Penicillium oxalicum mutant strain a2-13 and its application in preparation of raw amylase preparation and degradation of raw starch

A technology of Penicillium oxalicum and fungal agents, applied in the biological field, can solve the problems of limited development and utilization, low production of raw amylase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

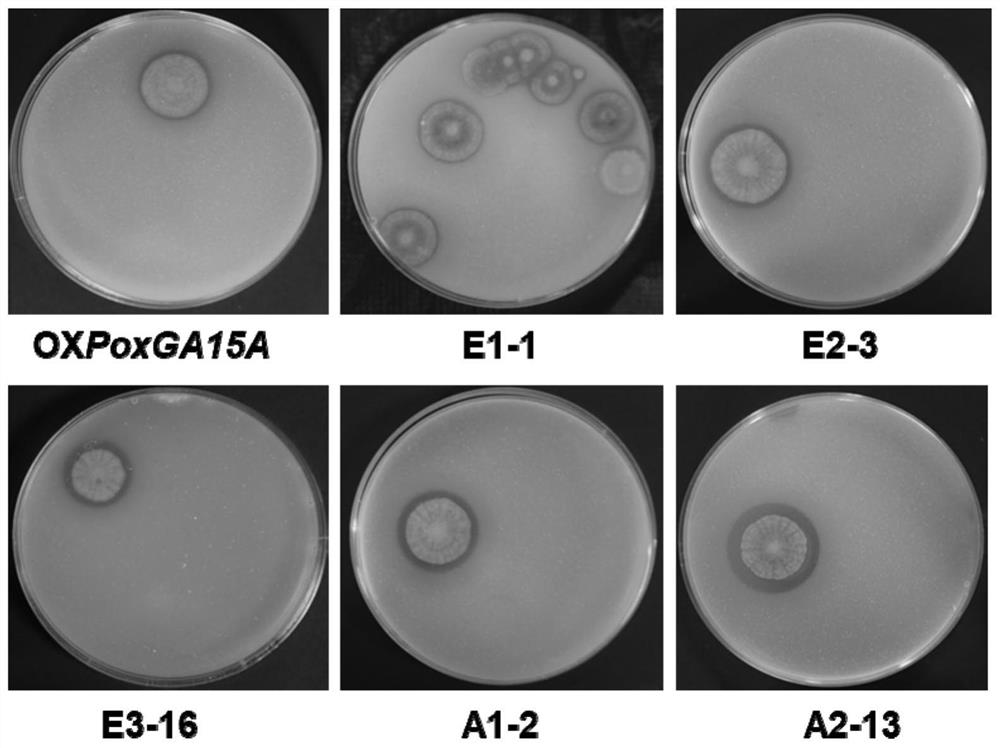

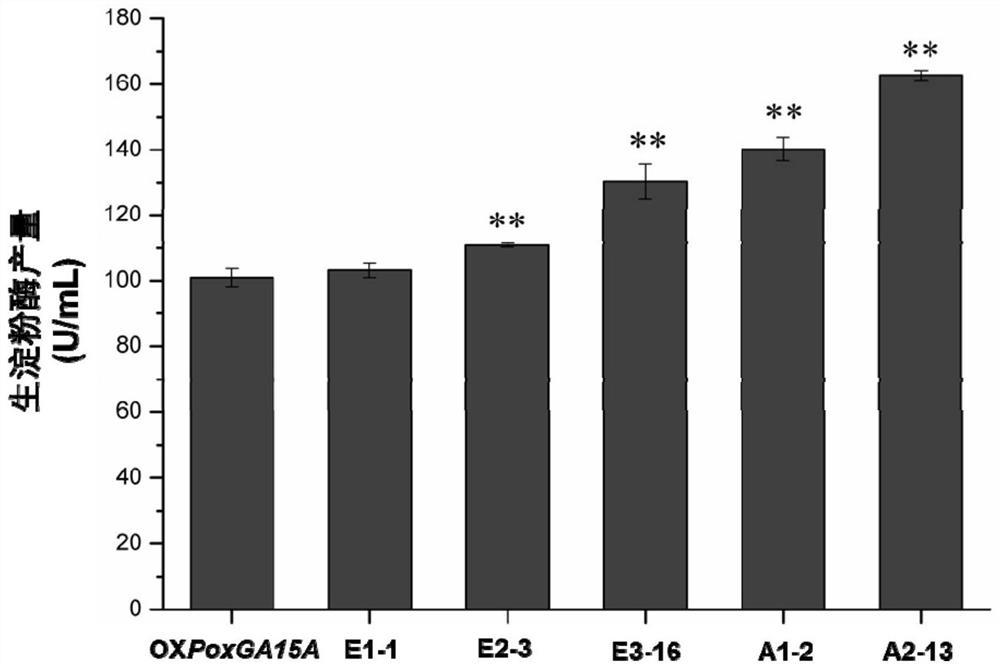

[0089] Embodiment 1, the screening of Penicillium oxalicum A2-13

[0090] Penicillium oxalicum A2-13 is obtained from the original fungal strains in the laboratory of the inventor of the present application through multiple rounds of physical and chemical random mutagenesis to obtain a strain with higher amylase activity. Using Penicillium oxalicum (Penicillium oxalicum) genetically engineered strain OXPoxGA15A (CCTCC NO: M 2017794; see Chinese patent application number CN201810816723.7) as the starting strain, three rounds of ethyl methylsulfonate (Ethylmethylsulfone, EMS) mutagenesis were used to obtain A mutant strain E3-16 with improved amylase activity compared with the starting strain OXPoxGA15A. E3-16 is carried out normal pressure and normal temperature plasma (mutagenesis again, obtains a bacterial strain A1-2 with higher amylase activity. Then bacterial strain A1-2 is carried out ARTP and EMS compound mutagenesis and screening, finally obtains mutant strain A2 -13. ...

Embodiment 2

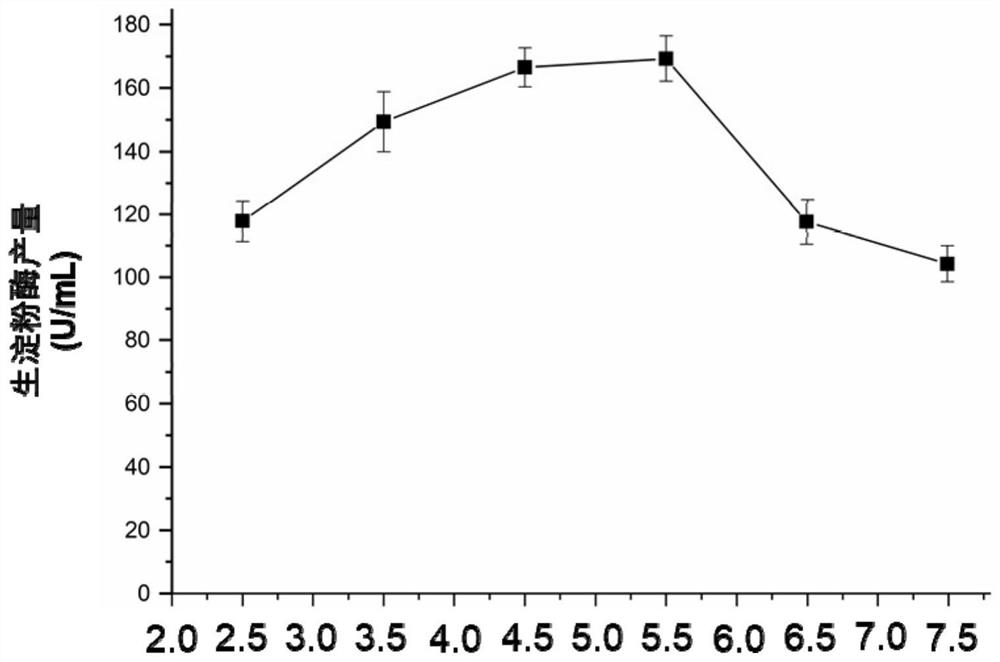

[0119] Embodiment 2, the optimization of amylase condition produced by liquid fermentation of Penicillium oxalicum A2-13

[0120] The experiment was repeated three times, and the specific steps of each repeated experiment were as follows:

[0121] 1. Preparation of spore suspension

[0122] 1. Sterilize the PDA solid medium at 121°C for 30 minutes to make a PDA plate.

[0123] 2. Wash the Penicillium oxalicum A2-13 spores cultivated on the PDA plate for 5 days with 0.1% (v / v) Tween 80 aqueous solution, and the preparation concentration is 1×10 8 per mL of spore suspension.

[0124] 2. Optimization of the initial pH of the medium

[0125] 1. Prepare fermentation media with different pH

[0126] Preparation of basal medium: basal medium consists of wheat bran, crystalline cellulose Avicel (PH-101, Sigma-Aldrich #11365) and saline solution. Wherein, the proportion of wheat bran, crystalline cellulose Avicel and salt solution is 4.0g:1.0g:100mL. Salt solution consists of wat...

Embodiment 3

[0175] Embodiment 3, utilize Penicillium oxalicum A2-13 to prepare raw amylase preparation

[0176] 1. Preparation of fermentation medium

[0177] Prepare the best culture medium for Step 7 of Example 2.

[0178] 2. Preparation of spore solution

[0179] The concentration of preparation embodiment 2 step one is 1 * 10 8 per mL of spore inoculum. Inoculate into the above-mentioned optimum medium at an inoculum amount of 1% (v / v).

[0180] 3. Preparation of raw amylase preparation

[0181] The fermentation medium of the Penicillium oxalicum A2-13 spore suspension inoculated in step 2 was placed in a constant temperature incubator at 28°C for static cultivation for 6 days to obtain a fermentation product; centrifuged (12,000rpm for 15min) to collect the supernatant, the The supernatant is the raw amylase preparation.

[0182] 4. Determination of the raw amylase activity of the raw amylase preparation.

[0183] The results were as follows: the raw amylase activity of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com