Preparation method for liquid composite alpha-amylase

An amylase and liquid technology, which is applied in the production, preparation and application of biological enzymes, can solve the problems of not being able to effectively improve the efficiency of catalytic degradation of starch, and the activation effect is small, so that the process parameters are easy to control, the price is reduced, and the application effect is excellent. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of medium temperature liquid compound α-amylase

[0021] Add 100L of medium temperature α-amylase with 10000 vigor to 500L reactor 1, and then add 150L of purified water to dilute into 4000 vigor α-amylase liquid, stir well and set aside.

[0022] Add 180L of purified water to the 500L reactor 2, then add 40 kg of sodium nitrate with a purity of 99%, stir and dissolve, then add 30 kg of polyethylene glycol (molecular weight 400), and stir for 30 minutes to obtain a mixed solution.

[0023] The α-amylase solution diluted in step 1 is added to the mixed solution in step 2, and stirred for 60 minutes to obtain a medium-temperature liquid composite α-amylase with high catalytic degradation activity.

Embodiment 2

[0025] Preparation of high-temperature liquid compound α-amylase

[0026] Add 100L of high temperature α-amylase with activity of 12000 to 500L reactor 1, and then add 100L of purified water to dilute into a liquid of α-amylase with 6000 activity, and stir well before use.

[0027] Add 240L of purified water to the 500L reactor 2, then add 30 kg of sodium nitrate with a purity of 99%, stir and dissolve, then add 30 kg of polyethylene glycol (molecular weight 400), and stir for 30 minutes to obtain a mixed solution.

[0028] The α-amylase solution diluted in step 1 is added to the mixed solution in step 2, and stirred for 60 minutes to obtain a high temperature liquid composite α-amylase with high catalytic degradation activity.

Embodiment 3

[0030] Preparation of wide-temperature liquid compound α-amylase

[0031] Add 50L of high-temperature alpha-amylase with activity of 12000 to 500L reactor 1, then add 50L of medium-temperature liquid amylase with activity of 10,000, and then add 100L of purified water to dilute to 5500-activity of alpha-amylase liquid, stir well and set aside.

[0032] Add 180L of purified water to the 500L reactor 2, then add 30 kg of sodium nitrate with a purity of 99%, stir to dissolve, then add 40 kg of polyethylene glycol (molecular weight 400), and stir for 30 minutes to obtain a mixed solution.

[0033] Add the α-amylase solution diluted in step 1 to the mixed solution in step 2, and stir and bond for 60 minutes to obtain a wide temperature liquid composite α-amylase with high catalytic degradation activity.

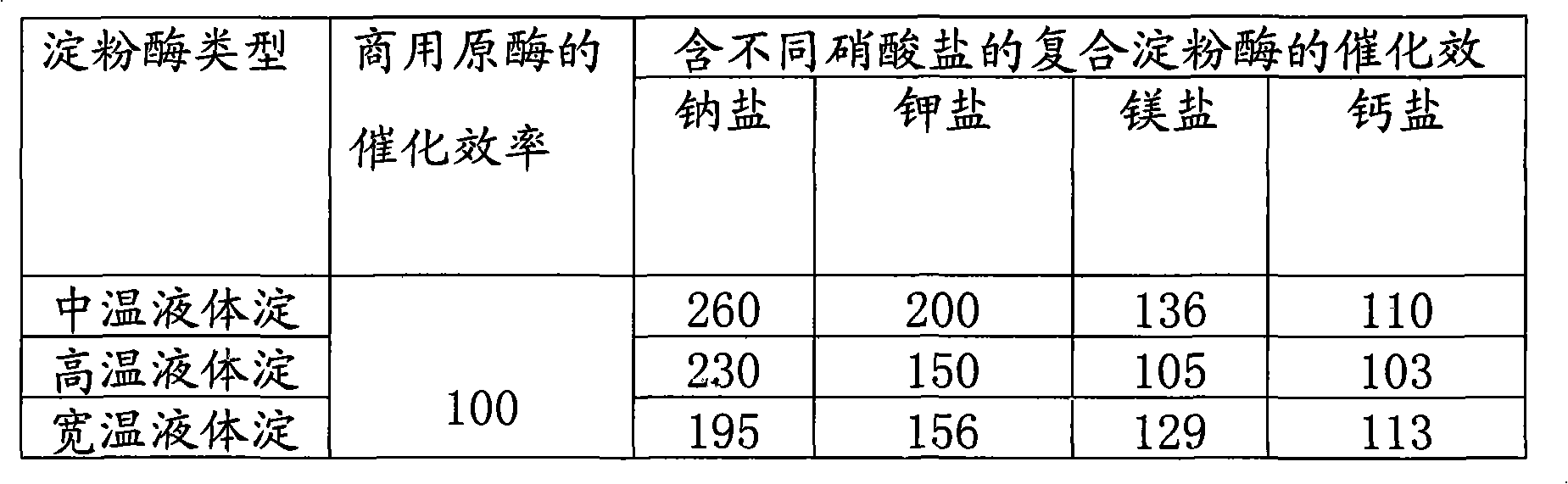

[0034] The test of the effect of the present invention is as follows:

[0035] 1. Determination of starch degradation efficiency by amylase

[0036] (1) Reagent

[0037] (1) Preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com