Method for preparing modified alpha-amylase

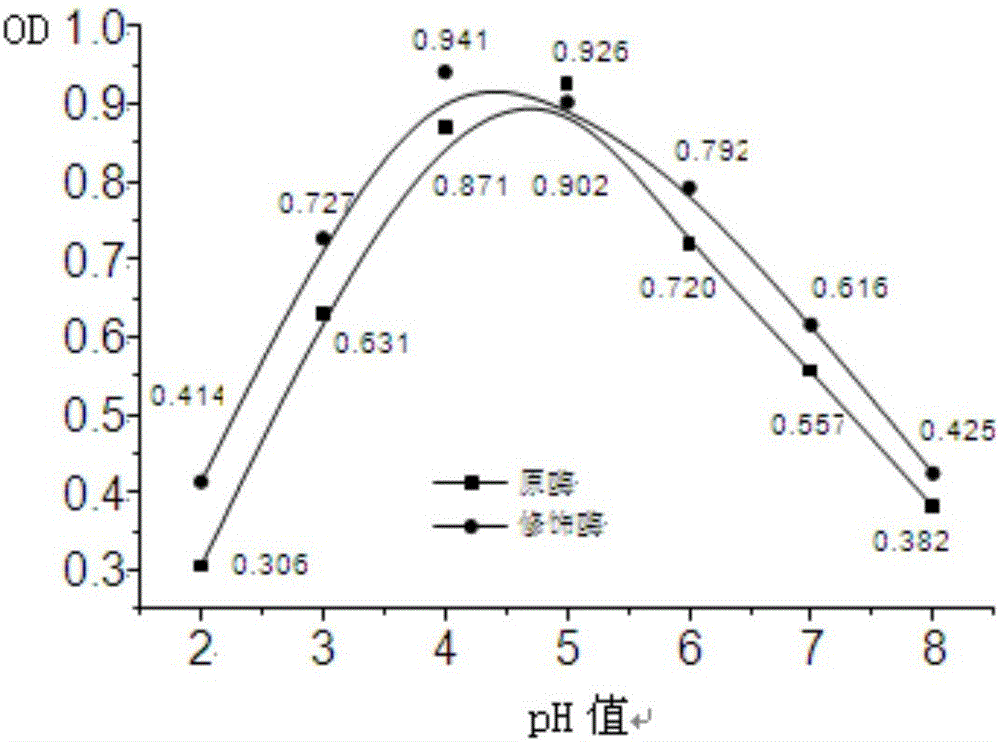

A amylase modification technology, applied in the field of bioscience enzyme engineering, can solve the problems of poor environmental adaptability, short enzyme activity retention time, poor stability, etc., and achieve the effect of improving physical and chemical properties and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Such as figure 1 , the embodiment of the present invention provides a preparation method of modified α-amylase, comprising:

[0035] Step S101: using an oxidizing agent to oxidize chitosan to obtain oxidized chitosan;

[0036] Chitosan is formed by condensation of 2-acetylamino-2-deoxy-β-D-glucan and 2-amino-2-deoxy-β-D-glucan through β-1,4 glycosidic bonds. The cationic biopolymer is the product of de-N-acetylation of chitin; the chitosan has good biocompatibility, good antibacterial activity and strong adaptability to the environment. The chitosan according to the embodiment of the present invention can be chitosan with a high deacetylation degree, and its deacetylation degree is above 85%, for example, it can be 85%-95%.

[0037] In the embodiment of the present invention, an oxidizing agent is used to oxidize chitosan to obtain oxidized chitosan. Specifically, the oxidizing agent oxidizes two adjacent carbon atoms respectively connected with hydroxyl groups on the...

Embodiment 1

[0074] Weigh 10 mg of chitosan and dissolve in 10 ml of sodium acetate buffer solution containing a certain concentration of sodium periodate, the pH of the sodium acetate buffer solution is 5.0, and the concentration is 50 mmol / L, and stir for 30 minutes under dark conditions. Add 14.5ml of ethylene glycol to stop the reaction and let stand for 2 hours. Under dark conditions, the above solution was dialyzed for 48 hours with pH 5.0 and 200 mmol / L sodium acetate buffer solution, and the water was changed 3 times in the middle. The oxidized chitosan solution was mixed with 8 mg of α-amylase, redissolved in 2.0 ml of acetic acid, and stirred for 4 hours in the dark. Then, 1.0 mol / L NaBH4 was added dropwise to the above solution with constant stirring and reacted for 4 hours. Finally, the obtained product was dialyzed for 48 hours in a sodium acetate buffer solution with a pH of 5.0 and a concentration of 50 mmol / L to obtain a modified α-amylase. All the above operations were p...

Embodiment 2

[0076] Weigh 10 mg of chitosan and dissolve it in 10 ml of sodium acetate buffer solution containing a certain concentration of sodium periodate, the pH of the sodium acetate buffer solution is 5.0, and the concentration is 50 mmol / L, and stir for 60 minutes under dark conditions. Add 14.5ml of ethylene glycol to stop the reaction and let stand for 2 hours. Under dark conditions, the above solution was dialyzed for 48 hours with pH 5.0 and 200 mmol / L sodium acetate buffer solution, and the water was changed 3 times in the middle. The oxidized chitosan solution was mixed with 10 mg of α-amylase, redissolved in 2.0 ml of acetic acid, and stirred for 4 hours in the dark. Then, 1.0 mol / L NaBH4 was added dropwise to the above solution with constant stirring and reacted for 6 hours. Finally, the obtained product was dialyzed for 48 hours in a sodium acetate buffer solution with a pH of 5.0 and a concentration of 50 mmol / L to obtain a modified α-amylase. All the above operations we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com