Method for producing plant extract food-grade beta-amylase preparation

A production method and food-grade technology, applied in the field of production of plant-extracted food-grade β-amylase preparations, can solve problems such as inability to produce high-purity maltose, unfavorable industrial production, and impure enzyme systems, and achieve stable quality and thermal stability. Good stability and the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

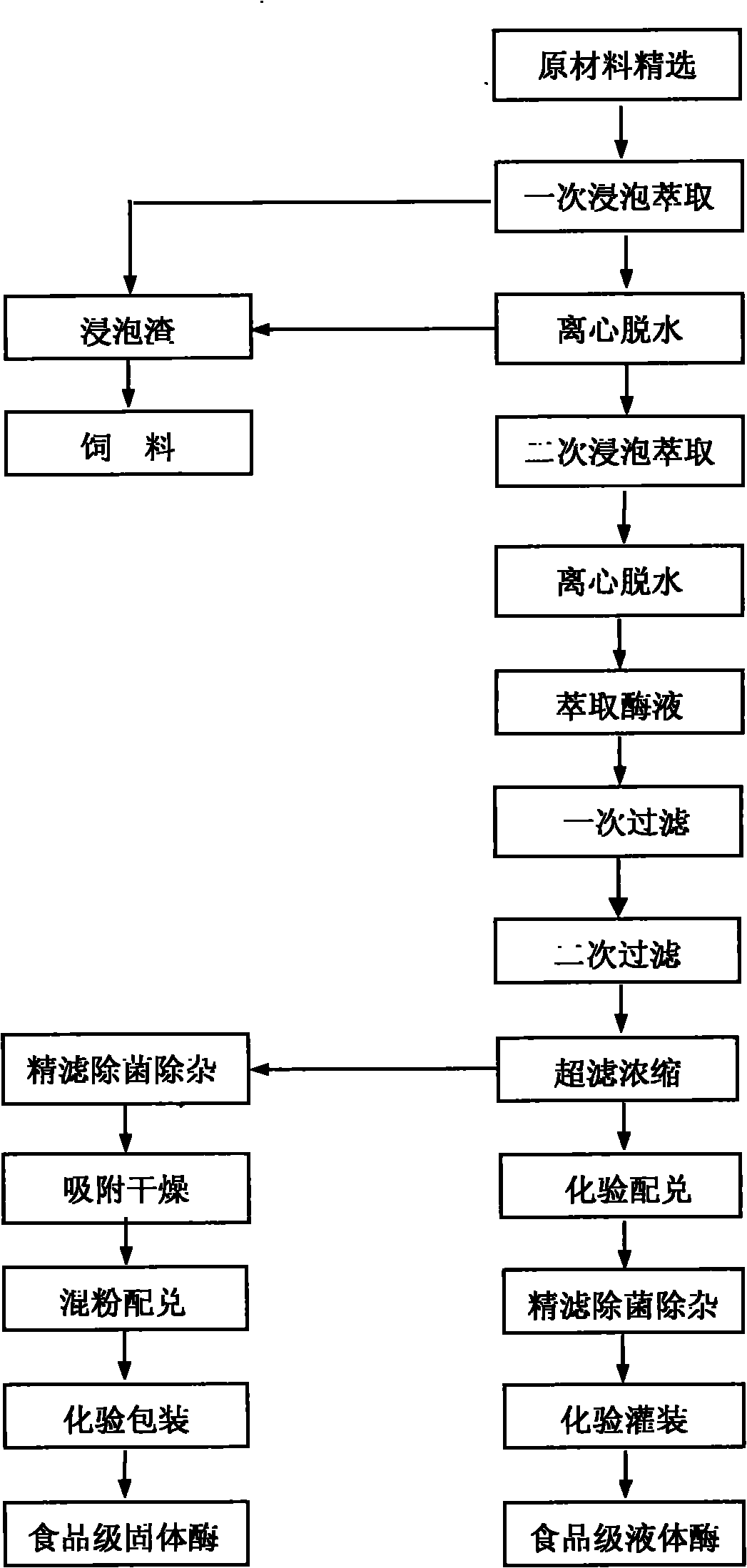

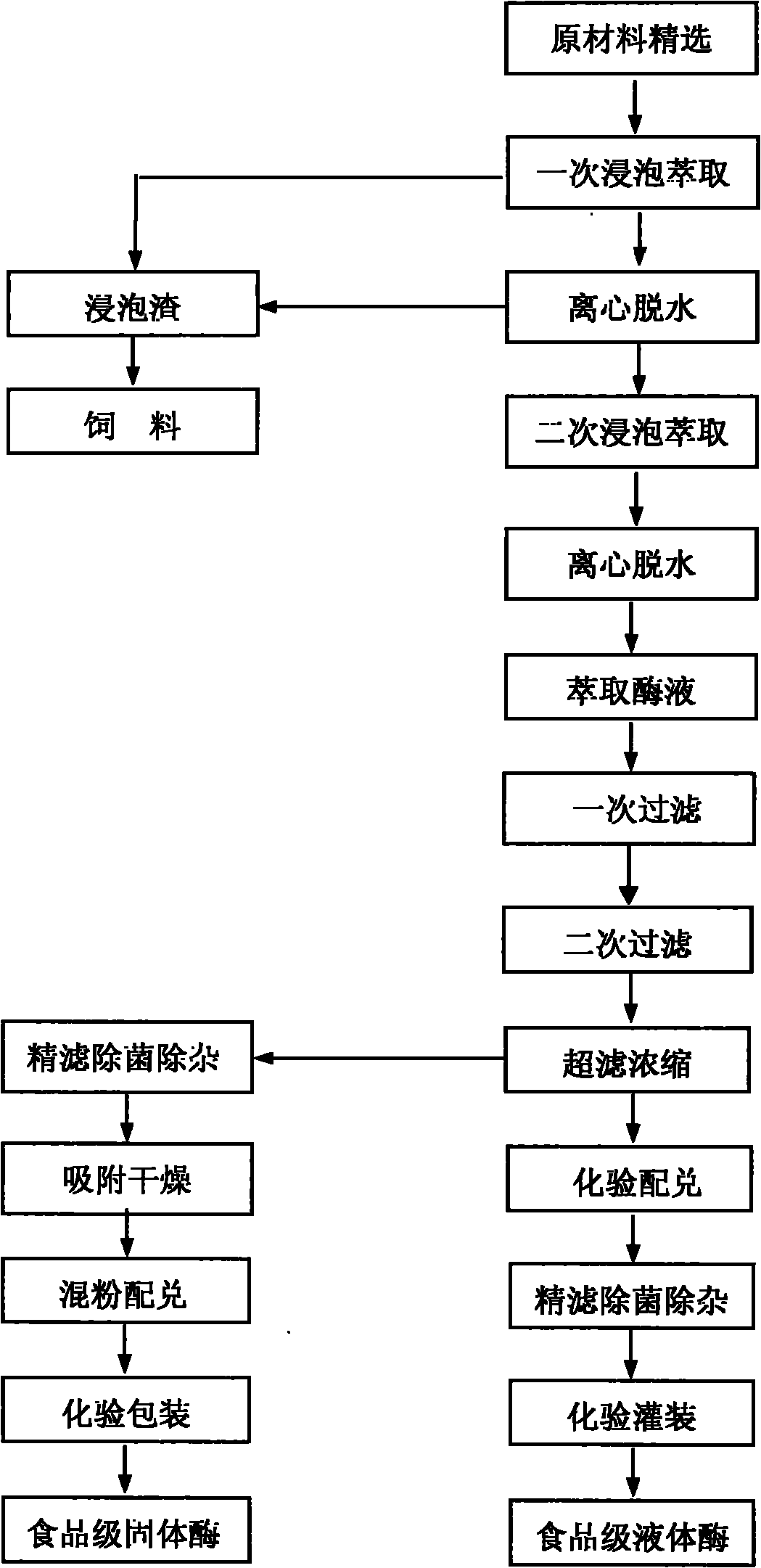

[0009] (1) First pump clean water into the soaking tank, then slowly add a certain amount of wheat bran into the soaking tank under stirring, the ratio of material to water is 1:5, pH6.2, after soaking at room temperature for 3 hours, soak the The food is dehydrated by centrifuge, and the waste residue can be used as feed; the extract is taken and wheat bran is added for the second soaking, and the process is the same as that of the first soaking.

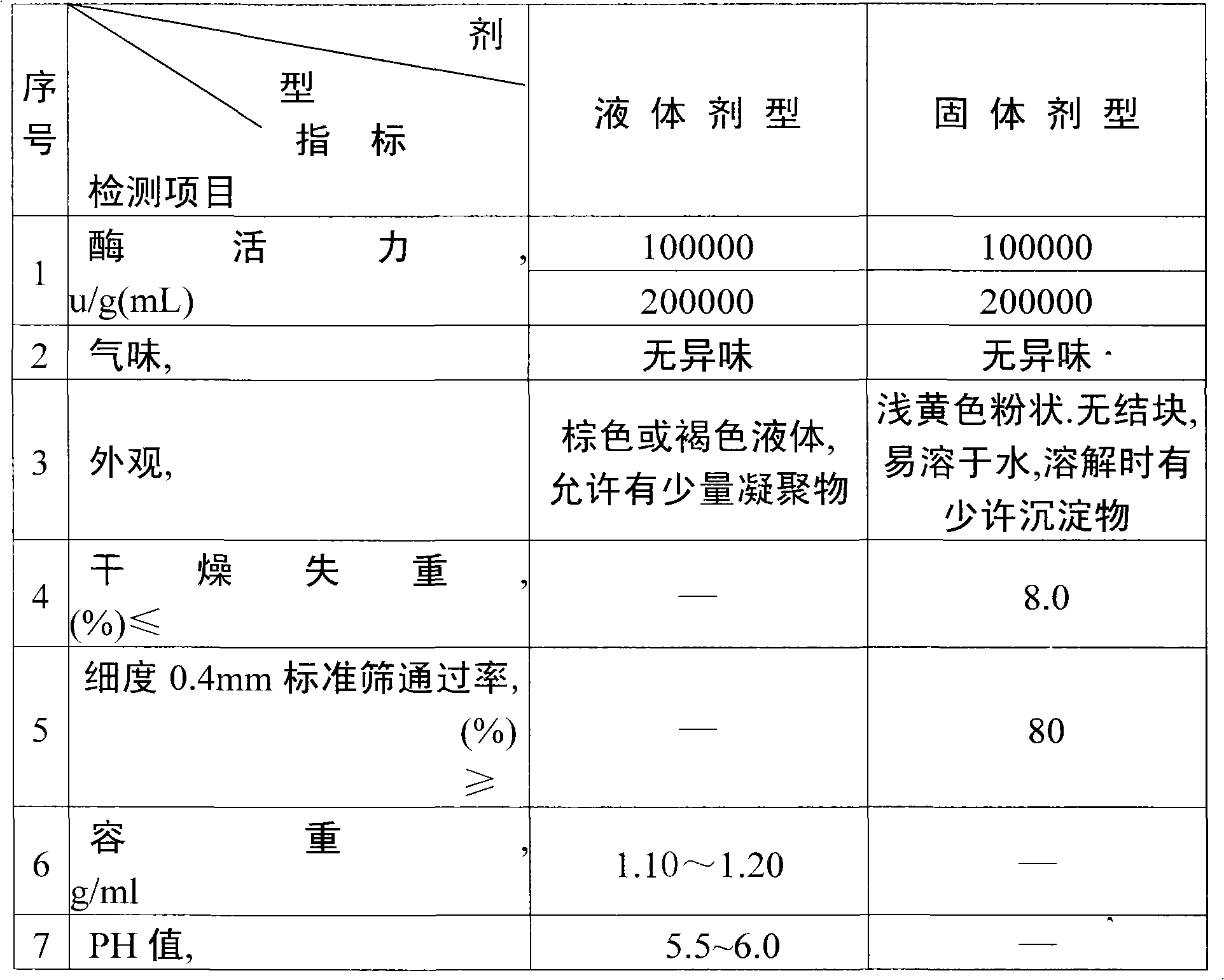

[0010] Pump the second extract into the storage tank, add filter aid diatomaceous earth 1kg / m3 and perlite 1.3kg / m3 under agitation, and then perform the first and second filtration. At a temperature of 23°C and a pressure of 0.4Mpa, the fluid material of each component is separated, classified, purified and concentrated by virtue of the difference in the selectivity of the mass transfer in the membrane due to the molecular weight of each component in the solution; After mixing, add 1.3kg / m3 of diatomaceous earth for fine filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com