Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "With adjustable function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

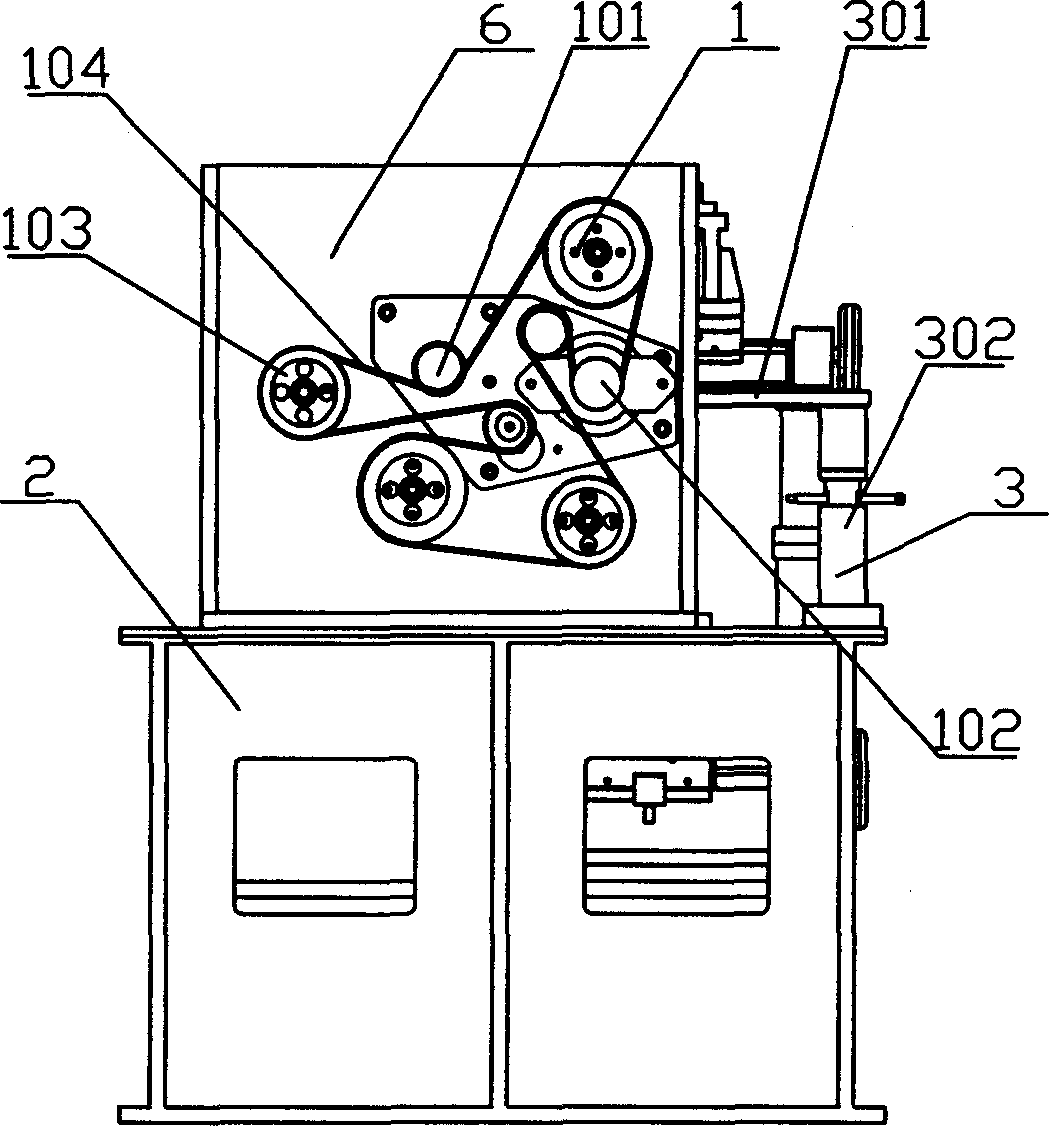

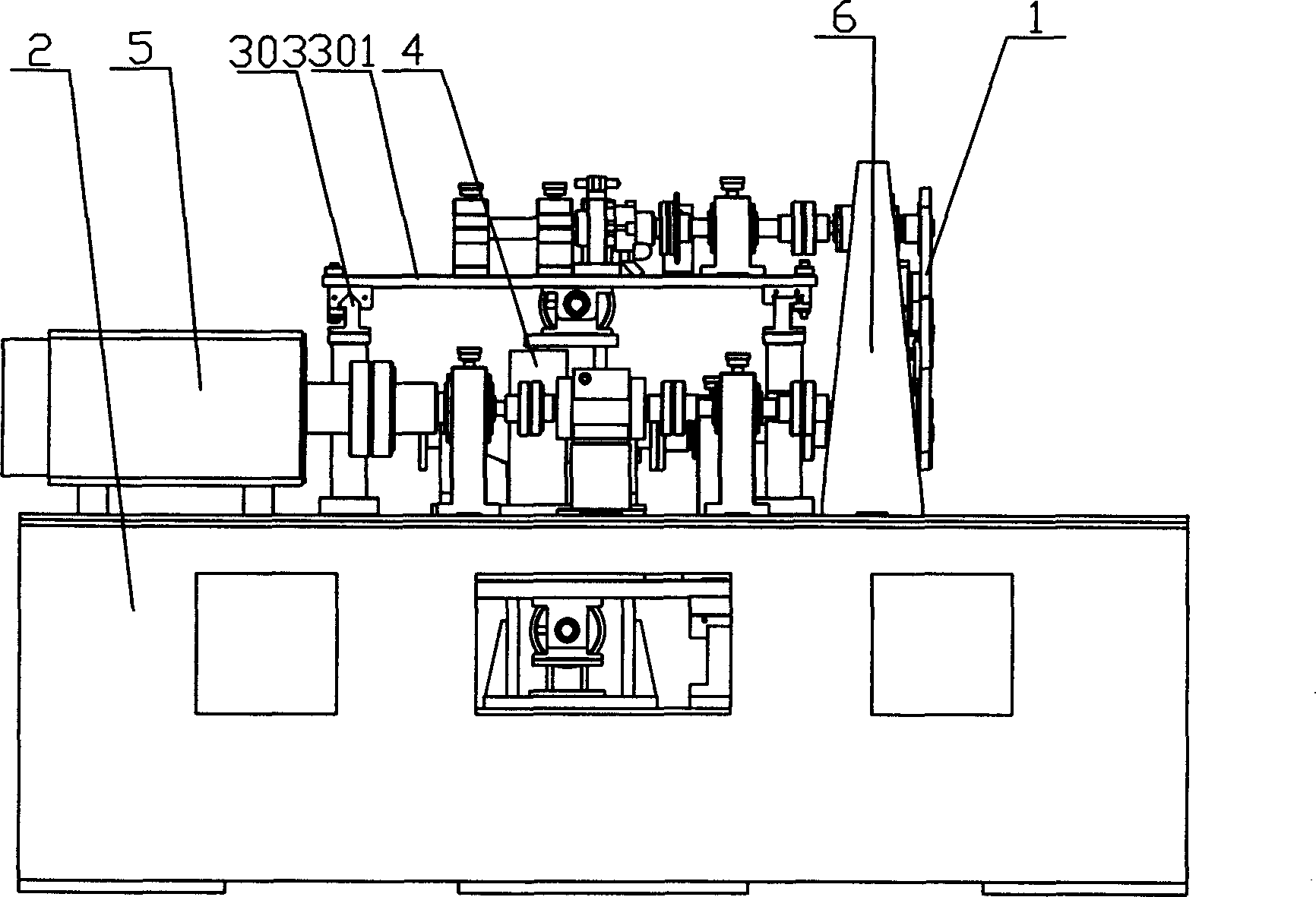

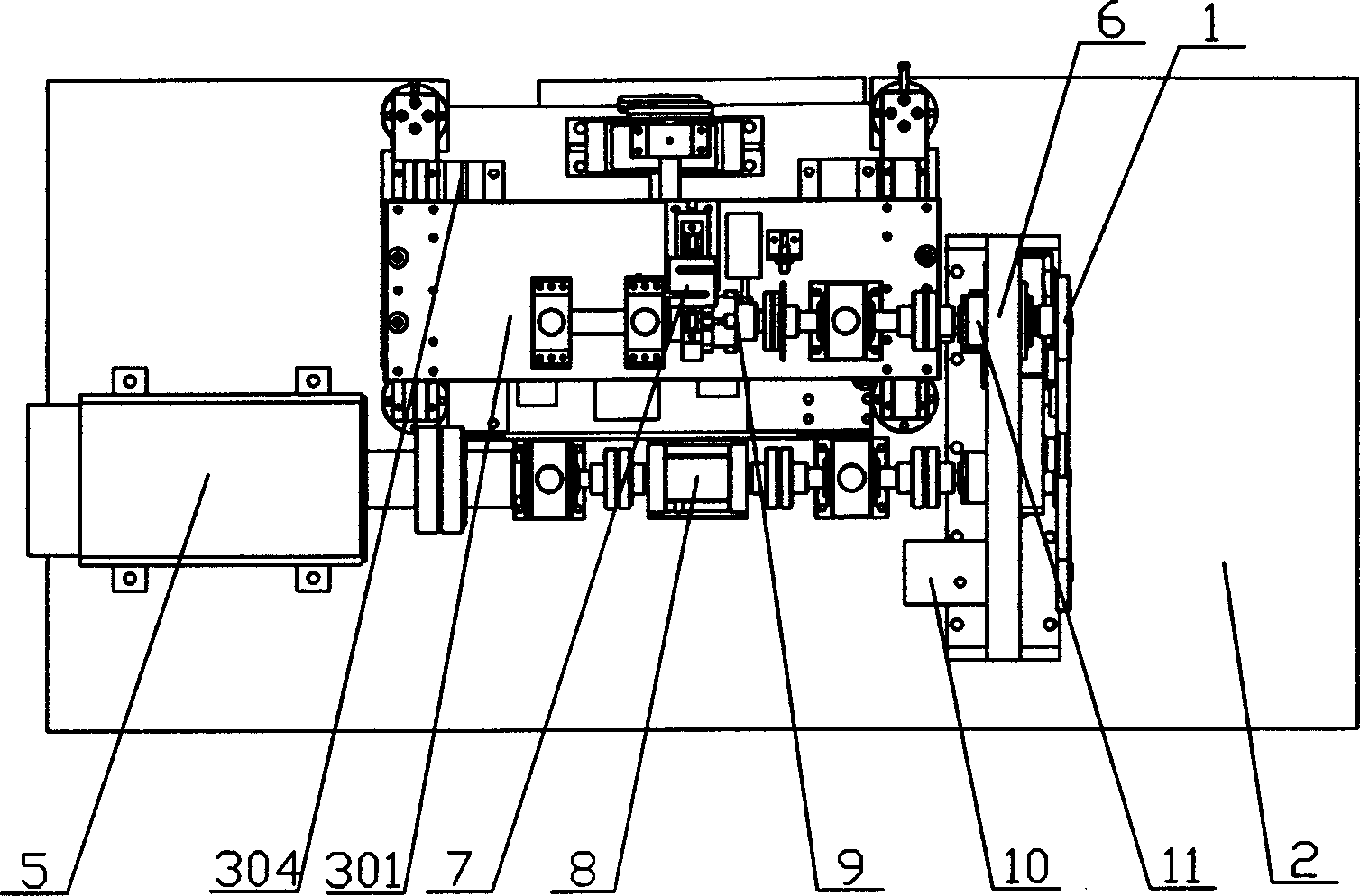

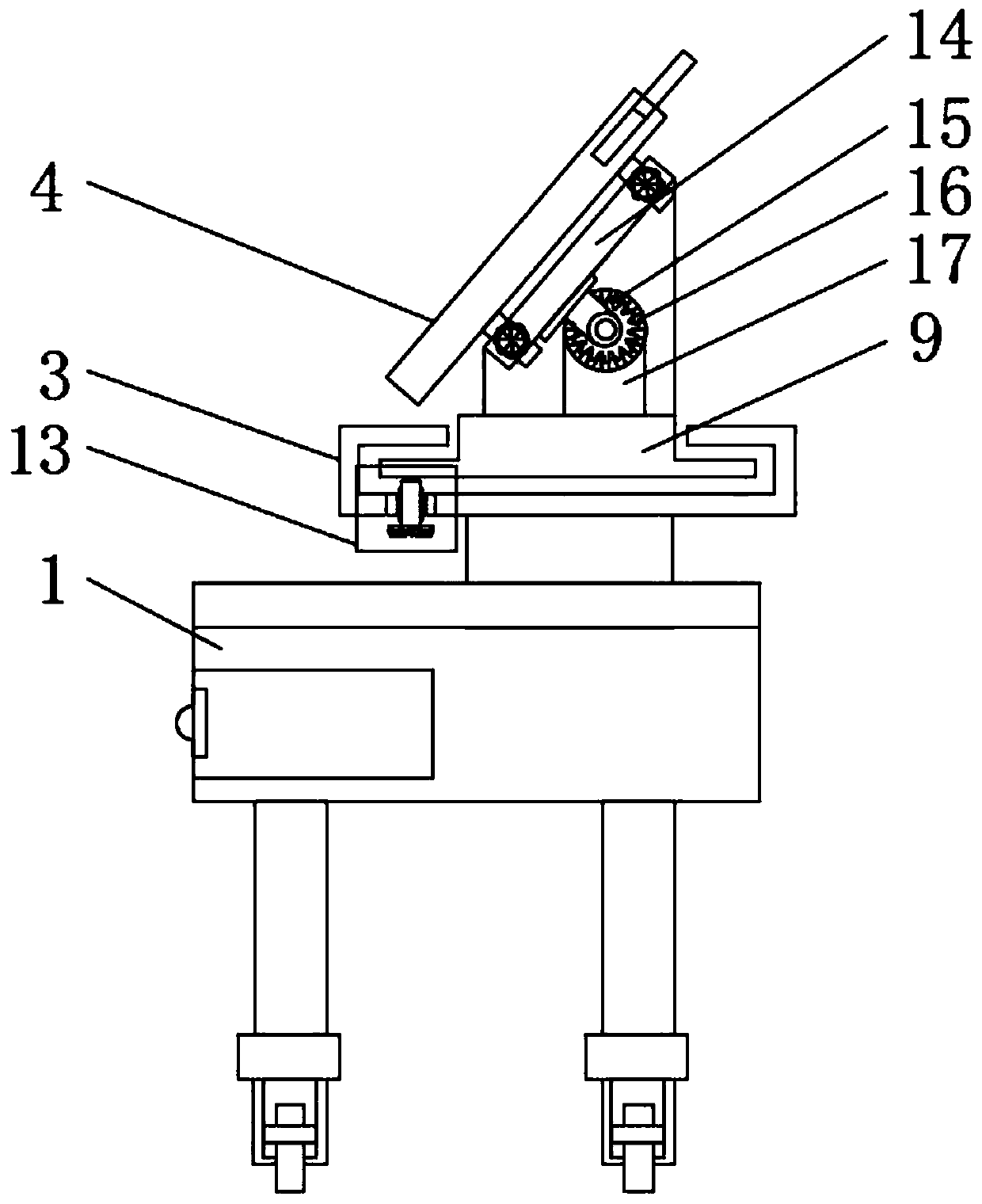

Test-bed for optimizing pulley train of engine

The invention relates to an engine belt pulley train optimization test table. It incldues table frame, motor used for simulating engine, load, support frame for mounting load and sensor for measuring parameters. On the table frame an intermediate plate is set, the motor and load are placed on one side of said itnermediate plate, the wheel train is placed on another side of said intermediate plate, and the signal output end of the sensor is connected with signal input end of computer. Said test table can simulate actual operation of the engine, and can test various related parameters in the operation processor, and the obtained various parameters can be inputted into computer. Said test table is simple in structure, convenient and safe in operation.

Owner:WUHAN UNIV OF TECH

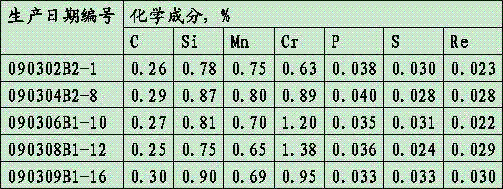

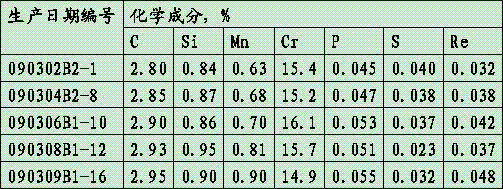

Process for casting wear-resistant hammer head by compounding two kinds of metal liquid

The invention relates to a process for casting a wear-resistant hammer head, in particular to a process for casting the wear-resistant hammer head by compounding two kinds of metal liquid. A method for synchronously smelting and pouring the two kinds of metal liquid, and molding by using a stripping plate molding machine is adopted. The process comprises the following steps of: manufacturing a mold, a core box, a sand core and the stripping plate molding machine, molding, smelting, pouring, opening the box for cleaning, and performing heat treatment. The hammer head cast by the process has the characteristics of high toughness, strength and wear resistance, the conditions of cracking and falling-off of a hammer handle and the hammer head can be avoided, and wear resistance is high; the stripping plate molding machine is convenient and easy to use, a casting mold is standard, production efficiency is high, and production cost is low; meanwhile, multiple purposes can be achieved, and hammer heads of multiple specifications can be provided for users.

Owner:QIANAN HONGXIN CASTING

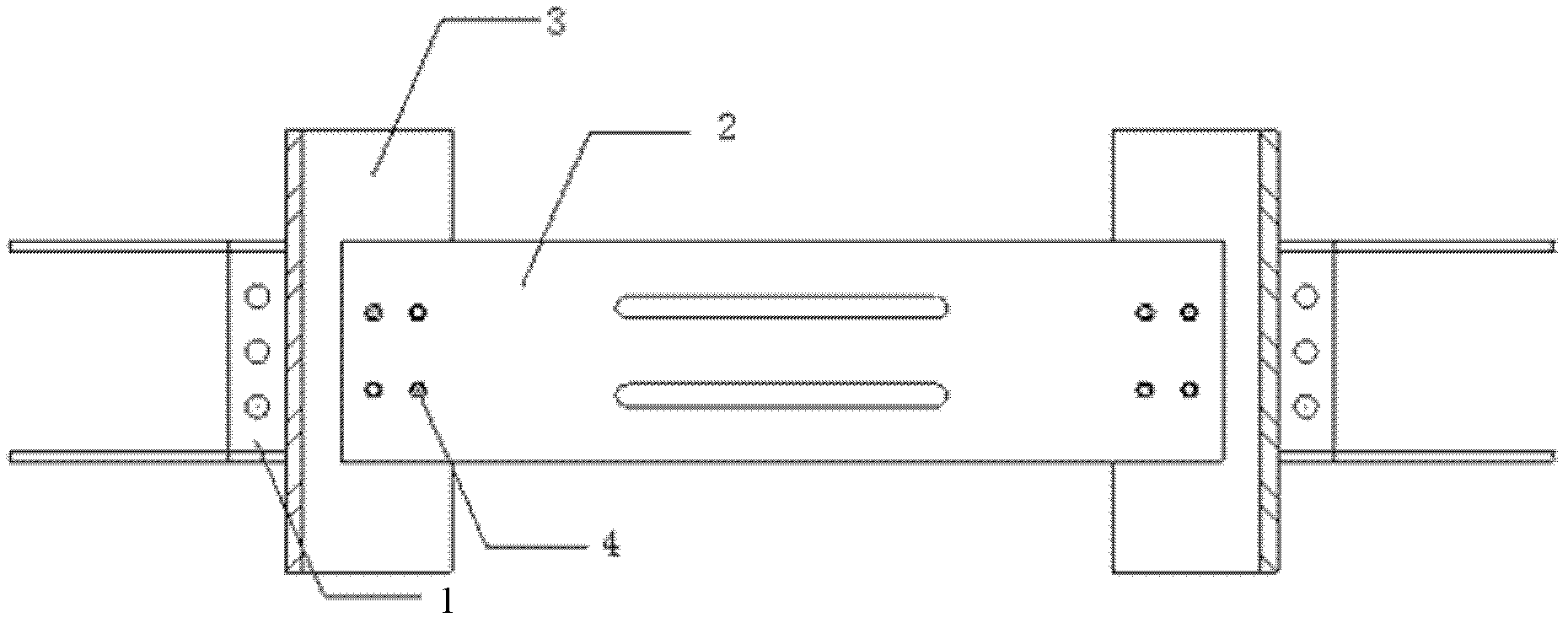

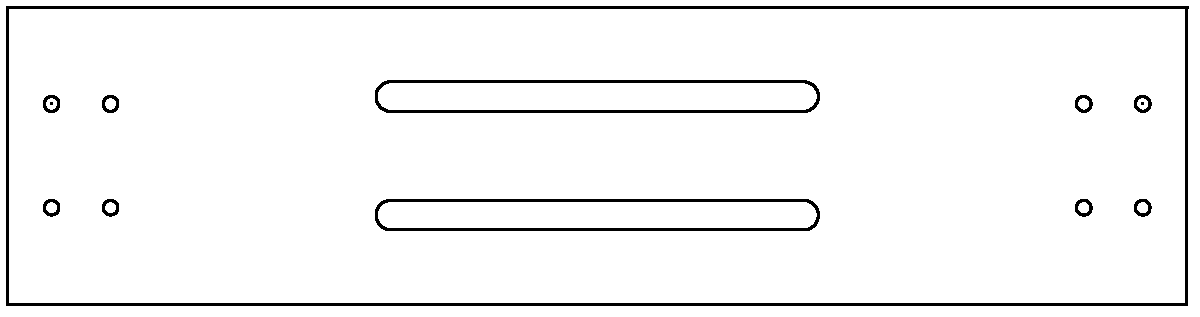

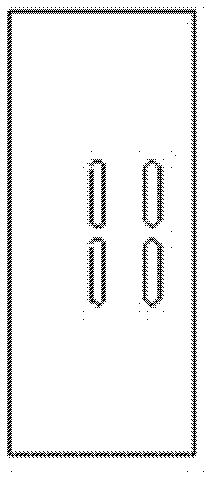

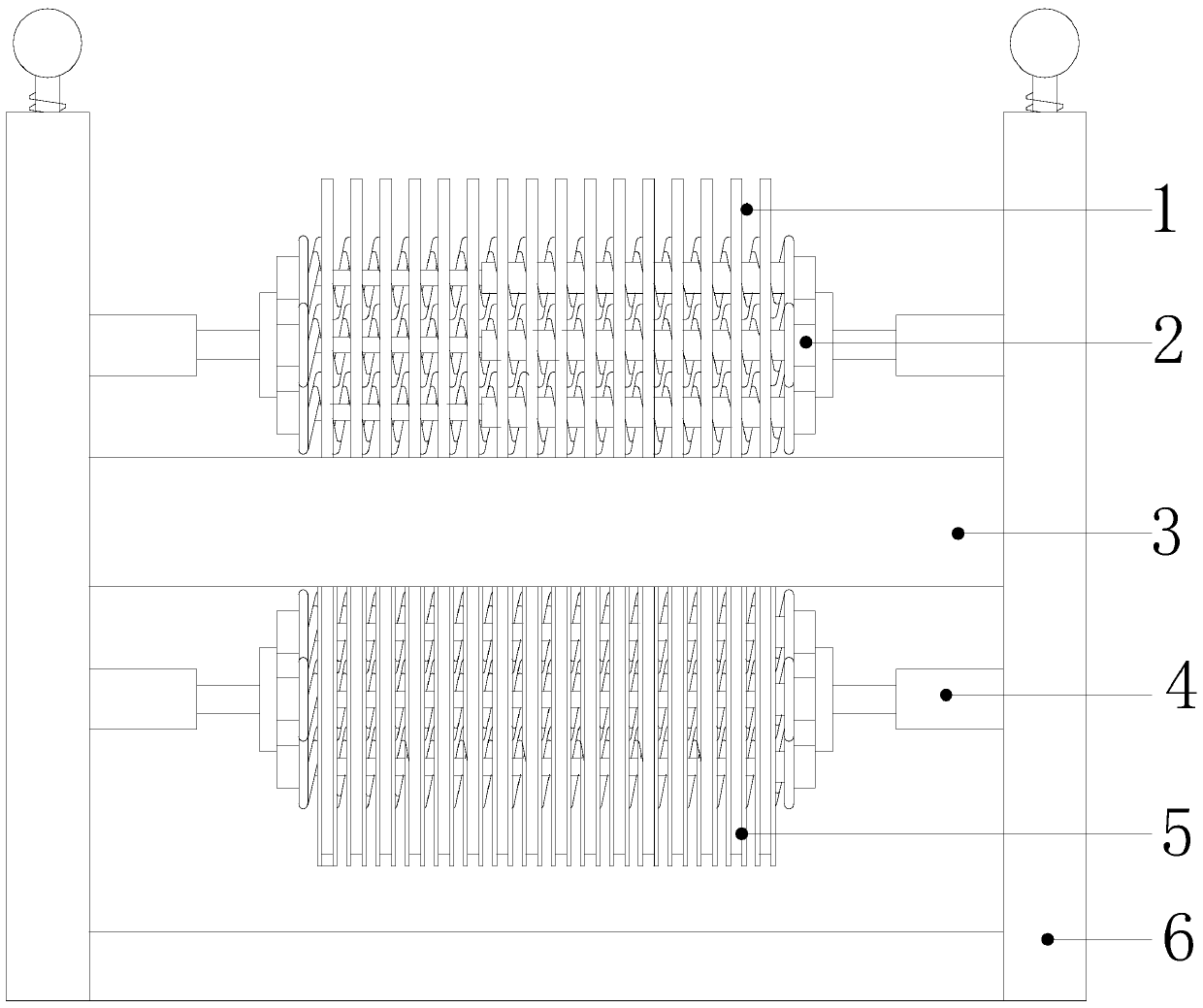

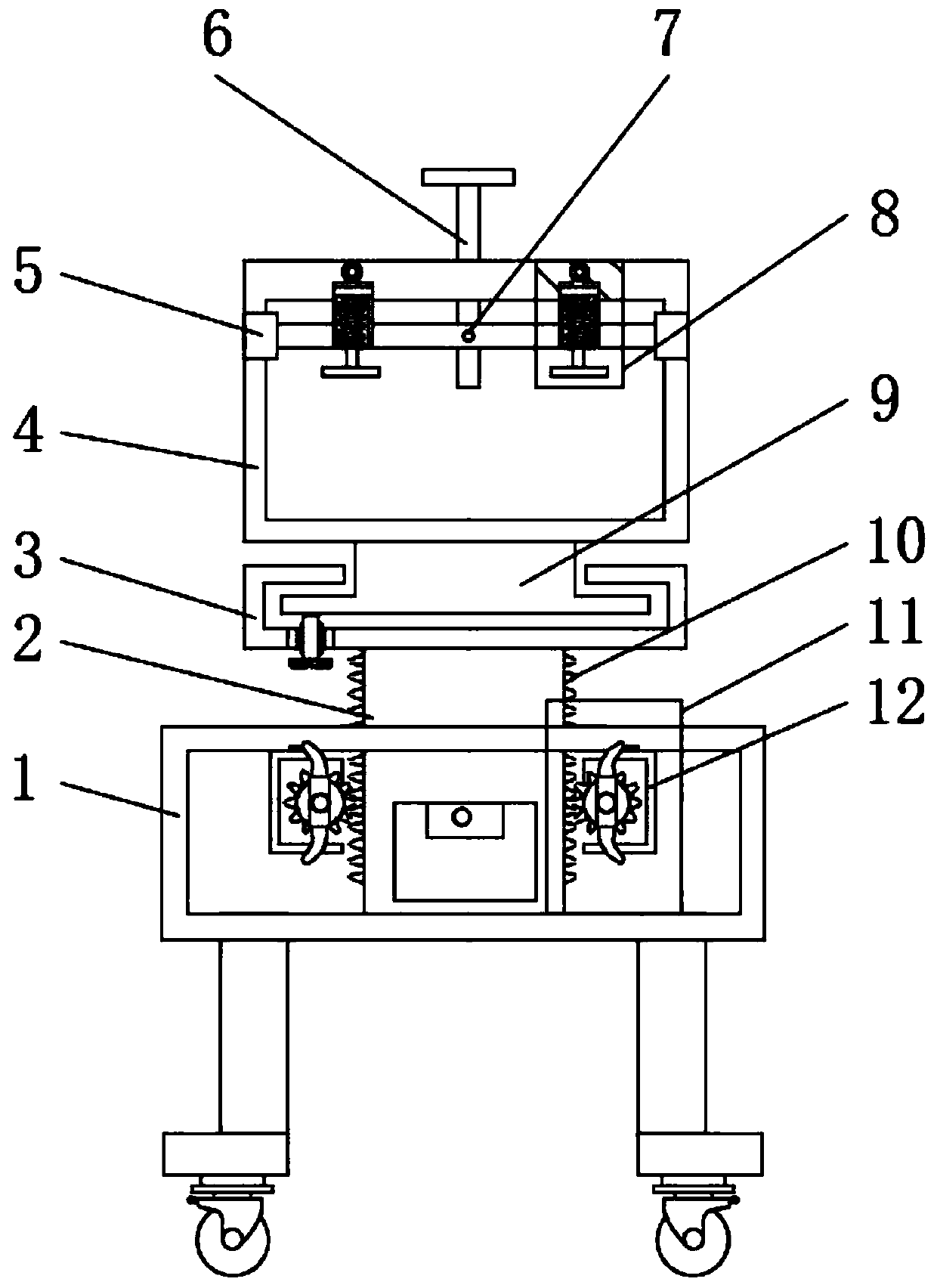

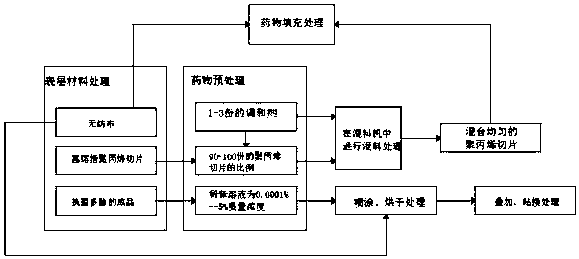

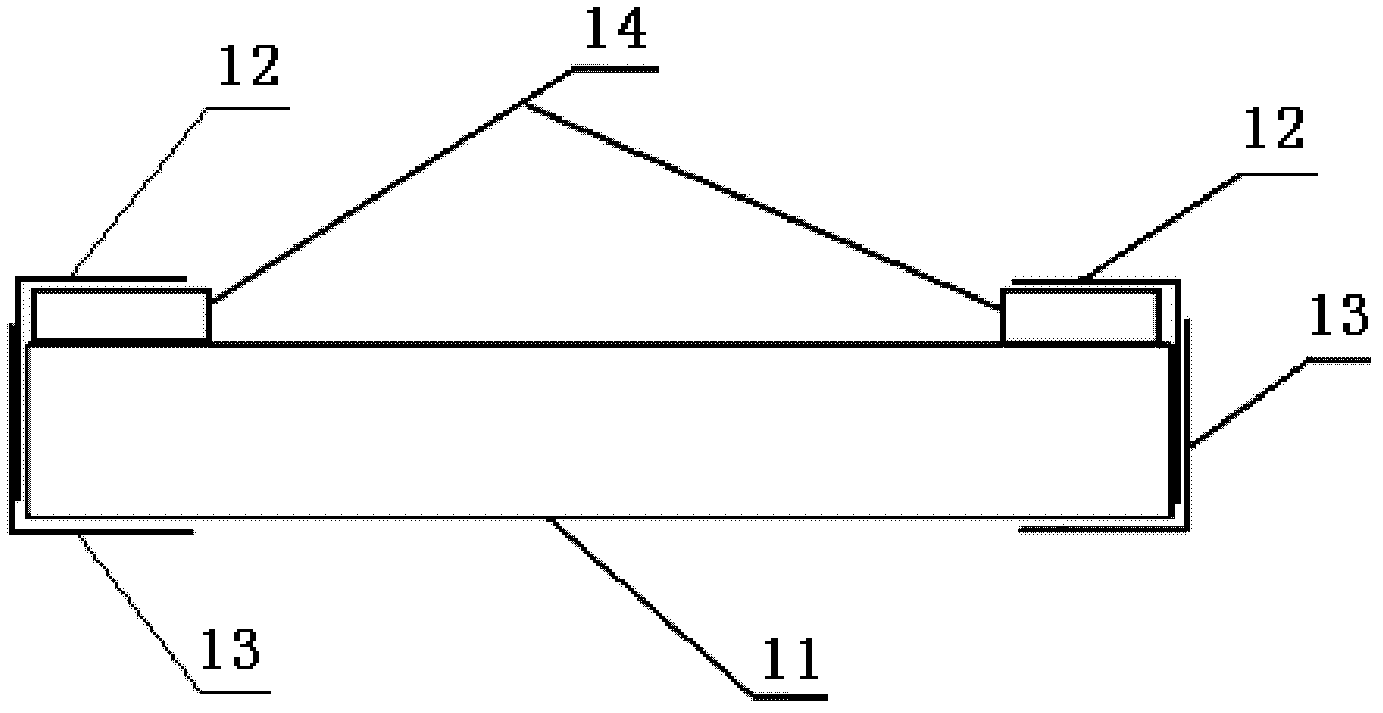

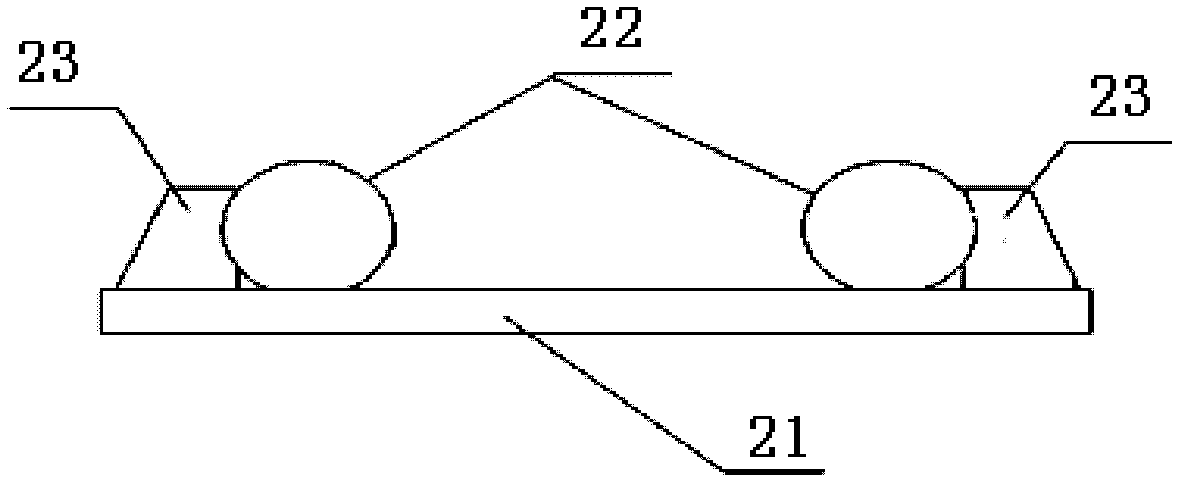

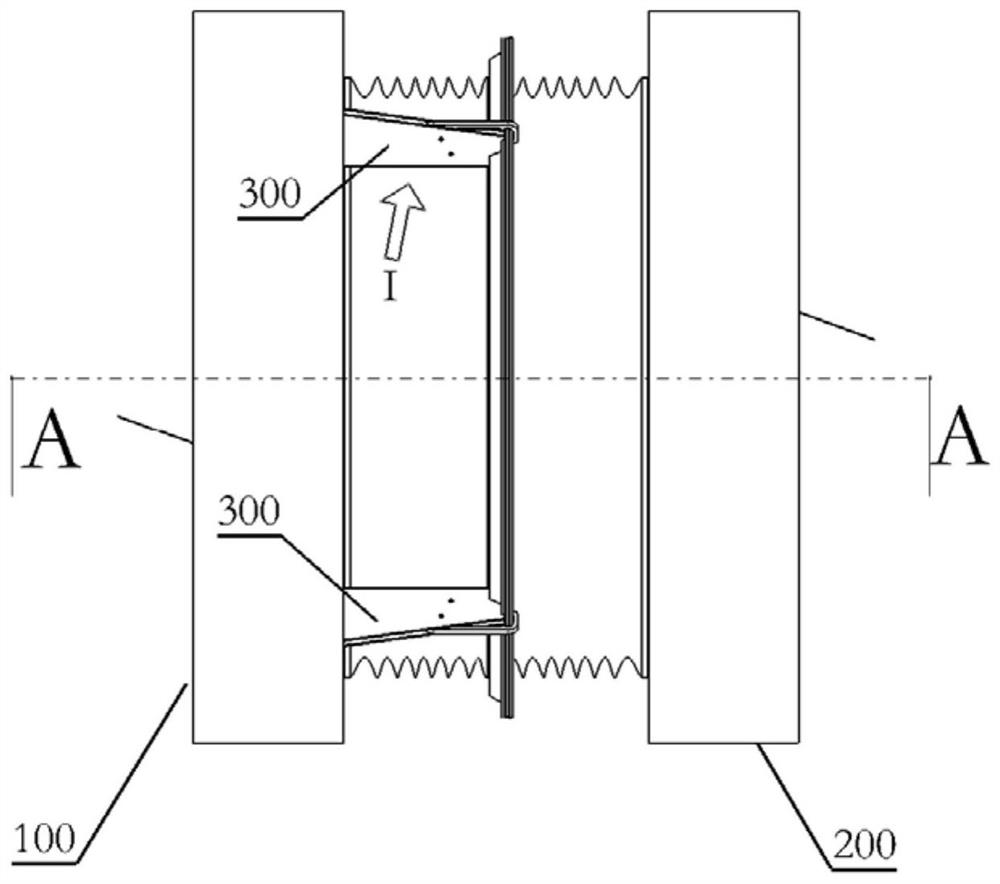

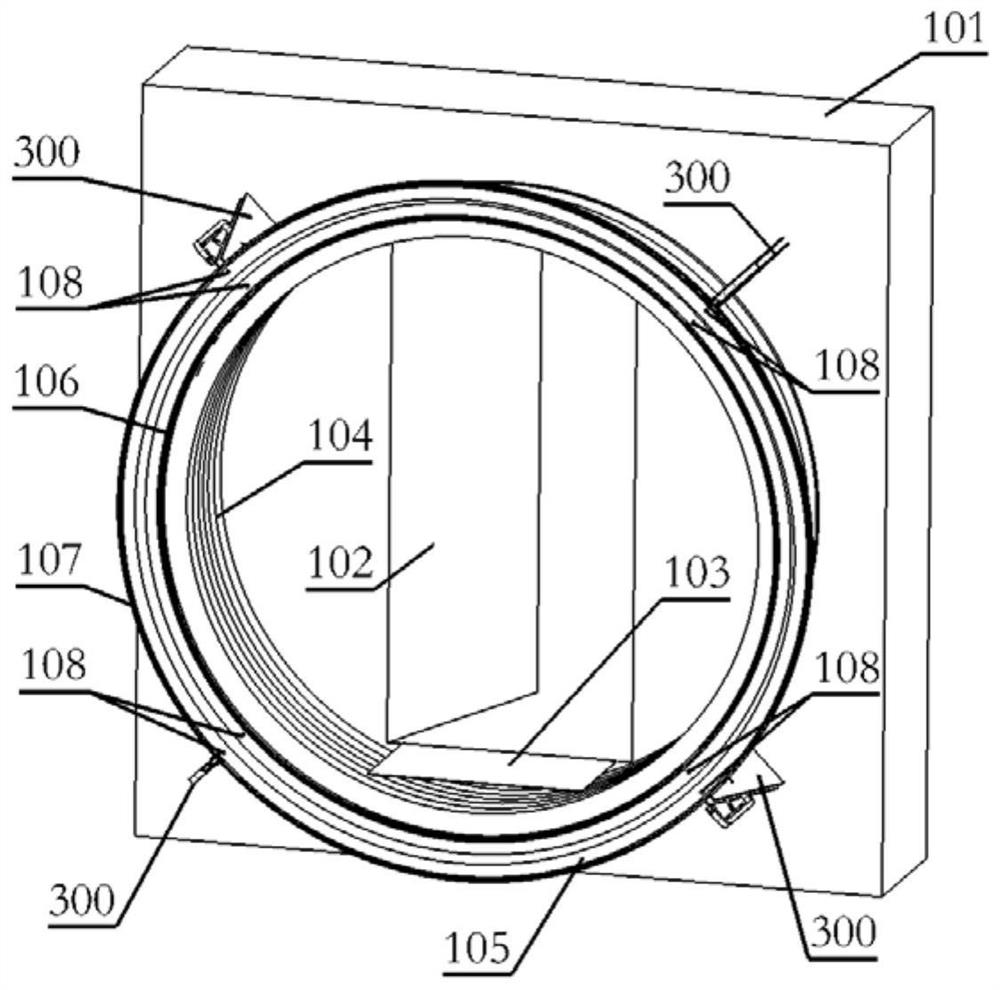

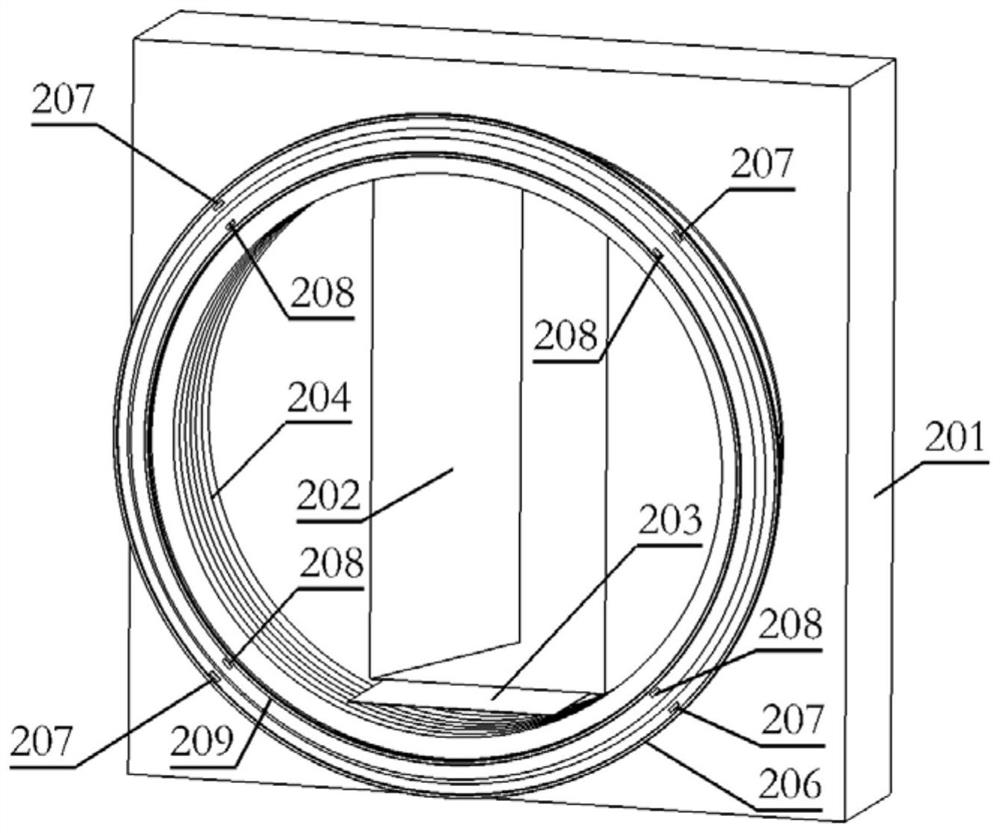

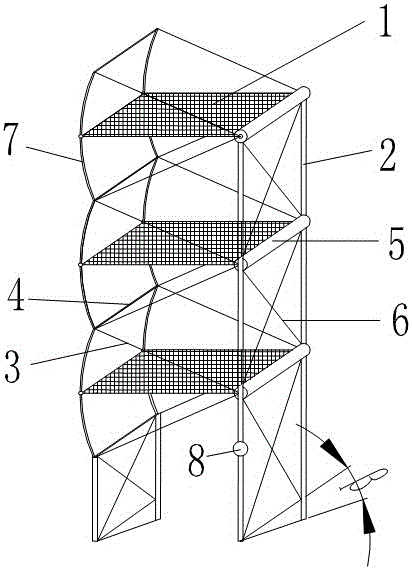

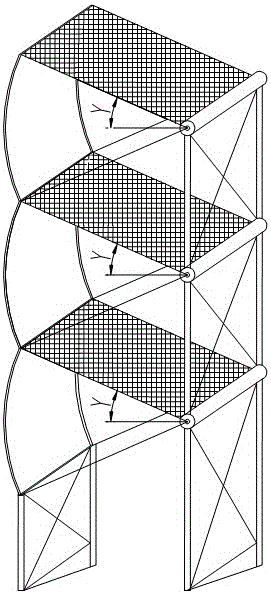

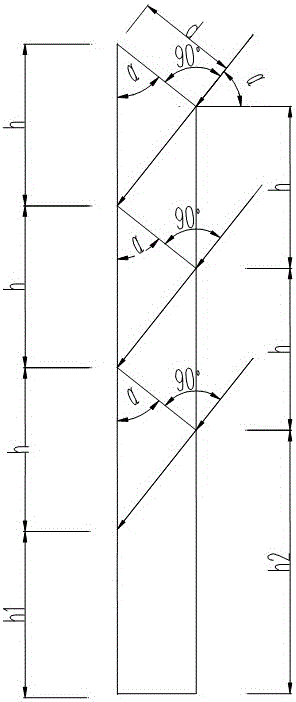

Friction-metallic yielding energy consumption combined control damping device applied to shear wall connecting beam and control method thereof

InactiveCN102535669AWith adjustable functionImprove energy consumptionShock proofingClassical mechanicsEngineering

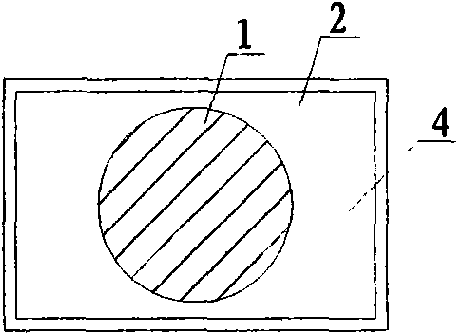

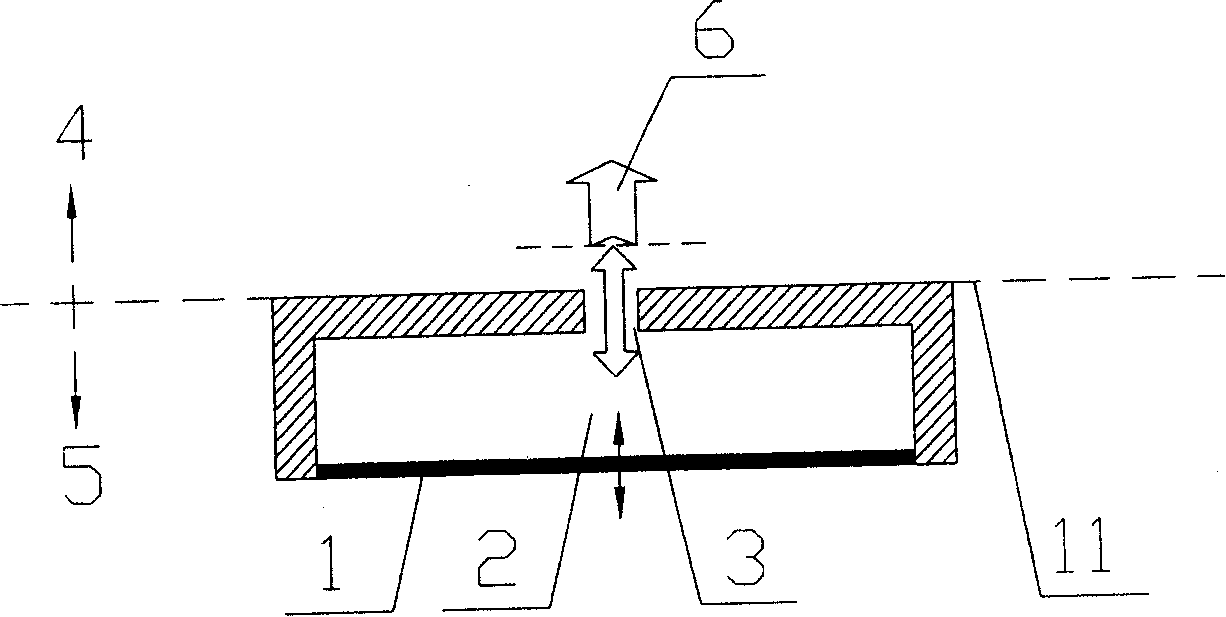

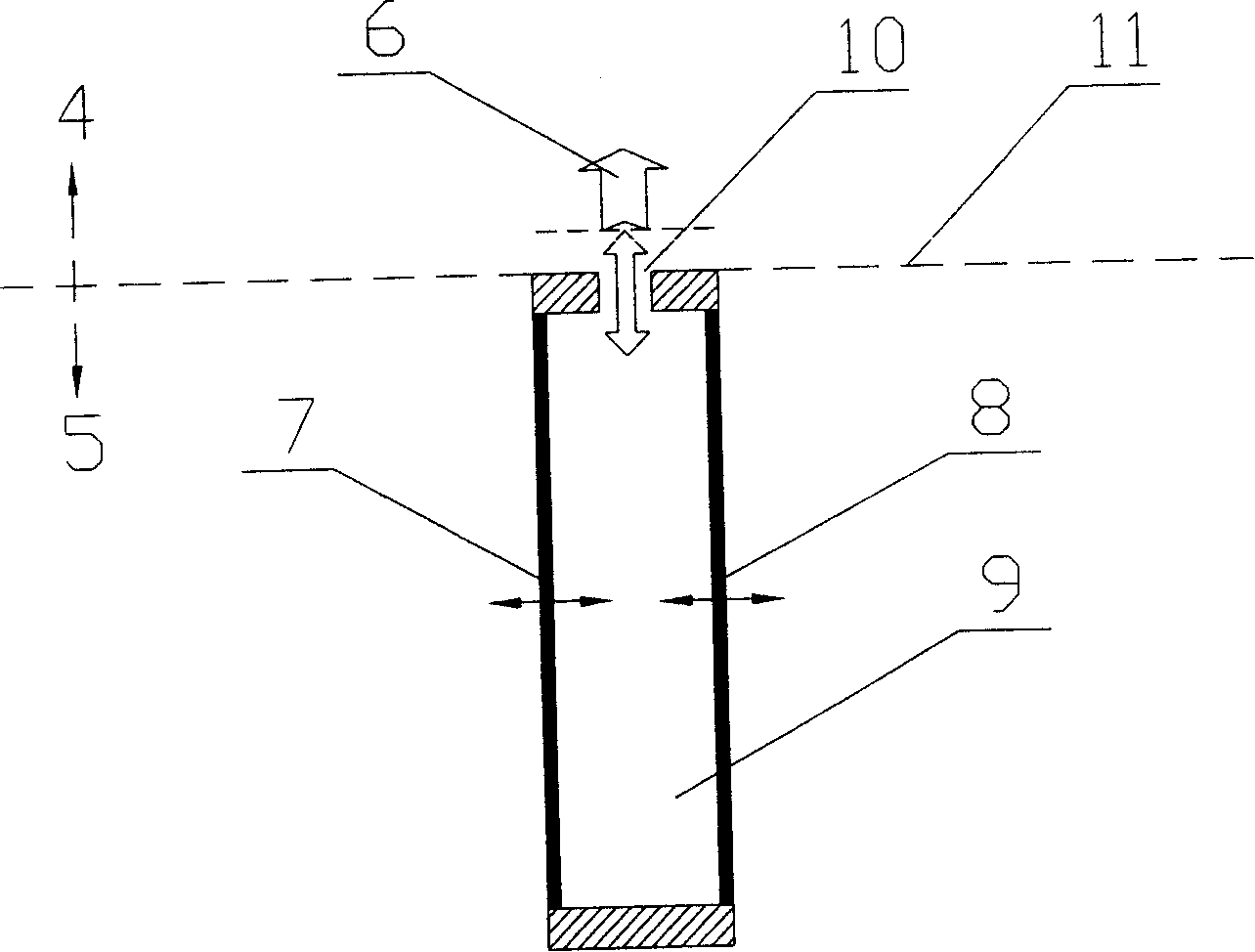

The invention discloses a damping device and a using method of the damping device, in particular relates to a friction-metallic yielding energy consumption combined control damping device applied to a shear wall connecting beam and a using and installation method of the damping device, belonging to the technical field of structural vibration control in civil engineering. The invention relates to a control method for combining a metallic yielding damper and a metal friction damper to improve an energy consumption vibration-damping performance of a damper, and the damping device mainly consists of a metal friction energy consumption area, a soft steel yielding energy consumption area and a built-in area connected with a shear wall. The purpose of energy consumption in a staging manner is achieved by soft steel yielding energy consumption and steel plate friction energy consumption, and the magnitude of pretightening force that the friction damper is connected with a bolt is adjusted to enable the combined control damper to have an adjusting function. The device and the method in the invention can be applied to a high-rise coupled shear wall structure to attach or replace the connecting beam, so as to improve the energy consumption performance and improve the structural seismic-resisting effect. The friction-metallic yielding energy consumption combined control damping device is convenient to manufacture, and has accurate working principle and good application prospect.

Owner:DALIAN UNIV OF TECH

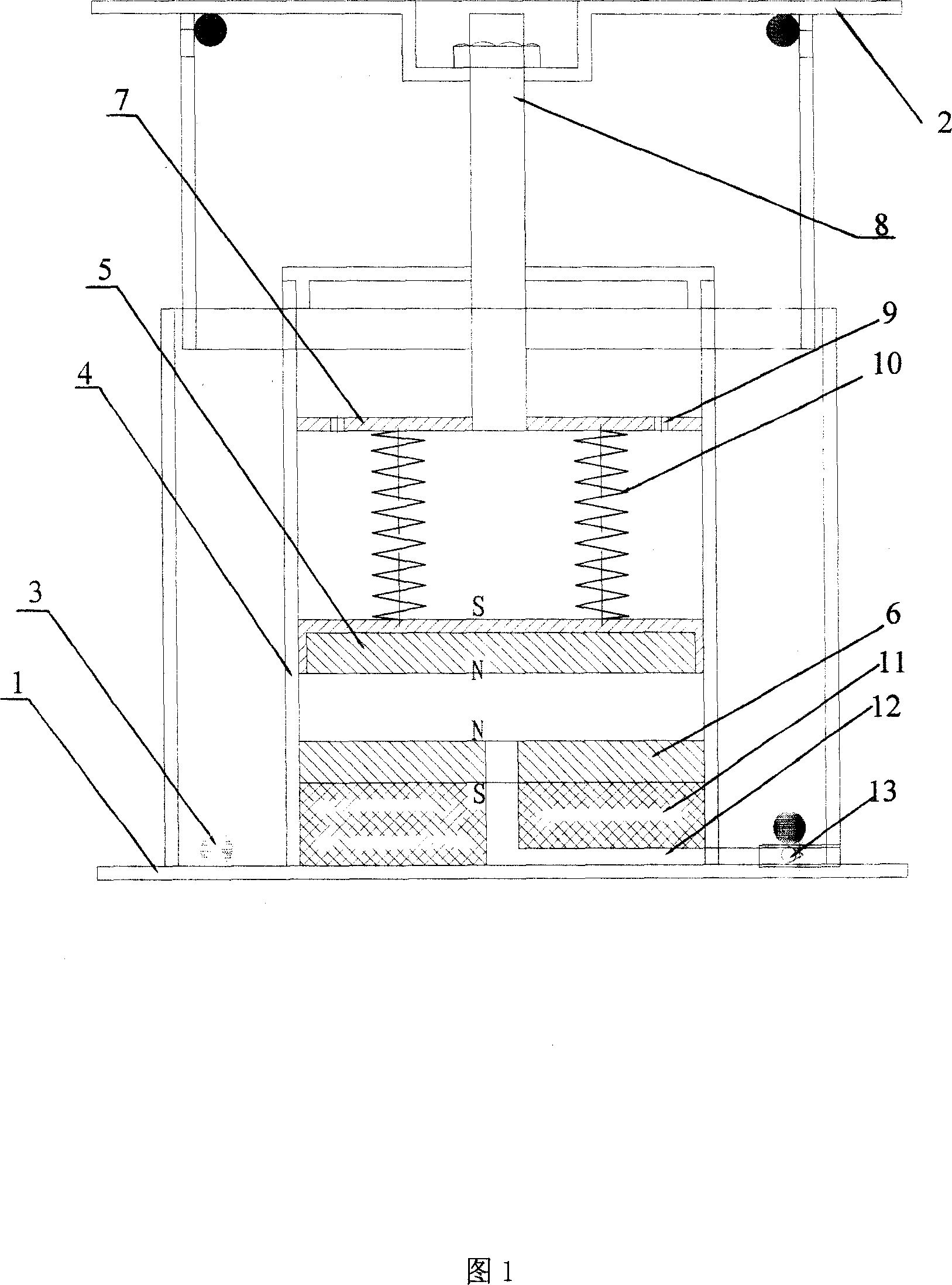

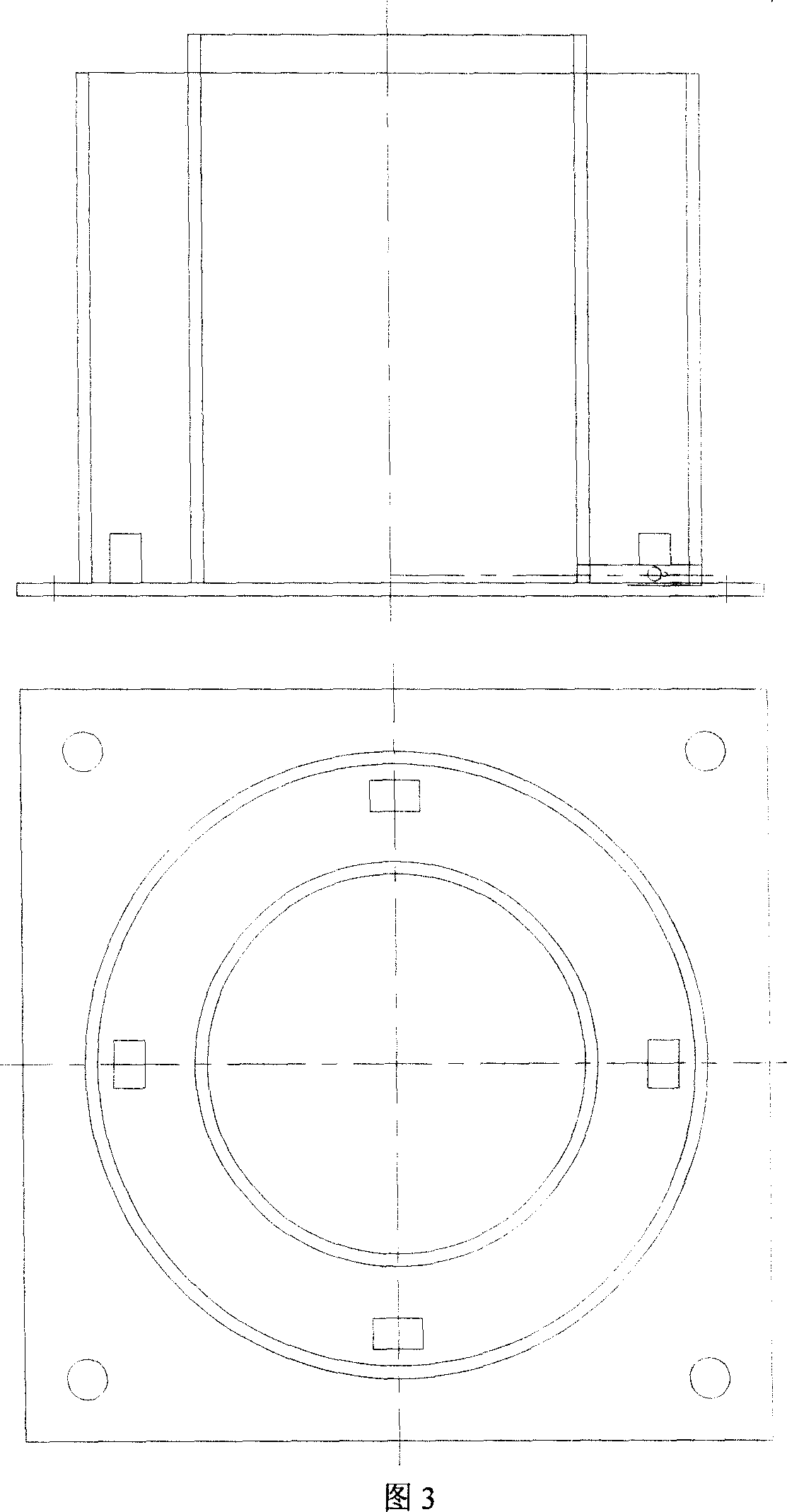

Composite magnetic damping vibration absorber

InactiveCN101012860AImprove bearing capacityImprove flexibilityMagnetic springsMagnetic dampingAir spring

The invention provides a composite magnetic floating damping vibration reducer, comprising a bottom plate and an upper cover above. The sides of the bottom plate and the upper cover are arranged with guide side plates between them to guide each other. The bottom plate and the upper cover are arranged with a main spring between to support the upper cover. The bottom plate is mounted with a cylinder which contains an upper and a lower permanent magnets with same polarity. The upper permanent magnet is arranged with a piston above, while the piston is connected to the upper cover via the piston rod. The upper permanent magnet and the piston are arranged with an auxiliary spring between. The invention has the advantage in the combination between main spring, damping structure, magnetic floating structure, and air spring, to improve the bearing function, improve the flexibility of main spring, and reduce the size of invention, with adjustable mounting height.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

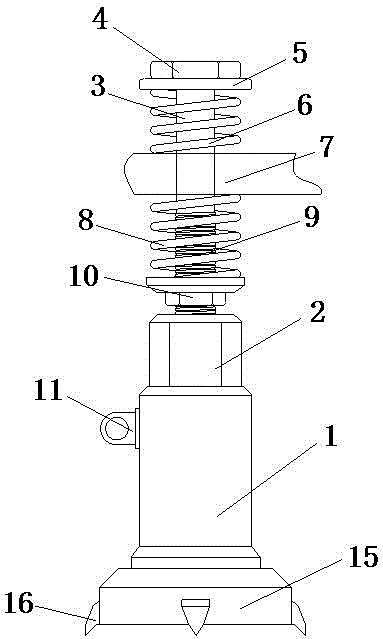

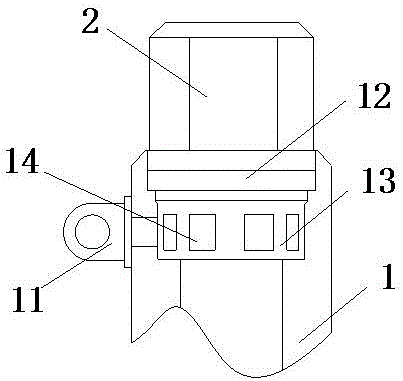

Damping supporting leg for mounting mine ventilator

Owner:WUXI HENGDA MINE MACHINERY

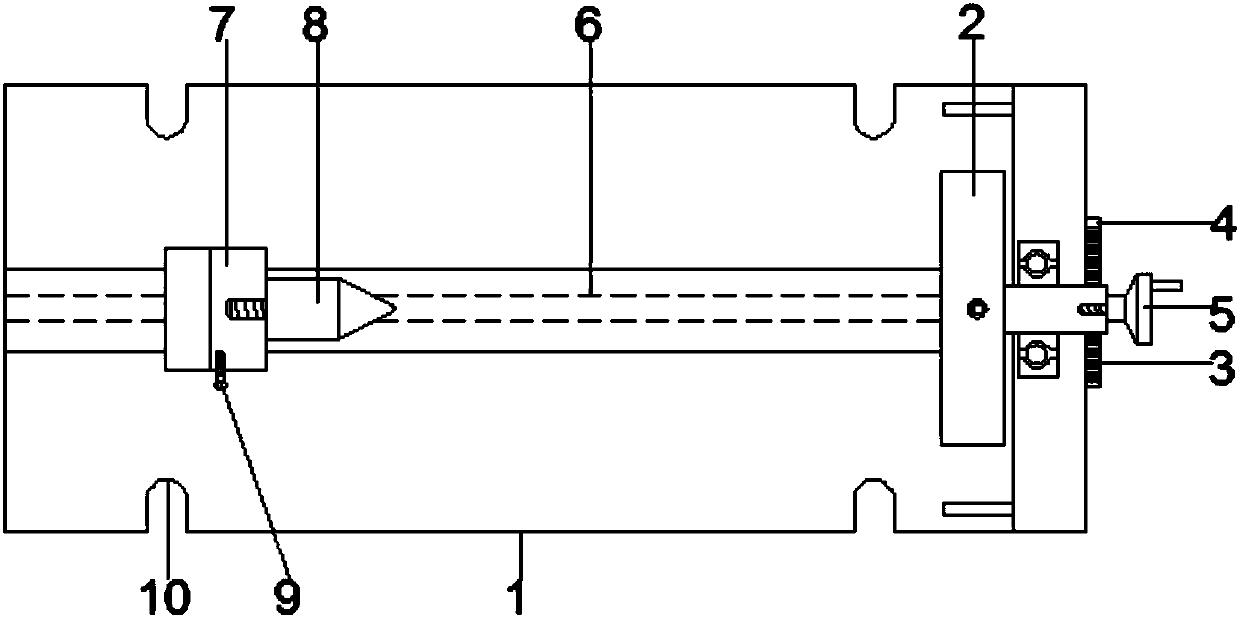

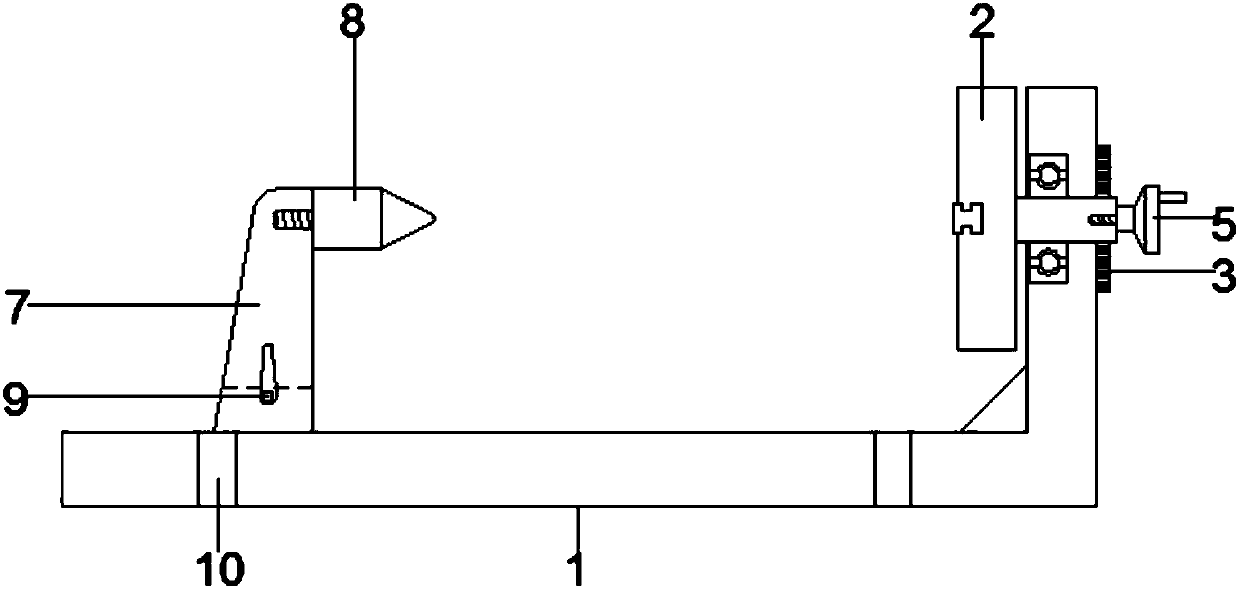

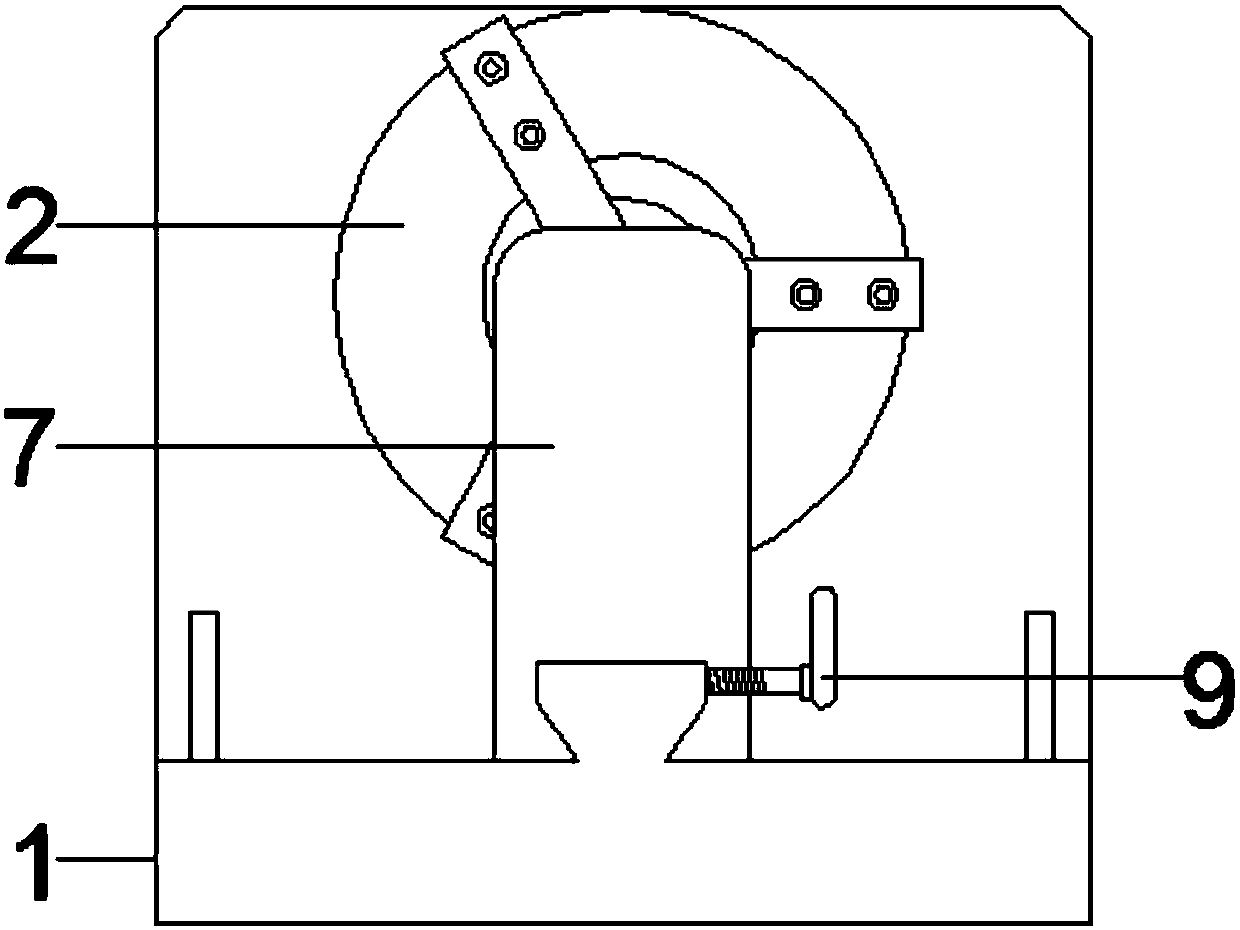

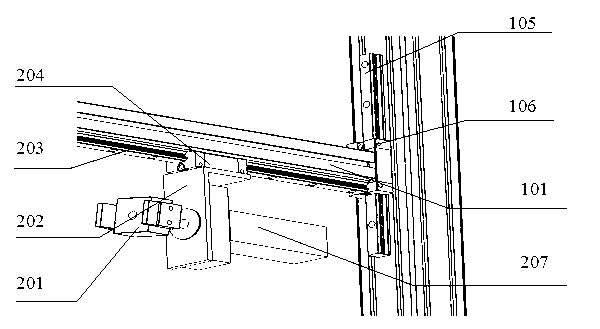

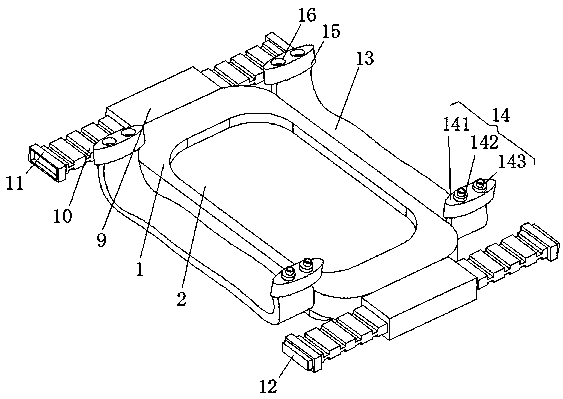

Steel pipe axial positioning device for drilling machine and fixture table

InactiveCN107825177APrevent the workpiece from being tilted by forceThe clamping structure is set reasonablyPositioning apparatusMetal working apparatusSteel tubeEngineering

The invention relates to the technical field of mechanical manufacturing, in particular to a steel pipe axial positioning device and a fixture table for a drilling machine, comprising: a fixture table, a chuck and a ratchet; the chuck is arranged on the upper part of the fixture table, and the chuck and the fixture table pass through The bearing is connected; the ratchet wheel is arranged at one end of the chuck, and the ratchet wheel and the chuck are connected by a pin-stud inlaid manner; the pawl is arranged on one side of the fixture table, and the pawl and the fixture table are connected by a rotating shaft; The crank handle is arranged at one end of the chuck, and the crank handle and the chuck are connected by screw connection. Through the structural improvement, it has the advantages of reasonable clamping structure setting to prevent the workpiece from slipping, rotating and tilting under force, the axial positioning processing method increases the diversification of processing functions, the structure connection is simple and the operation process is convenient, etc., so as to effectively solve the problem. The problems and deficiencies existing in the existing devices are solved.

Owner:惠州市梦芭迪工业产品设计中心(普通合伙)

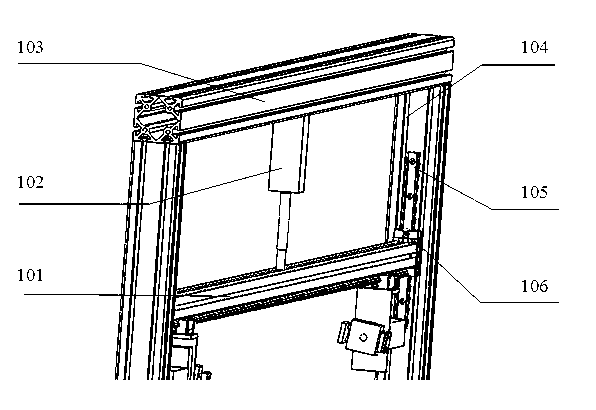

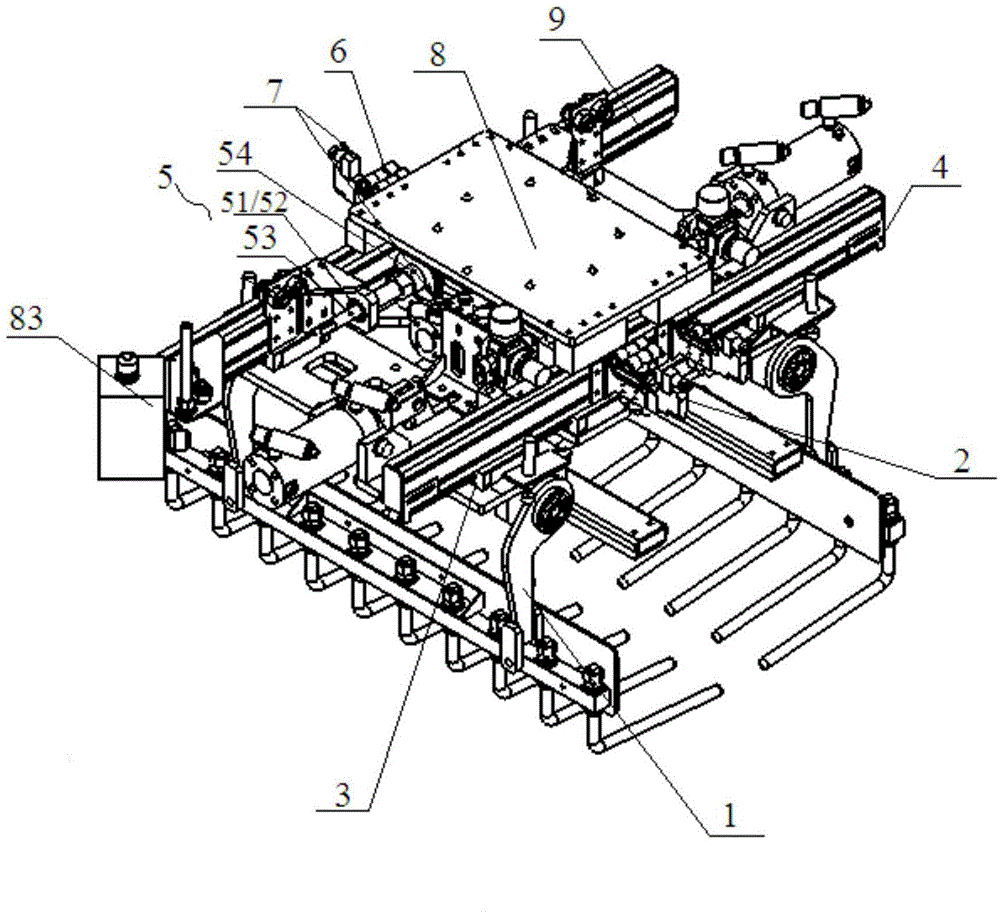

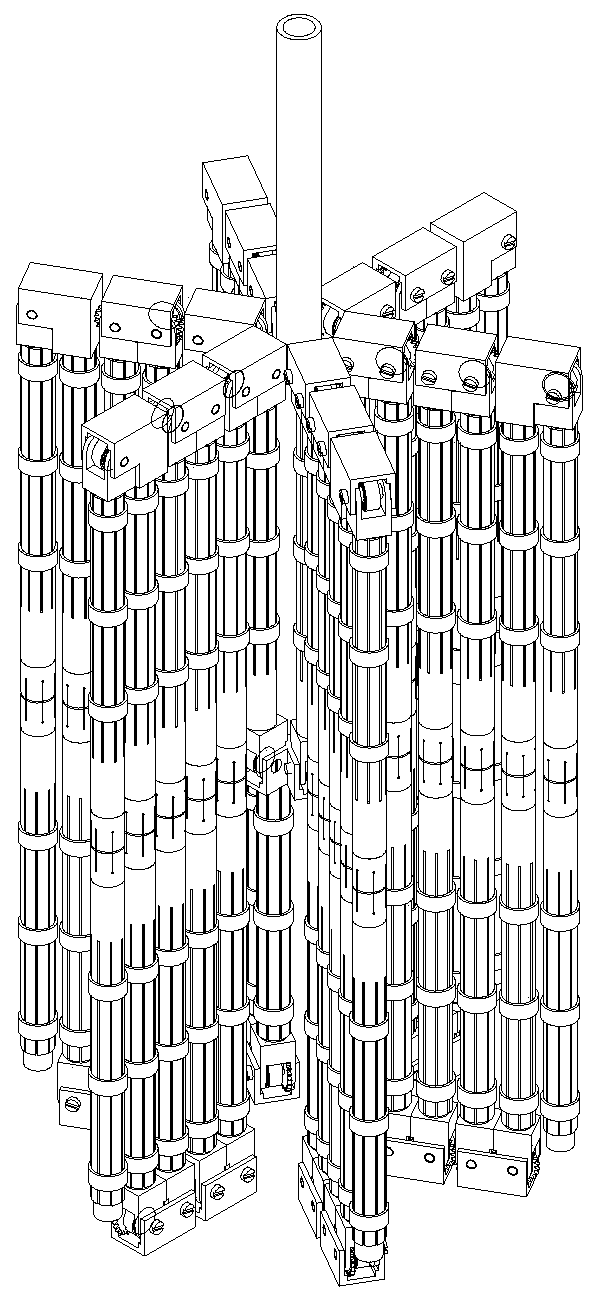

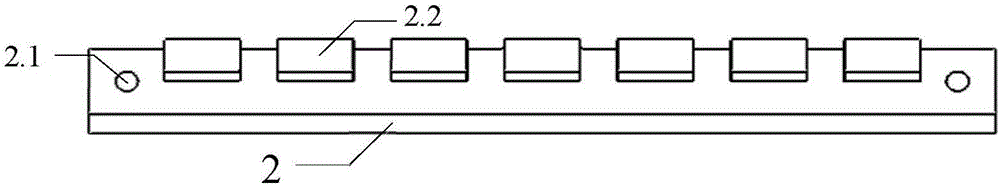

Material separating rotating mechanical hand

The invention discloses a material separating rotating mechanical hand, which mainly consists of a group workpiece separating module, a workpiece rotating module and a movement control system module and is characterized in that the group workpiece separating module comprises a fixed cross beam, a vertical beam, an upward and downward moving air cylinder, a moving cross beam, a vertical linear slide rail and a vertical slide block, wherein the upward and downward moving air cylinder is arranged in the middle of the bottom surface of the fixed cross beam, a piston rod of the upward and downward moving air cylinder is fixedly arranged in the middle of the upper surface of the moving cross beam, the fixed cross beam and the moving cross beam are in parallel arrangement in the same plane in the X direction, the two ends of the moving cross beam are respectively connected onto the vertical slide block of the vertical linear slide rail, the vertical linear slide rail is in symmetrical distribution at the two ends of the moving cross beam in the Z-axis direction and is fixedly arranged on the vertical cross beam at the two ends, the workpiece rotating module comprises two X-axis moving pairs and one X-axis rotating pair, one X-axis moving pair is characterized in that horizontal slide blocks do linear movement along the horizontal linear slide rail, and the other X-axis moving pair is characterized in that an extending swinging air cylinder does telescopic movement in the X-axis direction.

Owner:HEBEI UNIV OF TECH

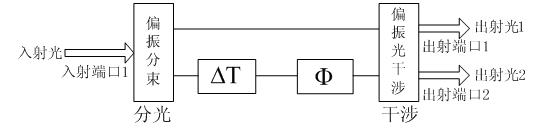

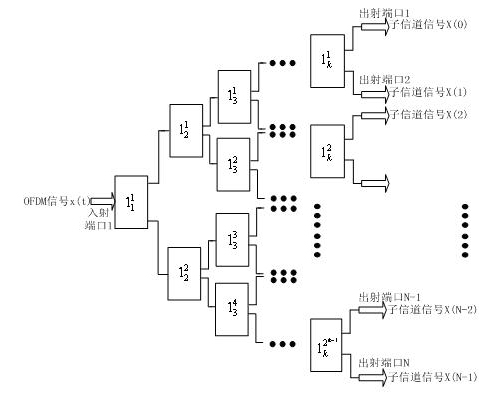

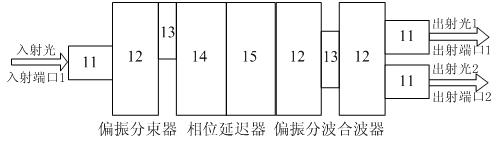

Polarization interference-based full-light OFDM signal multiplexing and demultiplexing device

InactiveCN102043255AWith separate extractionWith adjustable functionMulti-frequency code systemsOptical light guidesCarrier signalSubcarrier

The invention relates to a device for multiplexing and demultiplexing an orthogonal frequency division multiplexing (OFDM) signal by using a polarization interference principle. A demultiplexing device consists of (N-1) basic structural units in a cascade mode, wherein N is the number of subcarriers of the OFDM signal, and an optical signal is subjected to polarization beam splitting, time delay and phase shift, and polarization interference in each basic structural unit; the demultiplexing device is inverted to serve as a multiplexing device; and the multiplexing device and the demultiplexing device realize operational function of inverse Fourier transform and Fourier transform on data sequence information carried in the optical signal. The device realizes the operational function of the inverse Fourier transform and the Fourier transform needed by OFDM signal multiplexing and demultiplexing in a full-light mode, and effectively eliminates the electronic processing speed limitation. Compared with devices in other full-light OFDM modes, the device has high expansibility, easily multiplexes and demultiplexes sub-channel signals with a large number of optical carriers, and has adjustable function and high flexibility.

Owner:HUAZHONG UNIV OF SCI & TECH

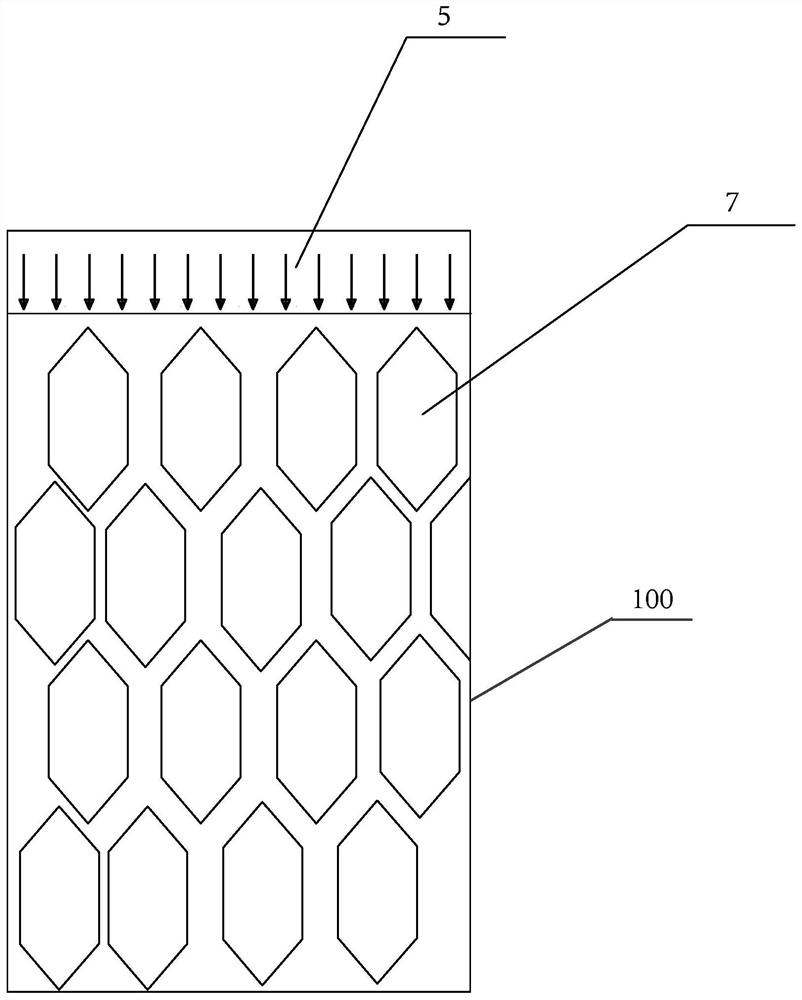

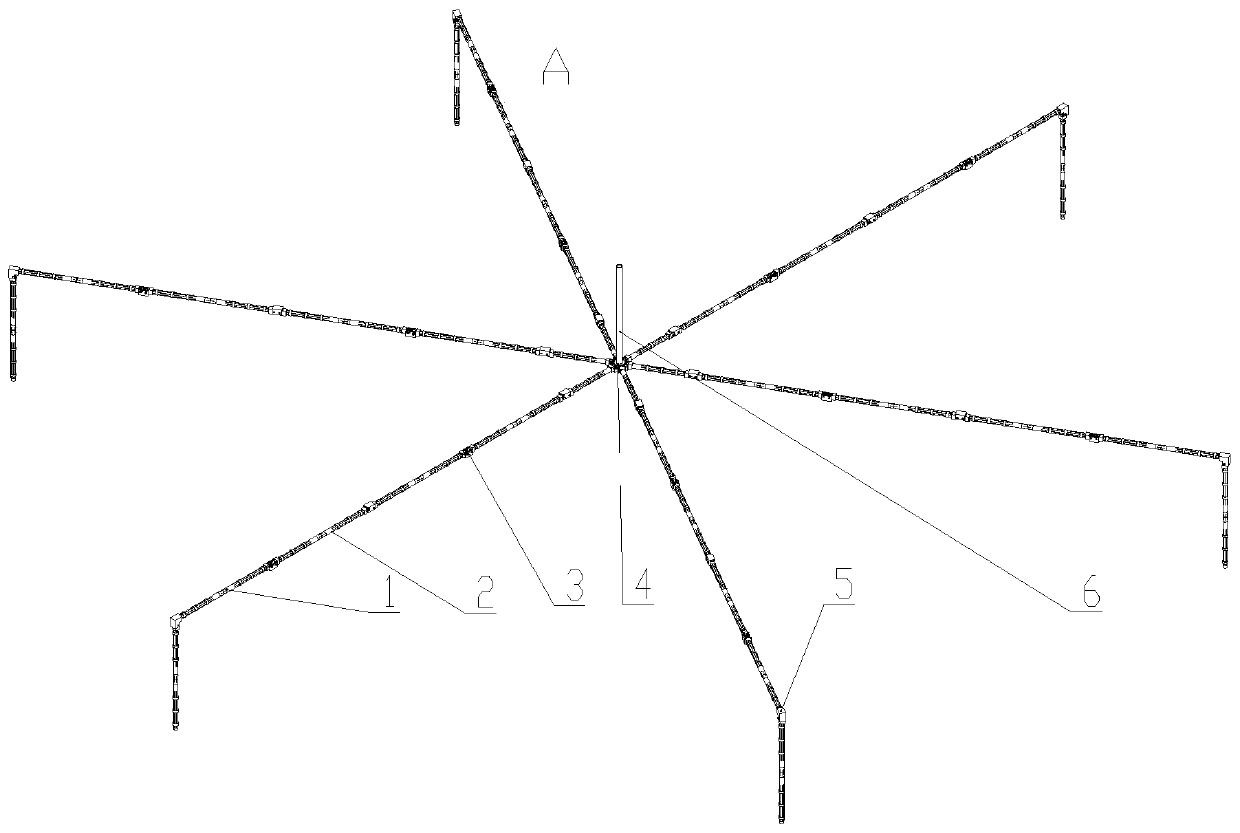

System for hindering falling of particles into solar heat absorber

PendingCN113007911AWith adjustable functionLow costSolar heating energyAbsorbing elementsEngineeringMechanical engineering

The invention discloses a system for hindering falling of particles into a solar heat absorber. The system is arranged inside the heat absorber and comprises a plurality of blocking mechanisms which are arranged in a staggered mode from top to bottom, each blocking mechanism comprises a horizontal adjusting rod and a plurality of blocking units which are arranged in the horizontal extending direction of the horizontal adjusting rod and movably connected with the horizontal adjusting rod, the blocking units comprise vertical connecting rods, sliding blocks, cams, elastic components, top plates and bottom plates, the upper ends of the vertical connecting rods are movably connected with the horizontal adjusting rods, the lower ends of the vertical connecting rods are movably connected with the cams, and the sliding blocks are attached to the left sides and the right sides of the edges of the cams correspondingly; the upper sides and the lower sides of the sliding blocks are in sliding fit with the inner side parts of the top plates and the bottom plates correspondingly, and the elastic components are fixed between the inner ends of the sliding blocks and the outer ends of the top plates, and therefore, the staying time and the heating temperature of the particles inside the heat absorber can be adjusted and controlled according to the intensity condition of solar illumination.

Owner:NORTH CHINA POWER ENG

Self-adaptive gripper for bag packages

The invention relates to a self-adaptive gripper for bag packages. The self-adaptive gripper comprises two parallel main connecting frames, a main connecting platform, two embracing and clamping units and two pressing units, wherein the main connecting platform is fixedly connected with the upper portions of the main connecting fames and is used for being connected with a robot terminal, and the two embracing and clamping units and the two pressing units are arranged below the main connecting frames and used for clamping and gripping materials. The self-adaptive gripper further comprises an automatic width adjustment unit, a manual width fine adjustment unit, and a controller which conducts linkage control over action execution of different air cylinders in the embracing and clamping units, the pressing units and the automatic width adjustment unit. Compared with the prior art, the self-adaptive gripper has the gripper width adjusting function, can simultaneously grip and release bag packages in various specifications, and has the advantages of being broad in using range, easy to manufacture, convenient to maintain and the like.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

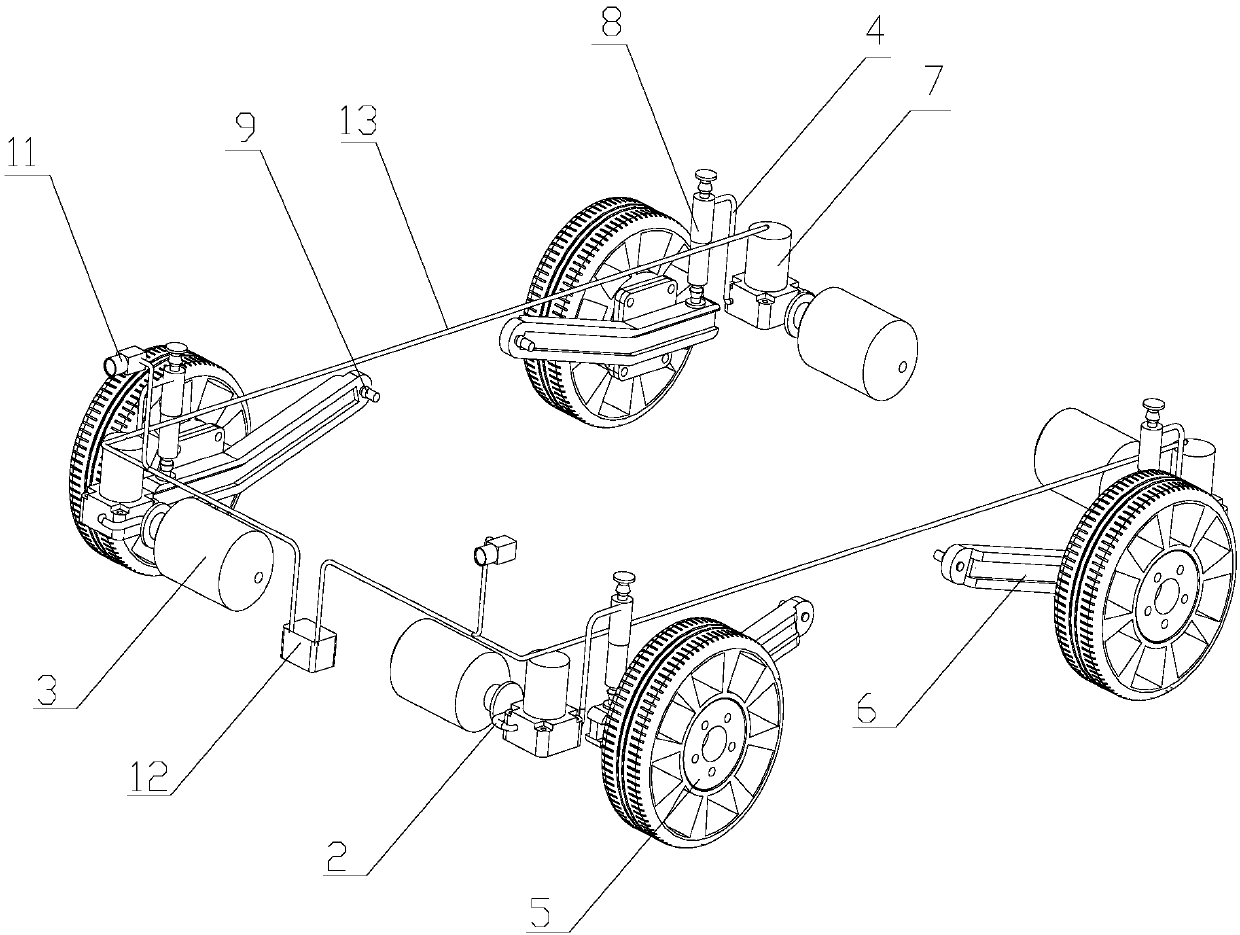

Fully-active suspension system and logistics vehicle applying same

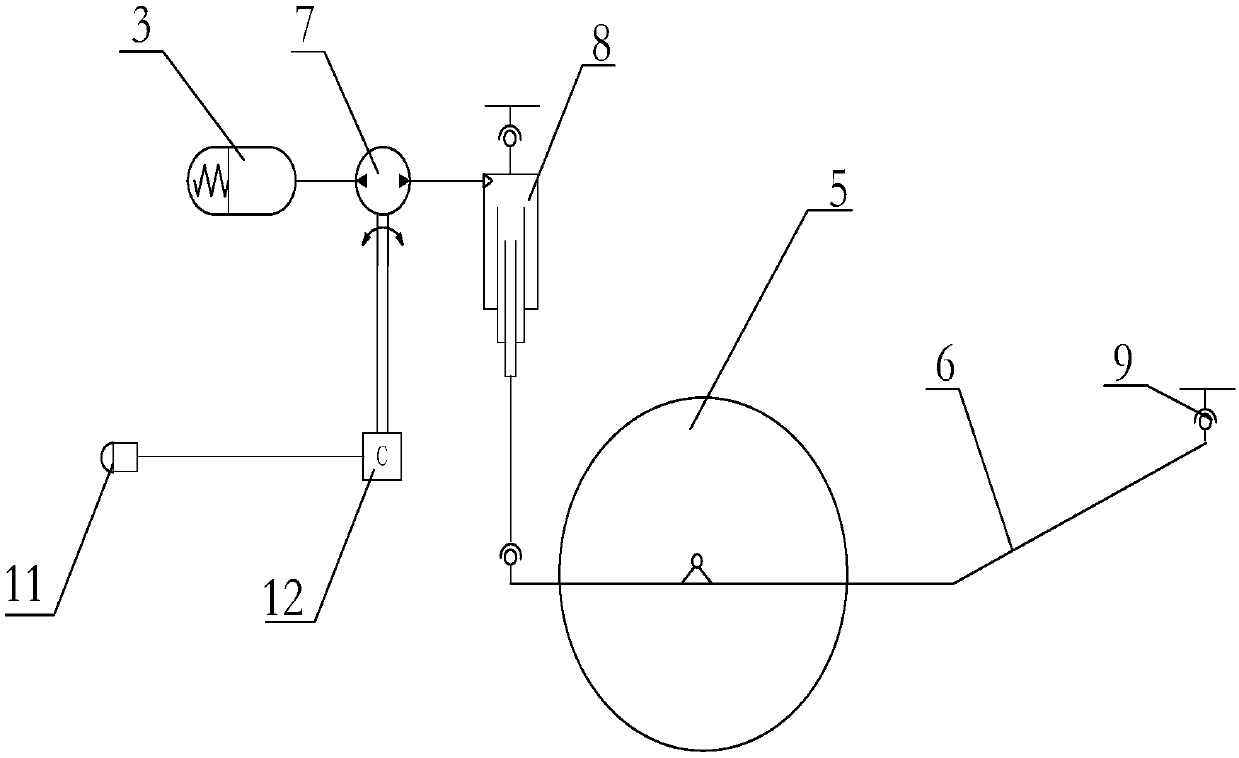

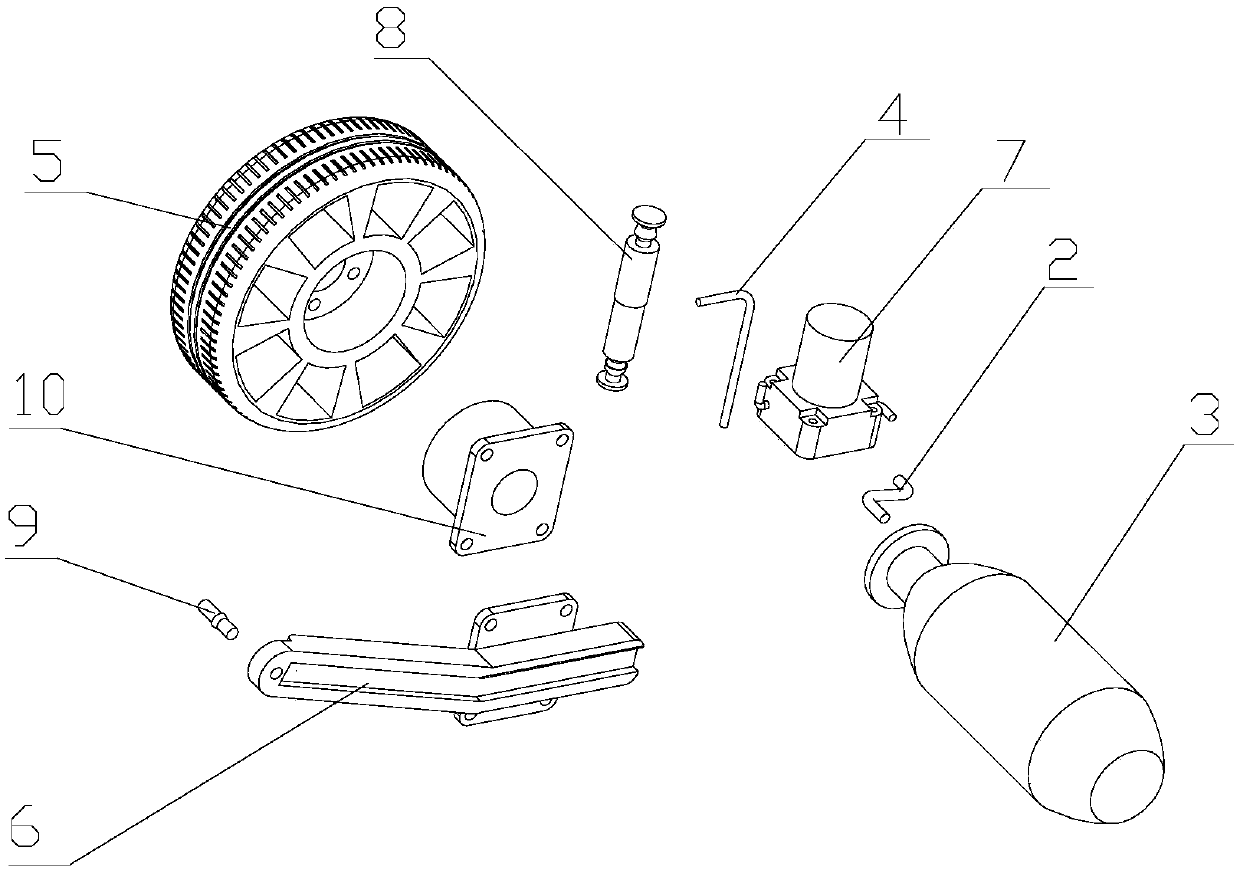

InactiveCN109606053ABest damping stateWith adjustable functionResilient suspensionsTerrainControl line

The invention relates to a fully-active suspension system which comprises energy accumulators, electronic gear pumps, power cylinders, swing arms, a control system and steering knuckles, wherein the front end of each steering knuckle is cylindrical and the rear end of each steering knuckle is of a plate-like structure; a hub motor stator of each wheel is fixedly connected with the cylinder of eachsteering knuckle; the plate-like structure of each steering knuckle is fixedly connected with the side of one end of each swing arm; the upper surface of one end, connected with a hub, of each swingarm is connected with each power cylinder through a ball joint; the other end of each swing arm is connected with a vehicle body through a ball joint; each power cylinder communicates with a high-pressure oil outlet of each electronic gear pump through a second oil pipe; a low-pressure oil inlet of each electronic gear pump communicates with each corresponding energy accumulator through a first oil pipe; and the control system is connected with the electronic gear pumps through control lines. All-terrain road driving of small-sized vehicles such as logistics vehicles and the like is realized,and efficient vibration suppression and vibration absorption can be achieved.

Owner:JILIN UNIV

Length-fixed antenna with special antenna adaptor device

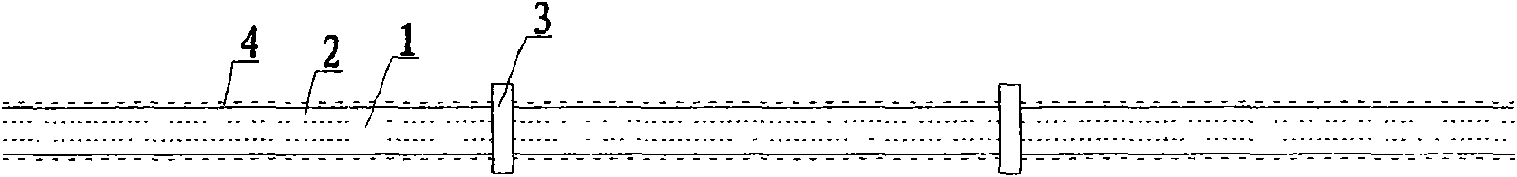

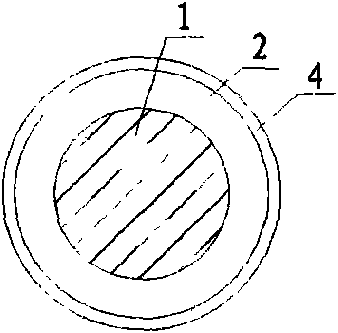

InactiveCN101593574AWith adjustable functionEasy to carryCoupling device connectionsInsulated cablesSpecific testField tests

The invention discloses a length-fixed antenna with special antenna adaptor device to solve the problem that the prior normal antenna has difficulties in meeting different requirements due to complex on-site test environment and working conditions of a structure during the field test of various engineering structures. According to the actual conditions of field test environments and the characteristics of different structures, the antenna adopts a waterproof film design and has a length adjusting function and a super-high pressure-resistance and waterproof function. Meanwhile, according to design, the antenna is available in circular and flat cross sections so as to meet the requirements on antennae of specific test environments. Obviously, the adjustable antenna for testing engineering structures can well meet the requirements of complex field test environments on the antennae, improve the safety and convenience of on-site test operations, and guarantee the smooth completion of the on-site test operations.

Owner:SOUTHEAST UNIV

Synthetic jetting excitor with single-membrane, double openings and double cavities

ActiveCN100381710CAvoid Ballast ProblemsWith adjustable functionFluid dynamicsDifferential pressureEngineering

The invention comprises a vibration diaphragm, and first and second cavities separated via the vibration diaphragm. First and second outlets are disposed on the first and second cavities separately. The invention can solve the ballast problem of the driver vibration diaphragm caused by the differential pressure between the controlled flow field and the environmental flow field.

Owner:NAT UNIV OF DEFENSE TECH

Multifunctional logistics warehouse storage rack

InactiveCN108041905AEasy to moveImprove handling efficiencyShow shelvesShow hangersLogistics managementEngineering

The invention discloses a multifunctional logistics warehouse storage rack. The multifunctional logistics warehouse storage rack comprises a base, the two sides of the bottom of the base are both provided with rectangular openings, the inner walls of the rectangular openings are fixedly connected with fixing frames, the bottom of one side of each fixing frame is fixedly and rotationally connectedwith a corresponding first connecting rod through a movable part, the bottom of the other side of each fixing frame is rotationally connected with a wheel frame, one end of each first connecting rod is rotationally connected with a corresponding second connecting rod through the movable part, one end of each second connecting rod is rotationally connected with the corresponding wheel frame throughthe movable frame, the joint portions of the first connecting rods and the second connecting rods are rotationally connected with hydraulic pressure rods, and the invention relates to the technical field of logistics. The multifunctional logistics warehouse storage rack has functions of extinguishing fire and adjusting the storage space sizes, is provided with a walking mechanism, and can retractand stretch, not only provides convenience for the whole movement of the storage rack, but also provides convenience for fixing, the production cost is greatly reduced, and the carrying efficiency ofthe storage rack is improved.

Owner:合肥超凡快递咨询有限公司界首营业部

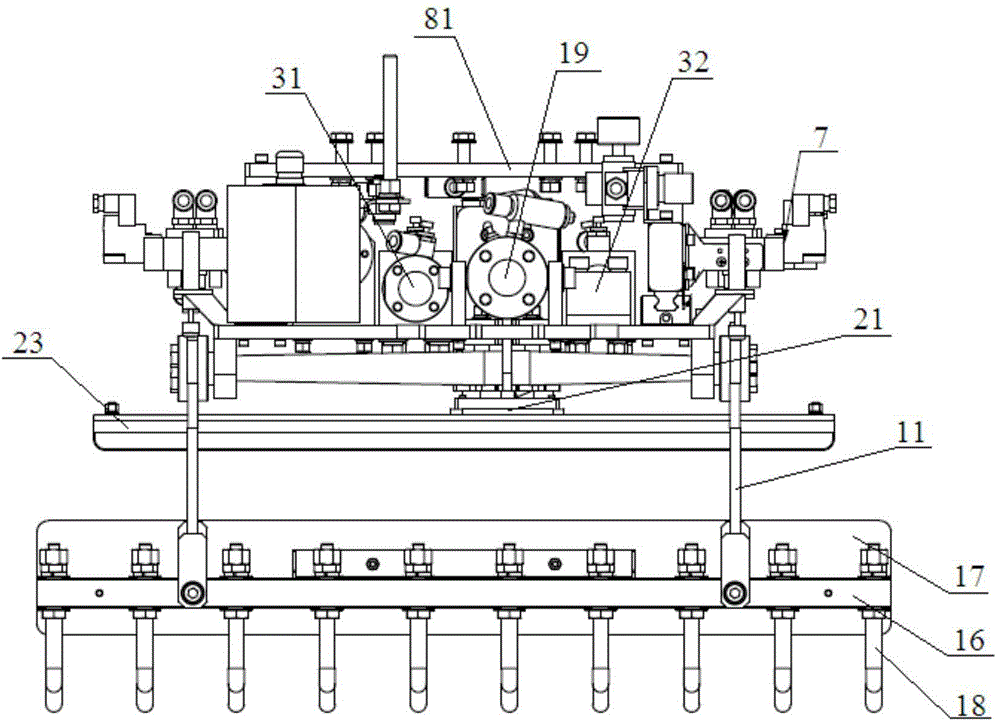

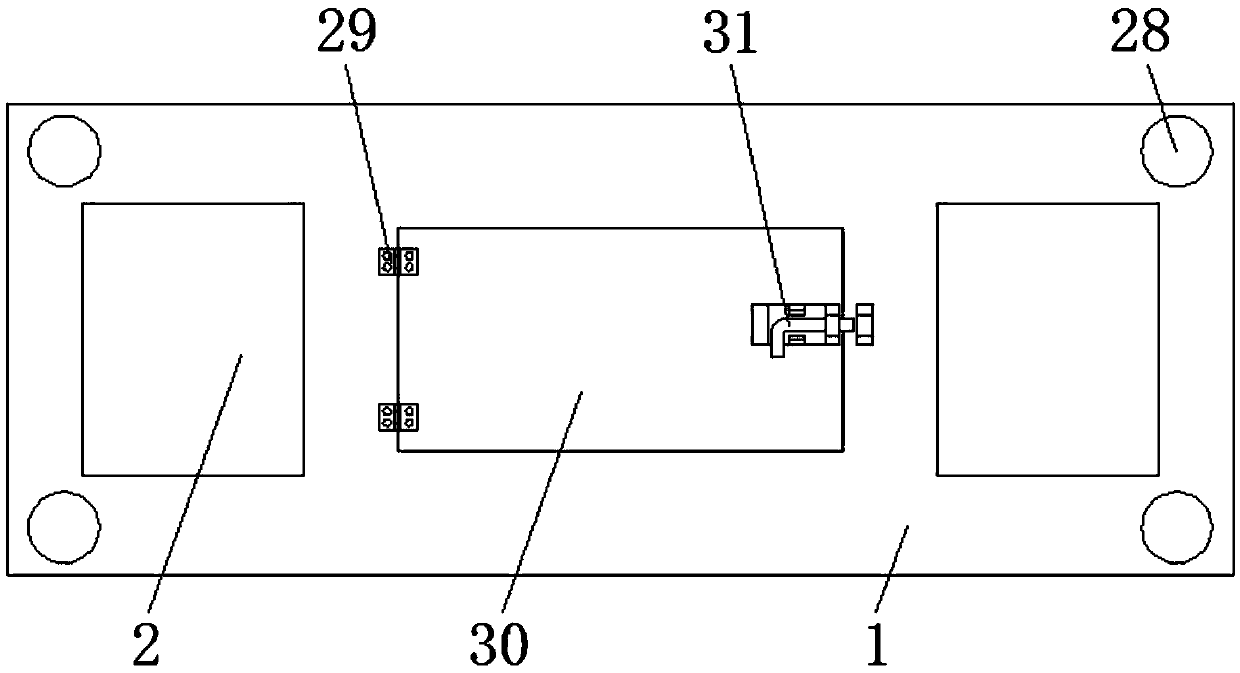

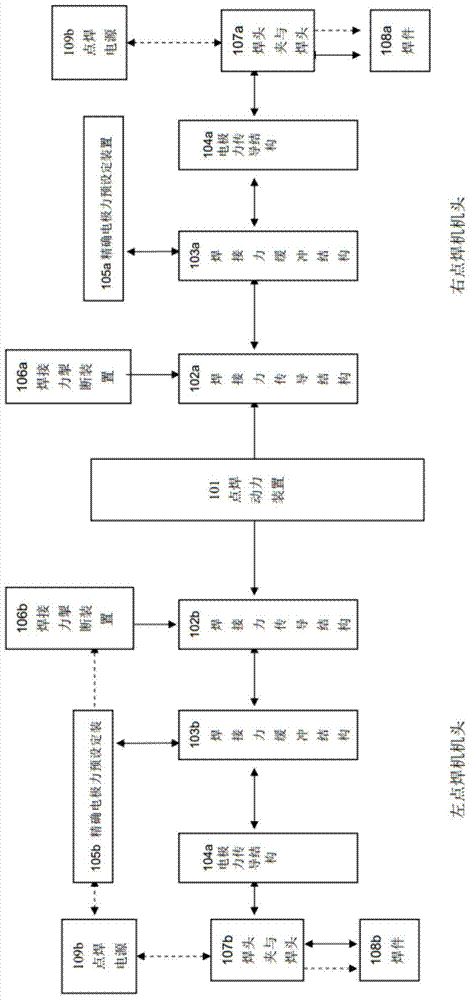

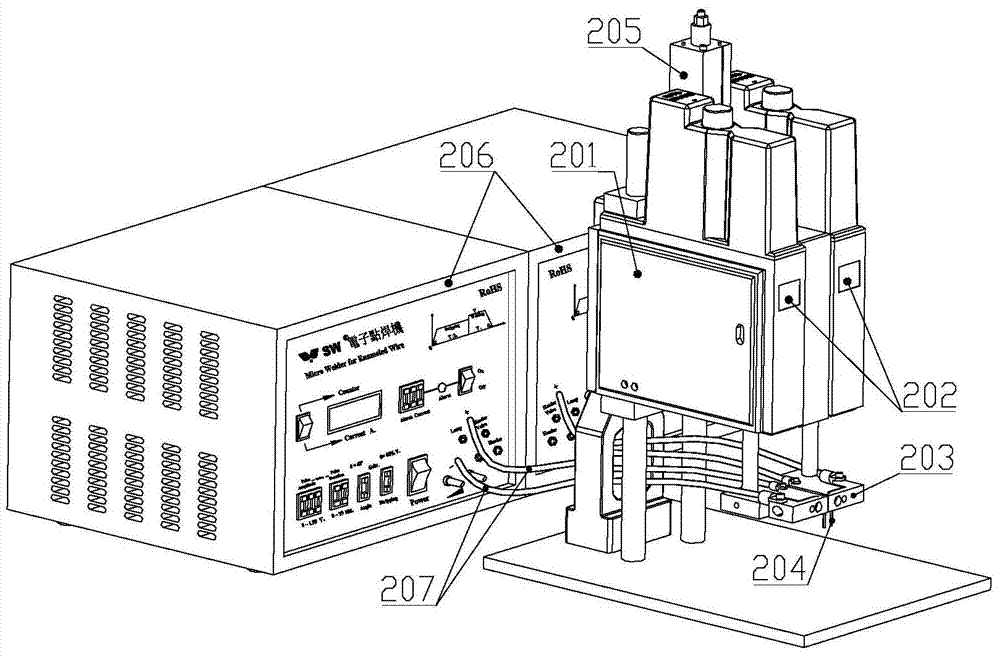

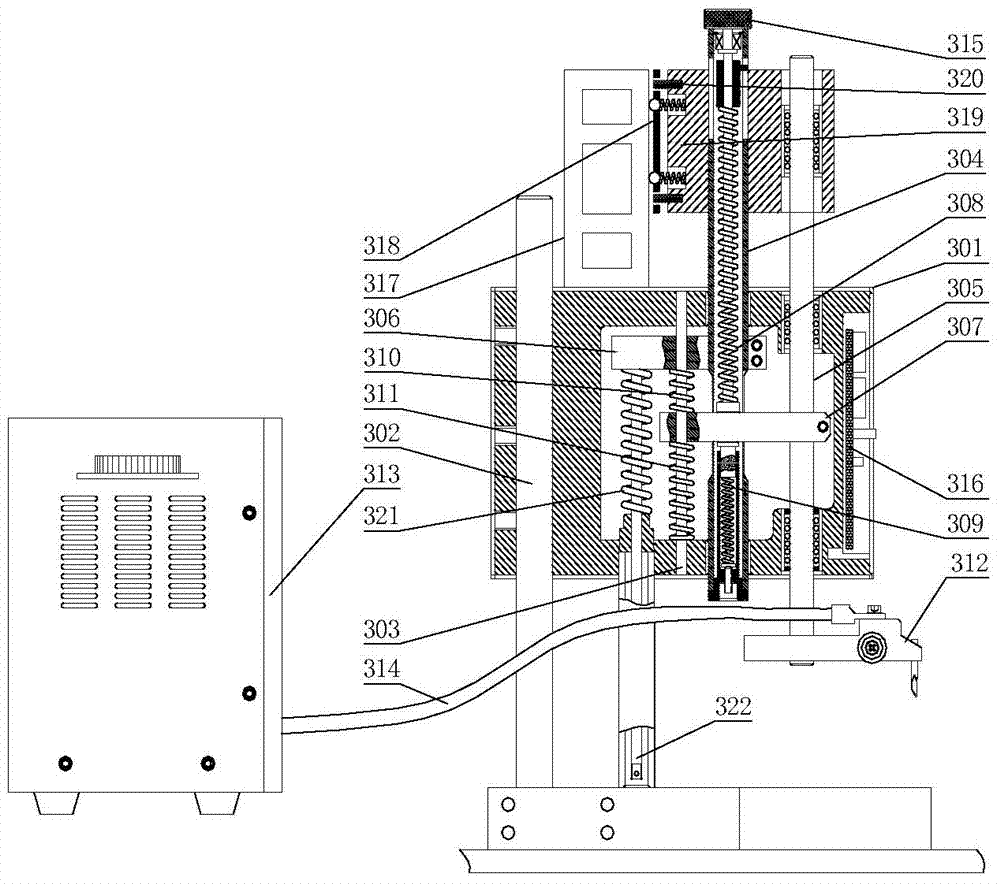

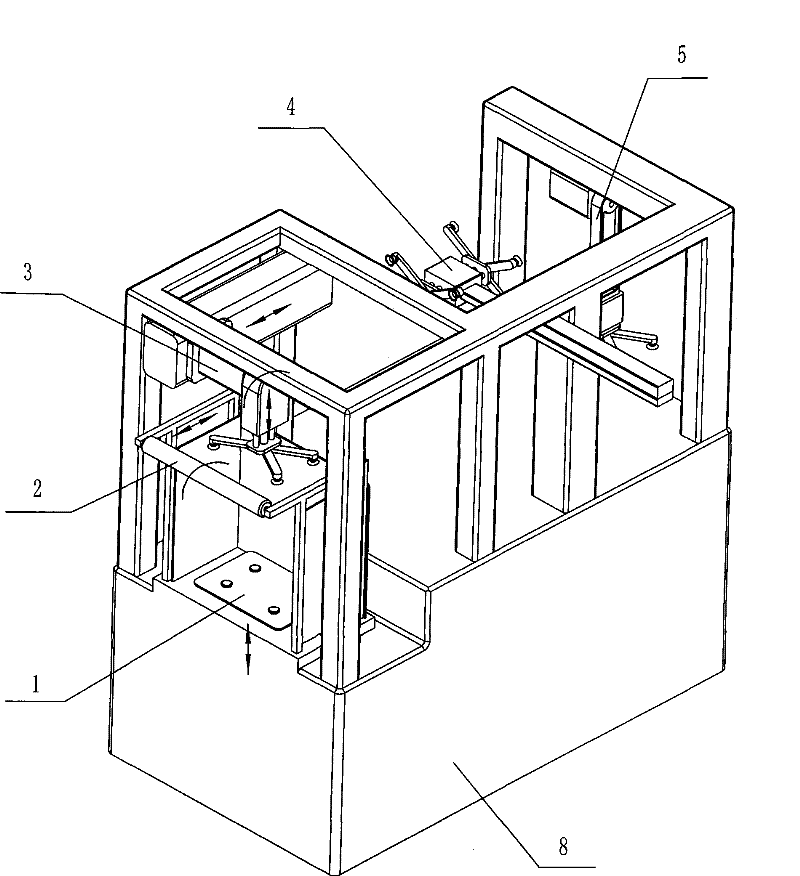

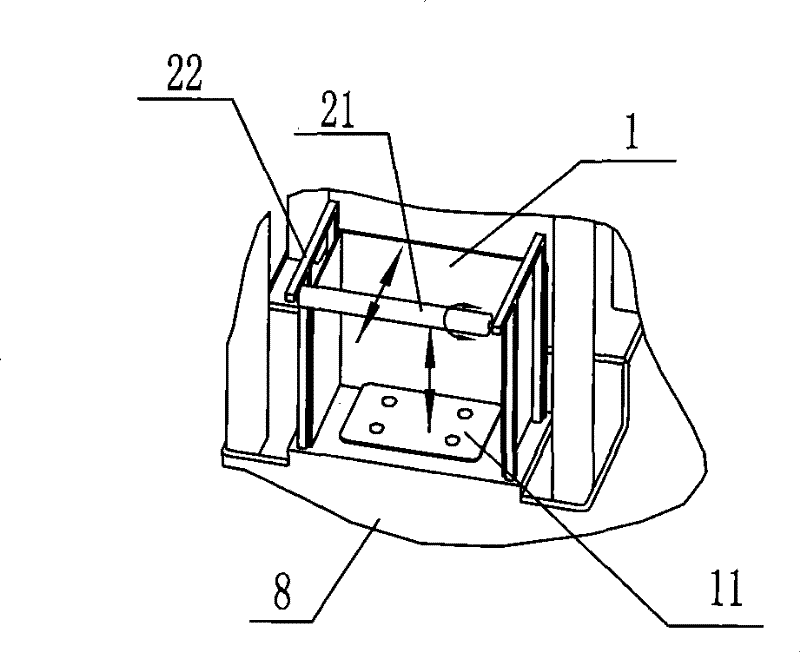

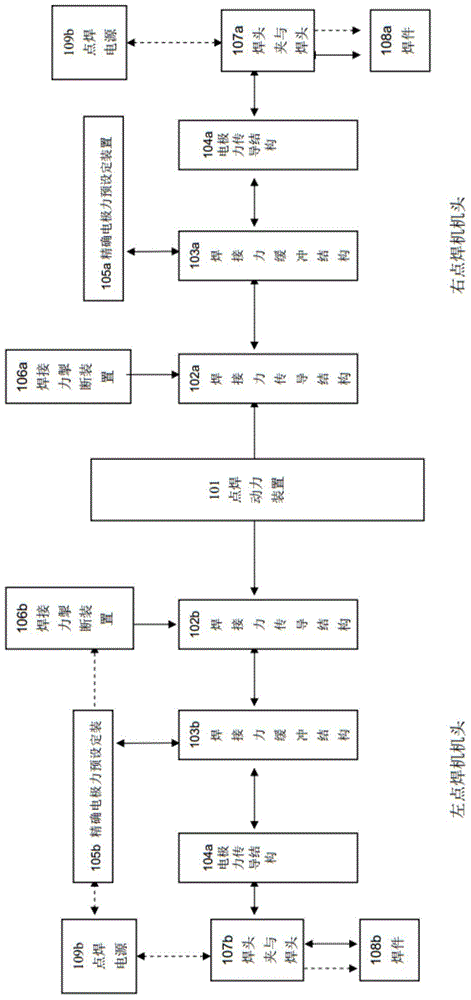

Integrated automatic microscopic welding equipment

InactiveCN103706933AImprove spot welding accuracyPrecise Electrode Force OutputResistance electrode holdersWelding electric suppliesEngineeringSpot welding

The invention relates to automation of welding, in particular to integrated automatic microscopic welding equipment. Automatic welding of two weldments can be realized at the same time through two integrally-mounted spot welding machine headpieces, two horizontally-clamping welding head clamps, two spot welding power sources and an automatic spot welding power device, wherein the welding head clamps are arranged at the same horizontal position side by side; welding parameters of two parallel electrode welding heads are independently adjusted to guarantee welding reliability and uniformity. Through improvements of frames of the spot welding machine headpieces, gaps between the horizontally-clamping welding head clamps which are arranged at the same horizontal position side by side can be adjusted. The brand-new automatic welding equipment is provided for production of electronic components.

Owner:GUANGZHOU MICRO WELDING EQUIP

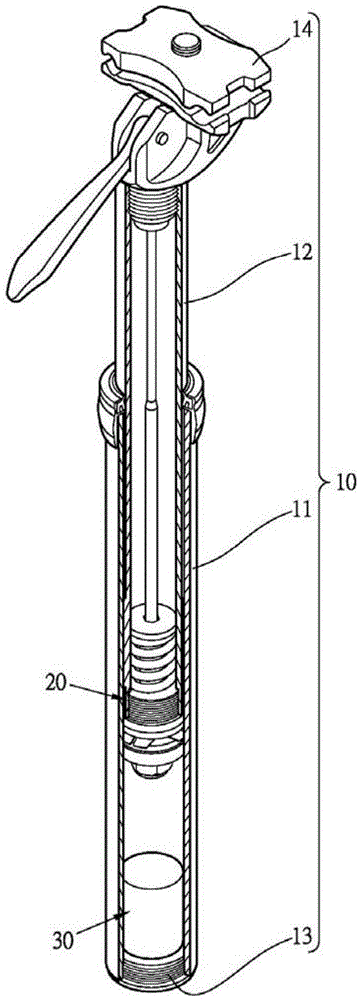

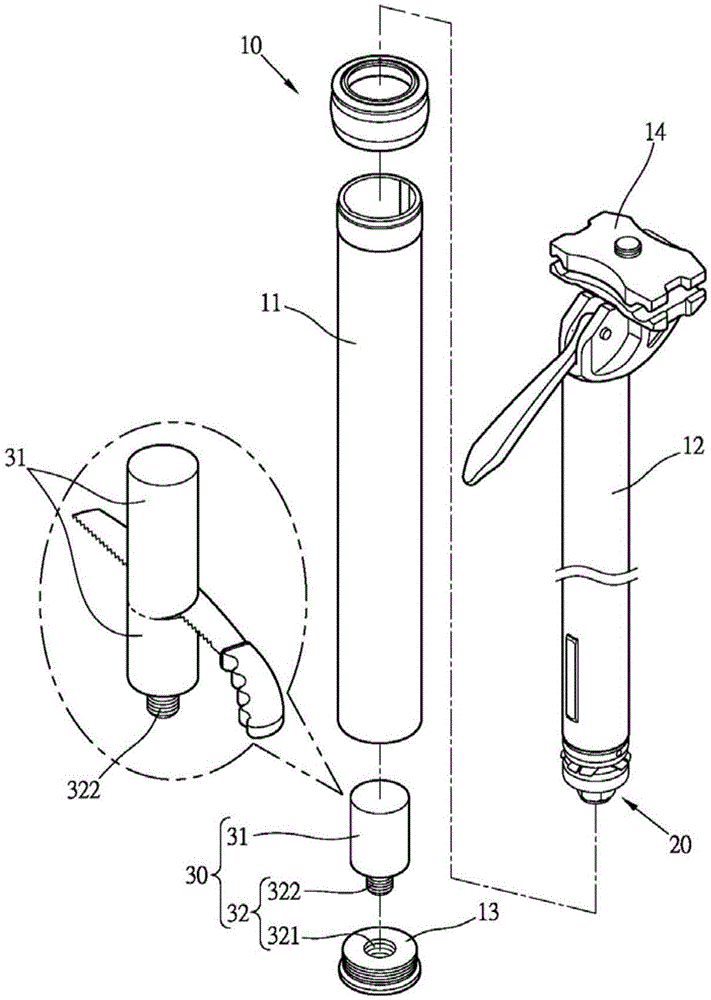

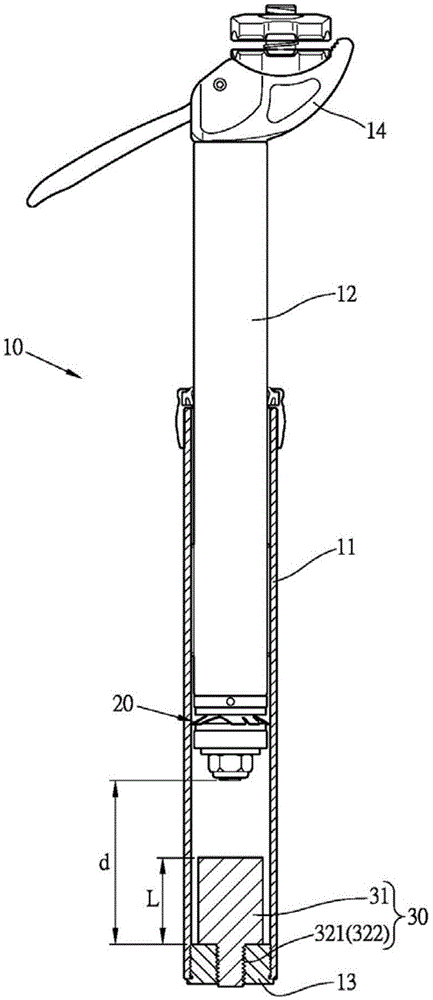

Adjustable limit device in bicycle seat tube

The invention discloses an adjustable limit device in a bicycle seat tube. The adjustable limit device comprises a seat tube set, an adjusting and locating device and a limit device body, wherein the seat tube set is provided with an outer tube and an inner tube, and the inner tube is sleeved with the outer tube; the limit device body is arranged in the outer tube, has a preset height and is provided with a limit assembly arranged within the moving distance, and the upper end edge of the limit assembly can effectively prevent the adjusting and locating device and the inner tube from continuing linear movement so as to limit the minimum height of the portion, exposed out of the outer tube, of the inner tube in the height adjusting process. In this way, the limit device body is additionally arranged in the seat tube set within the moving range, the inner tube cannot continue moving after moving to make contact with the limit device body, the lowest position of a seat is limited, the movable range of the inner tube is reduced, the locating function of slightly adjusting the seat height in a stepless mode can be achieved, and the effect of quick seat height adjustment and limiting is achieved. Meanwhile, the adjustable limit device is simple in disassembling and assembling structure, easy to disassemble and assemble, wide in overall structure application range and high in practicability.

Owner:DONGGUAN YUANYU MACHINERY CO LTD

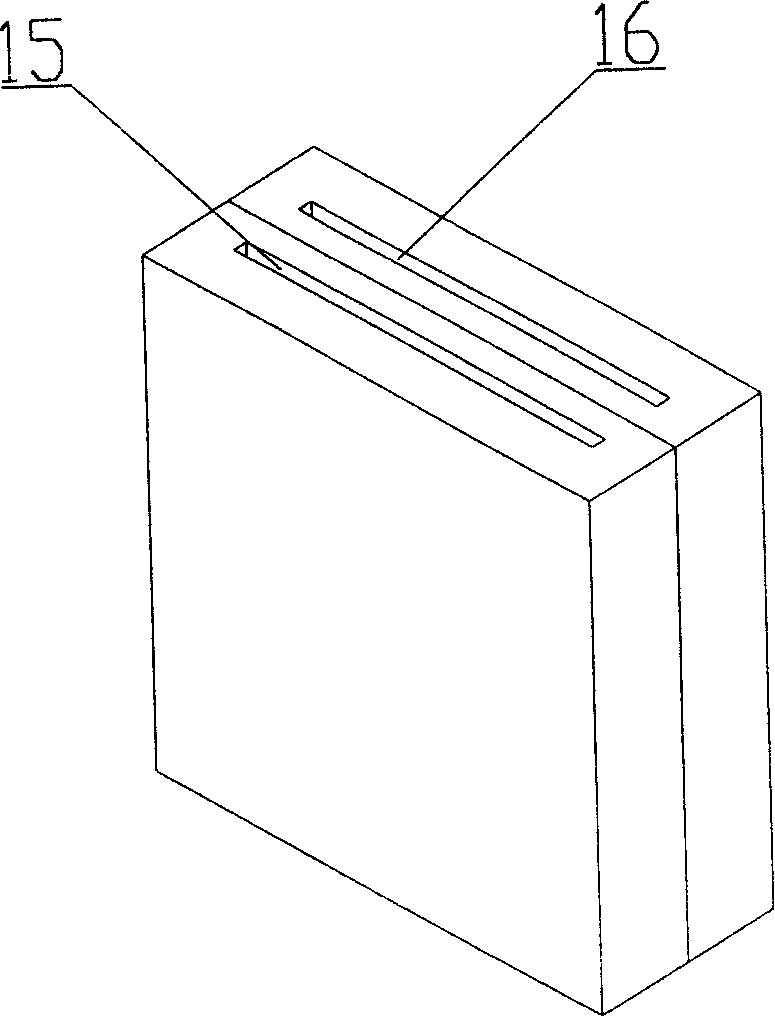

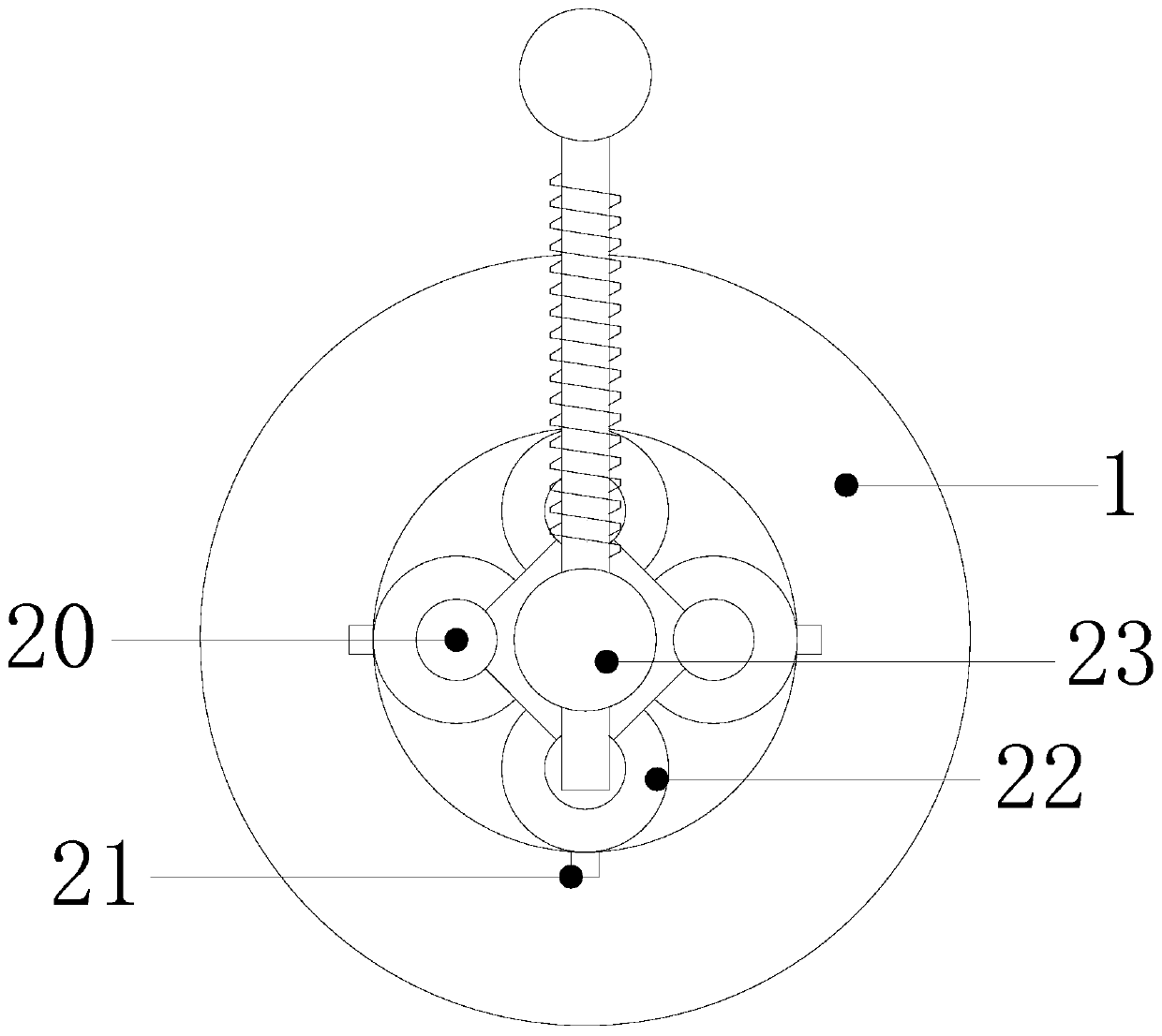

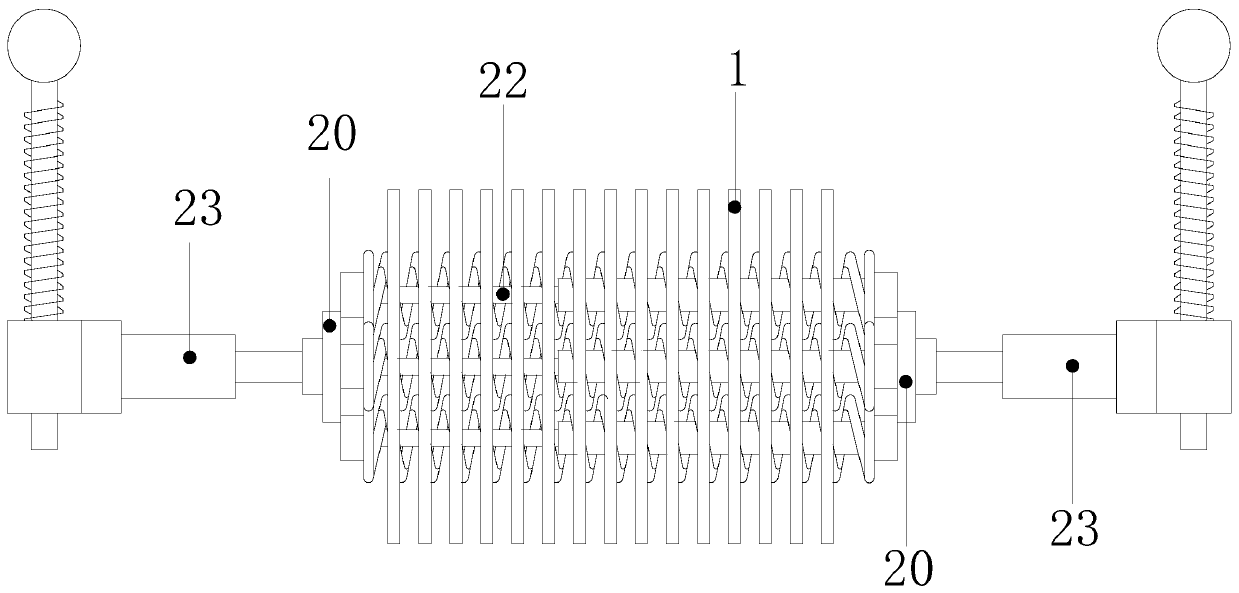

Cutter space one-time adjustable splitting cutter holder used for production and processing of lithium battery cover plate

The invention discloses a cutter space one-time adjustable splitting cutter holder used for production and processing of a lithium battery cover plate. The cutter space one-time adjustable splitting cutter holder structurally comprises upper splitting cutters, an upper cutter space adjusting device, a guide roller, a lower cutter space adjusting device, lower splitting cutters and a cutter holderbody, wherein the cutter holder body is provided with the lower cutter space adjusting device and the upper cutter space adjusting device in the sequence from down to up. Compared with the prior art,the cutter space one-time adjustable splitting cutter holder has the beneficial effects that, through the combination arrangement of connecting plates, ear clips, spring groups and rotary lifting groups, the space between each splitting two cutter is thus adjustable; based on the elasticity of the springs, spring rings of the springs can be enlarged or lessened in an equidistant mode, so that thespaces of a plurality of splitting cutters can be adjusted at one time, the adjusting frequency is high, and adjusting one by one is not needed, the speed of the space adjusting is fast, the requirements of the lithium battery cover plate at different splitting scales can be met, the application range is wide, the cost invested to the cover plate splitting is low, and the cutter space one-time adjustable splitting cutter holder is valuable to be popularized and used.

Owner:NANTONG NAIWEITE POWER SUPPLY CO LTD

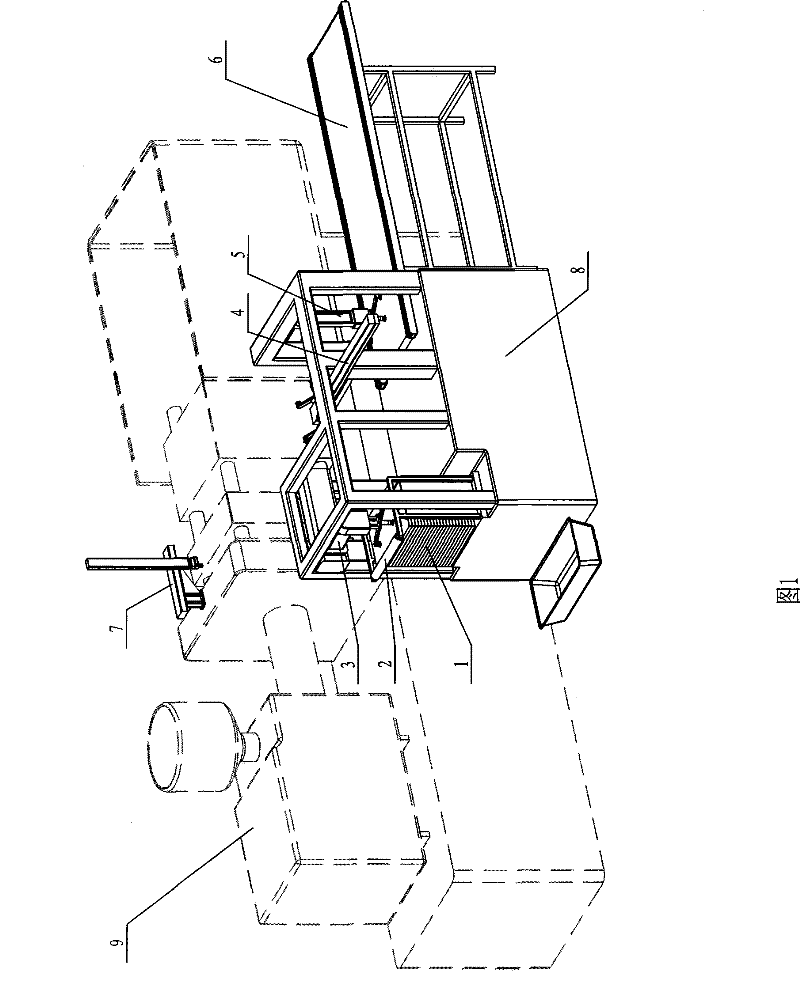

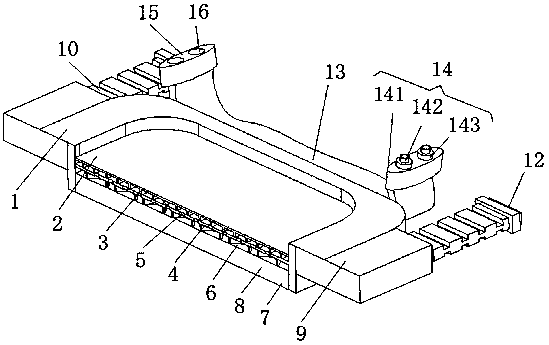

Perimeter injection moulding method and system device thereof

The invention relates to a periphery injection molding method and a system device thereof. The system device is provided with a feed bin, a paper removing unit, a loading unit, a fetching and delivering unit, a blanking unit and a conveyer belt. The method adopts a mode of concurrent working of all working units, glass is automatically placed in the mold cavity of an injection molding machine, after injection molding is finished, the finished product is automatically taken out and placed on the conveyer belt and a waste material water gap for injection molding is taken out to realize automatic recirculation. By adopting a feed bin feeding mode, the invention can automatically remove the interleave paper among glass, realize the functions of automatically loading material and taking products and simultaneously, can automatically take out the waste material water gap, thus shortening product manufacturing period, improving work efficiency and reducing labor intensity and realizing the automation of glass periphery injection molding; simultaneously, the invention has adjustable function and can be suitable for the production of products of different specifications.

Owner:宁波点鑫工贸有限公司 +1

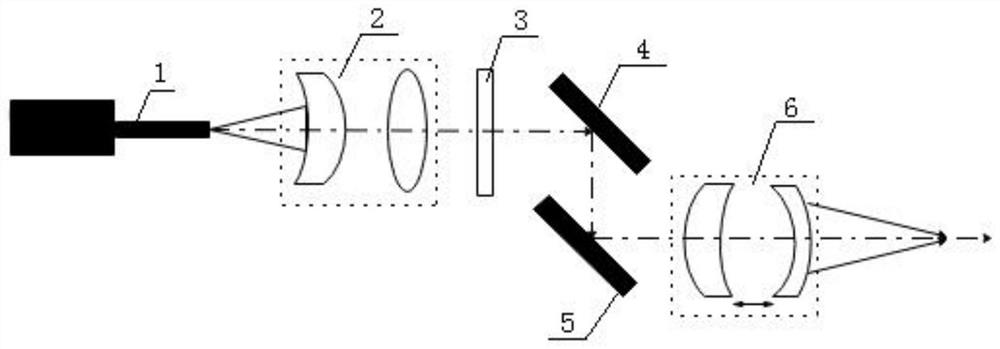

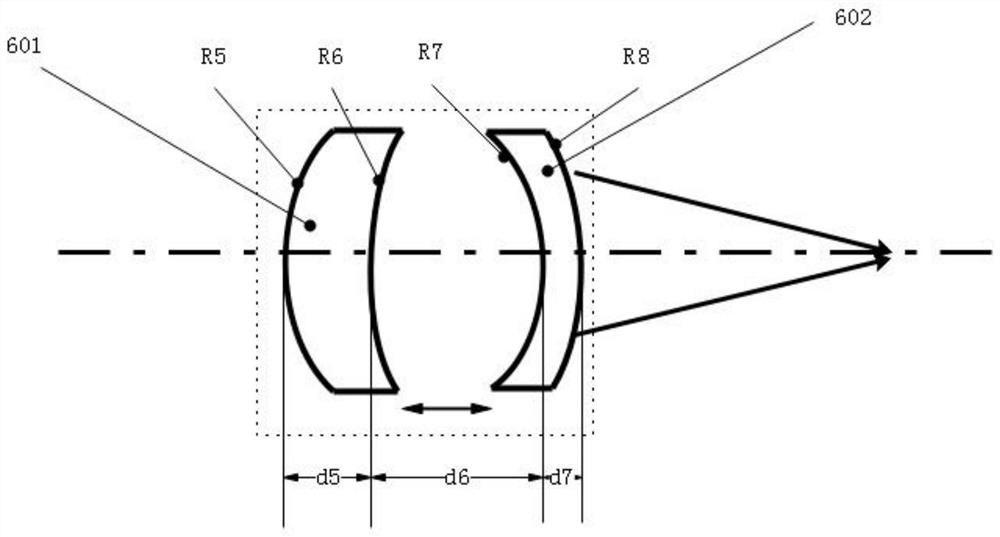

Laser welding beam shaping optimization device

ActiveCN111922513AMeet diameter requirementsReduce sizeLaser beam welding apparatusGaussian beamLight spot

The invention discloses a laser welding beam shaping optimization device which comprises a collimating lens group, a shaping lens group and a focus lens group. The collimating lens group is used for enabling a laser light emitted by a laser to become a parallel light, and emitting the parallel light to the shaping lens group; the shaping lens group is used for homogenizing a collimating gauss beam, modulating the light beam in gaussian distribution into a light beam with evenly distributed energy, and emitting the modulated light beam to the focus lens group; the focus lens group is used for gathering the modulated light onto a surface to be welded; the focus lens group can compensate the homogenized light beam, so that the focus light beam at a final focus state is more even; and meanwhile, the focus lens group has an adjustable function so as to be capable of changing the size of a laser spot. According to the laser welding beam shaping optimization device provided by the invention,the light spot can be flatly shaped, and the size of the light spot is adjustable.

Owner:WUHAN HGLASER ENG CO LTD

Integrated automatic microscopic welding equipment

ActiveCN103909335ARealize synchronous linkageImprove spot welding accuracyResistance electrode holdersWelding electric suppliesEngineeringElectronic component

Owner:GUANGZHOU MICRO WELDING EQUIP

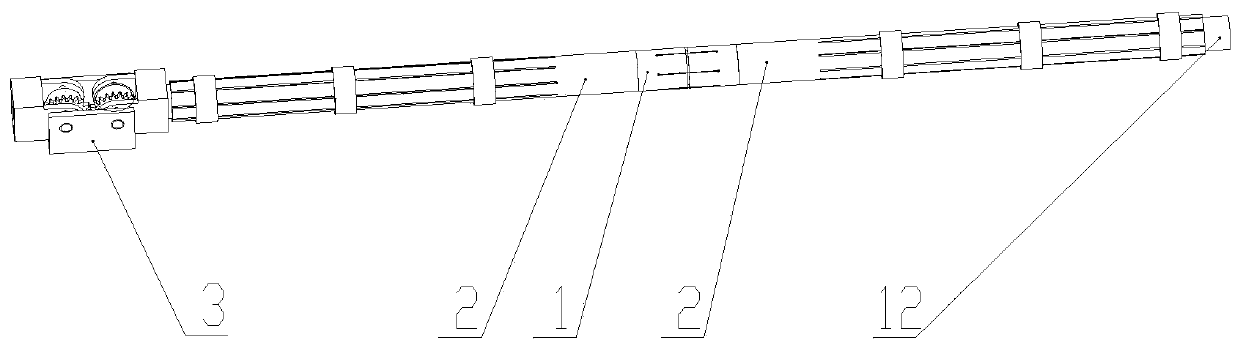

Damping component of large self-unfolding satellite antenna

ActiveCN111129689AImprove effectivenessImprove stabilityCollapsable antennas meansAntenna supports/mountingsSatellite antennasMetal rubber

The invention discloses a damping component of a large self-unfolding satellite antenna, and aims to solve a problem of profile precision errors caused by vibration in an unfolding process of an existing unfolding antenna mechanism and in a posture adjusting process after unfolding. The component comprises a multi-finger-petal friction damper, a self-resetting elastic support friction damper, an elastic driving hinge and a satellite structure rod piece. The multi-finger-petal friction damper controls transverse vibration of the satellite unfolding antenna and comprises a multi-finger-petal rodwhich is pressed on a structural rod piece through an adjustable pressing ring. The self-resetting elastic support friction damper controls axial vibration and comprises a metal rubber, a guide rod,an SMA pull wire and an outer sleeve. The elastic driving hinge provides unfolding power through a volute spring, and an unfolding speed and synchronism are controlled through a gear. The satellite structure rod piece is fixedly connected with other assemblies so that integrity of the unfolded antenna is ensured. The component is used for satellites and space detectors.

Owner:BEIJING UNIV OF TECH

Supporting holder which is applied to animation design and has adjustable function

The invention discloses a supporting holder which is applied to animation design and has an adjustable function. The supporting holder comprises a supporting platform, a lifting platform, an annular groove, elastic concave teeth and a placement plate. The lifting platform is mounted at the central position on the top of the supporting platform. The annular groove is fixed at the top end of the lifting platform. An annular concave block is hinged in the annular groove. A drawing board holder is set at the top end of the annular concave block. A cross beam is mounted on the top of the drawing board holder. Two groups of clamping mechanisms are set in the cross beam. A rivet is set at the central position of the cross beam. A limiting clamping plate is set in the cross beam at the lower sideof the rivet. One end of the limiting clamping plate extends outside of the drawing board holder. Racks are set on outer walls at two sides of the lifting platform. According to the supporting holder,adjustment of any angle can be carried out on a drawing board, design inspiration is improved, the supporting holder is convenient for a designer to draw, and drawing working efficiency is improved.

Owner:常州斑马智能科技有限公司

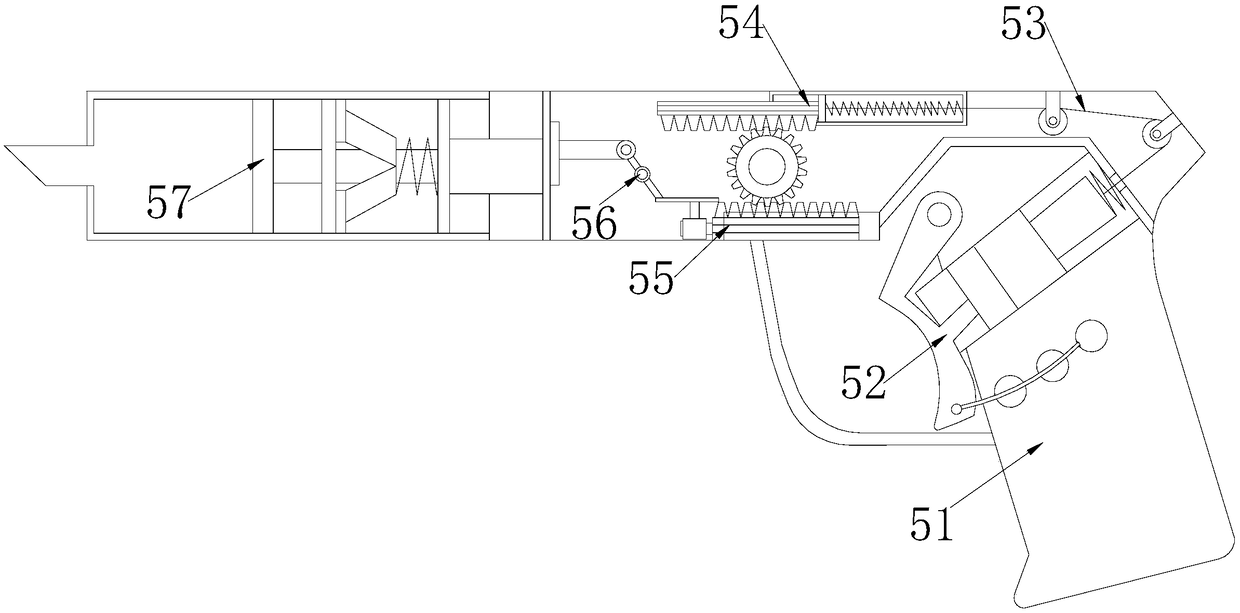

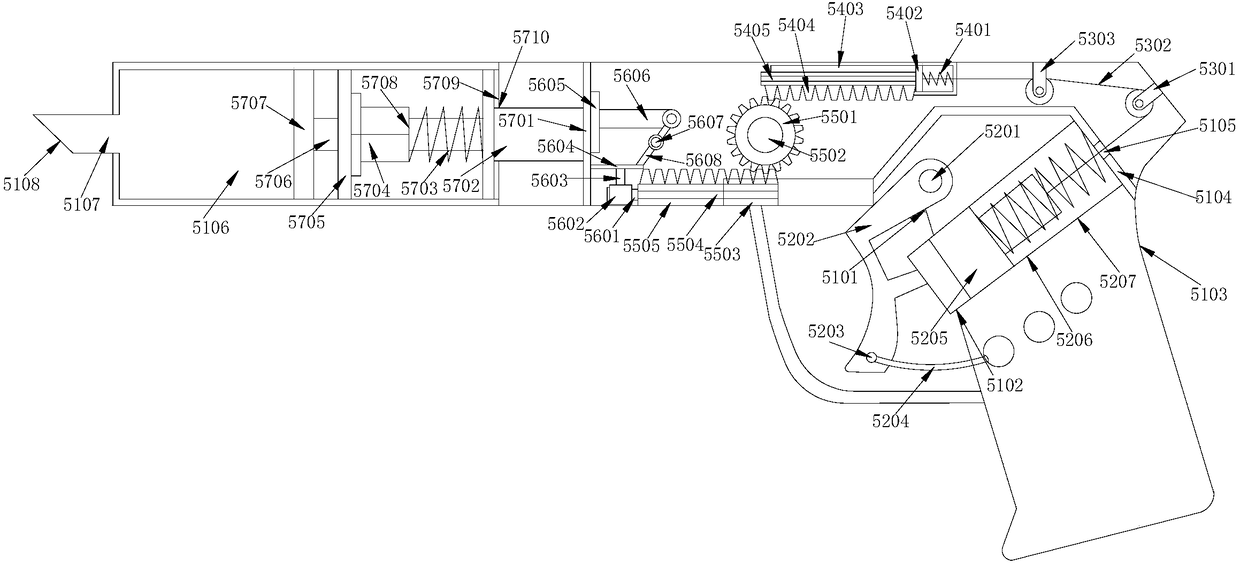

Output-quantity-adjustable environmentally-friendly glue bag

The invention discloses an output-quantity-adjustable environmentally-friendly glue bag. The output-quantity-adjustable environmentally-friendly glue bag structurally comprises a cover, a buckle handle, an anti-slip sleeve, adjustment hooks and a machine body. The bottom of the machine body is sleeved with the anti-slip sleeve in clearance fit with the machine body, the anti-slip sleeve is uniformly provided with anti-slip particles, wherein the anti-slip sleeve and the anti-slip particles are of an integrated structure, and the anti-slip particles are arranged at an equal interval. The adjustment hooks are arranged above the anti-slip sleeve, the three or more adjustment hooks are arranged at an equal interval. The output-quantity-adjustable environmentally-friendly glue bag has the beneficial effects that the environmentally-friendly glue bag adopts gun type design and has an adjustable function, the glue output quantity can be adjusted according to requirements, the situation that workers squeeze glue according to feelings is avoided, and the purpose of saving the glue is effectively achieved; and meanwhile, the use cost can also be reduced, and waste of the glue is avoided.

Owner:南安知风舟工业设计有限公司

Water-absorbent side-leakage preventing paper diaper structure and making method thereof

InactiveCN108542603AImprove water absorptionReduced usabilityAbsorbent padsBandagesPulp and paper industryColloid

The invention relates to the technical fields of daily articles for babies, and discloses a water-absorbent side-leakage preventing paper diaper structure and a making method thereof. The paper diaperstructure comprises a paper diaper main body, wherein a hip groove is formed in the middle of the paper diaper main body; primary adsorbent colloids are arranged at the bottom of the paper diaper main body; the ends, away from the paper diaper main body, of the primary adsorbent colloids are fixedly connected to the top of a filter laminated board; adsorbent filter holes are formed in the middleof the filter laminated board; stream guidance colloids are fixedly arranged at the bottom of the filter laminated board; and a liquid container is fixedly arranged at the bottoms of the stream guidance colloids. According to the water-absorbent side-leakage preventing paper diaper structure and the making method thereof, the abdomen and waist of a baby can be protected on the basis of the actionsof adhesion surrounding plates; and meanwhile, through waist fastening straps, clamping rubber grooves and clamping rubber blocks which are combined, a function of adjusting the elasticity of the paper diaper is guaranteed, and meanwhile, fitness of the paper diaper to the waist and the abdomen is effectively improved; therefore, the comfort of the paper diaper in a using process is further improved.

Owner:诸暨市开翎工业设计有限公司

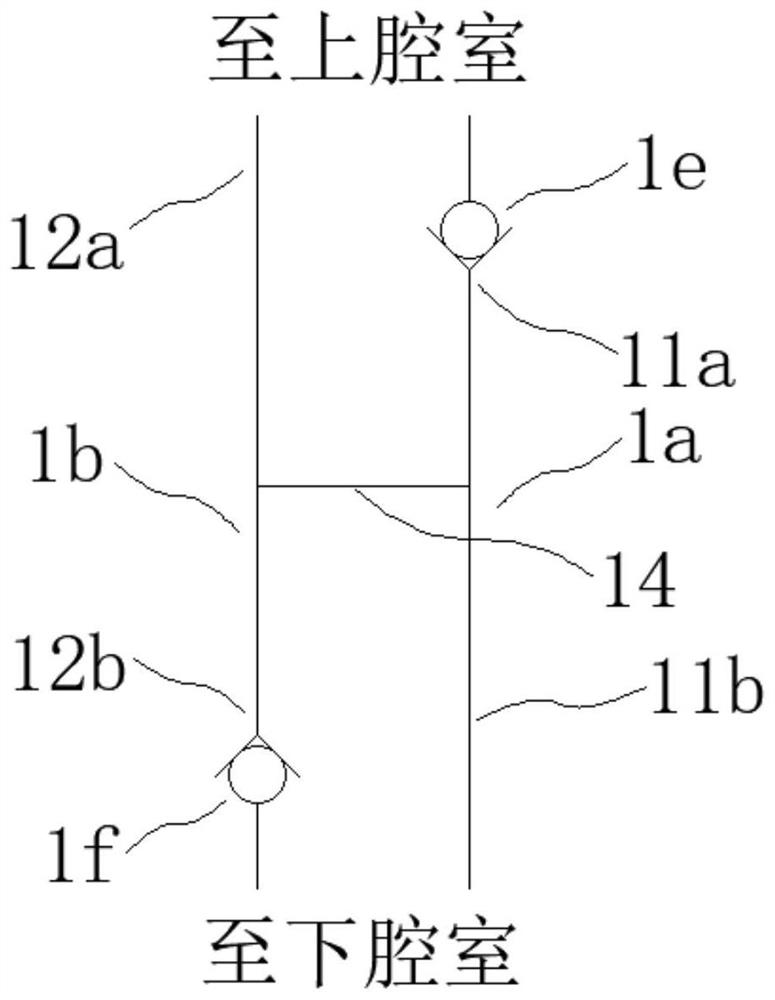

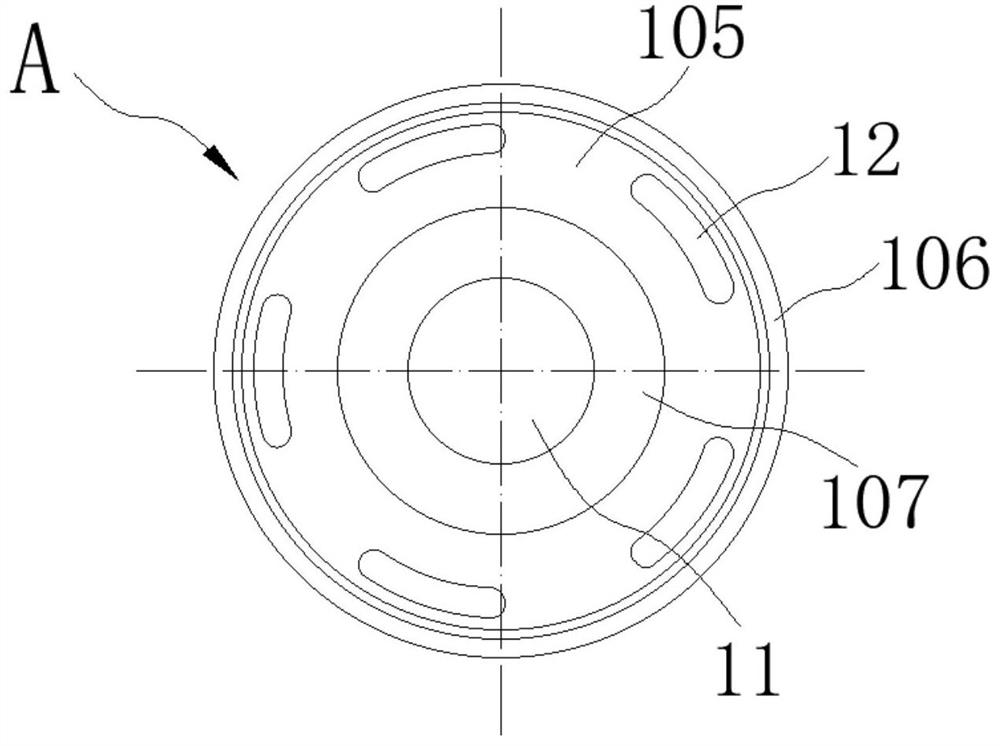

Low speed flow adjustable shock absorber piston

The invention discloses a shock absorber piston with adjustable low-speed flow. Fluid flows in or out through two channel groups arranged in the piston. Inflow from one channel group and flow out from the other channel group; and, the piston also includes an adjustment channel connecting the two channel groups, which allows the fluid to flow between the upper and lower chambers when the two one-way valves are in a closed state at low speed flow Between flow, so that the piston has the effect of low-speed flow adjustable.

Owner:NINGBO RUIFENG AUTO PARTS

Marine thick plate bending process

The invention discloses a marine thick plate bending process. Before being processed, a marine thick plate is a flat panel, and after being processed, curvature radius of the middle of the thick plate is required to be small while curvature radius of both ends of the thick plate is required to be large. A sectional cold bending method is utilized and includes firstly, processing the two ends of the marine thick plate through segment moulds; and secondly, processing the middle of the marine thick plate through a pressing mould. Self-made moulds used in the marine thick plate bending process are simple, practical and adjustable, processing and forming requirements on high-intensity thick plates within a large range can be met, curved thick plate products meeting different engineering requirements can be processed on the same pressure load, surface profiles of the processed products are smooth, indentations of the products are shallow, service requirements can be met completely, difficulty in processing of the high-intensity thick plates can be reduced, and production of 5100TEU container vessels can be promoted. In addition, quality defects of obvious indentions, scratches and crush damages caused by high deformation resistance generated in a single pressing process are avoided.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Split type full corrugated pipe butt joint interface and using method thereof

ActiveCN112960099ARealize shuttle channel requirementsWith adjustable functionAircraft accessoriesFuselagesInfectious DisorderHighly pathogenic

The invention belongs to the technical field of biochemical contamination isolation and medical treatment, and discloses a use method of a split type full corrugated pipe butt joint interface. The method is suitable for airtight connection between two square cabins. The split type full corrugated pipe butt joint interface comprises a lock interface arranged on a first square cabin, a to-be-butt-jointed interface arranged on a second square cabin and a butt joint lock arranged on the lock interface; the first square cabin and the second square cabin are any one of the two square cabins; and a first butt joint flange is arranged on the lock interface, a second butt joint flange is arranged on the to-be-butt-jointed interface, and the first square cabin and the second square cabin are in airtight connection through the first butt joint flange, the second butt joint flange and the butt joint lock. The butt joint interface for rapid butt joint and sealing is provided for the medical shelter for the biochemically contaminated sick and wounded and the highly pathogenic infectious diseases.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

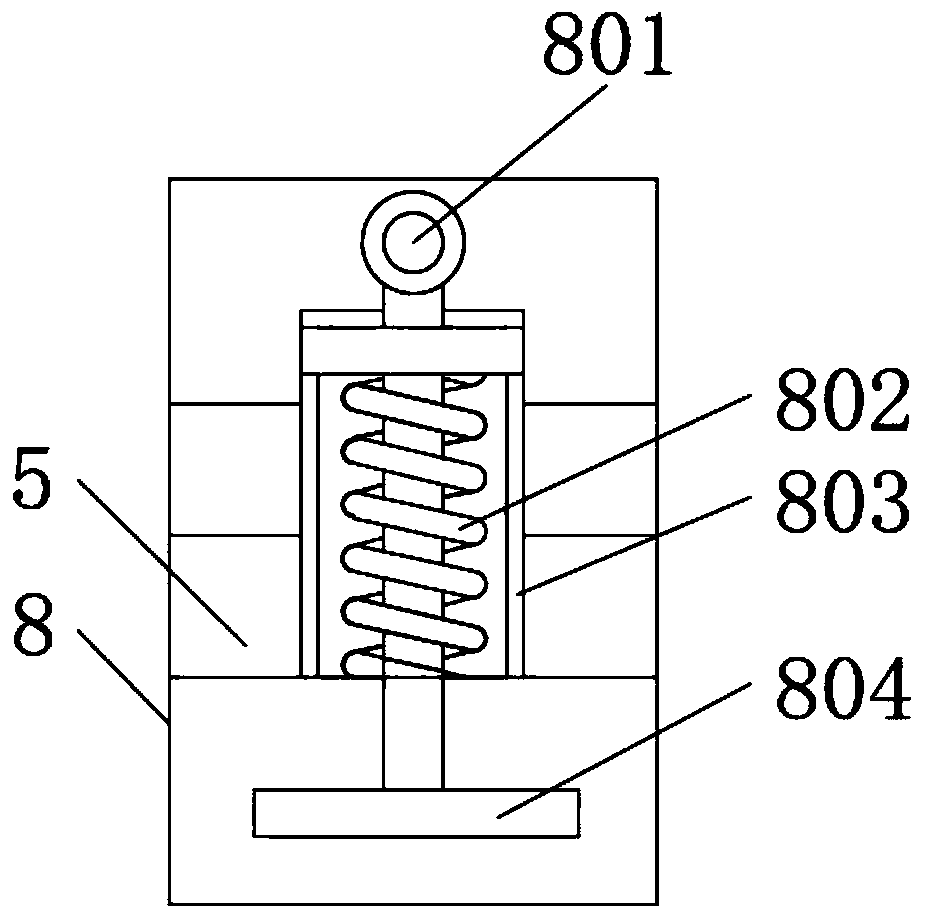

Adjustable solar photovoltaic power generation device

InactiveCN106301174AIncrease profitAdjust the rotation speedPhotovoltaic supportsSolar heating energyPhotovoltaic power generationSunlight

The present invention discloses an adjustable solar photovoltaic power generation device, comprising a net rack and a battery panel 1 which is supported by the net rack, wherein the net rack comprises a vertical bracing 2, a diagonal bracing 3, a transverse connecting rod 4, a rotating shaft 5, a scissor bracing 6 and an arc track 7; and a speed regulator 8 is arranged on the vertical bracing 2. By adopting the adjustable solar photovoltaic power generation device disclosed by the invention, the photovoltaic power generation capacity in a unit field area can be effectively increased so as to ensure that the land cost of photovoltaic power generation can be reduced; and in addition, the device has an adjustable function, the rotating speed of the rotating shaft can be adjusted according to incident angles of sunlight so as to ensure that the sunlight can be perpendicular irradiated to the battery panel, and thus the use ratio of solar energy can be greatly improved.

Owner:TONGJI UNIV

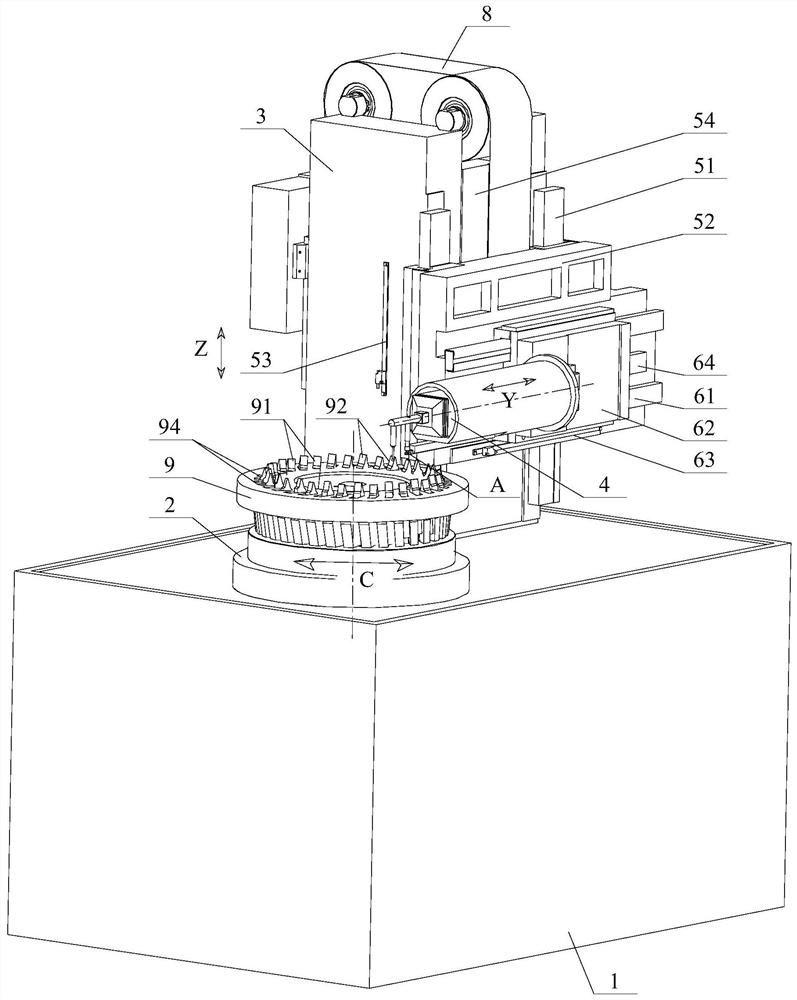

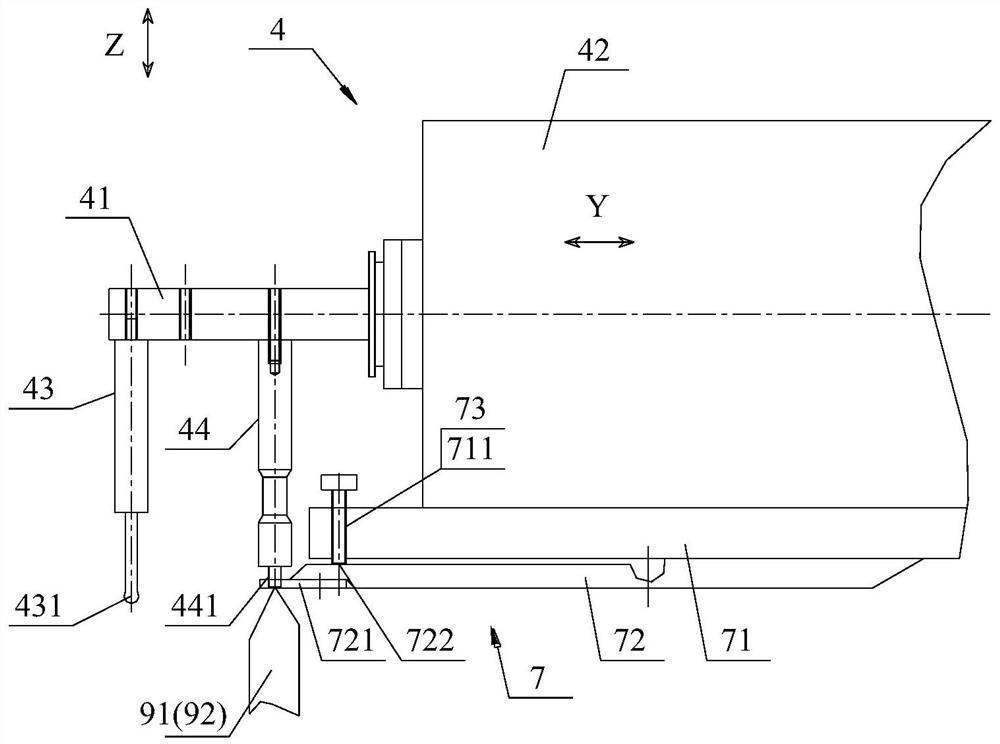

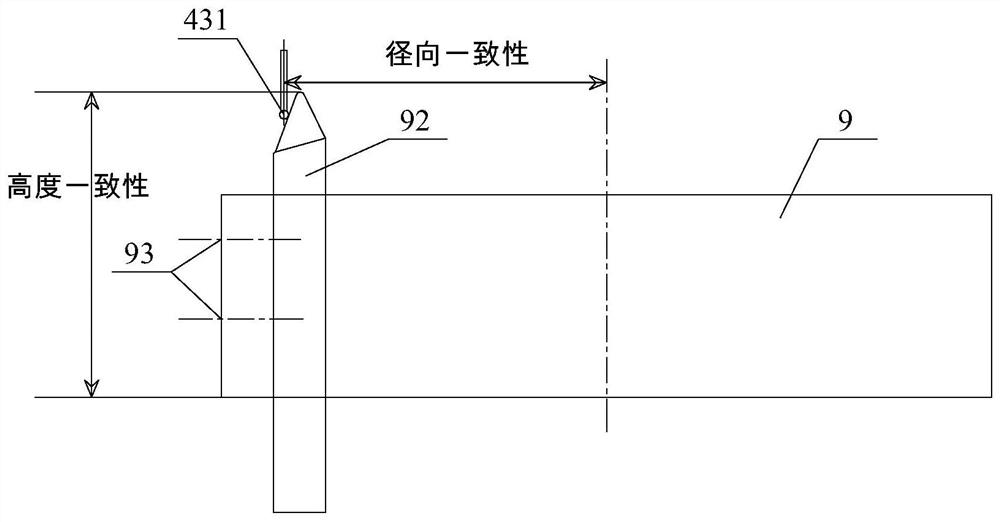

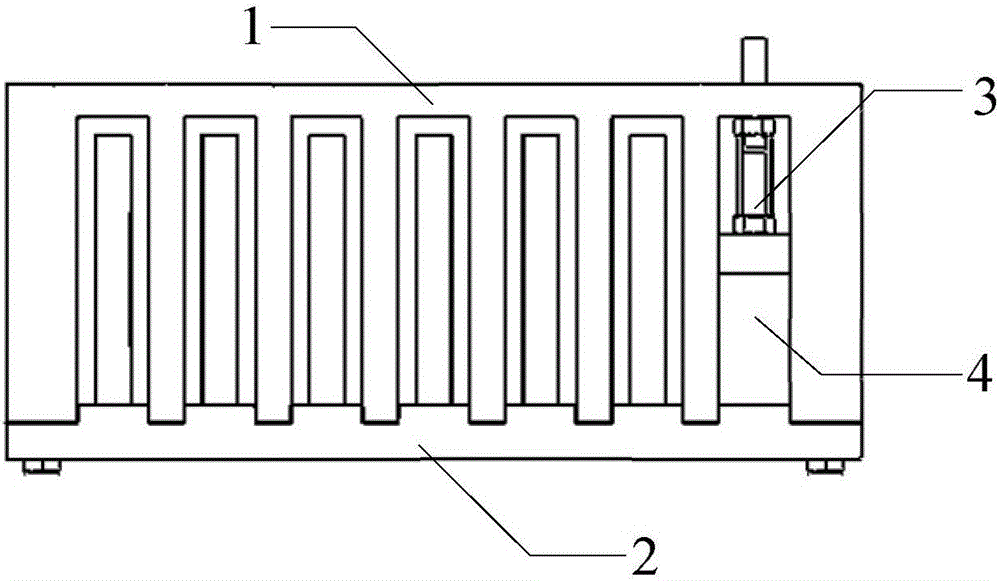

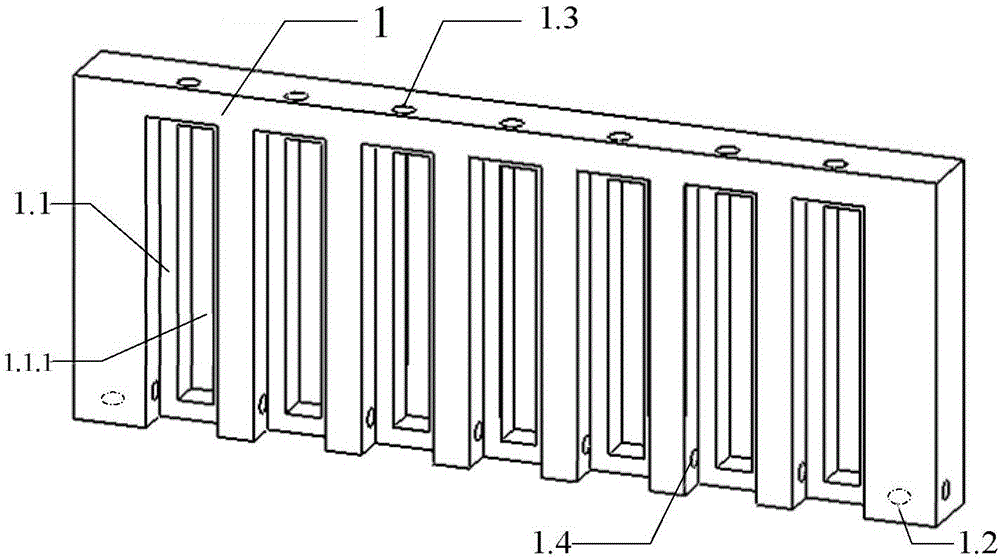

Vertical cutter installing machine

PendingCN113618365AEasy to operateHigh adjustment accuracyMetal working apparatusRadial positionStructural engineering

The invention discloses a vertical cutter installing machine, which is used for correcting a cutting tool of a spiral bevel gear and comprises a stand column and a workpiece main shaft which are arranged on a machine body and further comprises a three-dimensional measuring head which moves along the Y axis and the Z axis relative to the stand column through a sliding assembly, and a rotating shaft of the workpiece main shaft is parallel to the Z axis; a measuring rod of the three-dimensional measuring head extends out of a body of the three-dimensional measuring head, a height measuring needle and a radial measuring needle are arranged on the measuring rod, the height measuring needle is used for detecting the height position of a tool nose of a cutting tool to be detected, and the radial measuring needle is used for detecting the radial position of a blade of the cutting tool to be detected; and a tool pressing device is fixedly arranged on the body of the three-dimensional measuring head and provided with a tool pressing part, and the tool pressing part can abut against the tool nose of the cutting tool to be detected in a pressing mode along the Z axis. According to the scheme, the adjustment precision can be effectively improved through structural optimization, and the operation efficiency is improved.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

Adjustable cylindrical cell test clamp

PendingCN106124809APrevent slidingPrevent looseningElectrical testingMeasurement instrument housingEngineeringPosition fixing

The invention provides an adjustable cylindrical cell test clamp, comprising a clamp casing, a clamp base plate and cell compaction mechanisms. The clamp casing is uniformly provided with a plurality of positioning structures used for placing cylindrical cells, and line pass holes connected to each positioning structure and used for passing through leads; the clamp base plate is installed on the bottom of the clamp casing through bolts, and combines with the cell compaction mechanisms and the positioning structures on the clamp casing to be used for fixing cylindrical cells; the cell compaction mechanisms are arranged in the positioning structures of the clamp casing. The adjustable cylindrical cell test clamp can fix cylindrical cells of different specifications, guarantee uniform stress at two ends of a detected cell, guarantee position fixing when the cylindrical cells are in test through the clamp casing, the clamp base plate and the positioning structures on the cell compaction mechanisms, avoid cell sliding, loosening, and positive and negative electrode compressional deformation in test, and improve cell test accuracy; in addition, the adjustable cylindrical cell test clamp can enhance the heat dissipation capability in cell test, and guarantee security and accuracy in cell test.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com