Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Grating light valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

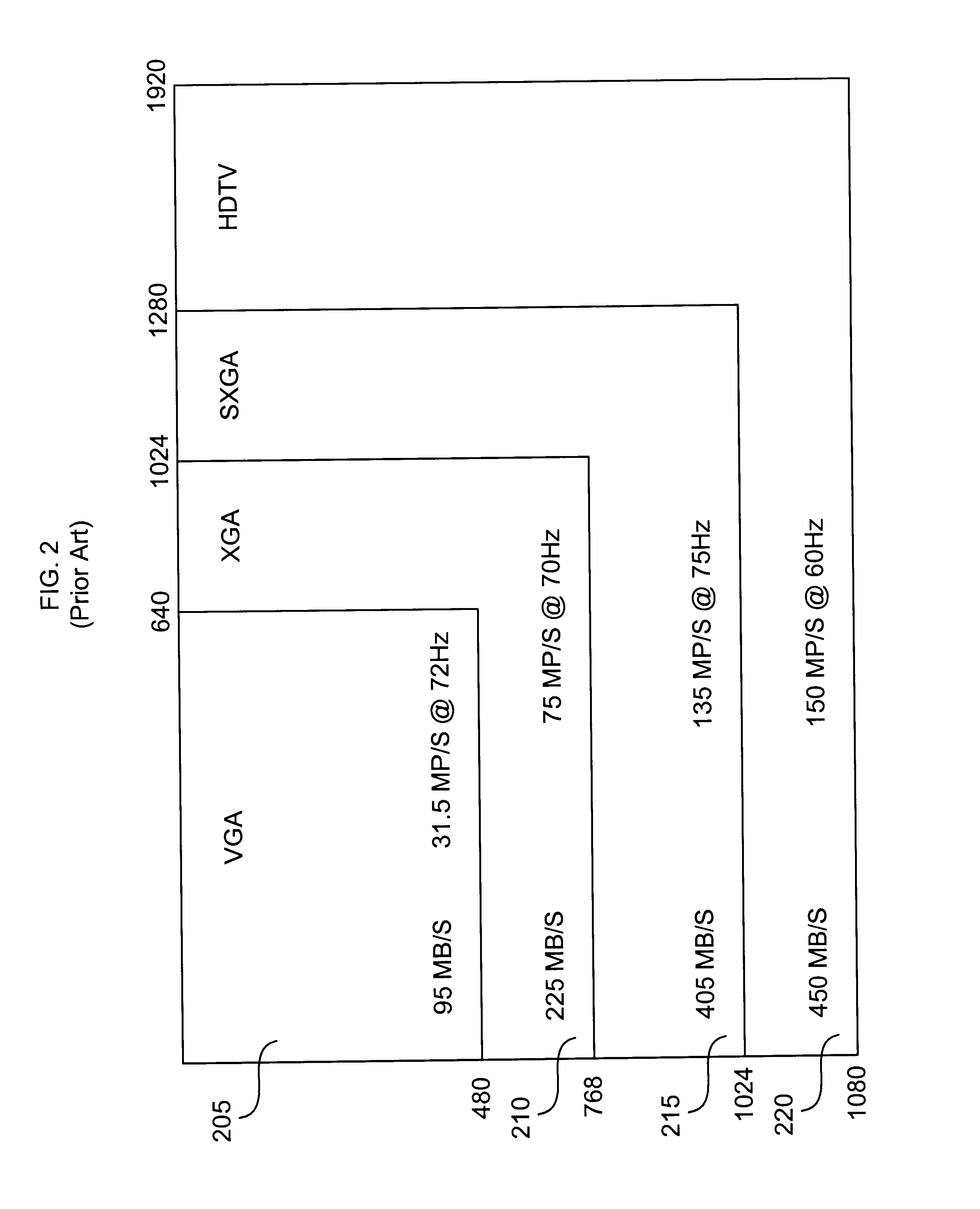

The grating light valve (GLV) is a "micro projection" technology which operates using a dynamically adjustable diffraction grating. It competes with other light valve technologies such as Digital Light Processing (DLP) and liquid crystal on silicon (LCoS) for implementation in video projector devices such as rear-projection televisions. The use of microelectromechanical systems (MEMS) in optical applications, which is known as optical MEMS or micro-opto-electro-mechanical structures (MOEMS), has enabled the possibility to combine the mechanical, electrical and optical components in very small scale.

Method and apparatus for using an array of grating light valves to produce multicolor optical images

InactiveUS6219015B1Improve accuracyMade smallStatic indicating devicesDiffraction gratingsPlane mirrorColored light

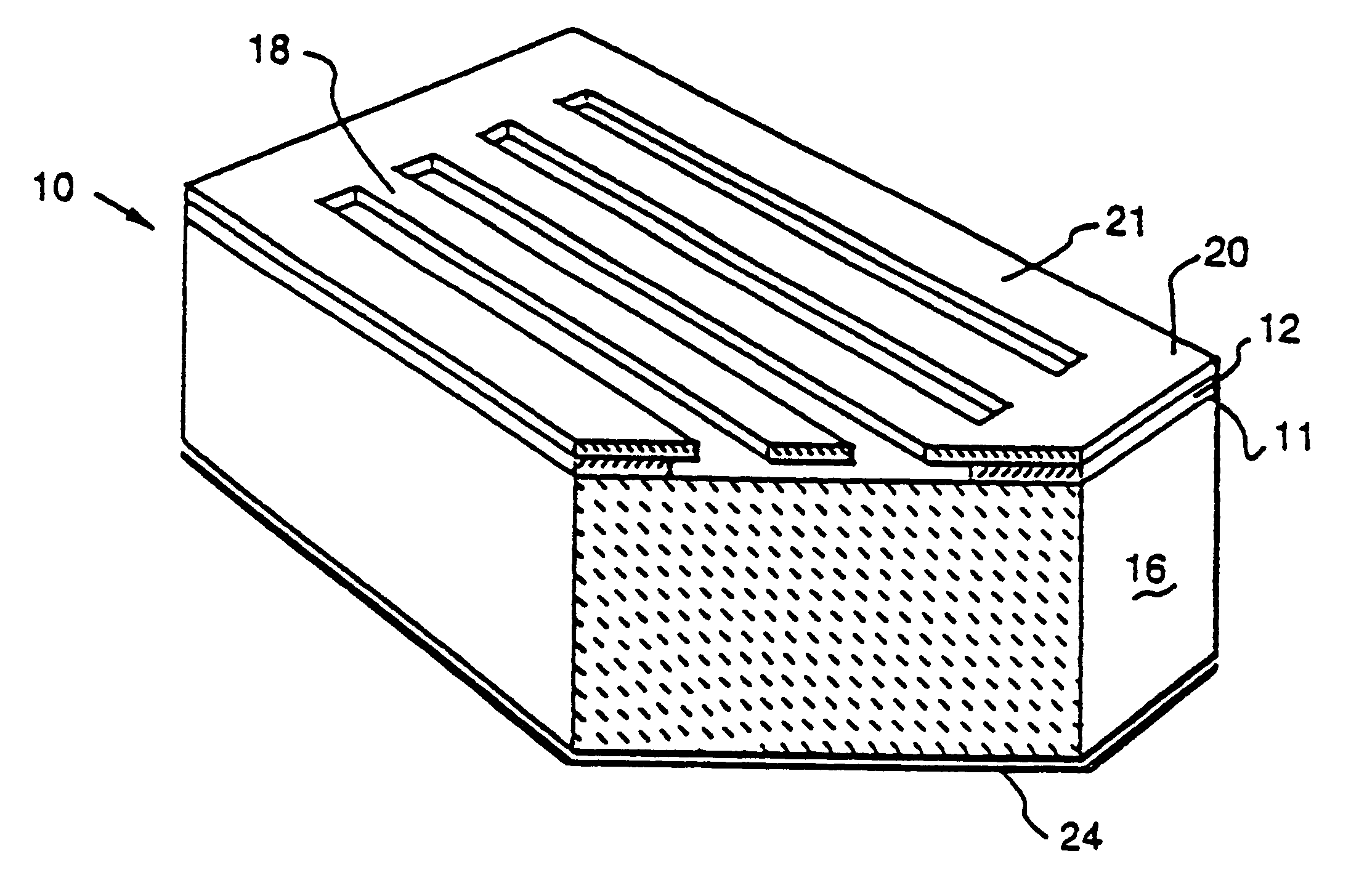

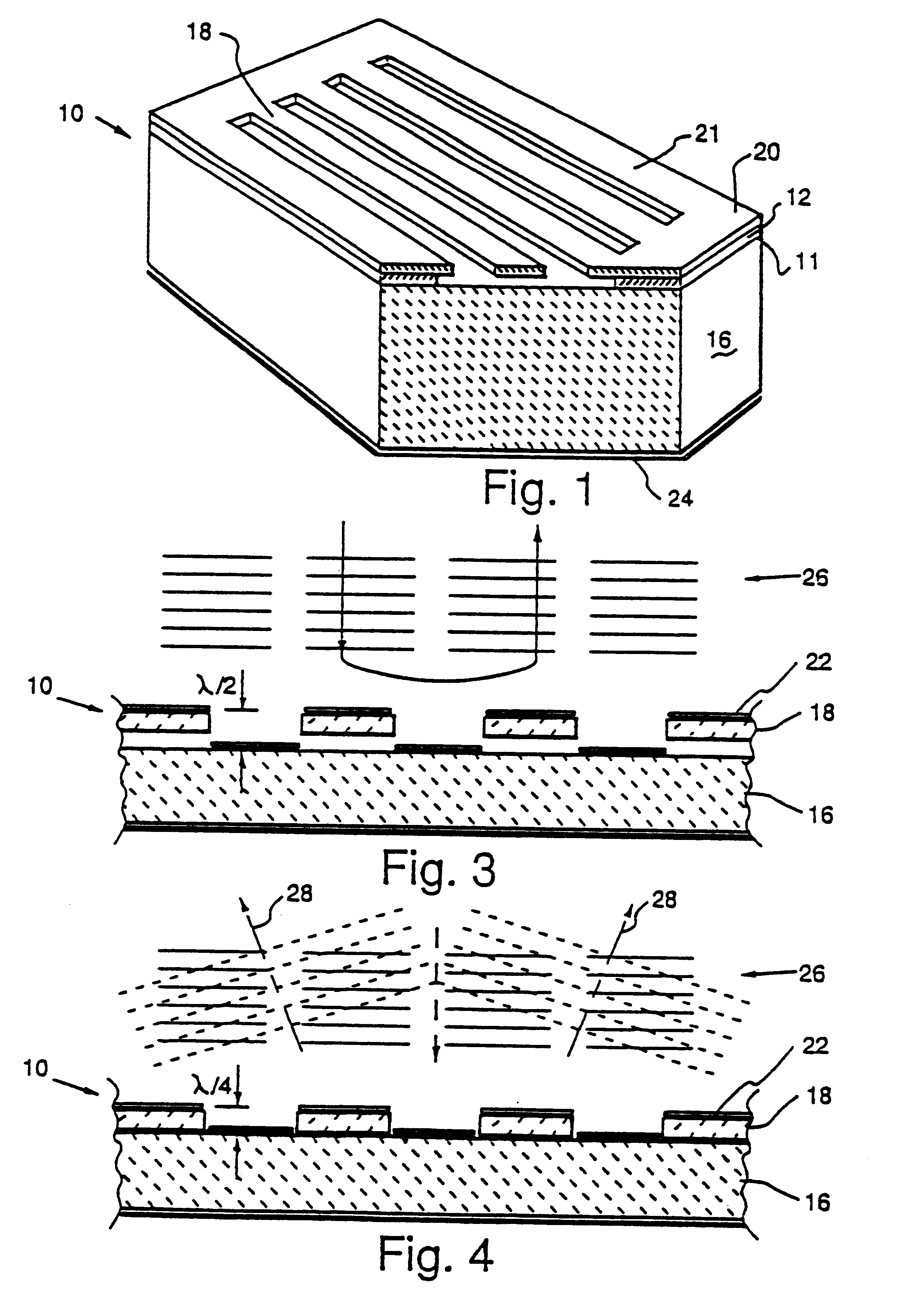

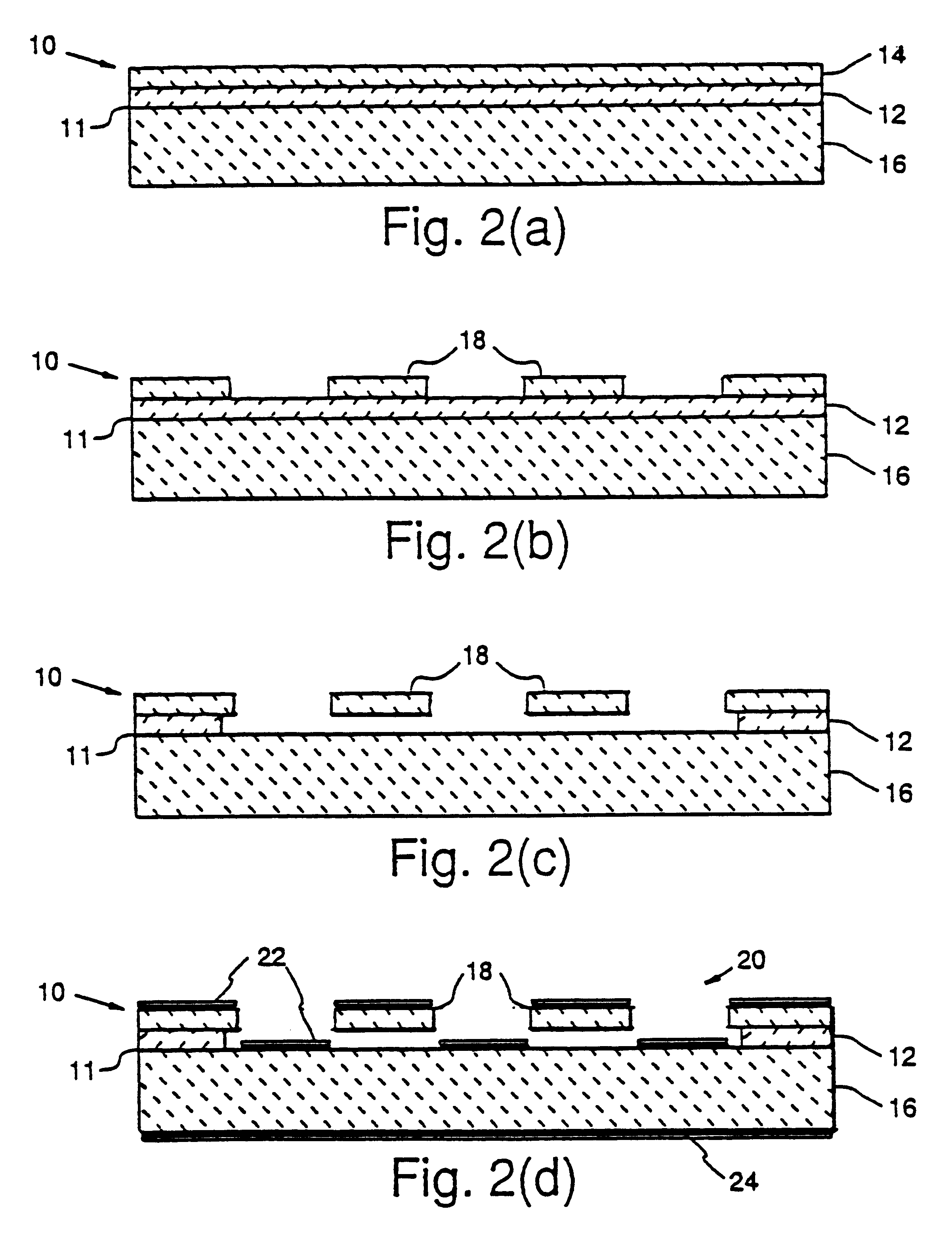

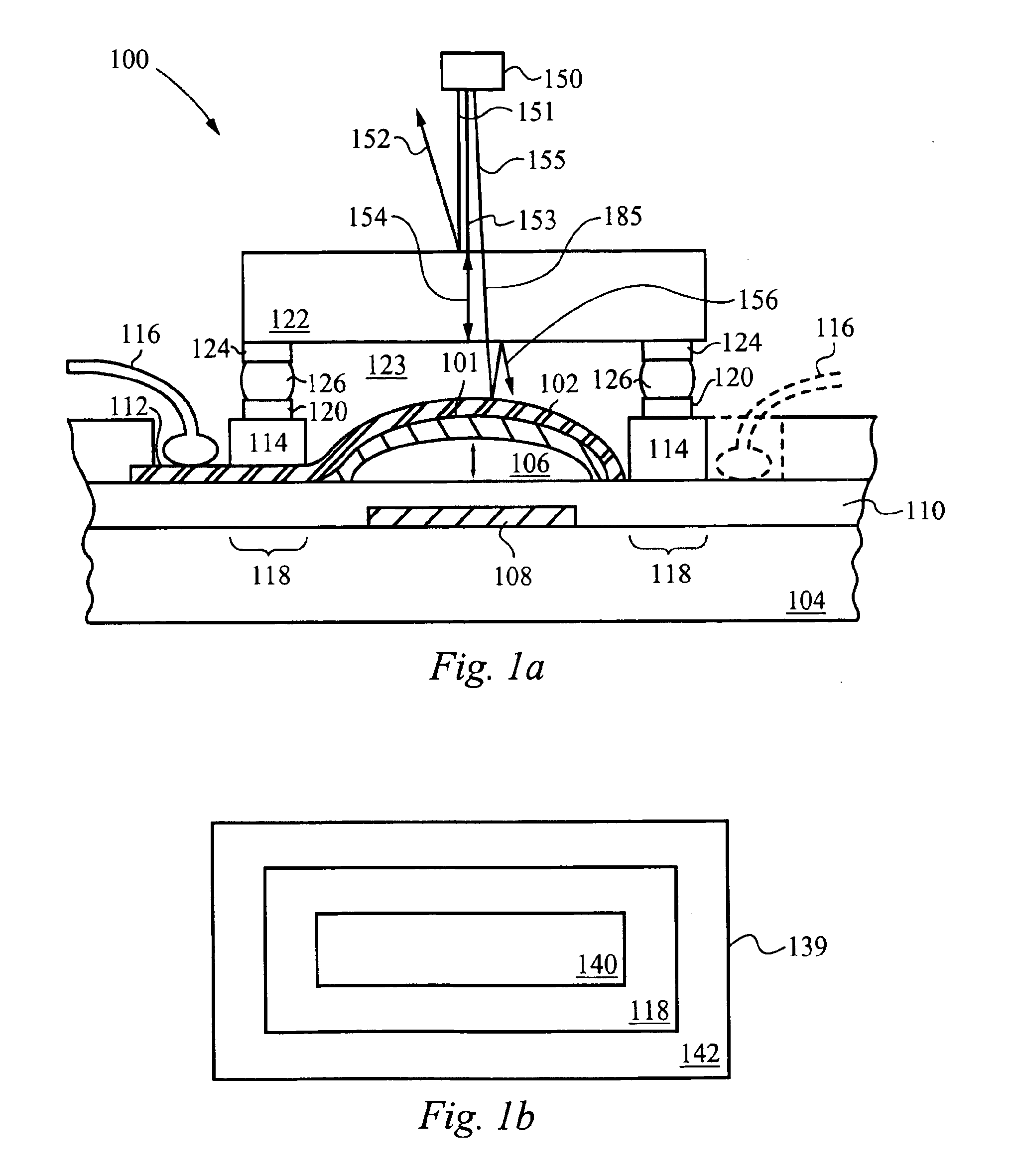

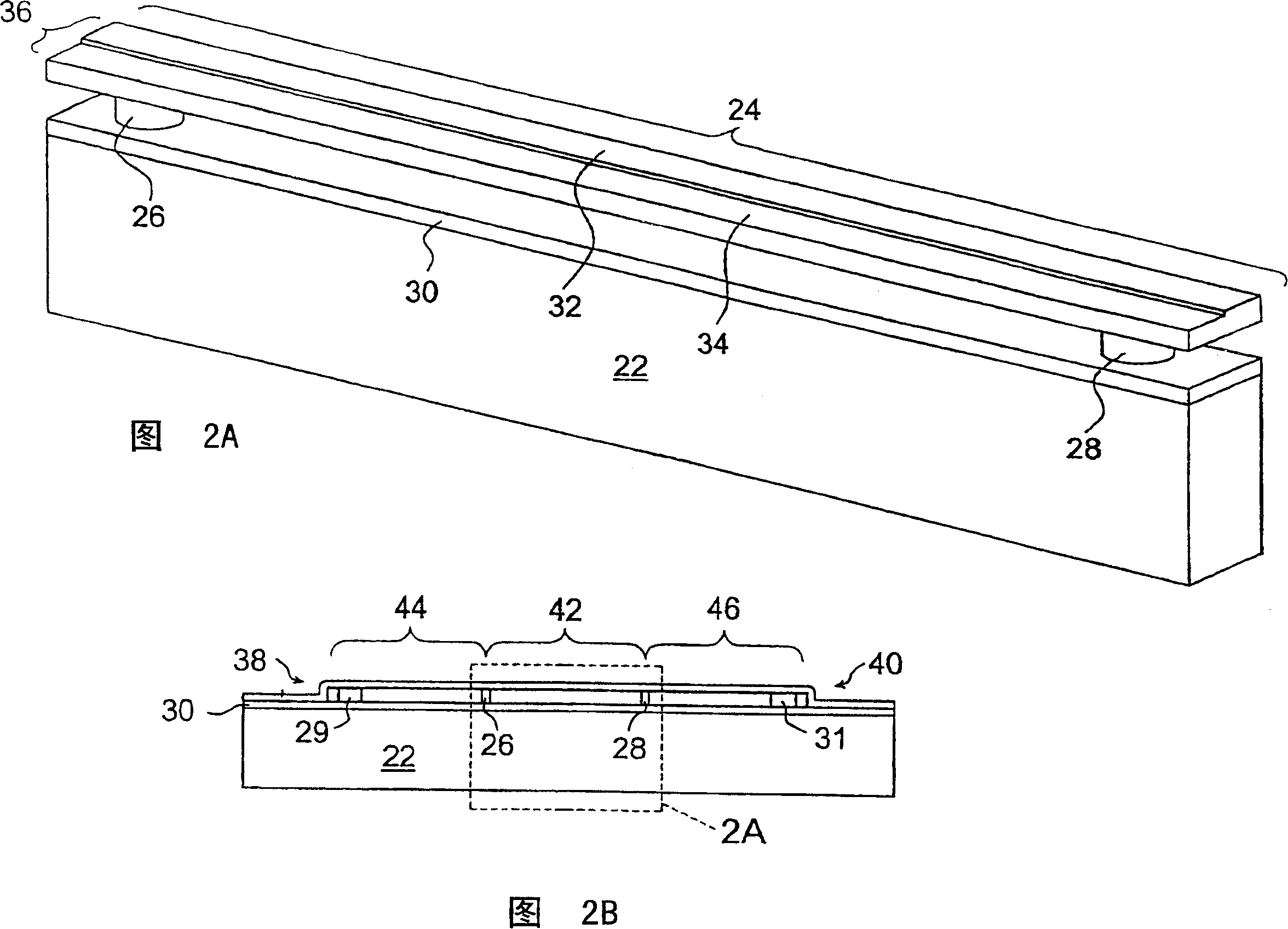

A multicolor optical image-generating device comprised of an array of grating light valves (GLVs) organized to form light-modulating pixel units for spatially modulating incident rays of light. The pixel units are comprised of three subpixel components each including a plurality of elongated, equally spaced apart reflective grating elements arranged parallel to each other with their light-reflective surfaces also parallel to each other. Each subpixel component includes means for supporting the grating elements in relation to one another, and means for moving alternate elements relative to the other elements and between a first configuration wherein the component acts to reflect incident rays of light as a plane mirror, and a second configuration wherein the component diffracts the incident rays of light as they are reflected from the grating elements. The three subpixel components of each pixel unit are designed such that when red, green and blue light sources are trained on the array, colored light diffracted by particular subpixel components operating in the second configuration will be directed through a viewing aperture, and light simply reflected from particular subpixel components operating in the first configuration will not be directed through the viewing aperture.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

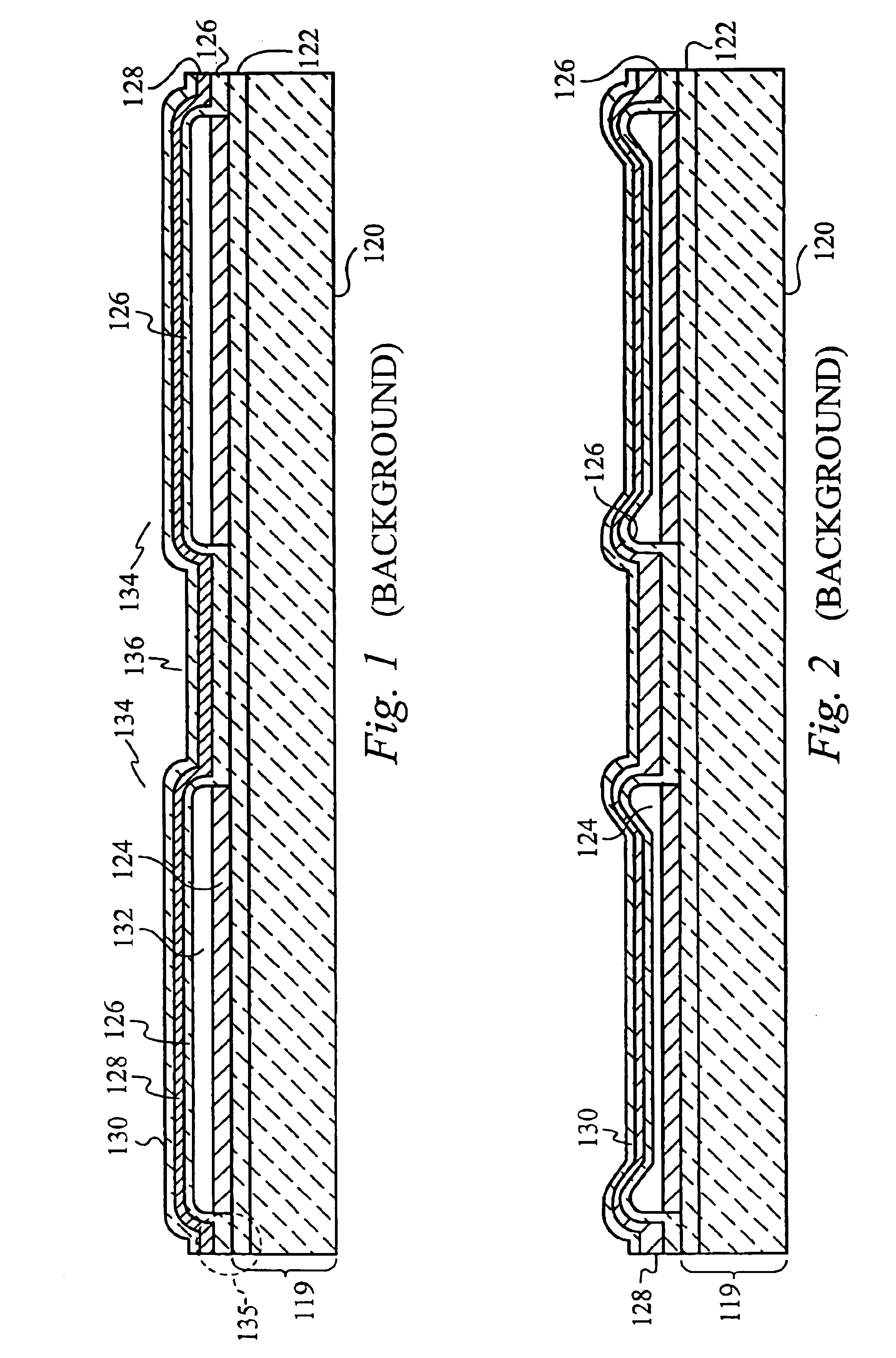

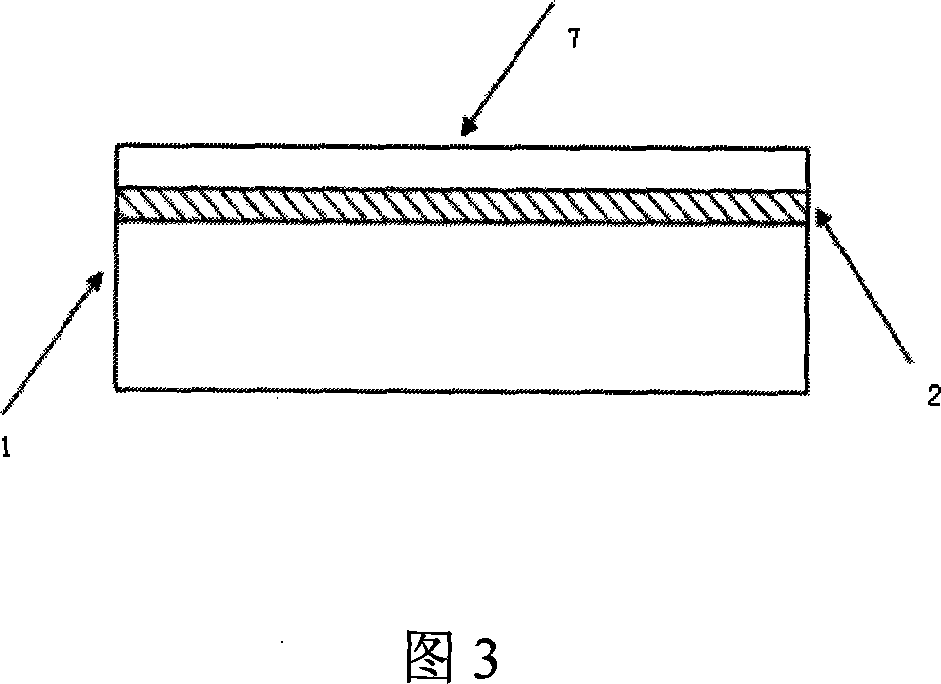

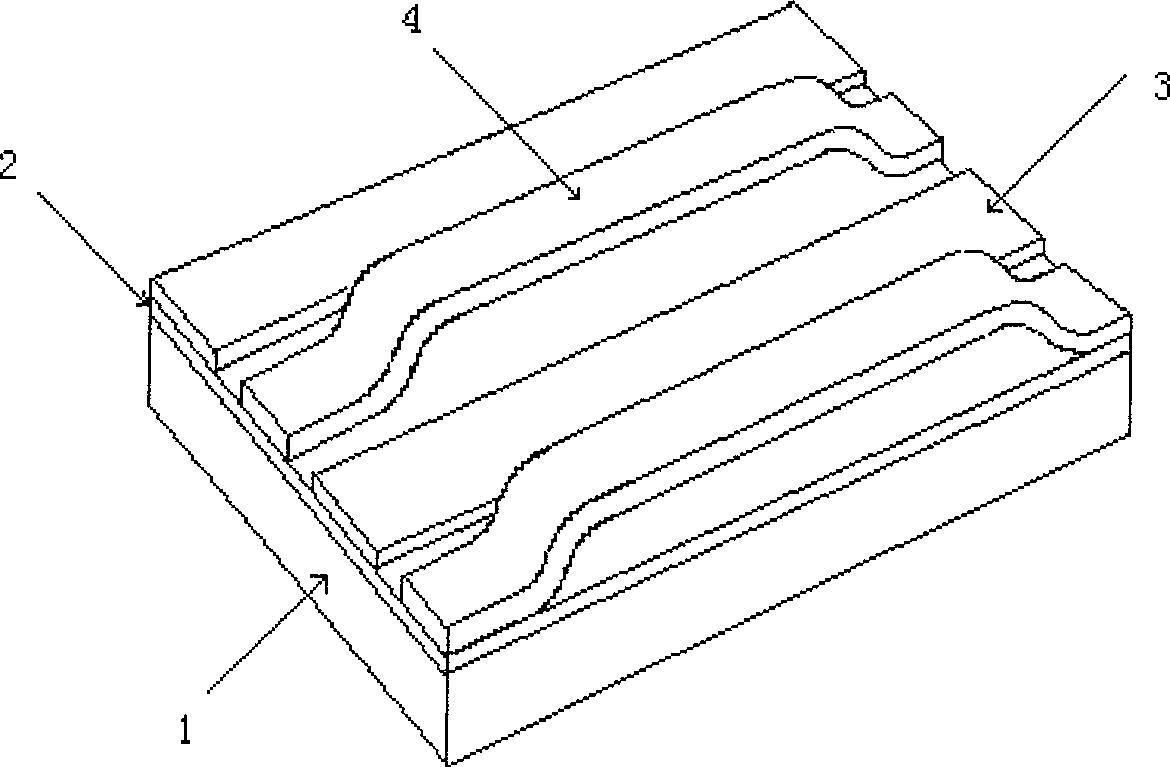

Method of sealing a hermetic lid to a semiconductor die at an angle

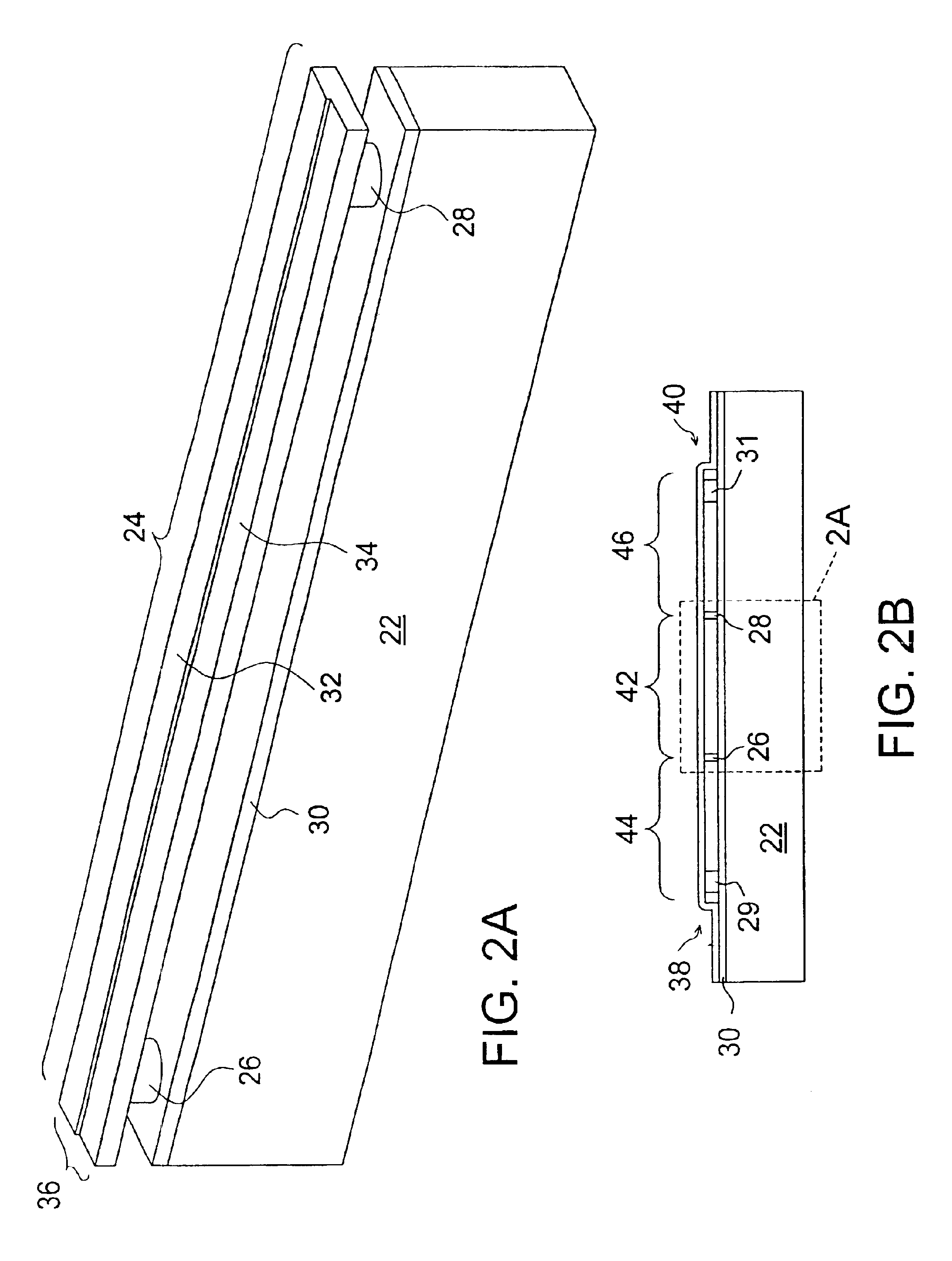

InactiveUS6872984B1Reduce Optical InterferenceSemiconductor/solid-state device detailsSolid-state devicesHermetic sealAsymmetric distribution

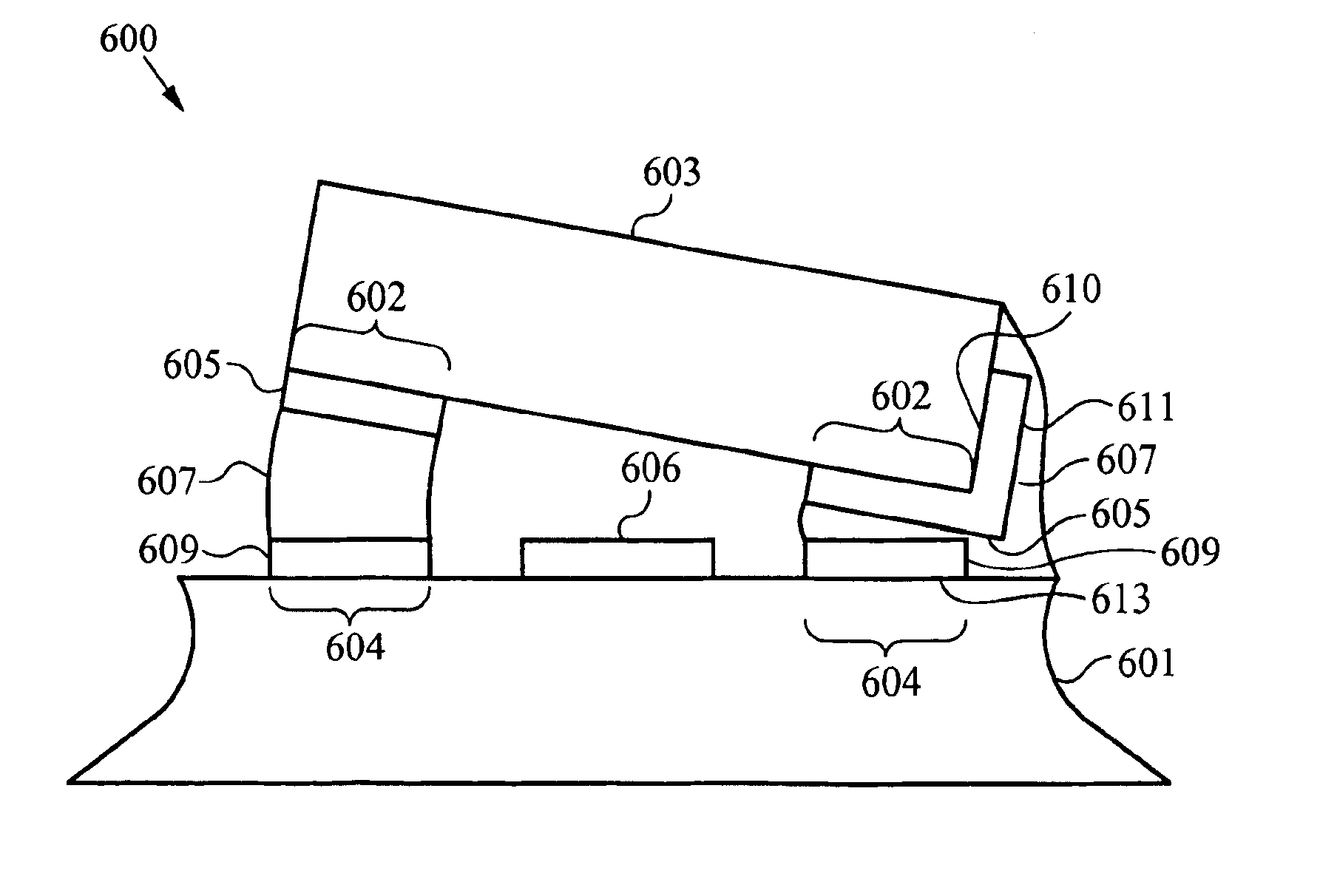

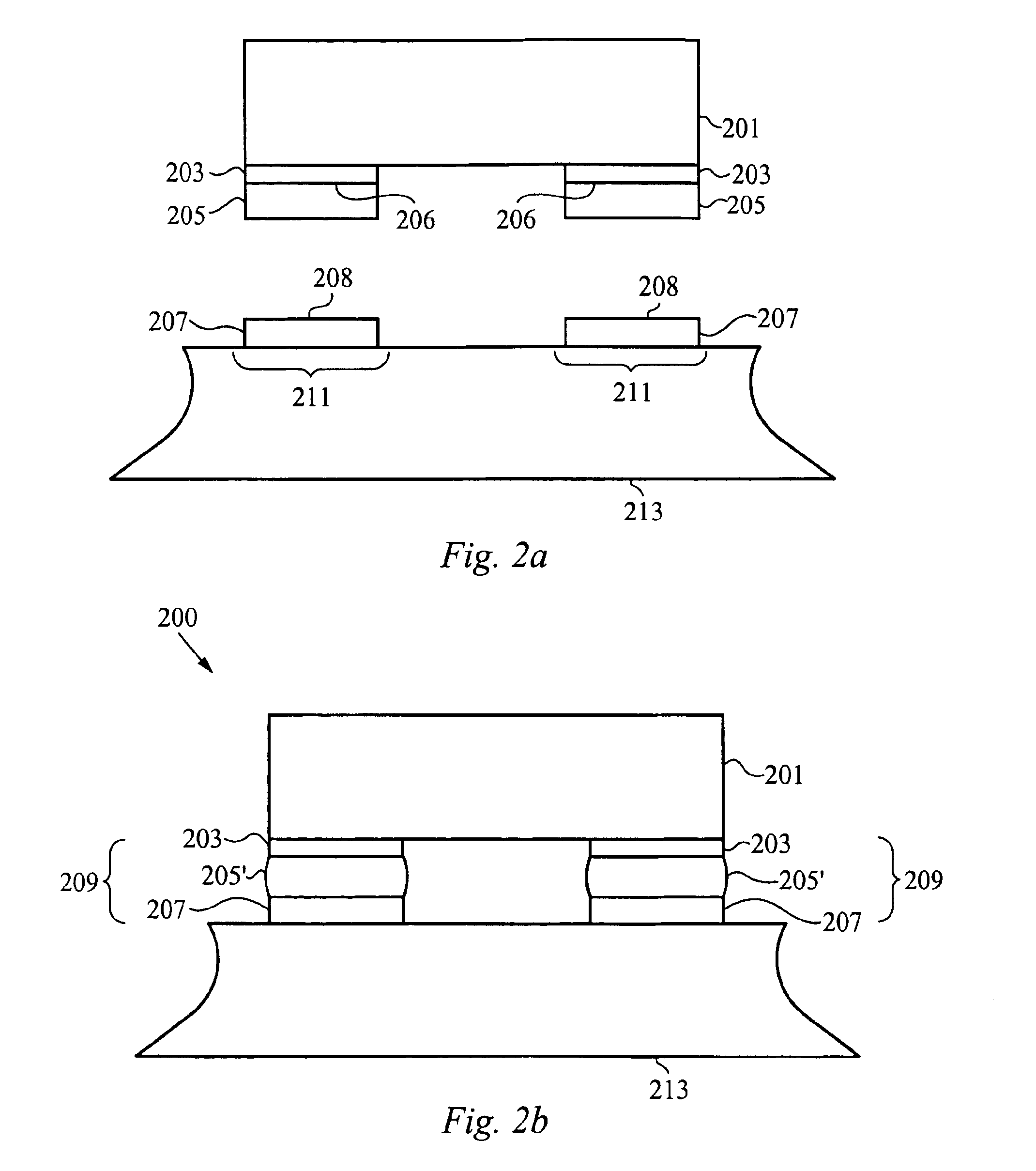

The current invention provides a optical MEM device and system with an angled lid for hermetically sealing an active MEMS structure. The lid is sealed through an asymmetric seal formed with sealing rings having an asymmetric distribution of solder wetting surfaces which tilts the lid, when the lid and a substrate are soldered together. The asymmetric distribution wetting surfaces can be provided by forming one or more edge features, by patterning portions of the sealing rings or both. Preferably, the lid is transparent to one or more wavelengths of light in a range of 300 to 3000 Angstroms and hermetically seals a grating light valve structure having a plurality of movable ribbon for modulating light through the lid.

Owner:SILICON LIGHT MACHINES CORP

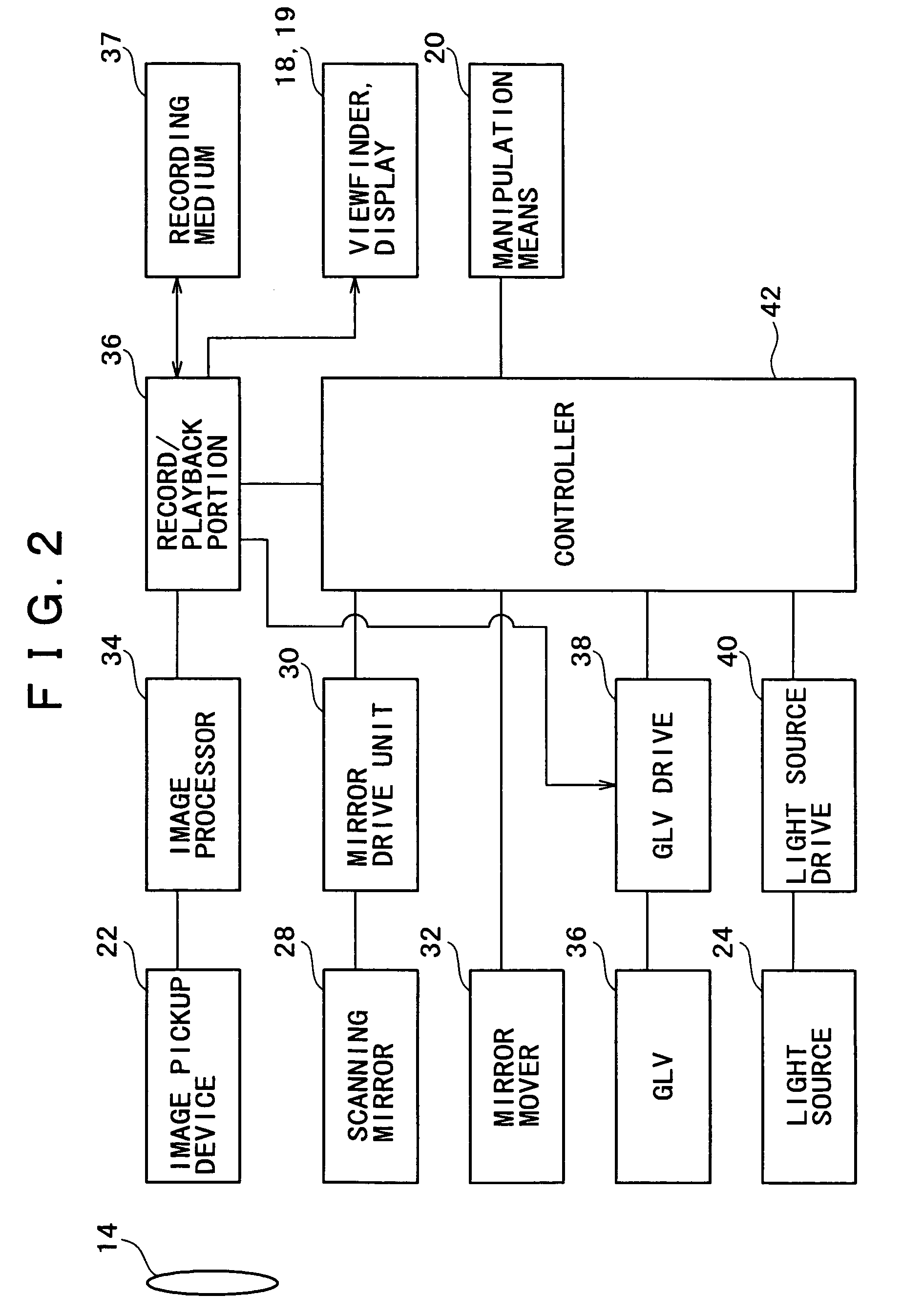

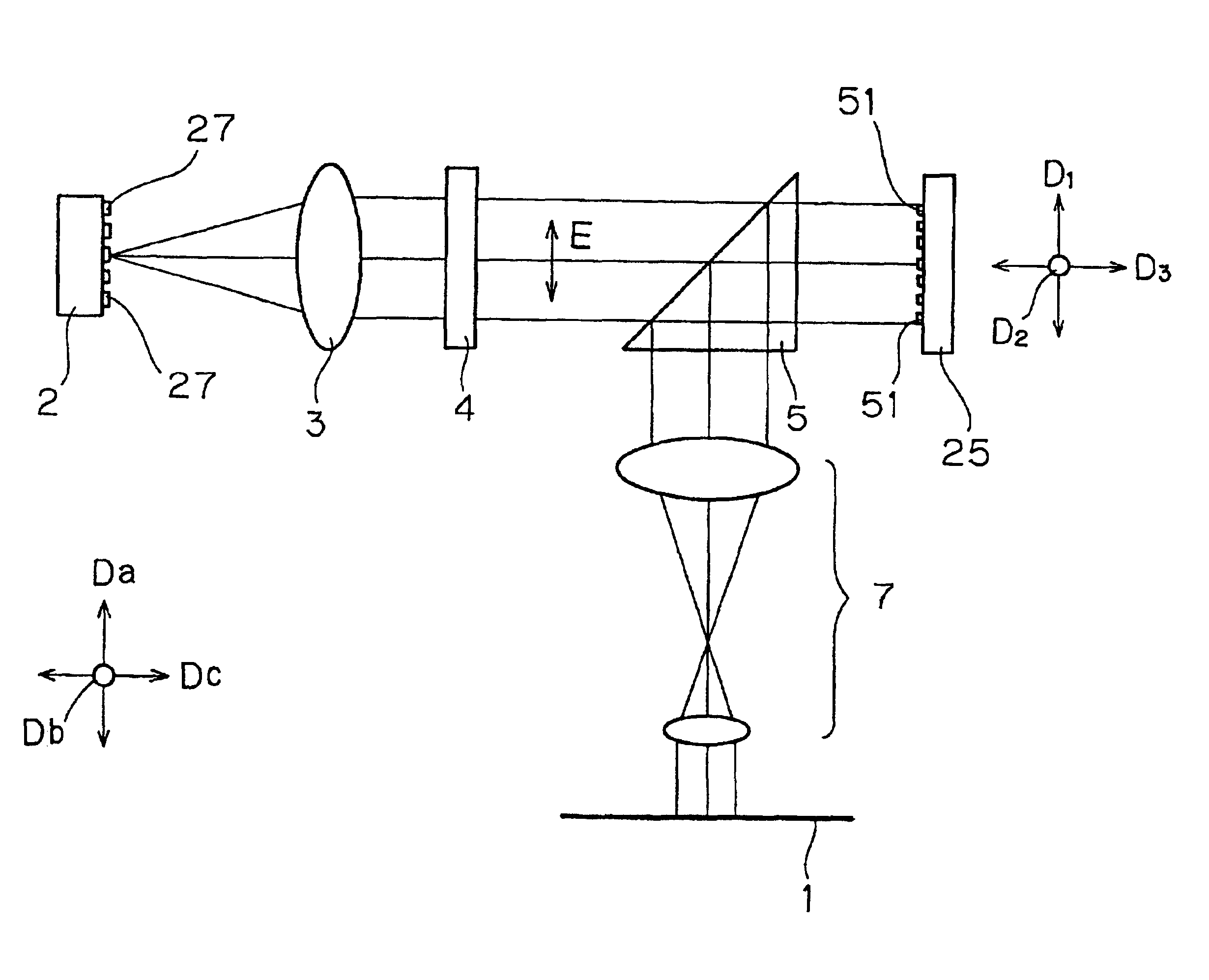

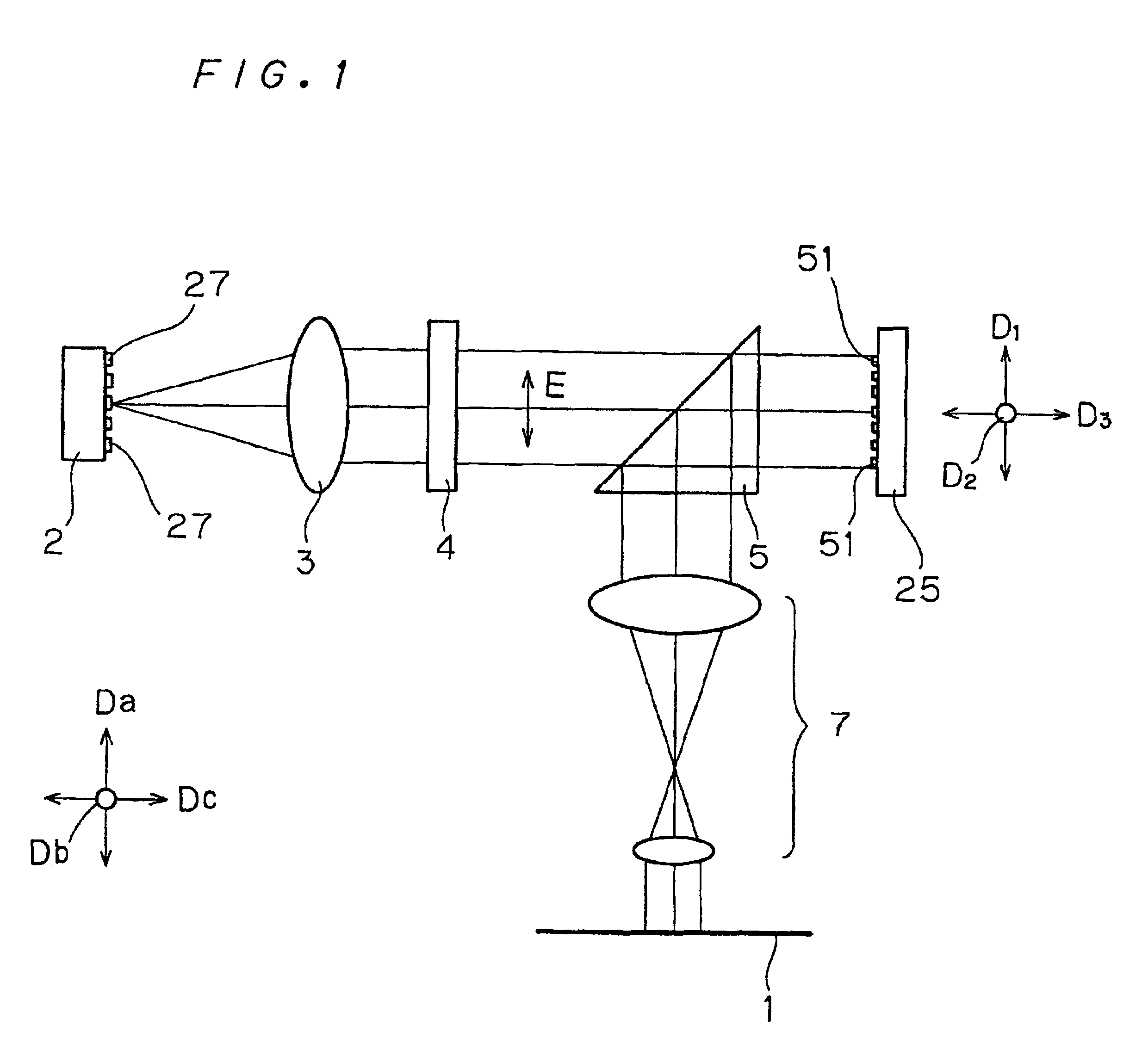

Imaging apparatus

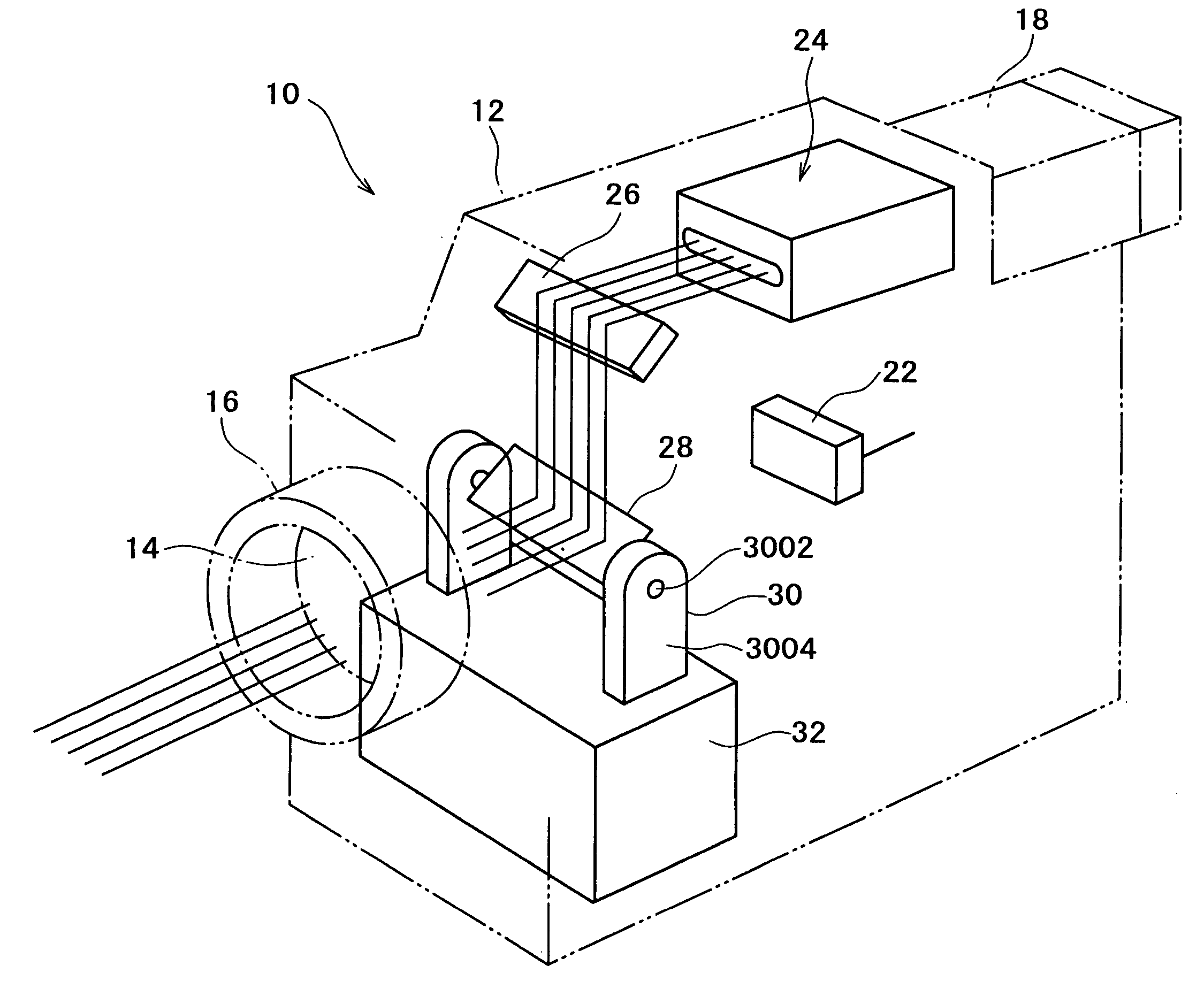

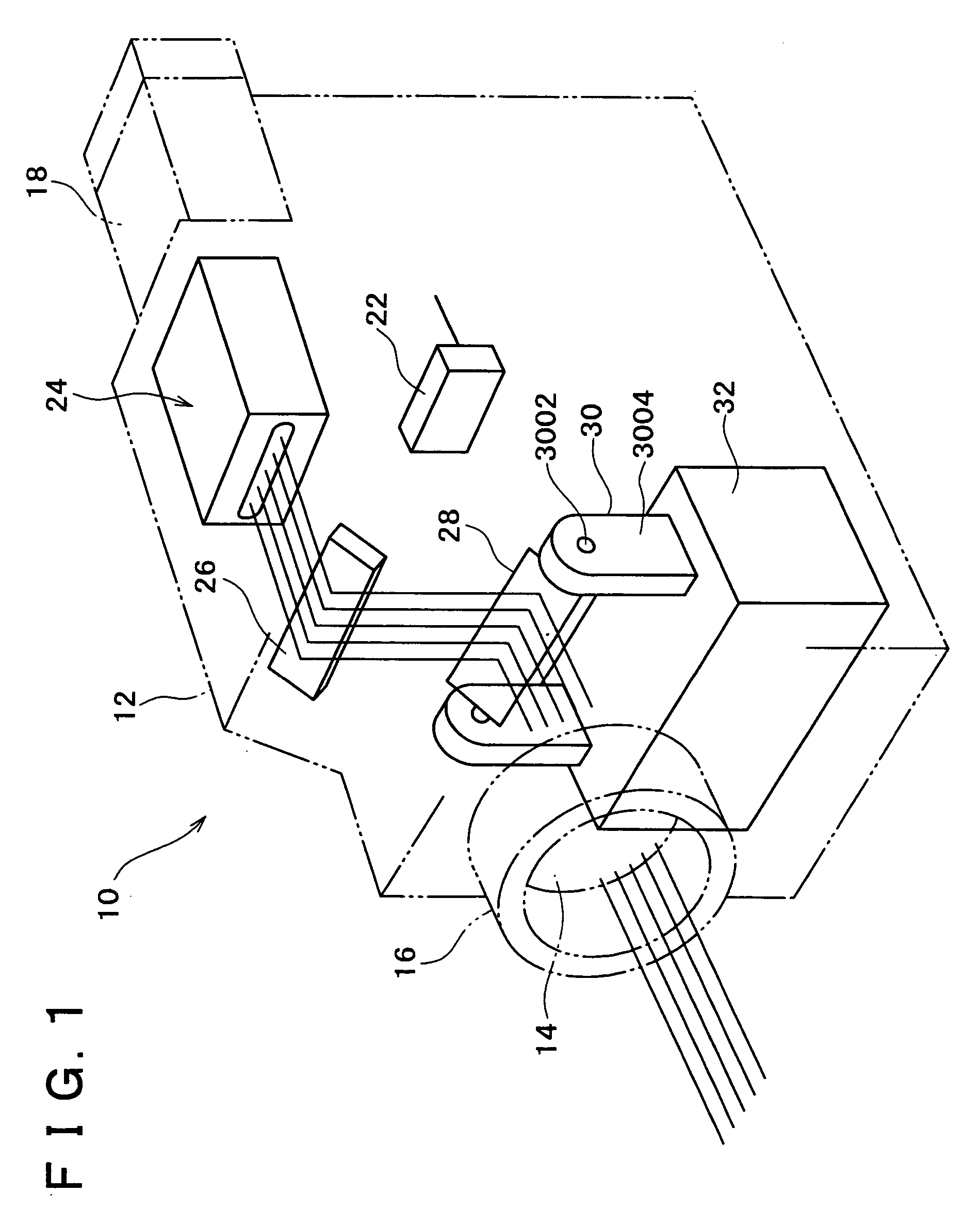

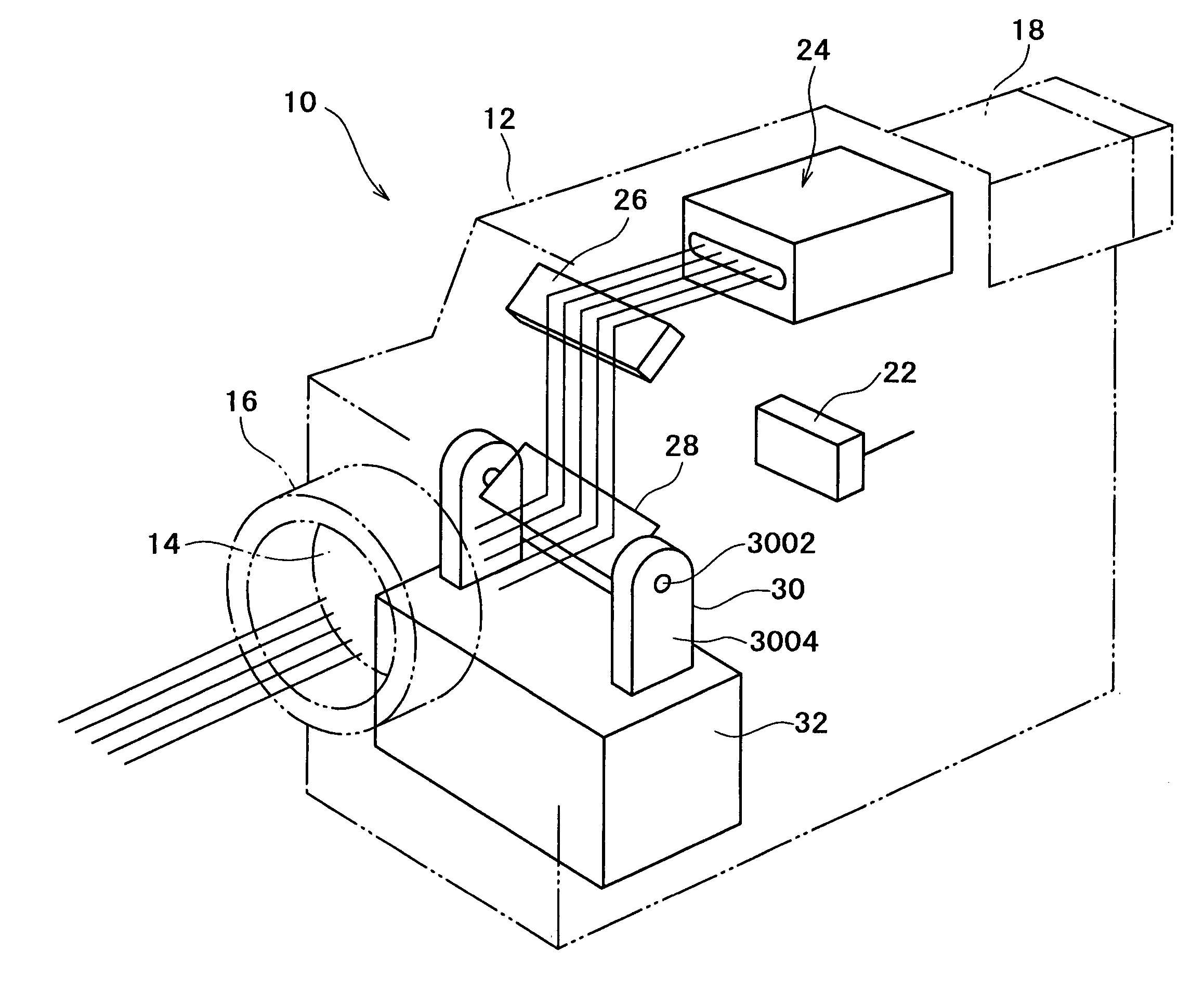

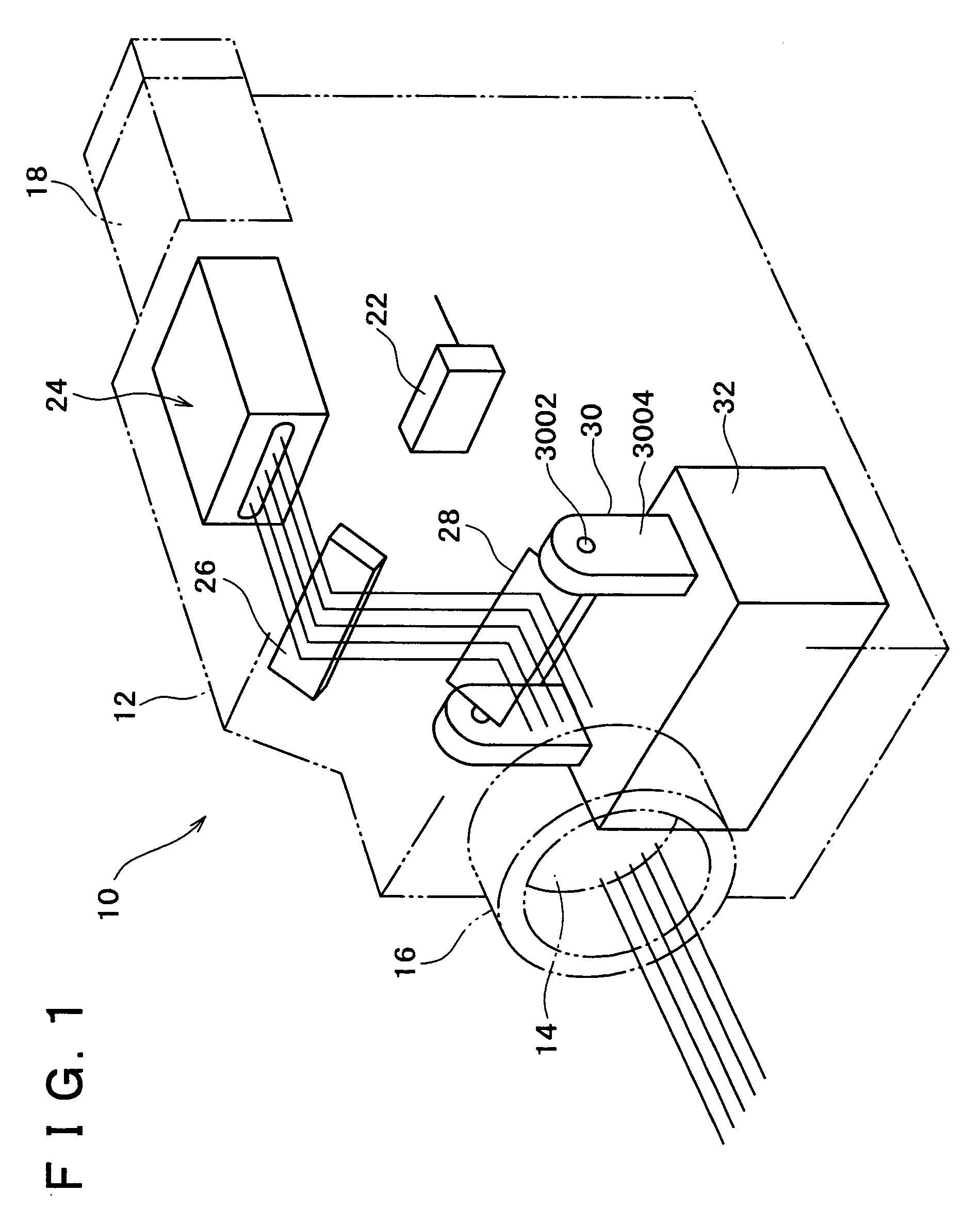

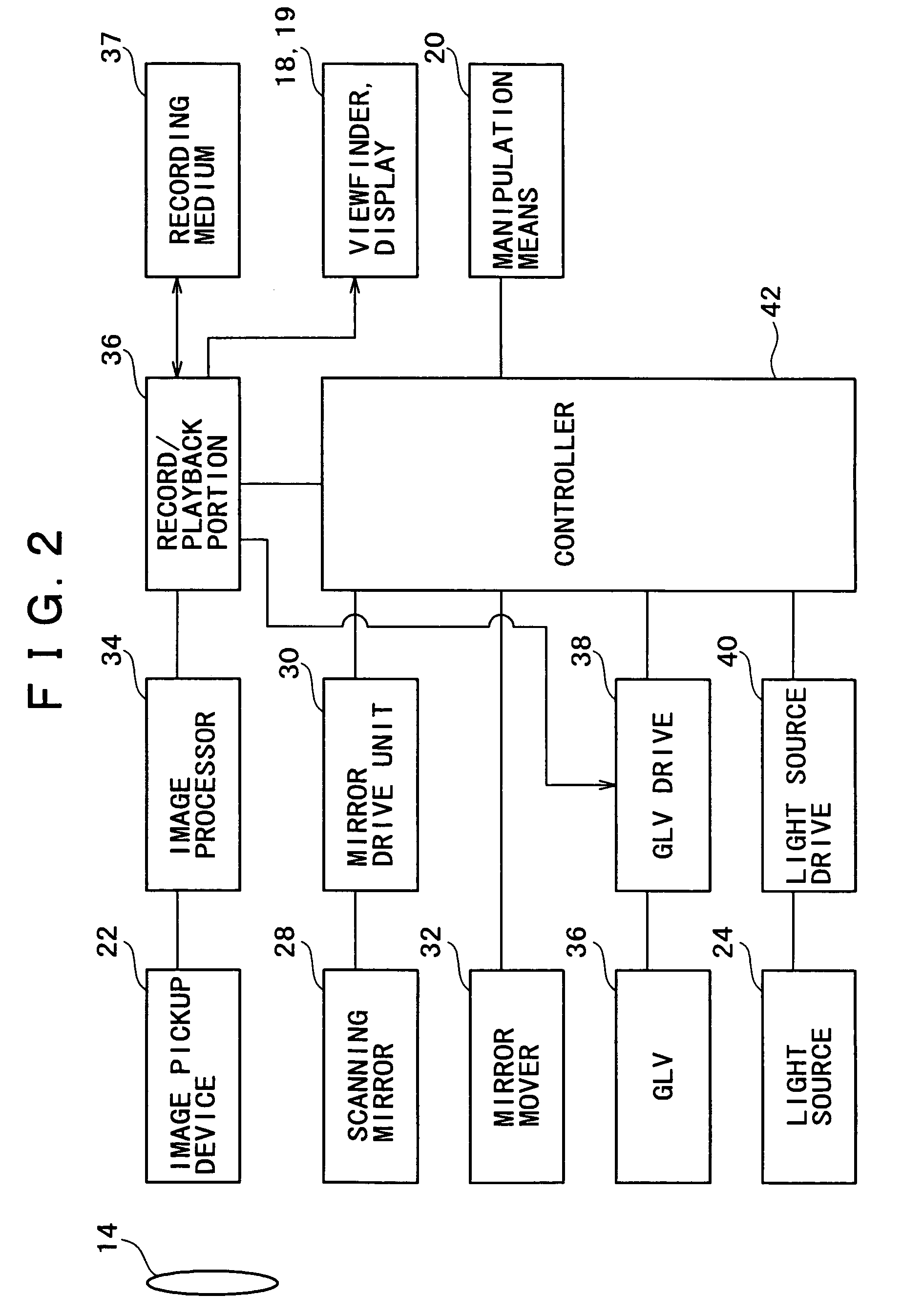

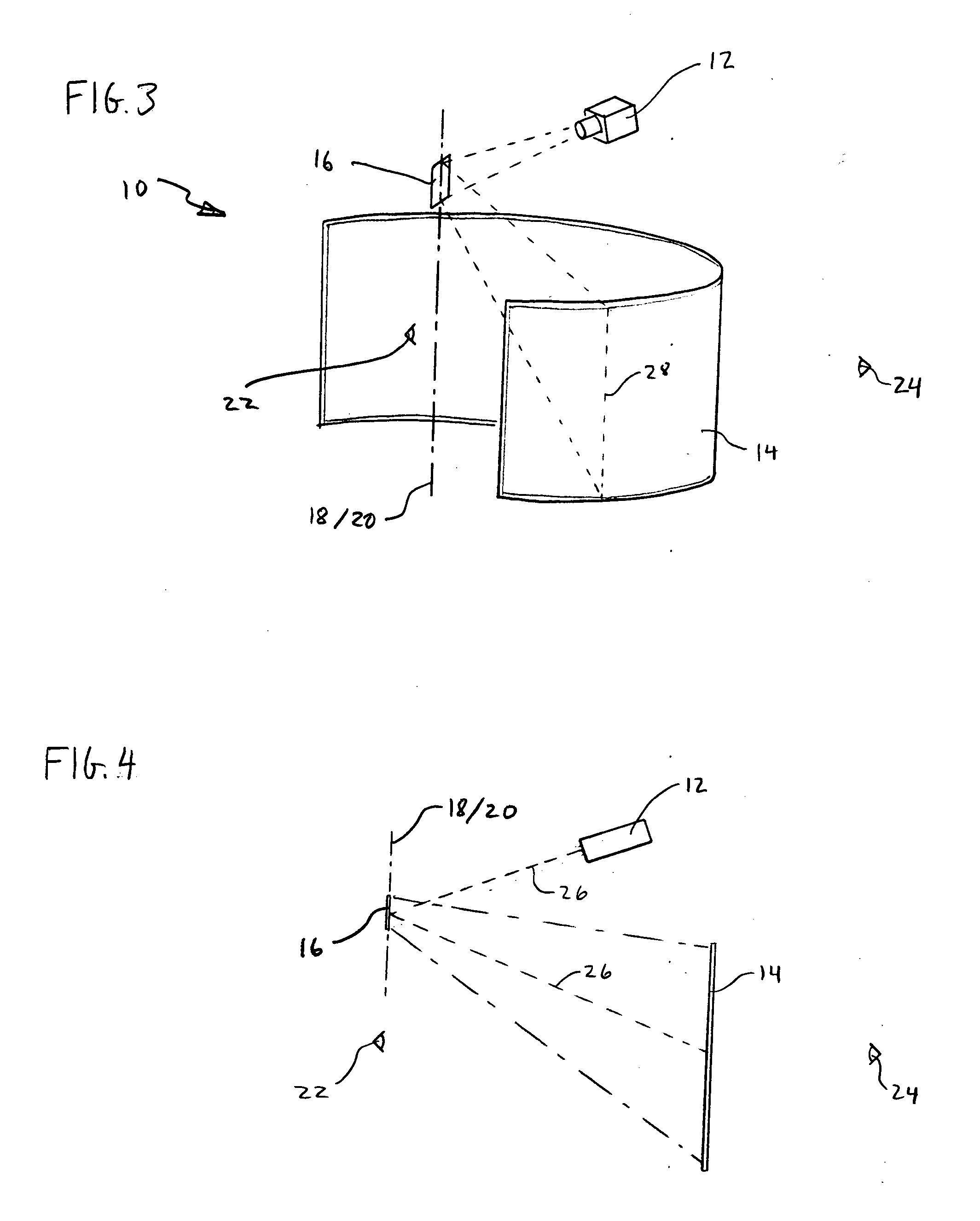

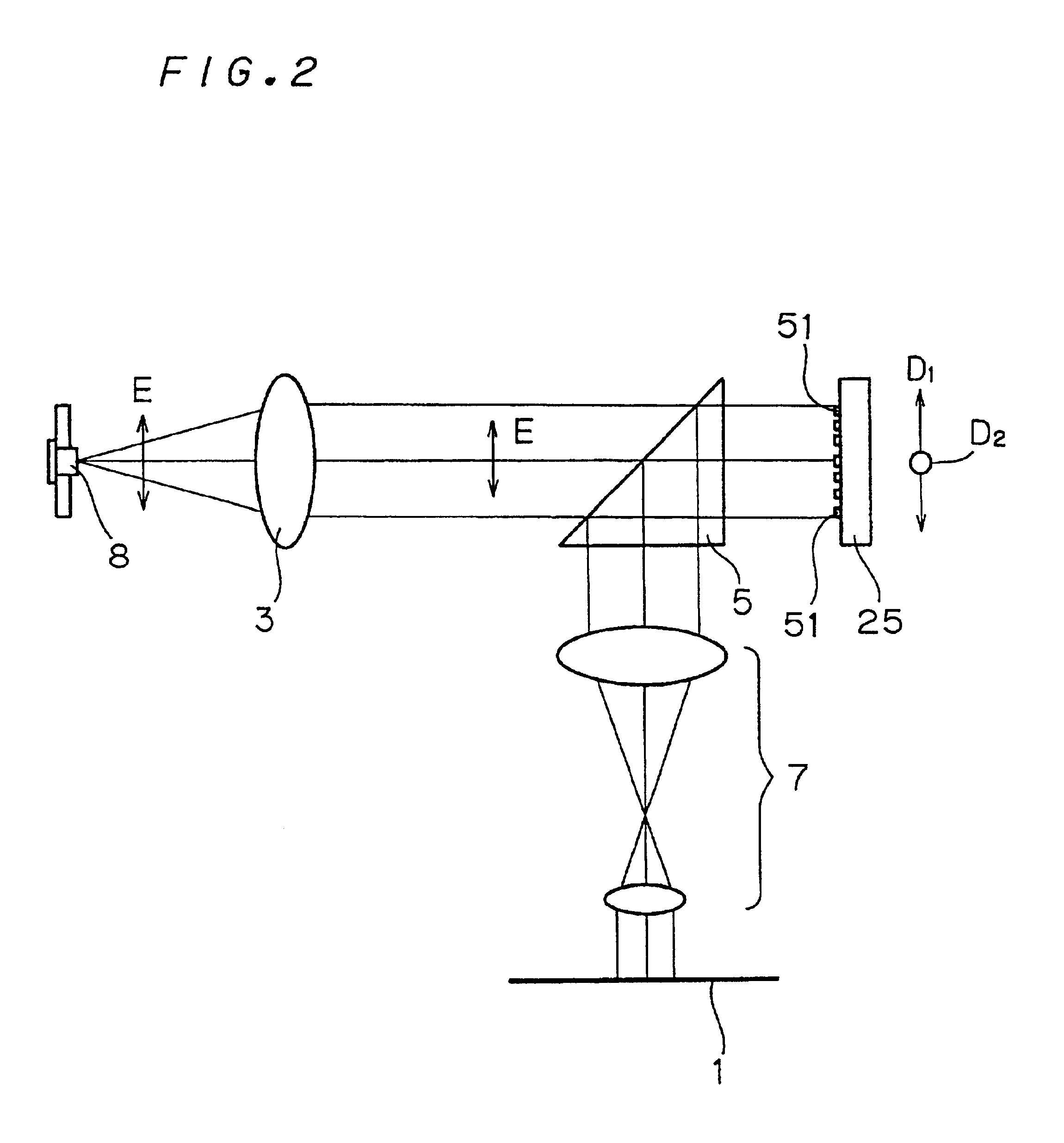

InactiveUS20050099664A1Reduce image sizeSmall sizeTelevision system detailsTelevision system scanning detailsProjection imageScanning mirror

An imaging apparatus having a projector function which is advantageous in reducing size is provided. A light source of the imaging apparatus is constituted by three semiconductor lasers which respectively frontward emit lights of red, green and blue, each slit-shaped. To a GLV (Grating Light Valve) is applied a drive voltage as modulated by a projection image signal, so that the GLV diffracts the three lights emitted from the light source, with varying the amount or intensity of each light in accordance with the drive voltage or projection image signal. A scanning mirror is disposed between a taking lens and an image pickup device, so as to reflect the lights diffracted by the GLV toward the taking lens, with having each diffracted slit-shaped light scan in a direction.

Owner:SONY CORP

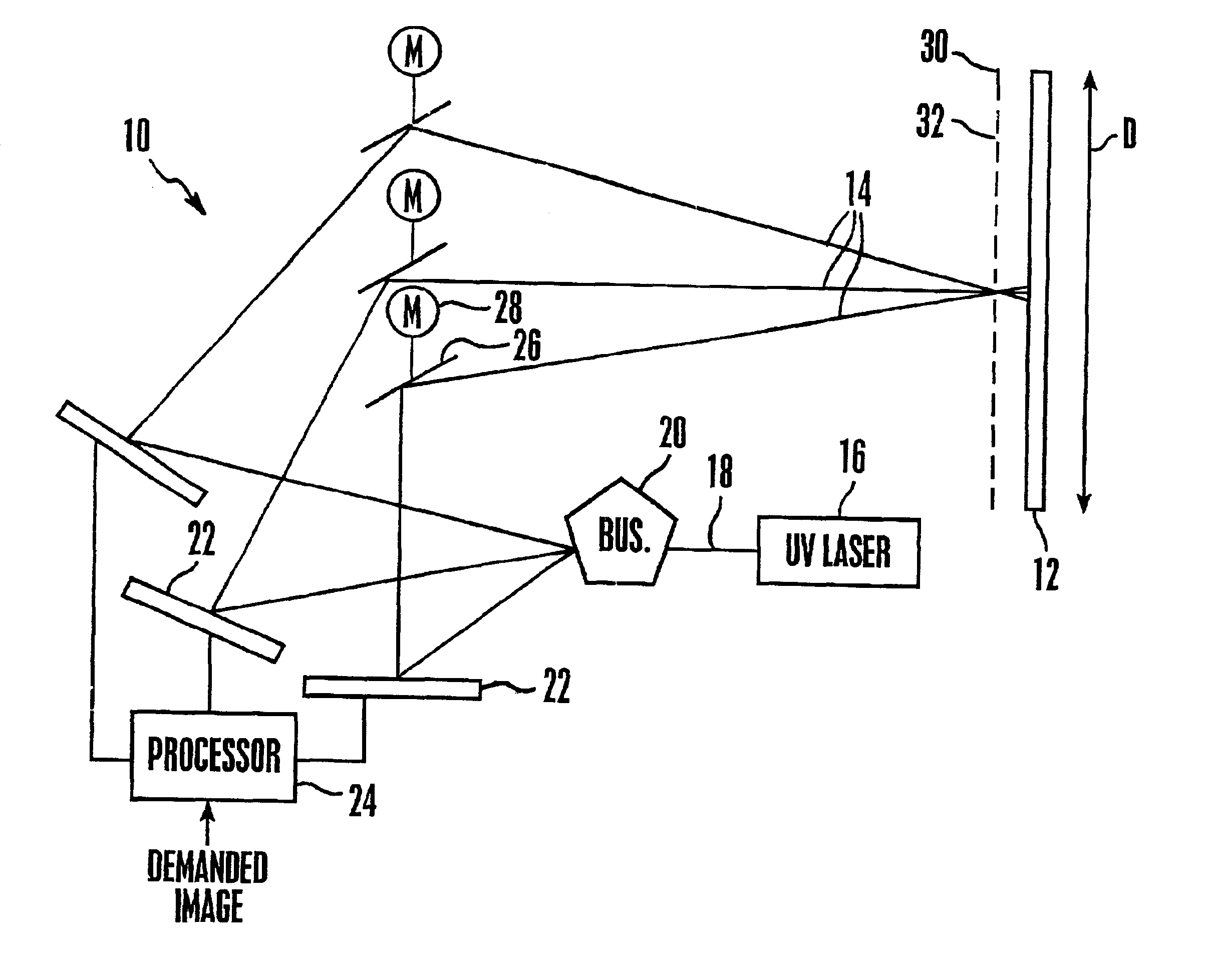

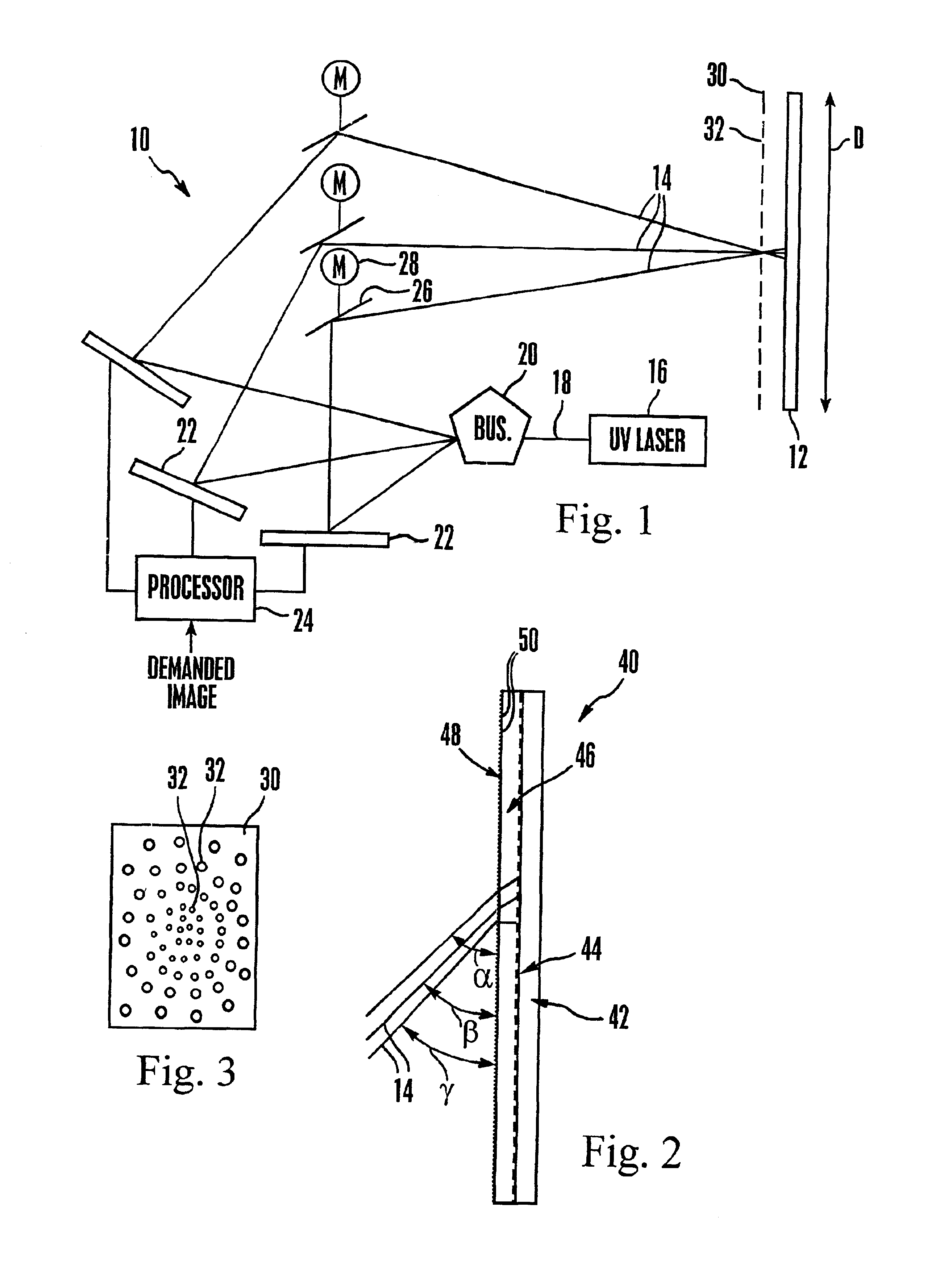

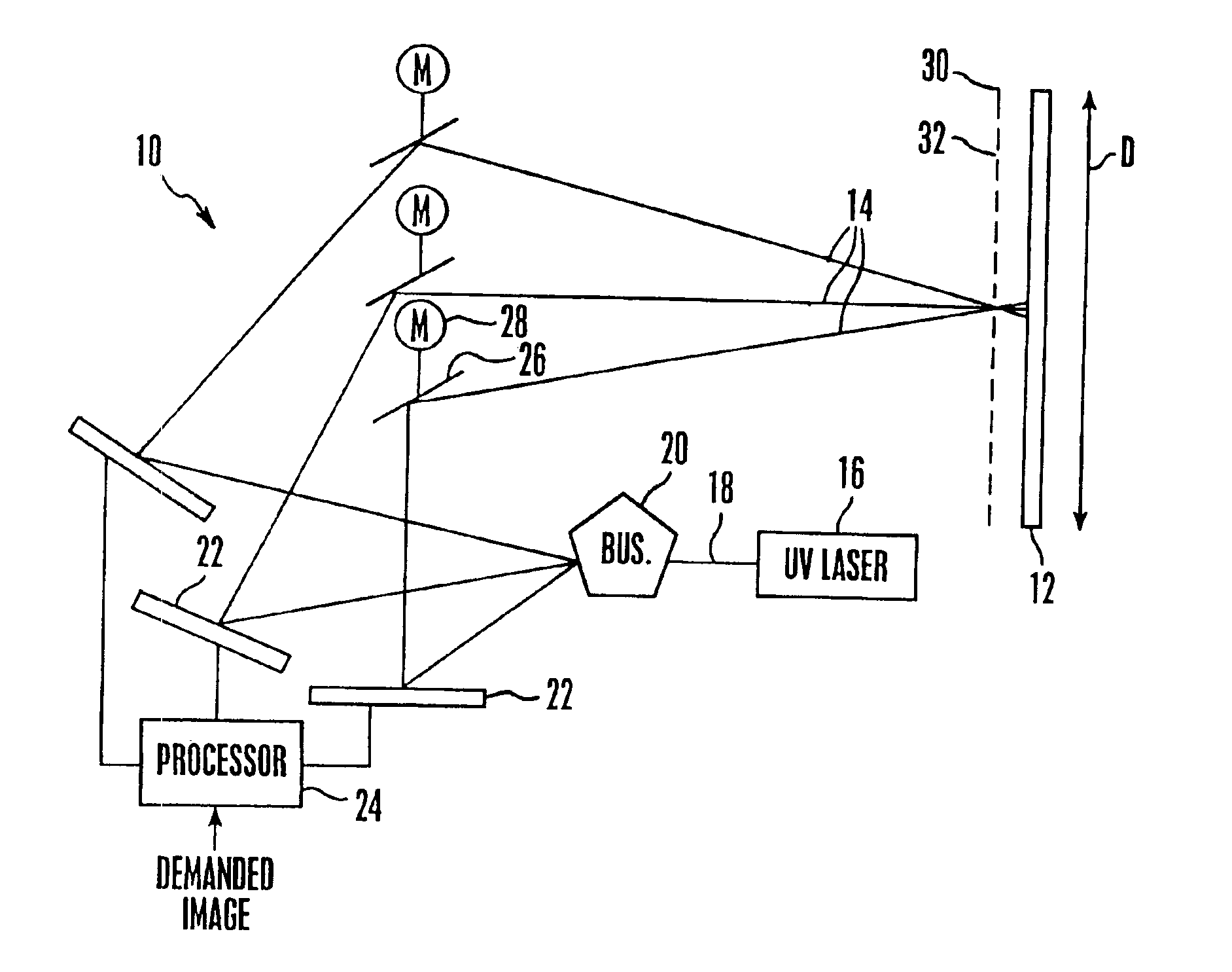

Emissive image display apparatus

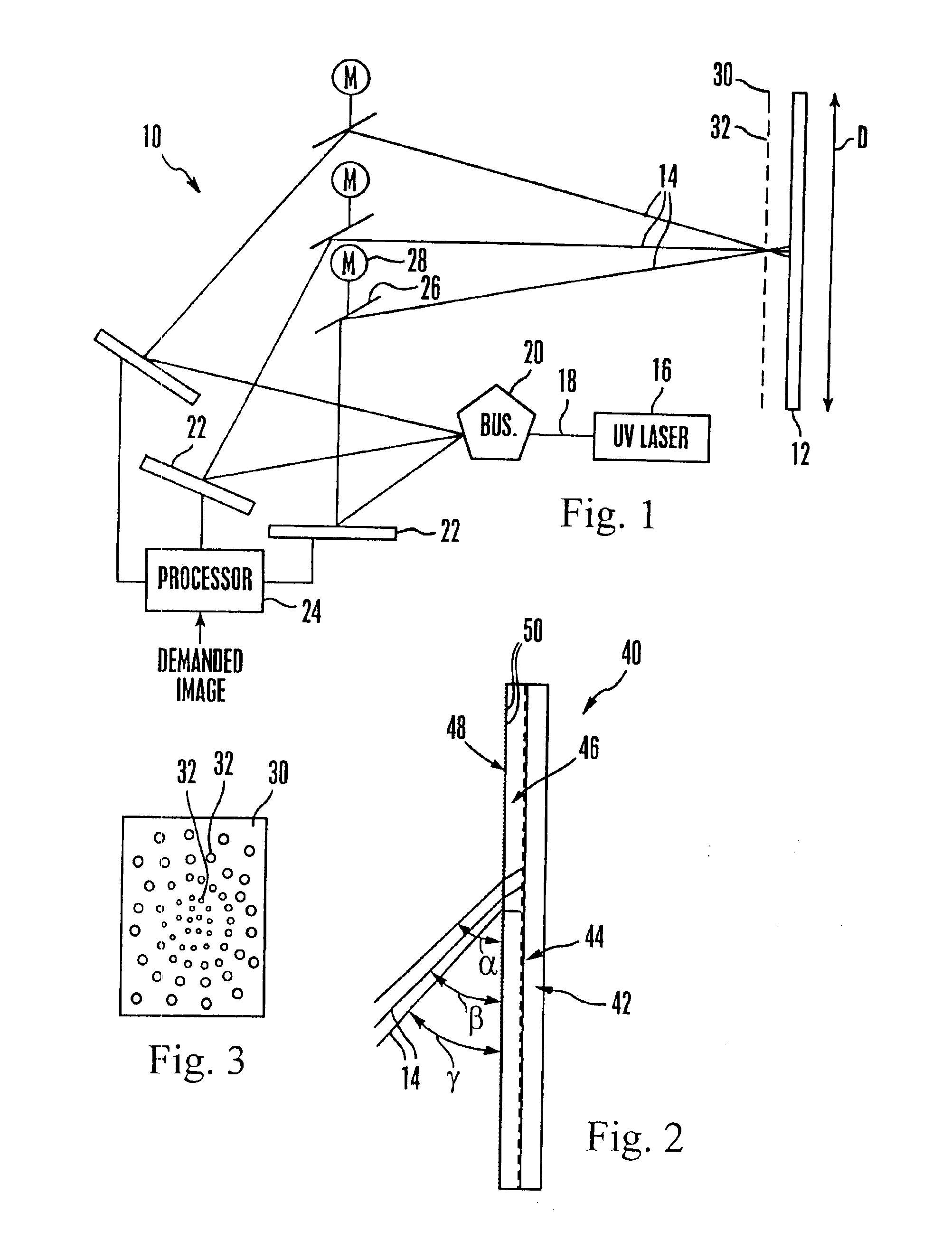

A large screen emissive display operating at atmospheric pressure includes pixels, the red, green, and blue subpixels of which are excited by UV laser light scanned onto the subpixels by a pixel activation mechanism. The pixel activation mechanism includes three grating light valves (GLVs) that are controlled by a processor in response to a demanded image to modulate the UV light as appropriate to produce the demanded image.

Owner:SONY CORP +1

Emissive image display apparatus

A large screen emissive display operating at atmospheric pressure includes pixels, the red, green, and blue subpixels of which are excited by UV laser light scanned onto the subpixels by a pixel activation mechanism. The pixel activation mechanism includes three grating light valves (GLVs) that are controlled by a processor in response to a demanded image to modulate the UV light as appropriate to produce the demanded image.

Owner:SONY CORP +1

Imaging apparatus

InactiveUS7116455B2Reduce image sizeSmall sizeTelevision system detailsTelevision system scanning detailsMedicineProjection image

An imaging apparatus having a projector function which is advantageous in reducing size is provided. A light source of the imaging apparatus is constituted by three semiconductor lasers which respectively frontward emit lights of red, green and blue, each slit-shaped. To a GLV (Grating Light Valve) is applied a drive voltage as modulated by a projection image signal, so that the GLV diffracts the three lights emitted from the light source, with varying the amount or intensity of each light in accordance with the drive voltage or projection image signal. A scanning mirror is disposed between a taking lens and an image pickup device, so as to reflect the lights diffracted by the GLV toward the taking lens, with having each diffracted slit-shaped light scan in a direction.

Owner:SONY CORP

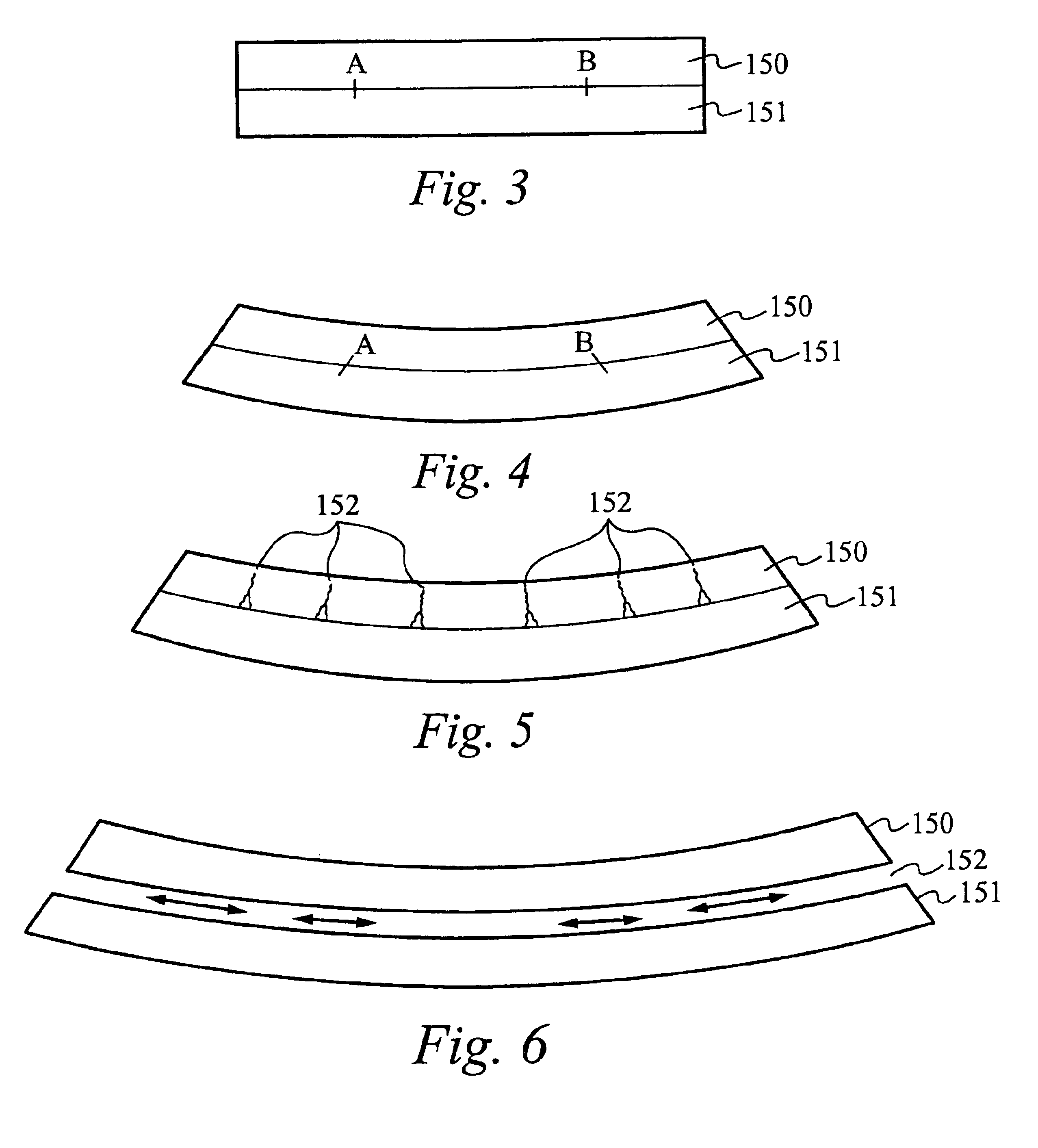

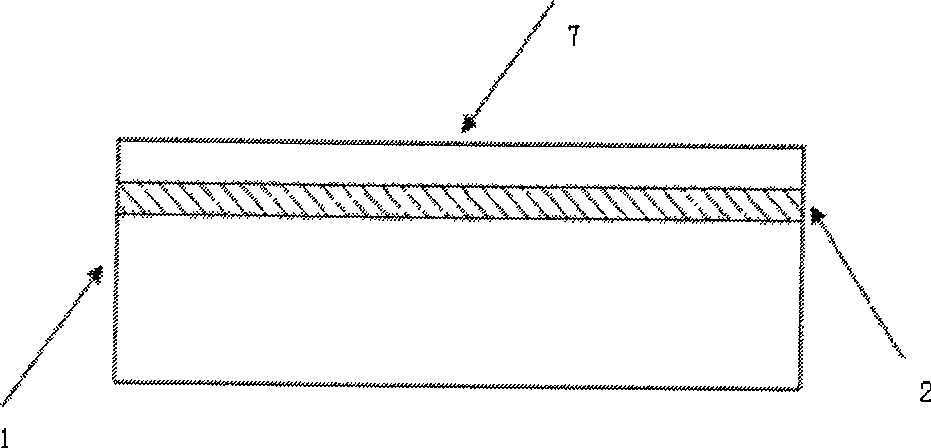

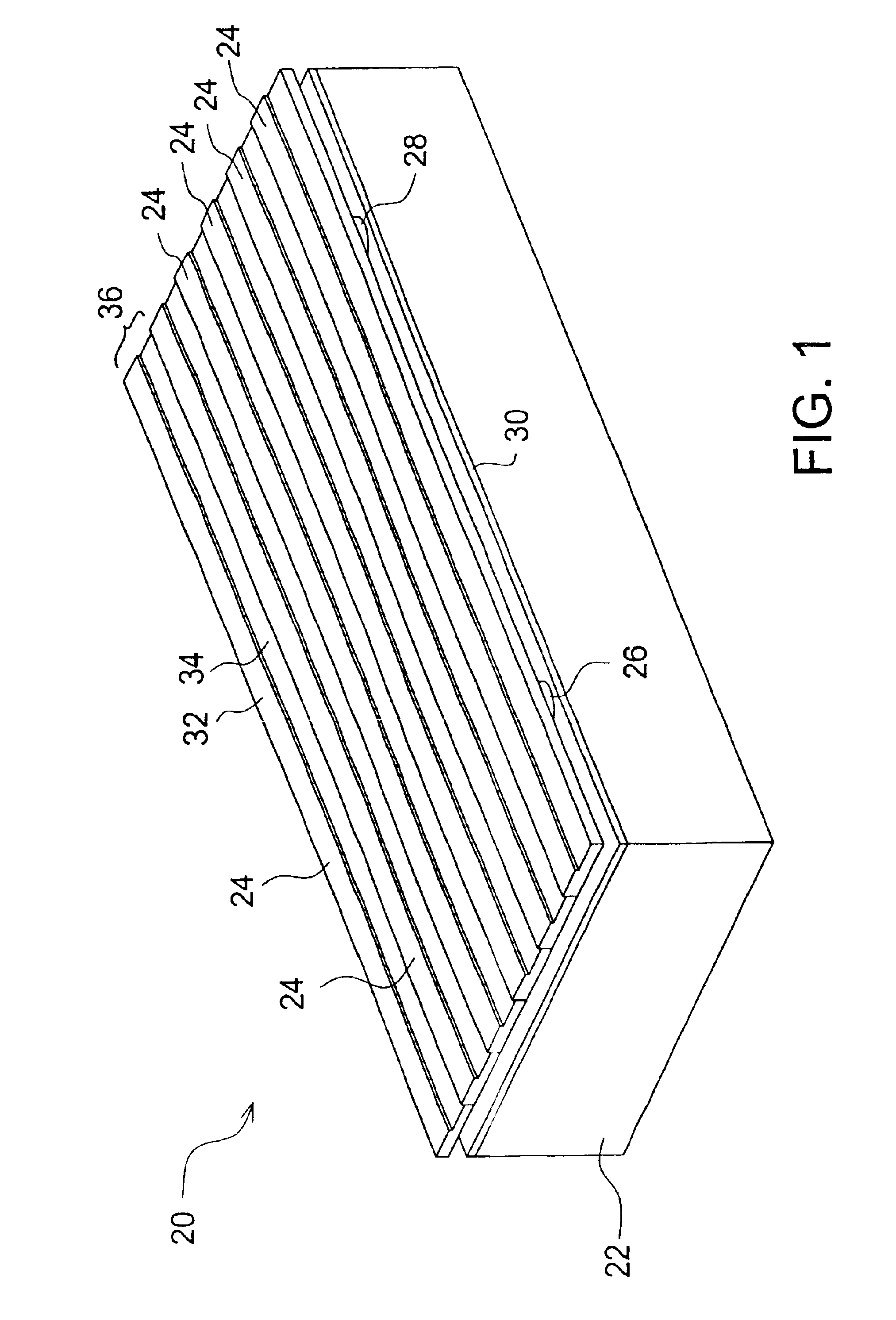

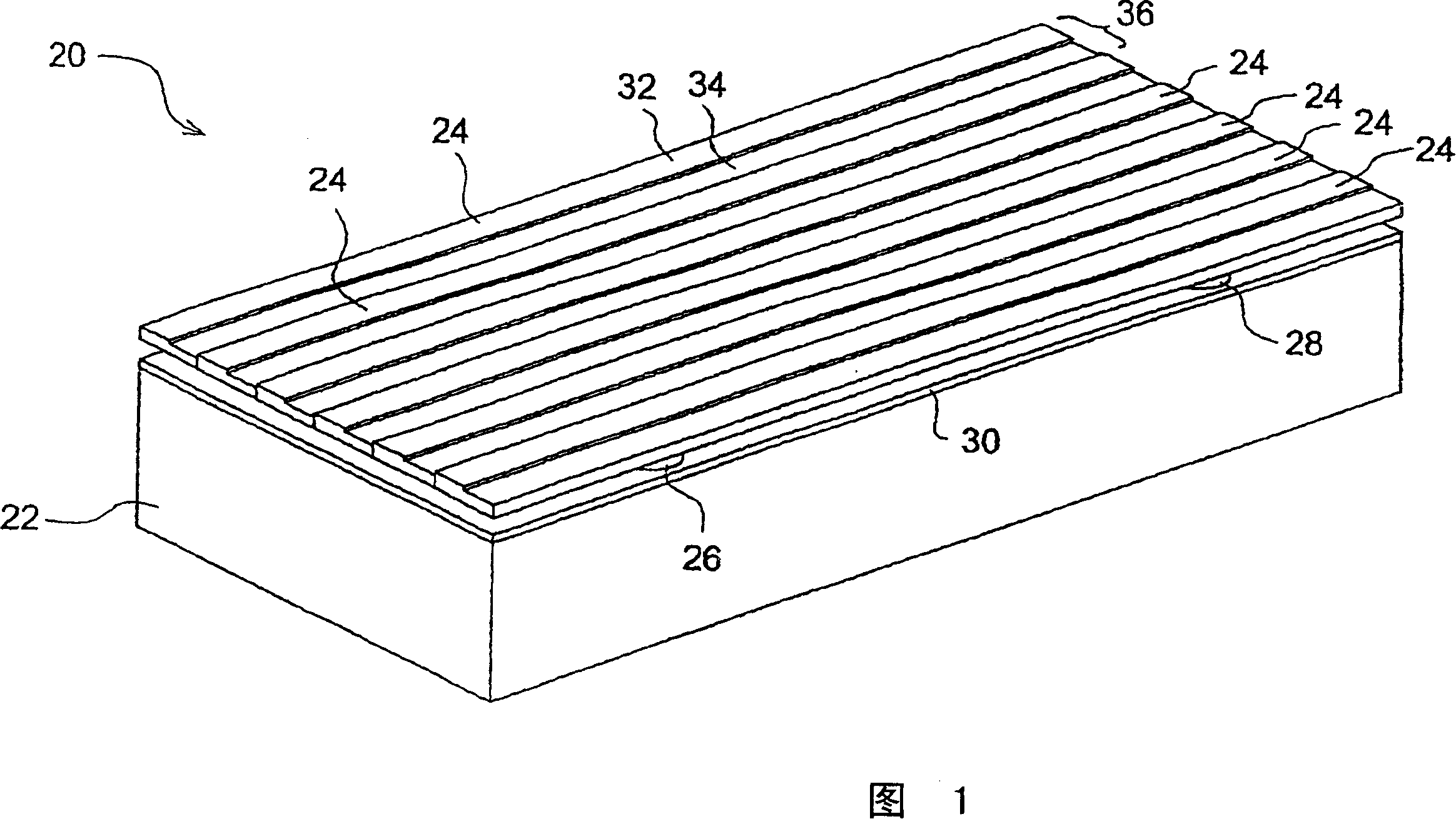

Method and apparatus for leveling thermal stress variations in multi-layer MEMS devices

InactiveUS6922272B1Reduce variationProcess stabilityDecorative surface effectsSemiconductor/solid-state device detailsThermal coefficientStress variation

A MEMS device such as a grating light valve™ light modulator is athermalized such that the force required to deflect the movable portion of the MEMS device remains constant over a range of temperatures. In MEMS embodiments directed to a grating light valve™ light modulator, a ribbon is suspended over a substrate, and the ribbon tension is kept constant over a temperature range by adjusting the aggregate thermal coefficient of expansion of the ribbon to match the aggregate thermal coefficient of expansion of the substrate. Various opposition materials have an opposite thermal coefficient of expansion as the aluminum layer of a grating light valve™ light modulator ribbon, using the thermal coefficient of expansion of the substrate as a zero coefficient reference. The adjustment of the thermal coefficient of expansion of the ribbon can be performed variously by thickening existing layers of opposition material or adding additional layers of new opposition material to the ribbon, or reducing the aluminum in aluminum layer. The aluminum layer may be reduced variously by reducing the thickness of the aluminum layer, or reducing the surface area that the aluminum covers, or reducing both the surface area and the thickness. Embodiments may combine the reduction of aluminum with the use of opposition materials.

Owner:SILICON LIGHT MACHINES CORP

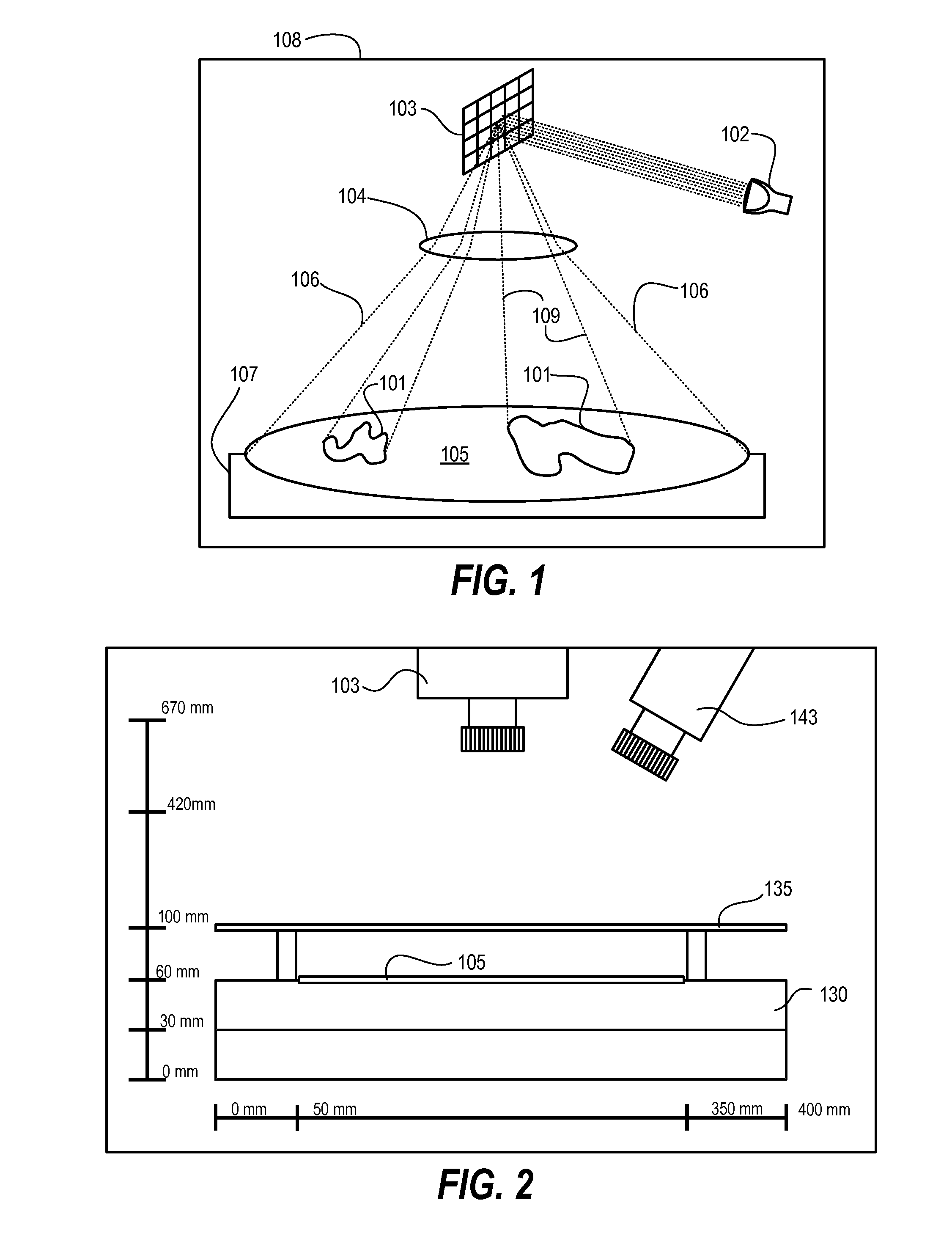

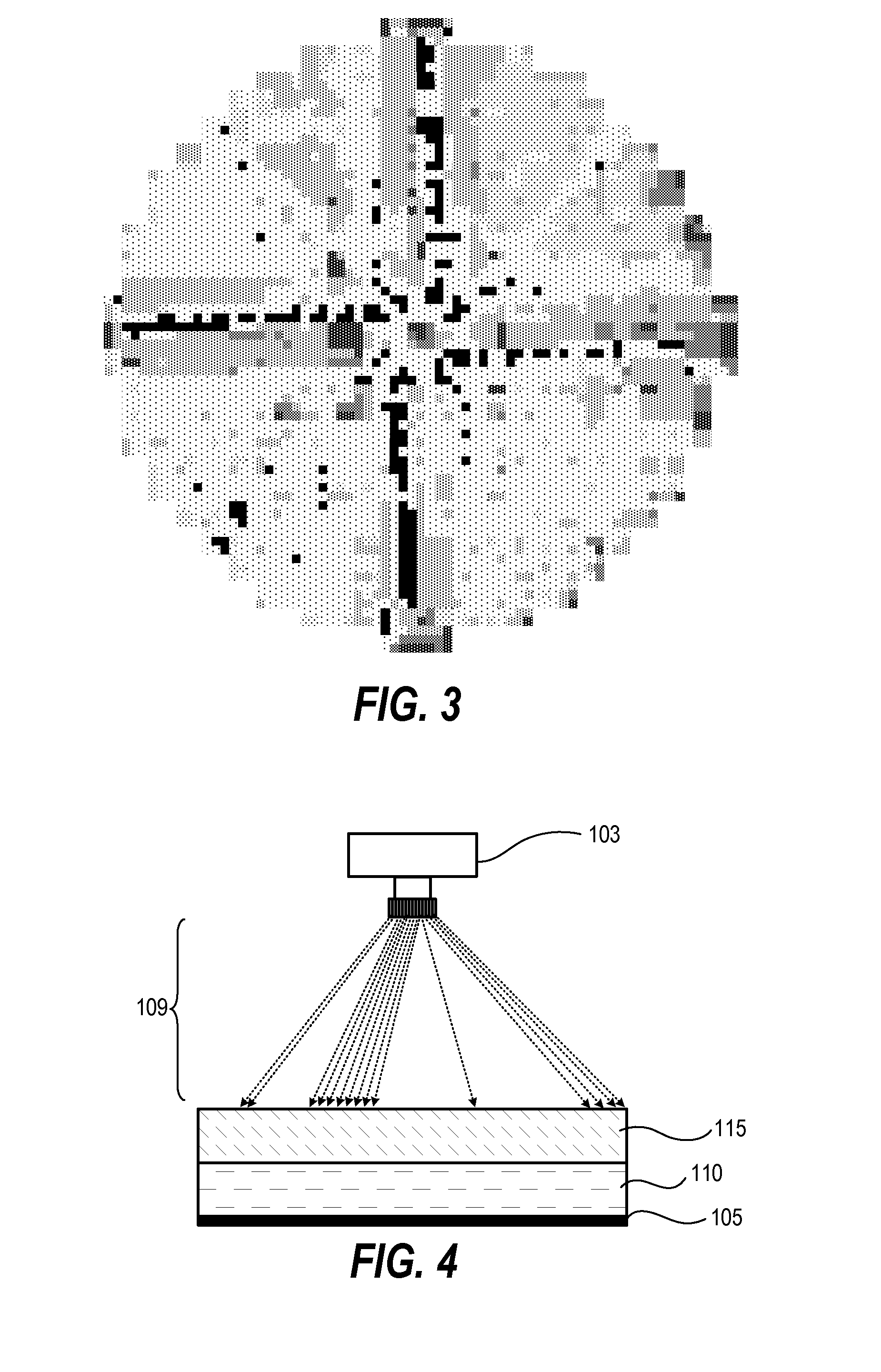

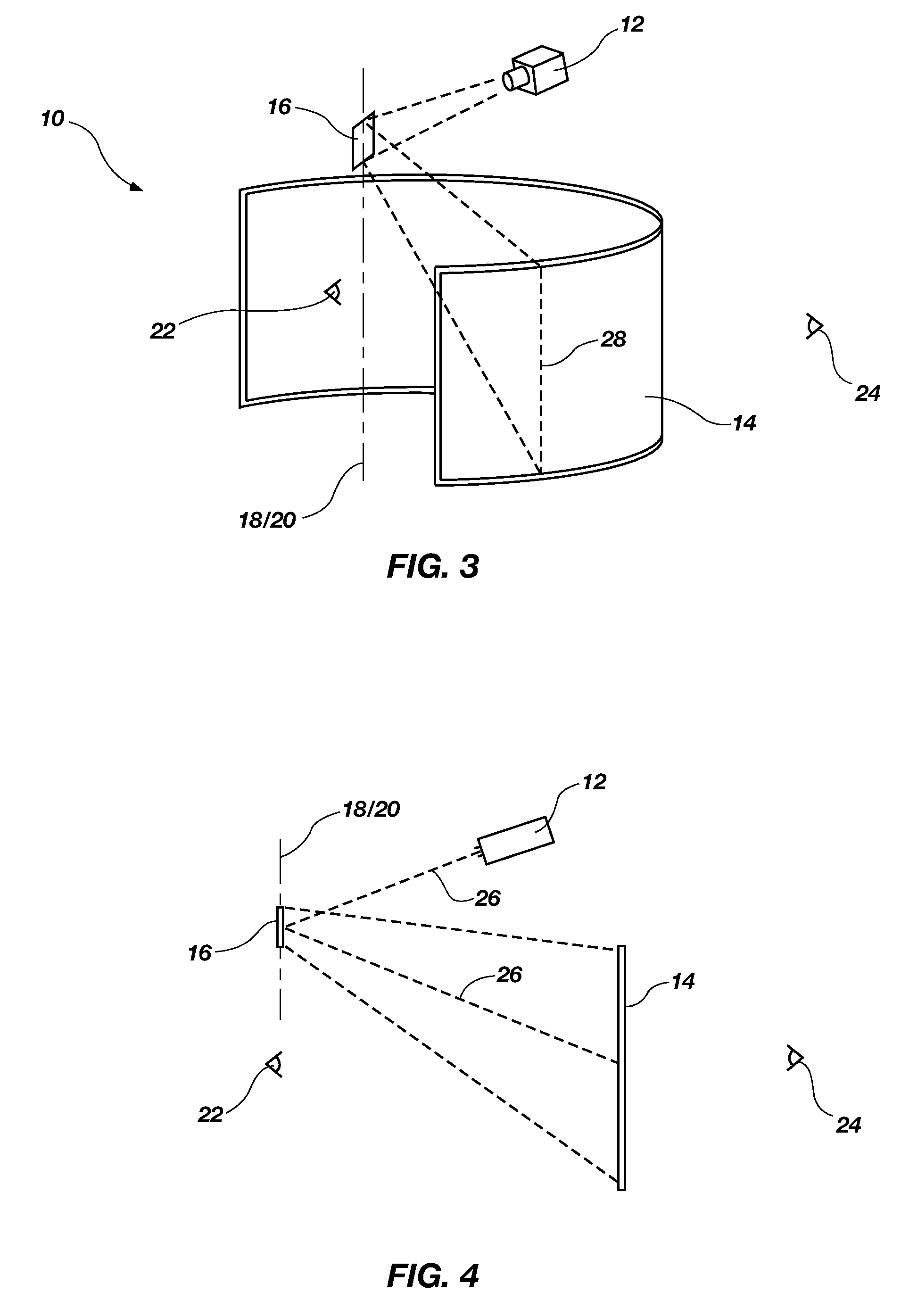

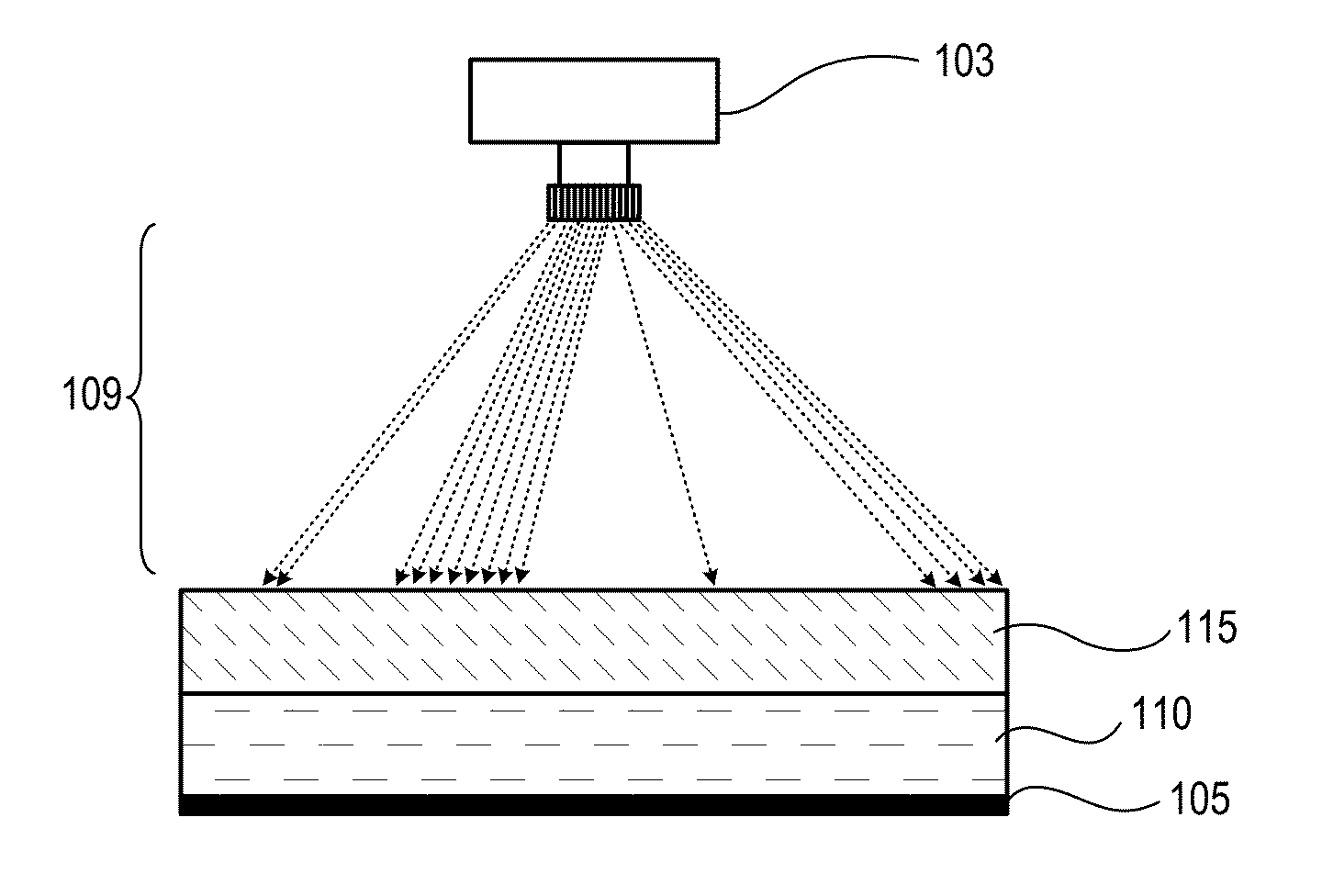

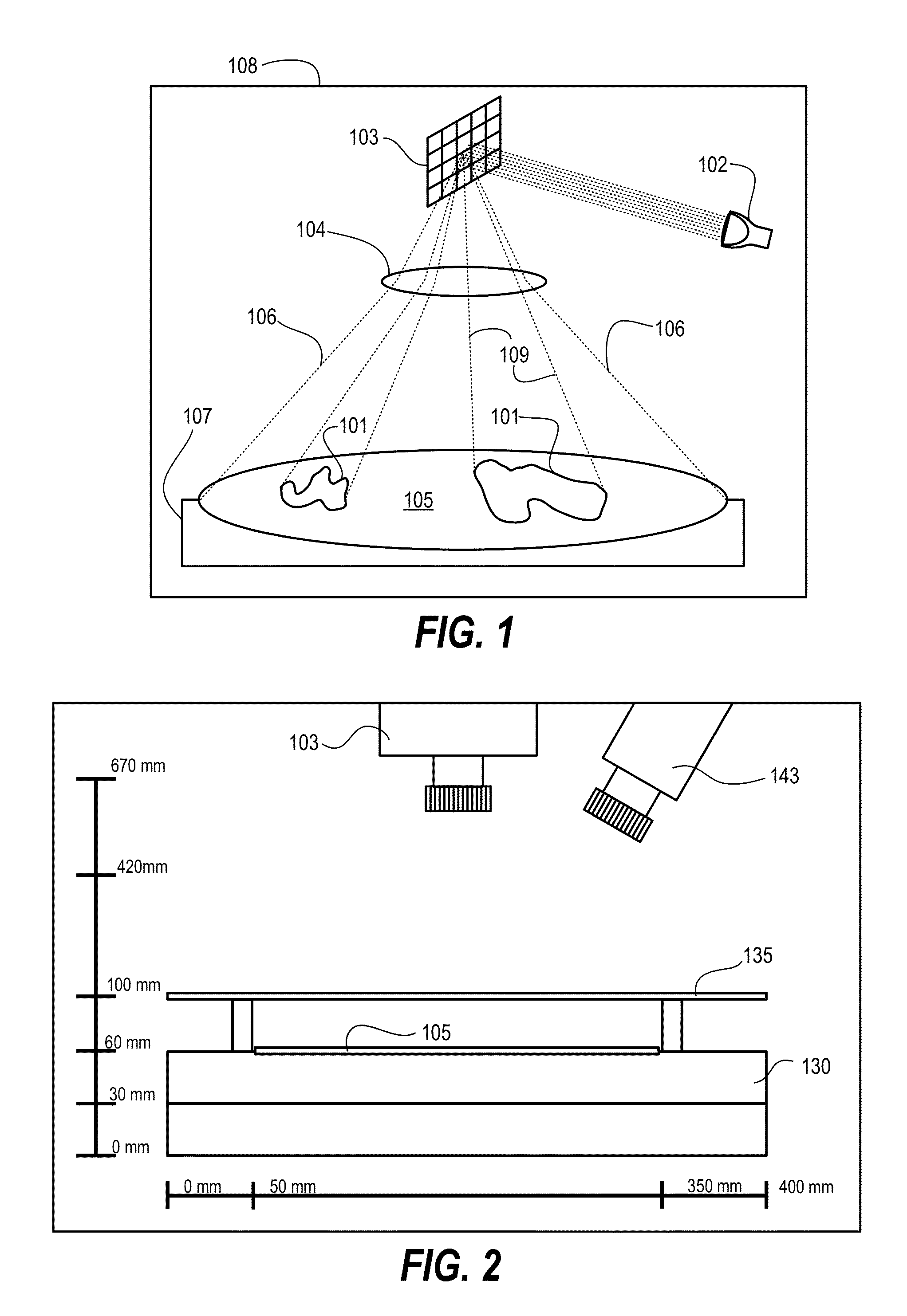

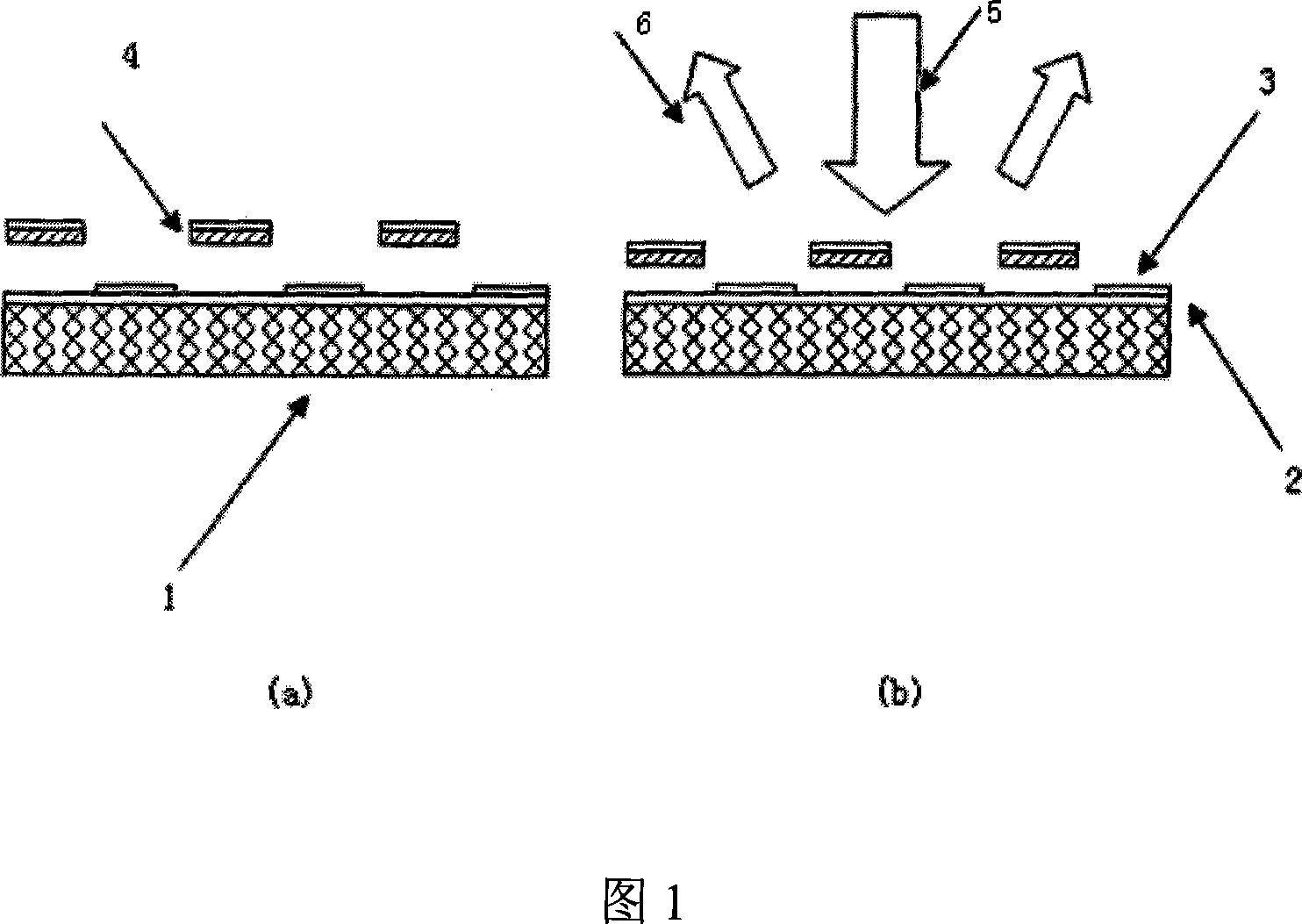

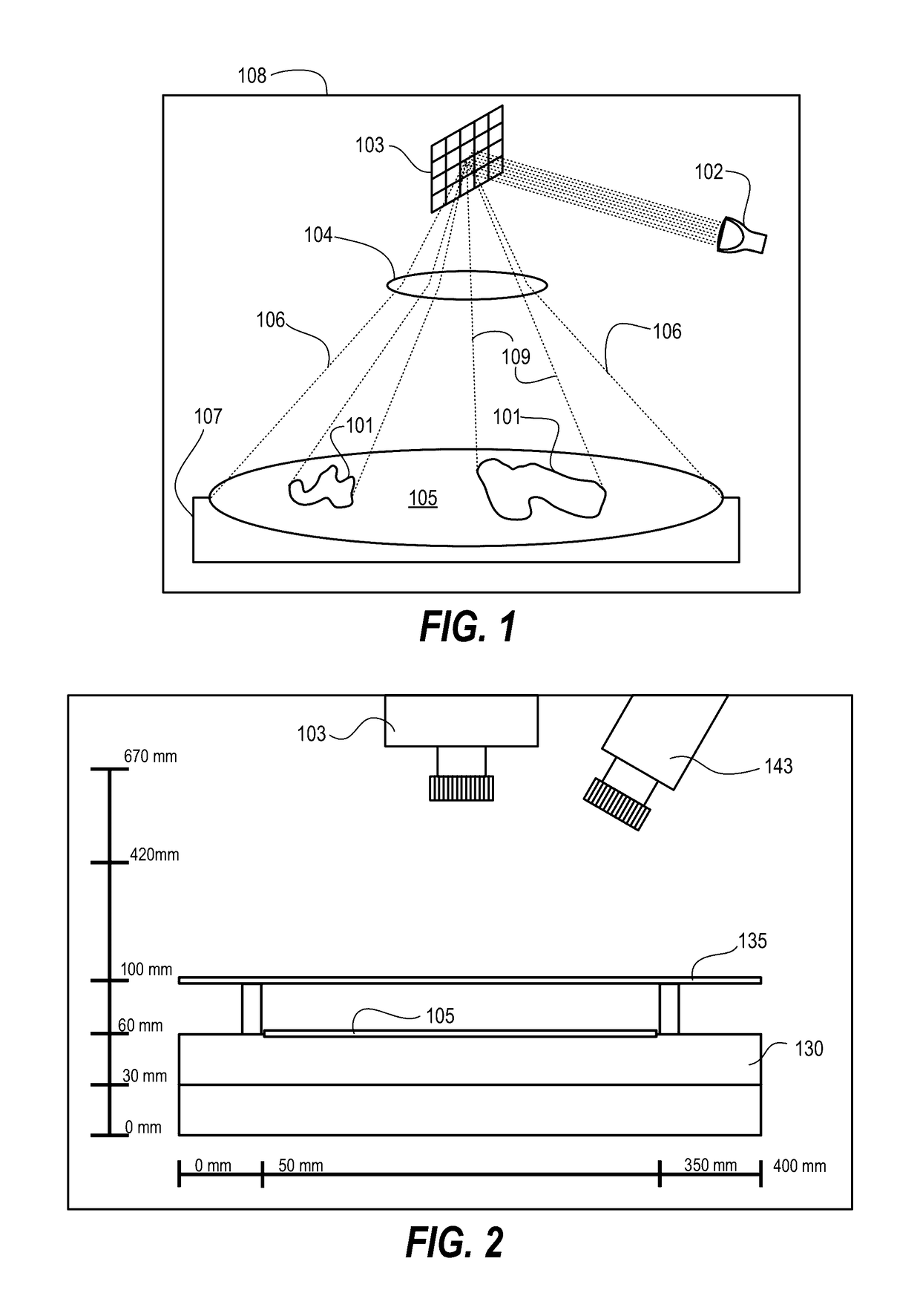

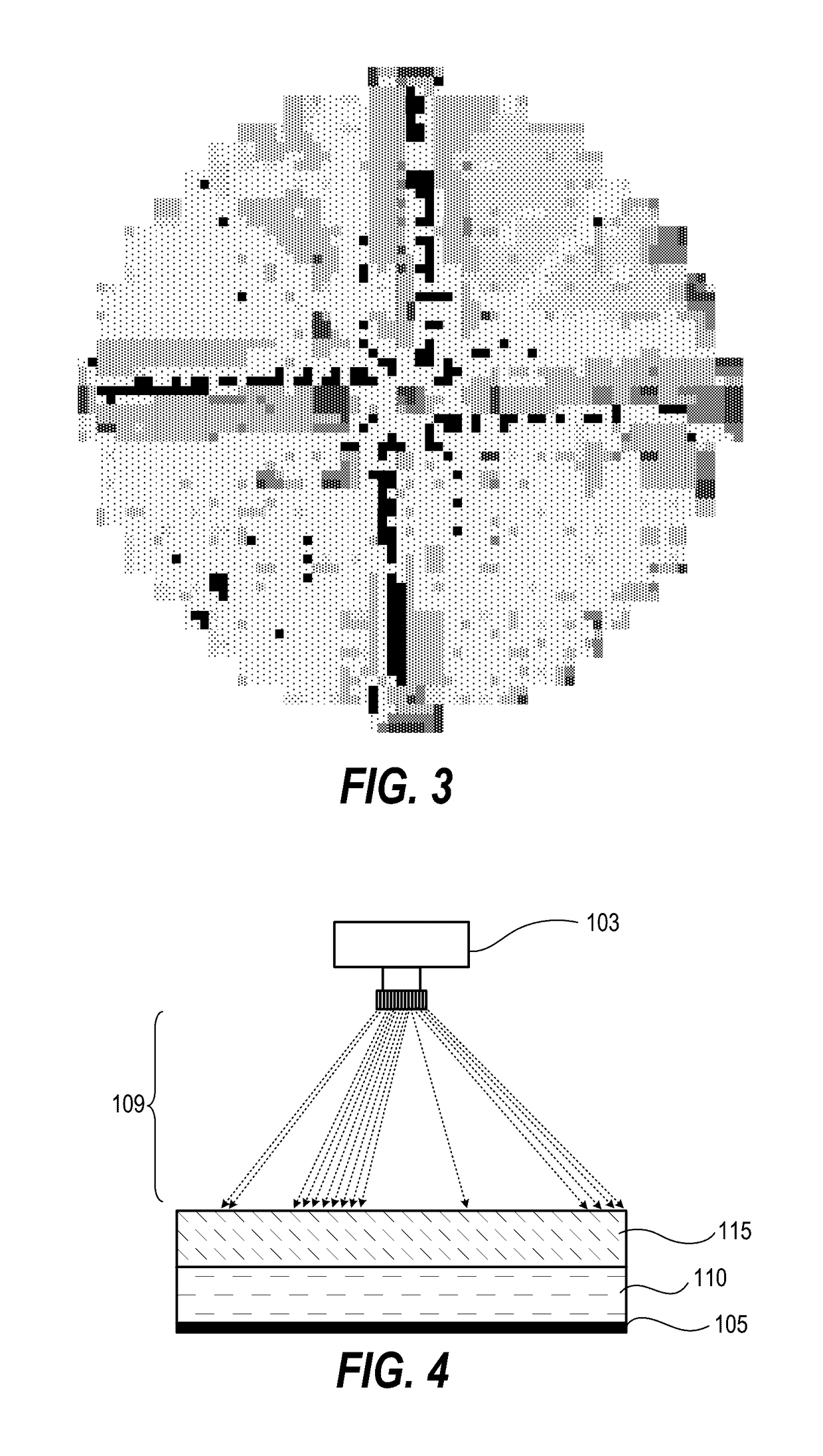

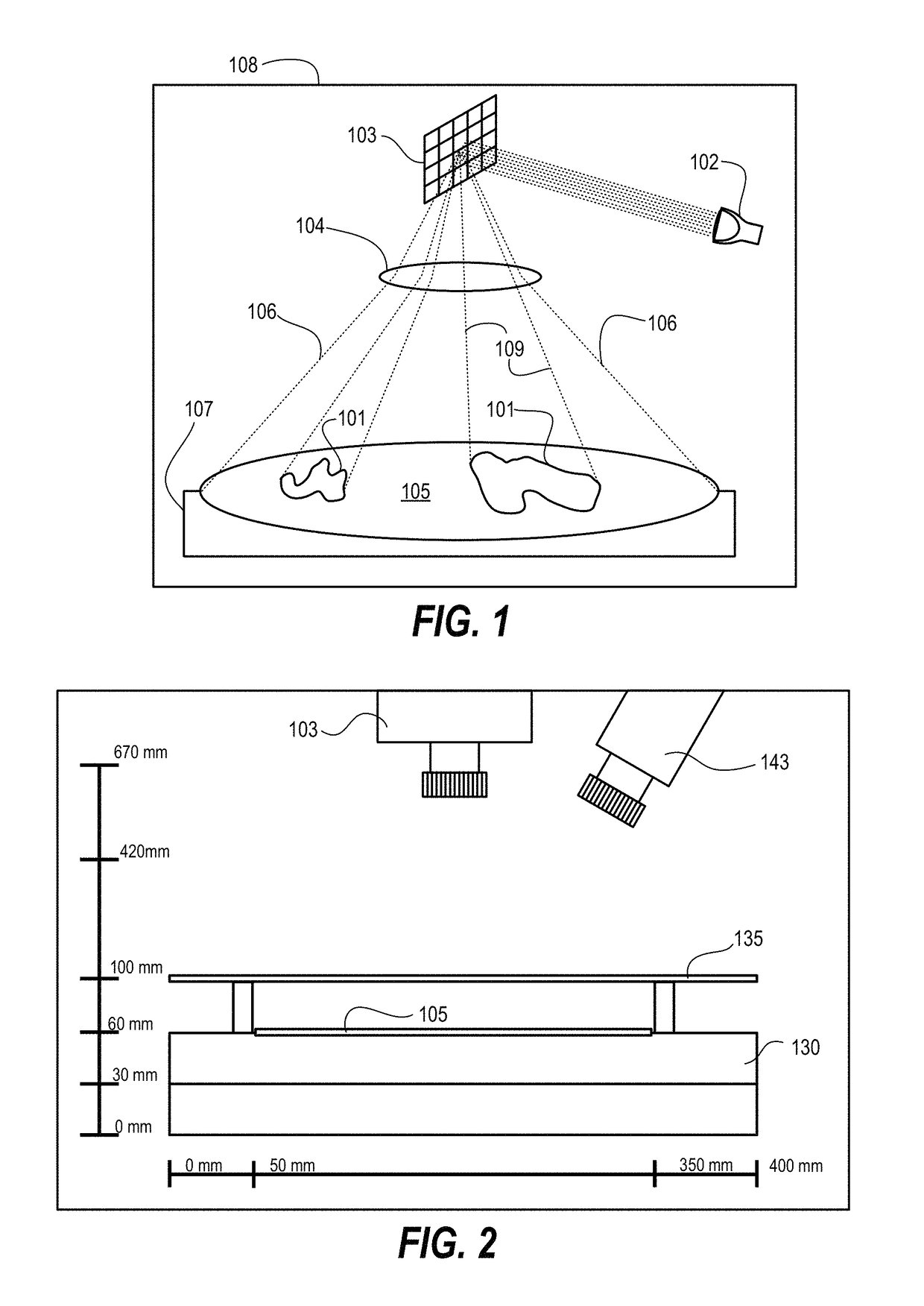

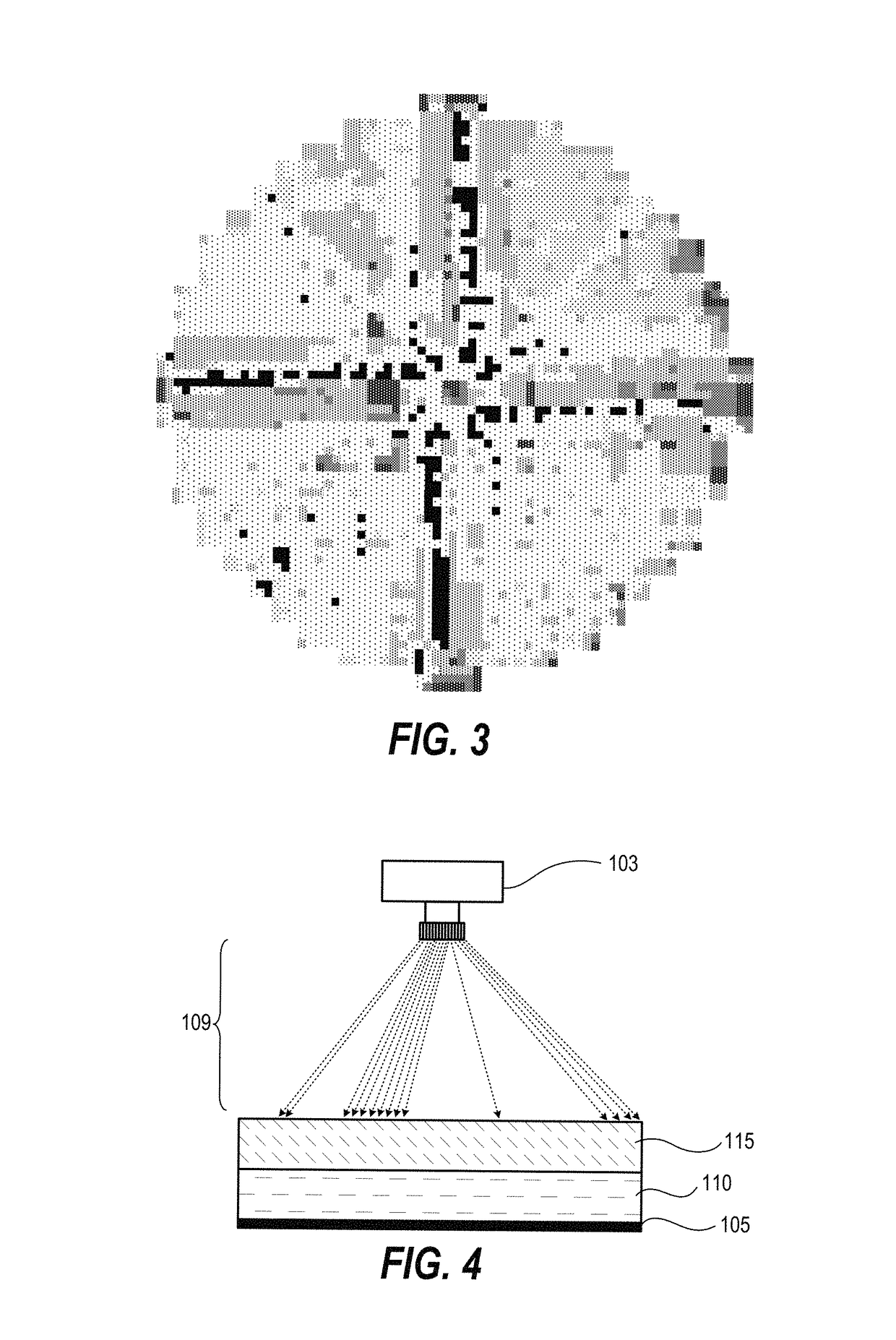

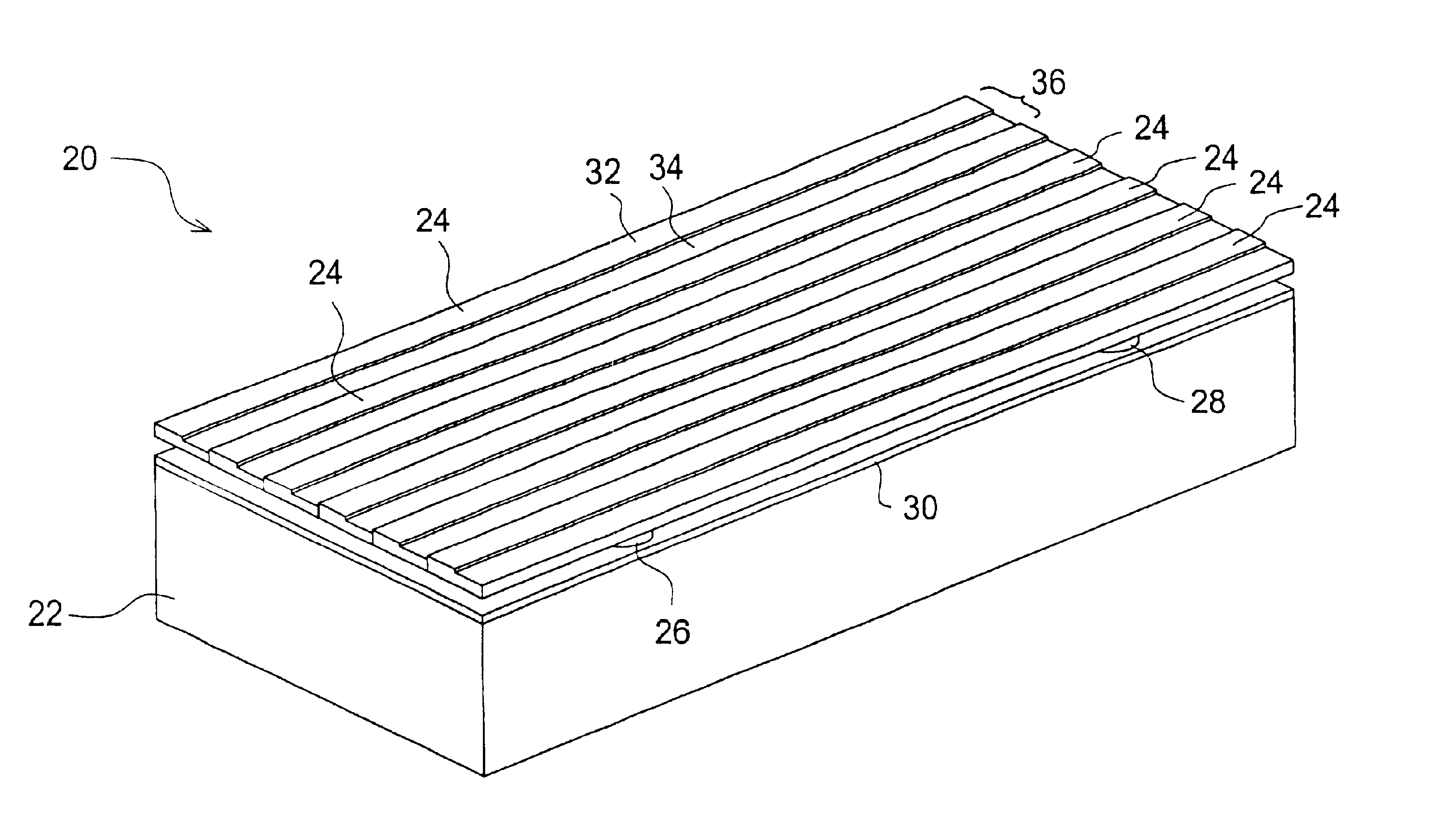

Substrate Tuning System and Method Using Optical Projection

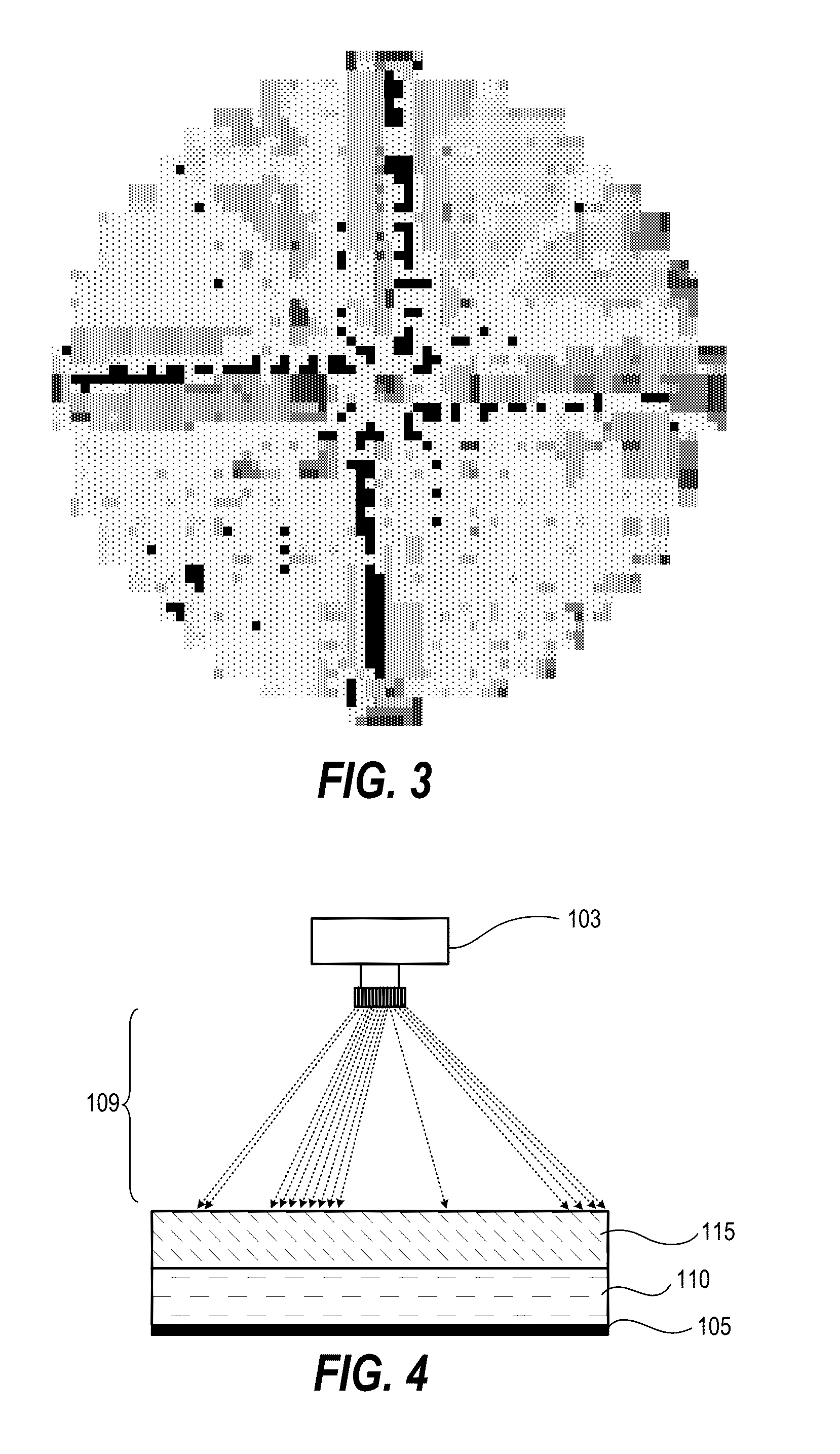

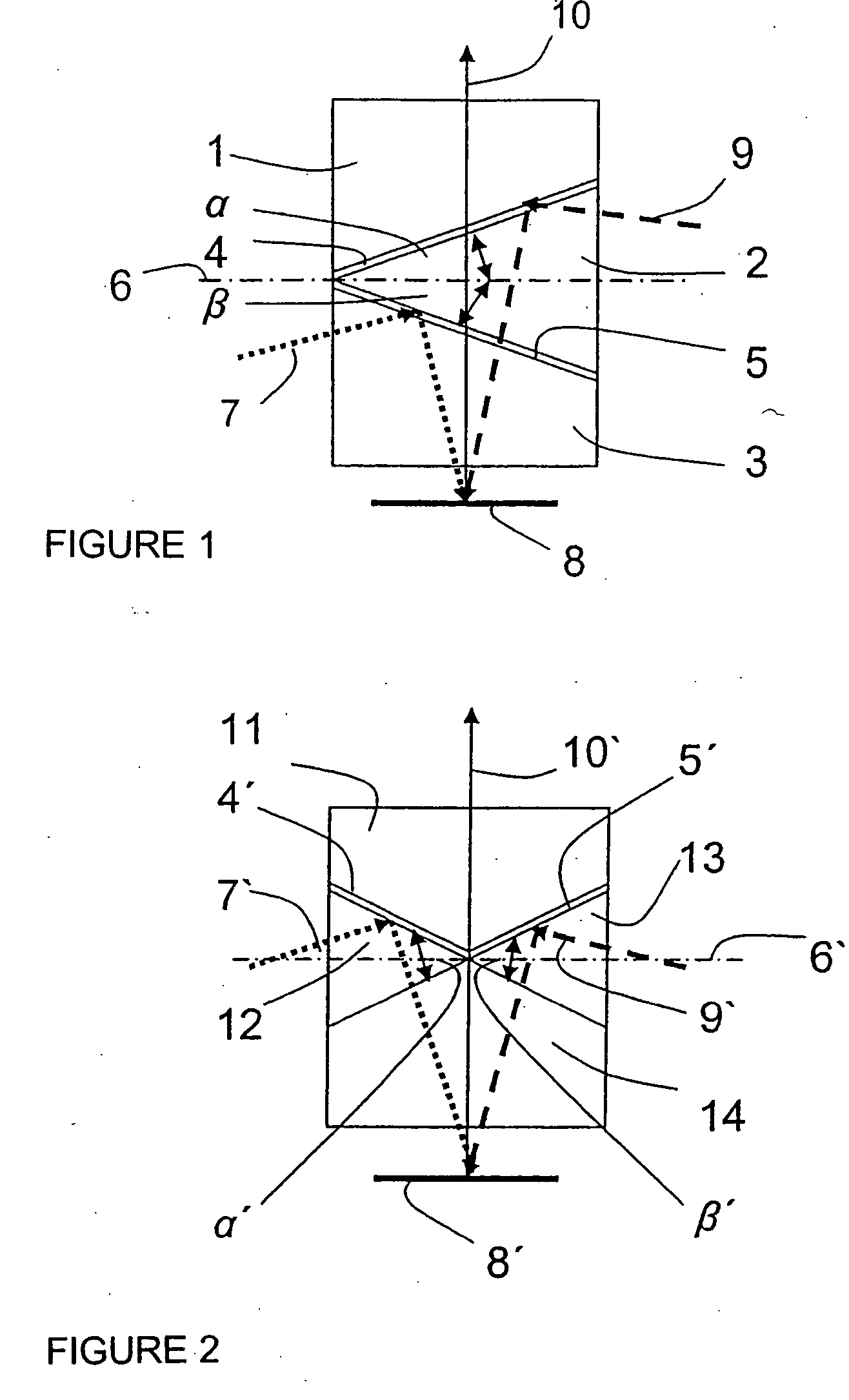

ActiveUS20150146178A1Improve temperature uniformityScaling continuesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGrid basedOptoelectronics

Techniques herein include systems and methods that provide a spatially-controlled or pixel-based projection of light onto a substrate to tune various substrate properties. A given pixel-based image projected on to a substrate surface can be based on a substrate signature. The substrate signature can spatially represent non-uniformities across the surface of the substrate. Such non-uniformities can include energy, heat, critical dimensions, photolithographic exposure dosages, etc. Such pixel-based light projection can be used to tune various properties of substrates, including tuning of critical dimensions, heating uniformity, evaporative cooling, and generation of photo-sensitive agents. Combining such pixel-based light projection with photolithographic patterning processes and / or heating processes improves processing uniformity and decreases defectivity. Embodiments can include using a digital light processing (DLP) chip, grating light valve (GLV), or other grid-based micro projection technology.

Owner:TOKYO ELECTRON LTD

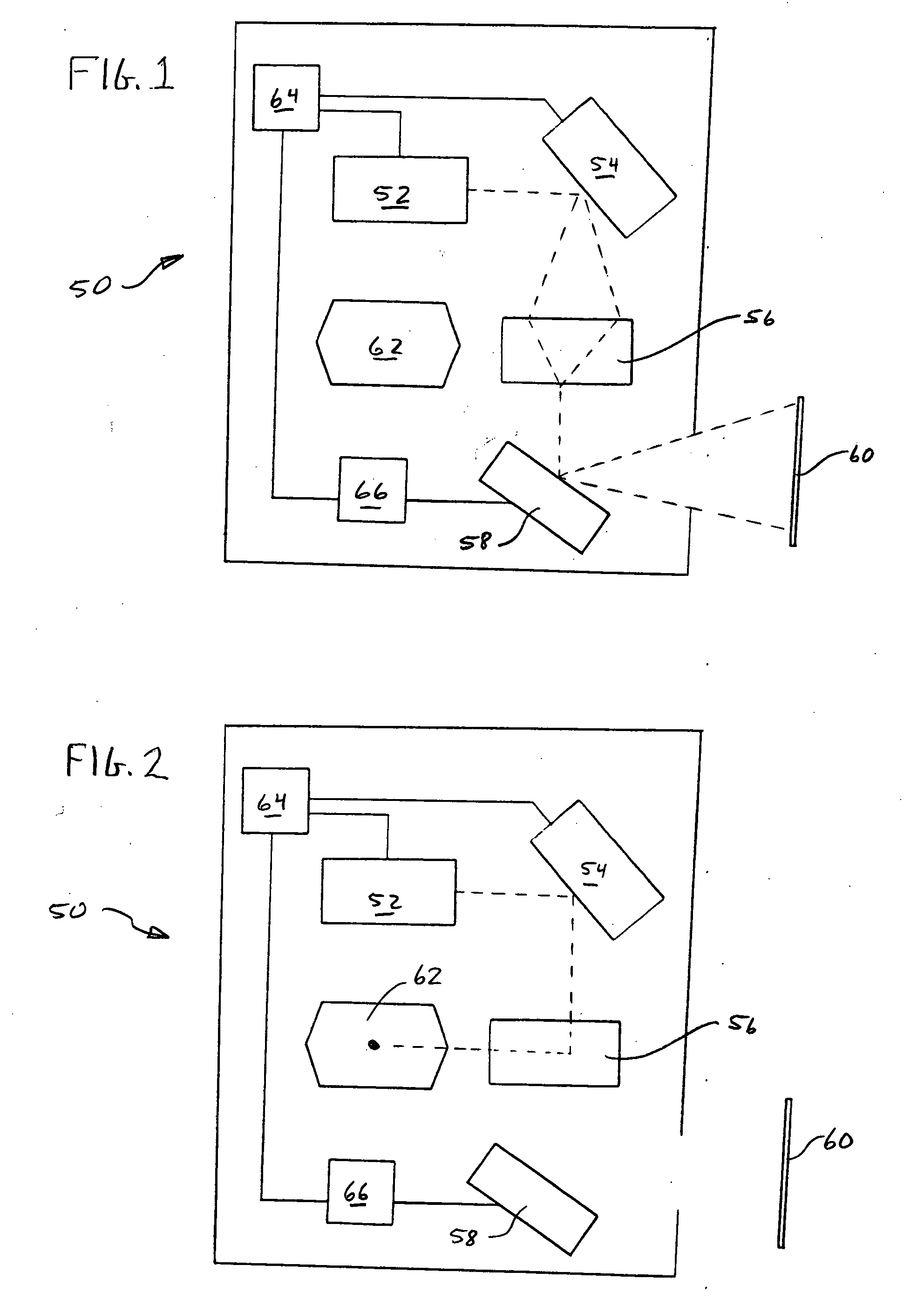

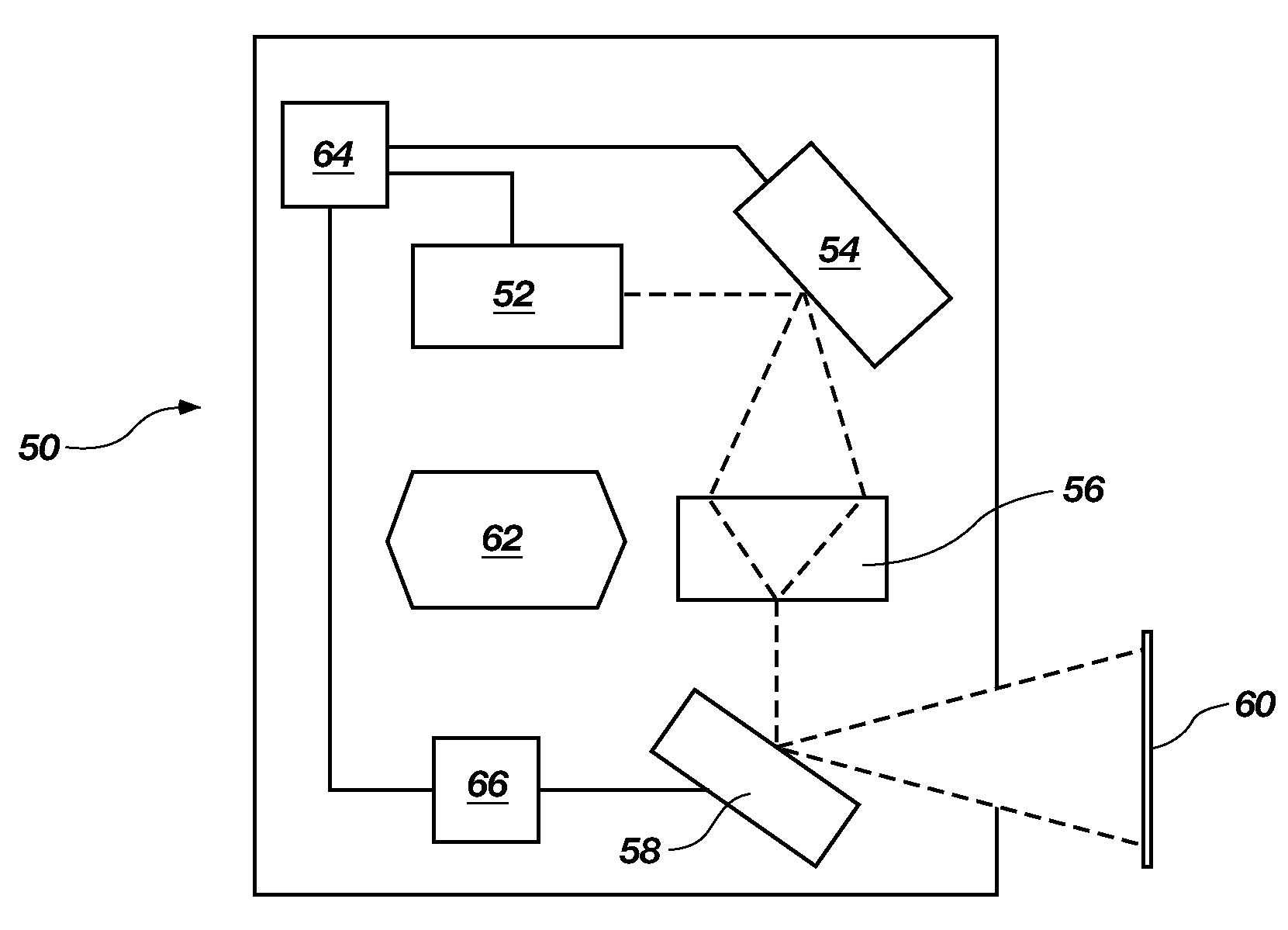

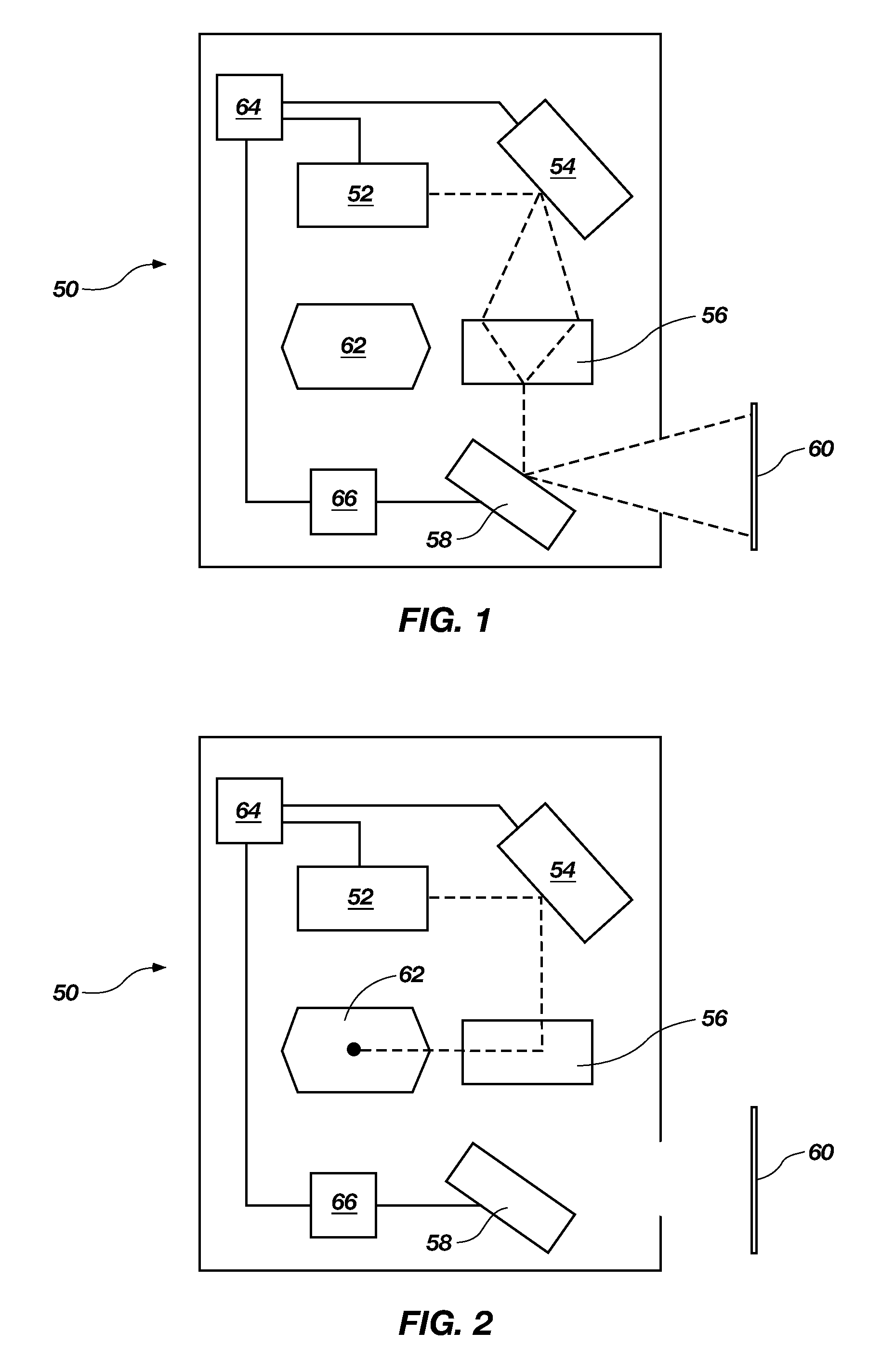

Shuttering system for scanning projectors

InactiveUS20050242185A1Avoid contactConvenient and quick escapeProjectorsSensing by electromagnetic radiationLaser lightLaser source

A shuttering system for a scanning projector having a laser source, a grating light valve light modulator, and a light steering scanner includes a feedback system interconnecting the scanner with the light modulator. The feedback system is configured to deactivate the light modulator in case of scanner malfunction, so as to redirect laser light away from the scanner.

Owner:EVANS & SUTHERLAND COMP

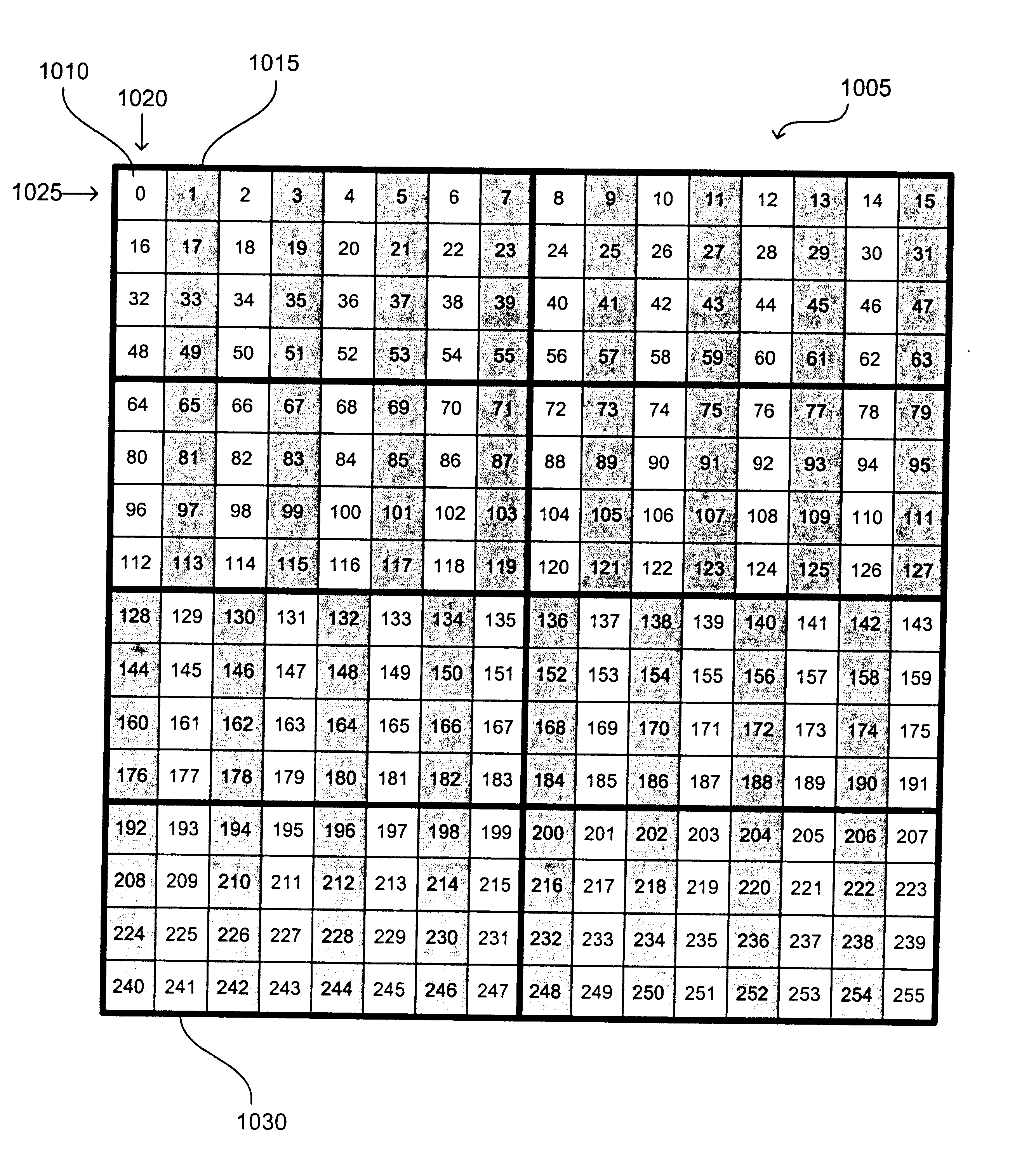

Swapped pixel pages

InactiveUS6850241B2Television system detailsTelevision system scanning detailsComputer graphics (images)Data source

Methods and apparatus for implementing a pixel page system providing swapped pixel pages for use with a GLV (grating light valve). In one implementation, a swapped pixel page system includes: a data source, providing pixel data for pixels in a first order, where each pixel is in a frame of pixels, the frame having horizontal rows of pixels, vertical columns of pixels, an upper half, and a lower half; a data destination, receiving pixel data for pixels in a second order; and at least two memory devices, each memory device having a plurality of memory pages including a plurality of memory locations, each memory location having an address; where pixel data for each pixel corresponds to an entry in one of a plurality of swapped pixel pages, each swapped pixel page having a plurality of pixel page rows each including a plurality of pixels and a plurality of pixel page columns each including a plurality of pixels, where pixel data is stored to the memory devices in the first order and retrieved from the memory devices in the second order, and where each memory page stores pixel data in multiple locations according to the first order and stores pixel data in multiple locations according to the second order, and where pixel data is retrieved in parallel for two pixels from different halves of the frame of pixels.

Owner:SONY CORP +1

Shuttering system for scanning projectors

InactiveUS7628327B2Avoid contactConvenient and quick escapeProjectorsSensing by electromagnetic radiationLaser lightLaser source

A shuttering system for a scanning projector having a laser source, a grating light valve light modulator, and a light steering scanner includes a feedback system interconnecting the scanner with the light modulator. The feedback system is configured to deactivate the light modulator in case of scanner malfunction, so as to redirect laser light away from the scanner.

Owner:EVANS & SUTHERLAND COMP

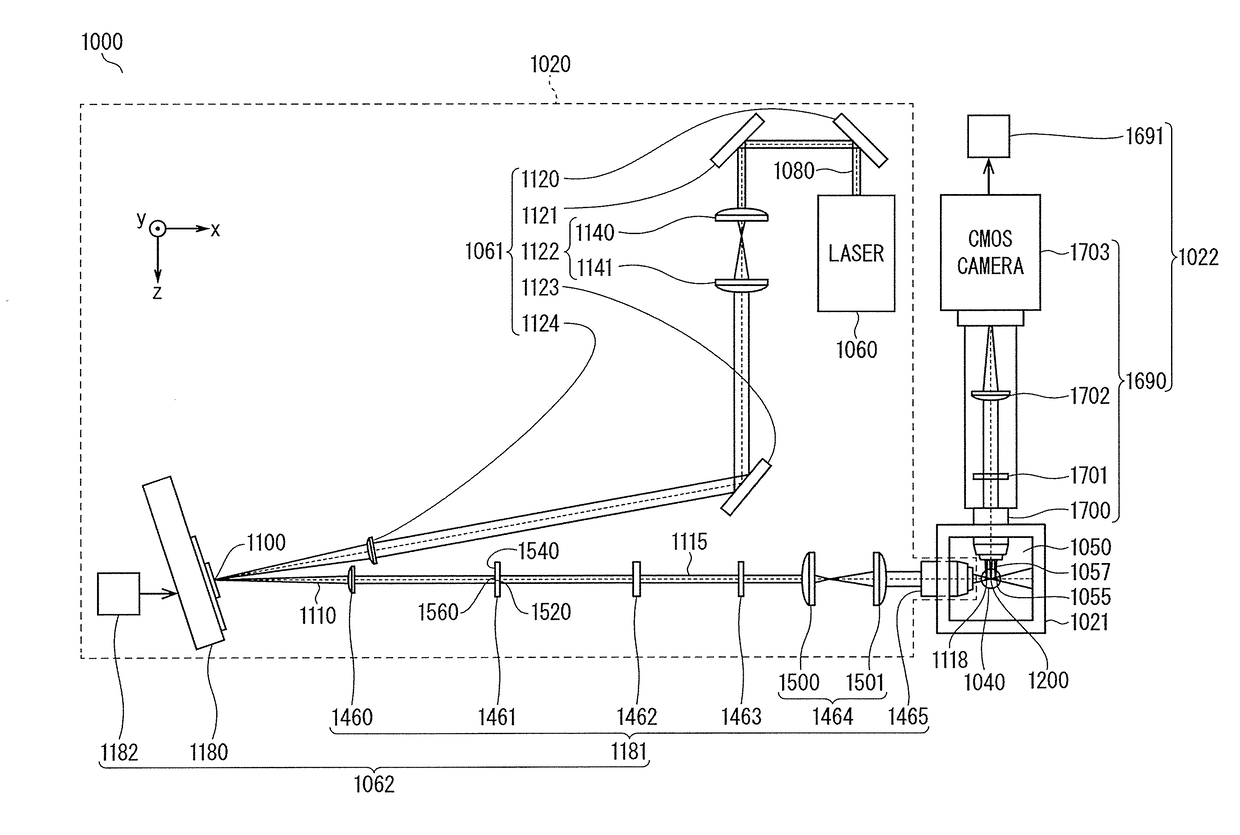

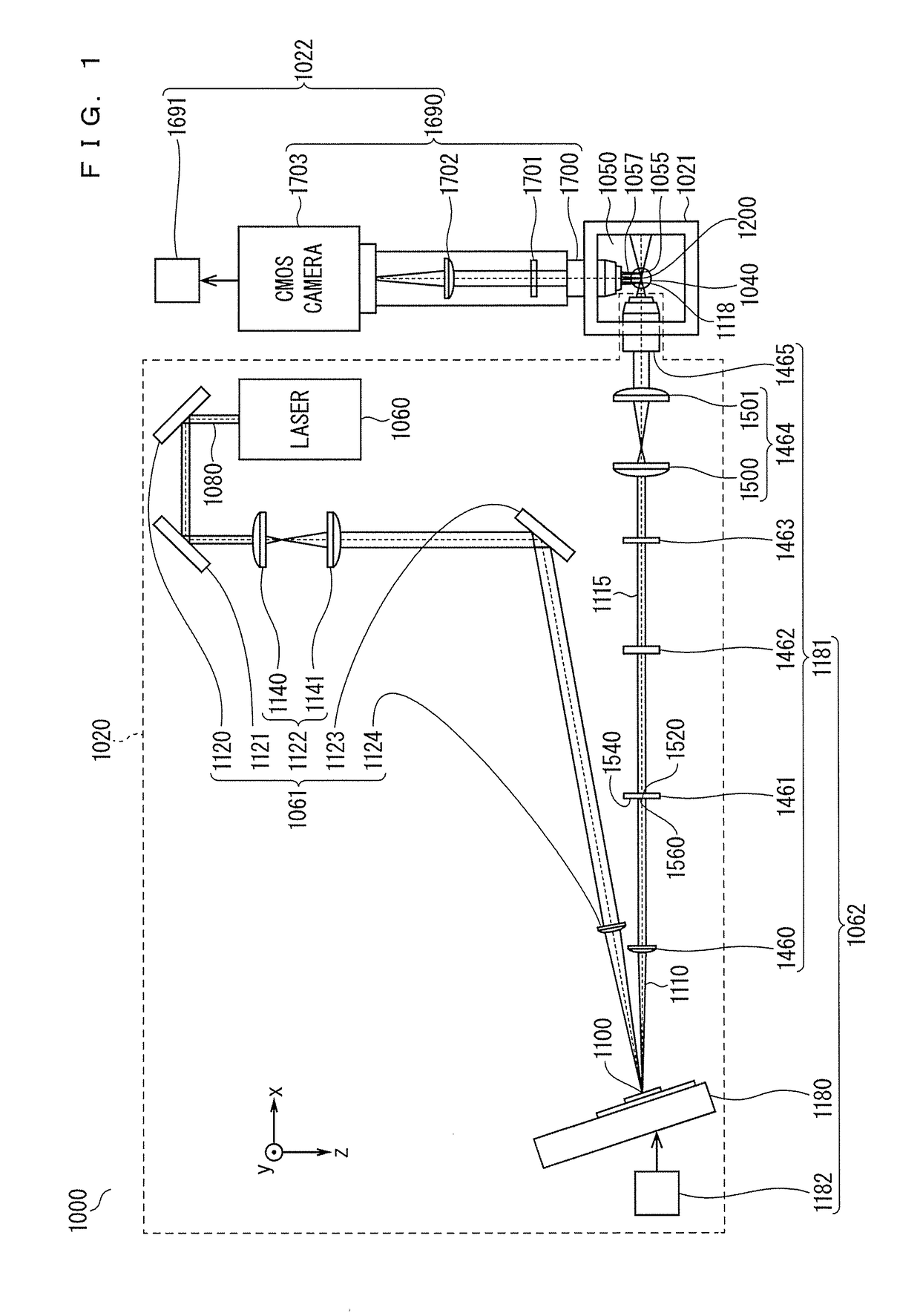

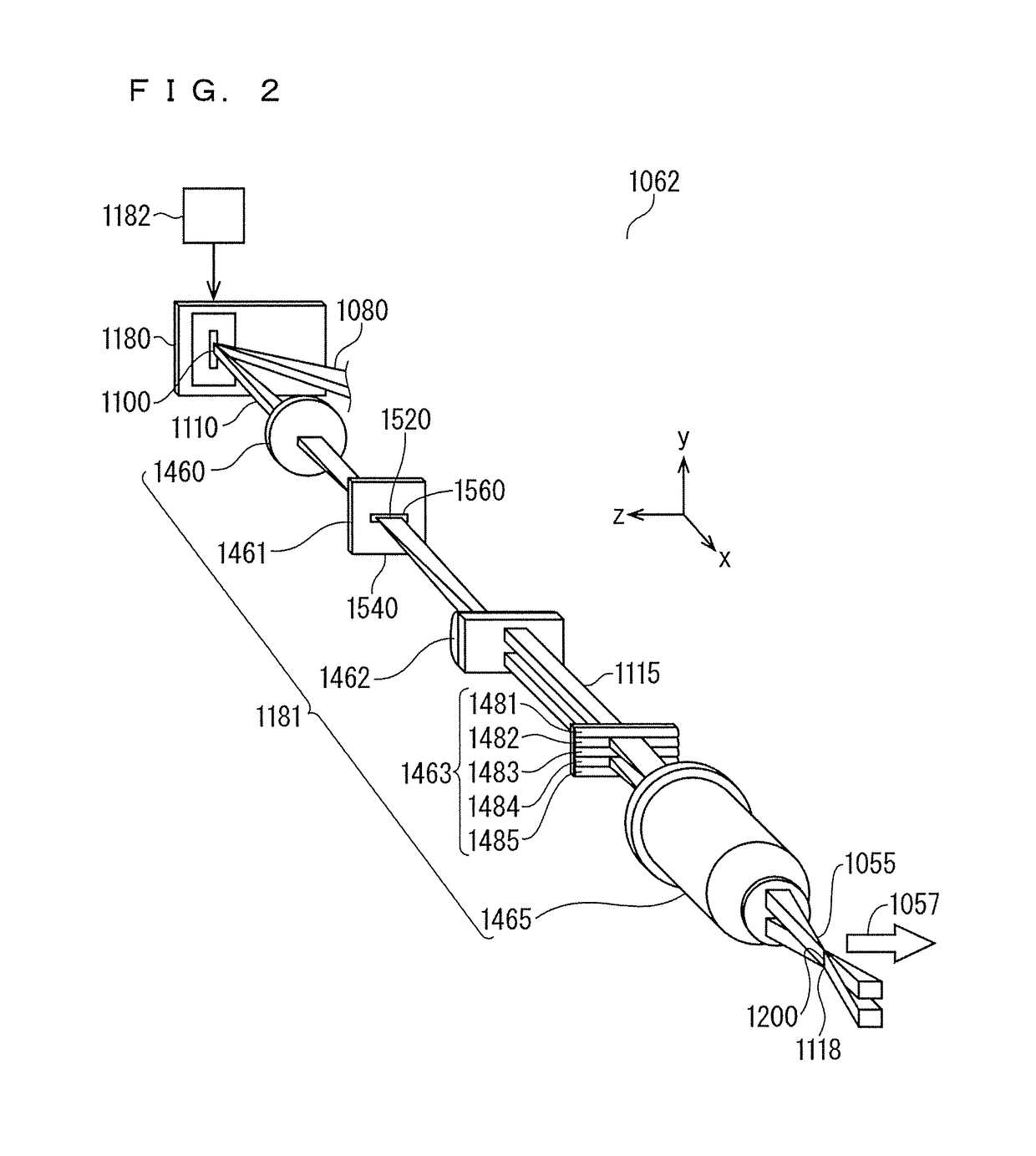

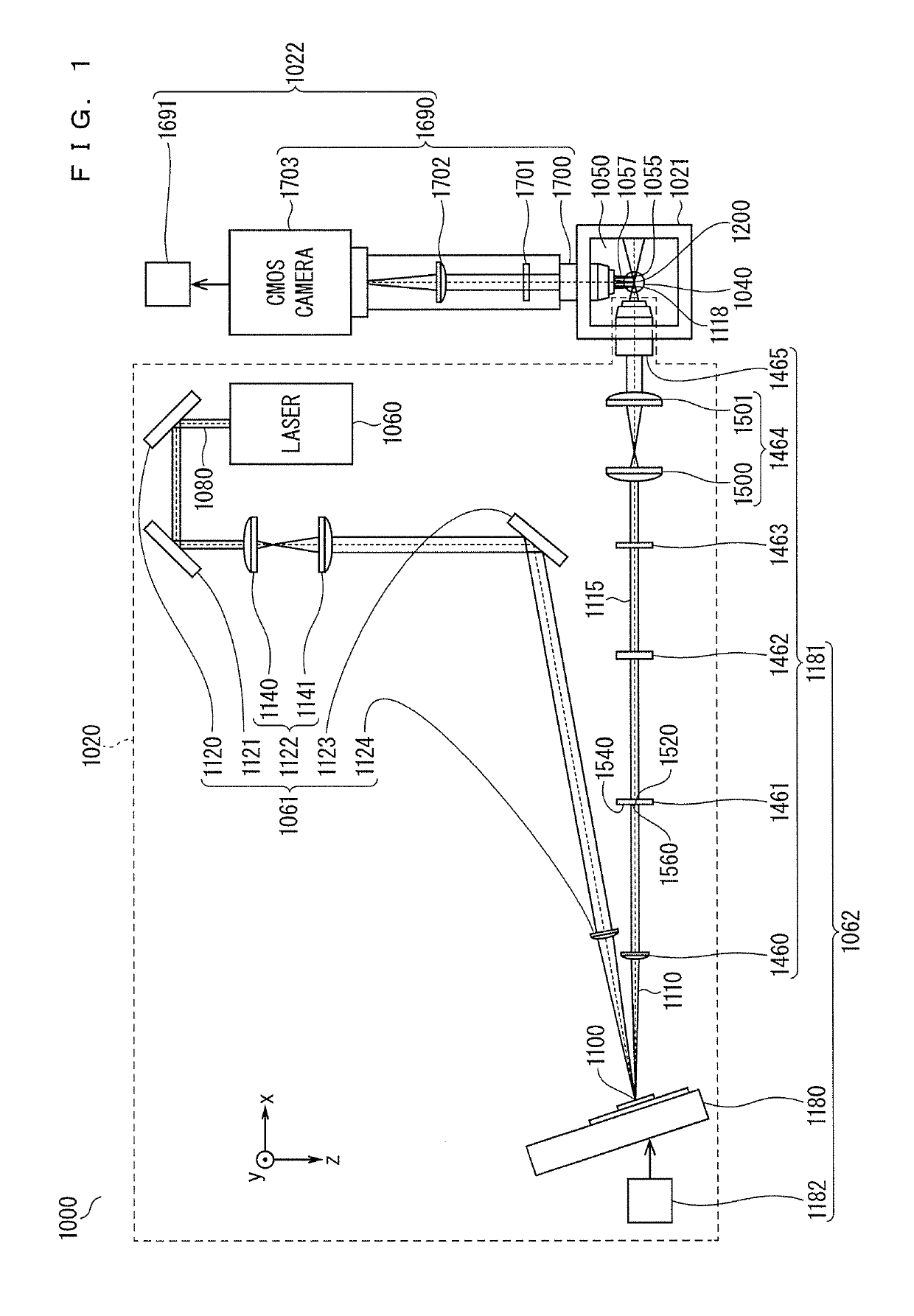

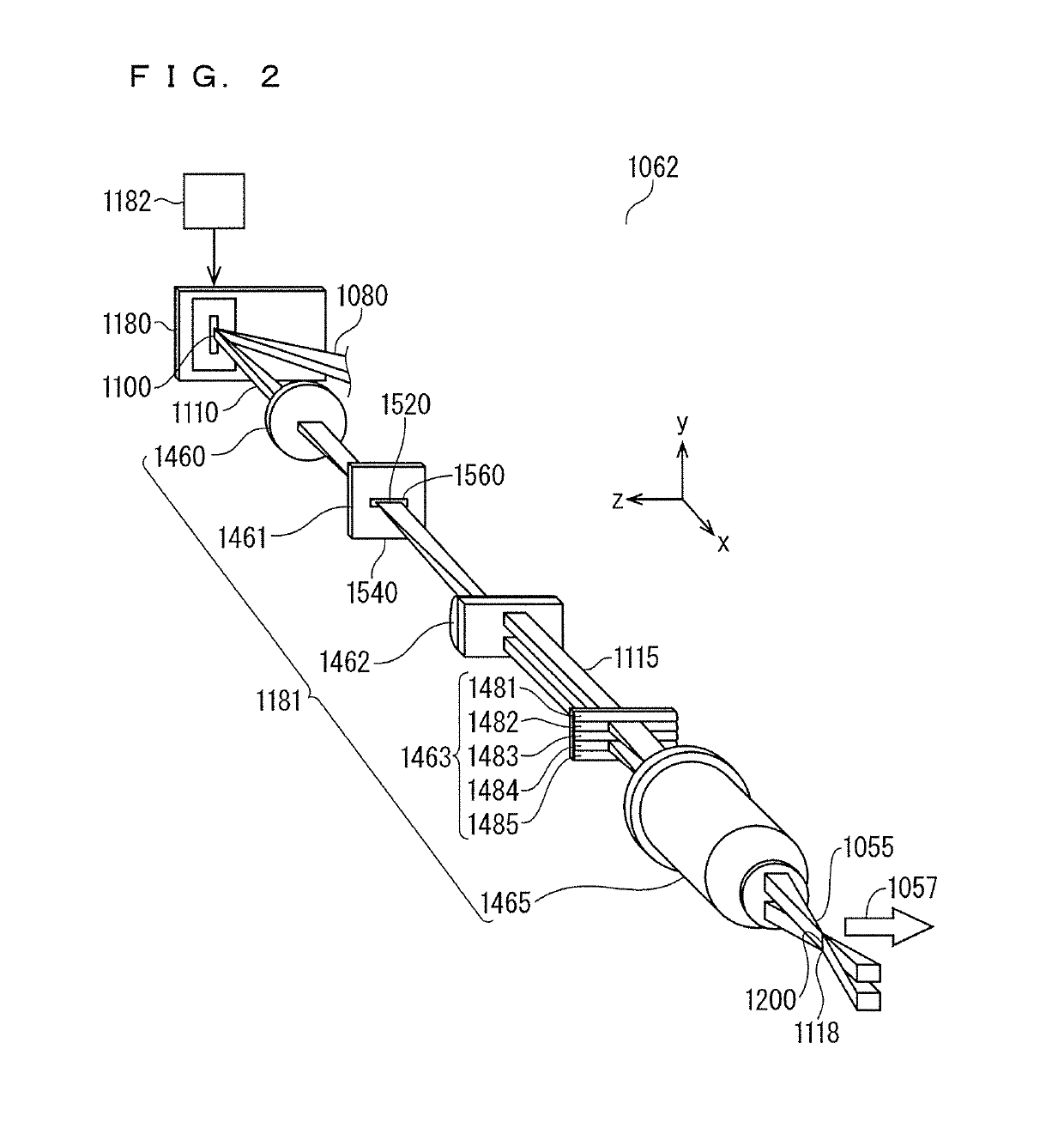

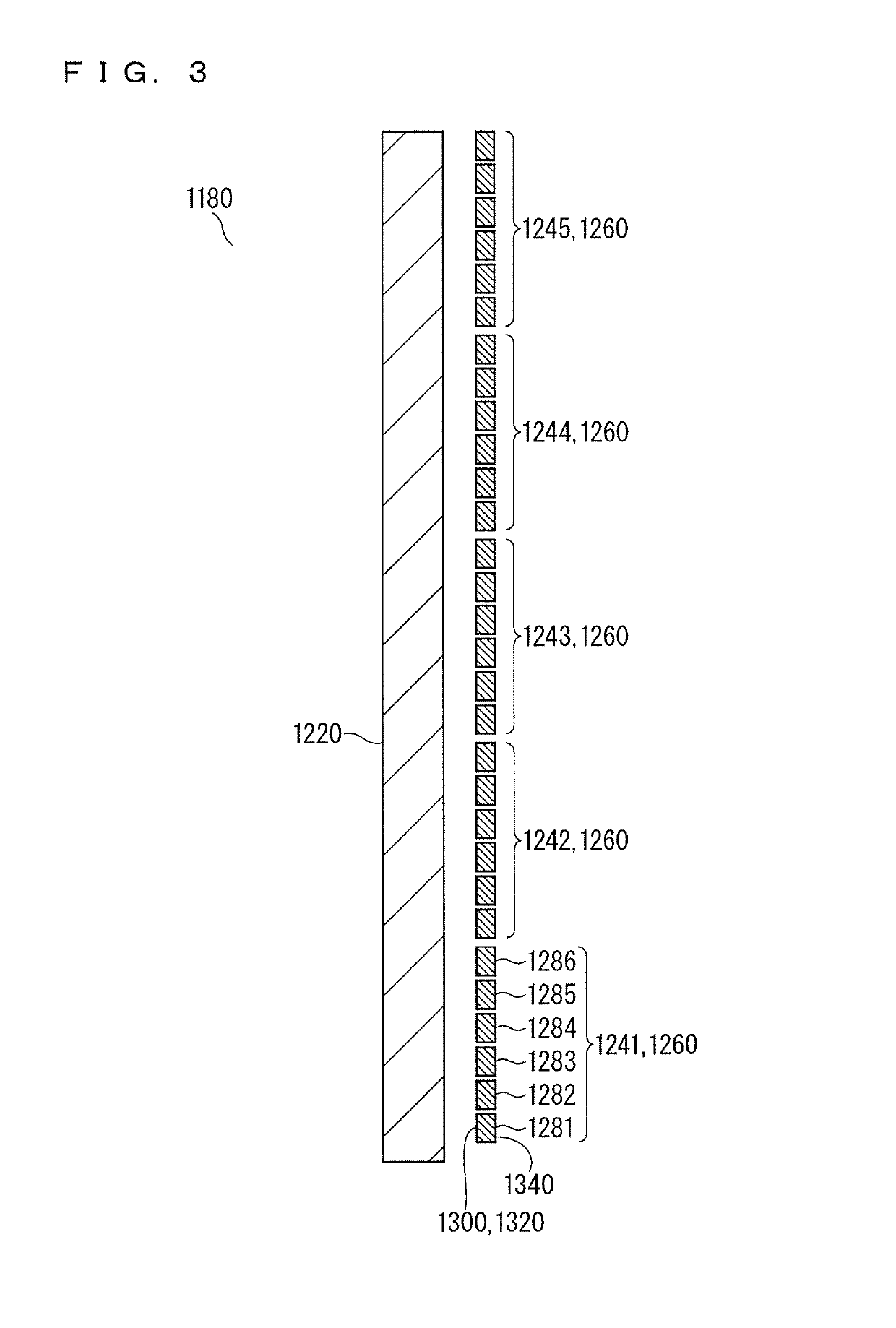

Converter, illuminator, and light sheet fluorescence microscope

ActiveUS20180088305A1Fast image acquisitionImprove image qualityMicroscopesNon-linear opticsImaging qualityVIRTUAL PIXEL

Improved image quality by structured illumination or pivoting illumination and faster image acquisition are both achieved. A line light enters first to fifth virtual pixels of a grating light valve, and first to fifth lights are emitted respectively from the first to fifth virtual pixels. The intensities and phases of the first to fifth 0th-order lights respectively depend on the arrangements of sub-pixels included in the first to fifth virtual pixels. The first to n-th 0th-order lights are extracted respectively from the first to n-th lights, and the first to n-th 0th-order lights are converted respectively into first to fifth light sheets. The first to fifth light sheets are created at a portion to be illuminated. The arrangements of the sub-pixels included in the first to fifth pixels are controlled such that a structured light sheet or pivoting light sheet is created at the portion to be illuminated.

Owner:DAINIPPON SCREEN MTG CO LTD +1

Substrate Tuning System and Method Using Optical Projection

ActiveUS20150147827A1Improve temperature uniformityScaling continuesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGrid basedOptoelectronics

Techniques herein include systems and methods that provide a spatially-controlled or pixel-based projection of light onto a substrate to tune various substrate properties. A given pixel-based image projected on to a substrate surface can be based on a substrate signature. The substrate signature can spatially represent non-uniformities across the surface of the substrate. Such non-uniformities can include energy, heat, critical dimensions, photolithographic exposure dosages, etc. Such pixel-based light projection can be used to tune various properties of substrates, including tuning of critical dimensions, heating uniformity, evaporative cooling, and generation of photo-sensitive agents. Combining such pixel-based light projection with photolithographic patterning processes and / or heating processes improves processing uniformity and decreases defectivity. Embodiments can include using a digital light processing (DLP) chip, grating light valve (GLV), or other grid-based micro projection technology.

Owner:TOKYO ELECTRON LTD

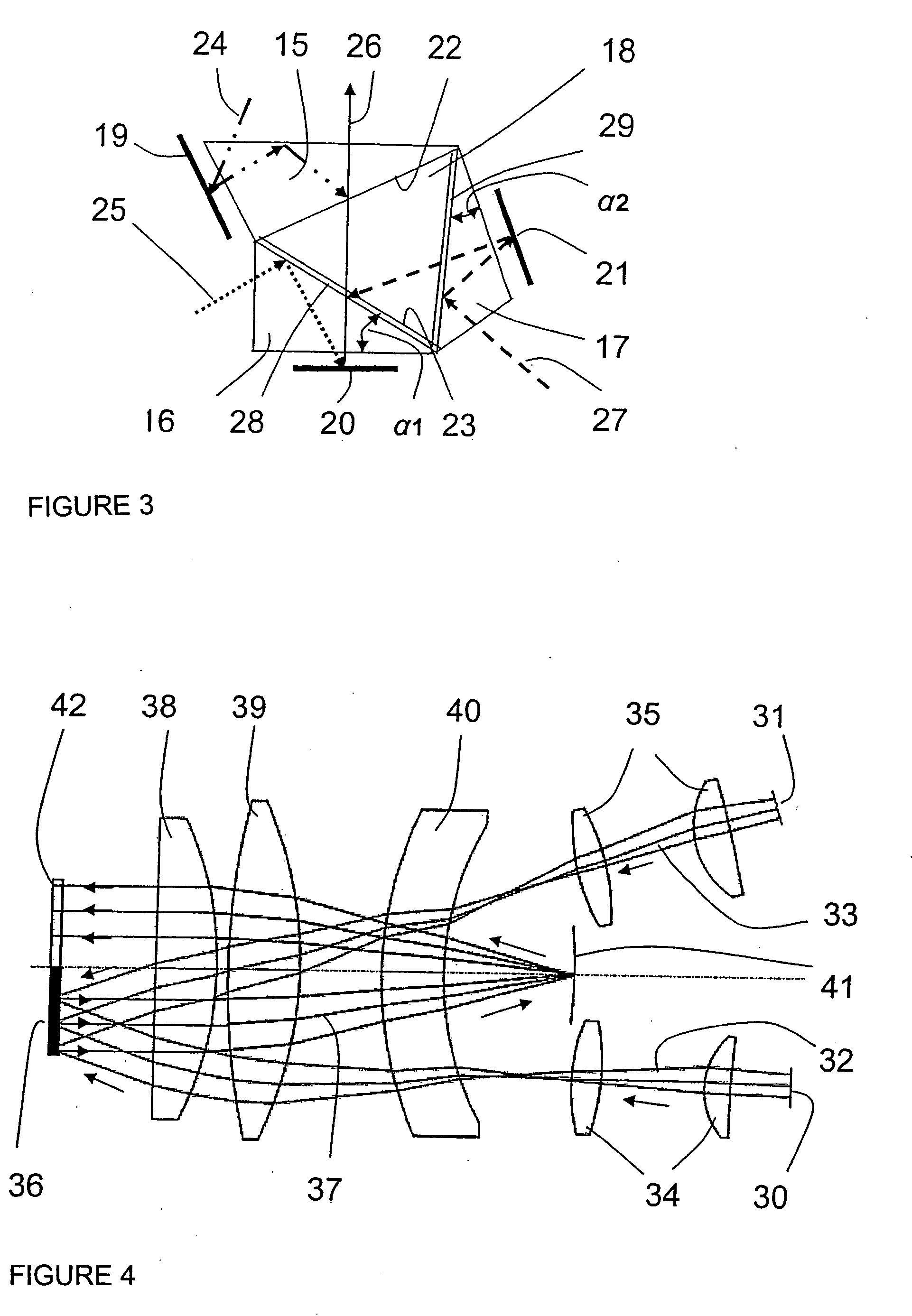

Illumination arrangement for color picture projection

InactiveUS20070177107A1Reduce system sizeSimple resourceProjectorsColor television detailsColor imageEffect light

This invention involves a lighting arrangement for color image projection with at least two lighting units, whose light will hit image-forming elements, such as DMDs or grating light valves via optical elements, so that a subsequent optical projection system will project a multi-colored image on a projection surface. This invention shows that the illuminating optical paths will hit one or more image-forming elements from different directions and that once they pass the image-forming element or elements, they will be combined into one common optical projection path.

Owner:CARL ZEISS JENA GMBH

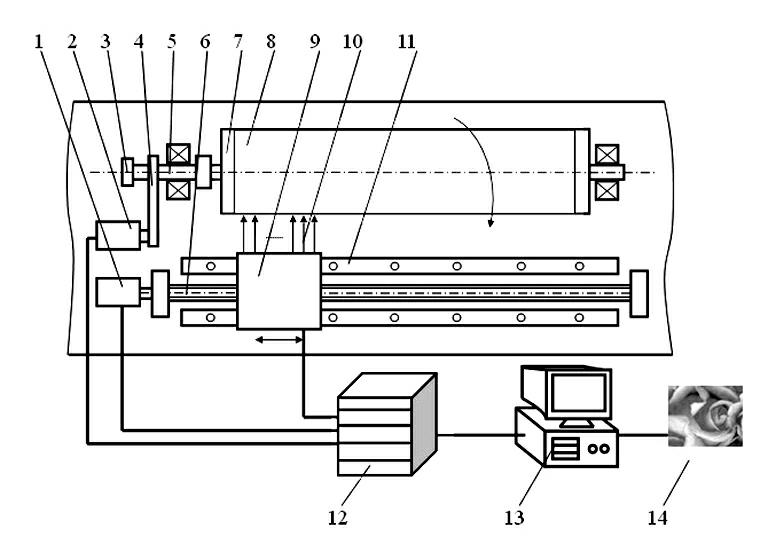

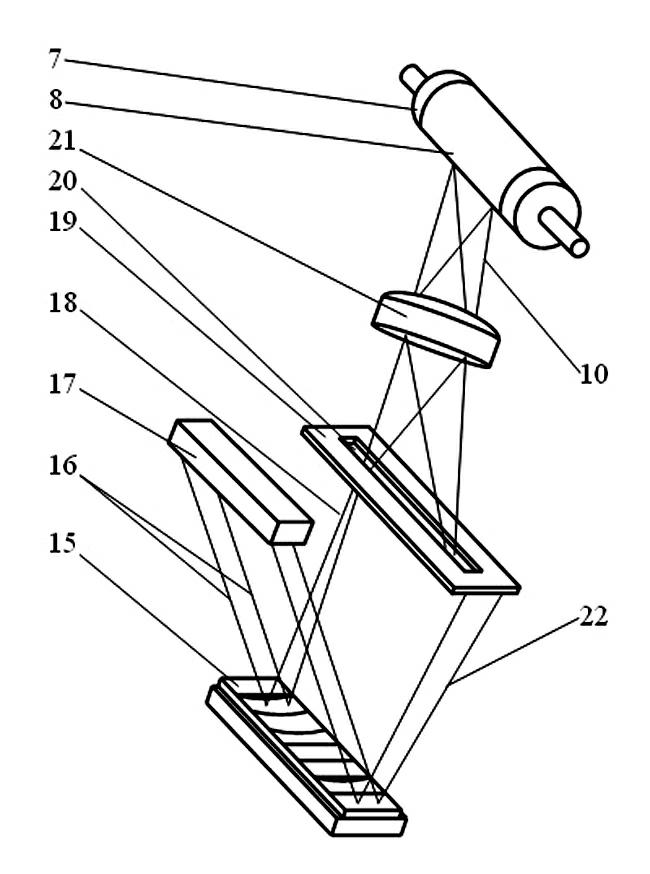

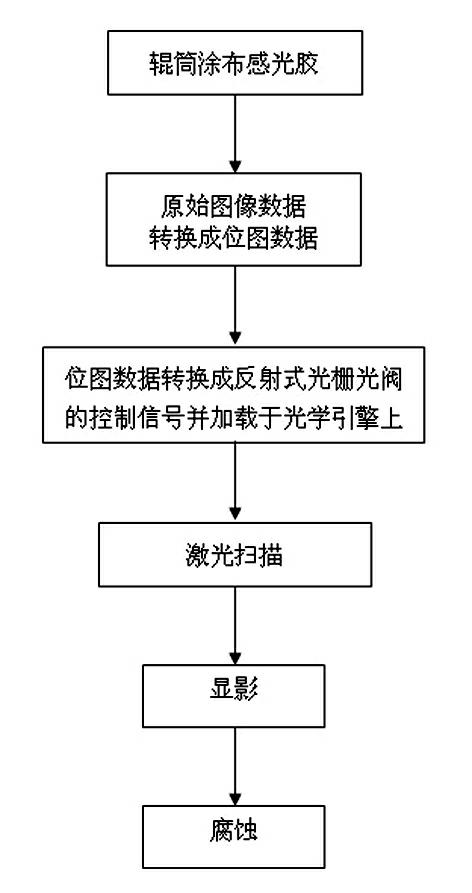

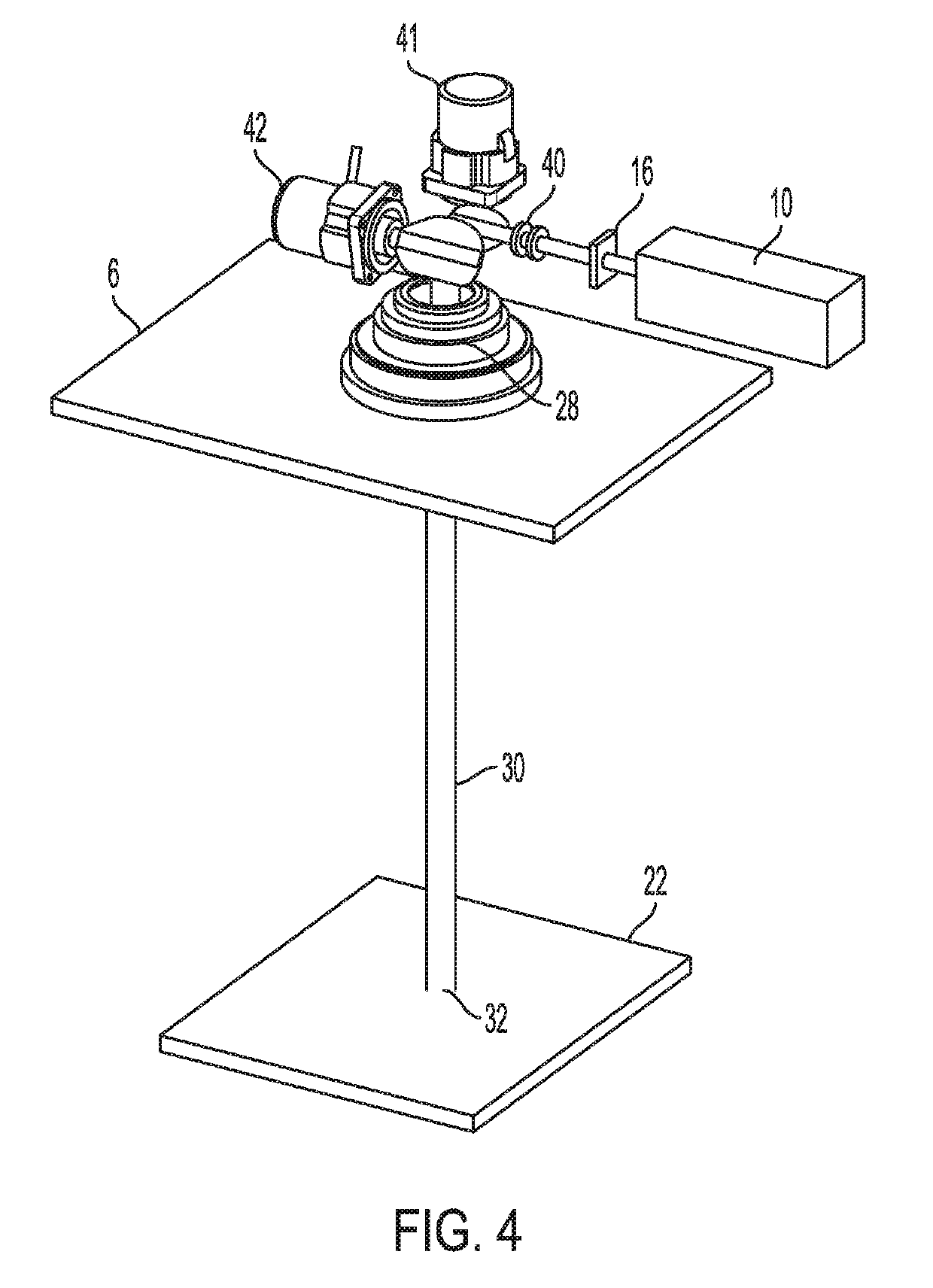

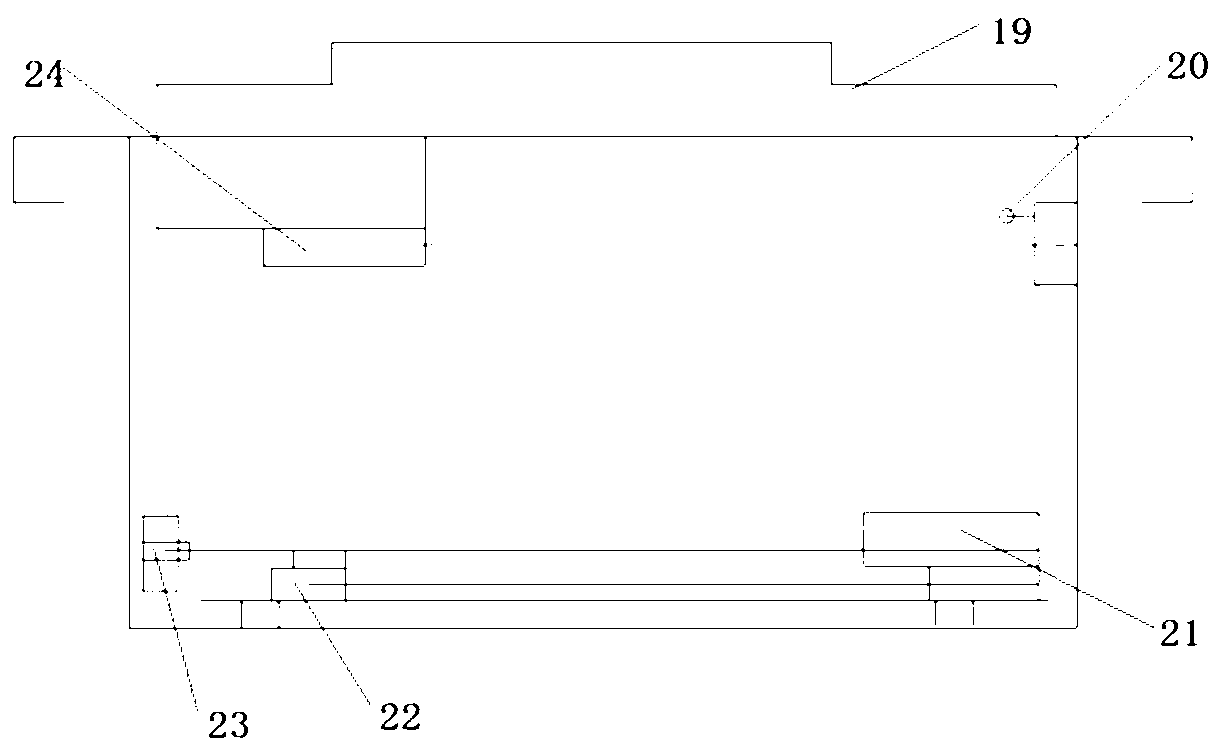

Blue-violet laser carving system and engraving method thereof

InactiveCN102602127ASmall laser spotEngraving with high resolutionForme preparationEngravingReduction drive

The invention provides a blue-violet laser carving system and an engraving method thereof. The blue-violet laser carving system comprises a main driving mechanism, a transverse movement mechanism, a photoelectric encoder, a computer with a control procedure and a controller, wherein the main driving mechanism comprises a main motor, a speed reducer and a main shaft, wherein the main shaft is connected with the speed reducer, the speed reducer is connected with the main motor, and a roller cylinder is connected with the main shaft; the transverse movement mechanism comprises a transverse movement motor, a lead screw and a guide rail, wherein an optical engine is connected with the lead screw, the lead screw is connected with the transverse movement motor, and the optical engine is arranged on the guide rail and can move; the controller is respectively connected with the optical engine, the transverse movement motor, the main motor, the photoelectric encoder and the computer; and a photosensitive material is sprayed on the roller cylinder. The engraving method comprises the following steps of: coating the photosensitive material on the roller cylinder; converting original image data into bitmap data; converting the bitmap data into a control signal of a reflecting type grating light valve and loading the control signal on the optical engine; carrying out laser scanning; and developing and corroding. The system and the method disclosed by the invention have the characteristics that performance is stable, engraving quality is high and the like, and are efficient and convenient.

Owner:方平

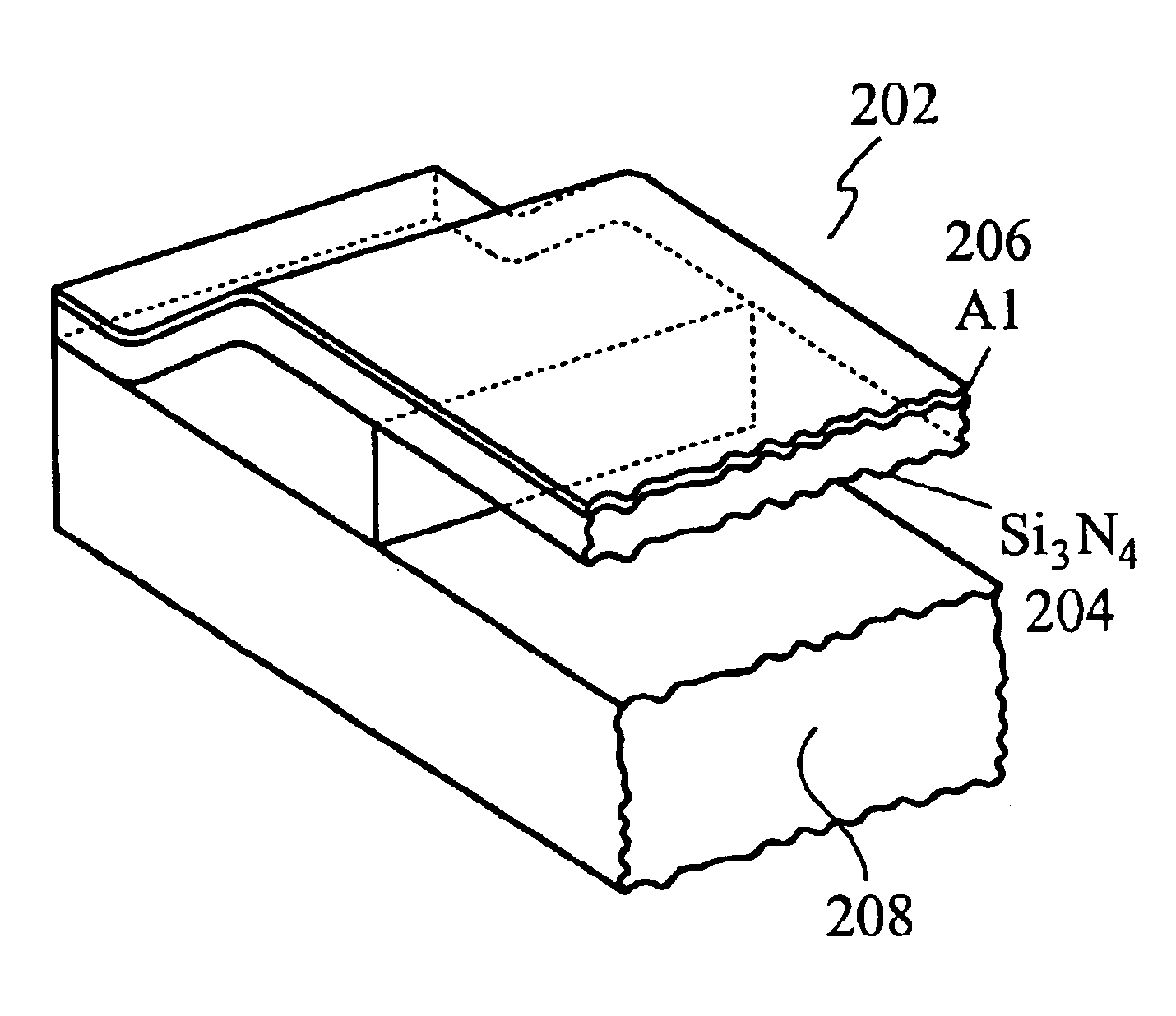

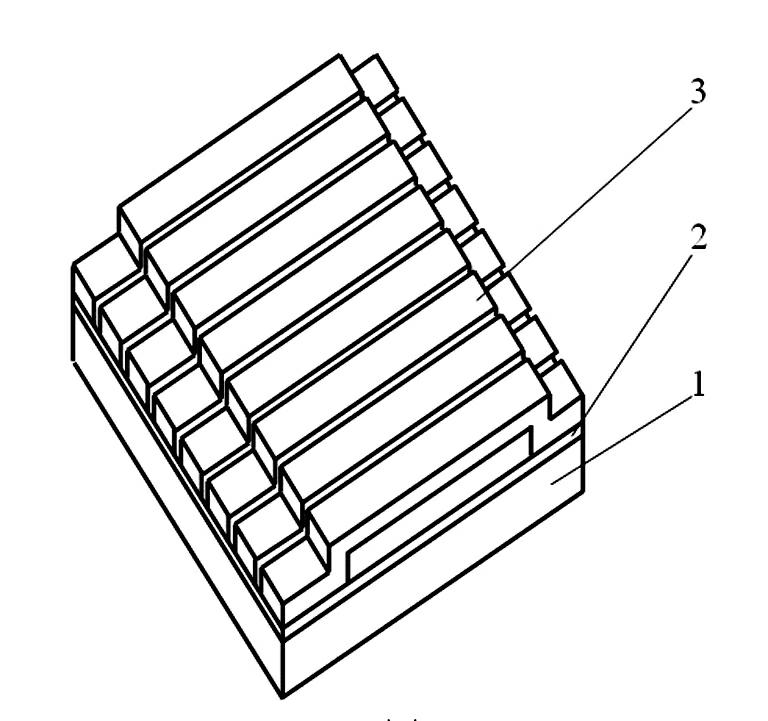

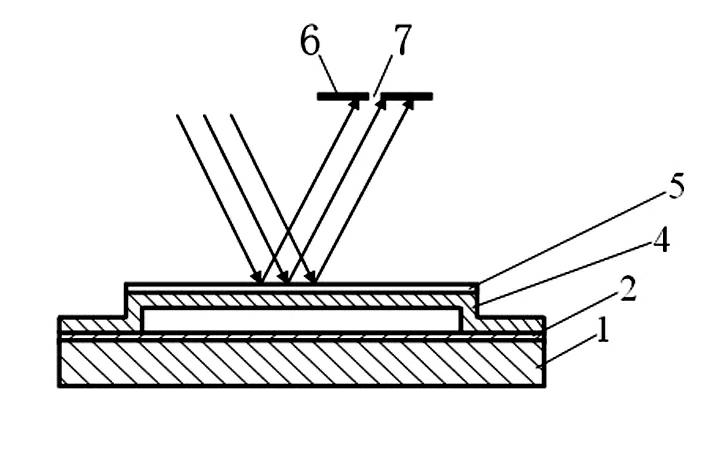

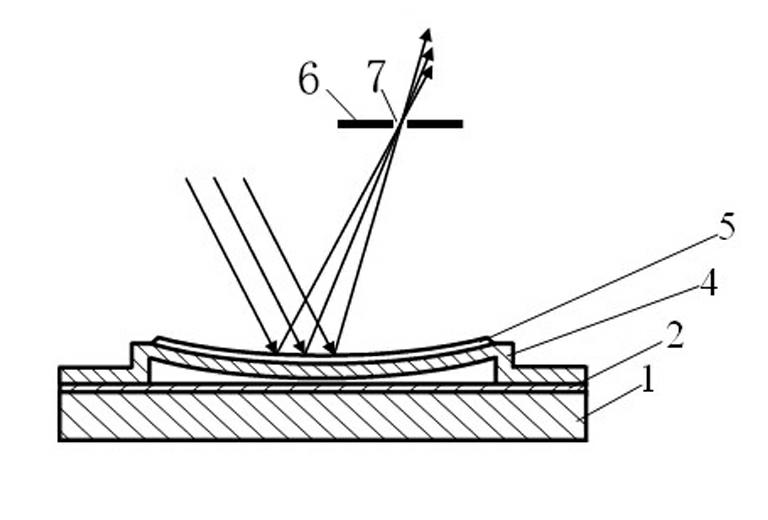

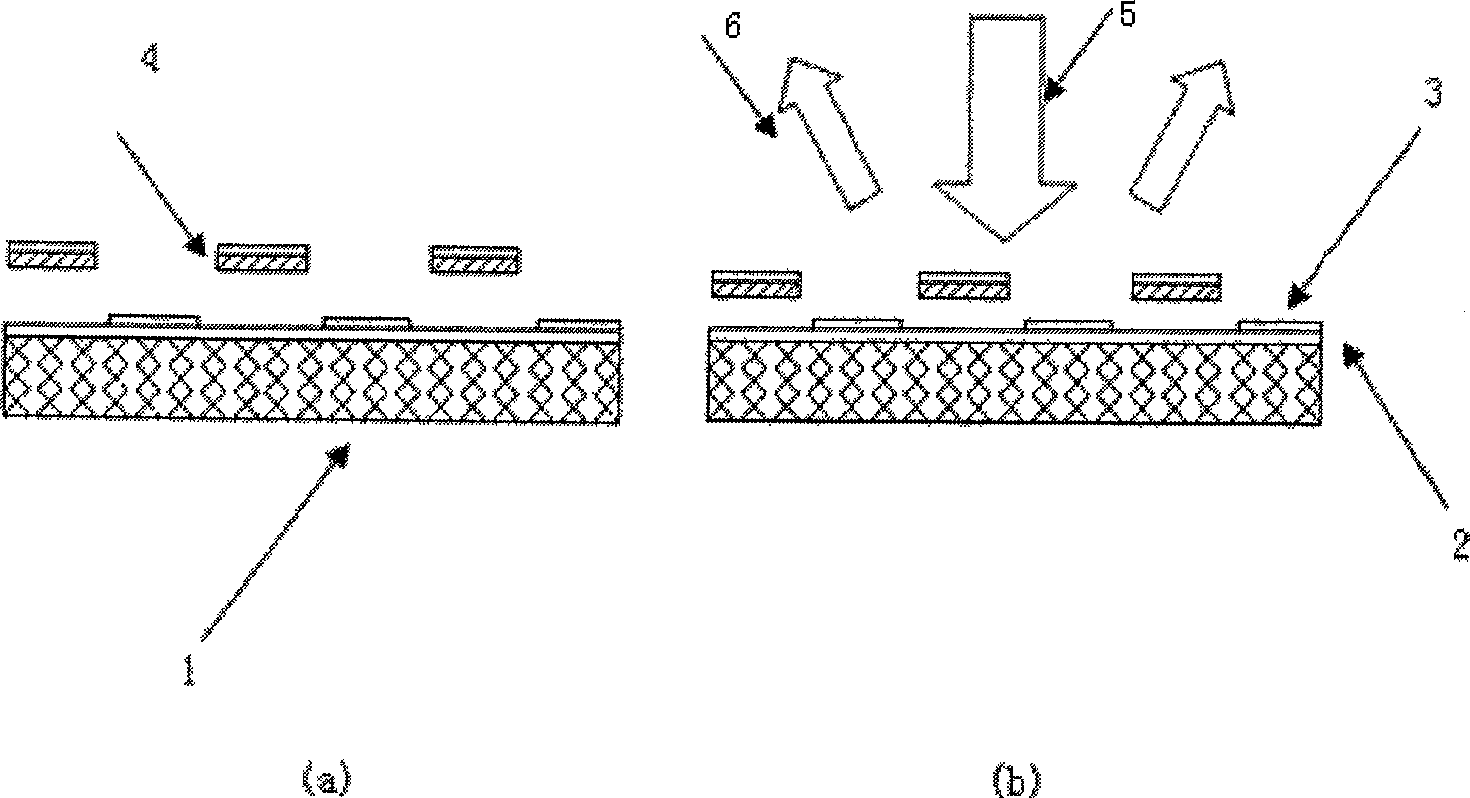

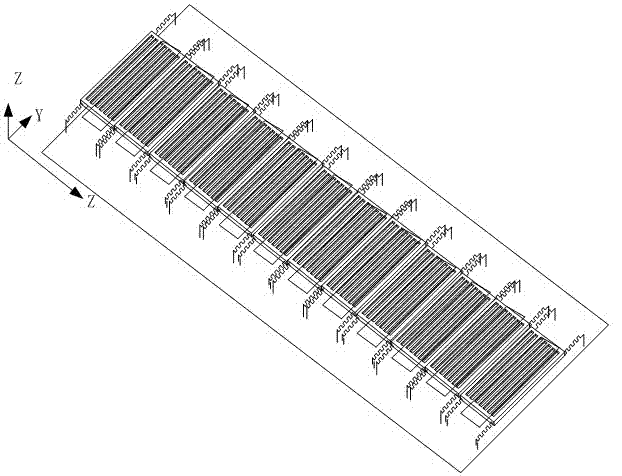

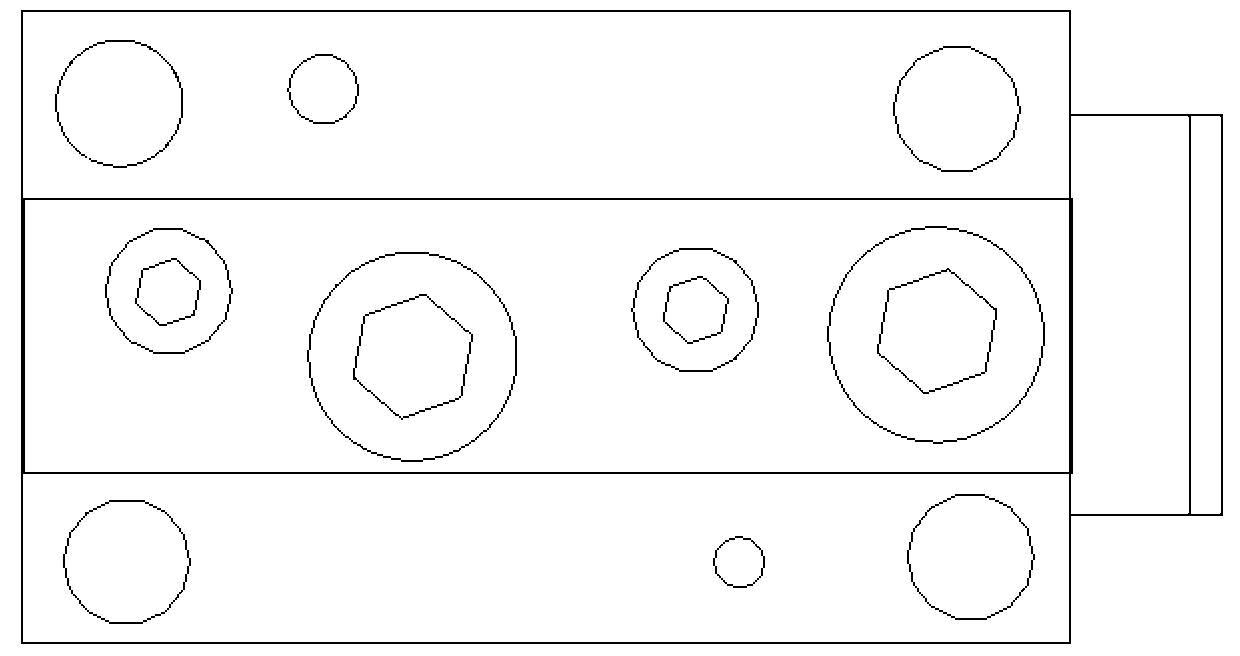

Reflecting type grating light valve and processing method thereof

InactiveCN102602160AImprove lighting efficiencyHigh extinction ratioDiffraction gratingsPrintingMetallic aluminumEtching

The invention relates to a reflecting type grating light valve and a processing method thereof. The reflecting type grating light valve mainly comprises a silicon substrate, a silicon dioxide layer and removable grating strips, wherein the silicon dioxide layer is arranged on the silicon substrate, a plurality of removable grating strips are arranged on the silicon dioxide layer, and the removable grating strips are mutually parallel and are also arranged in an equally spaced way; the removable grating strips are in a bridge shape with a suspended middle, and both ends of the removable grating strips are respectively fixed on the silicon dioxide layer. The processing method comprises the following steps that: the silicon dioxide layer is grown on the silicon substrate, a silicon sacrifice layer is grown on the silicon dioxide layer, and a silicon nitride layer is grown on the silicon sacrifice layer; the operation of ion etching is carried out on the silicon nitride layer by using an ion etching method, and a silicon-nitride beam part is remained; the operation of erosion is carried out on the sacrifice layer by using a chemical erosion method, the sacrifice layer is emptied, and a silicon-nitride beam with a suspended middle is obtained, wherein both ends of the silicon-nitride beam are fixed on the silicon dioxide layer; and the surface of the silicon nitride layer is evaporated with a layer of metallic aluminum or metallic silver as a metal reflecting layer and an upper electrode; the reflecting type grating light valve has high light efficiency, high extinction ratio and high response speed; and moreover, the reflecting type grating light valve has a simple processing process, can be used as a multi-path light modulating component of high-resolution laser engraving equipment and is applied to the high-resolution laser engraving equipment in the fields of high-quality printing and anti-counterfeiting packaging.

Owner:方平

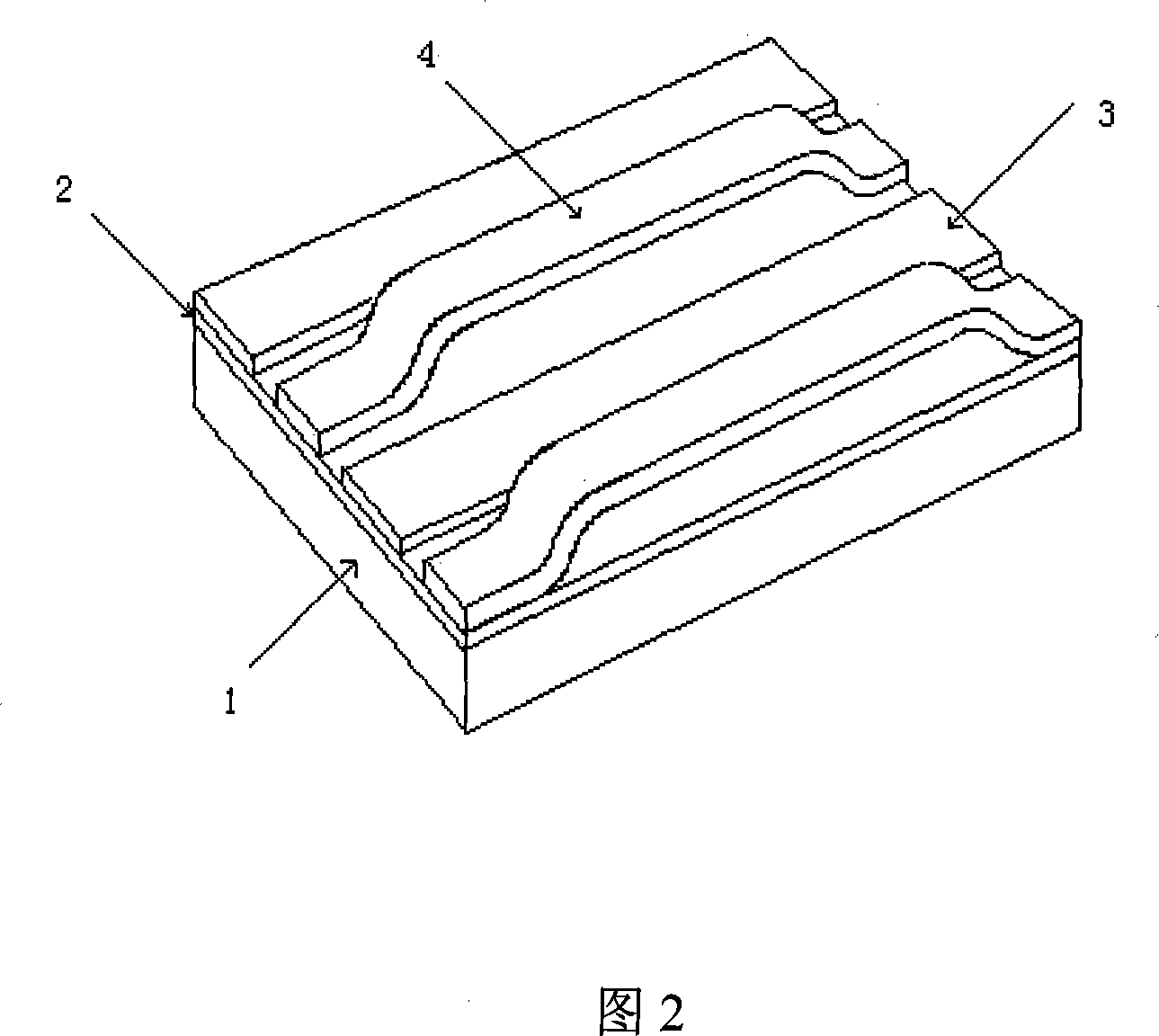

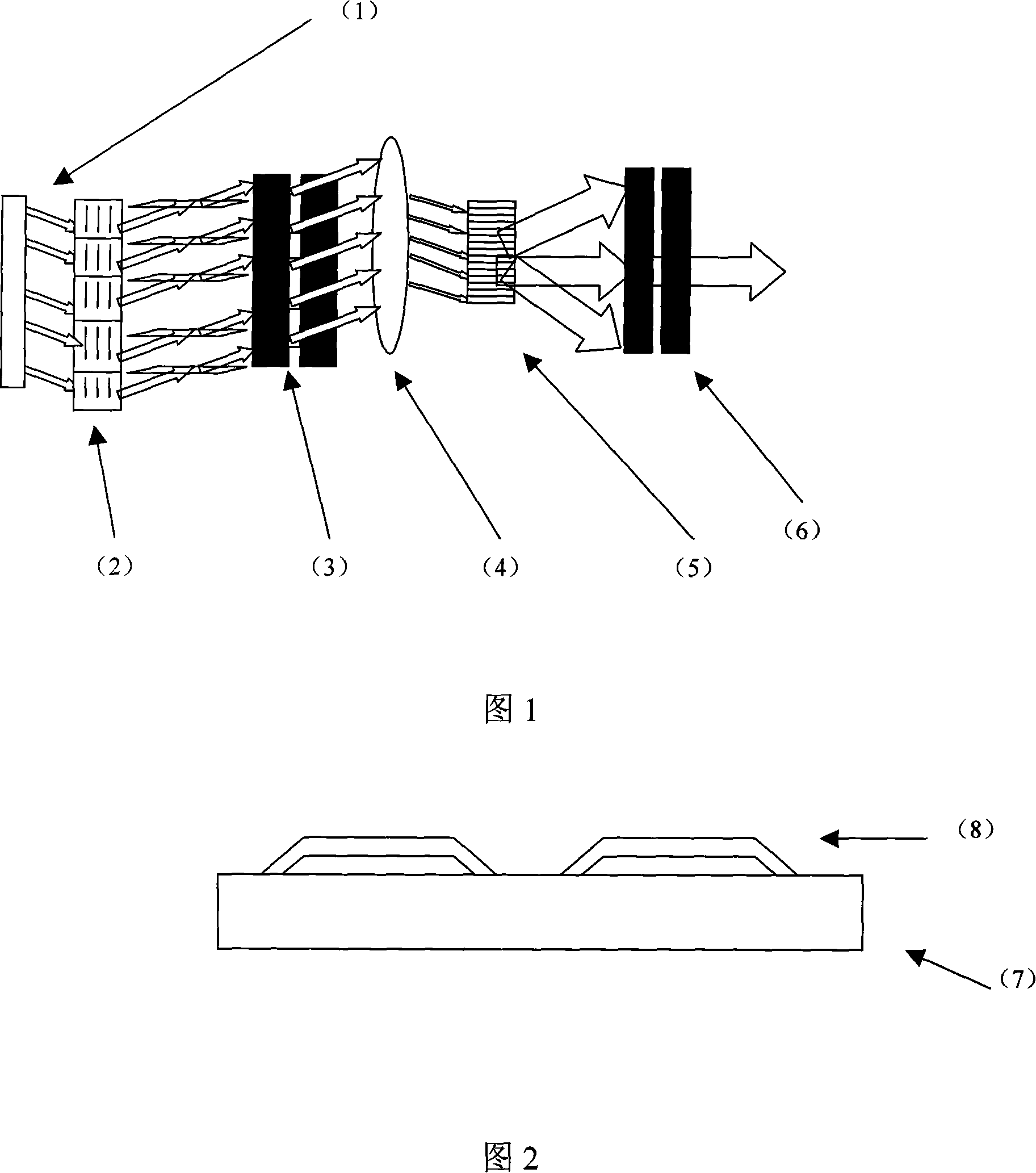

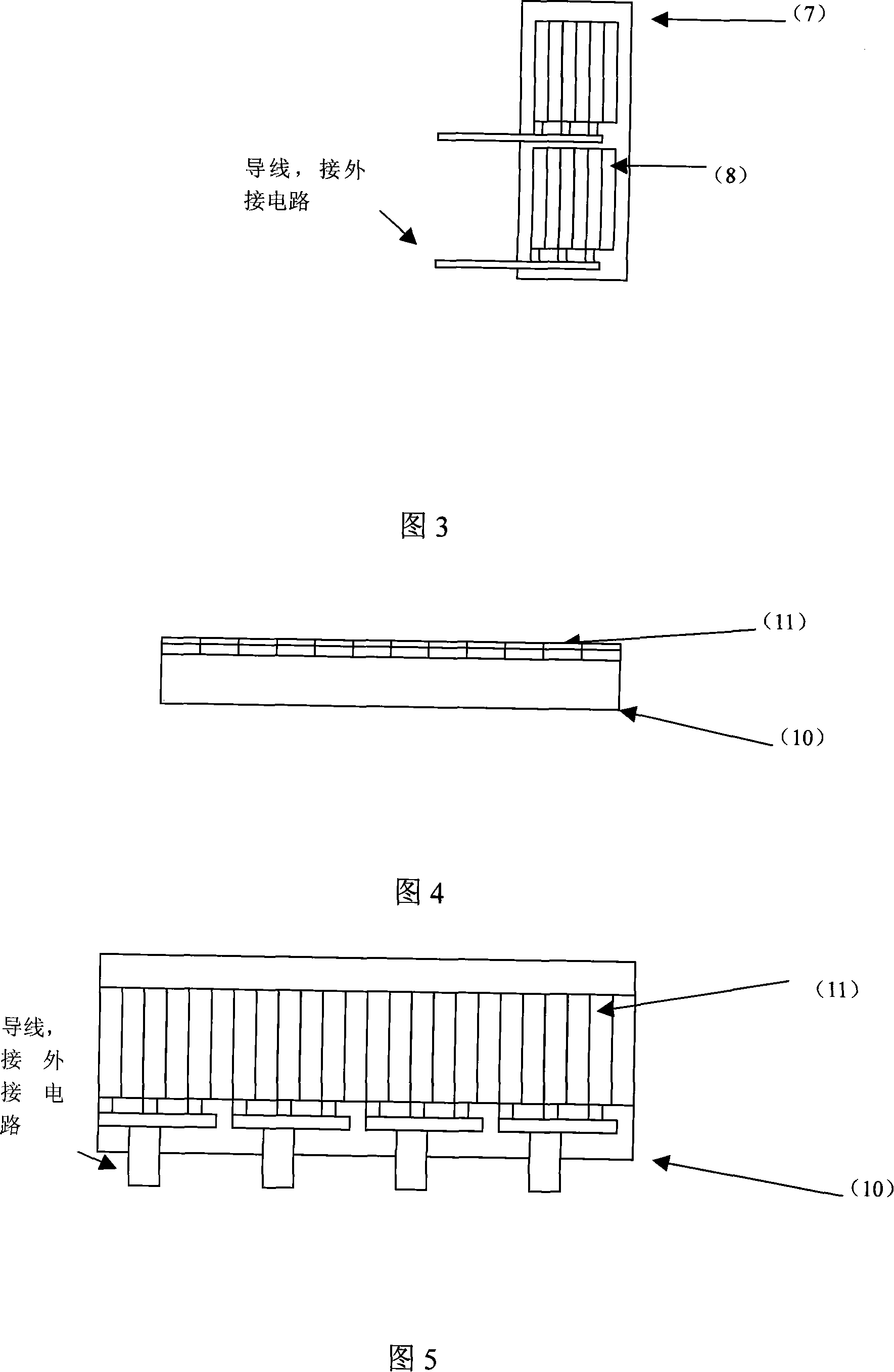

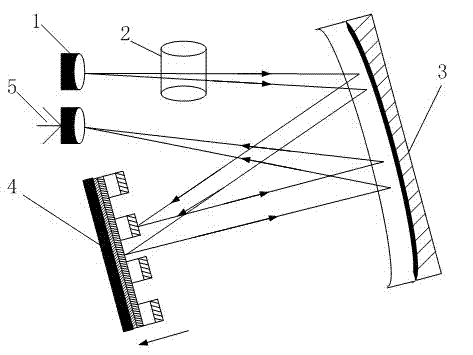

Raster and light valve array processed by electric microcomputer for laser filmsetting and its production

InactiveCN101073935AThe way to implement the scanQuick responsePhotomechanical apparatusDiffraction gratingsSilicon dioxidePt element

The invention is concerned with a raster light valve array with micro electromechanical systems for laser typesetter and its method. The array relates to silicon floor and there is silicon dioxide layer on the silicon floor. There are parallel fixed raster bar with equal alternation and movable raster bar on the silicon dioxide layer. The movable raster bar is the bridge shape with impending midst and the two ends of it fixes on the silicon dioxide layer. Develop a layer of silicon dioxide and sacrificial layer of silicon on the silicon floor, and develop silicon nitride, single crystal silicon or multi-crystalline silicon as cantilever beam on the sacrificial layer, and etch silicon nitride, single crystal silicon or multi-crystalline silicon with ion etching technology, using chemical corrosion to draw out the sacrificial layer, and at last, evaporate aluminum, platinum or silver as reflect surface and upper electrode. It applies into the laser typesetter system as laser scan control component. The component realizes multi-way scan of the system to increase the speed of laser typesetter greatly.

Owner:ZHEJIANG UNIV

Converter, illuminator, and light sheet fluorescence microscope

ActiveUS10310246B2Fast image acquisitionImprove image qualityMicroscopesNon-linear opticsImaging qualityVIRTUAL PIXEL

Improved image quality by structured illumination or pivoting illumination and faster image acquisition are both achieved. A line light enters first to fifth virtual pixels of a grating light valve, and first to fifth lights are emitted respectively from the first to fifth virtual pixels. The intensities and phases of the first to fifth 0th-order lights respectively depend on the arrangements of sub-pixels included in the first to fifth virtual pixels. The first to n-th 0th-order lights are extracted respectively from the first to n-th lights, and the first to n-th 0th-order lights are converted respectively into first to fifth light sheets. The first to fifth light sheets are created at a portion to be illuminated. The arrangements of the sub-pixels included in the first to fifth pixels are controlled such that a structured light sheet or pivoting light sheet is created at the portion to be illuminated.

Owner:DAINIPPON SCREEN MTG CO LTD +1

Methods for treating a substrate by optical projection of a correction pattern based on a detected spatial heat signature of the substrate

ActiveUS9646898B2Improve temperature uniformityScaling continuesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGrid basedOptoelectronics

Techniques herein include systems and methods that provide a spatially-controlled or pixel-based projection of light onto a substrate to tune various substrate properties. A given pixel-based image projected on to a substrate surface can be based on a substrate signature. The substrate signature can spatially represent non-uniformities across the surface of the substrate. Such non-uniformities can include energy, heat, critical dimensions, photolithographic exposure dosages, etc. Such pixel-based light projection can be used to tune various properties of substrates, including tuning of critical dimensions, heating uniformity, evaporative cooling, and generation of photo-sensitive agents. Combining such pixel-based light projection with photolithographic patterning processes and / or heating processes improves processing uniformity and decreases defectivity. Embodiments can include using a digital light processing (DLP) chip, grating light valve (GLV), or other grid-based micro projection technology.

Owner:TOKYO ELECTRON LTD

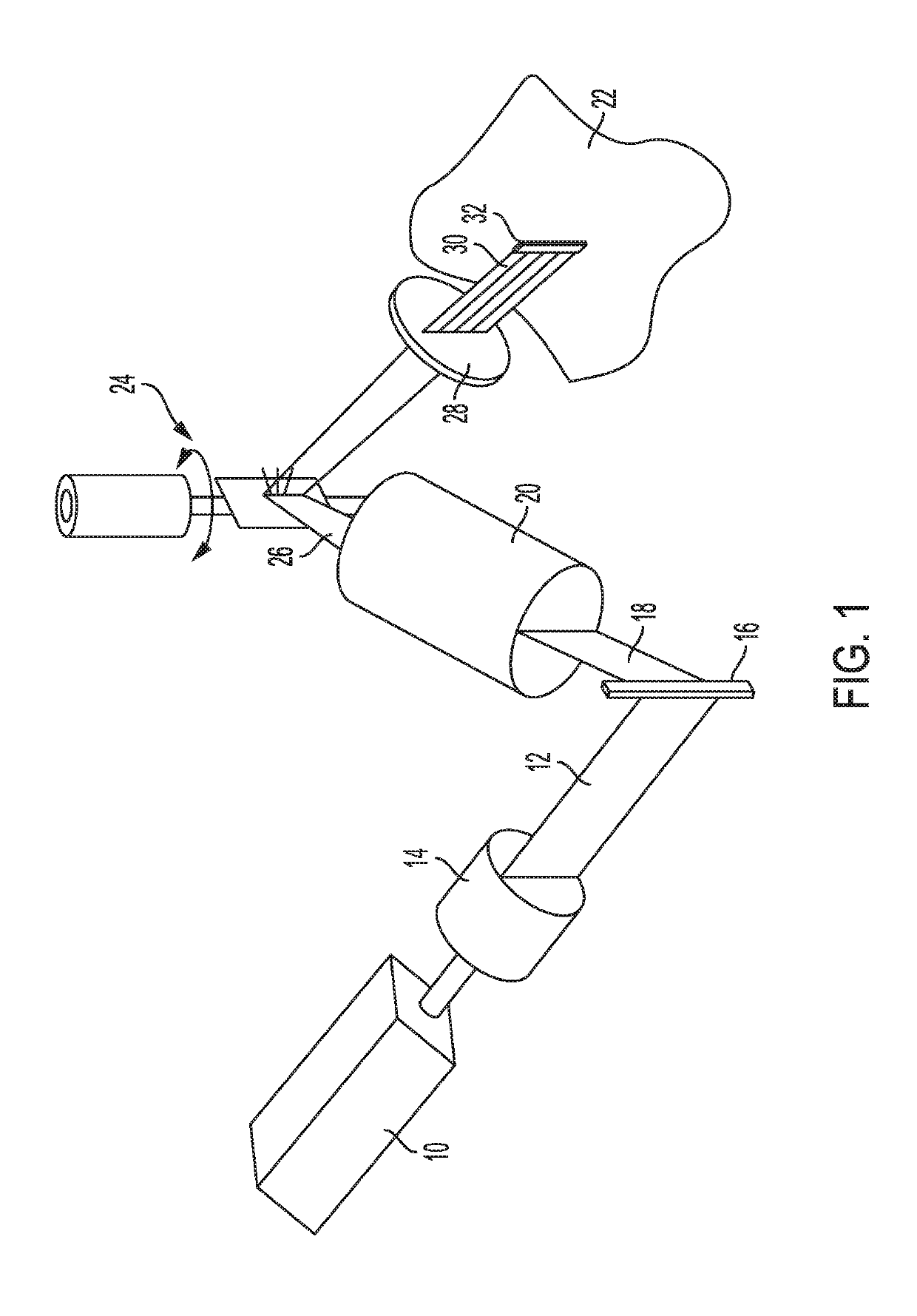

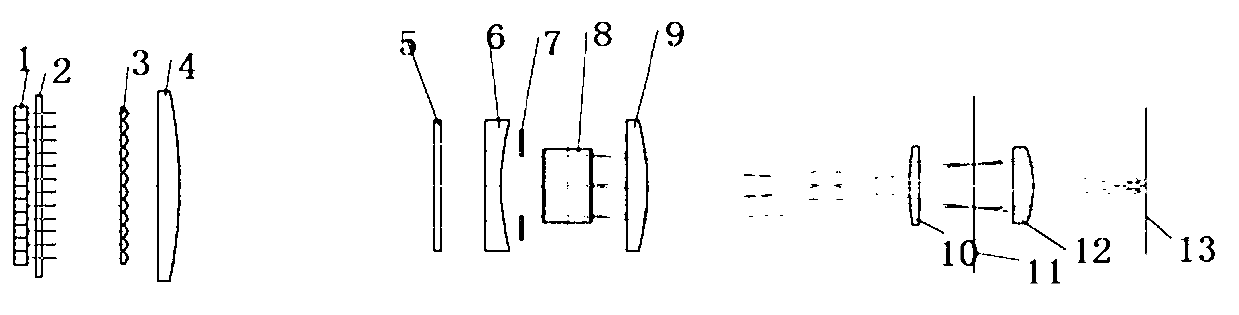

Laser irradiation device and image recorder

InactiveUS7050081B2Easy to useMinimizes light energy losses in the Grating LightLaser detailsPrintingLight beamPeak value

A laser source emits a laser beam having a peak wavelength within the range from 800 nm to 820 nm. The laser beam emitted from the source passes through an illumination lens, and then impinges on a Grating Light Valve™. The light valve splits the laser beam into a multiplicity of light beams, modulates the multiplicity of light beams in response to image signals, and produces zero-order diffracted signal beams. The zero-order diffracted beams pass through an imaging lens, and are imaged on a recording medium wrapped on the surface of a drum.

Owner:DAINIPPON SCREEN MTG CO LTD

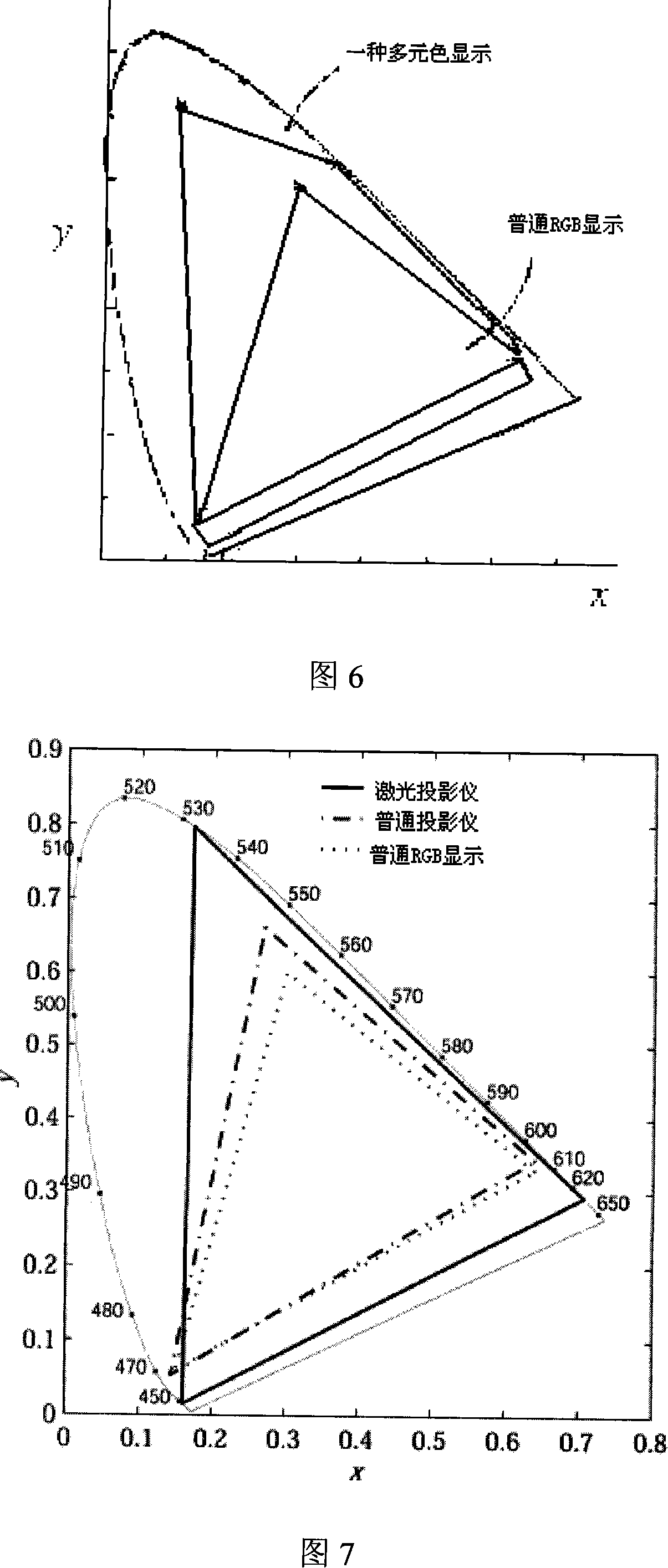

Totally colorful display system

InactiveCN101149473ASimple structureRich in colorProjectorsPicture reproducers using projection devicesFrequency modulationFull color

This invention discloses a kind of full-color display system. It is made up of one or more full-color display cells or one or more full-color display cells and one or more raster and light valves. The full-color display cell is deposited with a light source, a light frequency modulation raster array, a frequency selection diaphragm, a lens coupler, a first raster and light valve and a secondary selection diaphragm. The light frequency modulation raster array is set with the first basis. And the first basis is set with an array, which is made up of end-to-end placed and addressable raster. This invention has three beneficial effects: 1) compared to the tricolor mixing based display system, this system has the ability of displaying full colors or most of the colors. 2) Compared to the multiple colors mixing based display system, this system has the advantages of simple structure and ability of displaying more colors. 3) Compared to the individual modulating light frequency or light intensity modulator, the full-color display cell has the characteristic of modulating light intensity as well as frequency.

Owner:ZHEJIANG UNIV

Raster and light valve array processed by electric microcomputer for laser filmsetting and its production

InactiveCN100542805CThe way to implement the scanQuick responsePhotomechanical apparatusDiffraction gratingsLaser scanningOptoelectronics

The invention discloses a microelectromechanical processing grating light valve array and a method thereof for laser phototypesetting. The grating light valve array includes a silicon substrate, a silicon dioxide layer is arranged on the silicon substrate, fixed grating strips and movable grating strips are arranged in parallel at equal intervals on the silicon dioxide layer, and the movable grating strip is in the shape of a bridge suspended in the middle. Both ends of the movable grating bar are fixed on silicon dioxide. The method is to use silicon as the substrate, and then grow a silicon dioxide and silicon sacrificial layer on it. On the sacrificial layer, grow silicon nitride, single crystal silicon or polycrystalline silicon as a cantilever beam, use ion etching process to etch silicon nitride, single crystal silicon or polycrystalline silicon, then use chemical etching to hollow out the sacrificial layer, and finally evaporate Metal aluminum, platinum or metal silver is used as the reflective surface and the upper electrode. The invention is used as a laser scanning control device in a laser phototypesetting system. The device can realize multi-channel parallel scanning on the laser phototypesetting system, which greatly improves the film printing speed of the laser phototypesetting machine.

Owner:ZHEJIANG UNIV

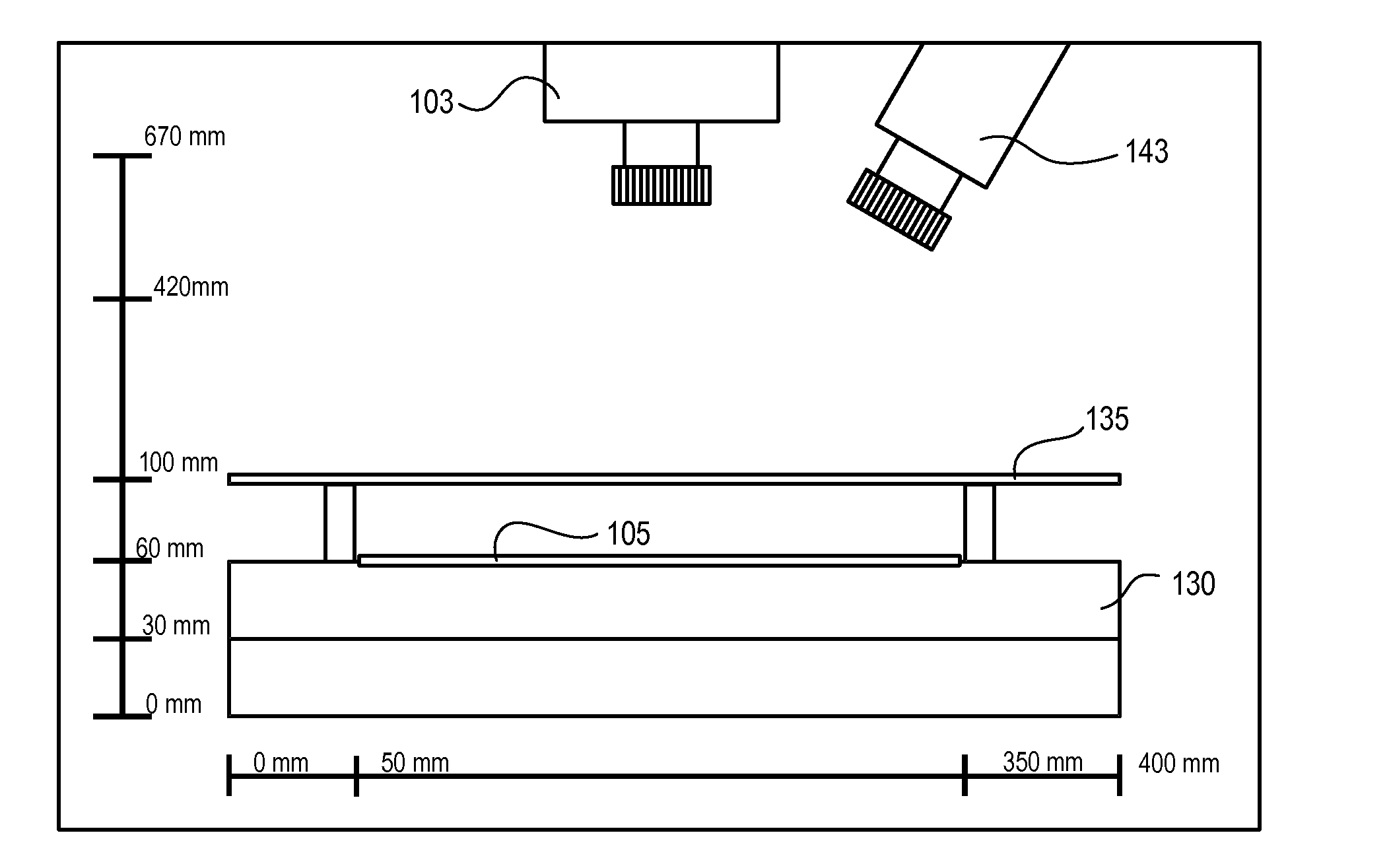

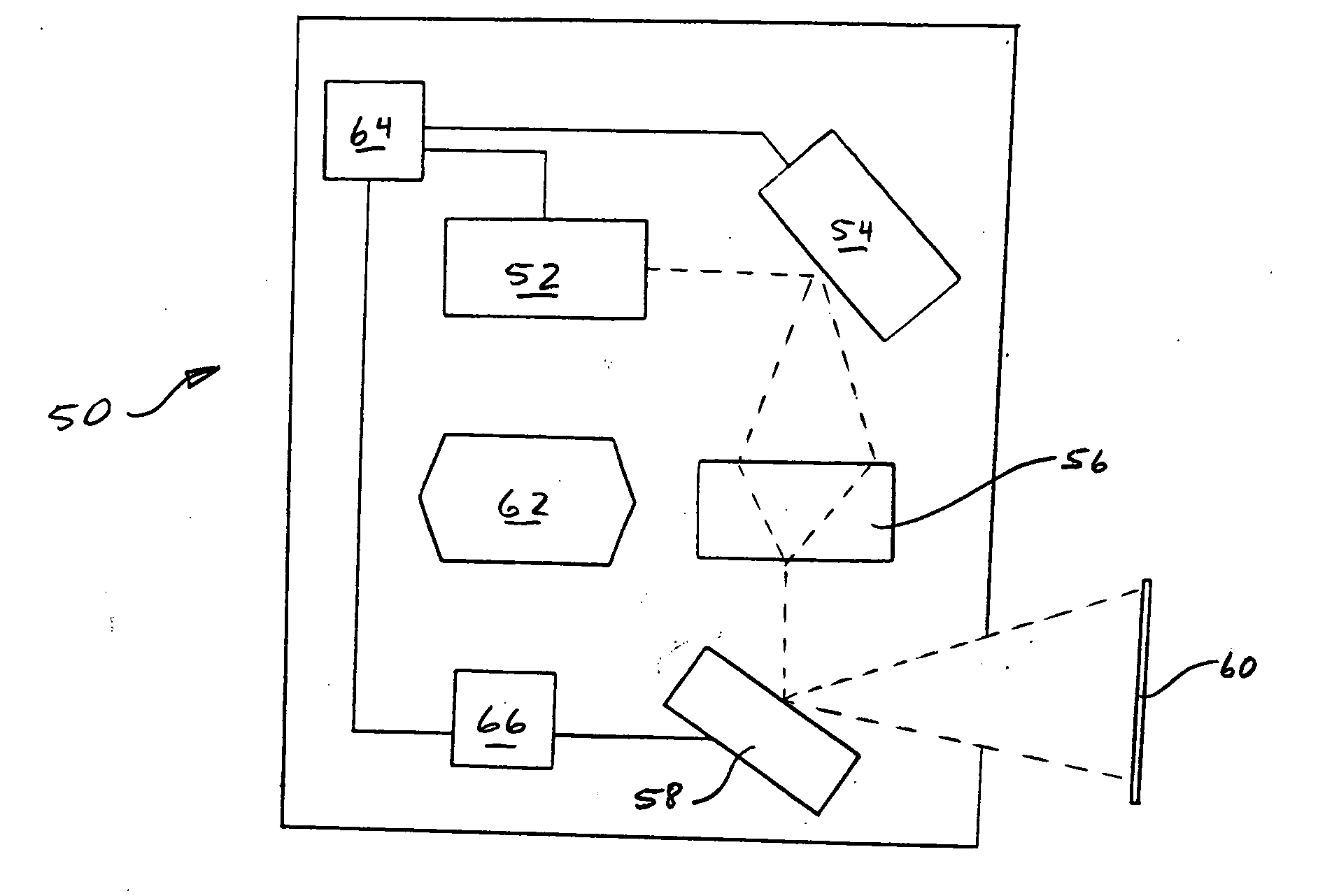

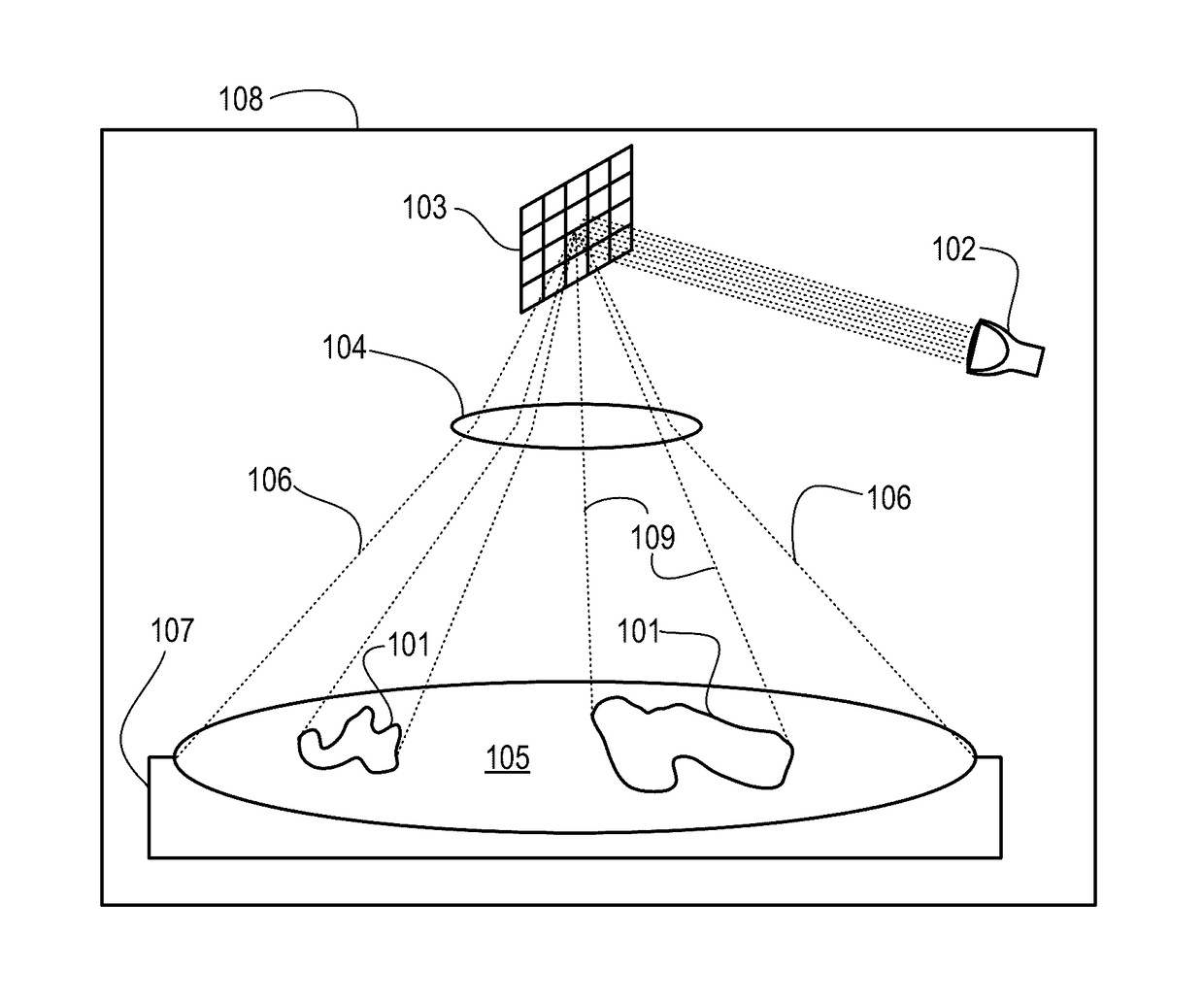

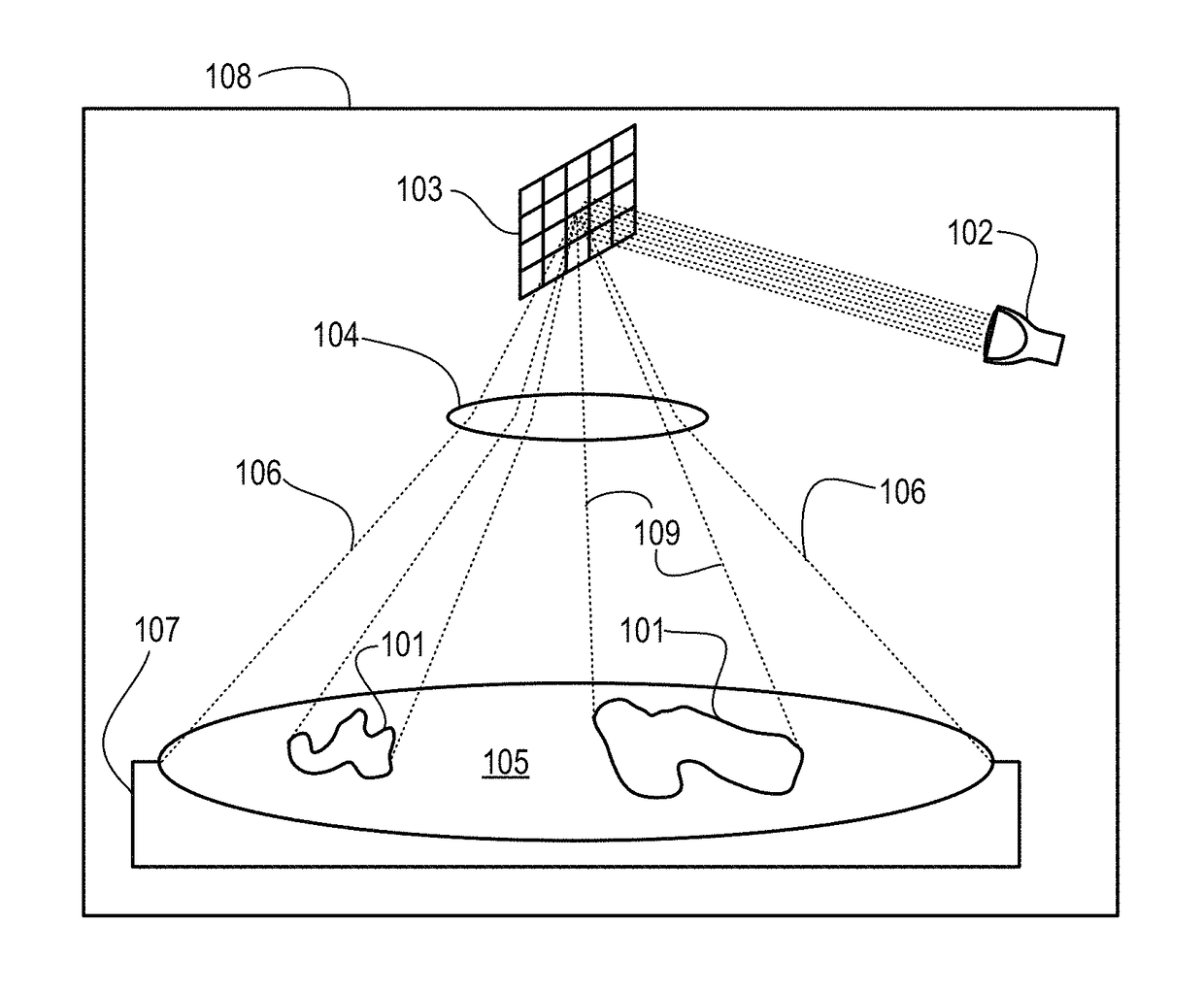

Additive manufacture system using light valve device

PendingUS20190202122A1Improve build speedFine detail improvedAdditive manufacturing apparatusIncreasing energy efficiencyLaser lightMelt temperature

An object build area is exposed to a radiation beam, such as a laser light source, which has been processed and controlled through a grating light valve or valves, or planar light valve, to thereby melt, sinter, fuse or cure predetermined portions of the build area corresponding to the equivalent of individually controlled pixels, with rapid movement and positioning of the resulting LV application output array on the build area. The LV arrangement is adapted to also generally heat an entire powder bed, or targeted areas of the bed, to just below melting temperature.

Owner:EOS OF NORTH AMERICA INC +1

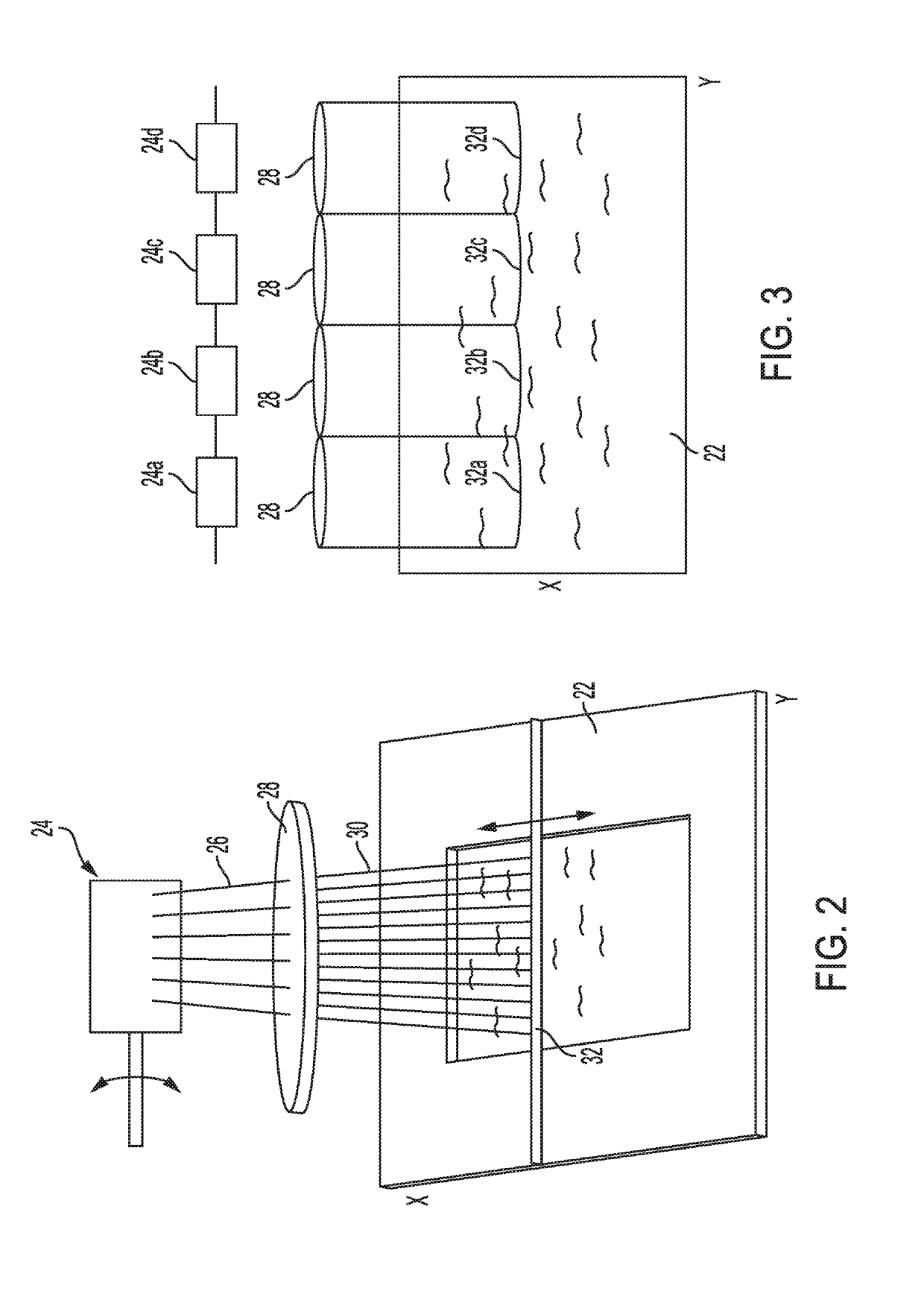

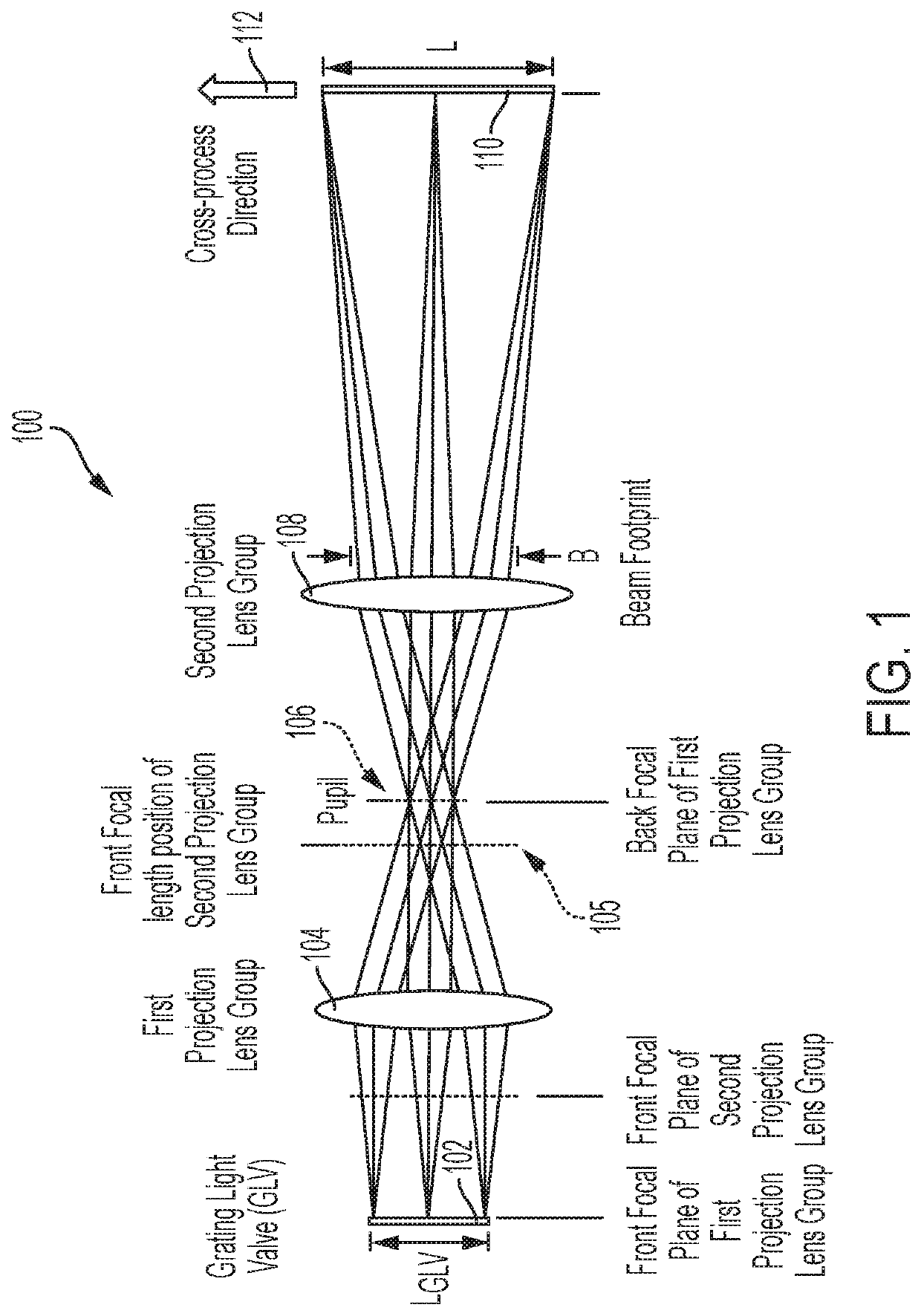

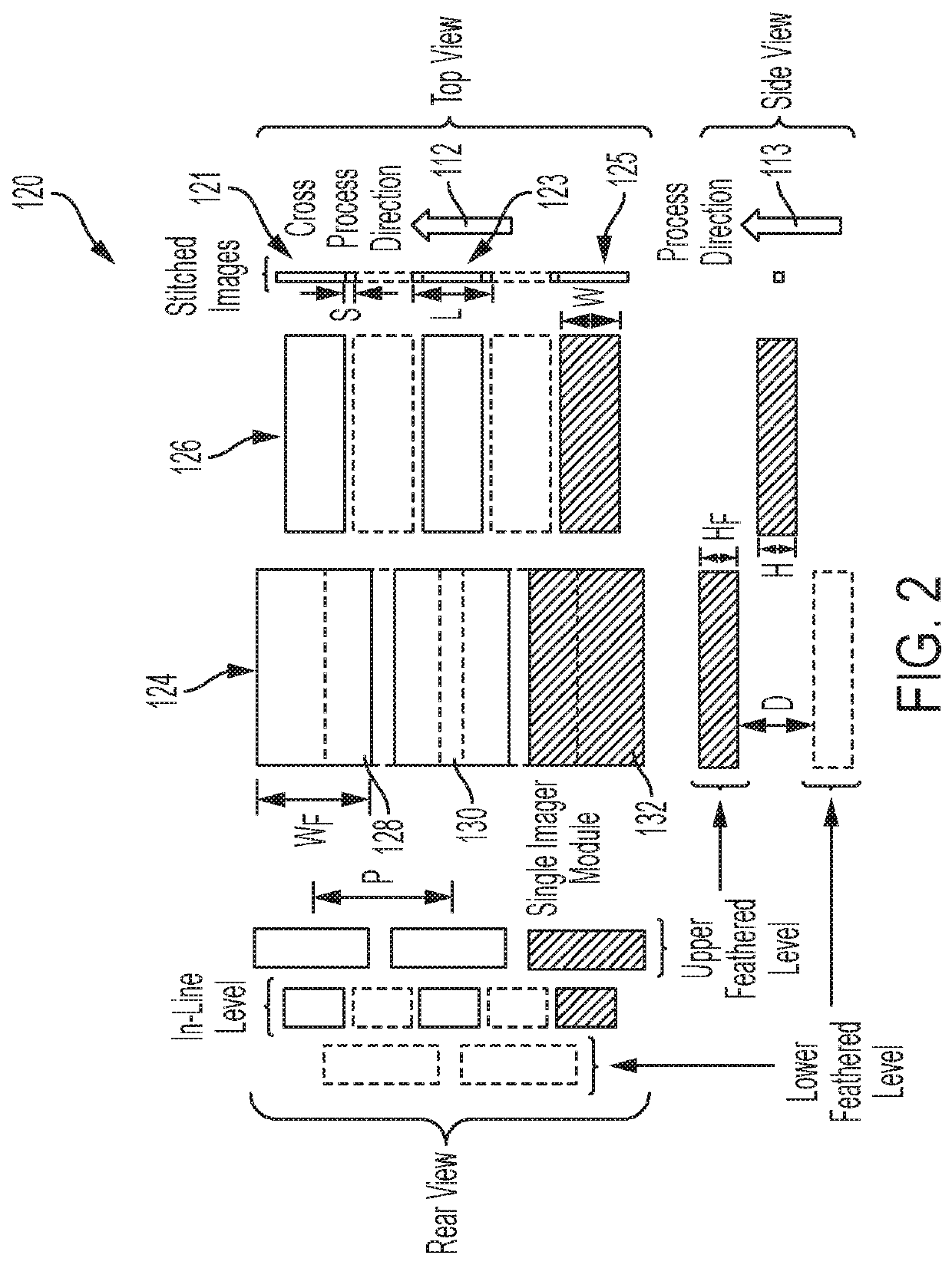

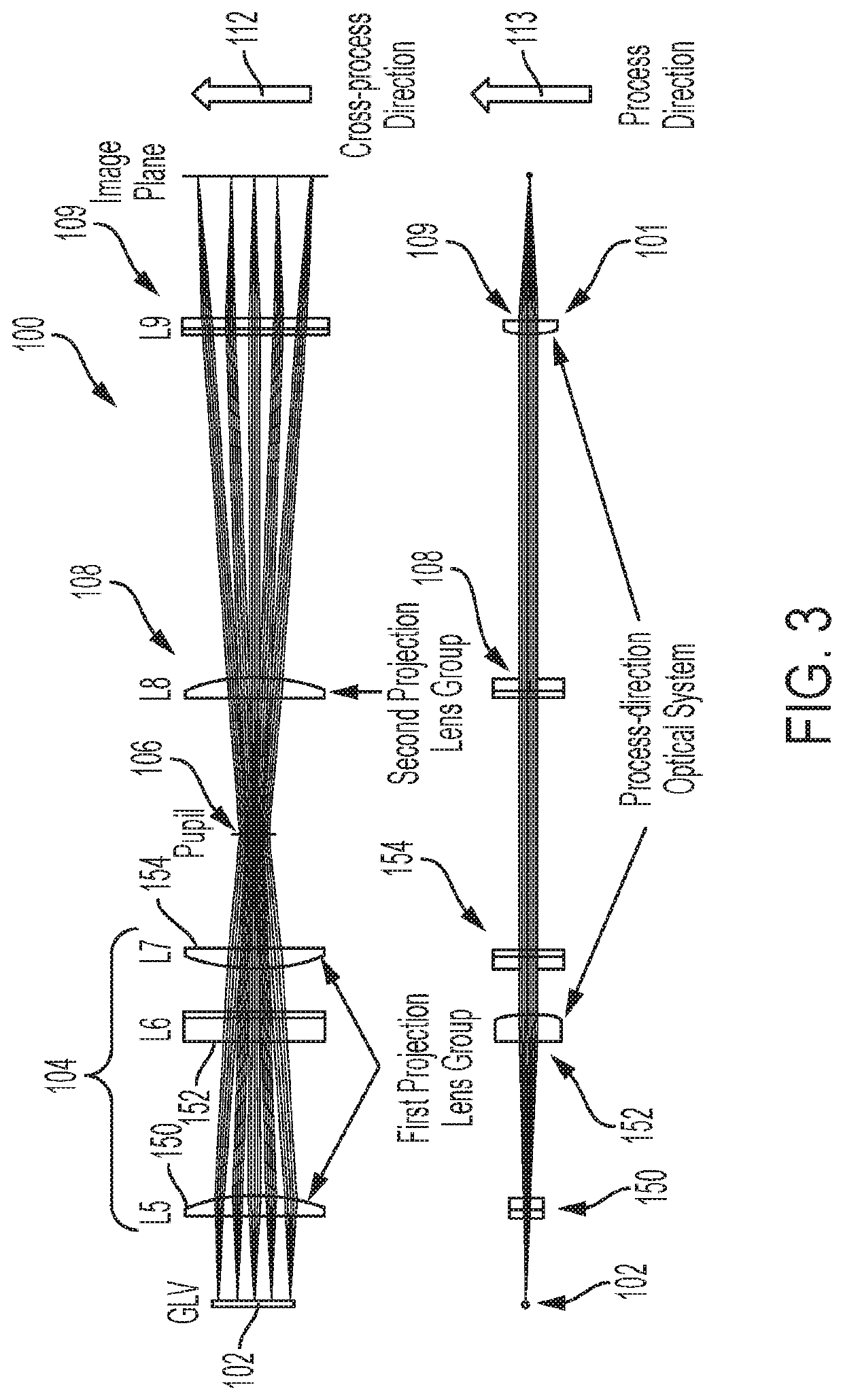

In-line stitched image optical system architecture for glv laser line imagers

ActiveUS20220011566A1Easy to optimizeAvoid mechanical interferencePicture reproducers using projection devicesPrintingSpatial light modulatorLaser light

An optical imager system and method of operating the optical imager system, can include one or more imager modules including a laser light source, a collimator, an illumination optical system, a grating light valve, a spatial light modulator and a projection optical system. A group of imager modules can include the one or more imager modules. The group of imager modules is operable in a stacked arrangement to produce an image from in-line stitching of individual images generated by the one or more imager modules. The illumination optical system can homogenize, shape, and direct a beam from the laser light source onto the grating light valve, and homogenization can occur in a cross-process direction.

Owner:XEROX CORP

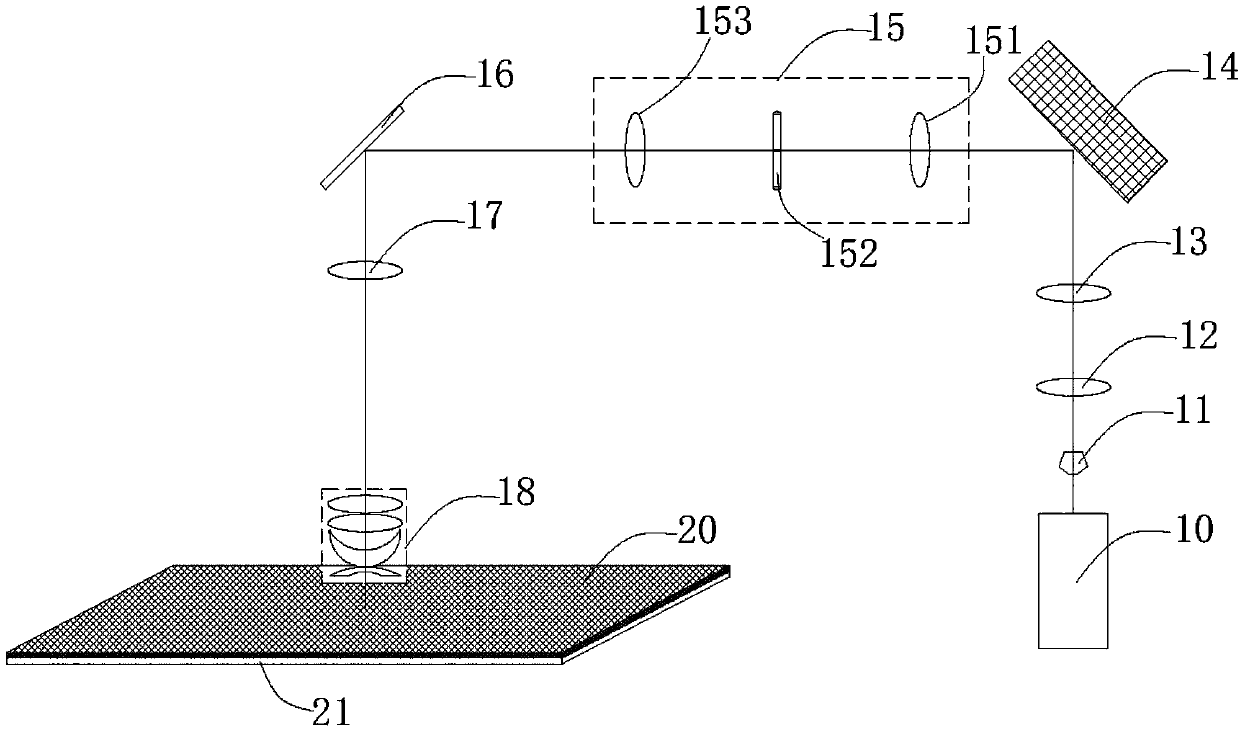

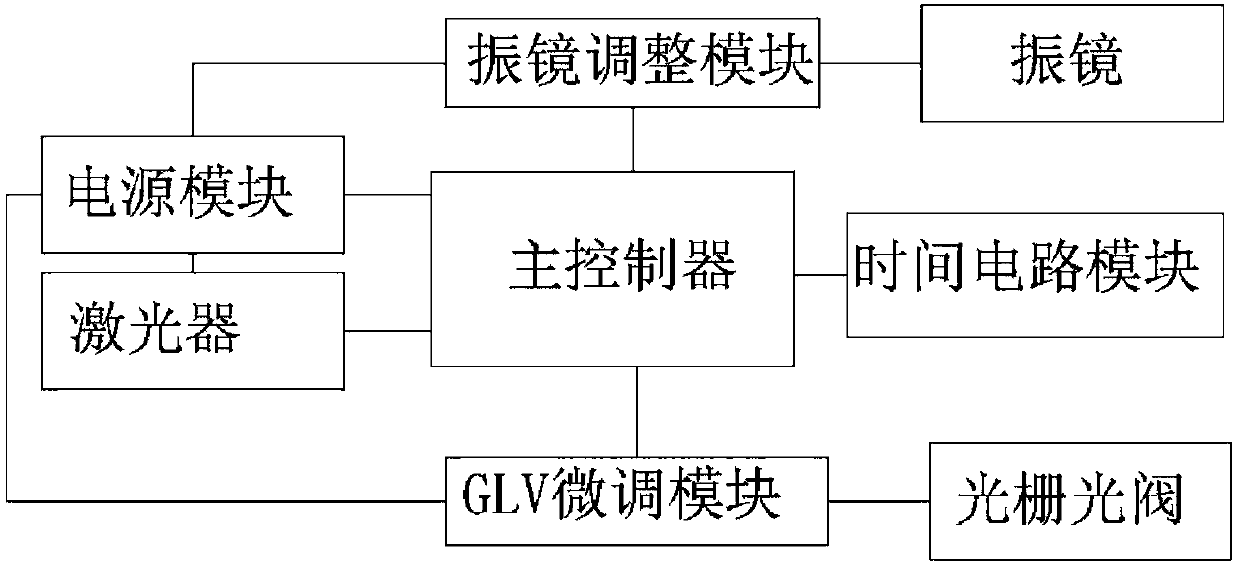

Semipermeable membrane mask plate LCVD repair system

PendingCN107678244AImplement patchingControl timeOriginals for photomechanical treatmentLight spotLaser scanning

The invention discloses a semipermeable membrane mask plate LCVD repair system. By adopting a laser scanning mode, the scanning light spot is smaller than 1 micron, and a chromium layer with controllable thickness and uniformity can be scanned and deposited uniformly, so that semipermeable membrane mask plate repair is realized. The repair system comprises a laser device, an optical grating lightvalve, a filtering assembly, a galvanometer and an objective lens assembly, wherein a light source emitted by the laser device is shaped into a linear light source; the linear light source is reflected after being irradiated onto the optical grating light valve to form a uniform linear light source; the uniform liner light source is gathered and irradiated onto the mask plate through the objectivelens assembly after being irradiated into the objective lens; the mask plate is arranged on an XY platform; a square uniform laser scanning light spot is formed by the objective lens on the mask plate; chromium carbonyl is decomposed, and chromium is deposited onto the mask plate.

Owner:深圳清溢光电股份有限公司

Substrate tuning system and method using optical projection

ActiveUS9735067B2Improve temperature uniformityScaling continuesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGrid basedOptoelectronics

Techniques herein include systems and methods that provide a spatially-controlled or pixel-based projection of light onto a substrate to tune various substrate properties. A given pixel-based image projected on to a substrate surface can be based on a substrate signature. The substrate signature can spatially represent non-uniformities across the surface of the substrate. Such non-uniformities can include energy, heat, critical dimensions, photolithographic exposure dosages, etc. Such pixel-based light projection can be used to tune various properties of substrates, including tuning of critical dimensions, heating uniformity, evaporative cooling, and generation of photo-sensitive agents. Combining such pixel-based light projection with photolithographic patterning processes and / or heating processes improves processing uniformity and decreases defectivity. Embodiments can include using a digital light processing (DLP) chip, grating light valve (GLV), or other grid-based micro projection technology.

Owner:TOKYO ELECTRON LTD

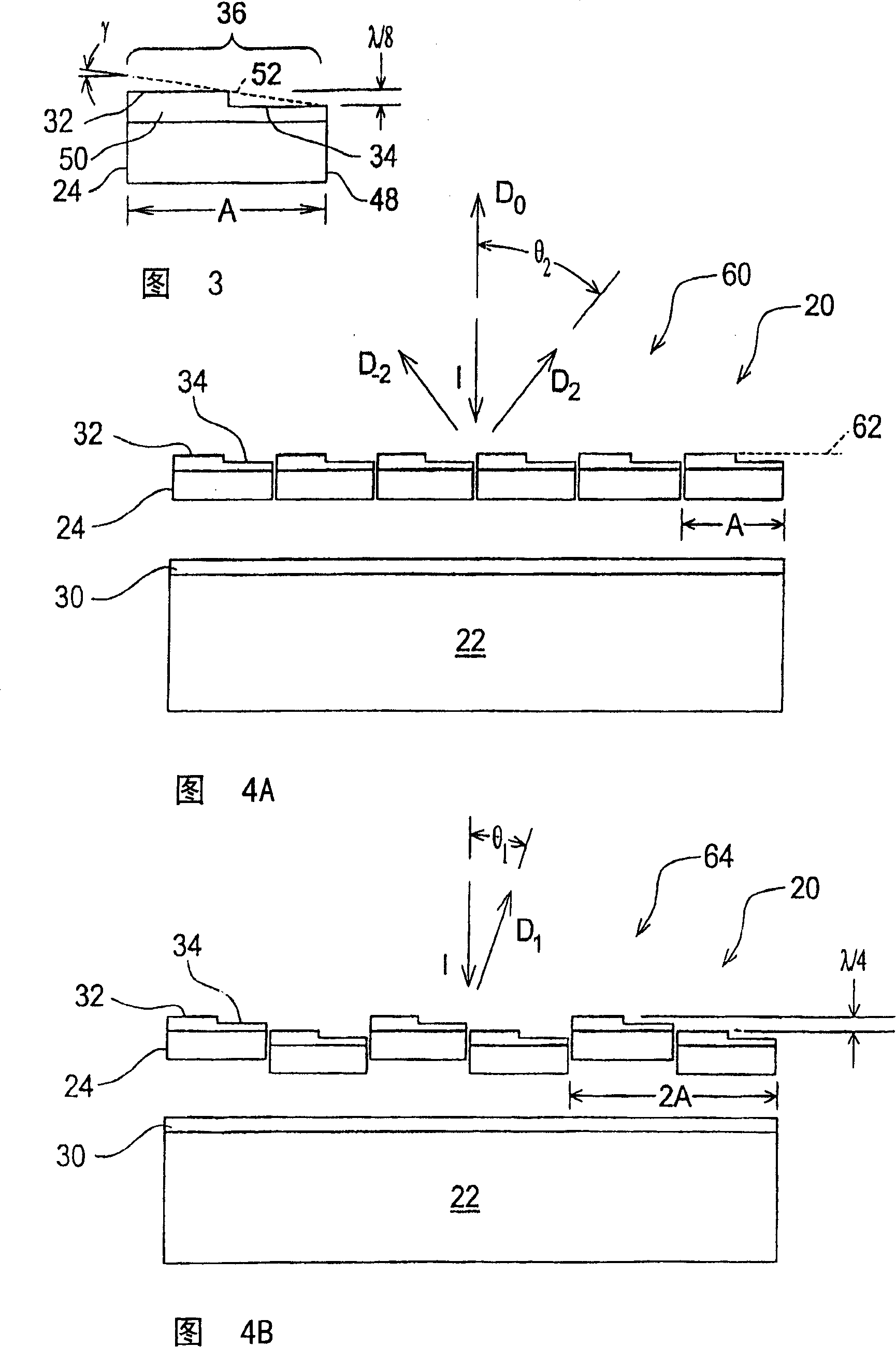

Blazed grating light valve

InactiveUS6896822B2Optical articlesSemiconductor/solid-state device manufacturingElectricityDiffraction order

A light modulator includes elongated elements arranged parallel to each other. In a first diffraction mode, the light modulator operates to diffract an incident light into at least two diffraction orders. In a second diffraction mode, the light modulator operates to diffract the incident light into a single diffraction order. Each of the elongated elements comprises a blaze profile, which preferably comprises a reflective stepped profile across a width of each of the elongated elements and which produces an effective blaze at a blaze angle. Alternatively, the blaze profile comprises a reflective surface angled at the blaze angle. Each of selected ones of the elongated elements comprise a first conductive element. The elongated elements produce the first diffraction when a first electrical bias is applied between the first conductive elements and a substrate. A relative height of the blazed portions are adjusted to produce the second diffraction when a second electrical bias is applied between the first conductive elements and the substrate. In an alternative embodiment, each of the elongated elements includes the first conductive element and multiple elongated elements are arranged in groupings, where each of the groupings includes at least three of the elongated elements. When the multiple elongated elements are at a first height, the incident light reflects from the elongated elements. When relative heights of the multiple elongated elements are adjusted by applying individual electrical biases between the first conductive elements and the substrate, the incident light diffracts into the single diffraction order.

Owner:SILICON LIGHT MACHINES CORP

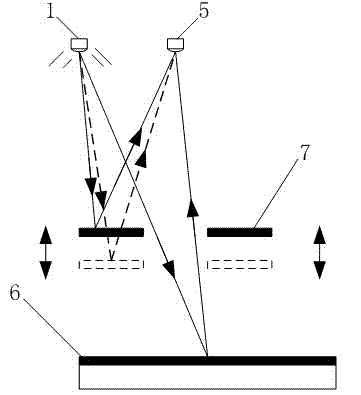

Translational grating light valve Fourier spectrometer

ActiveCN102175327BImprove accuracyHigh precisionInterferometric spectrometryOptical elementsSpatial light modulatorLight energy

The invention provides a translational grating light valve Fourier spectrometer, in which an MEMS technology, a spectrum analysis technology and a Fourier digital transform technology are used; a system comprises a light source, an imaging system, a programmable spatial light modulator array and a single detector; a wave surface from a laser wave surface to a modulator is divided, a portion of light is reflected from an upper surface while the other portion of light is reflected from a lower surface, and the two light beams are coherent light and interfere with each other; the altitude difference between the upper surface and the lower surface of the programmable spatial light modulator can be changed by electrostatic actuation, sequentially, the optical path difference of the coherent light is changed, and interference fringe modulation is implemented; the change of light energy is detected by the single detector, sample information is measured by the Fourier digital transform technology and an optical path difference correction technology; and a conventional light-splitting grating or ion beam splitter is unnecessary, a single device has the dual function of light splitting and gating, the system is simplified, and the light path is shortened, so that the spectrometer is more compact in structure and high in integrated level, and can be widely used in various production researches.

Owner:CHONGQING UNIV

256-grating light head device

ActiveCN103345136AEasy to produceLow production costElectrographic process apparatusLight spotResponse Frequency

The invention discloses a 256-grating light head device. The 256-grating light head device comprises a shell, a position regulation mechanism, a transducer module, a reflecting diaphragm, a reflecting mirror module and a laser module, wherein the reflecting mirror module is positioned at one end of the shell; the transducer module is arranged at the other end of the shell; the reflecting diaphragm is arranged between the transducer module and the reflecting mirror module; the laser module is arranged at one end of the upper part of the shell; the position regulation mechanism is arranged at the other end of the upper part of the shell. The response frequency of a modulator exceeds 10MHz, and the modulator is controlled by using ultrasonic waves. Compared with a device such as a grating light valve (GLV), the modulator has the advantages that a switch response speed exceeds over 10 times; ideal square light spots can be accurately generated. An ultrasonic acousto-optic modulator is applied to the industries of communication and the like for dozens of years, and is mature in production process, low in manufacturing cost and suitable for batch production.

Owner:AMSKY TECHNOLOGY CO LTD

Blazed grating light valve

Owner:SILICON LIGHT MACHINES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com