Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83 results about "Focus variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Focus variation is a method to calculate a sharp image and to measure the depth with an optics with limited depth of field.

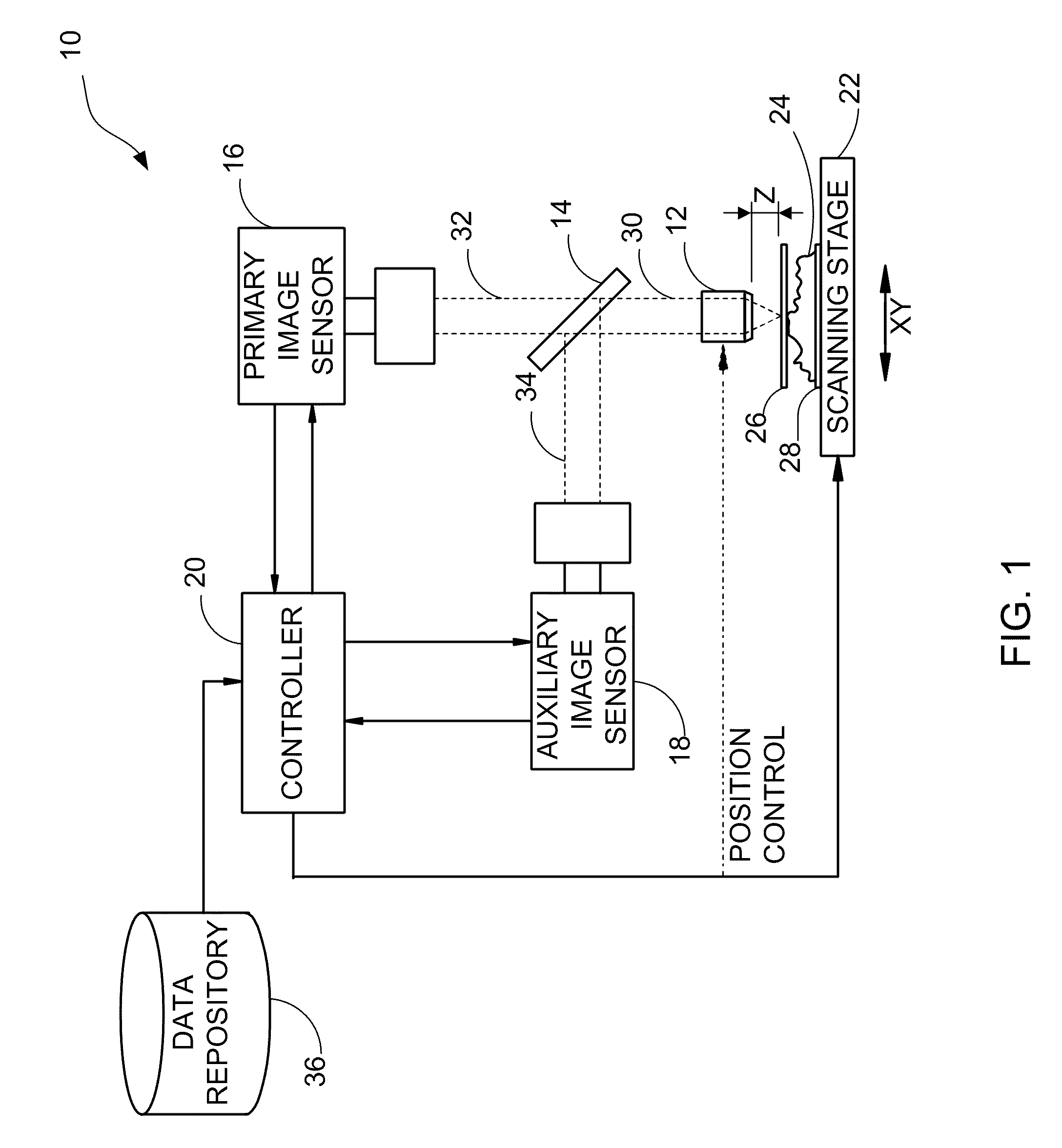

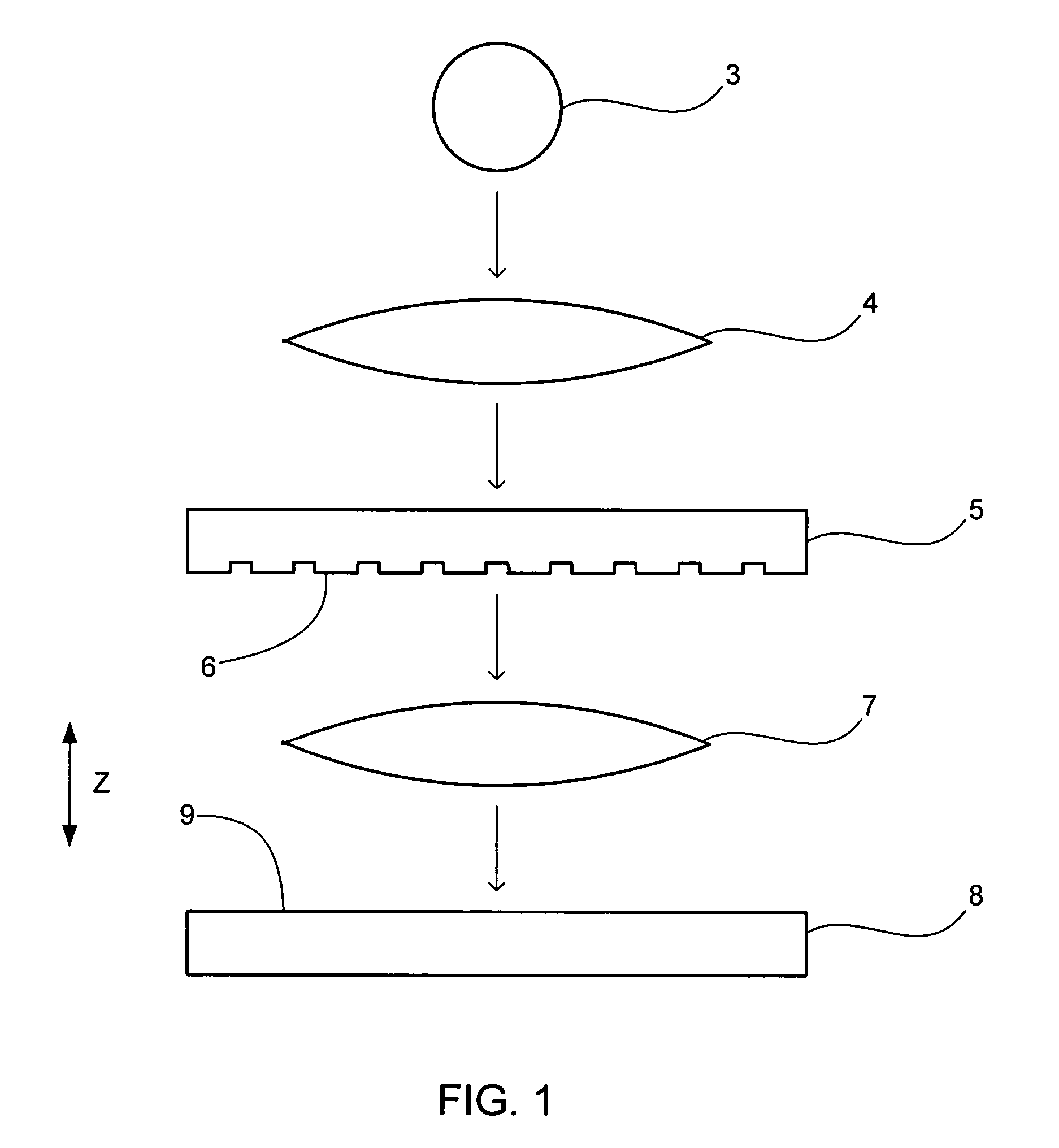

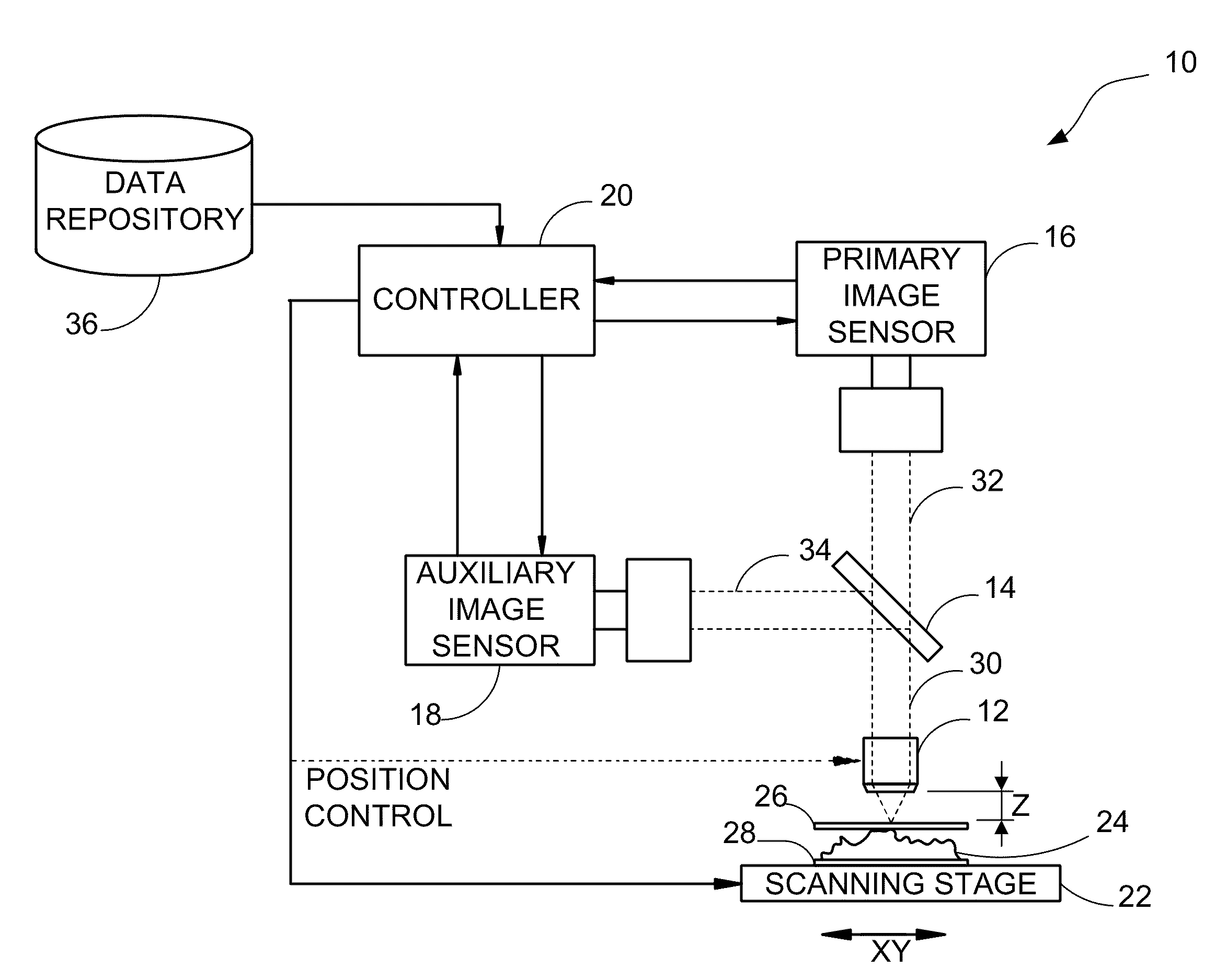

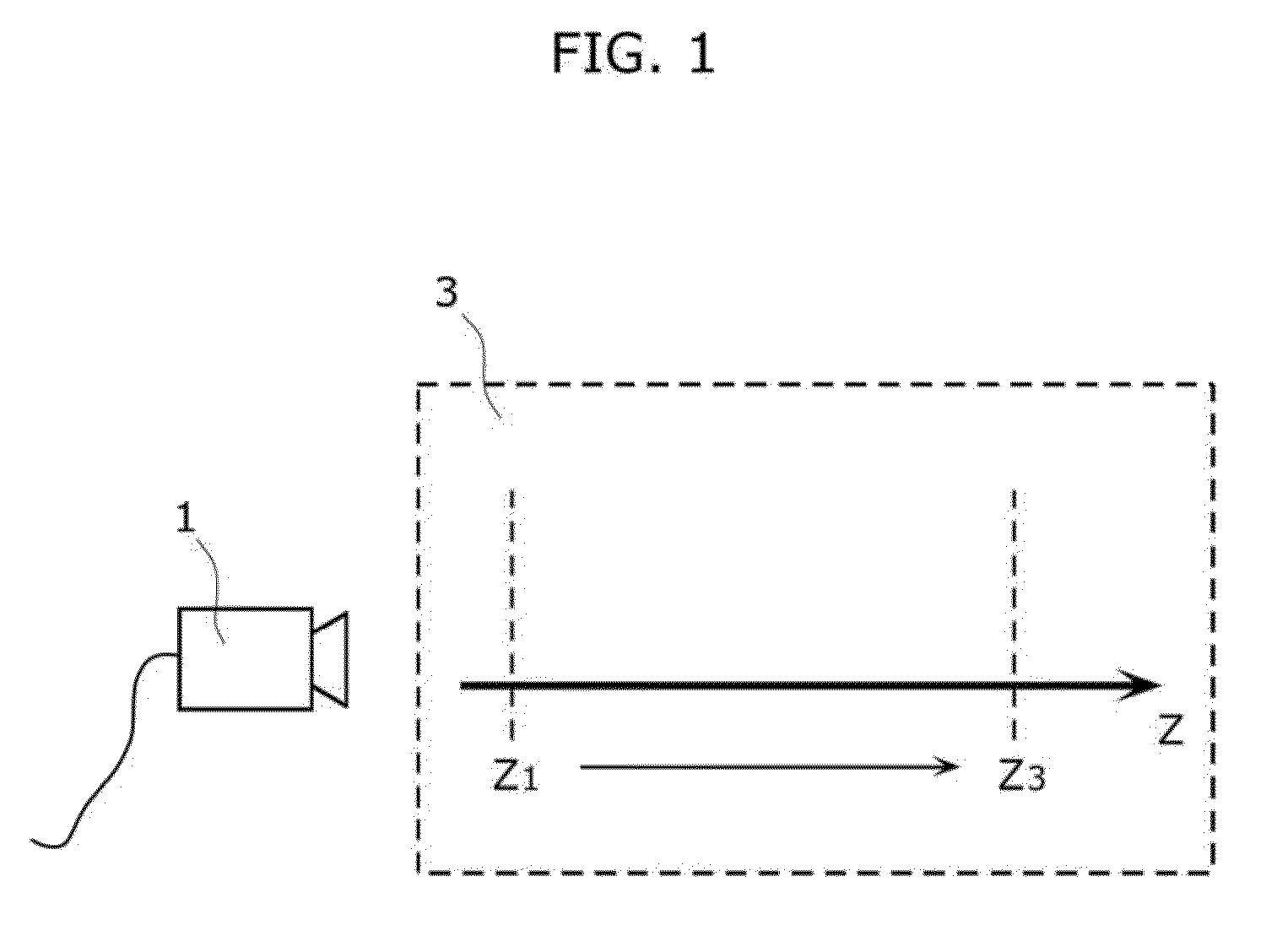

System and Method for Enhanced Predictive Autofocusing

In an imaging device having an objective and a stage for holding a sample to be imaged, a method for autofocusing is presented. The method includes determining a measured focus value corresponding to at least a first of a plurality of logical image segments. Further, the method includes imaging the first logical image segment using the measured focus value. The method also includes determining a predicted focus value for a second of the plurality of logical image segments using the measured focus value and a stored focus variation parameter. In addition, the method includes imaging the second logical image segment using the predicted focus value.

Owner:LEICA MICROSYSTEMS CMS GMBH

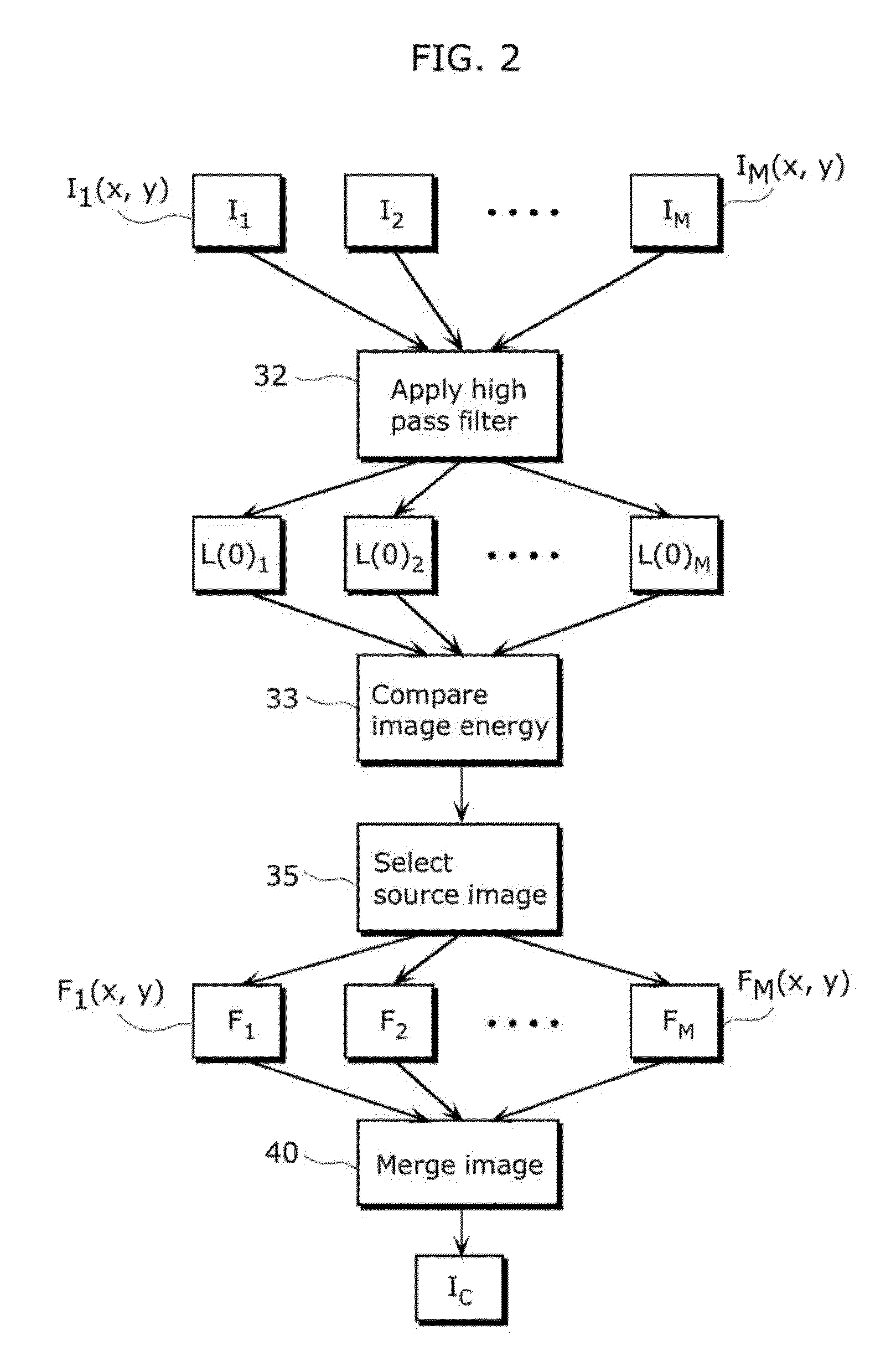

Image capturing device, image capturing method, program, and integrated circuit

InactiveUS20120281132A1Easy to operateReduce confusionImage enhancementTelevision system detailsSignal-to-noise ratio (imaging)Image resolution

An image capturing device includes: a pre-capturing module which captures an imaging target at each of different focus positions in a predetermined focus range and outputs, as a capturing result, a plurality of pre-captured images lower in resolution than the output image; an object sharpness evaluating module which computes a sharpness level of each of the pre-captured images captured by the pre-capturing module; a focus varying range determining module which determines a focus position varying range within the predetermined focus range based on sharpness levels computed by the object sharpness evaluating module, such that a signal-to-noise ratio of the output image is greater than or equal to a predetermined threshold; and an image capturing module which captures the imaging target while varying the focus position according to the focus position varying range determined by the focus varying range determining module, and outputs the output image as a capturing result.

Owner:SOVEREIGN PEAK VENTURES LLC

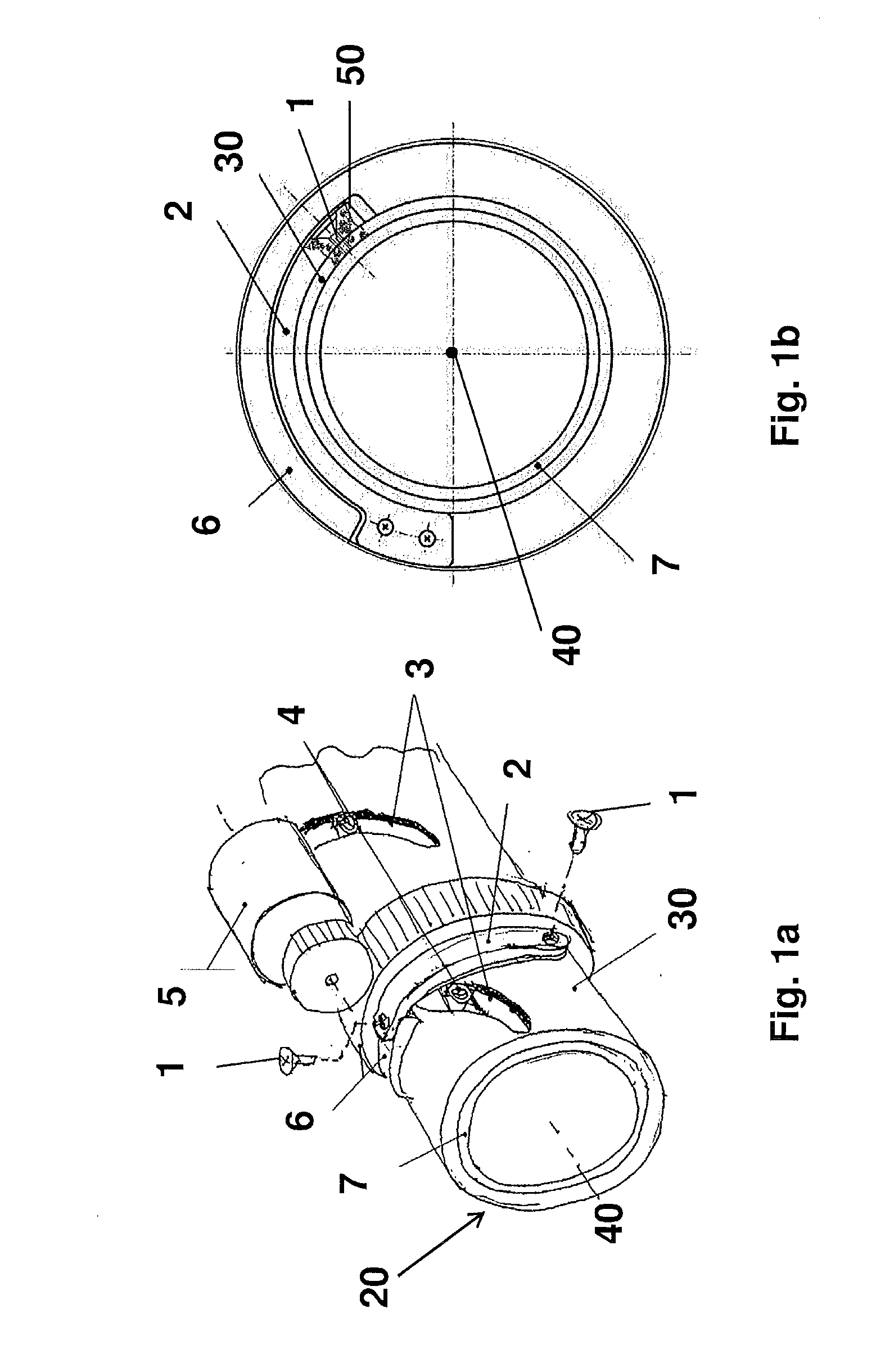

Lens assembly with integrated feedback loop for focus adjustment

This invention provides a removably mountable lens assembly for a vision system camera that includes an integral auto-focusing liquid lens unit, in which the lens unit compensates for focus variations by employing a feedback control circuit that is integrated into the body of the lens assembly. The feedback control circuit receives motion information related to the bobbin of the lens from a position sensor (e.g. a Hall sensor) and uses this information internally to correct for motion variations that deviate from the lens setting position at a desired lens focal distance setting. Illustratively, the feedback circuit can be interconnected with one or more temperature sensors that adjust the lens setting position for a particular temperature value. In addition, the feedback circuit can communicate with an accelerometer that reads a direction of gravity and thereby corrects for potential sag in the lens membrane based upon the spatial orientation of the lens.

Owner:COGNEX CORP

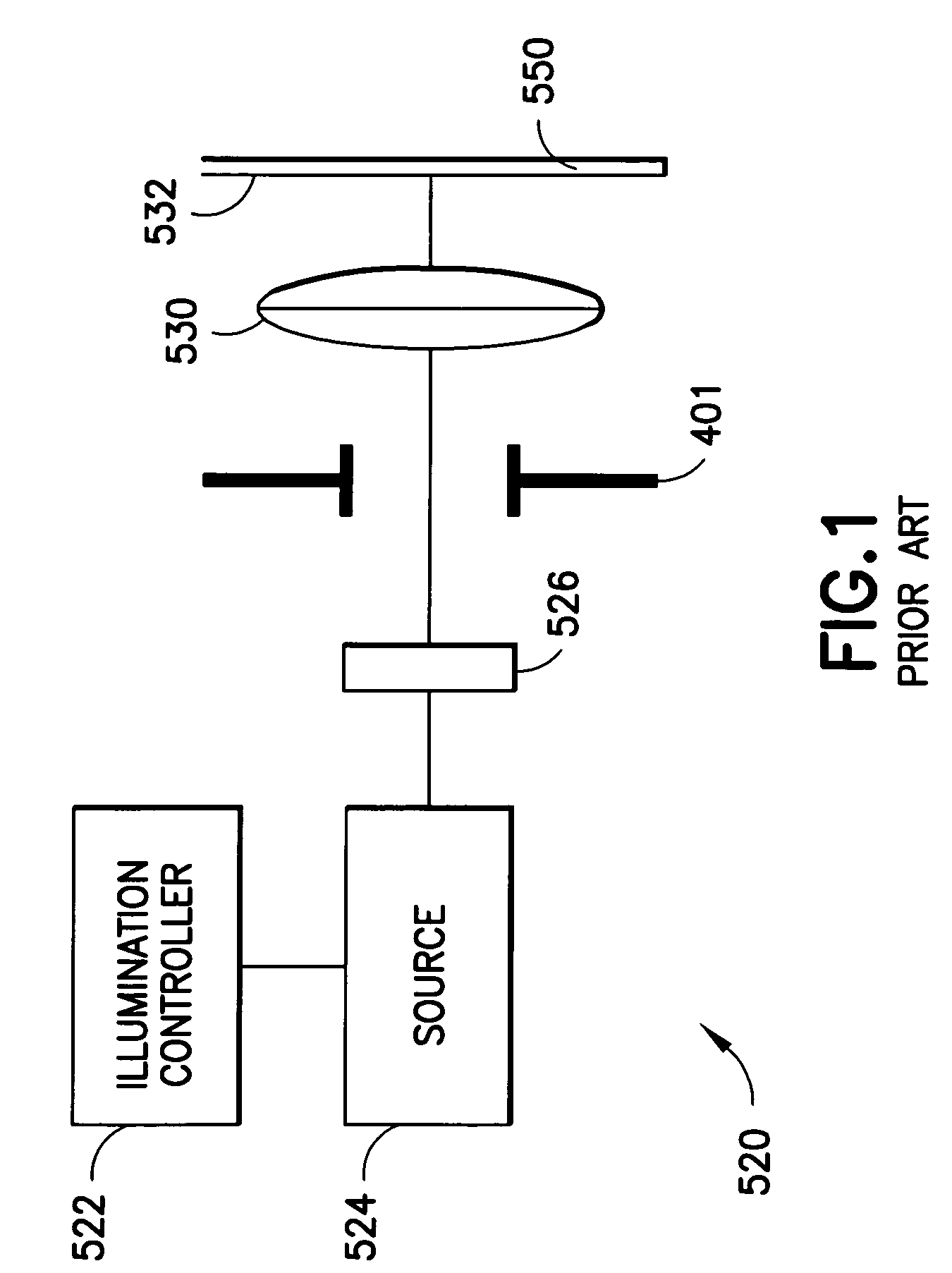

Printing a mask with maximum possible process window through adjustment of the source distribution

InactiveUS7057709B2Reduce lossesSemiconductor/solid-state device manufacturingUsing optical meansLight beamComputational physics

A lithographic mask is illuminated with light from different directions such that intensities of a plurality of incident beams of light provide a largest possible integrated process window defined in terms of an allowed range for defining shapes. Constrained sets of intensity parameters are imposed. A first set of intensity parameters represents maximum possible intensities that can be permitted for overexposed tolerance positions. A second set of intensity parameters represents minimum possible intensities that can be permitted for underexposed tolerance positions. Optimum source intensities of incident beams are defined using a linear program and constraints. The optimum source intensities maximize an integrated range of dose and focal variations without causing printed shapes to depart from the allowed range. Apparatus are detailed and variations are described.

Owner:GLOBALFOUNDRIES INC

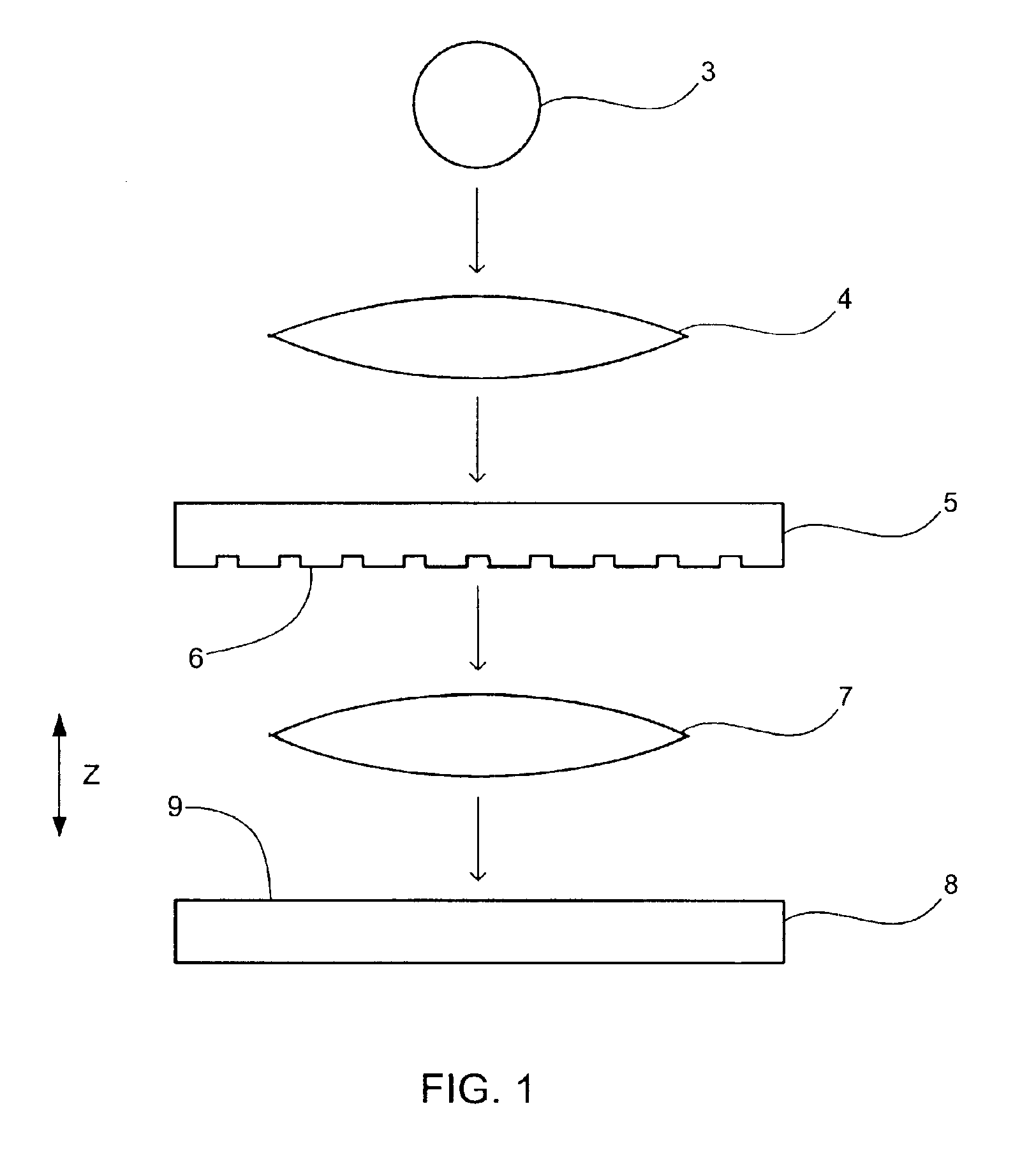

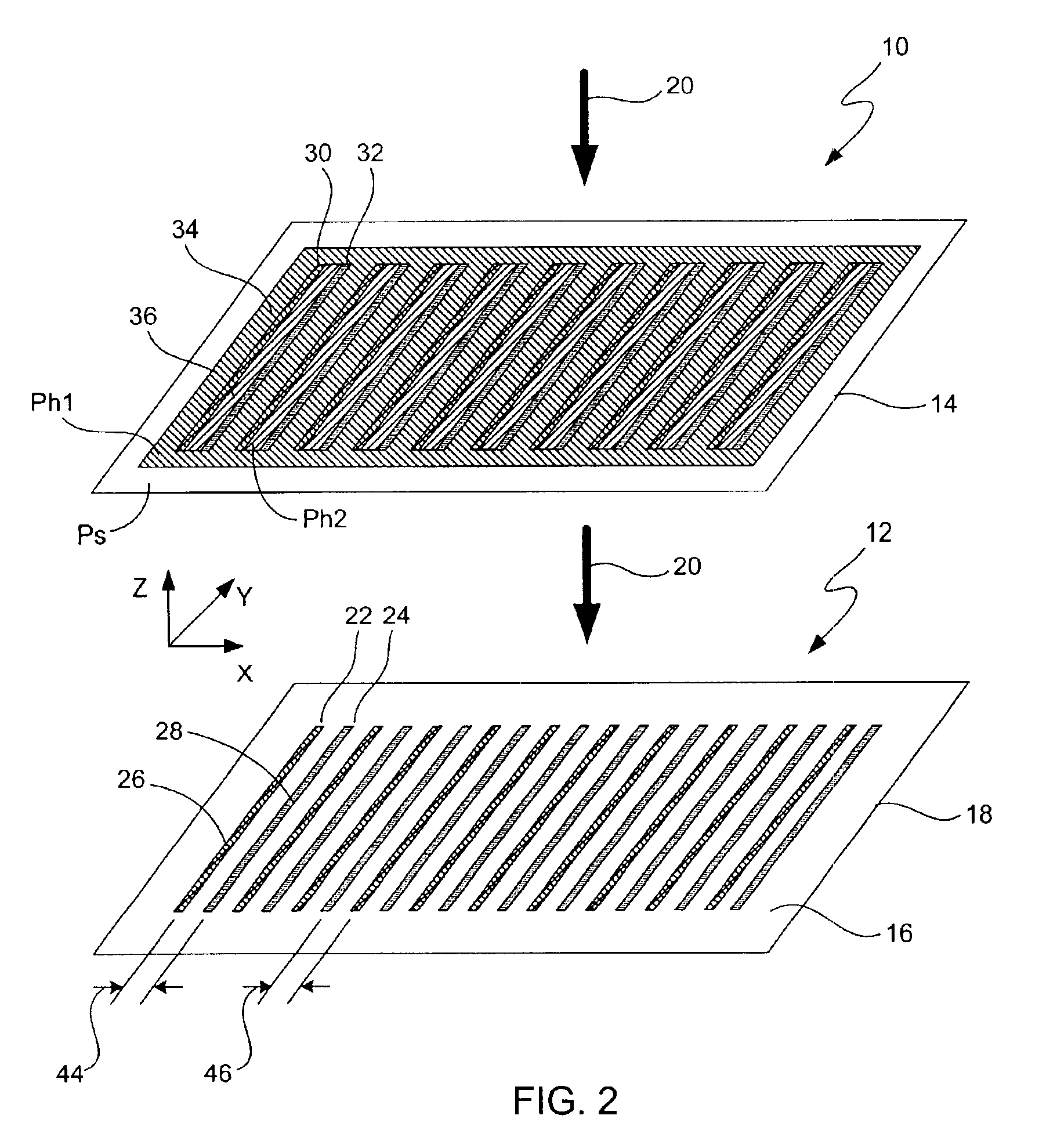

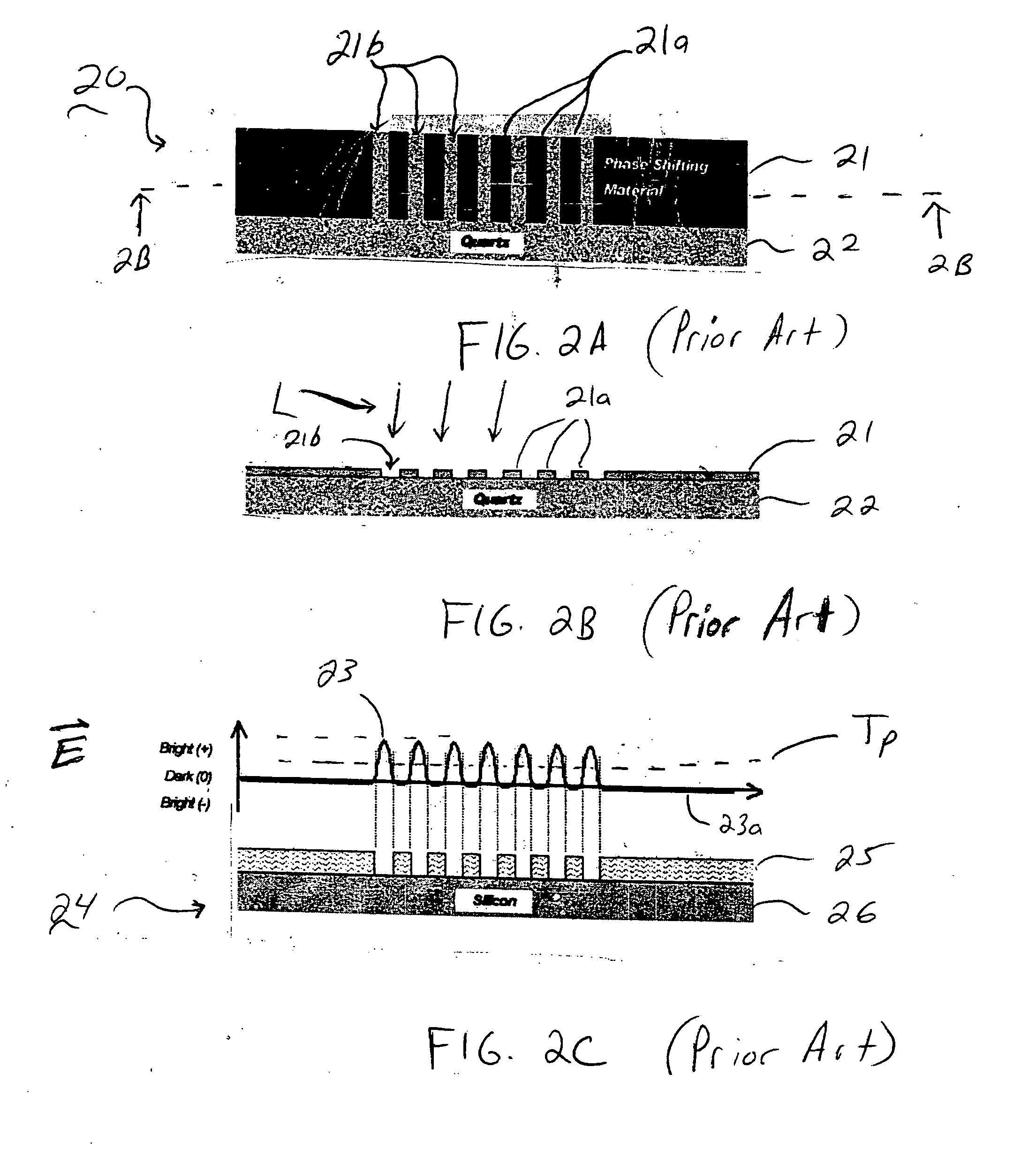

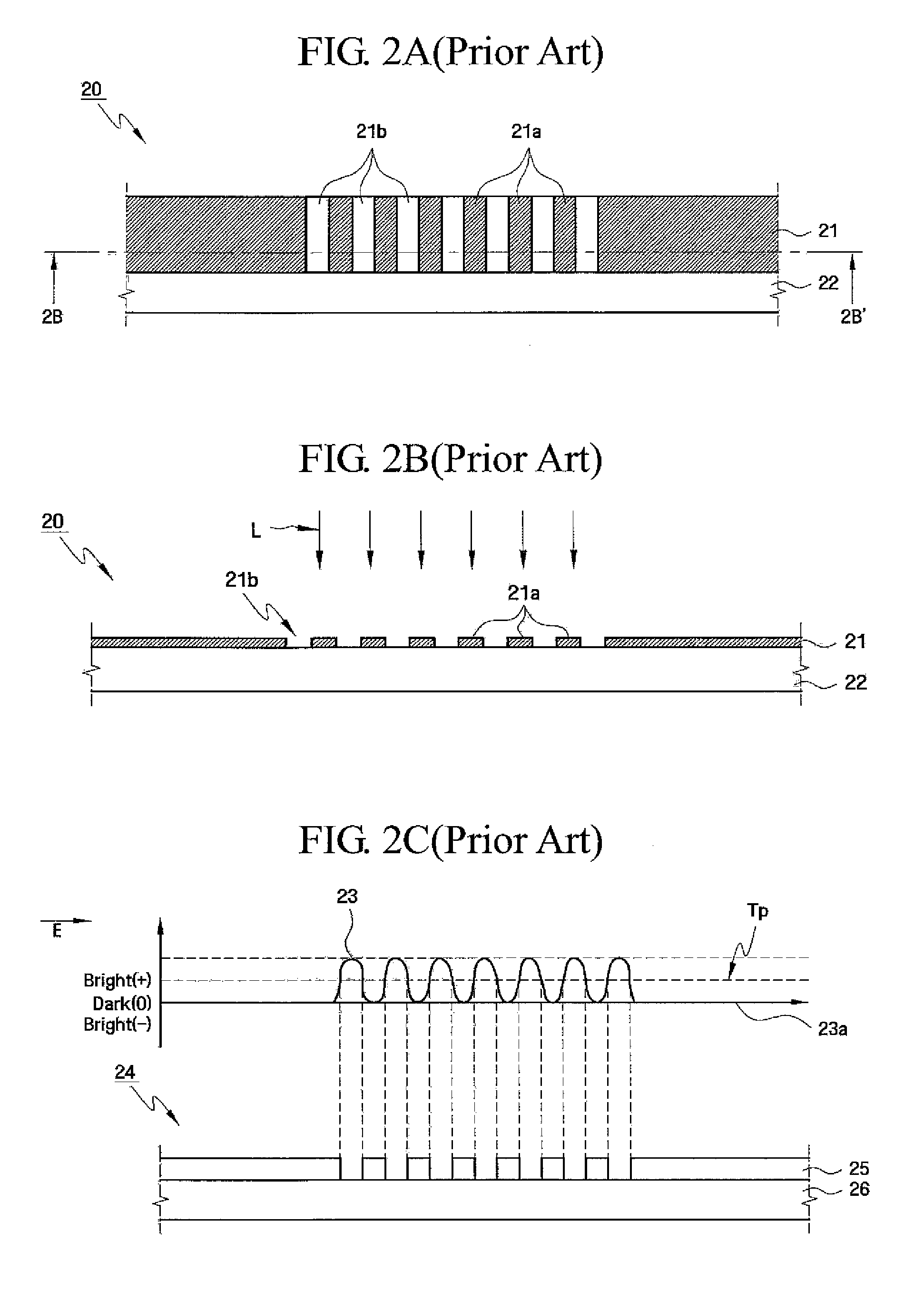

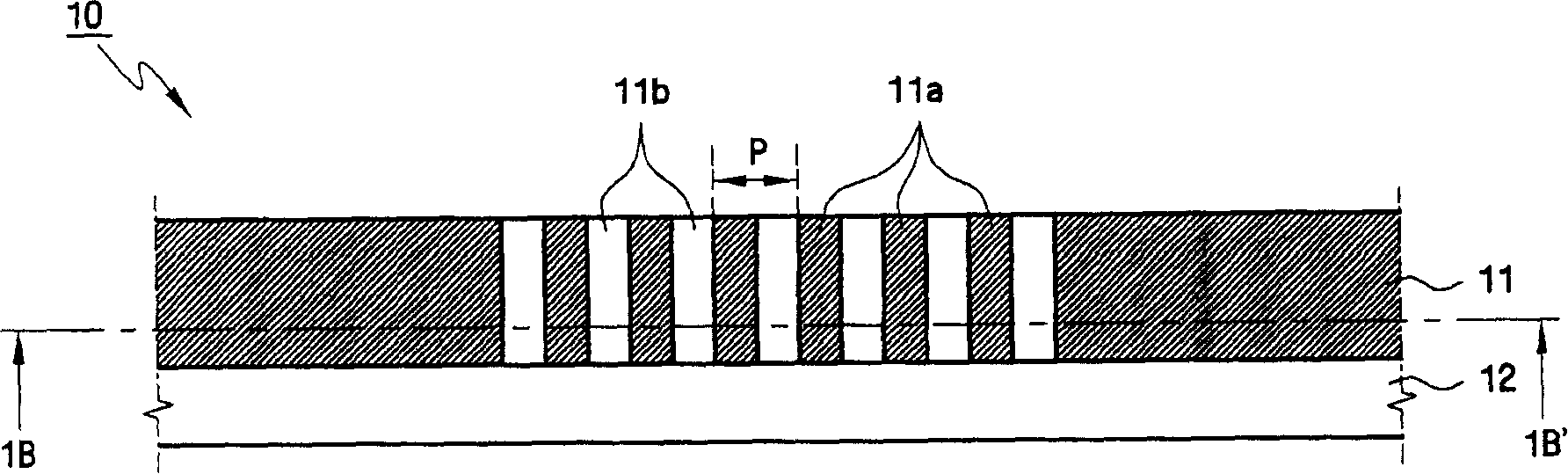

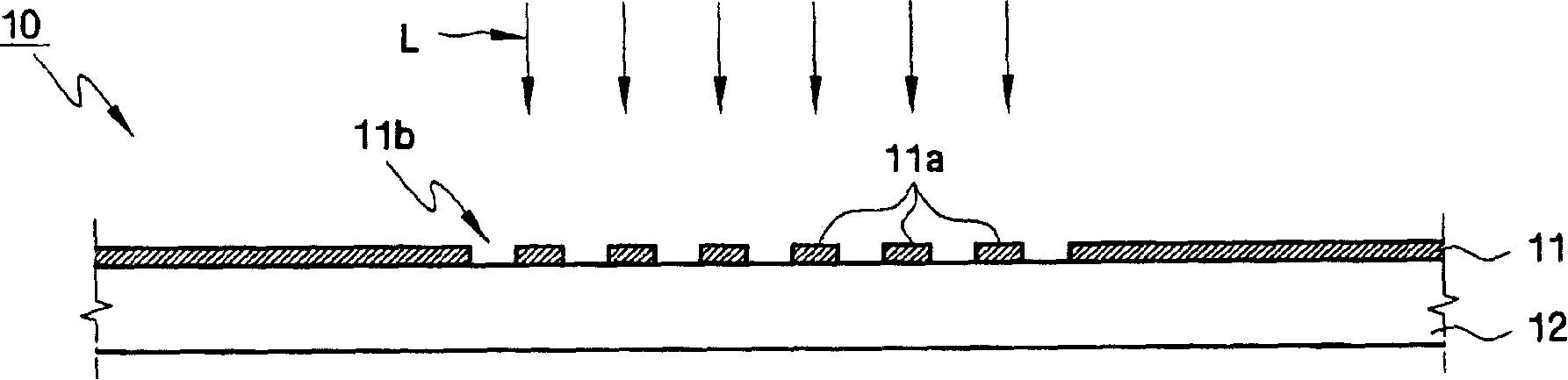

Focus masking structures, focus patterns and measurements thereof

InactiveUS7175945B2Testing sensing arrangementsSemiconductor/solid-state device manufacturingPhase shiftedEngineering

Methods and device structures used to determine the focus quality of a photolithographic pattern or a photolithographic system are disclosed. One aspect of the invention relates to focus masking structures configured to form focus patterns that contain focus information relating to the focus quality. The focus masking structures generally include a plurality of parallel source lines that are separated by alternating phase shift zones. Another aspect of the invention relates to focus patterns that change with changes in focus. The focus patterns generally include a plurality of periodic structures that form measurable shifts therebetween corresponding to the sign and magnitude of defocus. Another aspect of the invention relates to a method of determining the focus quality of a photolithographic pattern or a photolithographic system. The method generally includes: providing a focus masking structure, forming a focus pattern on a work piece with the focus masking structure, and obtaining focus information from the focus pattern. The focus information may be obtained using a variety of techniques, as for example, scatterometry techniques, scanning techniques, imaging techniques, phase based techniques, and the like.

Owner:KLA CORP

Focus masking structures, focus patterns and measurements thereof

InactiveUS6884552B2Testing sensing arrangementsSemiconductor/solid-state device manufacturingPhase shiftedEngineering

Methods and device structures used to determine the focus quality of a photolithographic pattern or a photolithographic system are disclosed. One aspect of the invention relates to focus masking structures configured to form focus patterns that contain focus information relating to the focus quality. The focus masking structures generally include a plurality of parallel source lines that are separated by alternating phase shift zones. Another aspect of the invention relates to focus patterns that change with changes in focus. The focus patterns generally include a plurality of periodic structures that form measurable shifts therebetween corresponding to the sign and magnitude of defocus. Another aspect of the invention relates to a method of determining the focus quality of a photolithographic pattern or a photolithographic system. The method generally includes: providing a focus masking structure, forming a focus pattern on a work piece with the focus masking structure, and obtaining focus information from the focus pattern. The focus information may be obtained using a variety of techniques, as for example, scatterometry techniques, scanning techniques, imaging techniques, phase based techniques, and the like.

Owner:KLA TENCOR TECH CORP

System and method for enhanced predictive autofocusing

Owner:LEICA MICROSYSTEMS CMS GMBH

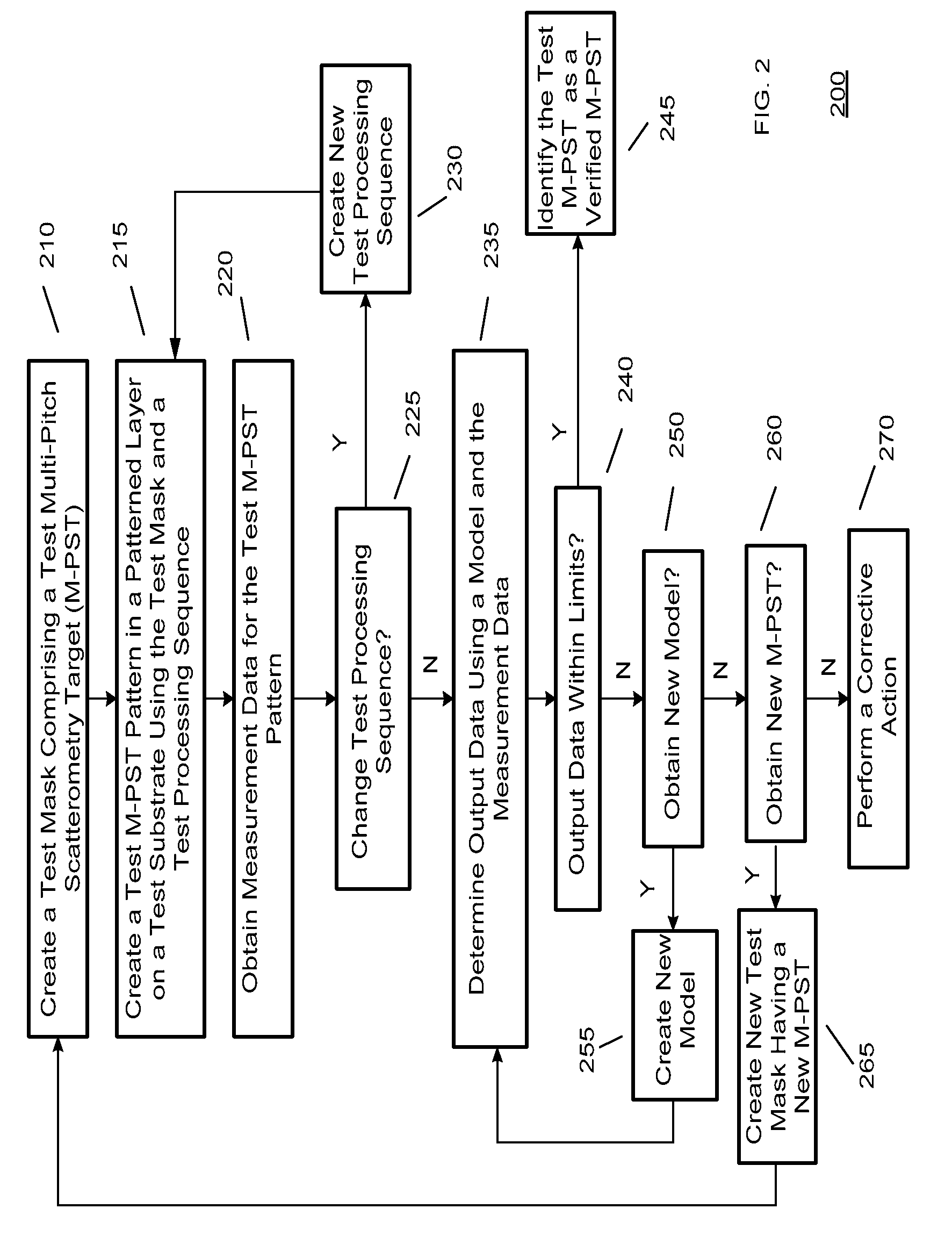

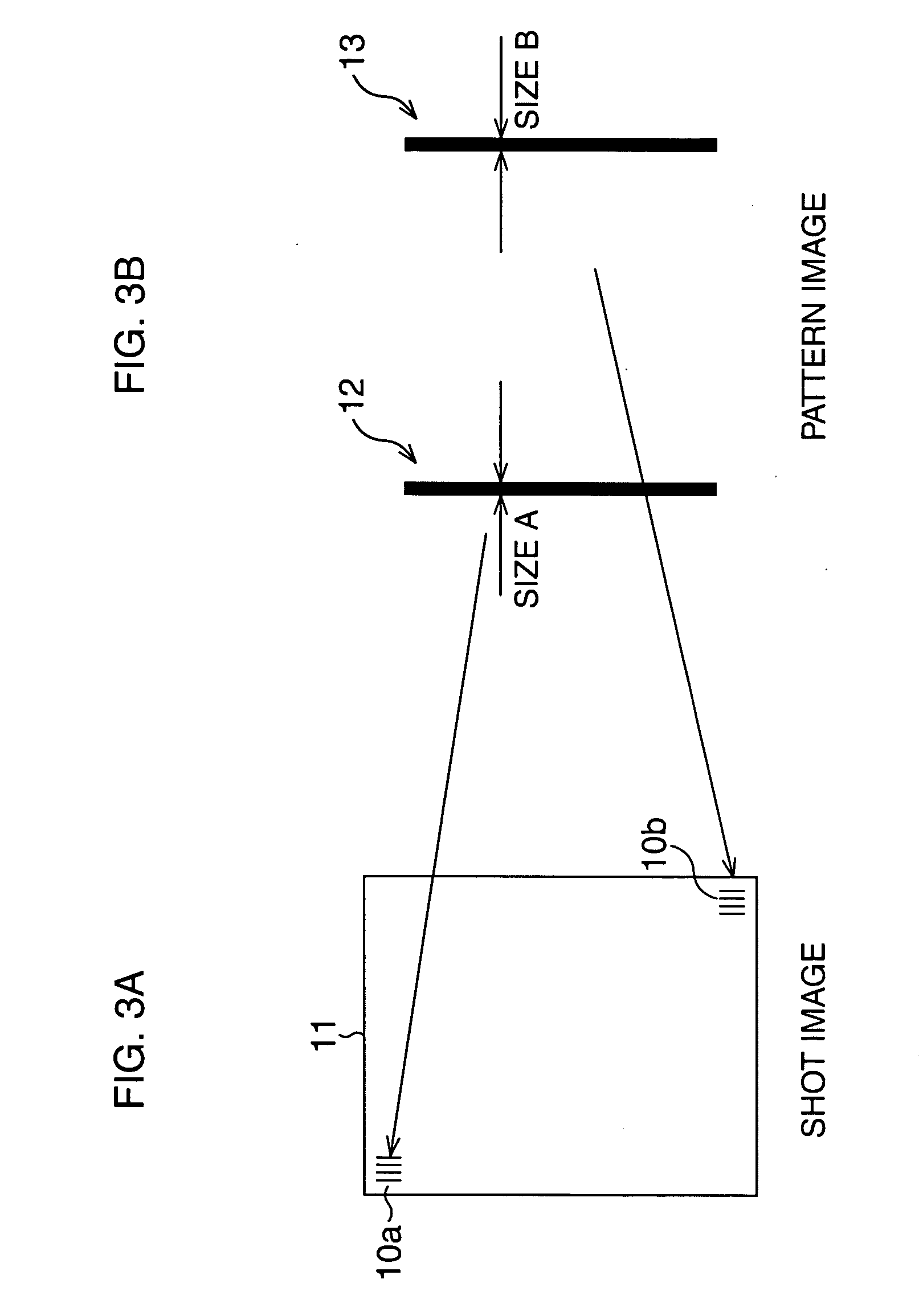

Systems and methods for detecting focus variation in photolithograph process using test features printed from photomask test pattern images

InactiveUS20060234136A1Semiconductor/solid-state device testing/measurementPhotomechanical apparatusEngineeringCritical dimension

Systems and methods are provided for detecting focus variation in a lithographic process using photomasks having test patterns adapted to print test features with critical dimensions that can be measured and analyzed to determine magnitude and direction of defocus from a best focus position of an exposure tool during the lithographic process.

Owner:SAMSUNG ELECTRONICS CO LTD

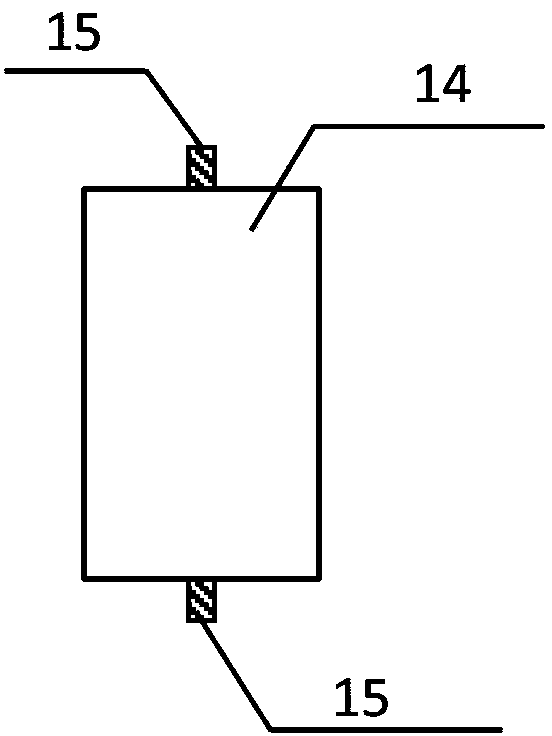

Liquid crystal lens element and optical head device

InactiveCN1914674AReduce thicknessImprove uniformityOptical beam sourcesRecord information storageOptical pickupOptical axis

The present invention provides liquid crystal lens element comprising no movable part, having a small size, having a lens function capable of being subjected to stable spherical aberration correction including the power component corresponding to the focus variation of the incident light. The liquid crystal lens element has a variable focal length to the light transmitted through a liquid crystal(16) interposed between a pair of transparent substrates(11, 12). The variable focal length can be varied with the voltage applied to the liquid crystal(16). The liquid crystal lens comprises transparent electrodes(13, 14) provided to the respective transparent substrates(11, 12) and used to apply a voltage to the liquid crystal(16) and an irregular part(17) which has a serrated cross section and a rotational symmetry with respect to the optical axis and is formed of a transparent material on one side of the transparent electrode(13). The liquid crystal(16) is placed at least in the recesses of the irregular part(17) so as to vary the substantial index of refraction of the liquid crystal(16) depending on the applied voltage.

Owner:ASAHI GLASS CO LTD

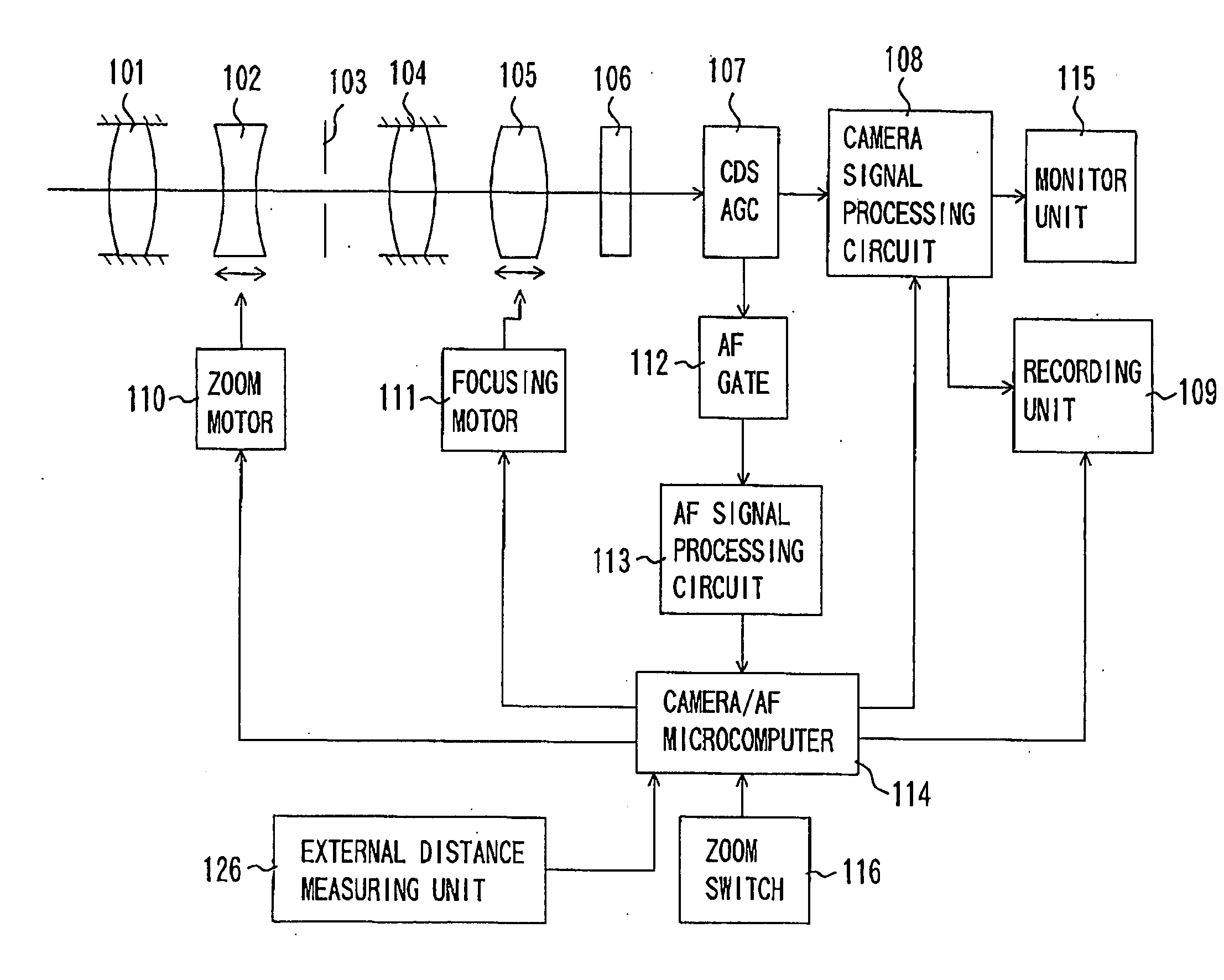

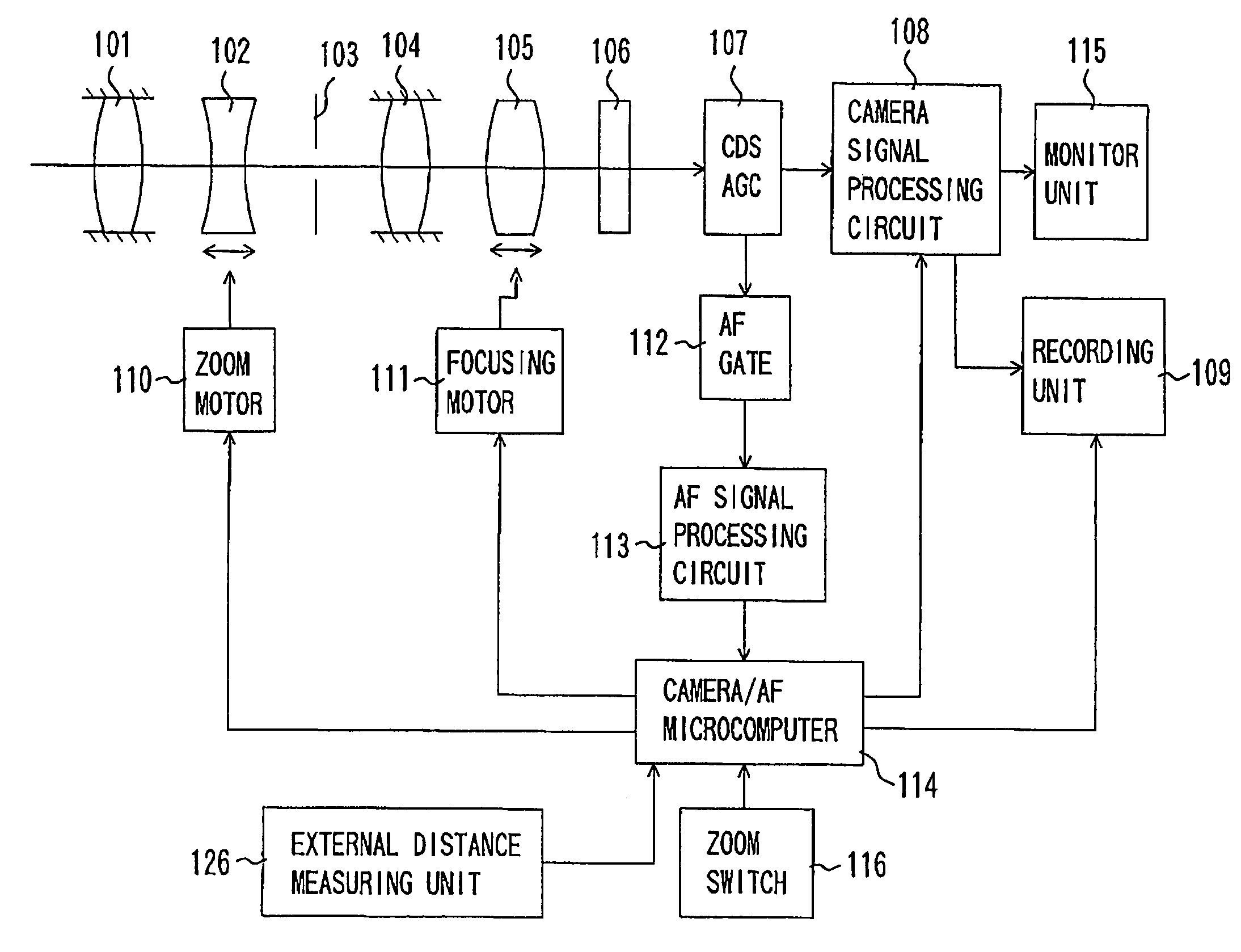

Image-taking apparatus

InactiveUS20050083429A1Improve accuracyShorten the timeTelevision system detailsColor television detailsFocus variationEngineering

An image-taking apparatus is disclosed which achieves focusing in a reduce time with higher accuracy of an in-focus position search in a TV-AF method to minimize occurrence of unnatural focus changes. The image-taking apparatus includes an image-taking element, a first detector which outputs a focus evaluation value signal based on a predetermined frequency component of an output signal of the image-pickup element, a second detector which outputs a detection signal different from the focus evaluation value signal, and a controller which performs first processing of obtaining information for an in-focus position search of the focus lens based on the focus evaluation value signal. The controller performs second processing of obtaining information on an in-focus position based on the detection signal from the second detector, and performs third processing different depending on a comparison result between the information from the first processing and the information obtained from the second processing.

Owner:CANON KK

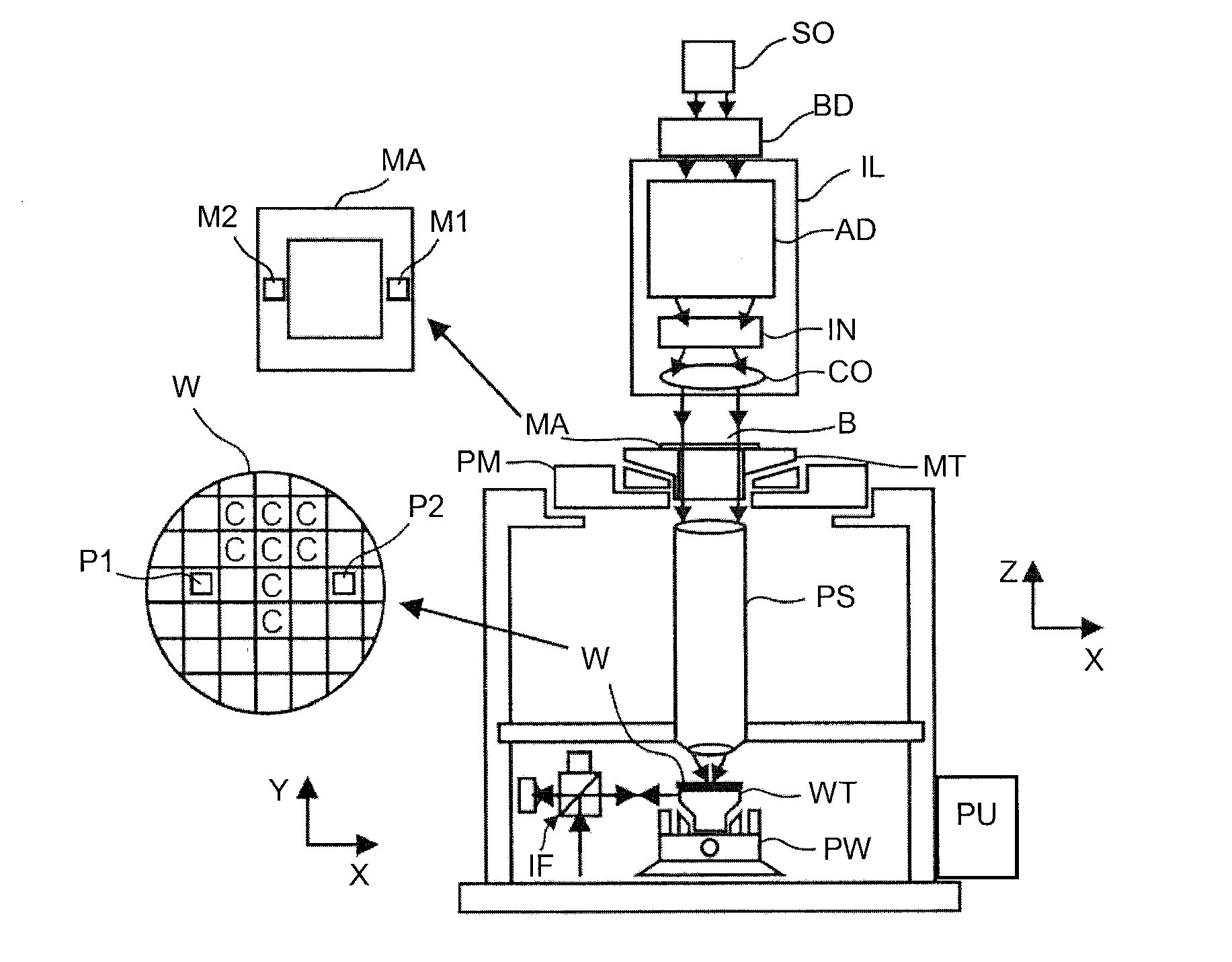

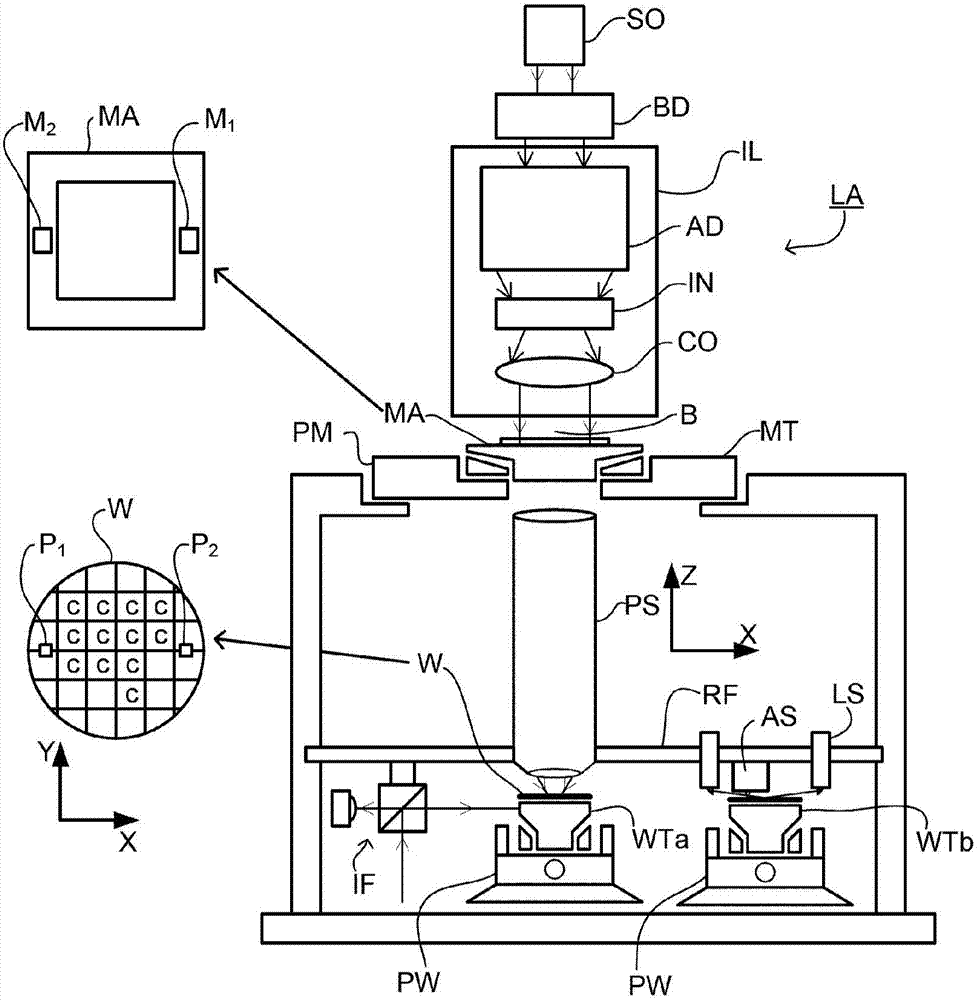

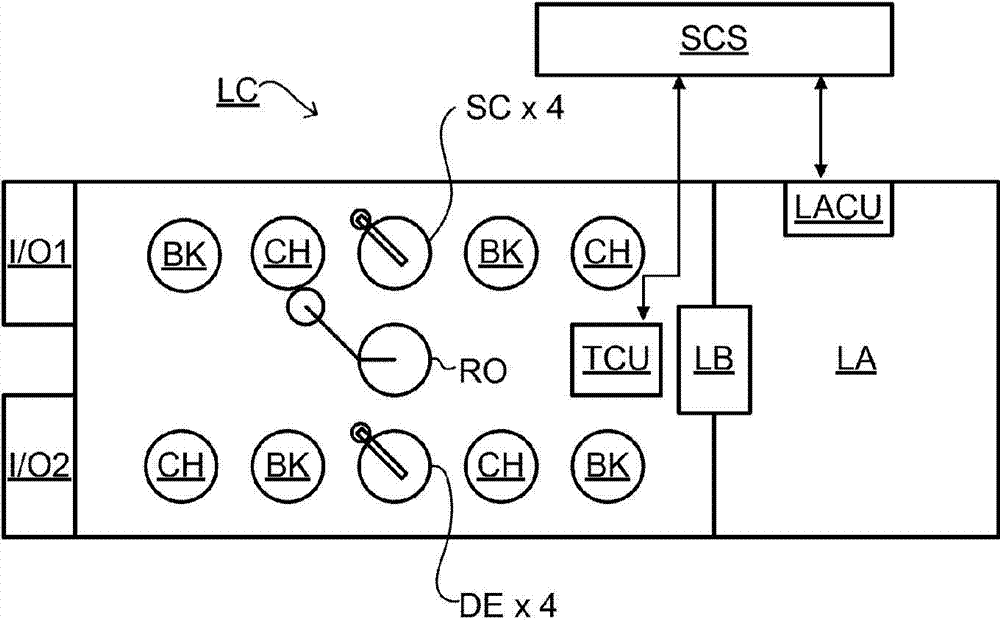

Lithographic apparatus, device manufacturing method, and method of applying a pattern to a substrate

InactiveUS20110164229A1Reduce delaysImprove throughputPhotomechanical treatmentUsing optical meansLevel sensorSurface level

A lithographic apparatus includes a patterning subsystem for transferring a pattern from a patterning device onto a substrate controlled in accordance with recorded measurements of level variations across a surface of the substrate. A level sensor is provided for projecting a level sensing beam of radiation to reflect from a location on the substrate surface and for detecting the reflected sensing beam to record the surface level at said location. The level sensor incorporates at least one moving optical element to scan the substrate surface by optical movement in at least one dimension to obtain measurements of surface level at different locations without mechanical movement between the level sensor and the substrate. Optical path length equalization measures may be employed, using shaped reflectors and / or additional moving mirrors, to avoid focus variation during the scan.

Owner:ASML NETHERLANDS BV

Methods for monitoring and adjusting focus variation in a photolithographic process using test features printed from photomask test pattern images; and machine readable program storage device having instructions therefore

InactiveUS7642019B2Semiconductor/solid-state device testing/measurementPhotomechanical apparatusFocal positionArtificial intelligence

Owner:SAMSUNG ELECTRONICS CO LTD

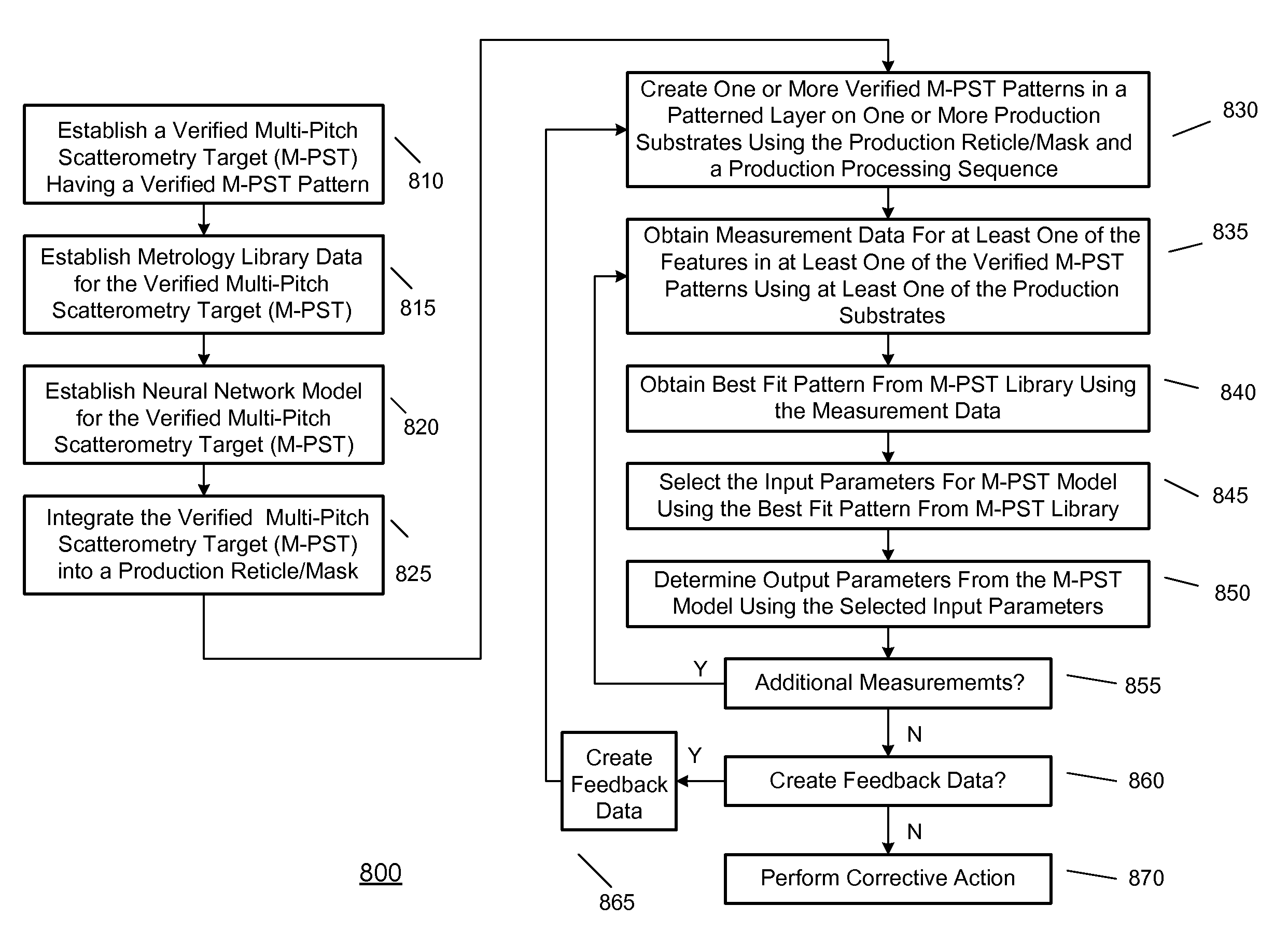

Multi-pitch scatterometry targets

ActiveUS8024676B2Semiconductor/solid-state device testing/measurementPhotomechanical apparatusCritical dimensionPost exposure

The invention can provide a method of processing a substrate using multi-pitch scatterometry targets (M-PSTs) for de-convolving lithographic process parameters during Single-Patterning (S-P), Double-Patterning (D-P) procedures, and Double-Exposure (D-E) procedures used to control transistor structures. The M-PSTs) can have critical dimension (CD) and sidewall angle (SWA) sensitivity to exposure focus variations, exposure dose variations, and post exposure bake (PEB) temperature variations. In addition, the variation can be de-convolved so that the individual measurement process variable contributor can be identified.

Owner:TOKYO ELECTRON LTD

Printing a mask with maximum possible process window through adjustment of the source distribution

InactiveUS20050122501A1Reduce lossesSemiconductor/solid-state device manufacturingUsing optical meansEngineeringProcess window

Disclosed is a method for illuminating a lithographic mask with light from different directions, in such a way that the intensities of the various incident beams provide the largest possible integrated process window. The process window is defined in terms of allowable ranges for printed shapes. For example, boundaries of the process window may be defined by shape limits corresponding to underexposed and overexposed conditions. Intensity parameters for representing the maximum possible intensities that can be permitted for overexposed tolerance positions are imposed through application of various constraints. Another set of intensity parameters for representing the minimum possible intensities that can be permitted for underexposed tolerance positions are imposed through application of various constraints. One parameter of each kind is defined for each of a number of different focal ranges. The optimum source intensities are determined from a linear program involving these and other constraints. The determined source intensities maximize the integrated range of dose and focal variations that can be tolerated without causing the printed shapes to depart from the allowed range of shapes.

Owner:GLOBALFOUNDRIES INC

Image projection optical system and image projection apparatus

An image projection optical system introduces light from an image-forming element by a zoom lens via an optical element. The optical element satisfies Sigma(DixNdi) / fw>4.0. The zoom lens includes, in order from a magnification side, first and second lens units, and lens units disposed closer to a reduction side than the second lens unit. The first lens unit is a negative lens unit. The lens units disposed closer to the reduction side than the second lens unit satisfy |dn / dt|<1.0x10-5. Magnification-side positive lens elements disposed closer to the magnification side than a negative lens element whose effective diameter is smallest in the lens units disposed closer to the reduction side than the second lens unit satisfy {9.0xSigma(1 / fpA)+5.0xSigma(1 / fpB)+0.5xSigma(1 / fpC)} / Sigma(1 / fp)<1. Reduction-side positive lens elements disposed closer to the reduction side than the negative lens element whose effective diameter is smallest satisfy {9.0xSigma(1 / fpA)+0.3xSigma(1 / fpB)+2.0xSigma(1 / fpC)} / Sigma(1 / fp)<1. Chromatic aberration is corrected and focus variations by temperature changes are reduced.

Owner:CANON KK

Image-taking apparatus

InactiveUS7403230B2Improve accuracyMinimize occurrenceTelevision system detailsColor television detailsEngineeringFocus variation

An image-taking apparatus is disclosed which achieves focusing in a reduce time with higher accuracy of an in-focus position search in a TV-AF method to minimize occurrence of unnatural focus changes. The image-taking apparatus includes an image-taking element, a first detector which outputs a focus evaluation value signal based on a predetermined frequency component of an output signal of the image-pickup element, a second detector which outputs a detection signal different from the focus evaluation value signal, and a controller which performs first processing of obtaining information for an in-focus position search of the focus lens based on the focus evaluation value signal. The controller performs second processing of obtaining information on an in-focus position based on the detection signal from the second detector, and performs third processing different depending on a comparison result between the information from the first processing and the information obtained from the second processing.

Owner:CANON KK

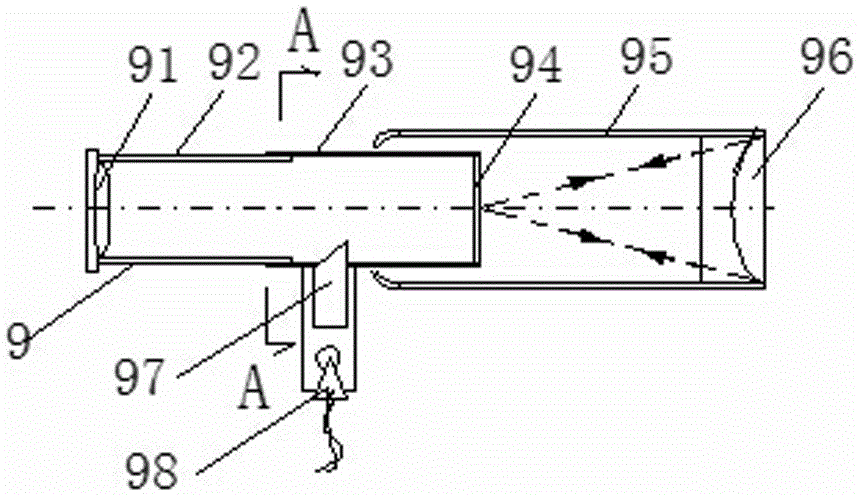

Spectrometer adjusting demonstrator

The invention provides a spectrometer adjusting demonstrator, which comprises a collimator, a telescope and an objective table. The collimator and the telescope are respectively supported at the two sides of the objective table. The spectrometer adjusting demonstrator is characterized in that the collimator and the telescope are assembled together via a convenient-to-assemble / disassemble structure. According to the technical scheme of the invention, the collimator and the telescope are assembled together via the convenient-to-assemble / disassemble structure, so that the internal structure of the spectrometer adjusting demonstrator can be displayed through disassembling the spectrometer adjusting demonstrator at any time as needed. A fluorescent layer arranged on a reticle is capable of displaying the focusing state of the light. Therefore, students can understand the focusing variation condition of the light during the adjusting process.

Owner:XIDIAN UNIV

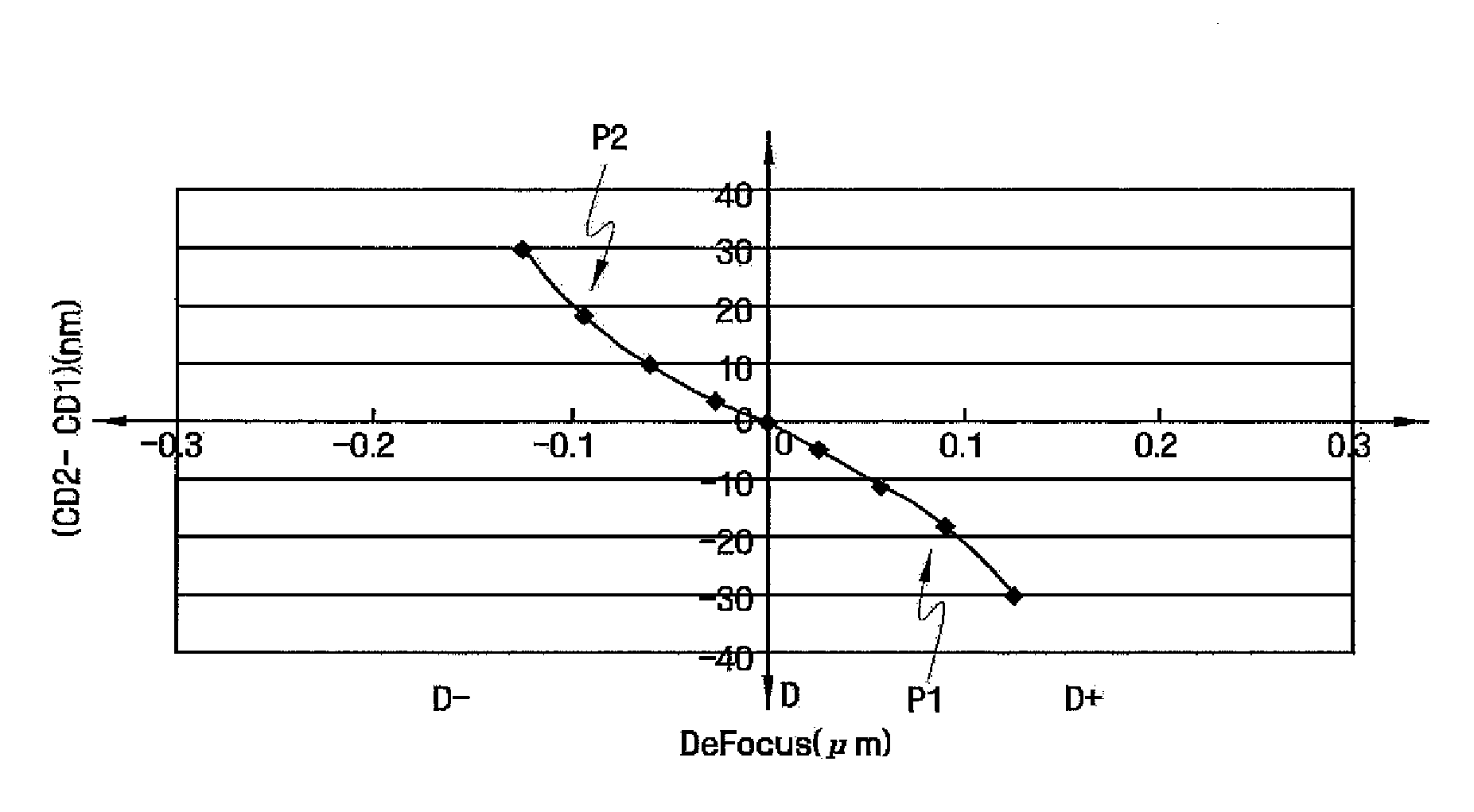

Exposure measurement method and apparatus, and semiconductor device manufacturing method

InactiveUS20050277035A1Focus error easilyImprove accuracySemiconductor/solid-state device manufacturingCharacter and pattern recognitionDevice materialDimension measurement

An exposure measurement apparatus is configured by including a size measurer measuring respective sizes of at least a pair of transferred patterns having mutually different optimal focus positions out of a plurality of transferred patterns formed by being transferred onto a transfer object, a difference value calculator obtaining a difference value between the size of one transferred pattern and the size of the other transferred pattern, a focus variation amount calculator calculating a focus variation amount of the transfer object using the difference value, and an exposure variation amount calculator calculating an exposure error amount of a wafer.

Owner:FUJITSU SEMICON LTD

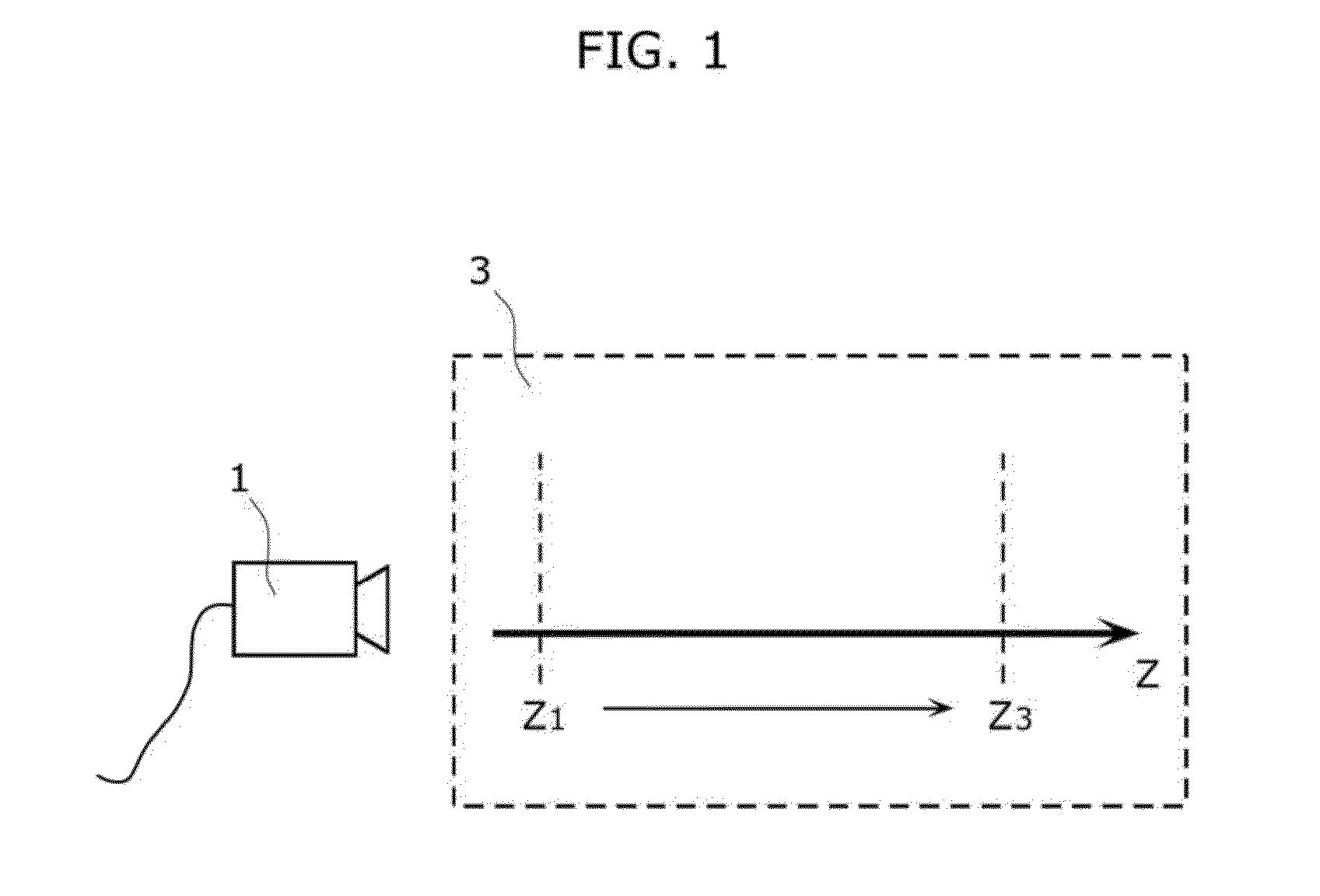

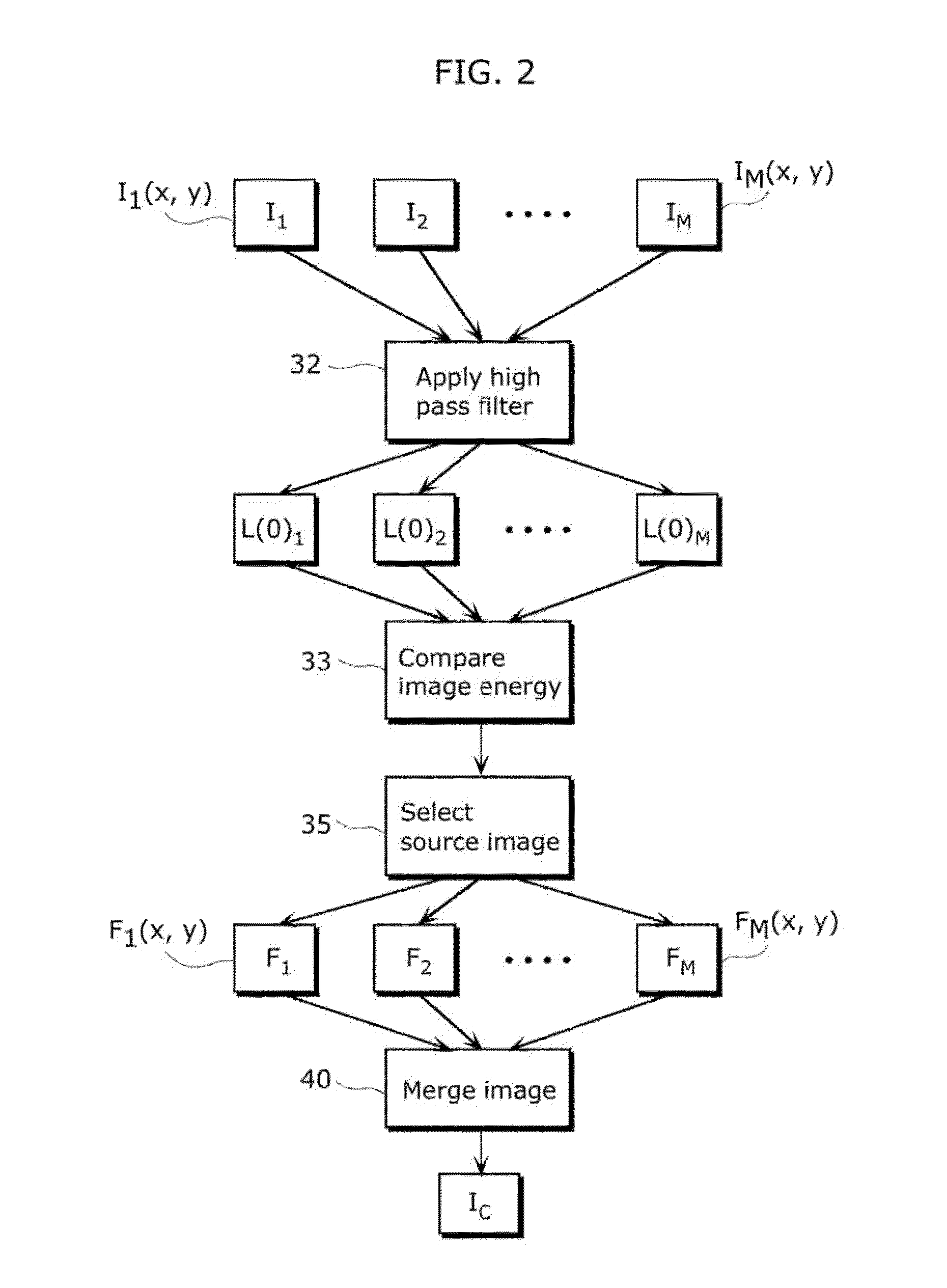

Method of acquiring microscopic image with super field depth

InactiveCN103499879ALarge depth of fieldKeep it lightweightMicroscopesMicroscopic imageDepth of field

The invention provides a method of acquiring a microscopic image with super field depth. The method comprises the steps: adding a liquid lens with focal length controlled by voltage in a digital microscope light path, performing a series of focusing on the continuous depth range of an observed object by utilizing the liquid lens as a variable focal length element, shooting a series of continuous local focusing pictures, and fusing a super-field-depth clear image including focus information of all heights by utilizing an image fusion processing means. The position where the liquid lens is optimized so as to maintain the amplification factor unchanged in the focus variation process. According to the method, the problems that the traditional optical microscope is excessively small in field depth and objects in a certain depth range cannot be clearly imaged can be effectively solved.

Owner:BEIHANG UNIV

A method of determining focus corrections, lithographic processing cell and device manufacturing method

InactiveCN103782238APhotomechanical exposure apparatusMicrolithography exposure apparatusComputer visionFocus variation

Disclosed is a method of, and associated apparatus for, determining focus corrections for a lithographic projection apparatus. The method comprises exposing a plurality of global correction fields on a test substrate, each comprising a plurality of global correction marks, and each being exposed with a tilted focus offset across it, measuring a focus dependent characteristic for each of the plurality of global correction marks to determine interfield focus variation information, and calculating interfield focus corrections from said interfield focus variation information.

Owner:ASML NETHERLANDS BV

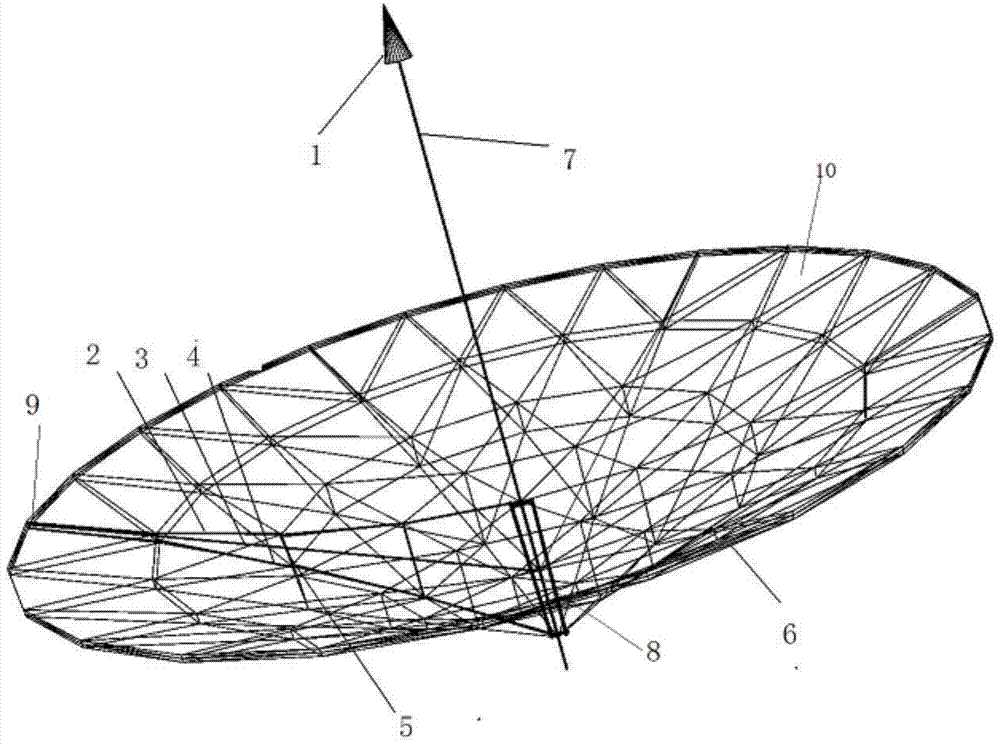

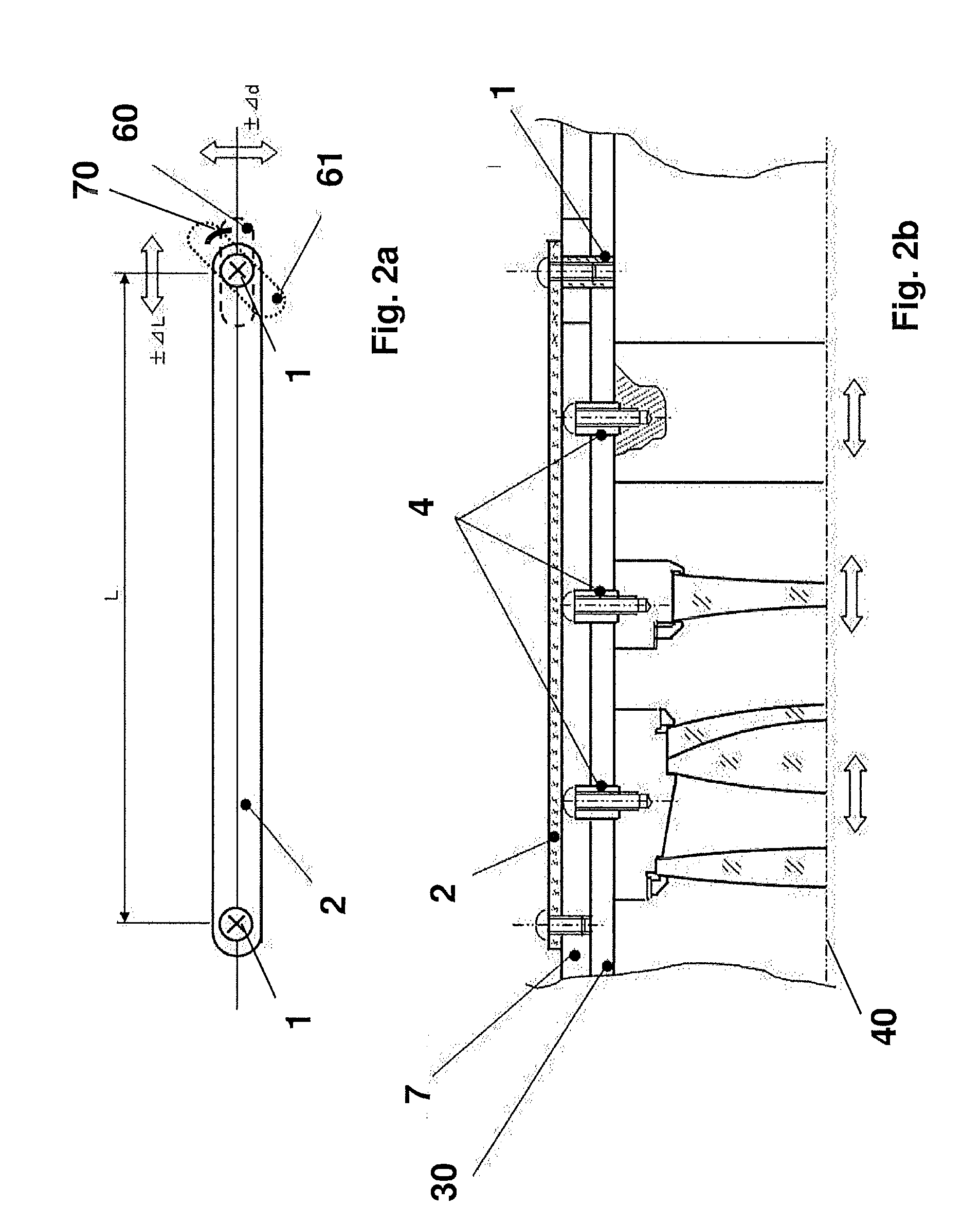

Varifocal reflecting surface system based on rib column cable network structure

The invention discloses a varifocal reflecting surface system based on a rib column cable network structure, and mainly aims to solve the problems that the focus of a conventional surface cannot be varied and the feed source position is fixed. The varifocal reflecting surface system comprises a feed source (1), a reflecting cable network (2), a support rib rod structure (3), a support cable network (4), vertical pull ropes (5), an annular fixing truss structure (6), a central support rod (7), annular rib joints (9) and a reflecting surface (10), wherein a varifocal sleeve (8) sleeves the outer side of the central support rod (7); the varifocal sleeve (8) is connected with the reflecting cable network (2) and the support cable network (4); the position of the varifocal sleeve (8) is adjusted to change the lengths of the reflecting cable network (2) and the support cable network (4), so that large-scale focus variation that the shape of the reflecting surface (10) transits to a plane from a parabolic plane is achieved. The varifocal reflecting surface system is simple, convenient and flexible in structure, the focus range and the reflection function of the reflecting surface are expanded, and the varifocal reflecting surface system can be applied to convergence or reflection of electromagnetic waves or optical energy of outer space, war ships or the ground.

Owner:XIDIAN UNIV

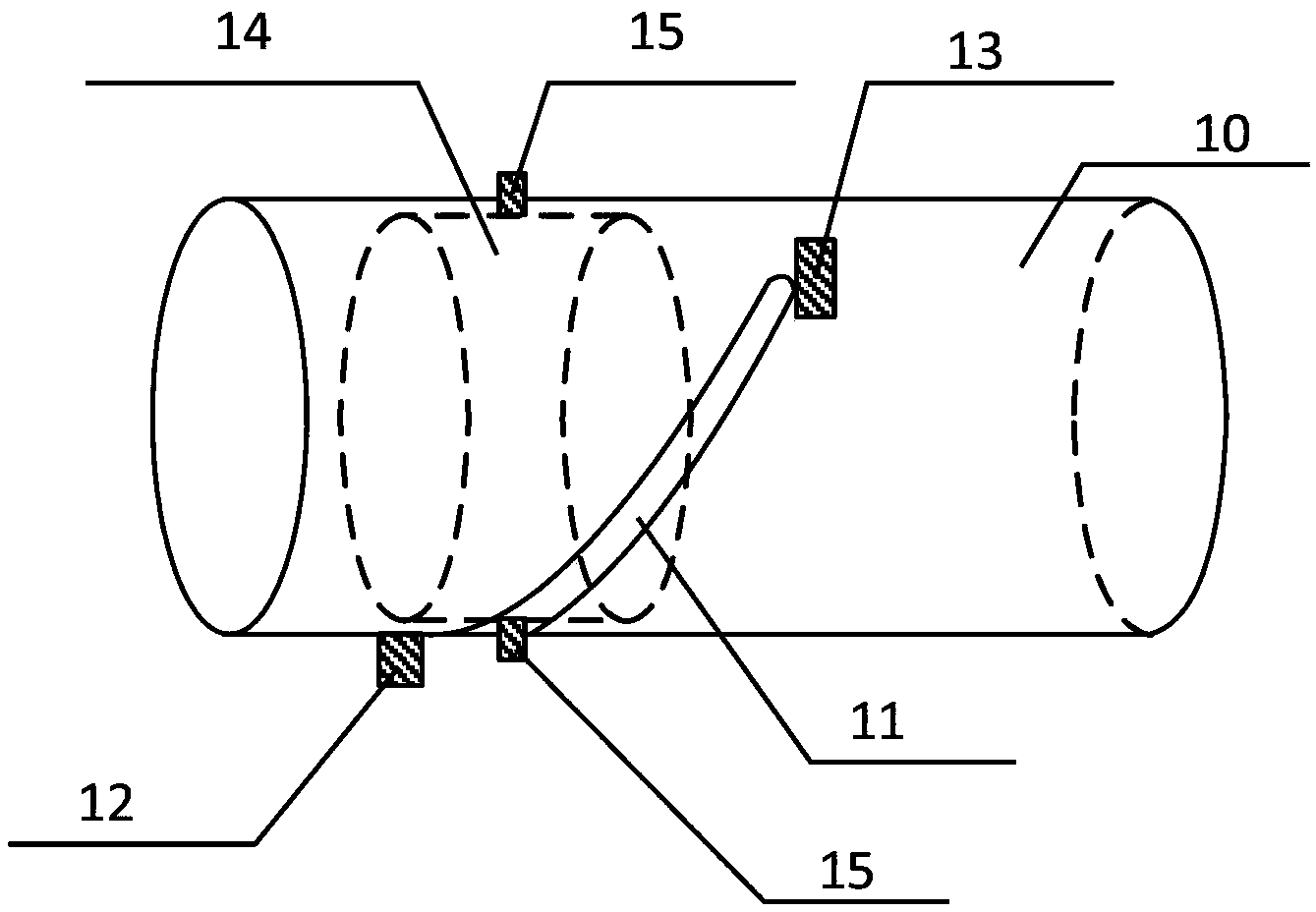

Lens-barrel sliding block, focusing lens, image collecting equipment, controller and control method

ActiveCN104076479AExtended service lifeAvoid Corrupted Abnormal BehaviorTelevision system detailsProjector focusing arrangementCamera lensControl theory

The invention discloses a lens-barrel sliding block, a focusing lens, image collecting equipment, a controller and a control method of the controller. The control method is used for controlling a motor to stop operating towards the same direction continuously when a lens set comprising a zooming lens set and a focus variation lens set moves to a limiting position, so that the abnormal behavior of damaging the synchronous focusing lens is avoided, and the service life of the lens is prolonged. The lens-barrel sliding block comprises a hollow circular cylinder, a first sliding groove and a second sliding groove, wherein the first sliding groove and the second sliding groove are formed in the inner wall of the hollow circular cylinder. The first sliding groove is a sliding groove for the zooming lens set, and the second sliding groove is a sliding groove for the focus variation lens set. At least one end of the first sliding groove and / or the second sliding groove is provided with a touch switch. When touched, the touch switch sends out a touch signal used for indicating that the lens-barrel sliding block needs to stop driving the zooming lens set and the focus variation lens set to continue to move towards the same direction.

Owner:ZHEJIANG DAHUA TECH CO LTD

System and method for enhanced predictive autofocusing

In an imaging device having an objective and a stage for holding a sample to be imaged, a method for autofocusing is presented. The method includes determining a measured focus value corresponding to at least a first of a plurality of logical image segments. Further, the method includes imaging the first logical image segment using the measured focus value. The method also includes determining a predicted focus value for a second of the plurality of logical image segments using the measured focus value and a stored focus variation parameter. In addition, the method includes imaging the second logical image segment using the predicted focus value.

Owner:GENERAL ELECTRIC CO

Image capturing device, image capturing method, program, and integrated circuit

InactiveUS9076204B2Easy to operateReduce confusionImage enhancementTelevision system detailsSignal-to-noise ratio (imaging)Image resolution

An image capturing device includes: a pre-capturing module which captures an imaging target at each of different focus positions in a predetermined focus range and outputs, as a capturing result, a plurality of pre-captured images lower in resolution than the output image; an object sharpness evaluating module which computes a sharpness level of each of the pre-captured images captured by the pre-capturing module; a focus varying range determining module which determines a focus position varying range within the predetermined focus range based on sharpness levels computed by the object sharpness evaluating module, such that a signal-to-noise ratio of the output image is greater than or equal to a predetermined threshold; and an image capturing module which captures the imaging target while varying the focus position according to the focus position varying range determined by the focus varying range determining module, and outputs the output image as a capturing result.

Owner:SOVEREIGN PEAK VENTURES LLC

Structure and method for compensating temperature dependent magnification and focus change

A method and device is described for compensating ambient temperature dependent magnification and focus change of a zoom lens system, whereby an ambient temperature compensation structure cooperates with a rotational ring and an optical-element adjusting member such that a phase variation between the rotational ring and the optical-element adjusting member in response to an ambient temperature change is compensated and whereby the phase variation characterizes an optical property of the zoom lens system such as magnification or focus.

Owner:BARCO NV

Photomask structures providing improved photolithographic process windows and methods of manufacturing same

InactiveCN1862385ASemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringProcess window

Systems and methods are provided for detecting focus variation in a lithographic process using photomasks having test patterns adapted to print test features with critical dimensions that can be measured and analyzed to determine magnitude and direction of defocus from a best focus position of an exposure tool during the lithographic process.

Owner:SAMSUNG ELECTRONICS CO LTD

Method of non-destructive testing a cutting insert to determine coating thickness

ActiveUS20180172430A1Cost-effectiveRaise the potentialWorkpiecesTurning toolsNon destructiveInterferometric microscopy

A method for non-destructive testing a cutting insert to determine coating thickness is disclosed. The method includes the steps of using a source of electromagnetic energy to ablate a surface of the cutting insert to non-destructively form a geometric feature and expose the substrate and each layer of the coating; and measuring the thickness of each layer of the coating. In one example, the geometric feature is a groove with a generally trapezoidal shape. In other examples, the groove can have a U-shape, V-shape, and the like. The thickness of each layer of the coating is determined using focus variation, contrast detection, confocal microscopy, an interferometric microscopy, an imaging interferometric microscopy, or similar technique.

Owner:KENNAMETAL INC

Optical compensation zoom lens

ActiveCN103197409AAchieve confocal imagingClearly display monitoring targetsMountingsCamera lensFocus variation

An optical compensation zoom lens comprises a compensating lens group and a zoom lens group. Focus variation of the whole lens is adjusted by changing relative positions of the compensating lens group and the zoom lens assembly. The compensating lens group comprises a convex-concave negative light focal power lens serving as a first lens, a double-concave negative light focal lens serving as a second lens and a double-convex positive light focal lens serving as a third lens, wherein the first lens, the second lens and the third lens are arranged on one side of an object. The zoom lens group comprises a double-convex negative light focal power lens serving as a fourth lens, a concave-concave negative light focal lens serving as a fifth lens and a double-convex positive light focal lens serving as a sixth lens, a concave-concave negative light focal lens serving as a seventh lens, a double-convex positive light focal lens serving as a eighth lens, a concave-concave negative light focal lens serving as a ninth lens, wherein the fourth lens, the fifth lens, the sixth lens, the seventh lens, the eighth lens and the ninth lens are arranged on one side of the object. The optical compensation zoom lens achieves con-focus of visible light imaging and infrared light imaging through the structures of the lens and parameter setting.

Owner:DONGGUAN YUTONG OPTICAL TECH

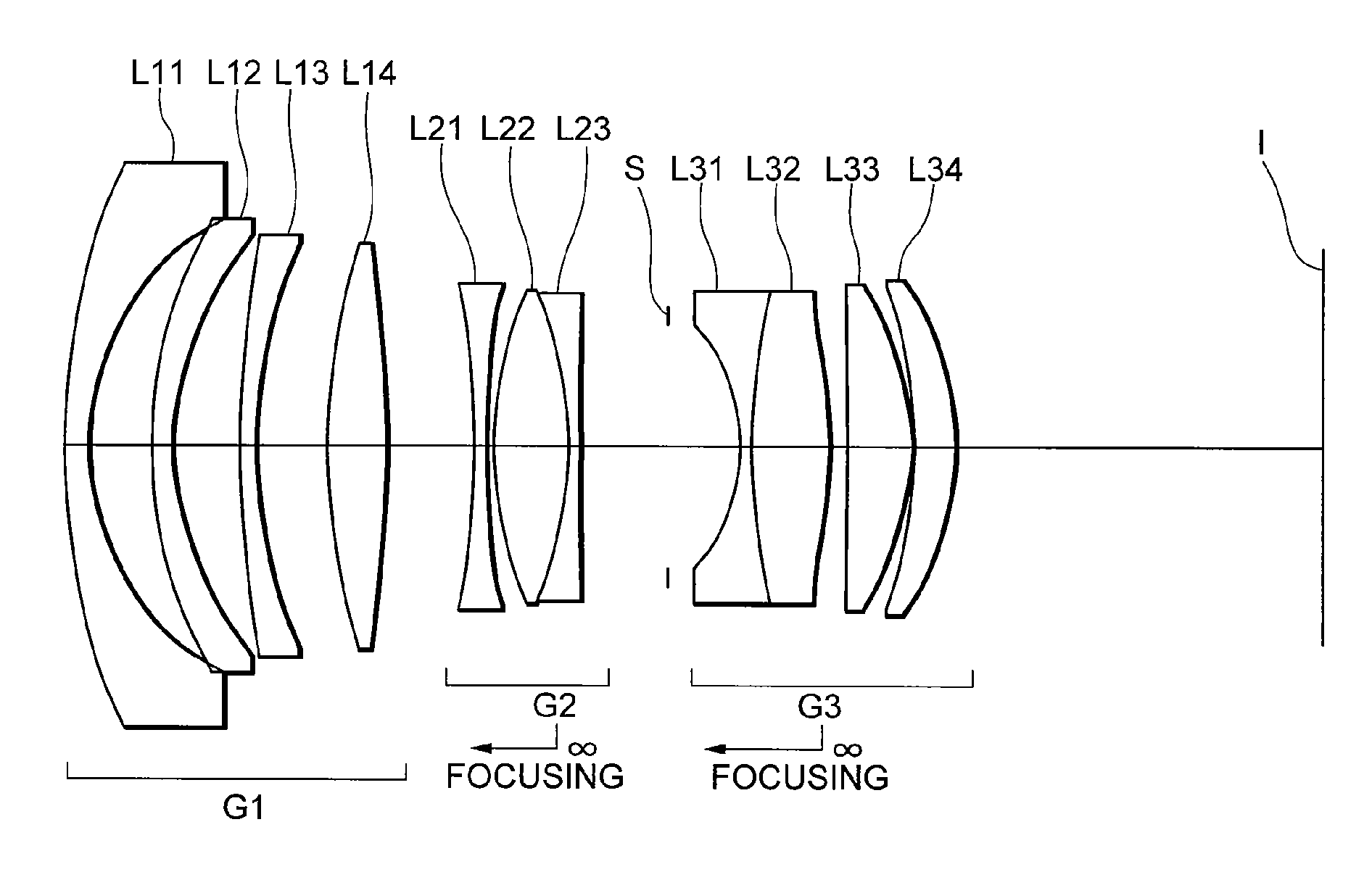

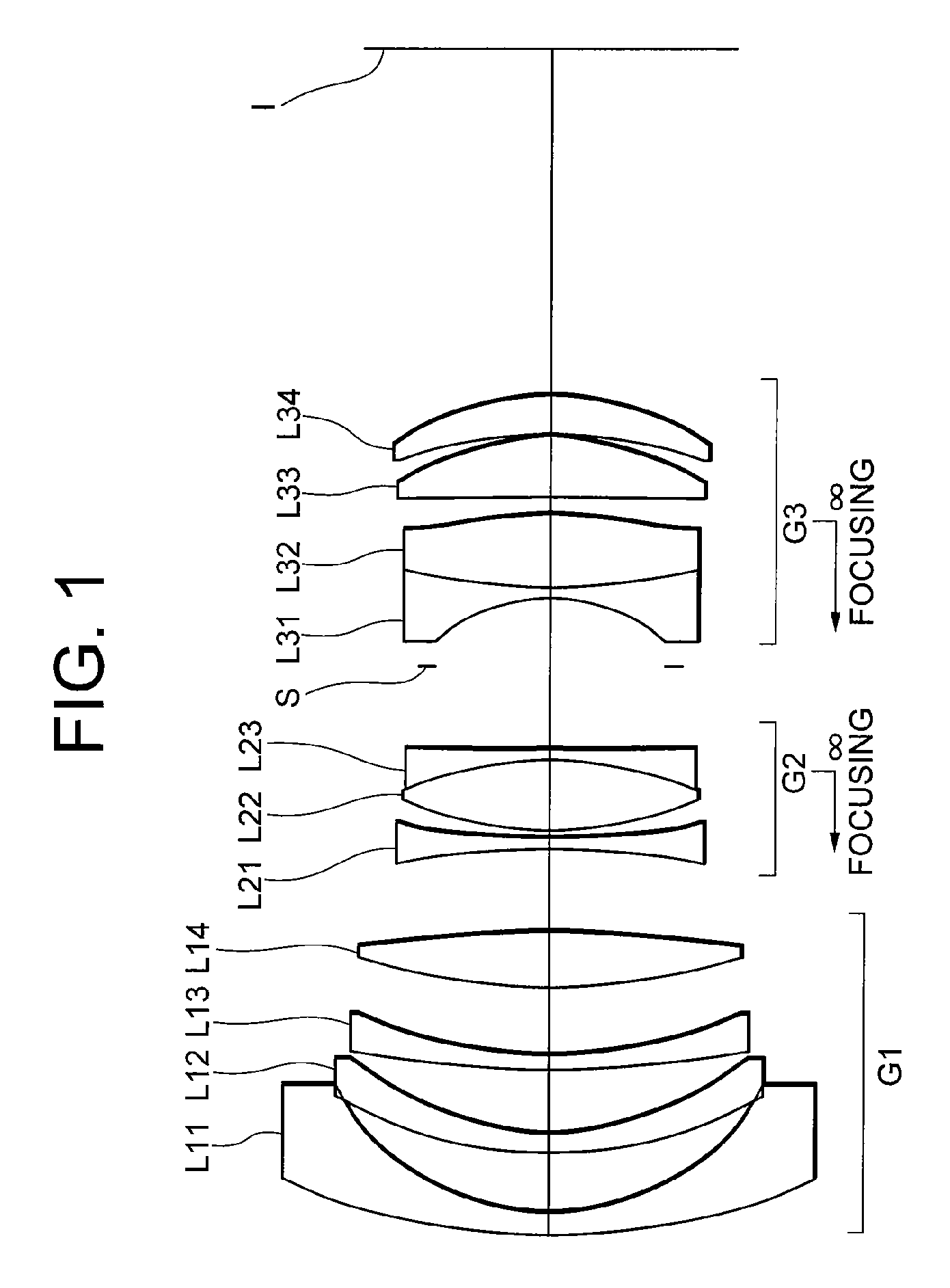

Wide-angle lens, optical apparatus, and method for focusing

InactiveUS8000035B2Good optical performanceCoatingsSpecial surfacesConditional expressionFocus variation

Owner:NIKON CORP

Mask With Focus Measurement Pattern And Method For Measuring Focus Value In Exposure Process Using The Same

ActiveUS20080160425A1Easy to manufactureMeasure directlyPhotomechanical apparatusCharacter and pattern recognitionReference patternsFocus variation

A mask with a focus measurement pattern and a method for measuring a focus value in an exposure process using the same that are capable of improving the measurement of a focus change, wherein the mask includes an outer reference pattern which provides a position reference for focus measurement, and focus measurement patterns which are provided apart from the outer reference pattern and formed in a line shape extending in two different directions. Accordingly, the focus change caused in the exposure process can be measured by measuring the line shortening of the focus measurement patterns.

Owner:SK HYNIX INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com