL)1.4=<WL / WH=<(DPH / DPL)1.8. The water soluble polyvinyl alcohol foam is prepared by the following steps: mixing polyvinyl alcohol with different polymerization degrees according to a specific ratio, and then subjecting the mixture to a series of processes in carbon dioxide with a specific temperature and pressure range; and the structure and performance of the water soluble polyvinyl alcohol foam are excellent. In a conventional technology, a large amount of non-polyvinyl alcohol substances is added, the water solubility is reduced, the performance becomes unstable, and polyvinyl alcohol easily precipitates during the using process, the provided method solved the abovementioned problems; moreover, the formula and technology are simple and are easy to operate, and the method has a good application prospect therefore.

Owner:YONGAN SYF WATER SOLUBLE FILMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com