Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Amylase preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

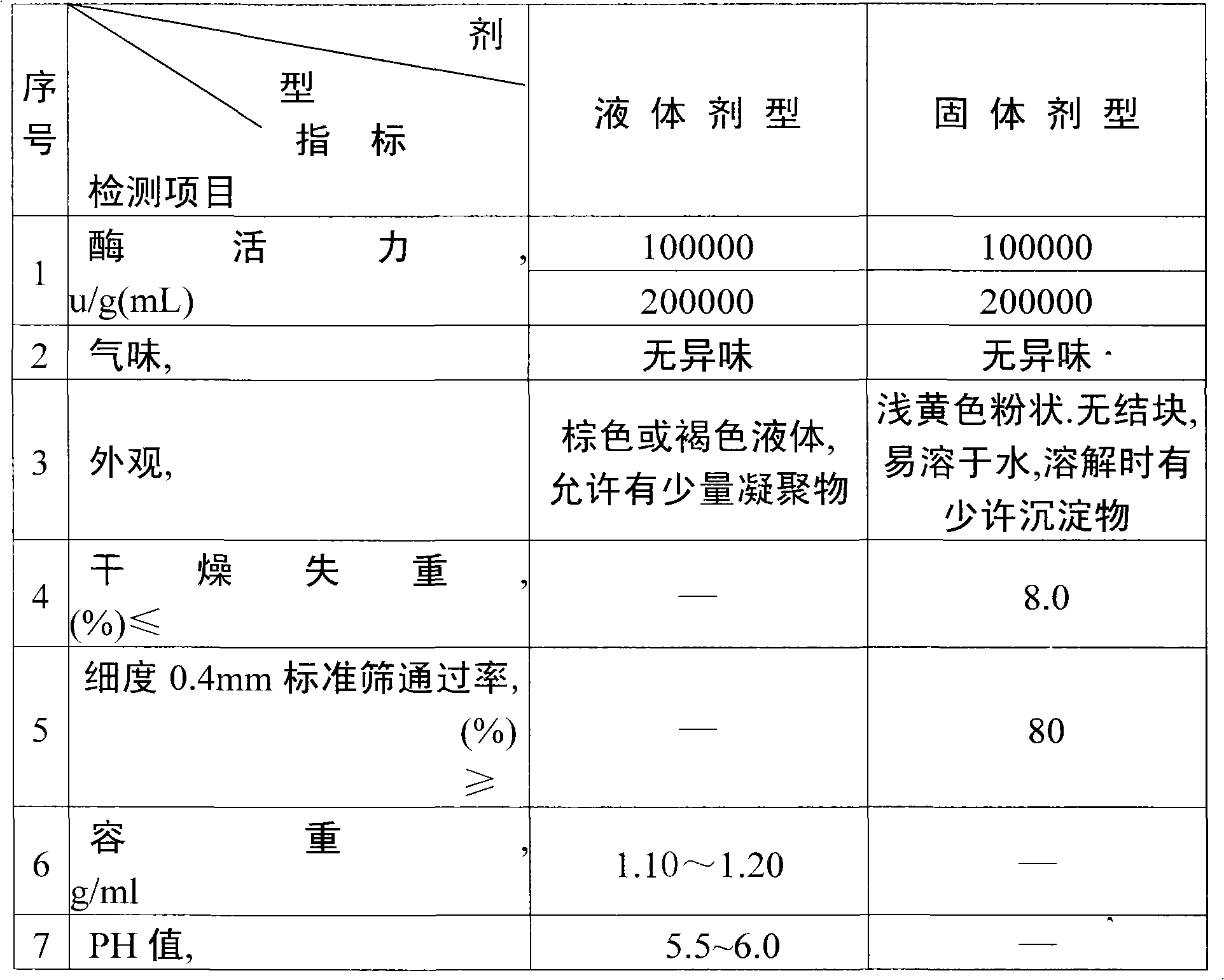

Acid-proof high-temperature amylase strain and method for producing acid-proof high-temperature amylase

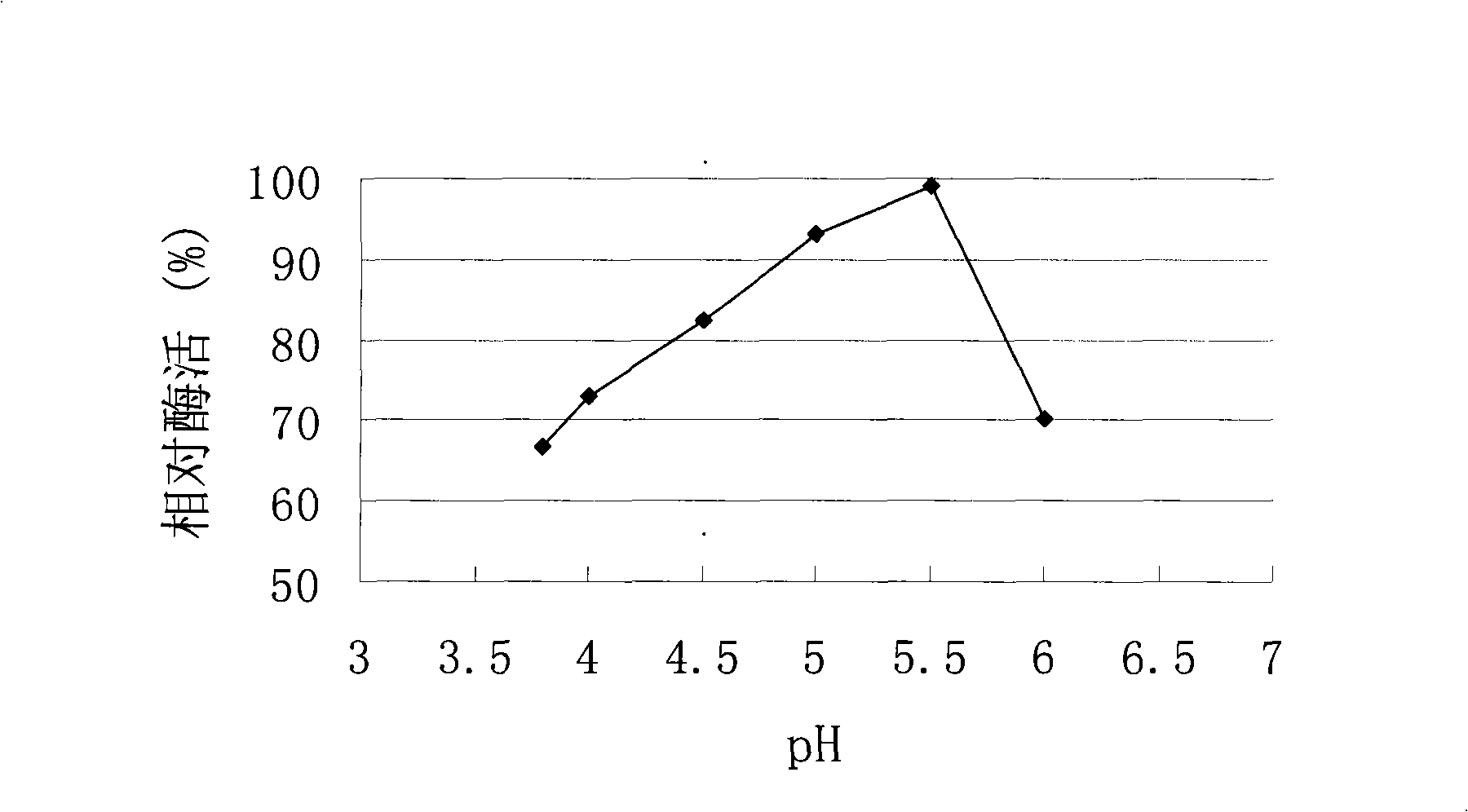

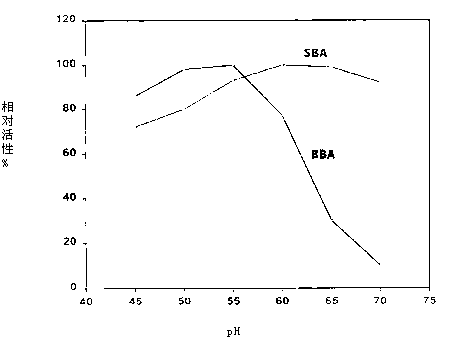

InactiveCN101514327AGood acid resistanceBacteriaMicroorganism based processesBacillus licheniformisMonosodium glutamate

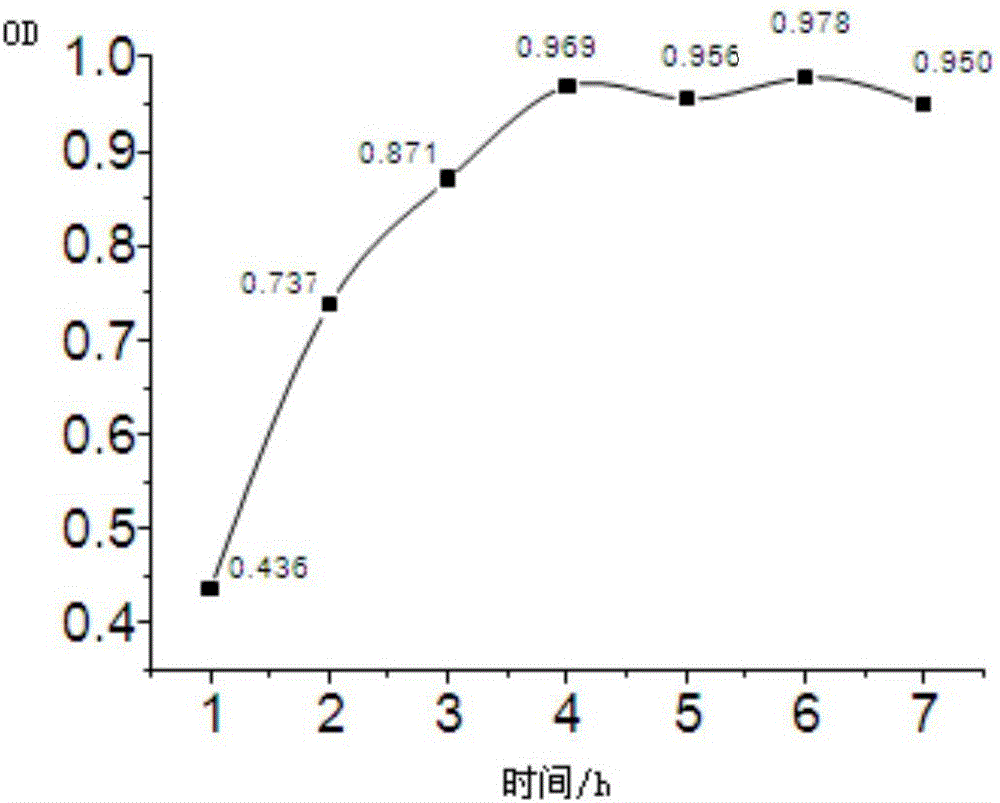

The invention provides an acid-proof high-temperature amylase strain and a method for producing acid-proof high-temperature amylase, and belongs to the technical field of biological engineering. The invention discloses Bacillus licheniformis BL-mut 08 for producing the acid-proof high-temperature amylase, which has the preservation number of CCTCC NO: M207193, and is obtained through compound mutation of the prior Bacillus licheniformis system, preservation, rejuvenation and a selective breeding method; and then the Bacillus licheniformis is optimized by a culture medium formulation and optimized by fermenting technological conditions so as to establish the method for producing the acid-proof high-temperature amylase, wherein the method comprises the following steps: air culturing the Bacillus licheniformis for about 72 hours at a temperature of 37 DEG C to reach an enzyme generating peak; and obtaining concentrated enzyme fluid through flocculating treatment, pressure filtration and ultra-filtration concentration or obtaining different amylase preparations such as micro pills, granules or powder through other post treatment modes. The produced high-temperature amylase has good acid-proof activity, and can be widely applied in the food and medicament industries, particularly the industries such as alcoholic fermentation, monosodium glutamate, antibiotics, textile and papermaking.

Owner:无锡德冠生物科技有限公司

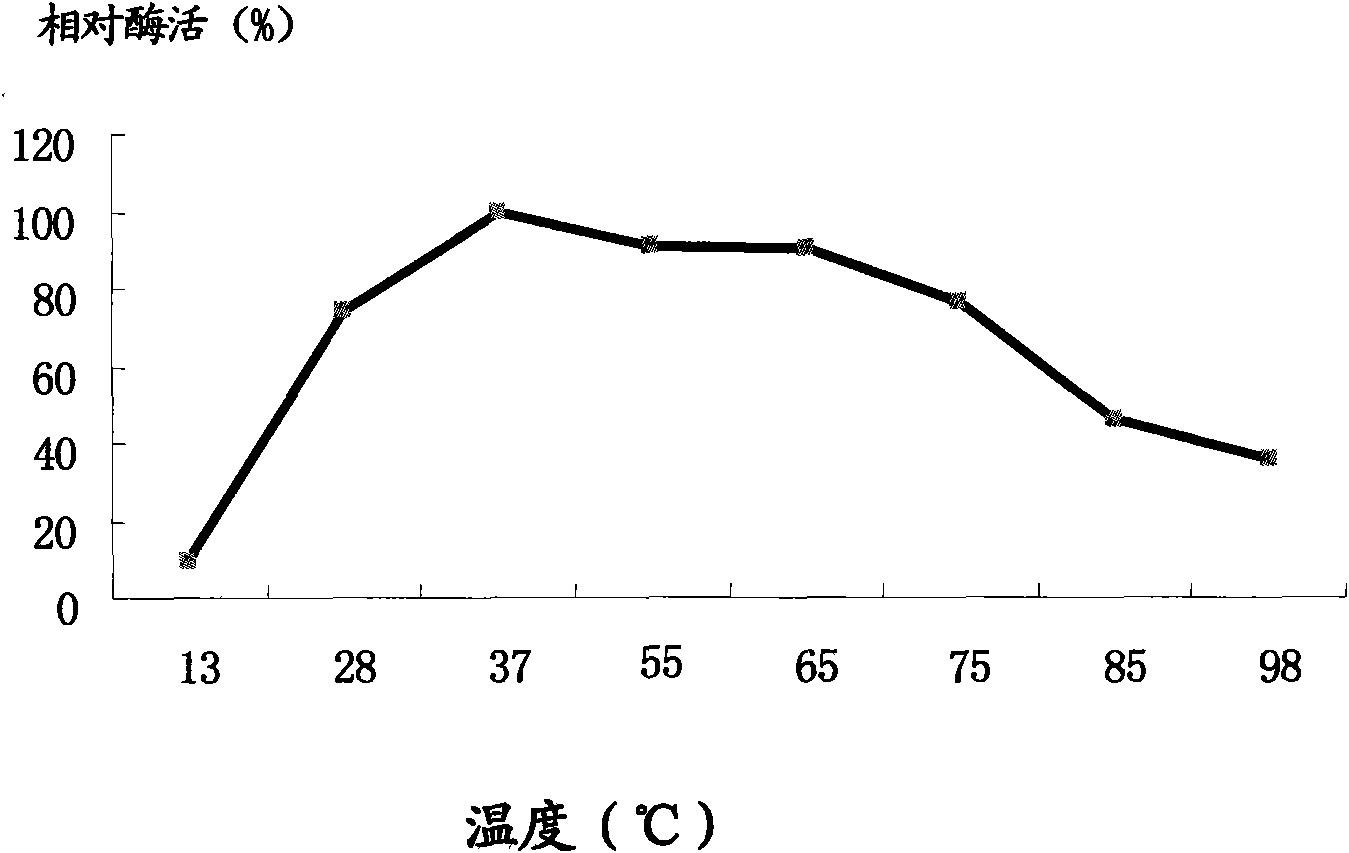

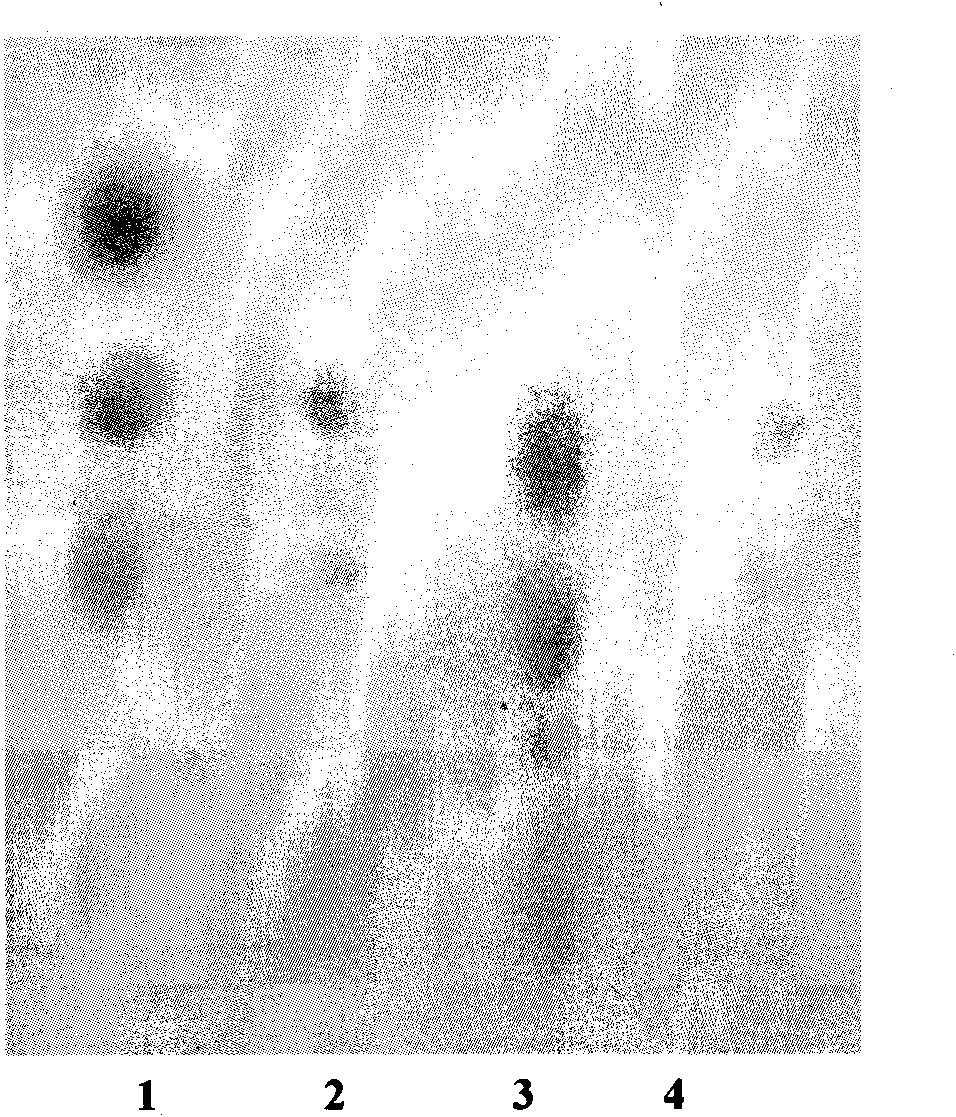

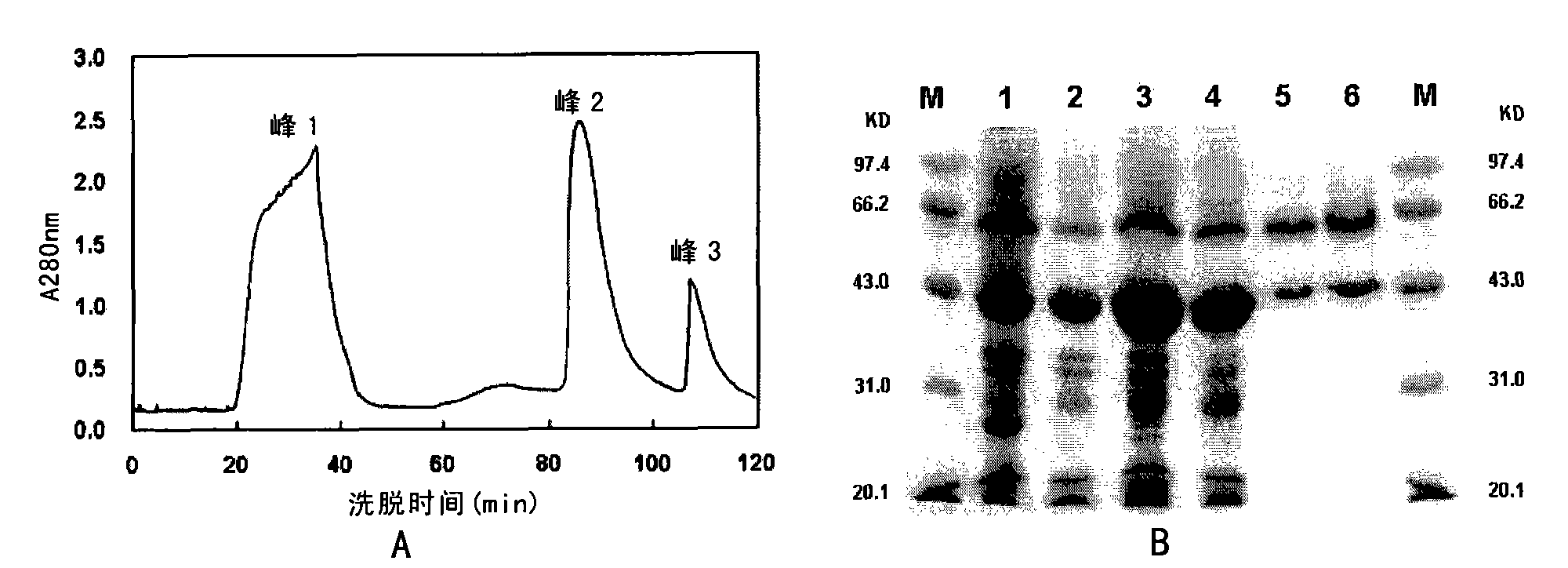

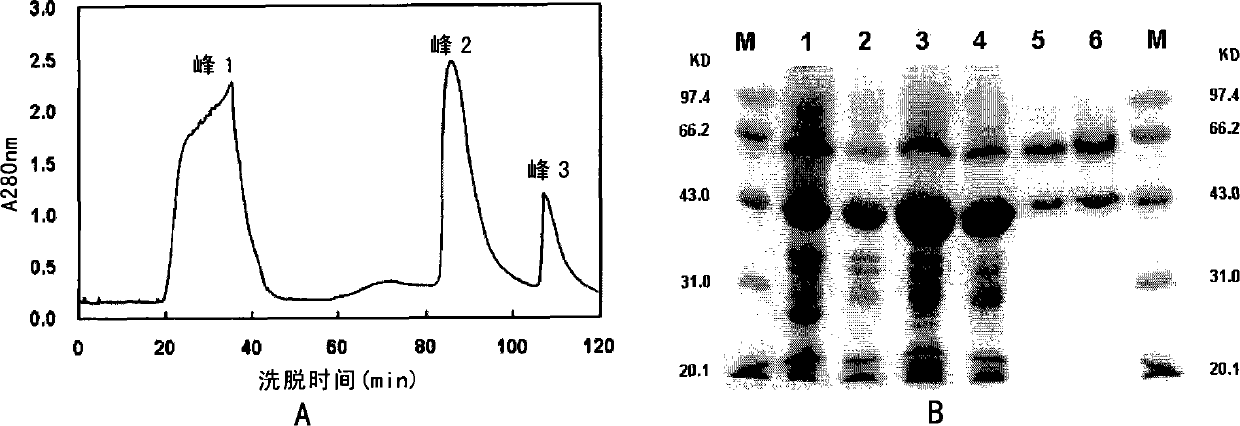

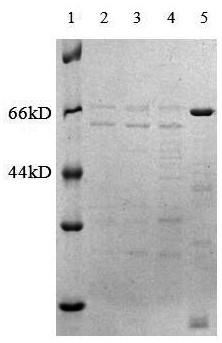

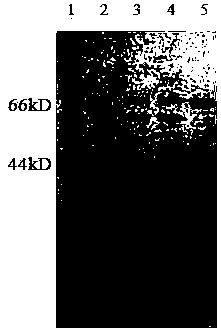

Method for preparing alpha-amylase by high-temperature laceyella sacchari RHA1 virus strain and purification method thereof

The invention discloses a method for preparing high-temperature alpha-amylase by a heat resistant high-temperature laceyella sacchari RHA1 virus strain and a purification method thereof. The high-temperature laceyella sacchari RHA1 virus strain is white and transparent, has corrugations, dry surfaces, different positive colors and negative colors, ball shapes, laceyella sacchari gram-positive bacterium, no flagella or no pilus; and a large number of mycelium is produced when culturing liquid. The method for preparing the amylase by the high-temperature laceyella sacchari RHA1 comprises the following steps: carrying out ultrafilter concentration and ammonium sulfate precipitation on a fermentation supernatant through an ultrafilter envelope of 1KD to obtain crude enzyme liquid, and filtering by Superdex 75 10 / 300 gelatin to obtain pure heat resistant alpha-amylase. The molecular weight of the alpha-amylase obtained in the invention is only 11.9 KDa, and the alpha-amylase is a monomer protein and is an amylase with the minimal molecular weight reported recently. The alpha-amylase hydrolyzes amylose and soluble starch to obtain maltose and maltotriose, can resist high temperature and has wide action temperature range and application values in food processing, medicines, detergents and the like.

Owner:KUNMING UNIV OF SCI & TECH

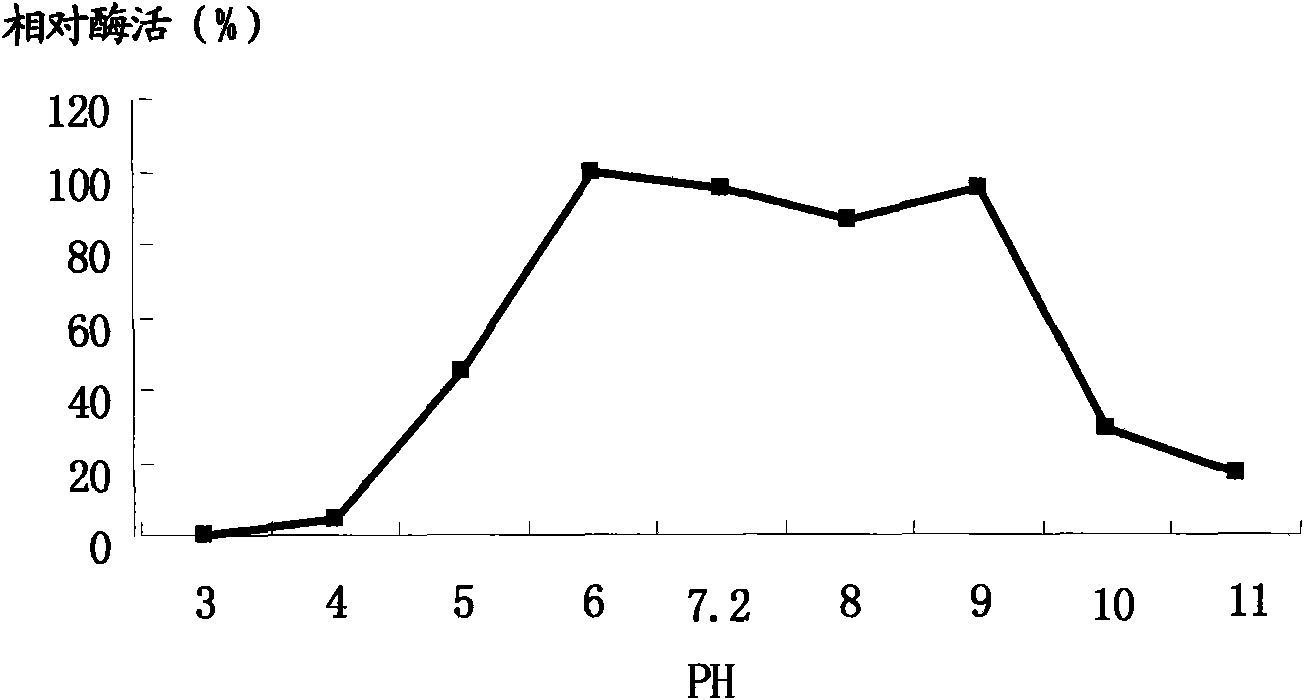

Fungal alpha-amylase by liquid fermentation and preparation method thereof

InactiveCN101691564AImprove thermal stabilityAdaptableWort preparationPre-baking dough treatmentUltrafiltrationFiltration

The invention provides a fungal alpha-amylase by liquid fermentation and a preparation method thereof, belonging to alpha-amylases from microbial origins. The fungal alpha-amylase by liquid fermentation is characterized in that a. enzymatic characteristics include optimum pH of 6.0, stable pH of 5.5-7.0 and optimum action temperature of 50-60 DEG C; and b. Aspergillus oryzae which is preserved in CICC and is numbered 2436 is selected as the enzyme production strain, liquid fermentation process is adopted for preparation and the following process technology indexes are achieved: (1) the level of enzyme production by fermentation is more than or equal to 7200u / ml; and (2) the recovery rate of liquid enzyme is more than or equal to 80% after extraction by filter pressing, clarifying filtration, ultrafiltration and refining filtration, so as to reach the food grade health standard. The fungal alpha-amylase product has higher thermal stability and strong adaptability under the condition of lower optimum pH. The preparation method is characterized by saved equipment investment, high production capability, convenient process operation, high enzyme productivity and lower cost. The fungal alpha-amylase conforms to the food grade health standard and is suitable for starch syrup, oligosaccharide, beer, baking food, flour products and flour processing and brewing industries.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

Preparing purification method for thermophilic alpha-amylase

InactiveCN101063115AImprove purification efficiencyLow costEnzymesFermentationAlkalinityPurification methods

The invention discloses a preparing method of thermophilic alpha-amylase (PFA), which comprises the following steps: heating and dissolving recombinant protein inclusion body under the condition of alkalinity; diluting; compositing; separating and purifying through column layer. This method possesses high reclaiming ratio and high alpha-amylase activity.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI

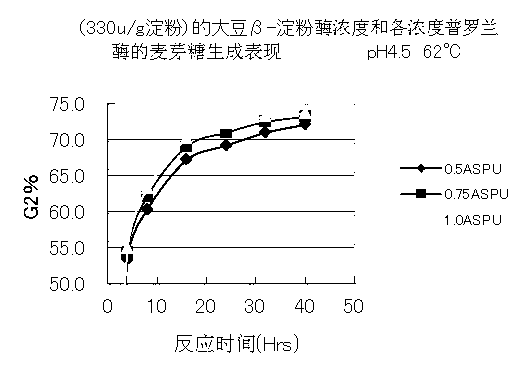

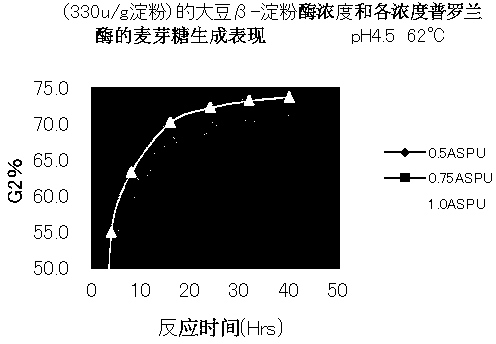

Preparation method for high-activity beta-amylase

The invention relates to a separation and purification method for amylase in a plant, and particularly relates to a method for industrially producing high-activity beta-amylase. The preparation method for the beta-amylase disclosed by the invention comprises the following steps of: collecting separation water; pre-treating; precipitating and dissolving out the beta-amylase; forming a composite precipitate from polyacrylic acid and the beta-amylase in the solution; dissolving the composite precipitate; and adjusting the pH to be greater than or equal to 6.0, and dissolving out the beta-amylase. The invention provides a preparation method for beta-amylase, which is less in resource consumption, high in yield (of about 75%), and high in activity (of 700000-900000 u / ml generally); and the obtained product is good in tolerance to temperature and pH value, and low in cost in case of being applied to maltose production.

Owner:山东绿健生物技术有限公司

Method for renaturing and purifying recombinant extremely heat-resistant alpha-amylase

InactiveCN101613681AImprove solubilityEffect of enzyme activityEnzymesInclusion bodiesHeat resistance

The invention discloses a method for preparing a thermophilic alpha-amylase, which comprises the following steps: dissolving an inclusion body of the thermophilic alpha-amylase by using detergent solution so as to obtain solution containing the thermophilic alpha-amylase; and separating out the thermophilic alpha-amylase from the obtained solution. The thermophilic alpha-amylase obtained by the method has consistent enzymatic activity and heat resistance of native proteins. The method has the characteristics of simplicity, high efficiency, low cost and easy amplification, and is particularly suitable for the mass preparation of recombinant thermophilic alpha-amylase. Simultaneously, the method is also suitable for the renaturation and the purification of other thermophilic proteins expressed in forms of insoluble inclusion bodies.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI

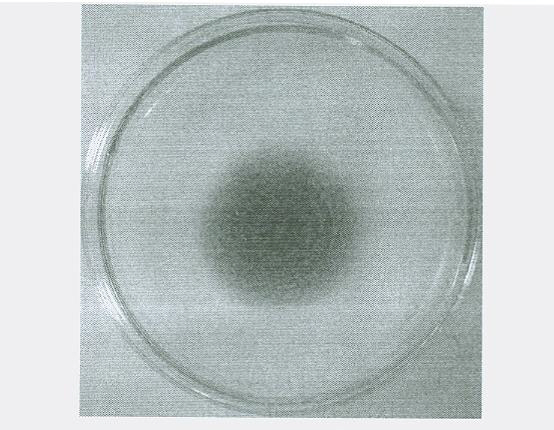

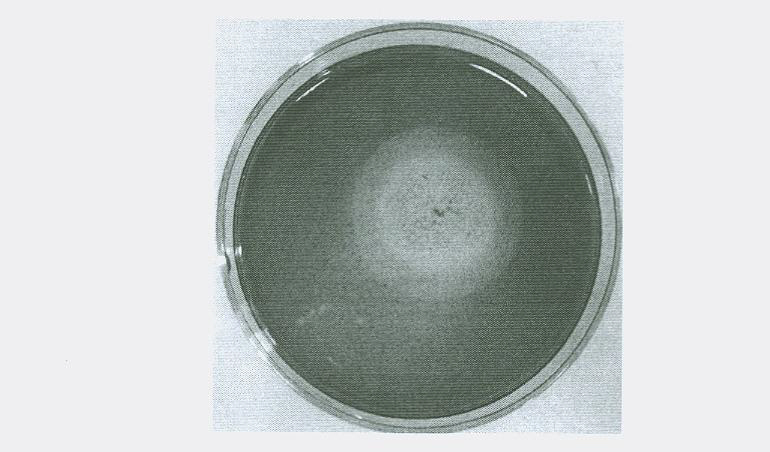

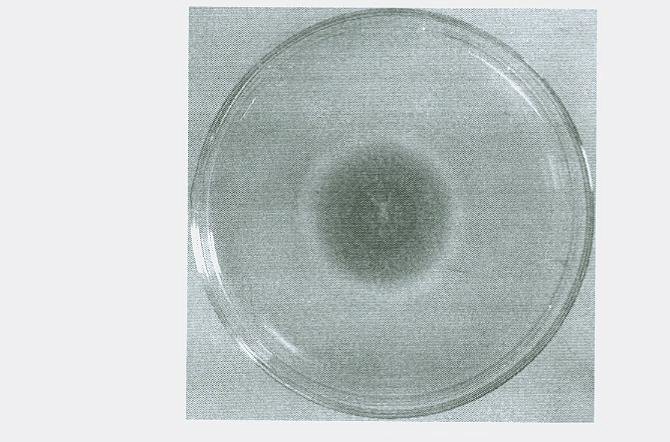

Raw-starch amylase producing penicillium and raw-starch amylase preparation produced thereby

InactiveCN101955887ALow costAvoid high temperature cookingFungiHydrolasesPenicilliumAmylase preparation

The invention discloses raw-starch amylase producing penicillium and a raw-starch amylase preparation produced thereby. The invention provides penicillium sp. GXU20 CGMCC No.3690. The invention also provides the raw-starch amylase preparation produced by fermentation of penicillium GXU20. The penicillium GXU20 and the raw-starch amylase preparation both can be used in alcohol production for avoiding thermophilic digestion of raw materials and saving a large amount of energy; the addition of alpha-amylase is avoided, and cost is saved; and saccharification and fermentation are performed in the same container, and equipment cost is reduced. The raw-starch amylase producing penicillium and the raw-starch amylase preparation produced thereby are expected to solve the problem of high alcohol production cost caused by the thermophilic digestion of starch.

Owner:GUANGXI UNIV

Preparation method for immobilized alpha-amylase with graphene/titanium oxide composite porous microspheres as carrier

InactiveCN107287183AImprove adsorption capacityImprove stabilityOther chemical processesOn/in inorganic carrierAlpha-amylaseThermal stability

The invention discloses a preparation method for immobilized alpha-amylase with graphene / titanium oxide composite porous microspheres as a carrier. The preparation method particularly includes the steps of: 1) preparing the graphene / titanium oxide composite porous microspheres; 2) preparing an alpha-amylase solution, mixing and stirring the graphene / titanium oxide composite porous microspheres with the alpha-amylase solution for 1-2 h, and performing ultrasonic treatment for 1-4 h at the power of 300 W, and filtering the liquid to obtain a solid; 3) washing the solid with a buffer solution composed of citric acid and sodium citrate, and drying the solid to obtain the immobilized alpha-amylase. The immobilized alpha-amylase is low in deactivation, has excellent repeatability, and is good in thermo-stability.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Preparation method of amylase

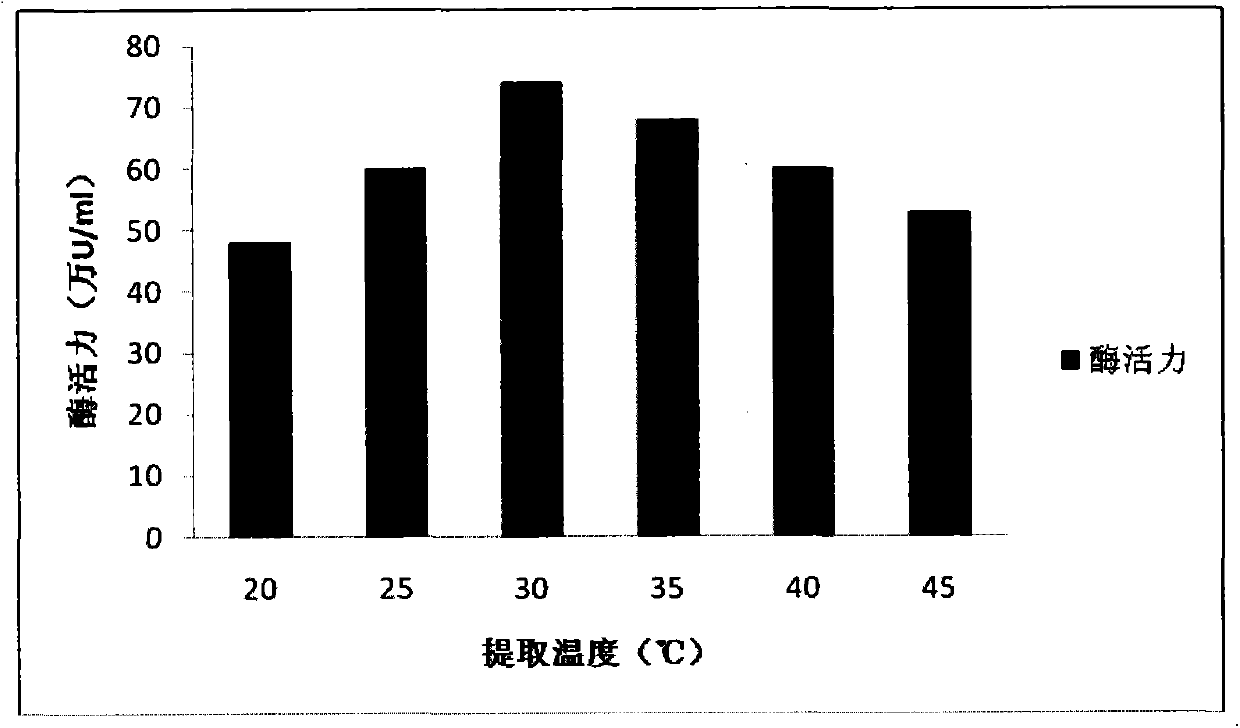

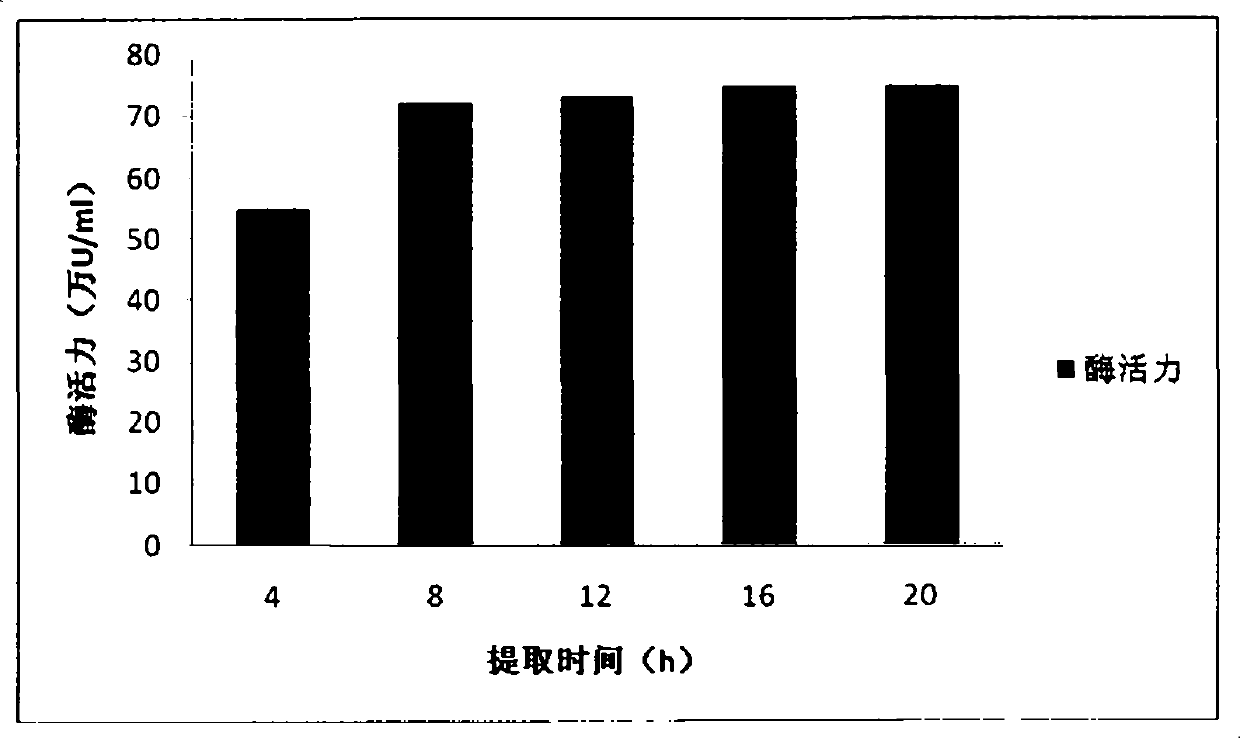

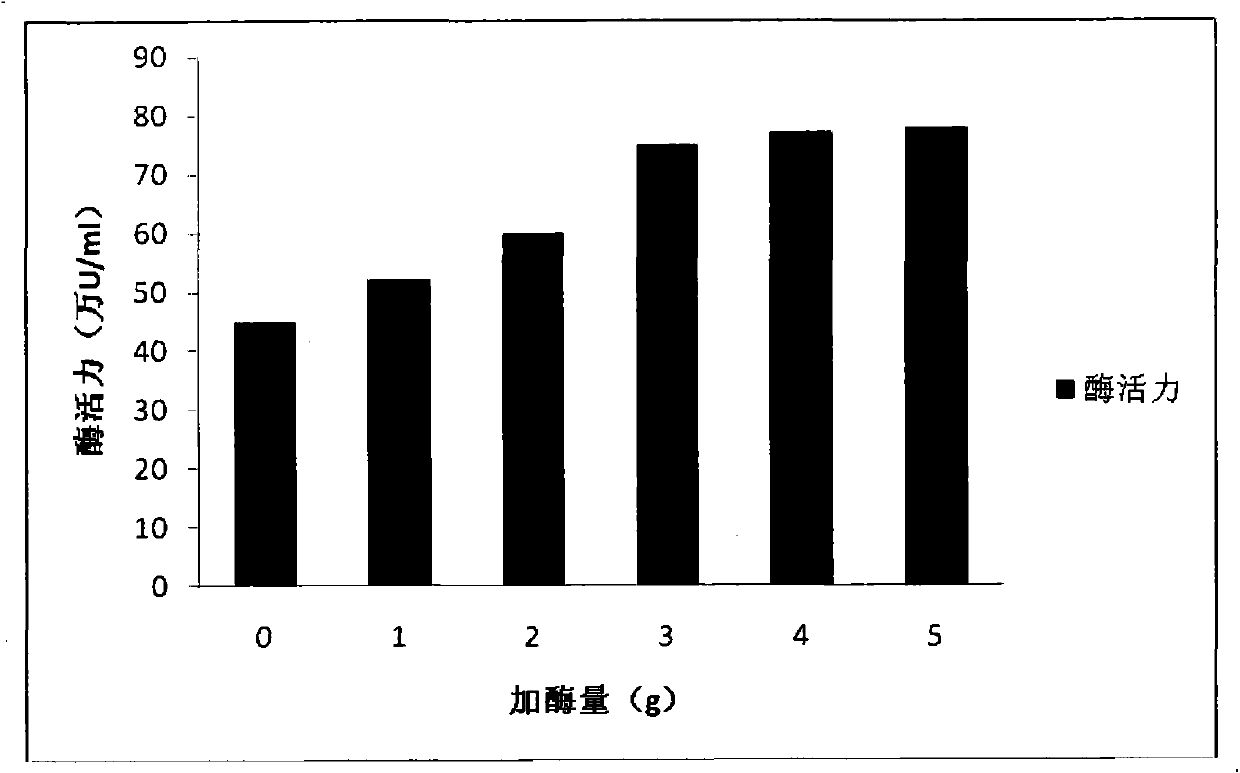

The invention discloses a preparation method of amylase. With barley malt as a raw material, the method comprises the following steps: grinding of barley malt, extraction of amylase, preliminary filtration of the extract liquid, enrichment of the amylase, precipitation of the extract liquid, fine filtration of the extract liquid, ultrafiltration concentration, blending, secondary fine filtration and aseptic packaging. By adopting the method disclosed by the invention, the enzyme activity of the prepared amylase is not lower than 700,000U / ml, the purity is high, the stability is good, and the application prospect is broad.

Owner:DUODUO PHARMA

Machine dishwasher detergent

InactiveUS20130079268A1Detergent compounding agentsDetergent materialsCleansing AgentsELEVATED AMYLASE

A liquid cleaning agent containing: a) 20 to 70 wt % water, b) at least one amylase preparation, c) at least one Ca2+-ion source, d) lactic acid or a lactic acid salt, is notable for elevated amylase stability and improved cleaning performance.

Owner:HENKEL KGAA

Wide-temperature amylase production method

InactiveCN102618518AWide operating temperatureImprove heat resistanceMicroorganism based processesEnzymesBiotechnologyBacillus licheniformis

A wide-temperature amylase production method belongs to the technical field of bioengineering. A strain used in the method is BL-mut08 (bacillus licheniformis-mut08), which is preserved in CCTCC (china center for type culture collection) and encoded as CCTCC NO.M207193, and is disclosed in China patent 200810020635.2. By means of compound mutation, preservation, rejuvenation and breeding of an original BL system and optimizing a medium formula and fermentation process conditions, the method of producing wide-temperature amylase is established, and the amylase produced has a wide range of an action temperature and high heat resistance. The strain reaches a peak of amylase production after being cultured for 72 hours at 37 DEG C. fermentation liquor is flocculated, press-filtered, super-filtered and concentrated to obtain the concentrated liquid, and different amylase preparations, such as pellets, particles or powder, are obtained by other post-processing methods. The amylase preparation is widely applicable to food and medicine industries, especially textile industry, paper industry and industries of alcoholic fermentation, monosodium glutamate, antibiotics and the like.

Owner:无锡德冠生物科技有限公司

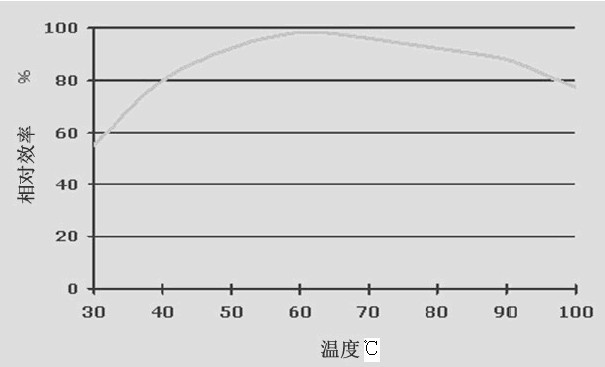

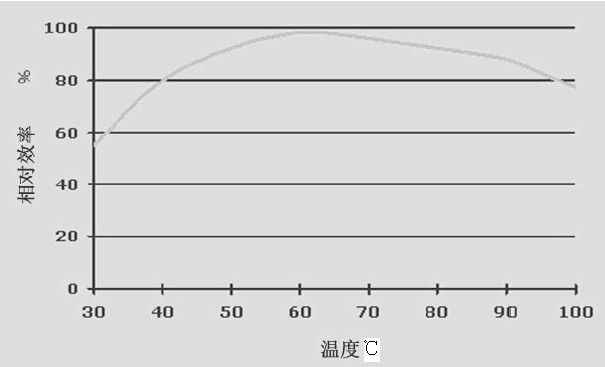

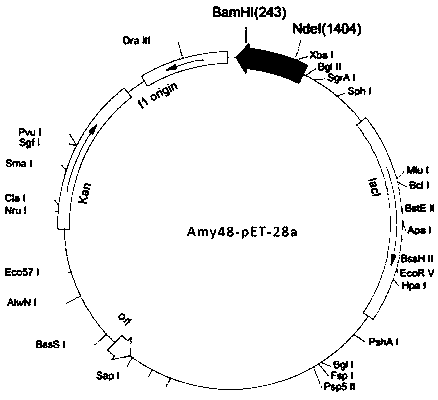

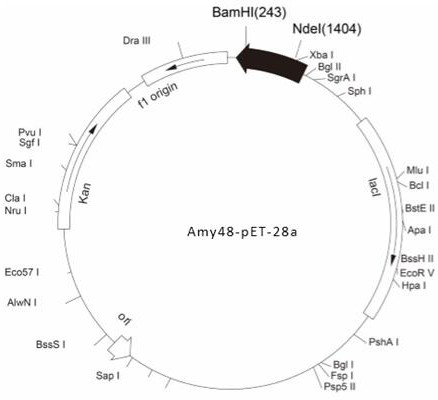

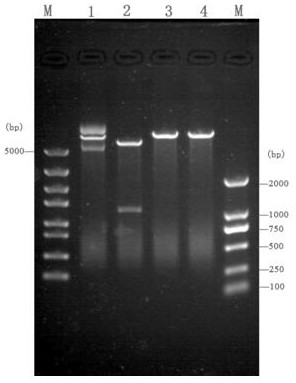

Alpha-amylase gene and application thereof

ActiveCN109182304AQuality impactConvenient time controlBacteriaMicroorganism based processesBiotechnologyEscherichia coli

The invention discloses an alpha-amylase gene. The alpha-amylase gene is prepared from Bacillus sp. 48-1, containing the constructed recombinant vector, the genetically engineered bacterium and the recombinant amylase preparation produced by the genetically engineered bacterium. Having an endotangent. The amino acid sequence of the amylase with alpha-1, 4 glycosidic bond activity is shown in SEQ ID NO: 1, and the coding sequence of the gene is the nucleotide sequence shown in SEQ ID NO: 2. The recombinant vector is constructed and expressed in E. coli, and the product of expression has Alpha-1, 4 endoglycosidic bond function. The present invention describe that amylase plays an important role in promote tobacco leaf alcoholization and the like.

Owner:CHINA TOBACCO YUNNAN IND

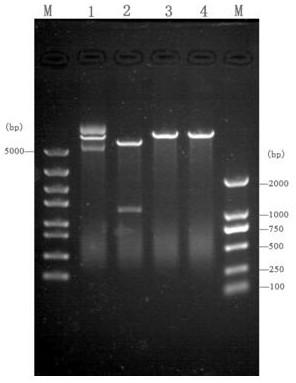

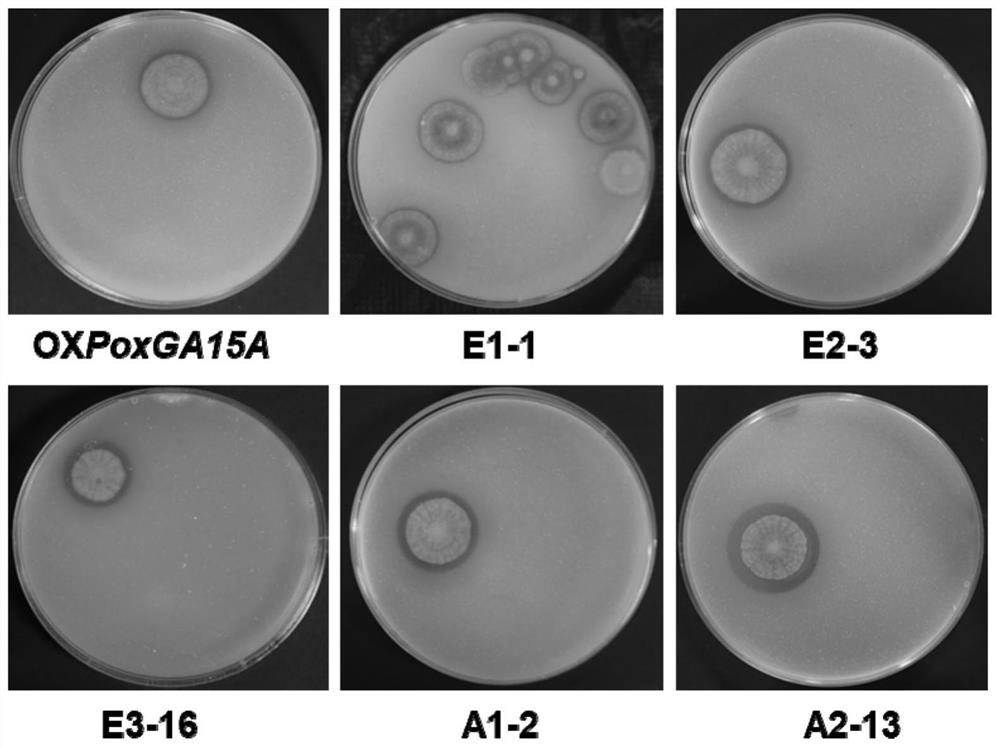

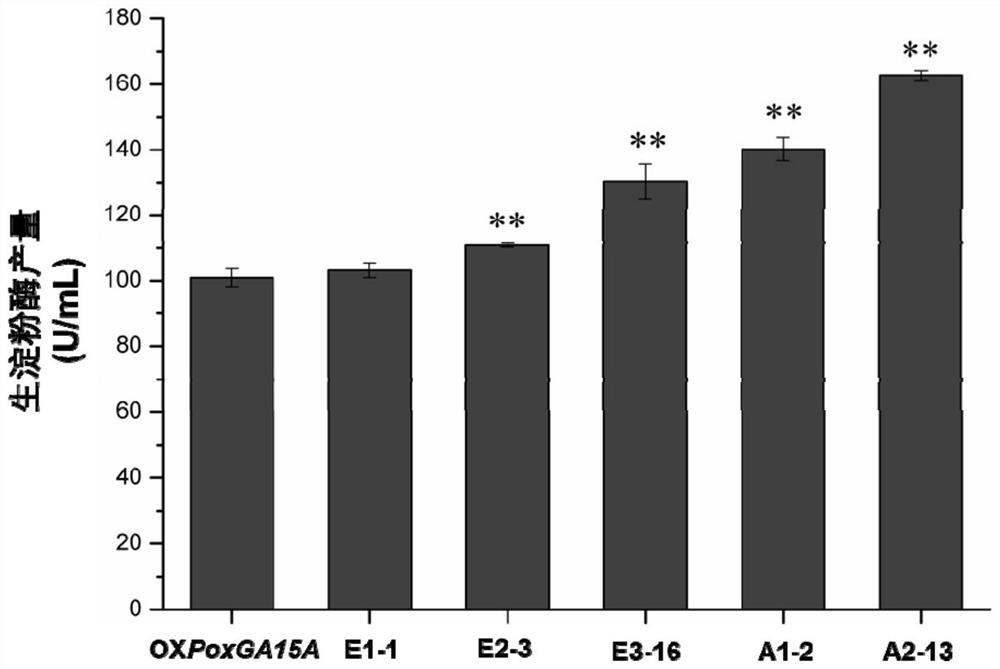

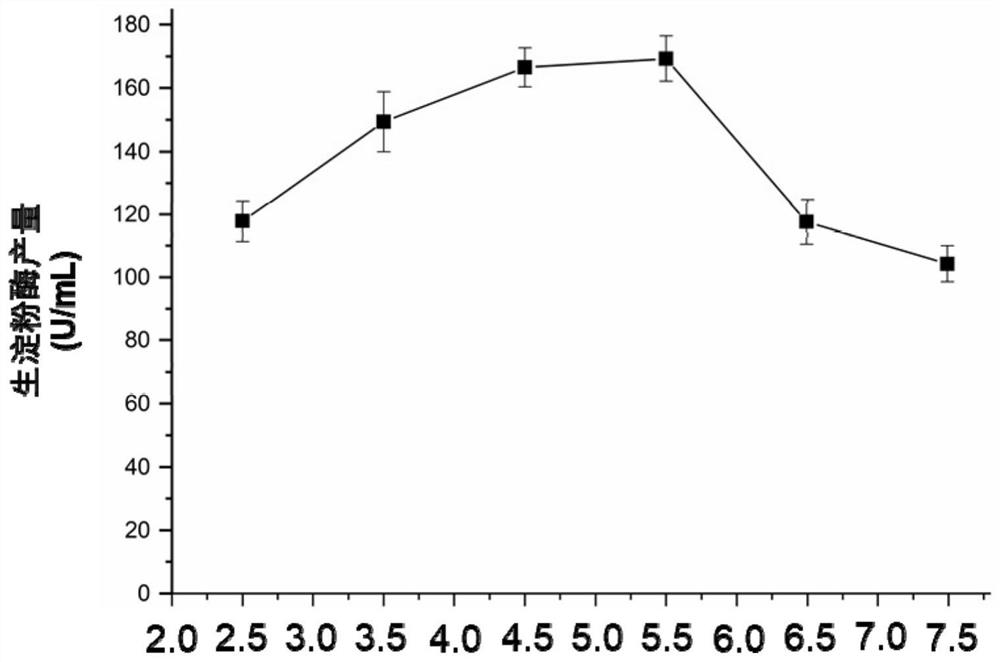

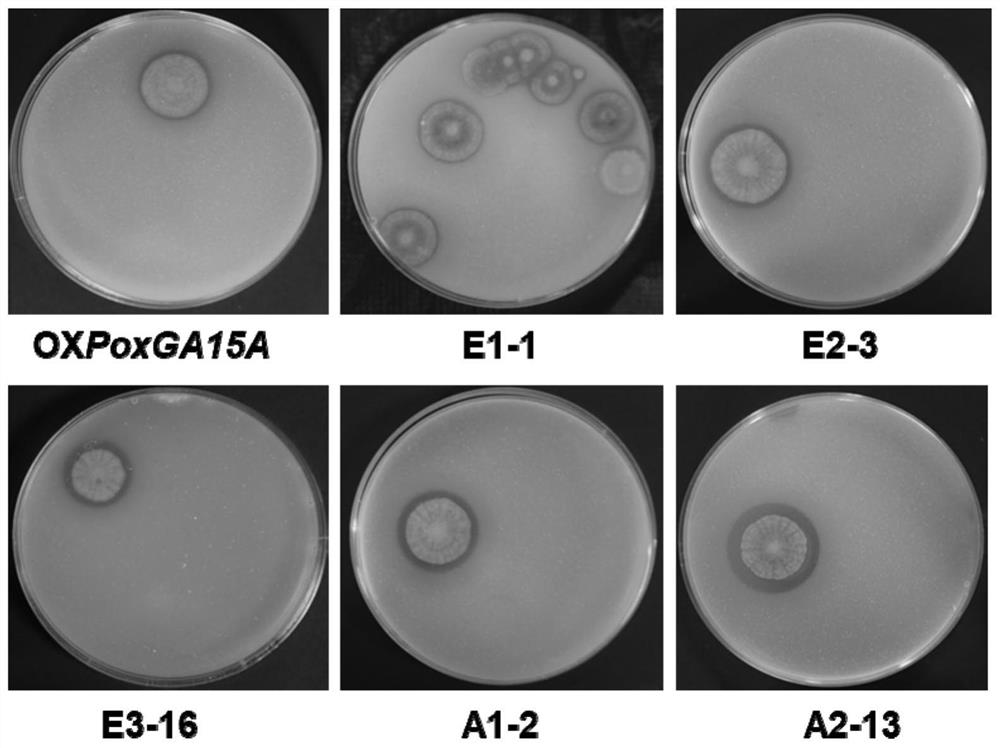

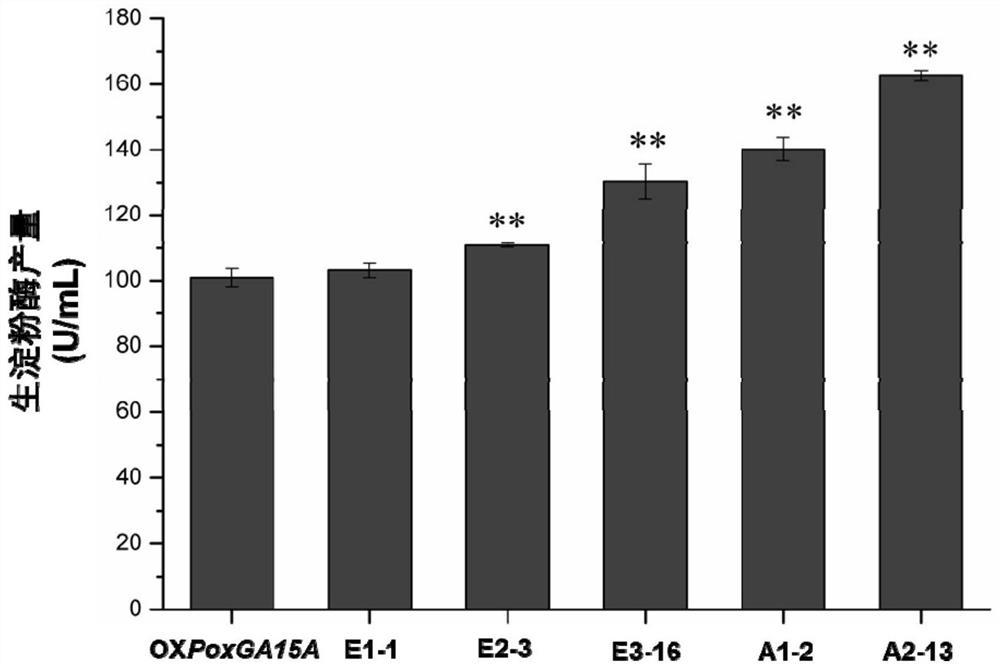

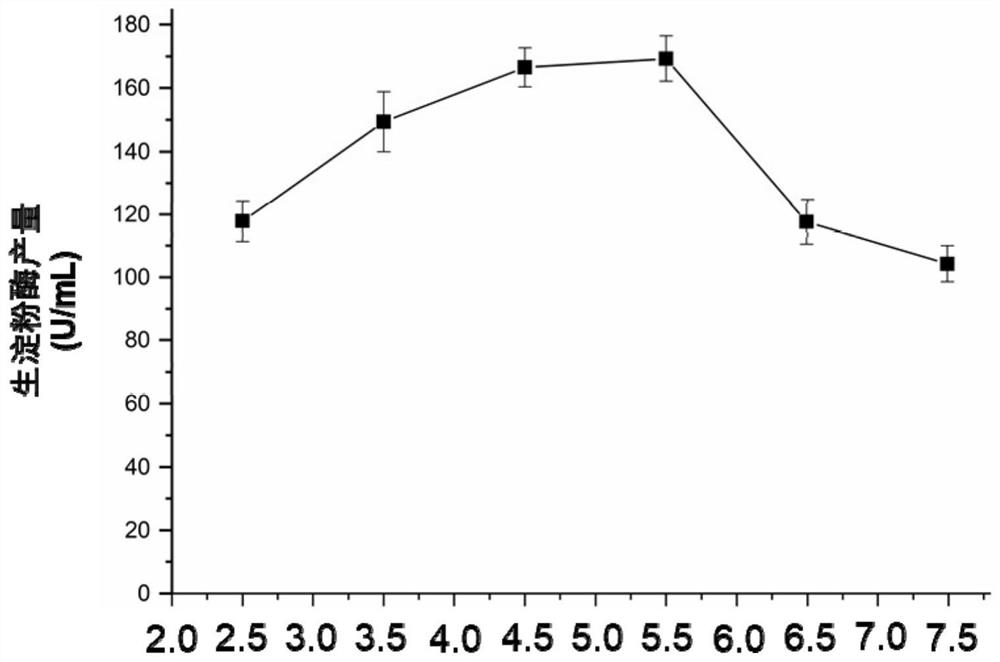

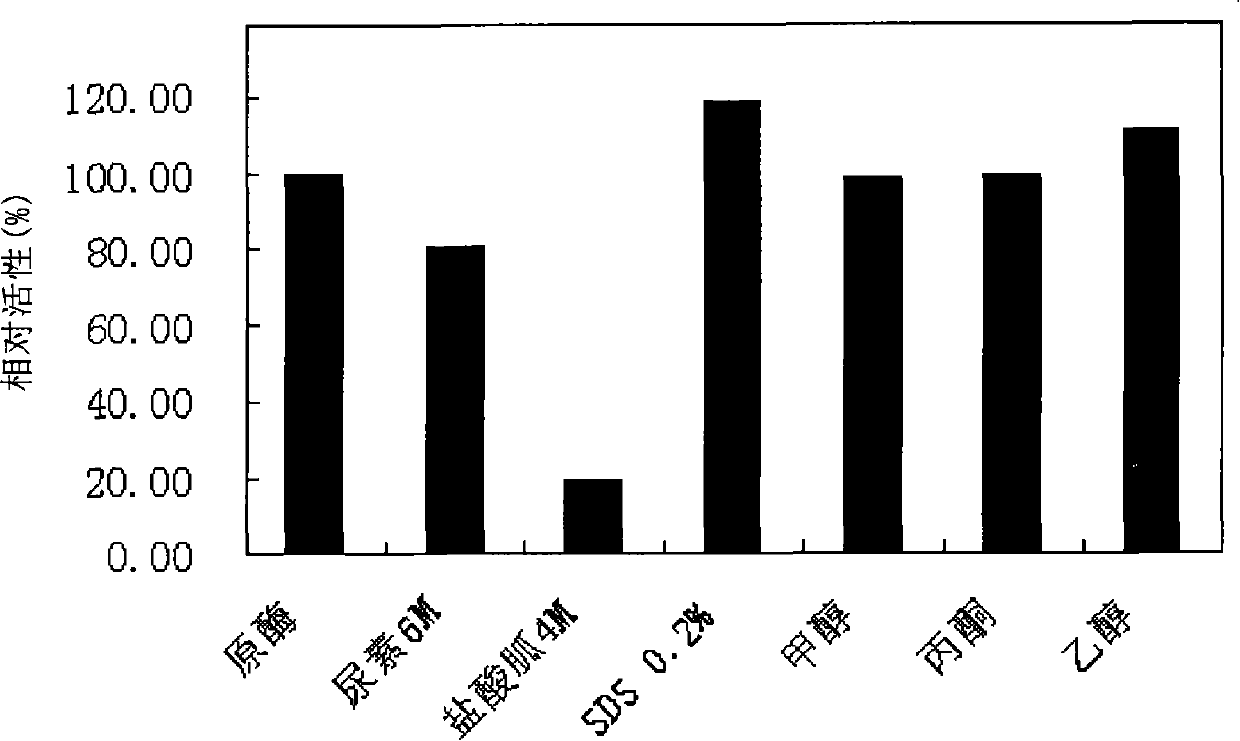

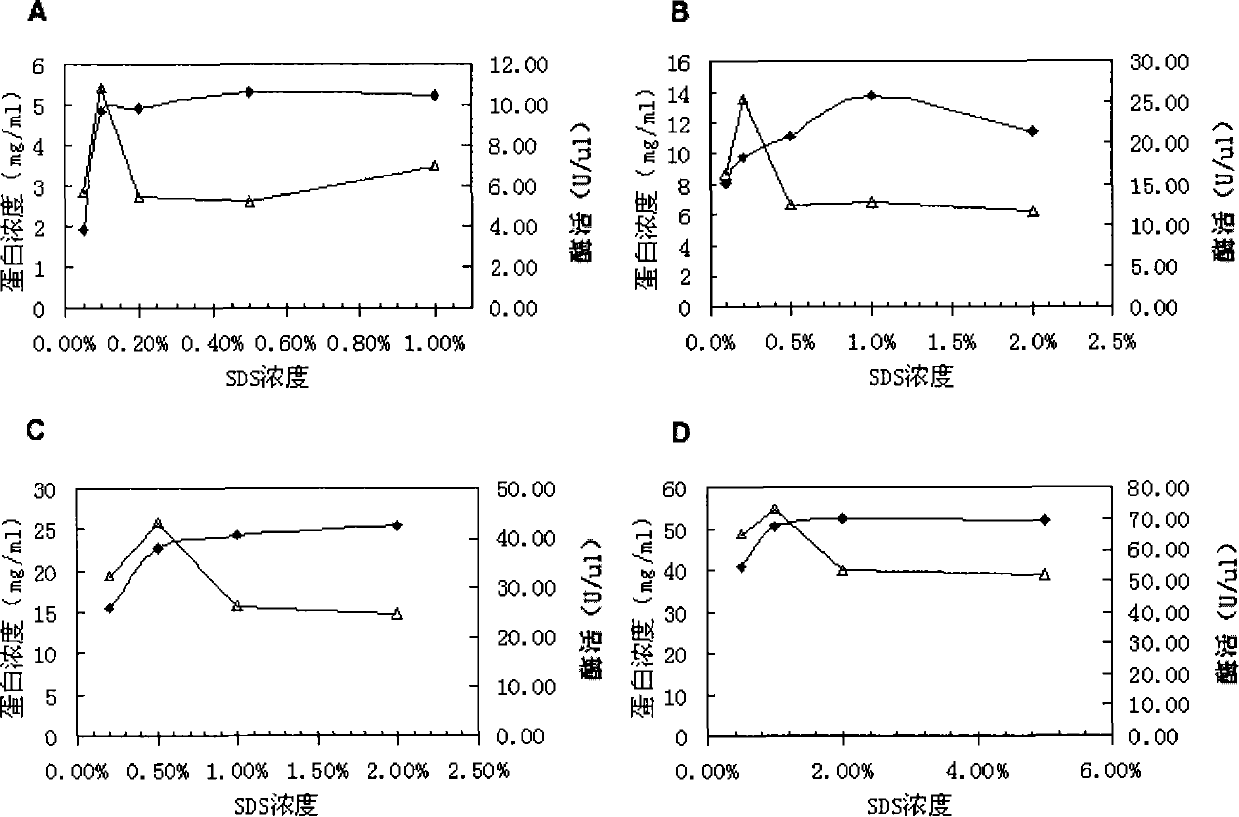

Penicillium oxalicum mutant strain A2-13 and application thereof in preparation of raw amylase preparation and degradation of raw starch

The invention discloses a Penicillium oxalicum mutant strain A2-13 and application thereof in preparation of a raw amylase preparation and degradation of raw starch. The invention provides the Penicillium oxalicum A2-13, and the preservation number of the Penicillium oxalicum A2-13 in China Center for Type Culture Collection is CCTCC NO: M 2020319. The invention also provides a method for producing raw amylase or the raw amylase preparation by using the Penicillium oxalicum A2-13. The method comprises the following steps of: culturing the Penicillium oxalicum A2-13 in a basic or optimized fermentation culture medium for a certain time, collecting a fermentation product, centrifuging and collecting supernatant to obtain the raw amylase or the raw amylase preparation. Experiments prove thatthe Penicillium oxalicum A2-13 obtained by the invention can be used for producing the raw amylase preparation; the preparation can be used for efficiently hydrolyzing raw cassava starch and raw cornstarch; and in addition, a hydrolysis end product mainly comprises glucose. The preparation can be used for producing alcohol.

Owner:GUANGXI UNIV

Method for preparing immobilized alpha-amylase by using spherical tannin as carrier

The invention relates to a method for preparing immobilized alpha-amylase, in particular to a method for preparing immobilized alpha-amylase by using spherical tannin as a carrier. The method is characterized by comprising the following steps: 1) adding the spherical tannin into solution of alpha-amylase to obtain mixed solution of the spherical tannin carrier and the alpha-amylase; 2) performing an absorption action in the mixed solution at 4 to 50 DEG C, adding glutaraldehyde solution, and performing crosslinking at 4 to 50 DEG C; and 3) filtering to remove filtrate, washing with neutral phosphate buffer solution and drying by absorption to obtain the alpha-amylase immobilized on the spherical tannin. The prepared alpha-amylase immobilized on the spherical tannin has uniform shape and large surface area; the average amylase activity recovery rate is up to over 80 percent; and compared with solution enzyme, the affinity of the immobilized alpha-amylase with a substrate (starch) is improved by more than 12 times.

Owner:FUJIAN NORMAL UNIV

Raw-starch amylase producing penicillium and raw-starch amylase preparation produced thereby

InactiveCN101955887BLow costAvoid high temperature cookingFungiHydrolasesBiotechnologyAlcohol production

The invention discloses raw-starch amylase producing penicillium and a raw-starch amylase preparation produced thereby. The invention provides penicillium sp. GXU20 CGMCC No.3690. The invention also provides the raw-starch amylase preparation produced by fermentation of penicillium GXU20. The penicillium GXU20 and the raw-starch amylase preparation both can be used in alcohol production for avoiding thermophilic digestion of raw materials and saving a large amount of energy; the addition of alpha-amylase is avoided, and cost is saved; and saccharification and fermentation are performed in the same container, and equipment cost is reduced. The raw-starch amylase producing penicillium and the raw-starch amylase preparation produced thereby are expected to solve the problem of high alcohol production cost caused by the thermophilic digestion of starch.

Owner:GUANGXI UNIV

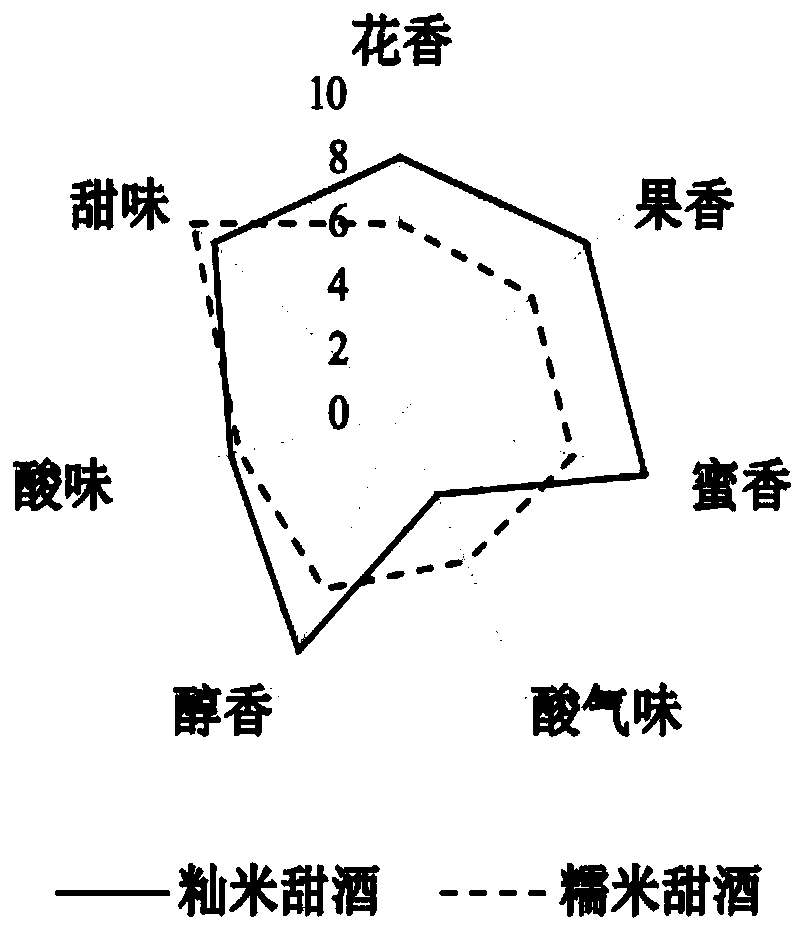

Method for making fermented special sweet wine by using indica rice

PendingCN111187692AGood for saccharification and fermentationReduce generationAlcoholic beverage preparationMicroorganism based processesBiotechnologyChaptalization

The invention discloses a method for making fermented special sweet wine by using indica rice. The method comprises the following steps: (1) treating indica rice; (2) spraying an amylase preparation;(3) performing mixing with koji; (4) performing saccharifying and fermenting; (5) performing fermenting at low temperature; and (6) performing pasteurization. According to the invention, indica rice is used as a raw material for making the sweet wine, then rhizopus and sacchromycopsis fibuligera are used for preparing the compound strain sweet wine koji, and the compound strain sweet wine koji isused for fermentation. According to detection, the content of beta-phenylethanol in the obtained sweet wine is obviously improved, and generation of bad flavors such as bitterness and the like in a fermentation process is reduced by adopting low-temperature fermentation. In addition, maltose amylase is added in the early stage of fermentation of the indica rice sweet wine to solve the problem of regeneration of indica rice, and the finally made fermented special sweet wine has the characteristics of outstanding fragrance and clear color. Compared with conventional glutinous rice sweet wine made by rhizopus yeast, the fermented special sweet wine has the advantages that operation is simple, raw material cost can be greatly reduced by making sweet wine by using indica rice, quality of the sweet wine is better, and thus the method has a good application prospect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

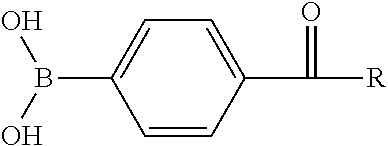

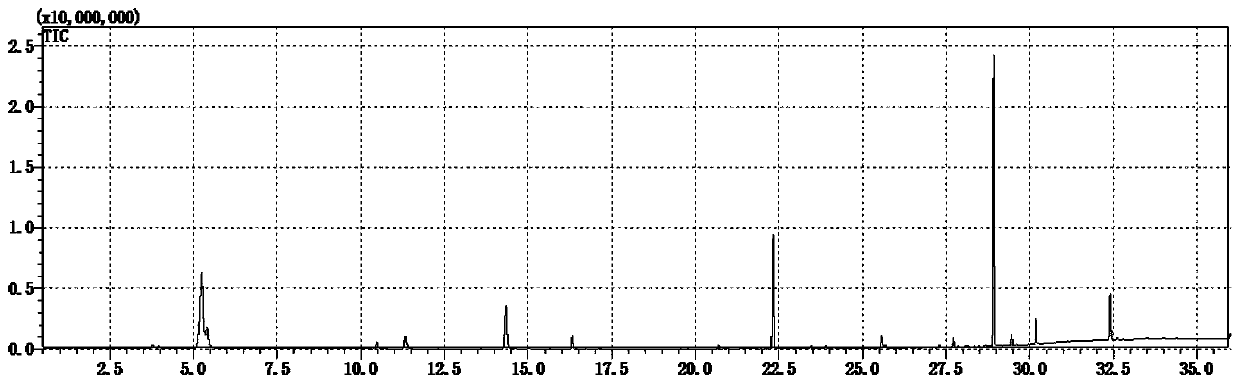

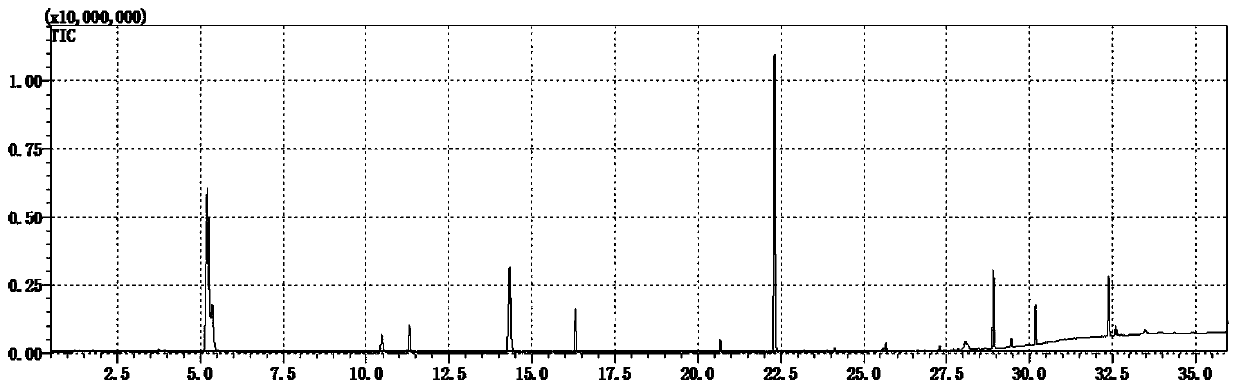

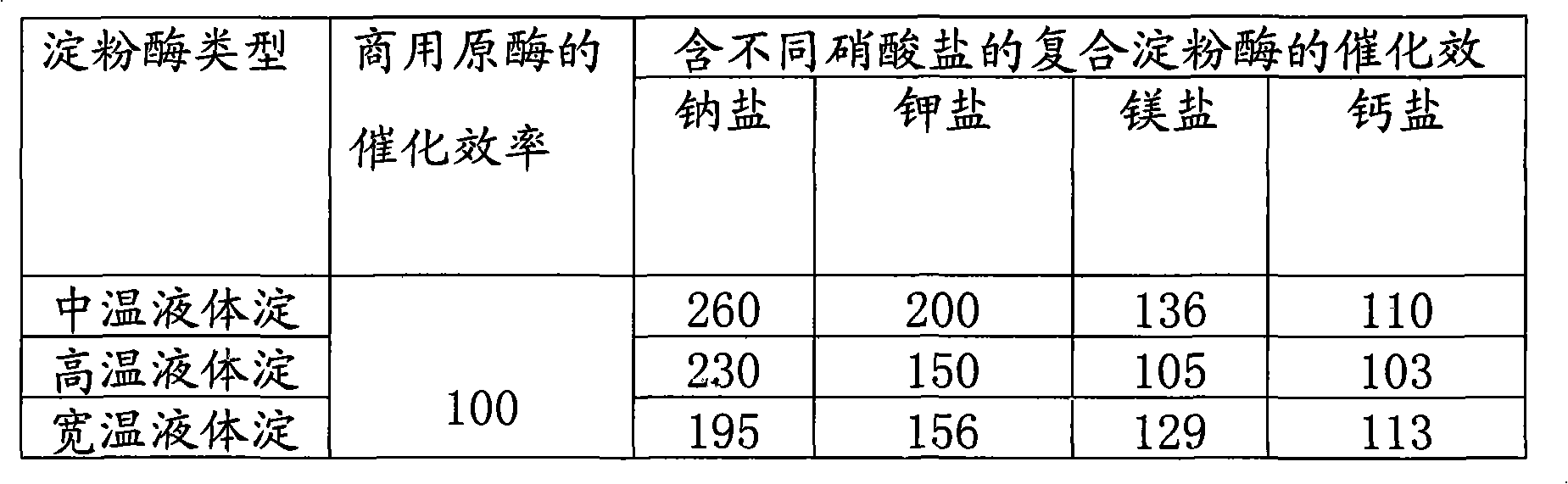

Preparation method for liquid composite alpha-amylase

InactiveCN101570749AImprove degradation efficiencyImprove applicabilityEnzyme stabilisationDecompositionAlpha-amylase

The invention provides a preparation method for liquid composite alpha-amylase. Through the combination of alpha-amylase and multiple chemicals with special structures, special linking action is generated between the chemicals and the macromolecules of amylase protein so as to enhance structural stability and adhesion to substrate, thereby realizing the large promotion of the catalytic activity of the amylase. The method has the advantages of simple preparation technology, convenience in operation, no need of special equipment, little investment, little contamination, easy control of technological parameters; compared with traditional commercial amylase, the decomposition efficiency of the prepared product for starch can increase by 100% to 200%, and the cost can be greatly lowered at the same time.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

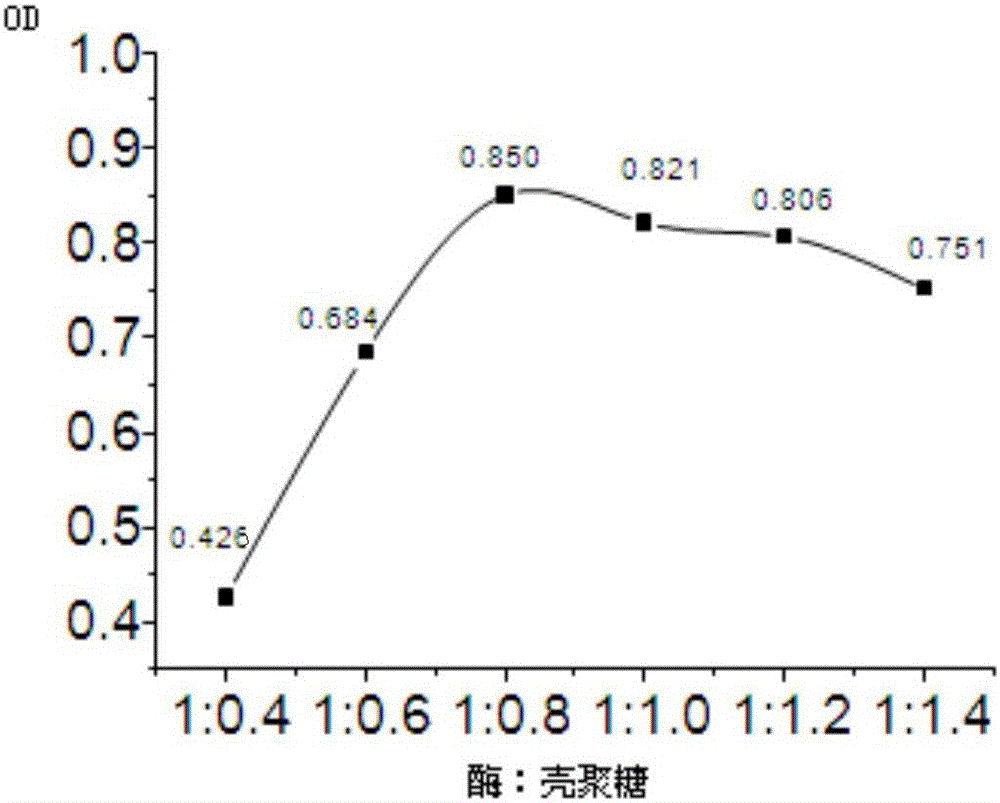

Method for preparing modified alpha-amylase

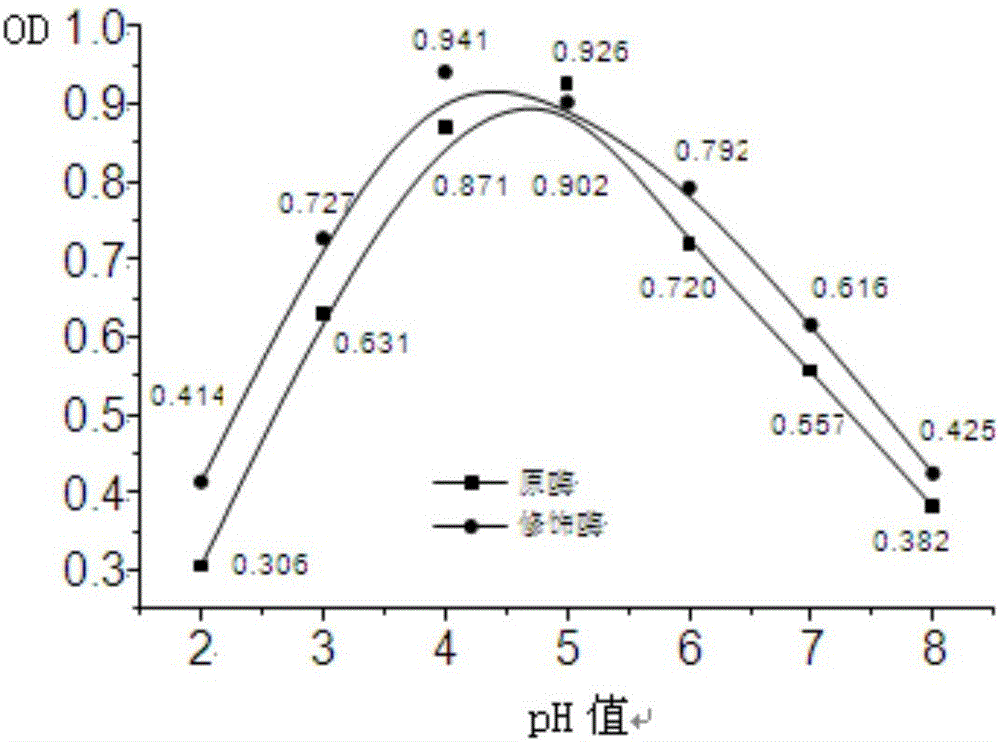

ActiveCN105802939AImprove thermal stabilityImprove physical and chemical propertiesEnzyme stabilisationGlycosylasesCross-linkAlpha-amylase

The invention discloses a method for preparing modified alpha-amylase. The method includes the steps that chitosan is oxidized through an oxidizing agent to obtain oxidized chitosan; the oxidized chitosan and alpha-amylase are reacted to obtain a cross-linking reaction mixture; a reducing agent is added into the cross-linking reaction mixture, reacting is carried out, and the modified alpha-amylase is obtained. By means of the mode, the environmental suitability and the stability of the alpha-amylase can be improved.

Owner:SHENZHEN POLYTECHNIC

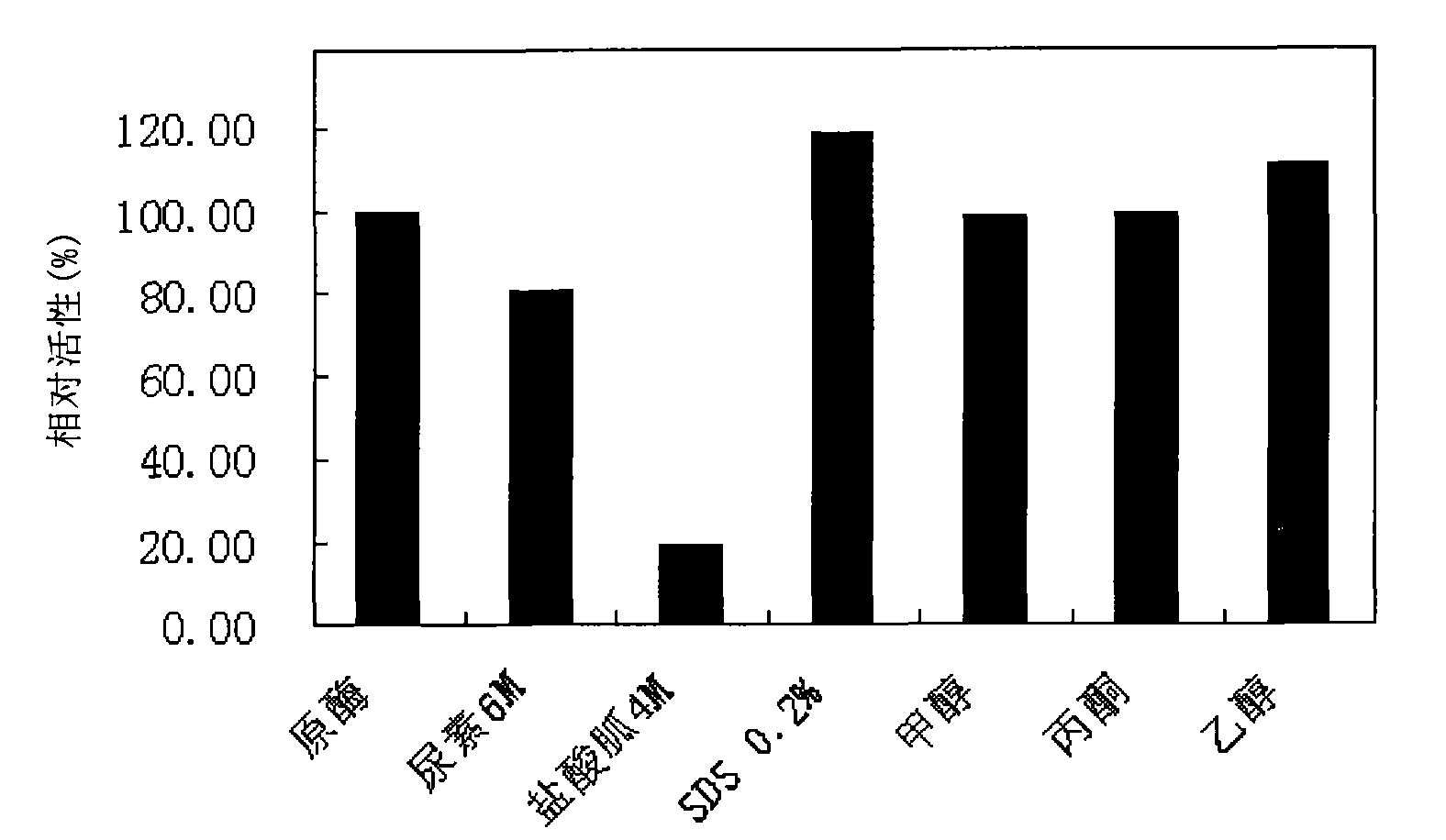

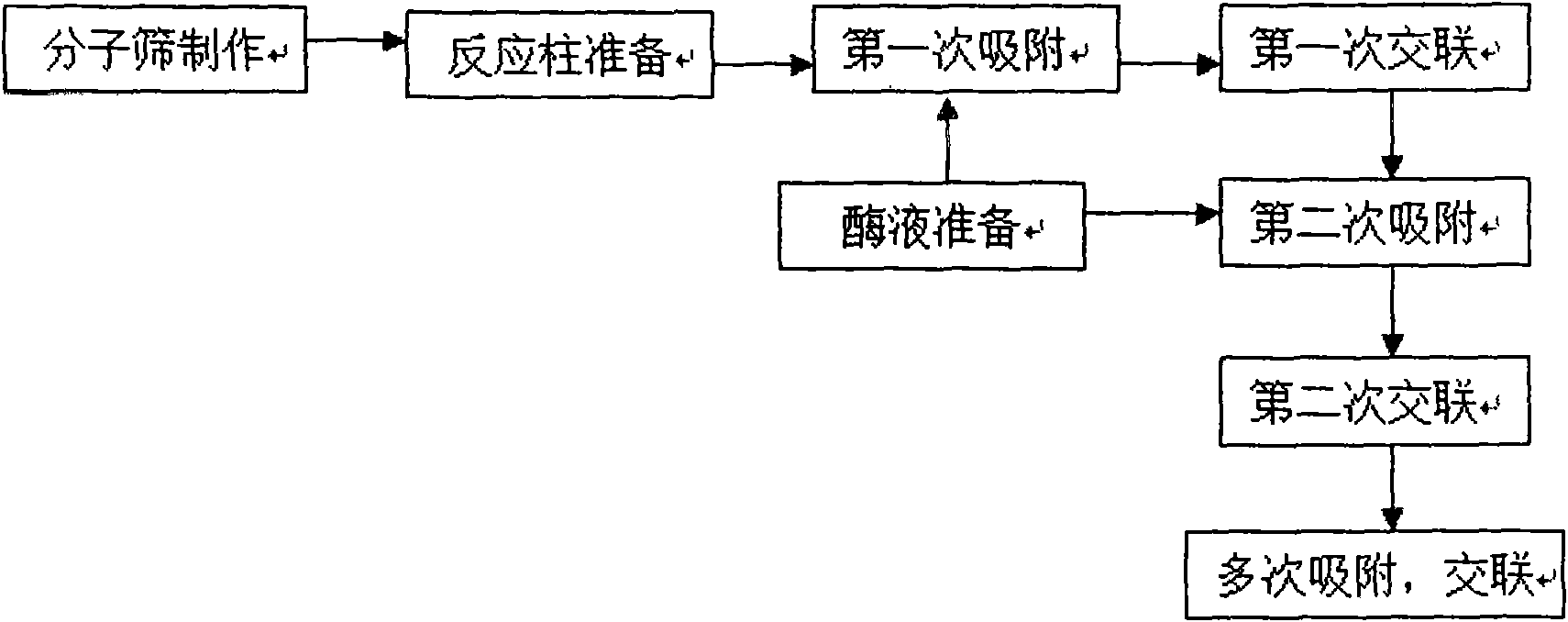

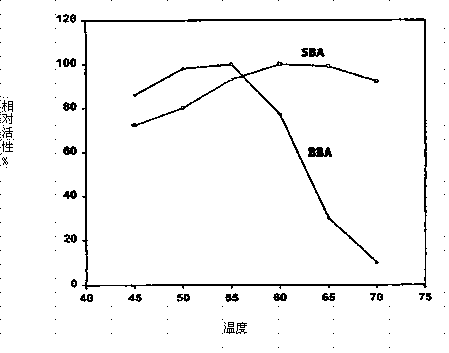

Preparation method of immobilized barley beta-amylase taking reconstructed macroporous molecular sieve as carrier thereof

InactiveCN101624590ASimple preparation processMild conditionsOn/in inorganic carrierMolecular sieveStable fixation

The invention relates to a preparation method used for producing the immobilized enzyme of malt syrup, in particular to a preparation method of immobilized barley beta-amylase taking reconstructed macroporous molecular sieve as the carrier thereof. The method takes the reconstructed macroporous molecular sieve as the carrier, adopts the method of multiple adsorb crosslinking, and prepares stable immobilized barley beta-amylase. The method has the advantages that the production technology of immobilized enzyme is simple, the condition is mild, multiple adsorption and crosslinking can be performed, the required amount of enzyme is small, the quantity of hanging enzyme is large, the mechanical property is good, the operation is stable, the stability of the immobilized enzyme is good, the quality of the produced malt sugar is good, and the carrier can be repeatedly used, and the method is applicable to the packed bed reactors.

Owner:郸城财鑫糖业有限责任公司

A method for preparing high maltose syrup from cadmium rice

A method for preparing high maltose syrup from cadmium rice, comprising the following steps: (1) soaking and refining: adding citric acid-sodium citrate buffer solution to cadmium rice, soaking, refining, filtering, and continuing to stir the filtrate to obtain rice Slurry; (2) Liquefaction: Add citric acid-sodium citrate buffer solution to the rice slurry, and add high-temperature-resistant α-amylase preparation, stir evenly, heat to react, filter, and obtain rice dregs protein and liquefaction liquid; (3) Saccharification: cool down the liquefied liquid, add glucoamylase preparation, stir evenly, keep warm and react to obtain the saccharified liquid; (4) Ion exchange: pass the saccharified liquid through secondary ion exchange to obtain a clear and transparent liquid; (5) Concentrate and dry: The clear and transparent liquid is evaporated and concentrated to obtain high maltose syrup. The method of the invention does not need to add a cadmium removal step, and the cadmium content of the obtained product is less than 0.03 mg / kg, and the maltose content is more than 75%. The method of the invention is simple, practical, safe and reliable.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Preparation method for high-activity beta-amylase

ActiveCN103232982BReduce CODImprove the environmentHydrolasesPurification methodsResource consumption

The invention relates to a separation and purification method for amylase in a plant, and particularly relates to a method for industrially producing high-activity beta-amylase. The preparation method for the beta-amylase disclosed by the invention comprises the following steps of: collecting separation water; pre-treating; precipitating and dissolving out the beta-amylase; forming a composite precipitate from polyacrylic acid and the beta-amylase in the solution; dissolving the composite precipitate; and adjusting the pH to be greater than or equal to 6.0, and dissolving out the beta-amylase. The invention provides a preparation method for beta-amylase, which is less in resource consumption, high in yield (of about 75%), and high in activity (of 700000-900000 u / ml generally); and the obtained product is good in tolerance to temperature and pH value, and low in cost in case of being applied to maltose production.

Owner:山东绿健生物技术有限公司

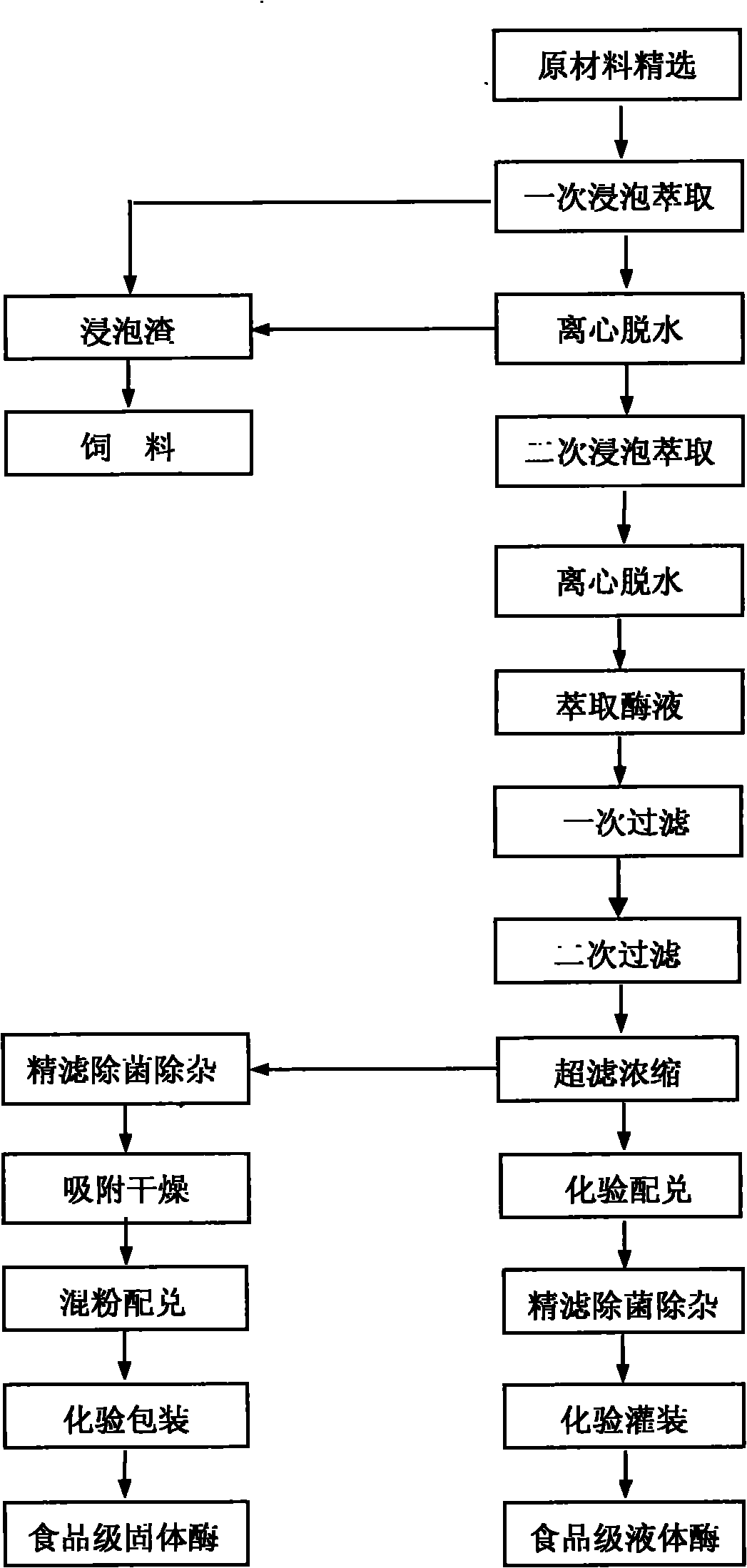

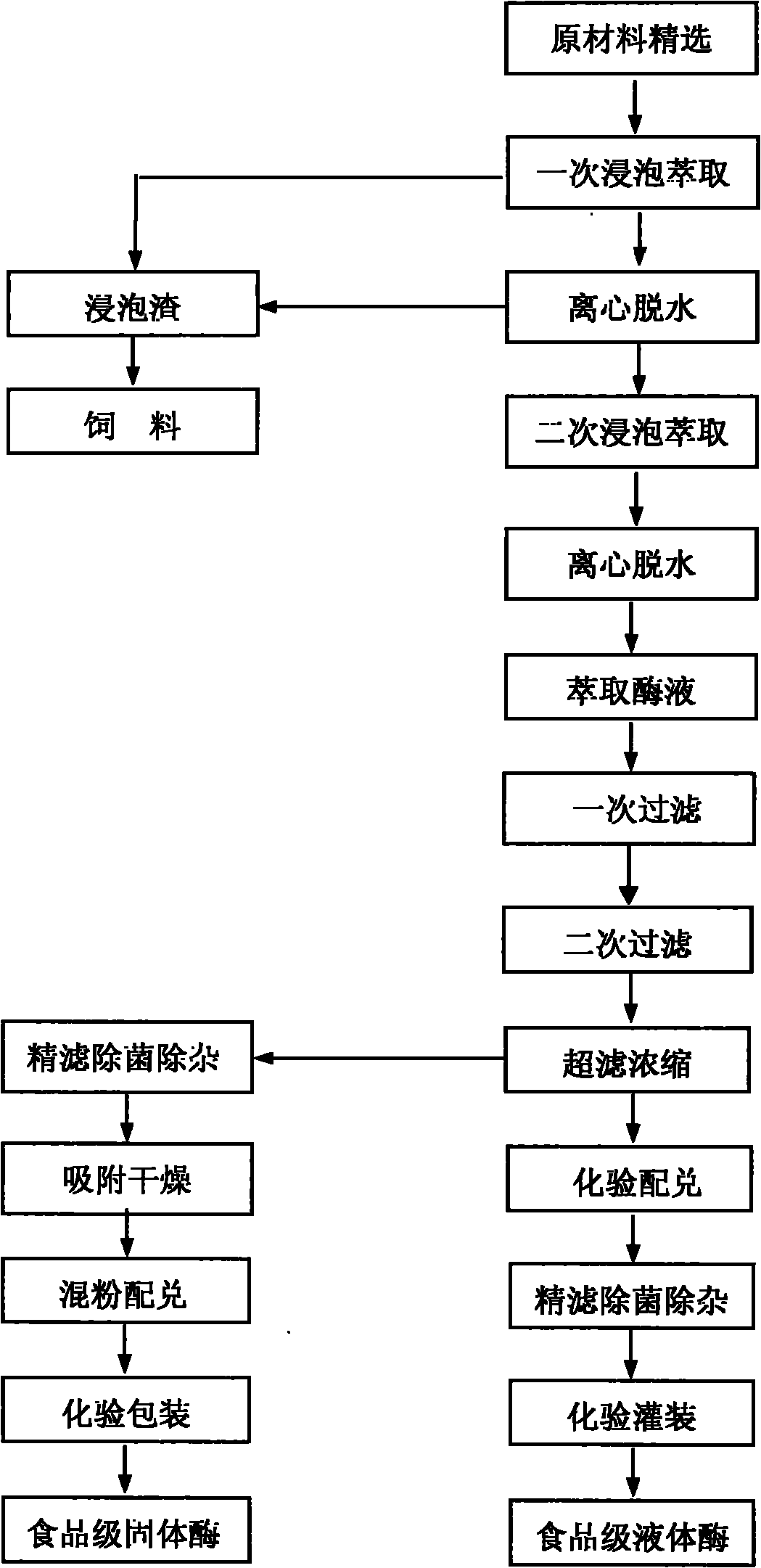

Method for producing plant extract food-grade beta-amylase preparation

The invention discloses a method for producing a plant extract food-grade beta-amylase preparation, which comprises: adding wheat bran into a soaking tank with stirring, soaking at normal temperature, dewatering the soaked material in a centrifuge, collecting extract, adding wheat bran into the extract for soaking, pumping the secondary extract into a tank, adding kieselguhr and perlite as a filter aid, and performing primary filtration and secondary filtration; separating, grading, purifying and concentrating component fluid substance by using a roll film; and testing, blending, performing fine filtration to remove competitor bacteria and impurities from solution, refining to obtain the high-purity, high-bioactivity food-grade liquid beta-amylase preparation. The food-grade beta-amylase preparation can also be prepared into food-grade solid beta-amylase preparation product. The plant extract food-grade beta-amylase preparation is directly extracted from the wheat bran by multistage soaking without any microbe strain nor chemical substance. The method has the advantages of low energy consumption, high efficiency, pure enzyme system and stable quality and is suitable for large-scale industrial production.

Owner:南宁雄晋生物科技有限公司

A kind of α-amylase gene and its application

ActiveCN109182304BQuality impactConvenient time controlBacteriaMicroorganism based processesEnzyme GeneNucleotide

The invention discloses an α-amylase gene, which is obtained from Bacillus Bacillus It is isolated from sp.48‑1, and contains its constructed recombinant vector, genetically engineered bacteria and its produced recombinant amylase preparation. The amylase amino acid sequence with endo-α-1,4 glycosidic bond activity is shown in SEQ ID NO.1, and the coding sequence of its gene is the nucleotide sequence shown in SEQ ID NO.2. By constructing a recombinant vector and expressing it in Escherichia coli, the expression product has the function of endocutting α-1,4 glycosidic bonds, and the present invention describes that amylase plays an important role in promoting alcoholization of tobacco leaves.

Owner:CHINA TOBACCO YUNNAN IND

Preparation method of liquefied amylases capable of resisting superhigh temperature

The invention relates to a method for producing coenzymes Q10 via the fermentation of genetic recombinant bacteria. According to the method, NAD (Nicotinamide Adenine Dinucleotide) kinase genes are transferred into strains of reducing coenzymes Q10 with high-efficiency expression. The culture condition of optimizing the recombinant bacteria comprises (1) cant activation; (2) seed culture; and (3) fermentation culture. The recombinant bacteria constructed by a genetic engineering means are strong in stability; compared with original strains, the coenzymes Q10 of the recombinant bacteria has the advantages that the yield is increased by 21.6% and reaches 1.63g / L. Thus, the requirement of industrial production is satisfied.

Owner:HUNAN HUXIANG BIOTECH CO LTD

Penicillium oxalicum mutant strain a2-13 and its application in preparation of raw amylase preparation and degradation of raw starch

The invention discloses the Penicillium oxalicum mutant strain A2-13 and its application in preparing raw amylase preparation and degrading raw starch. The present invention provides Penicillium oxalicum A2‑13, whose preservation number in China Center for Type Culture Collection is CCTCC NO: M 2020319. The present invention also provides a method for producing raw amylase or raw amylase preparation with Penicillium oxalicum A2-13, comprising the following steps: cultivating the above-mentioned Penicillium oxalicum A2-13 in a basic or optimized fermentation medium for a certain period of time time, collect the fermentation product, centrifuge and collect the supernatant to obtain raw amylase or raw amylase preparation. Experiments of the present invention prove that the Penicillium oxalicum A2‑13 obtained in the present invention can produce raw amylase preparations, which can efficiently hydrolyze raw tapioca starch and raw corn starch, and the final product of hydrolysis is mainly glucose. This preparation can be used to produce alcohol.

Owner:GUANGXI UNIV

Method for renaturing and purifying recombinant extremely heat-resistant alpha-amylase

The invention discloses a method for preparing a thermophilic alpha-amylase, which comprises the following steps: dissolving an inclusion body of the thermophilic alpha-amylase by using detergent solution so as to obtain solution containing the thermophilic alpha-amylase; and separating out the thermophilic alpha-amylase from the obtained solution. The thermophilic alpha-amylase obtained by the method has consistent enzymatic activity and heat resistance of native proteins. The method has the characteristics of simplicity, high efficiency, low cost and easy amplification, and is particularly suitable for the mass preparation of recombinant thermophilic alpha-amylase. Simultaneously, the method is also suitable for the renaturation and the purification of other thermophilic proteins expressed in forms of insoluble inclusion bodies.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI

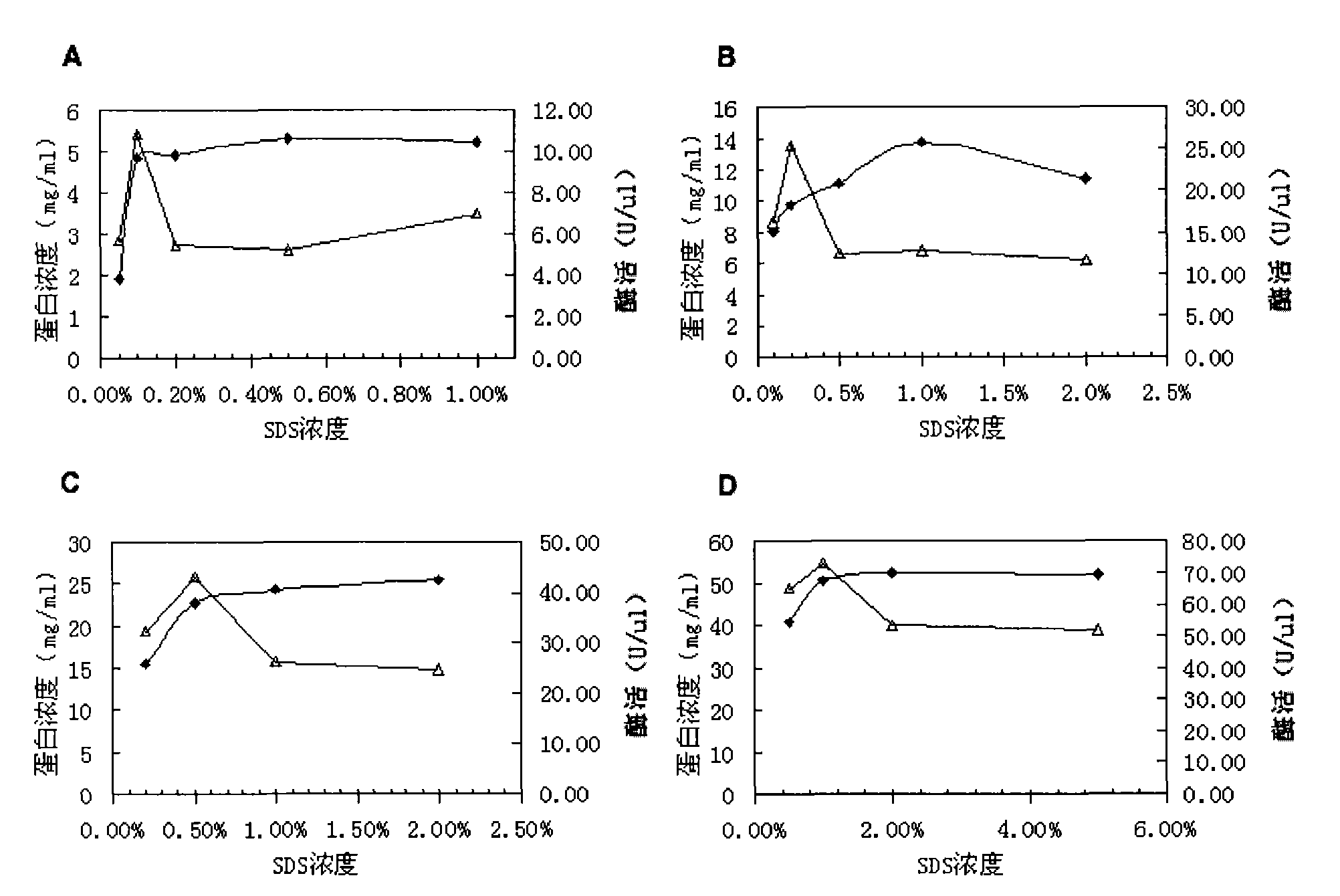

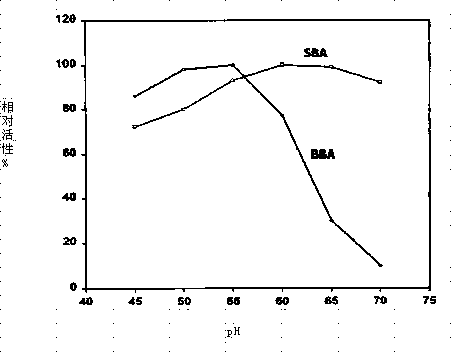

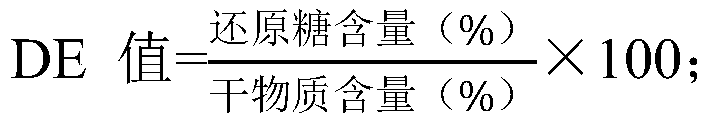

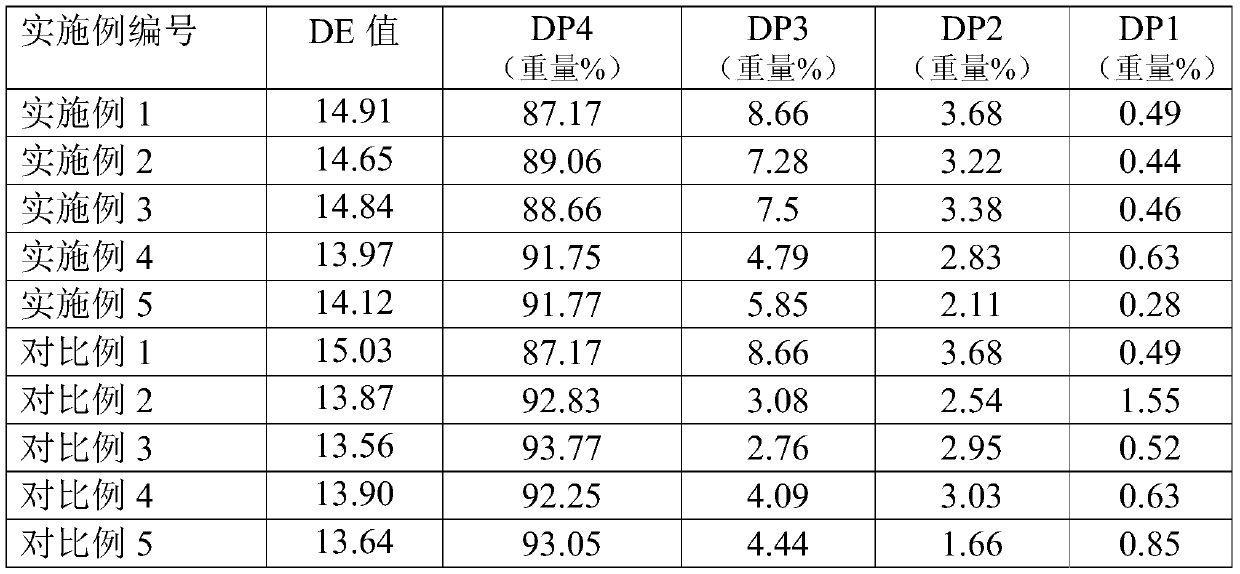

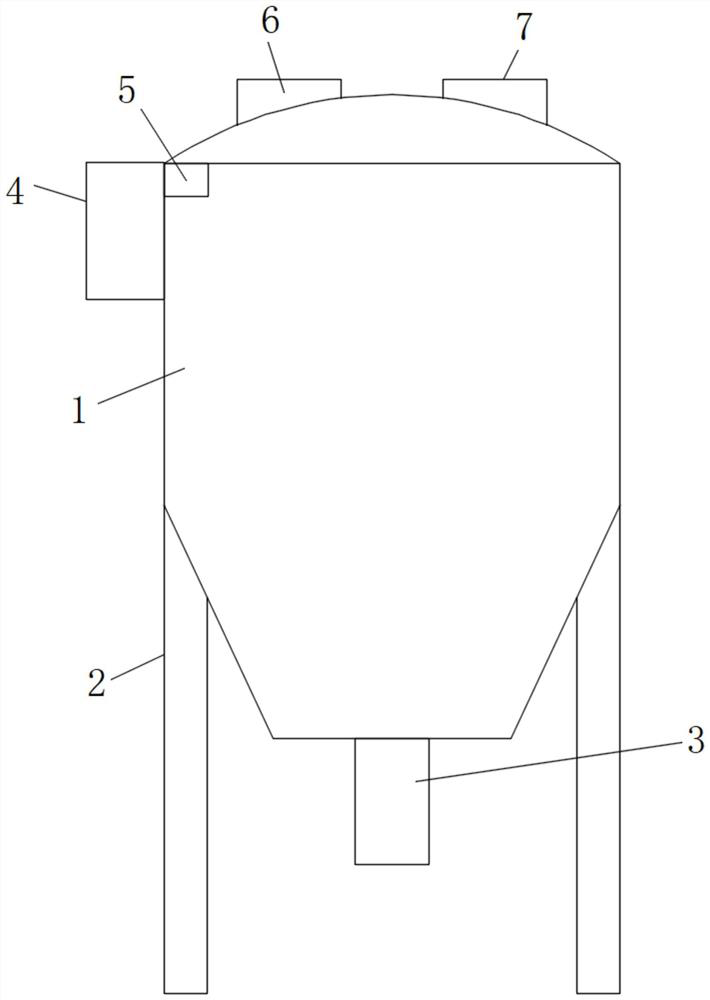

Compound amylase preparation, application thereof in starch liquefaction and starch liquefaction method

ActiveCN109777795AIncrease the degree of liquefactionWell mixedEnzymesFermentationHigh concentrationWater activity

The invention relates to the field of starch sugar preparation, and discloses a compound amylase preparation, an application thereof in starch liquefaction and a starch liquefaction method. The compound amylase preparation comprises L-type amylase and S-type amylase, wherein the amino acid sequence of the L-type amylase has at least 95% sequence consistency with the amino acid sequence shown in SEQ ID NO: 1, and the amino acid sequence of the S-type amylase has at least 95% sequence consistency with the amino acid sequence shown in SEQ ID NO: 2. The method comprises the following steps of: adding the compound amylase preparation into starch feed liquid, and spraying. The compound amylase preparation can rapidly reduce the viscosity of a system in high-concentration starch feed liquid (under the condition of relatively low water activity), enables the feed liquid to be uniformly mixed, is favorable for pumping, has better thermal stability, can be sprayed and liquefied at a higher temperature, enables starch particles to be completely destroyed, and is favorable for complete liquefaction.

Owner:COFCO GROUP +2

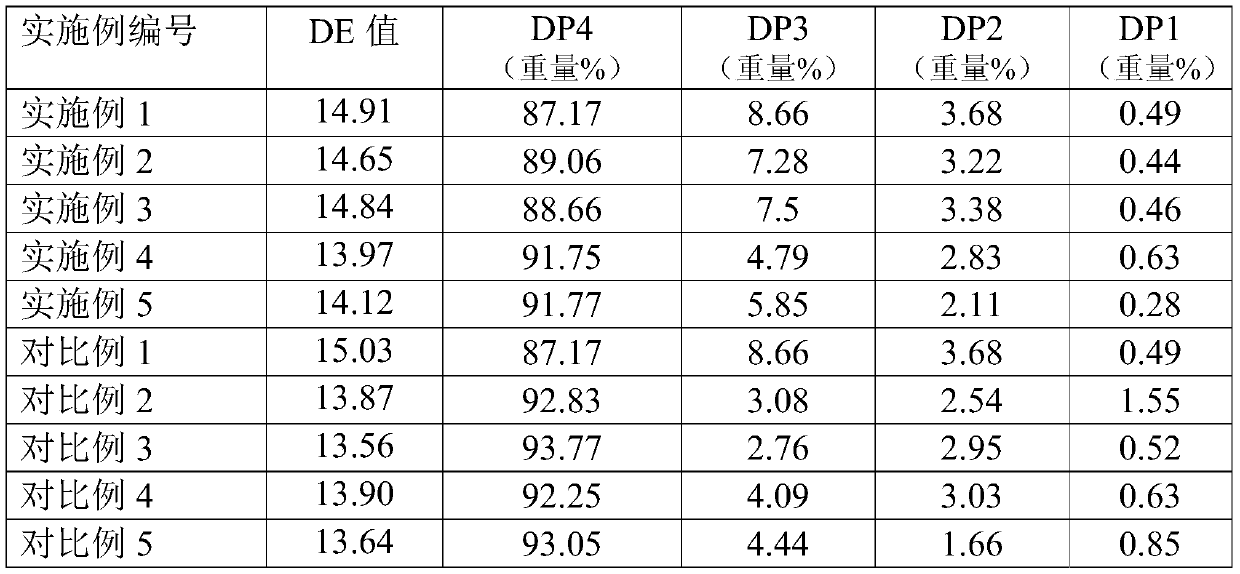

Preparation method of α-amylase

ActiveCN106566820BImprove securityEasy purificationNucleic acid vectorVector-based foreign material introductionAlpha-amylasePolyhistidine-tag

The invention provides a preparation method of Alpha-amylase. The preparation method can solve the technical problems that in the prior art, when the Alpha-amylase is prepared form bacillus subtilis, the later-period purification steps are complicated, and the pure product cannot be easily obtained. The method comprises the following steps of (2) adding an e3 SD sequence at the upstream of an Alpha-amylase gene, adding a histidine tag at the downstream part of the Alpha-amylase gene, and obtaining the modified Alpha-amylase gene; (3) connecting the modified Alpha-amylase gene onto a vector pxmj19-aph213, and obtaining a recombinant expression vector pxmj19-aph213-amy; (4) transferring the recombinant expression vector pxmj19-aph213-amy into corynebacterium glutamicum to obtain recombinant bacteria; (5) culturing the recombinant bacteria, and performing secretory expression on the Alpha-amylase; and (6) performing Alpha-amylase purification: performing affinity chromatography on supernatant containing the Alpha-amylase, wherein the medium is a nickel column.

Owner:SHENZHEN INNOVATION CENT OF SMALL MOLECULE DRUG DISCOVERY CO LTD

Compound amylase preparation and its application in starch liquefaction and starch liquefaction method

ActiveCN109777795BIncrease the degree of liquefactionWell mixedEnzymesFermentationHigh concentrationProcess engineering

The invention relates to the field of starch sugar preparation, and discloses a compound amylase preparation, an application thereof in starch liquefaction and a starch liquefaction method. The compound amylase preparation comprises L-type amylase and S-type amylase, wherein the amino acid sequence of the L-type amylase has at least 95% sequence consistency with the amino acid sequence shown in SEQ ID NO: 1, and the amino acid sequence of the S-type amylase has at least 95% sequence consistency with the amino acid sequence shown in SEQ ID NO: 2. The method comprises the following steps of: adding the compound amylase preparation into starch feed liquid, and spraying. The compound amylase preparation can rapidly reduce the viscosity of a system in high-concentration starch feed liquid (under the condition of relatively low water activity), enables the feed liquid to be uniformly mixed, is favorable for pumping, has better thermal stability, can be sprayed and liquefied at a higher temperature, enables starch particles to be completely destroyed, and is favorable for complete liquefaction.

Owner:COFCO GROUP +2

Fungal amylase preparation and storage method

InactiveCN113957062AIncrease acquisition rateIncrease productivityBacteriaBio-packagingBiotechnologyBacillus subtilis

The invention provides a fungal amylase preparation method. The fungal amylase preparation method comprises the following steps that bacillus subtilis reacts with raw material starch to obtain alpha-amylase liquid; the alpha-amylase liquid is purified to obtain a purified alpha-amylase liquid; the purified alpha-amylase liquid is washed, precipitated and dried to obtain the alpha-fungal amylase. According to the fungal amylase preparation method, the acquisition rate of fungal amylase is improved, the production efficiency is further improved, and the production cost is saved.

Owner:湖南康捷生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com