Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Troubleshooting the connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

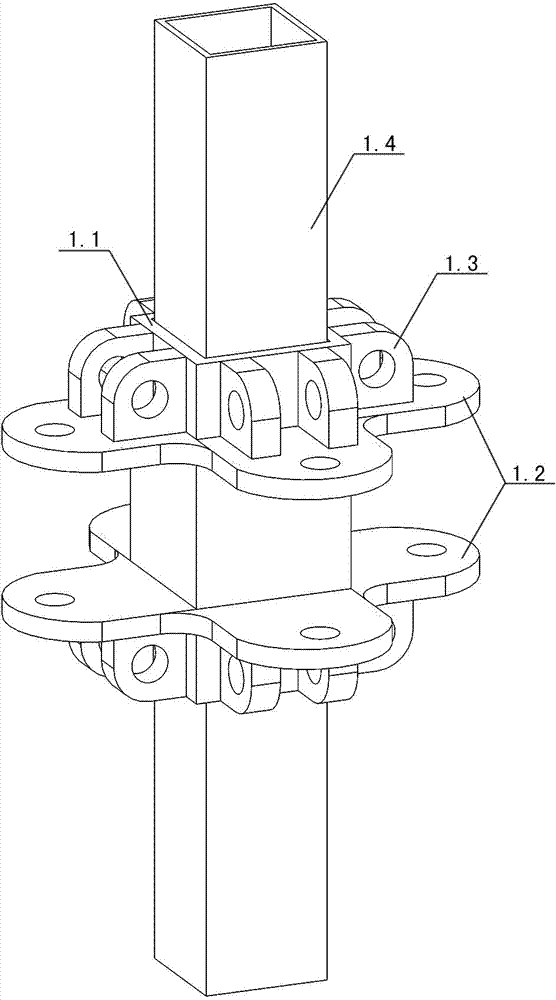

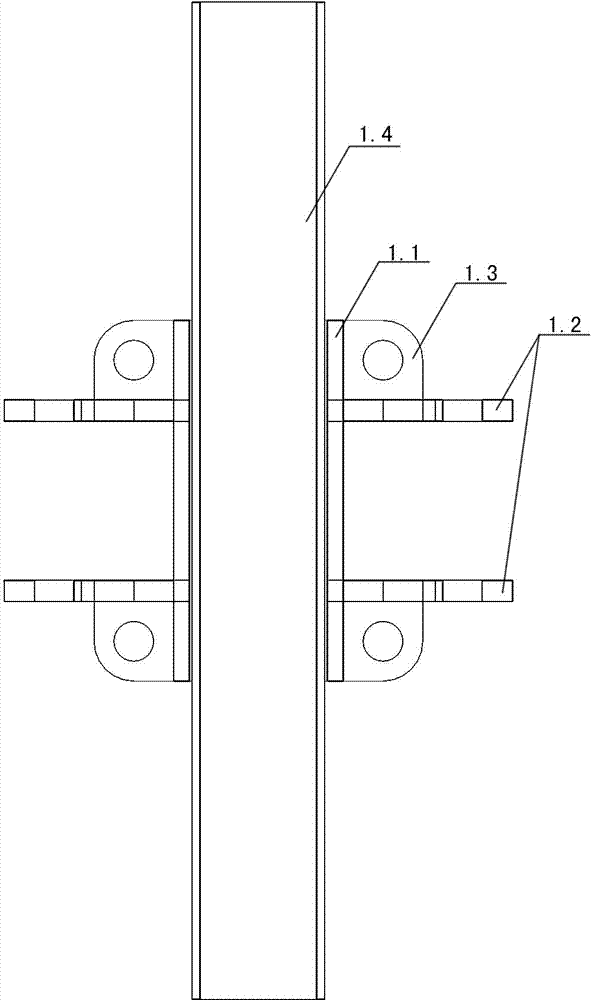

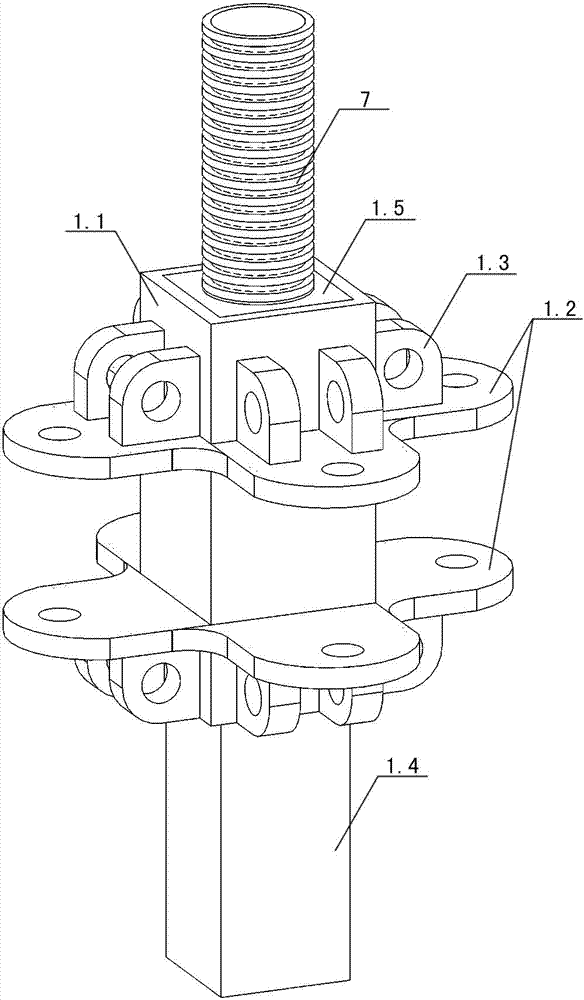

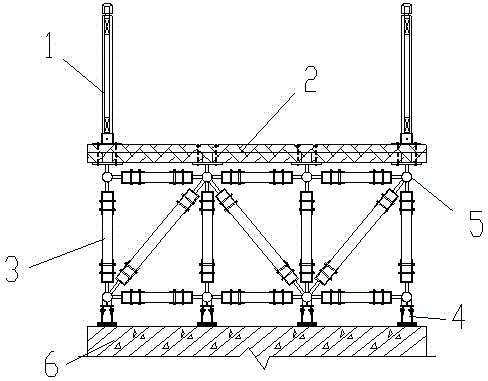

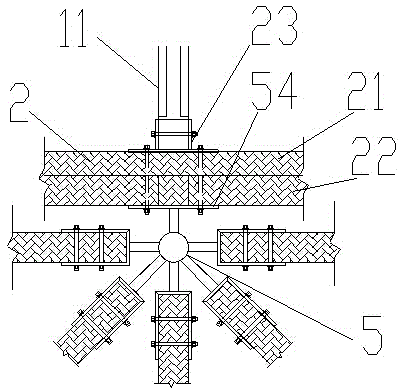

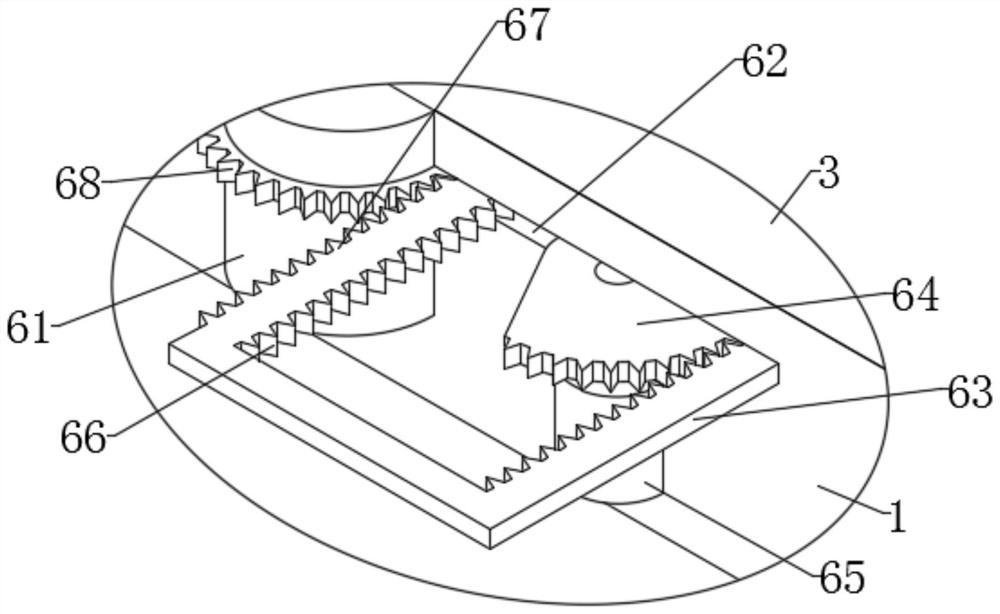

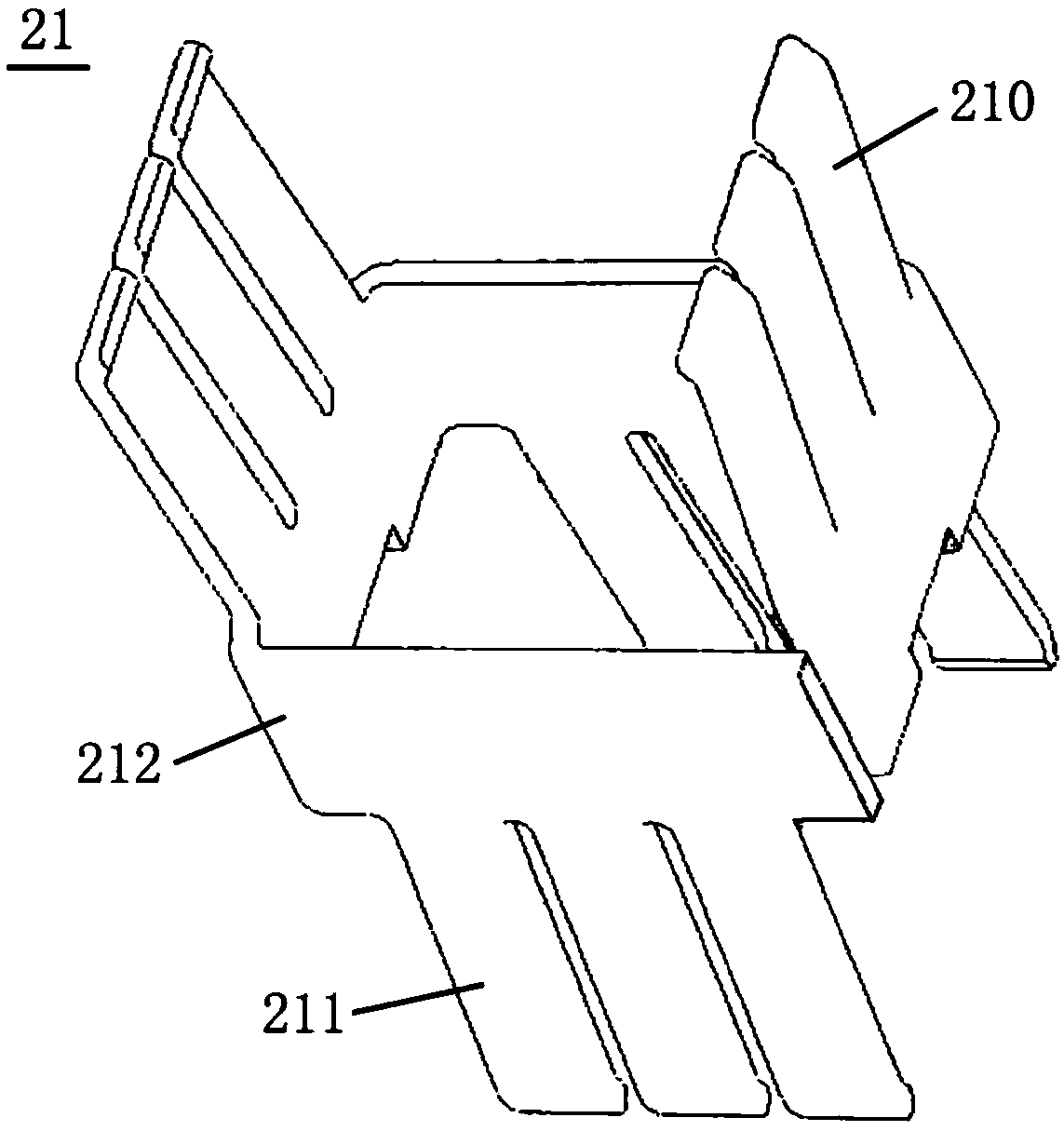

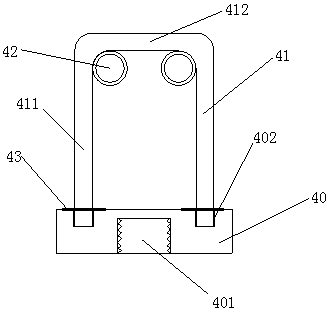

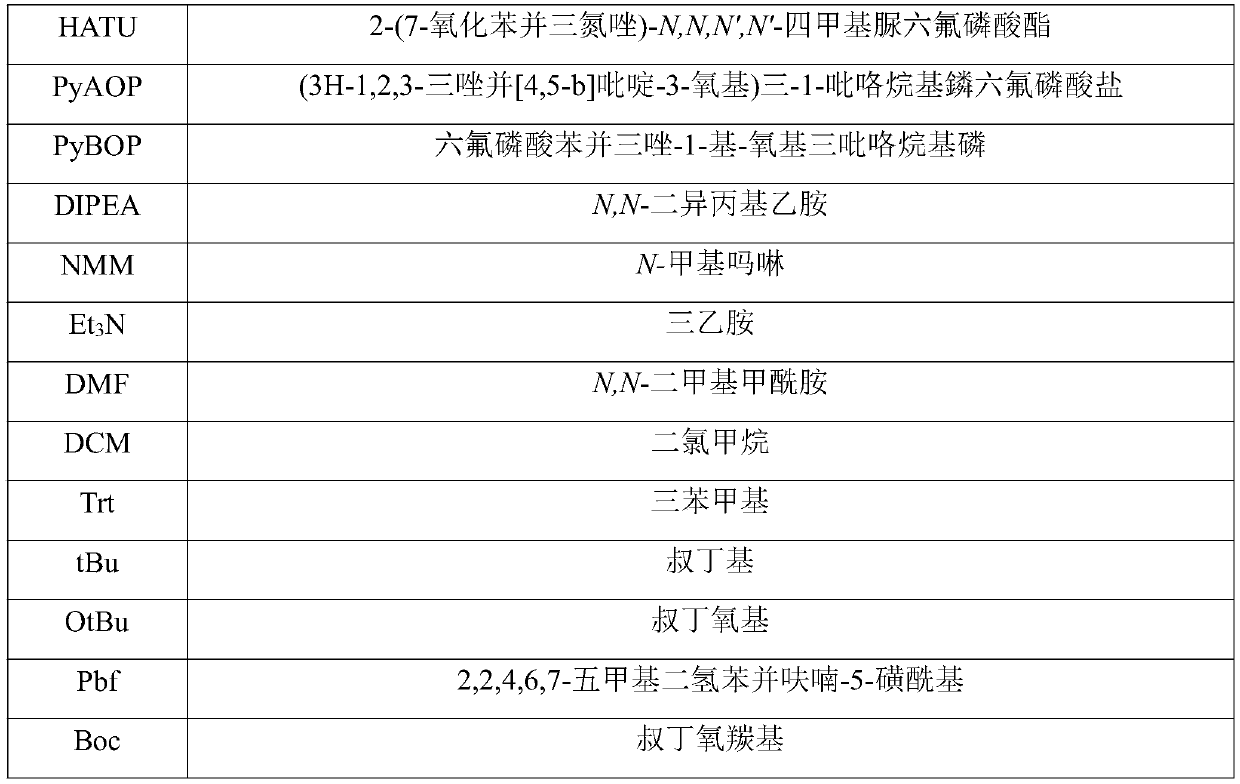

Positively-biased multidirectional three-dimensional connected clamp plate link, quick-release frame, application and method of positively-biased multidirectional three-dimensional connected clamp plate link and quick-release frame

ActiveCN104763717AForce relationship is clearSimple design and constructionScaffold connectionsRod connectionsMechanical engineeringMulti directional

The invention discloses a positively-biased multidirectional three-dimensional connected clamp plate link, a quick-release frame, an application and a method of the positively-biased multidirectional three-dimensional connected clamp plate link and the quick-release frame. The clamp plate link comprises a knob core, a clamp plate, a clamp ring and a knob pin, and is an independent connecting piece capable of simultaneously realizing forwardly, obliquely and multidirectional connecting or concentrically connecting in a same point way; the quick-release frame is a planar frame or a three-dimensional frame formed by mutually assembling an upright bar, a flat bar and an oblique bar; the clamp plate link and the quick-release frame can be applied to a carrying frame, a bailey frame, a bridge frame, a storage rack, a frame, a crane carriage, an elevator frame, a suspension frame, a lifting frame and a carrying frame to be quickly dismounted, especially a scaffold, a template support and the like in the engineering construction field; the independent nodes and independent rod pieces of the quick-release frame can be realized in a solderless manufacturing and pin fixed connection way, the same-point, same-node, coplanar and concentric connection can be realized, the multi-directional bearing, flexibility and diversity and variation can be realized; in addition, the clamp plate link is safe and convenient, firm and durable, accurate and quick.

Owner:朱宏宇

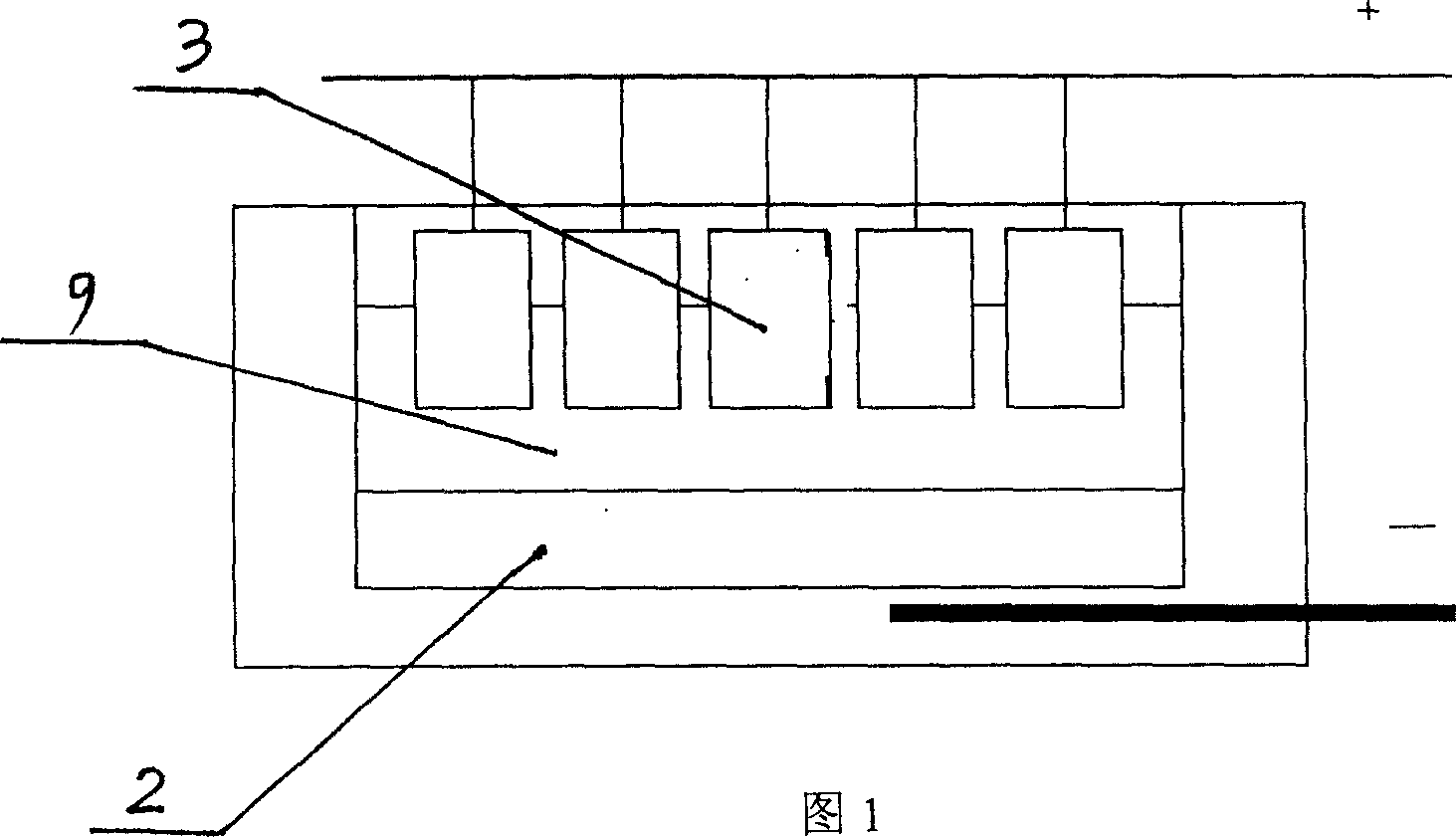

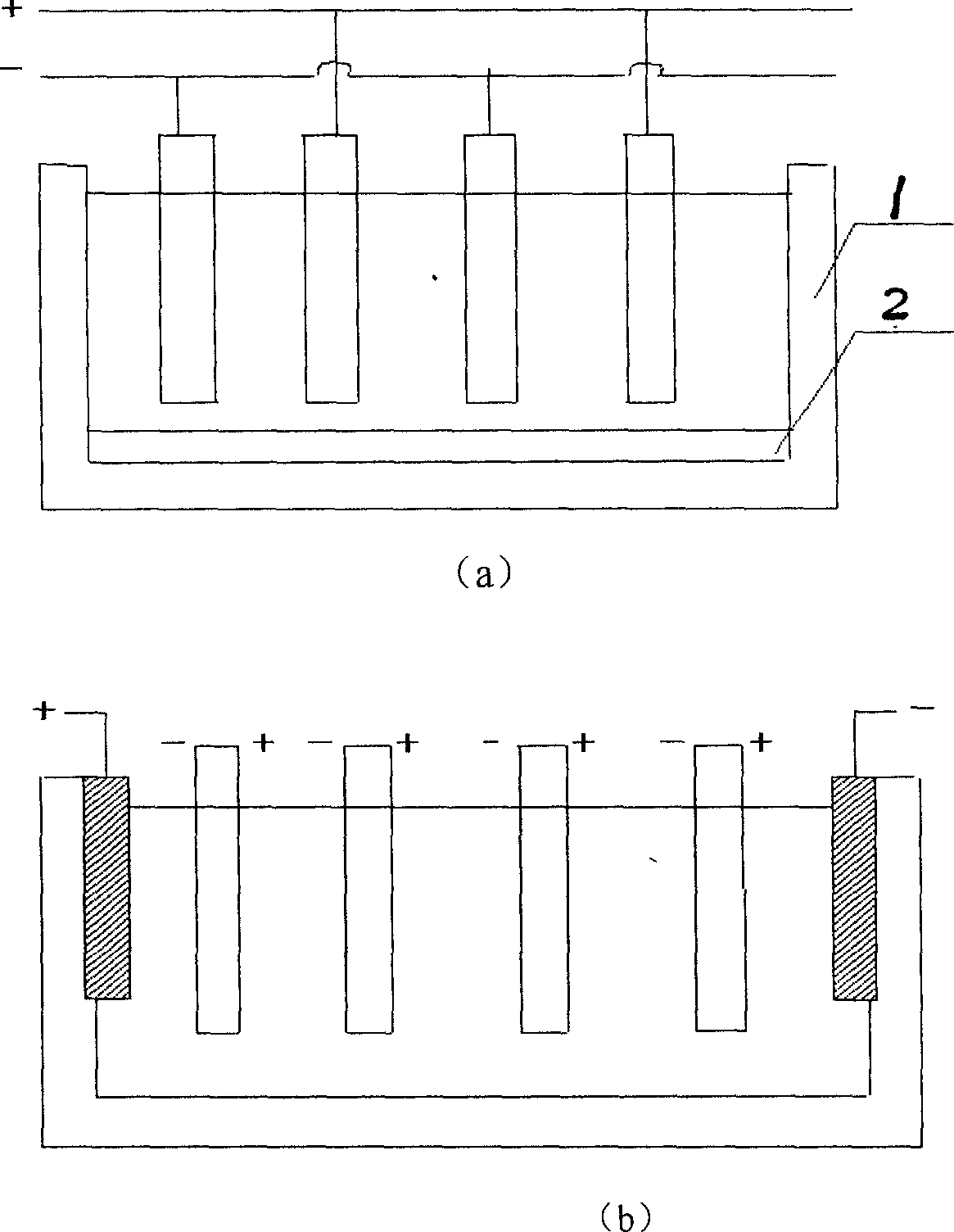

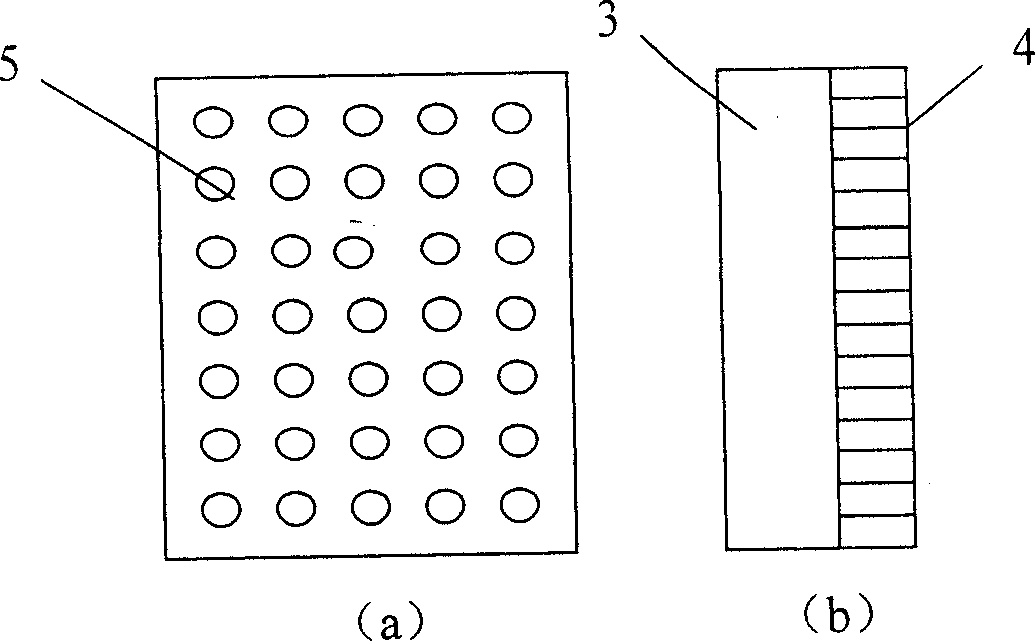

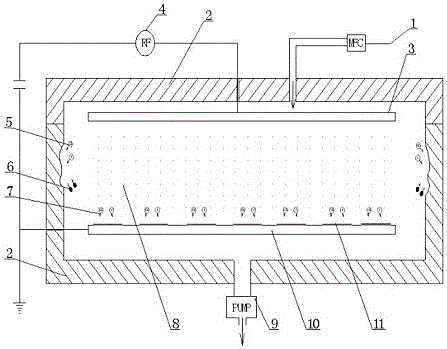

Bi-polar composite electrode for electrolyzing aluminum

The present invention provides a bipolar composite electrode for aluminum electrolysis that is composed of cathode material with aluminum wetness and inert anode material. The anode layer and the cathode layer both of 2-200mm thick are joined together by compaction or cementing. The cathode layer is also a porous structure with aperture of 1mm-10mm and the interstitial surface area takes 20-80% of the electrode area. This bipolar composite electrode features that small amount of Aluminium that deposits at cathode is moved to the working face of the anode to form a compact protecting oxide film with equal dissolving rate and forming rate to depress the corrosion of the anode. The electrodes are arranged in series without connecting wires solving the connection problem of inert eletrodes. The electrolysis tank has a simple structure and convenient operation, which will reduce the cost of aluminum production.

Owner:NORTHEASTERN UNIV

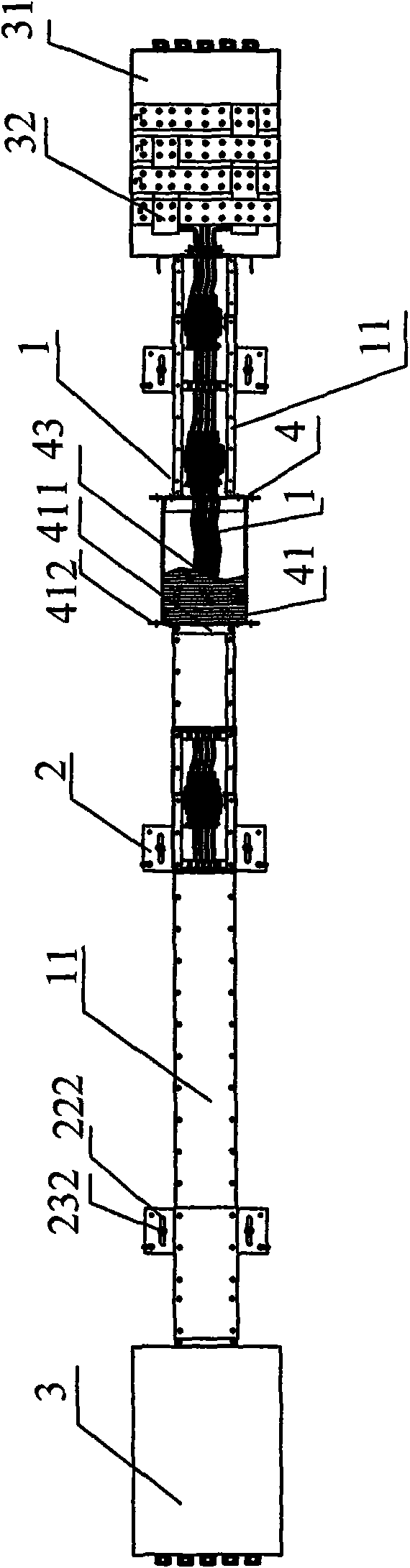

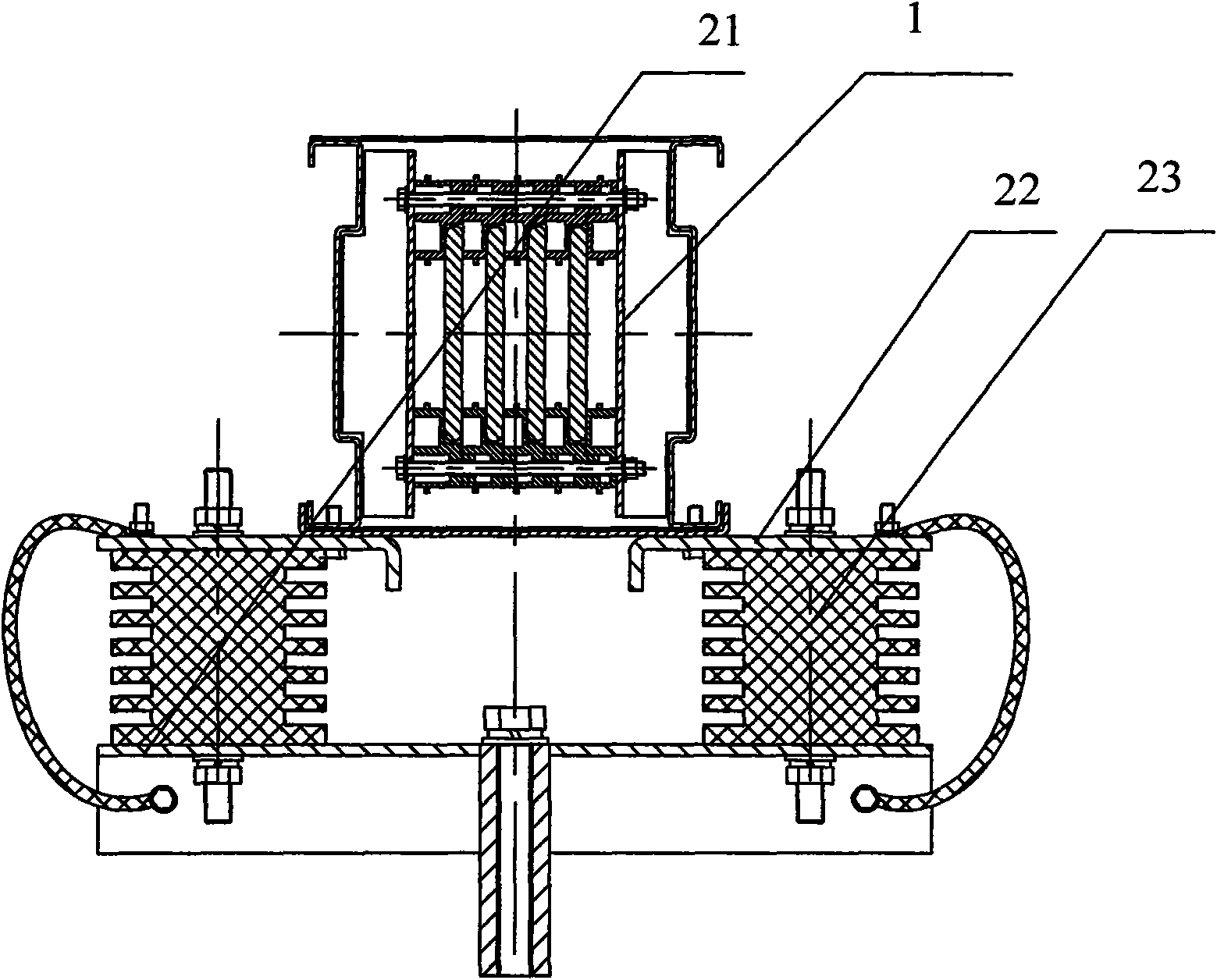

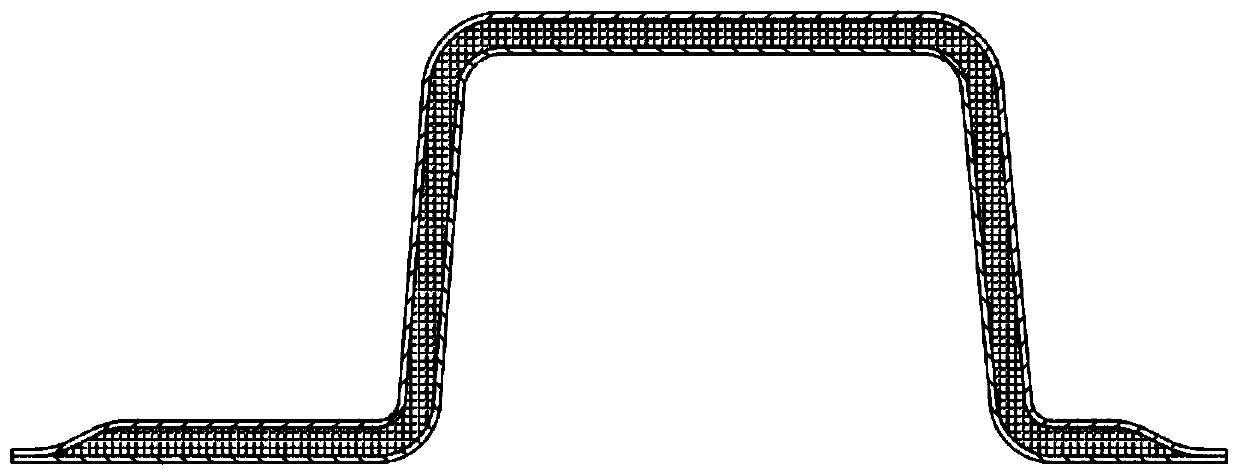

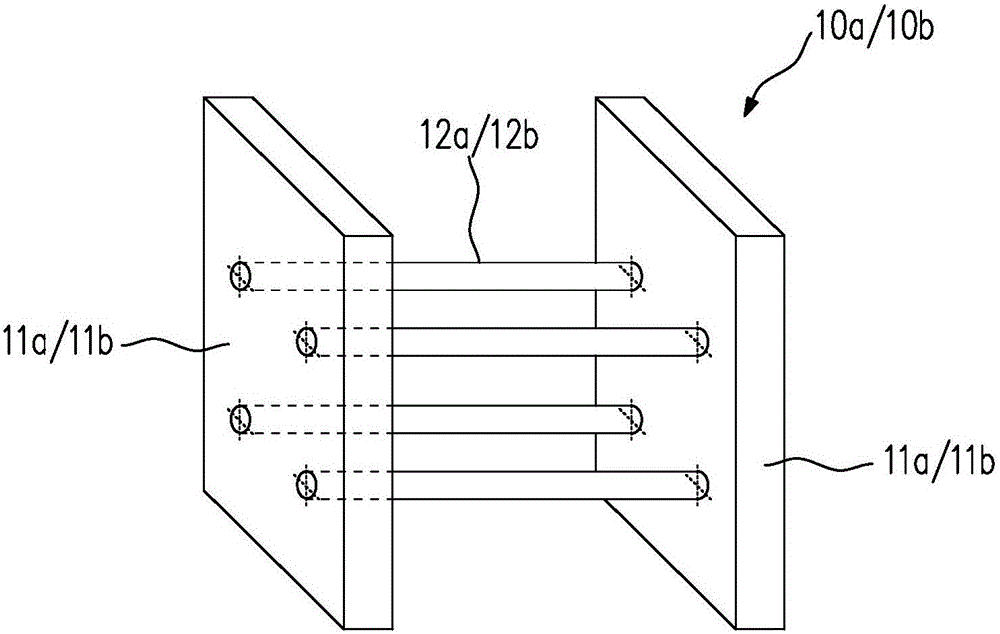

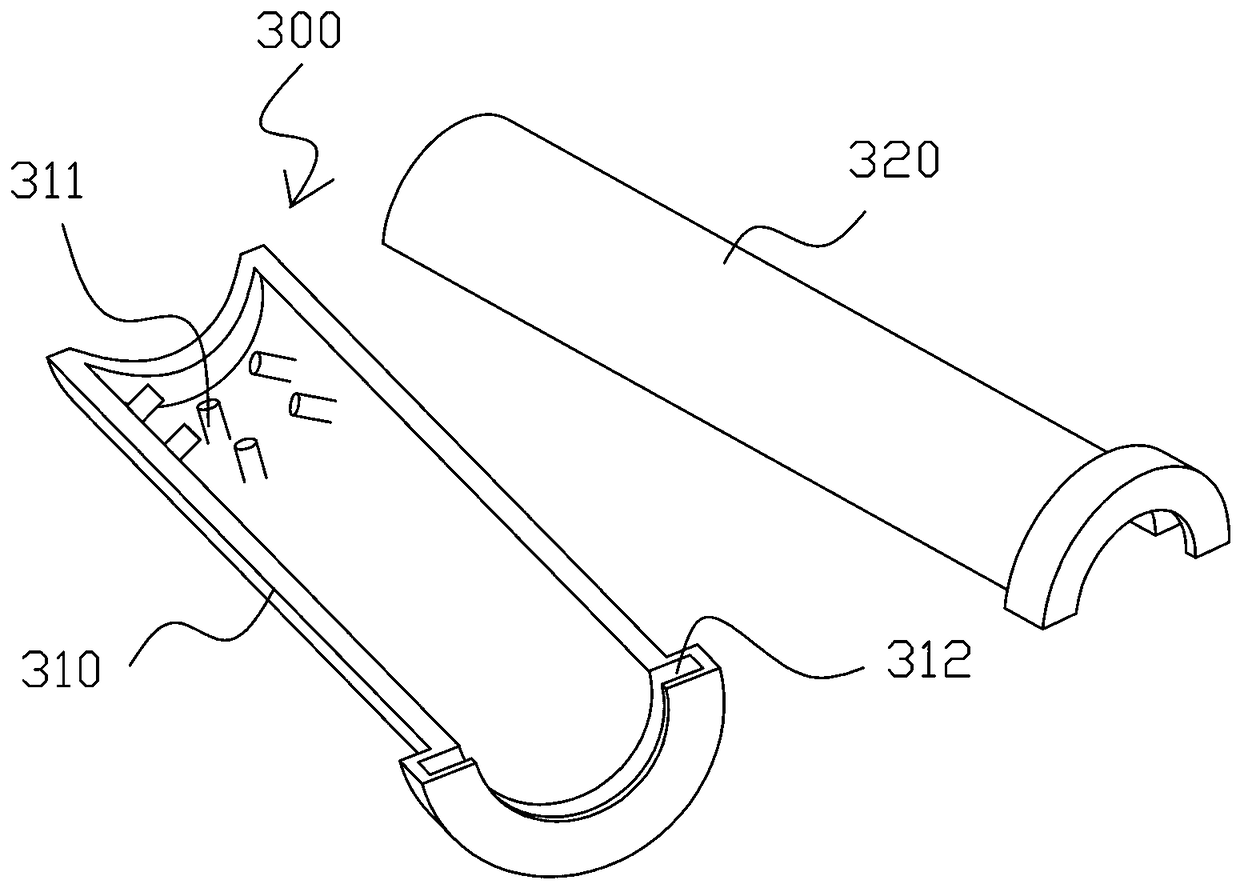

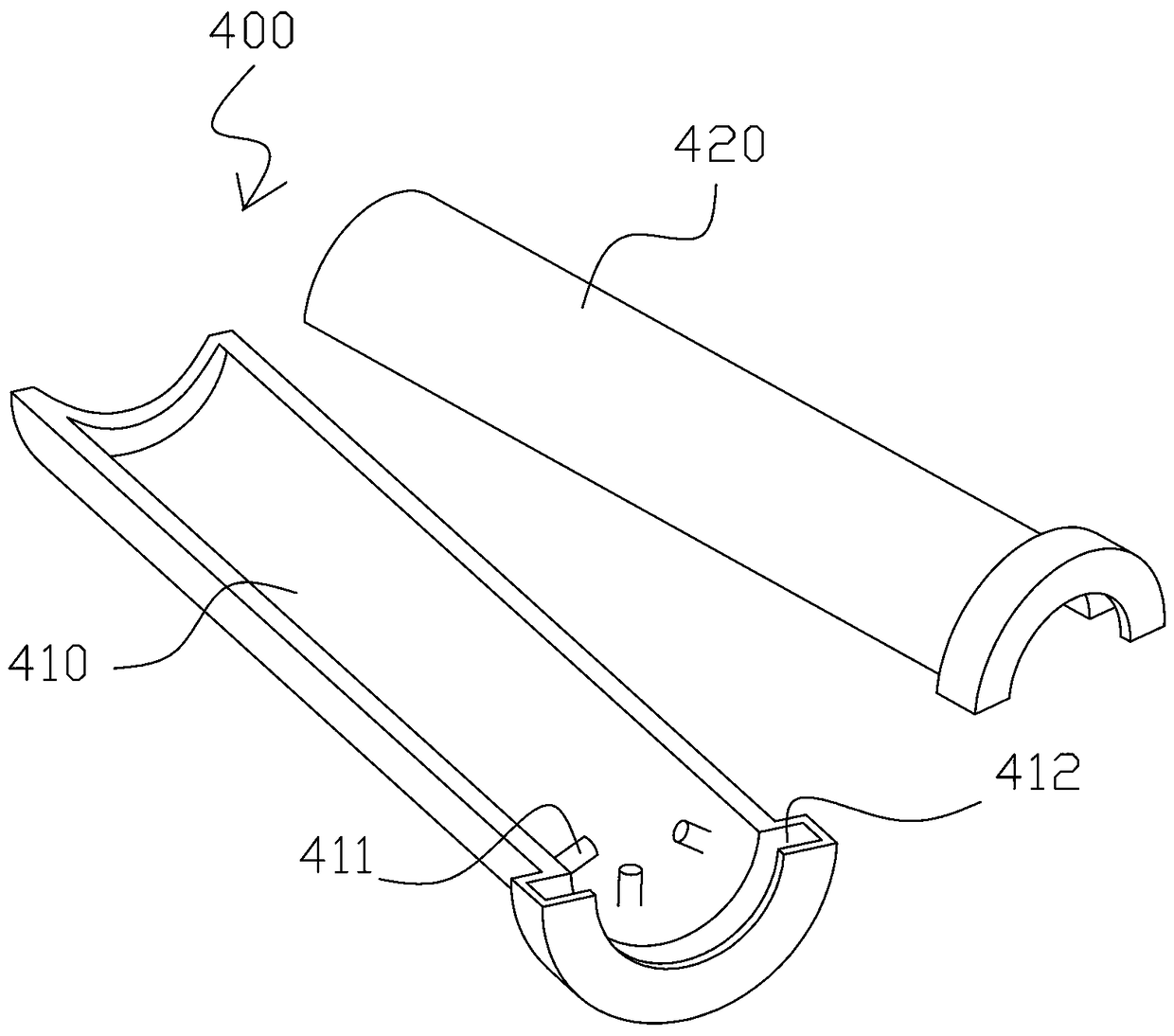

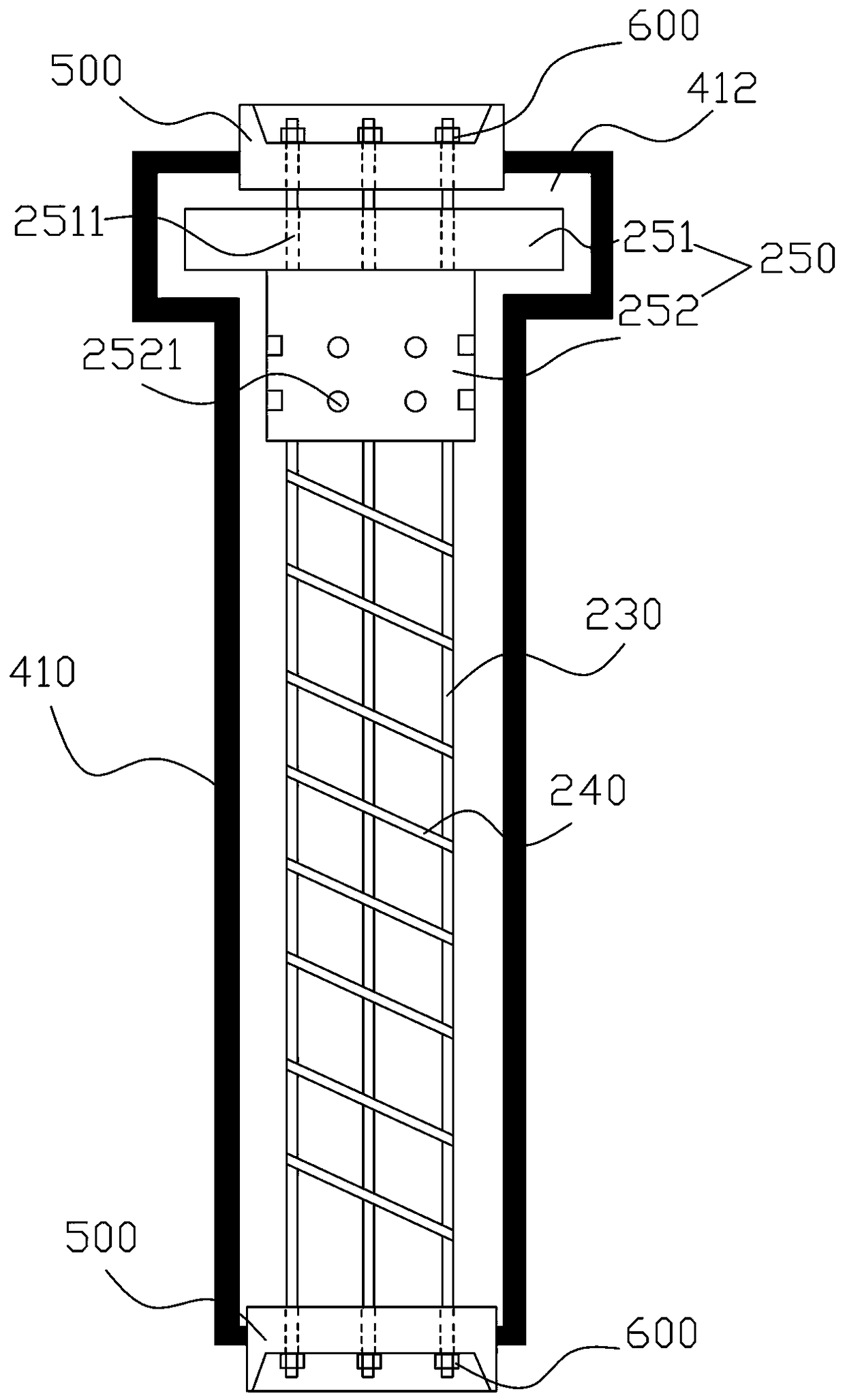

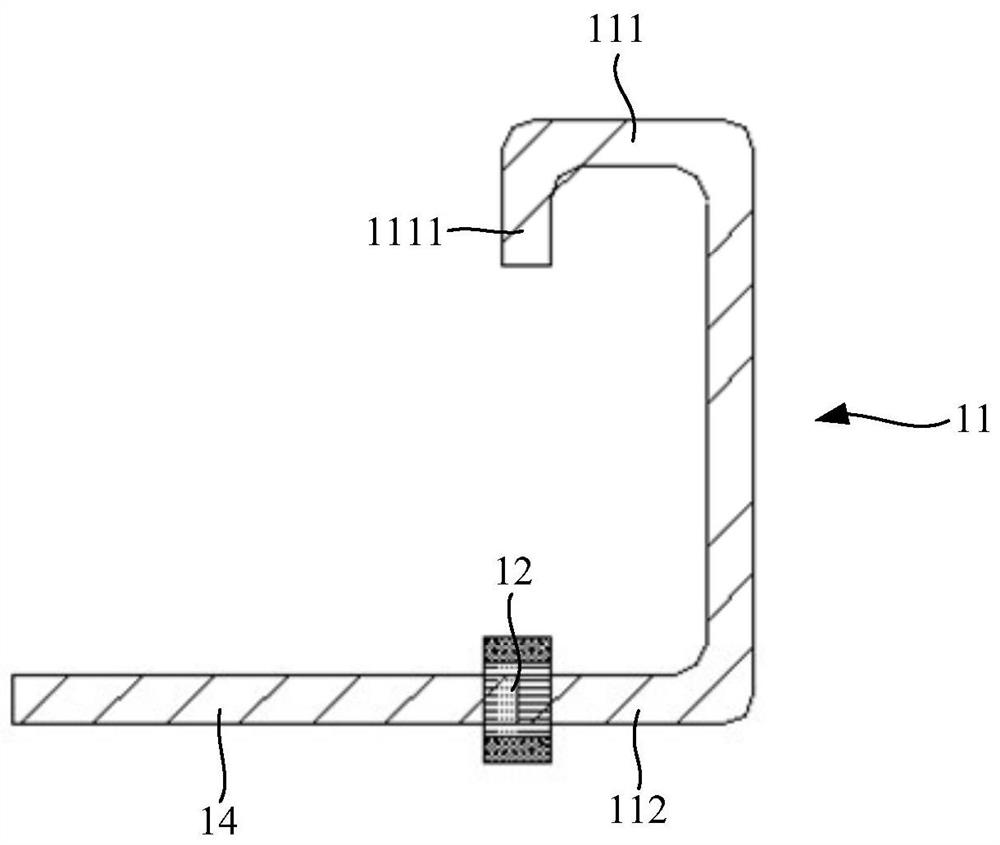

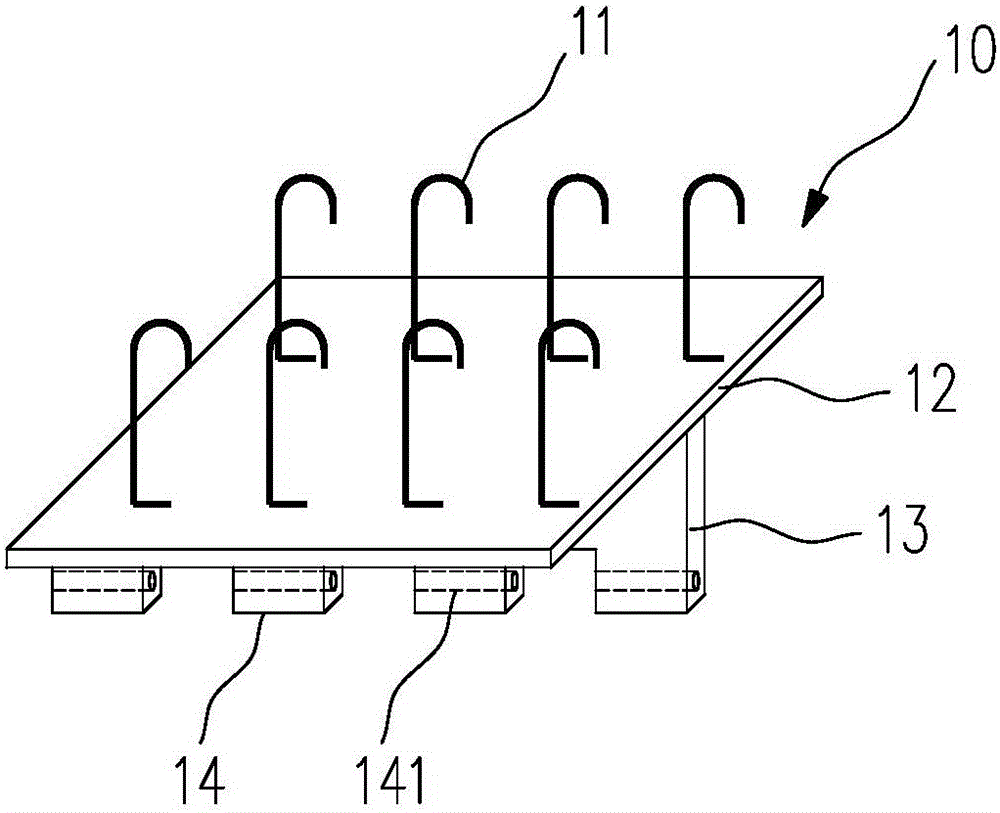

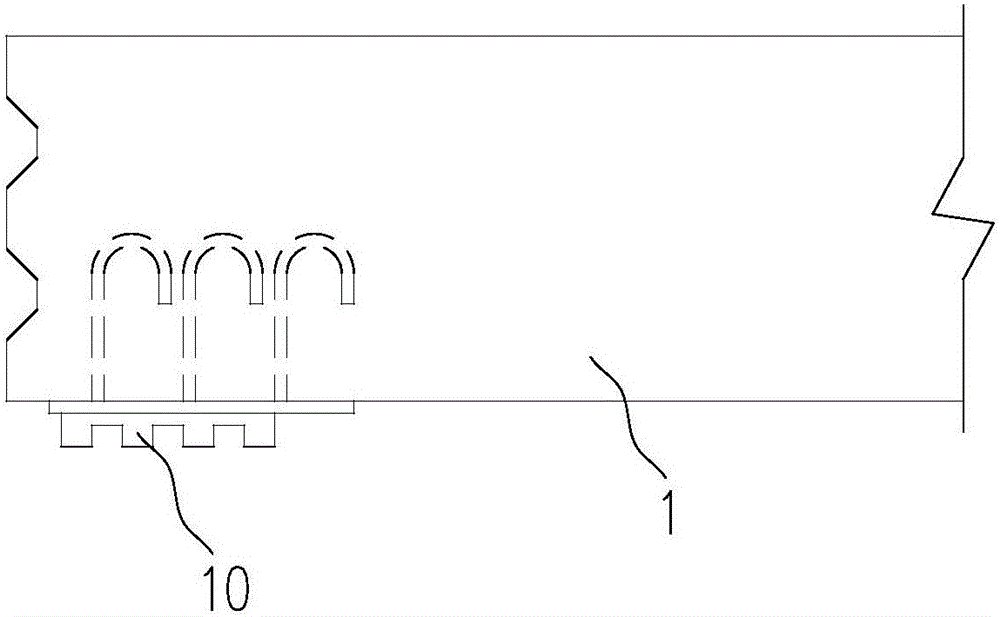

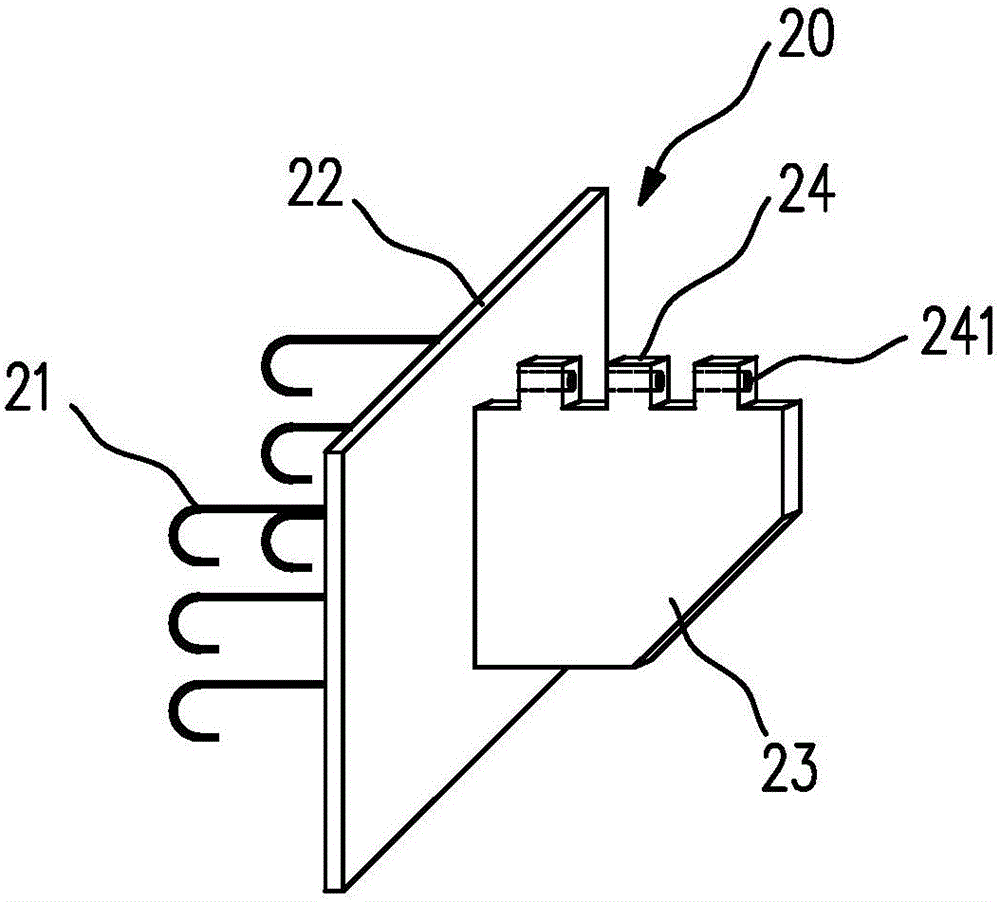

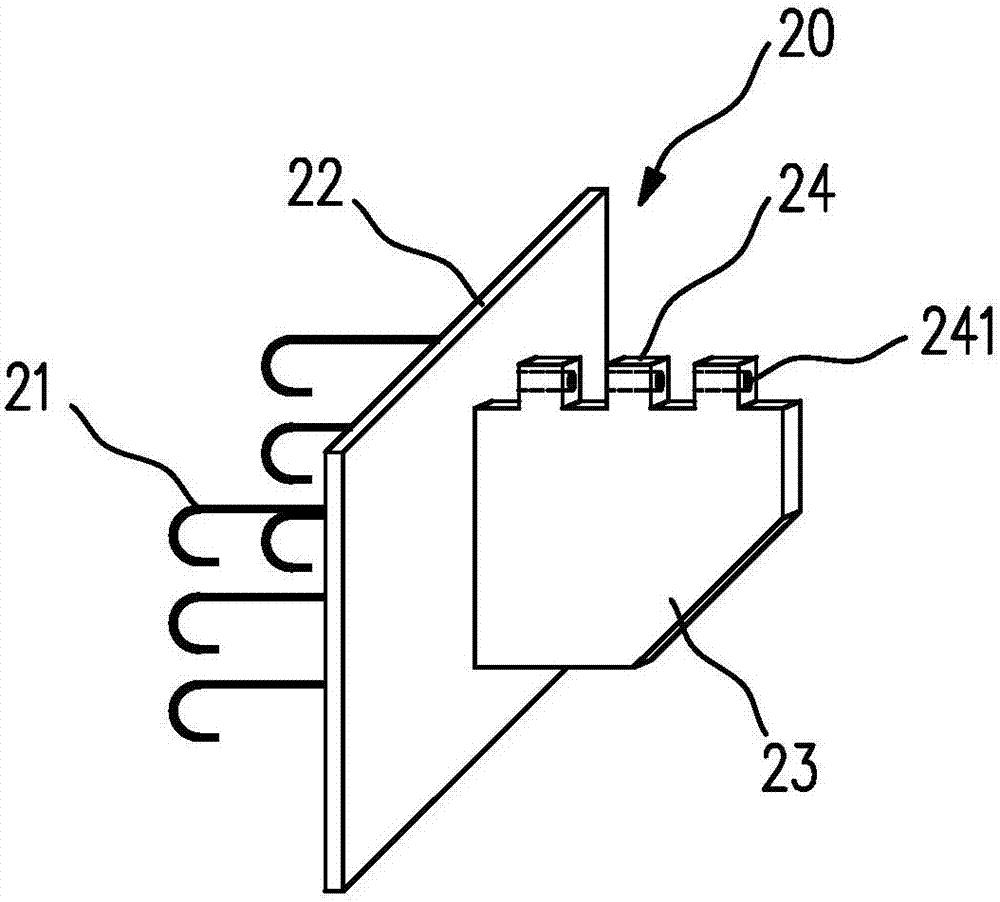

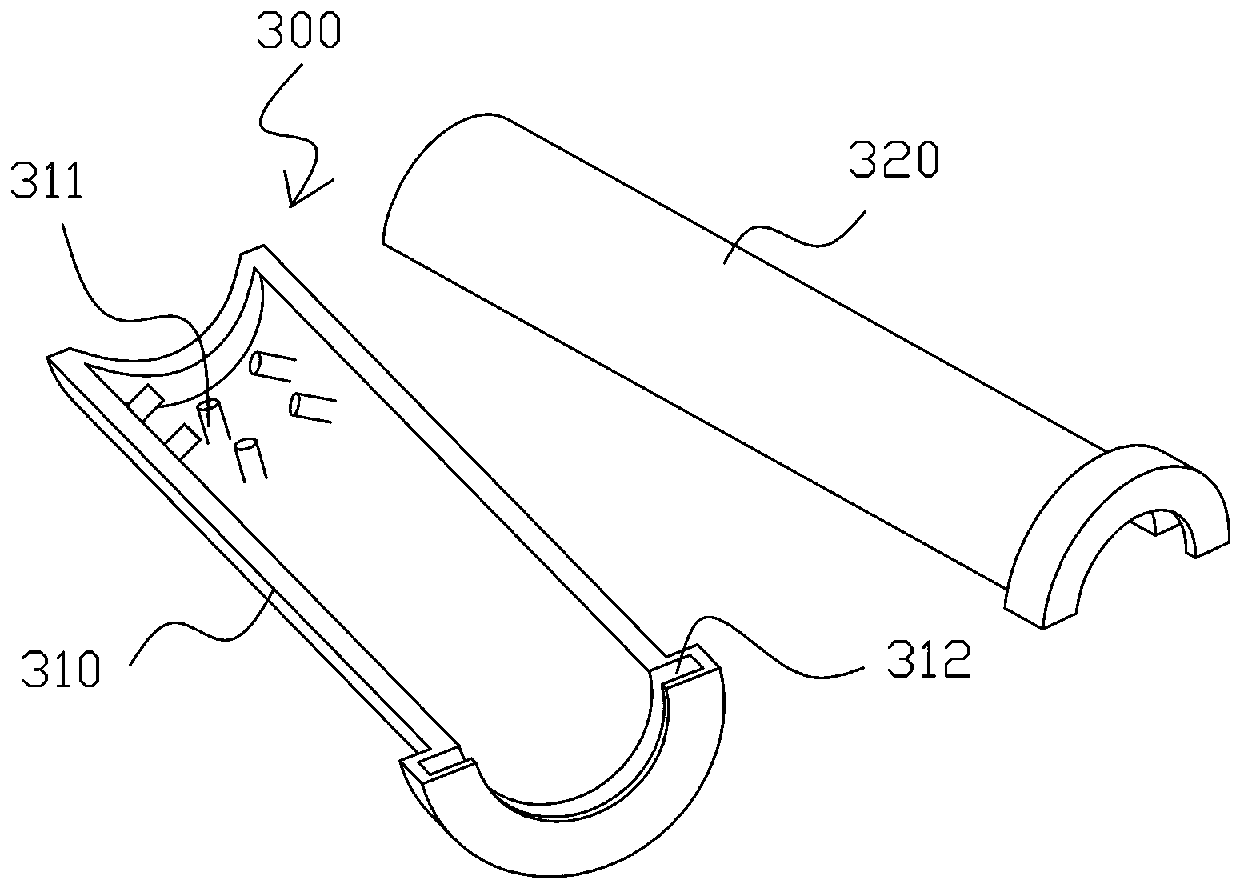

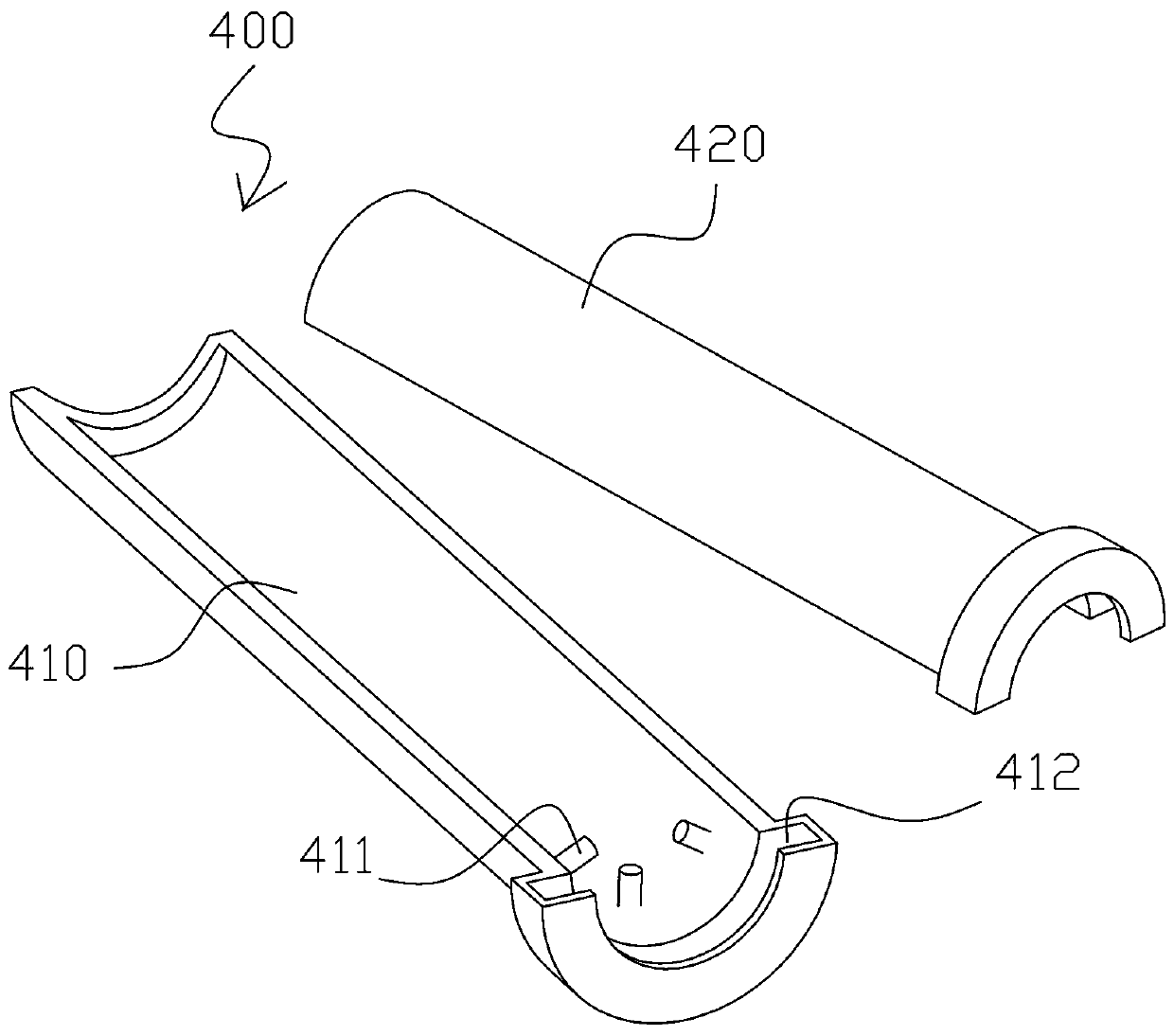

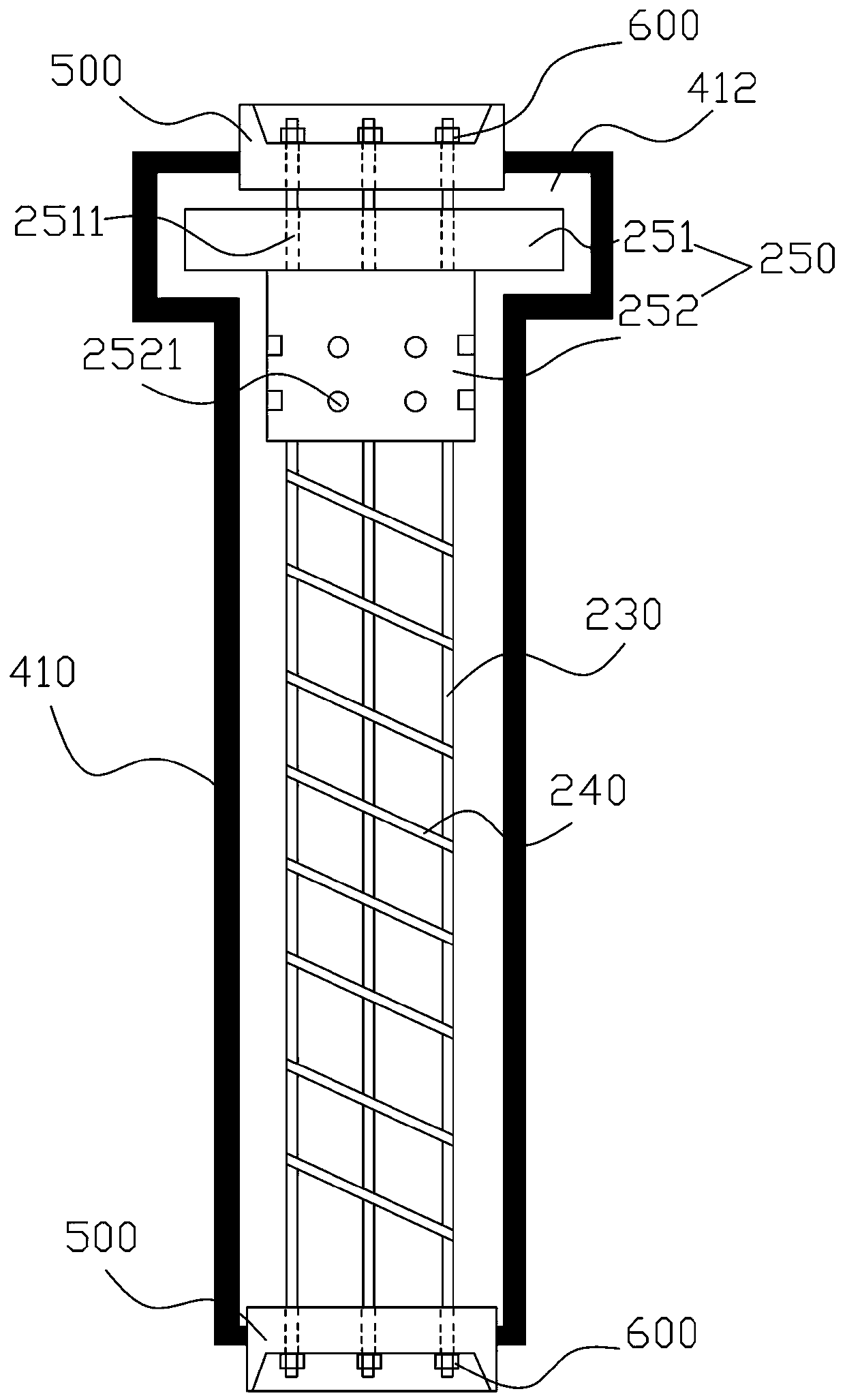

Bus duct system special for wind power generation

InactiveCN101651317AExtended service lifeAvoid damageCoupling device connectionsOpen bus-bar installationsElectrical conductorTower

The invention provides a bus duct system special for wind power generation. The system comprises bus ducts, mounting brackets and joint boxes, wherein each bus duct consists of a plurality of bus bodycomponents which are connected into a whole through a flexible bridge; the joint boxes are respectively arranged at both ends of each bus duct; mounting seats of the mounting bracket are fixed in a wind tower, and fixing angle irons of the mounting bracket are fixedly connected with shells of the bus ducts; each flexible bridge comprises a metallic corrugated tube and a soft conductor, and both ends of each metallic corrugated tube and each soft conductor are respectively connected with corresponding shells of the bus ducts; the soft conductors are arranged in the metallic corrugated tubes, and both ends of each soft conductor are respectively and fixedly connected with bus bars of corresponding bus ducts into a whole; an insulating spacer is arranged between every two adjacent soft conductors, and both ends of each insulating spacer are respectively and fixedly connected with the bus bars of the corresponding bus ducts. The invention enables the connected bus ducts to be adjusted inmultiple directions.

Owner:江苏向荣母线有限公司

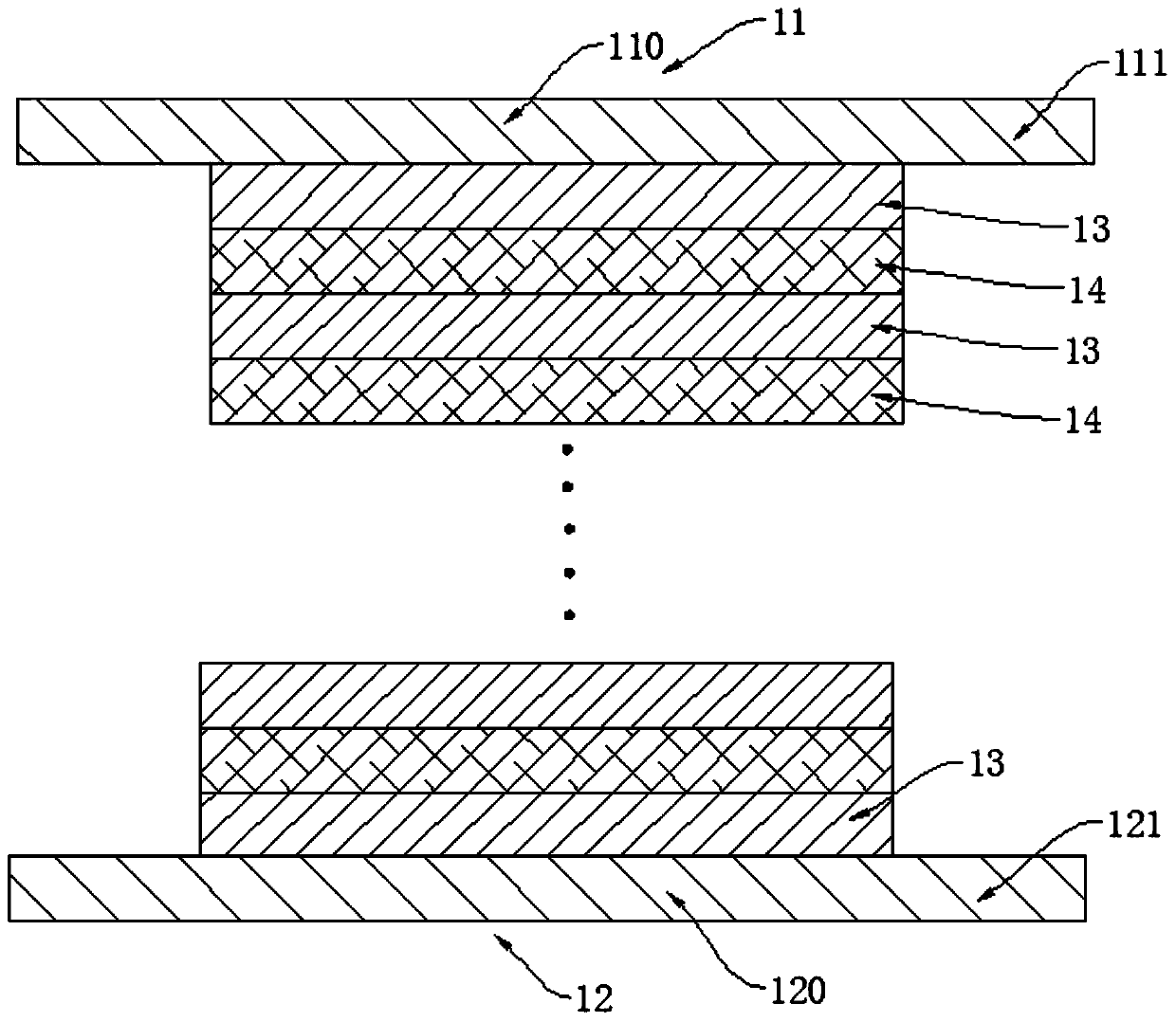

Carbon fiber composite structural member with multilayer structure, and preparation method thereof

ActiveCN110843285ATroubleshooting the connectionRealize "weldingLamination ancillary operationsLaminationMetal matrix compositeSpot welding

The invention discloses a carbon fiber composite structural member with a multilayer structure. The carbon fiber composite structural member comprises a first metal layer and a second metal layer, andan alloy layer and a carbon fiber layer which are formed between the first metal layer and the second metal layer; the alloy layers and carbon fibers are alternately stacked; the first metal layer and the second metal layer are respectively provided with a first extending part and a second extending part which exceed the alloy layer and the carbon fiber layer, and the first extending part and thesecond extending part are fixedly connected, and can be conveniently connected with other structural parts. According to the carbon fiber composite structural member, the carbon fiber layer and the outer high-melting-point metal layers are connected together through the low-melting-point alloy layer, and the alloy layer can fully infiltrate the carbon fiber layer; the first metal layer and the second metal layer can be fixedly connected with the first extending part and the second extending part in a spot welding mode, and therefore it is guaranteed that the alloy layer and the carbon fiber layer are fixed in position during forming. The carbon fiber composite structural member prepared through the above method is high in strength, light in weight and easy to weld, and the problems that atraditional metal matrix composite is prone to aging, low in interlayer binding force and the like are solved.

Owner:SUZHOU PRESSLER ADVANCED FORMING TECHNOLOGIES CO LTD

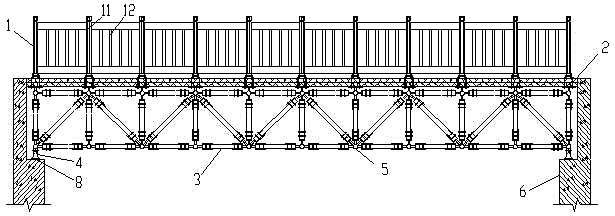

Construction method for modern bamboo pedestrian truss bridge

InactiveCN104631327AGood tension and compression performanceCompact structureTruss-type bridgeBridge structural detailsHandrailPedestrian

The invention discloses a construction method for a modern bamboo pedestrian truss bridge. A truss bridge structure comprises a pairs of bridge piers, two columns of erection supports and a main truss, wherein the bridge piers are made of concrete; the erection supports are fixed on the bridge piers and made of steel materials; the main truss is connected to the erection supports and composed of ball node elements and connecting rods, the ball node elements are made of the steel materials, and the connecting rods are made of heavy bamboo materials. The truss bridge structure further comprises a bridge deck slab and handrails, and the bridge deck slab and the handrails are made of the heavy bamboo materials. The construction method is characterized by comprising the steps of element prefabricating, preassembling, bridge pier forming by cast-in-place, full framing constructing to complete bridge body installation and waterproof paint painting. The construction method for the modern bamboo pedestrian truss bridge has the advantages that the element connection is convenient, the construction is simple and fast, the modulization production is facilitated, the bridge weight is light, the anti-seismic property is good, and nodes are stable and reliable; therefore the obtained pedestrian truss bridge has the advantages of being green, low carbon, environment-friendly and economical, and the requirements of the normal use and the durability of a bridge structure are met.

Owner:CHONGQING JIAOTONG UNIVERSITY

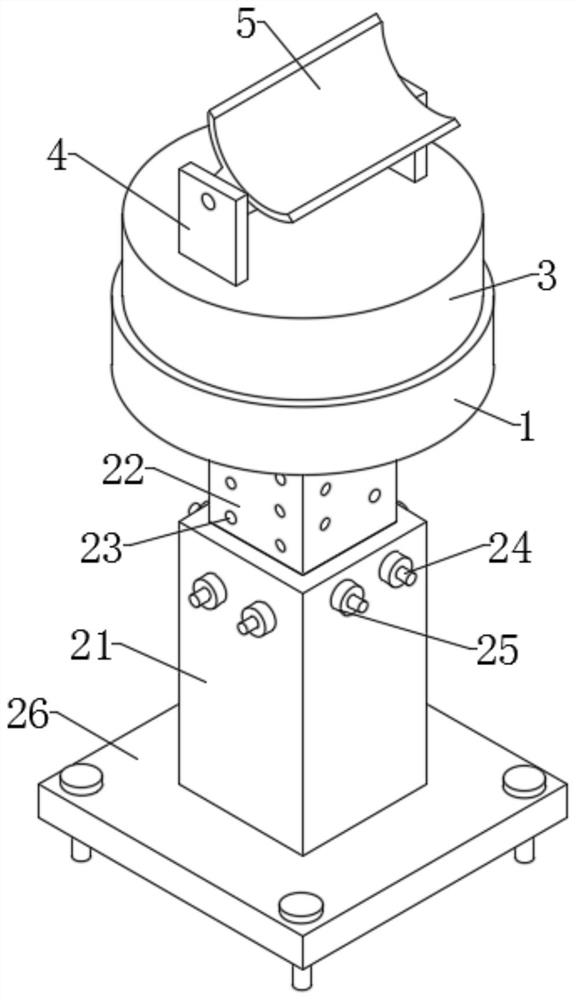

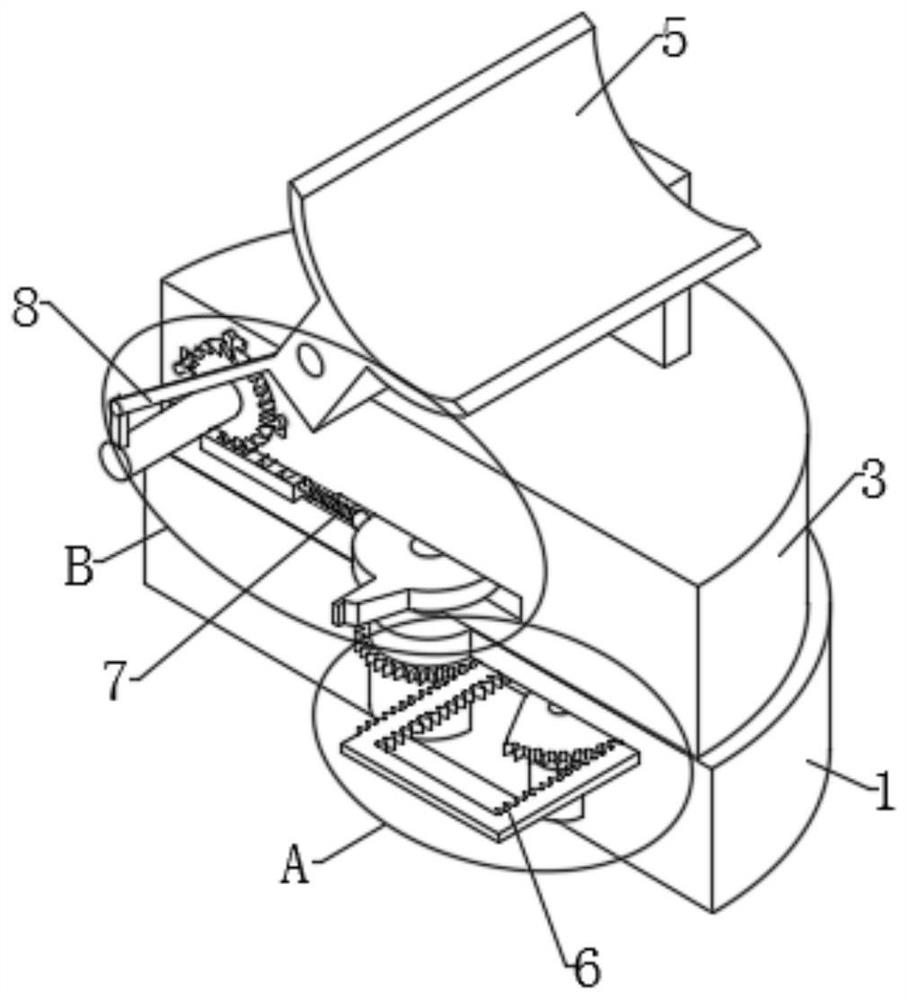

Radar equipment with antenna azimuth turntable and use method thereof

InactiveCN114740429ATo achieve installation at different heightsTroubleshooting the connectionWave based measurement systemsRadarControl theory

The invention discloses radar equipment with an antenna azimuth turntable and a use method thereof, and belongs to the technical field of radar, the radar equipment comprises a fixed seat, an adjusting seat is mounted at the bottom of the fixed seat, a rotating seat is rotatably mounted at the top of the fixed seat, two fixed plates are fixedly mounted on the top surface of the rotating seat, and an antenna is mounted between the fixed plates; a swing mechanism is installed between the fixed seat and the rotating seat, a swing mechanism is installed between the rotating seat and the antenna, and a linkage mechanism is installed between the swing mechanism and the swing mechanism. The mounting height of the antenna is adjusted through the adjusting seat, the slewing mechanism drives the rotating seat to rotate in a reciprocating mode, the antenna rotates in a reciprocating mode for inspection, line connection difficulty caused by continuous rotation is avoided, meanwhile, the swing mechanism is driven through the linkage mechanism, the pitch angle of the antenna is synchronously changed, and the purpose of all-directional monitoring is achieved.

Owner:盐城格跃智能科技有限公司

Shower tray convenient to assemble and disassemble

PendingCN111772517AInstalled and disassembledFirmly connectedBathsDouchesStructural engineeringMechanical engineering

The invention relates to the technical field of shower basins and particularly discloses a shower tray convenient to assemble and disassemble. The shower tray comprises a basin base shaped like a Chinese character 'kou', the upper end of the basin base is connected with a movable pedal; a clamping groove is formed in the inner side edge of the upper surface of the basin base; a sealing rubber strip is arranged at the joint of the upper end of the clamping groove and the movable pedal; the upper surface of the clamping groove is lower than the upper surface of the basin base, a water guide groove is formed in the position, close to the outer side of the clamping groove, of the upper surface of the basin base, a drainage pipe is arranged at the position, corresponding to the water guide groove, of the middle of the inner side wall of the basin base, and an adjusting plate is arranged on one side edge of the basin base. According to the shower tray, the movable pedal and the tray base aredesigned in a separated mode, installation and maintenance are convenient, the existing integrally-formed shower tray structure is broken through, the upper surface of the movable pedal is designed to be high in the middle and low in the periphery, water can be conveniently guided to the periphery, and the problem that a user slips when stepping on the movable pedal in the next use process is solved.

Owner:GUANGDONG WIEBORN SANITARY WARE CO LTD

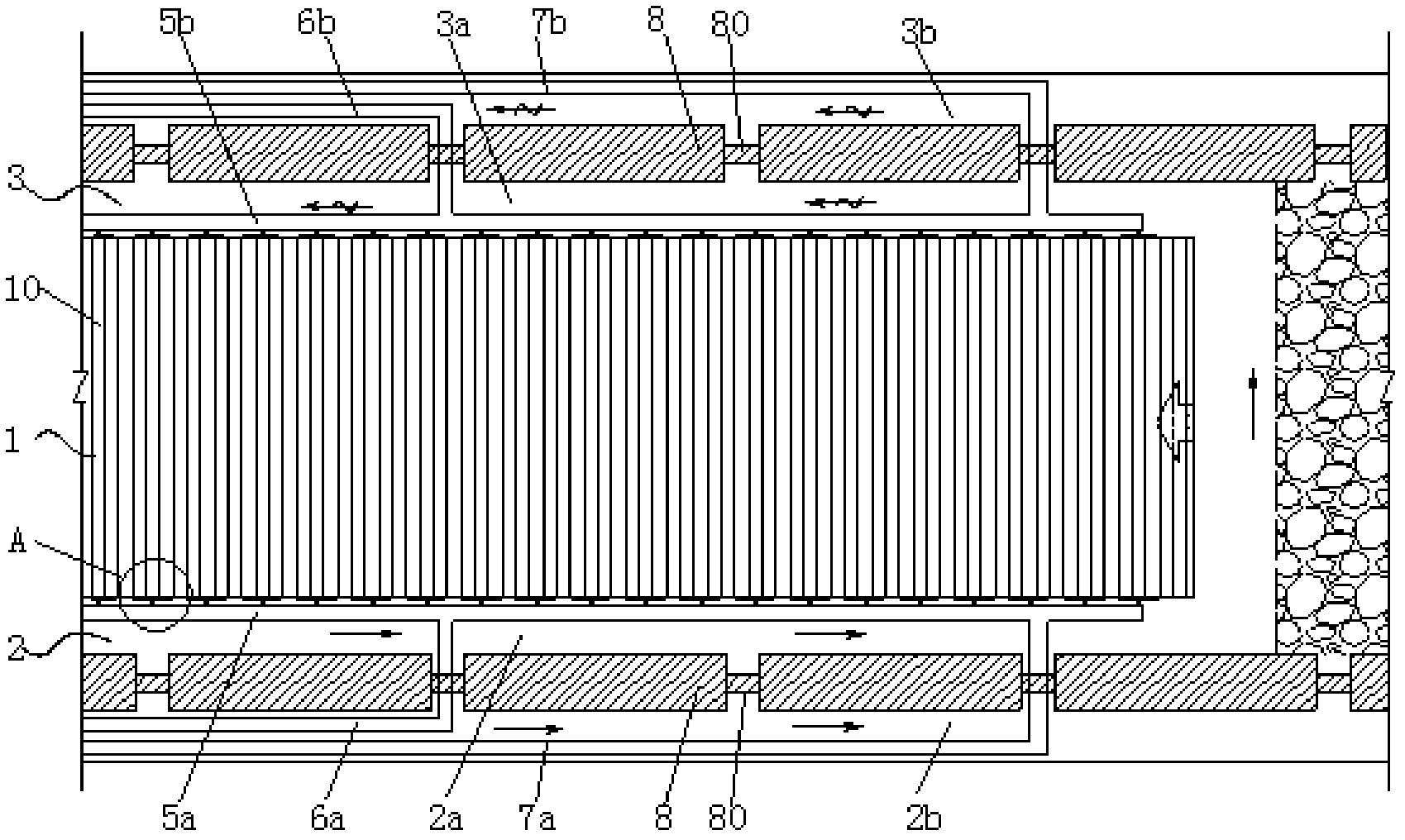

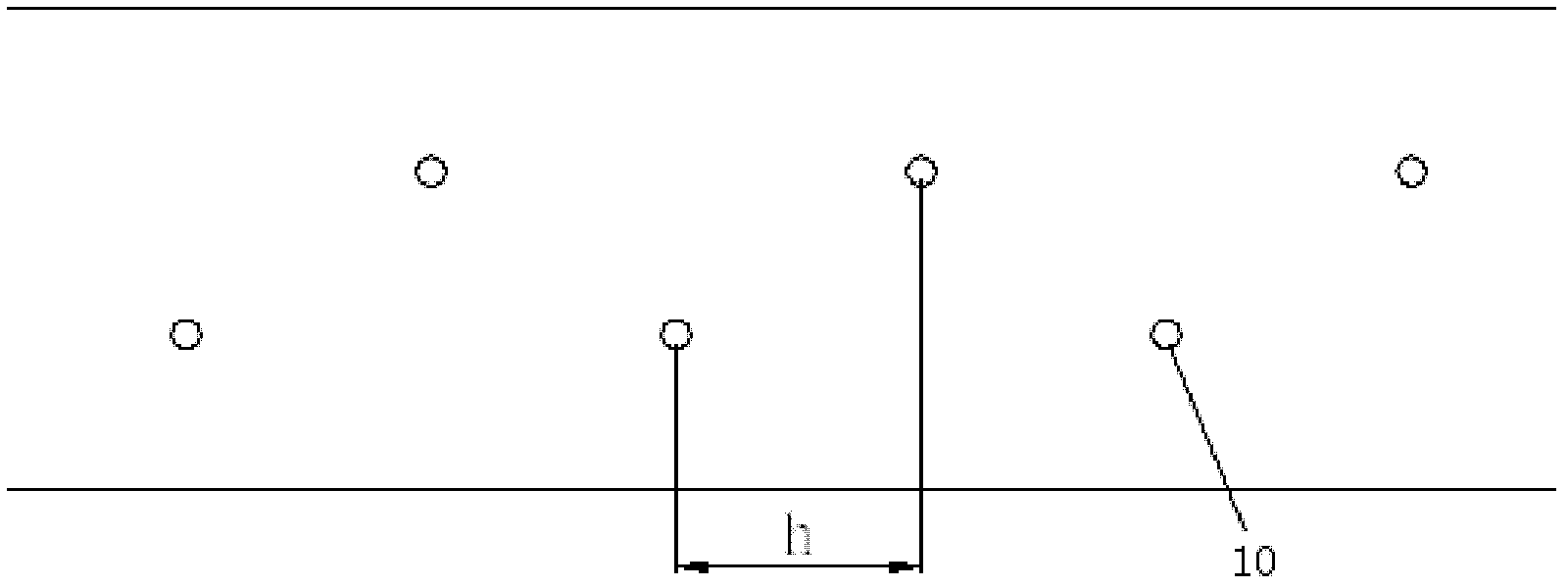

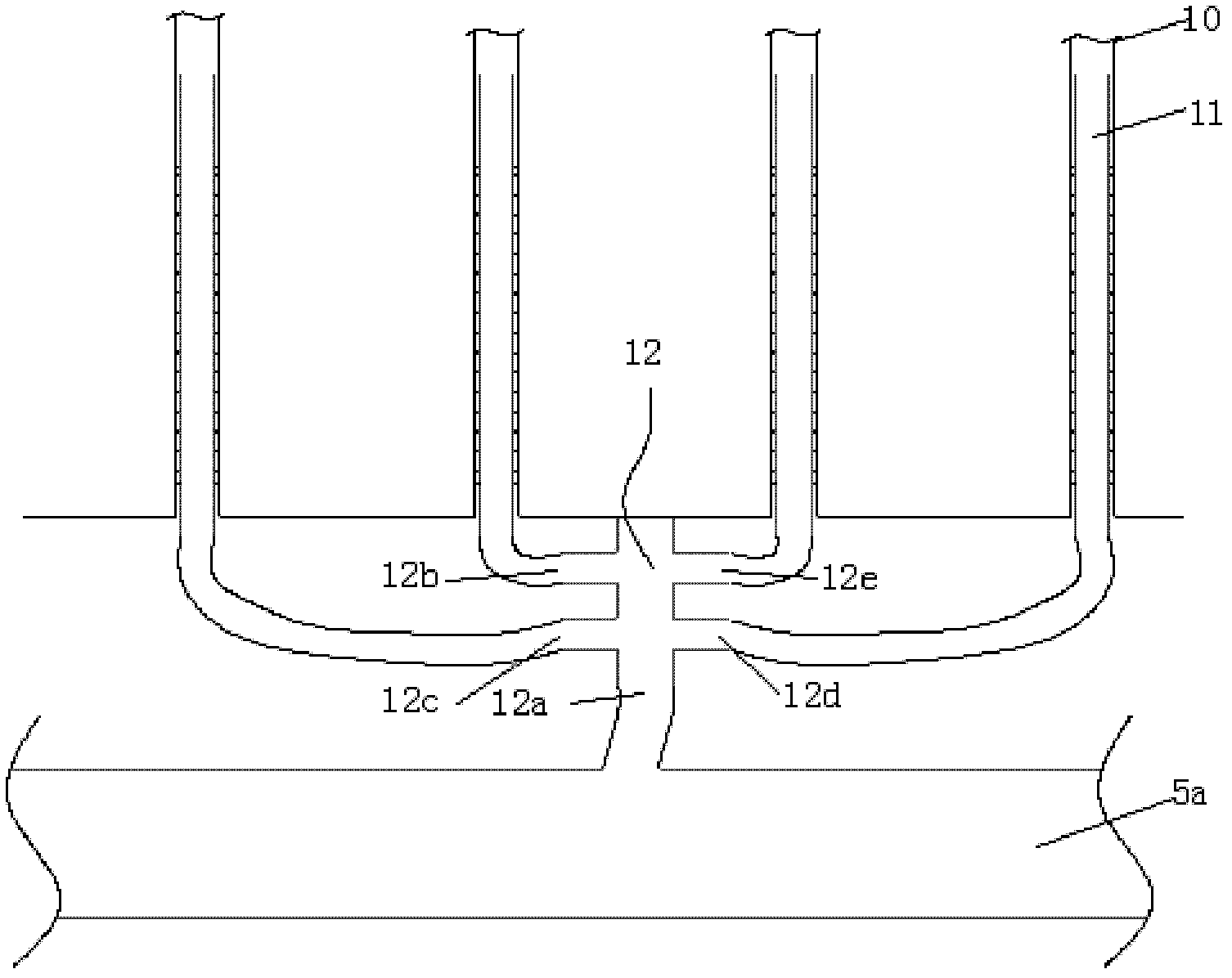

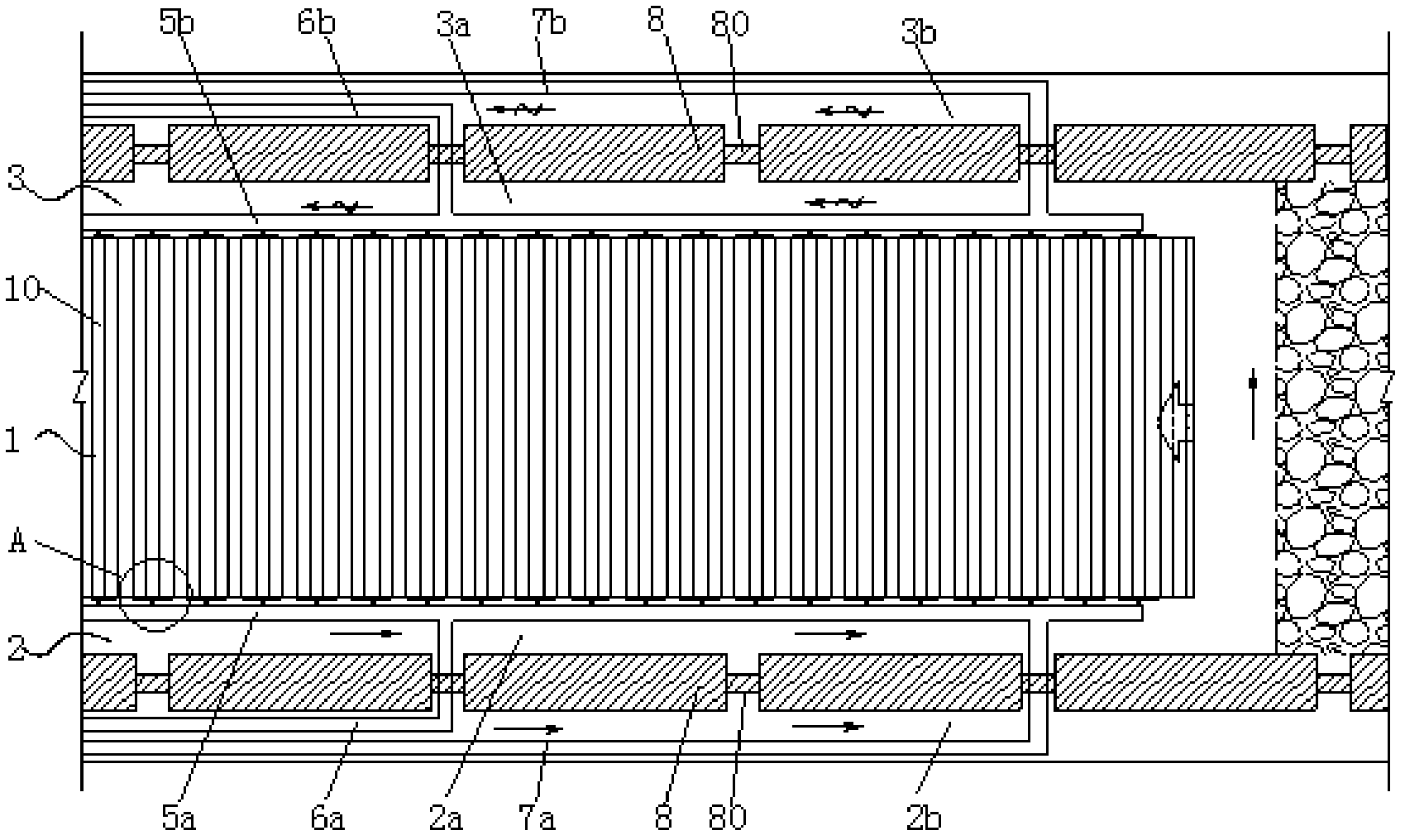

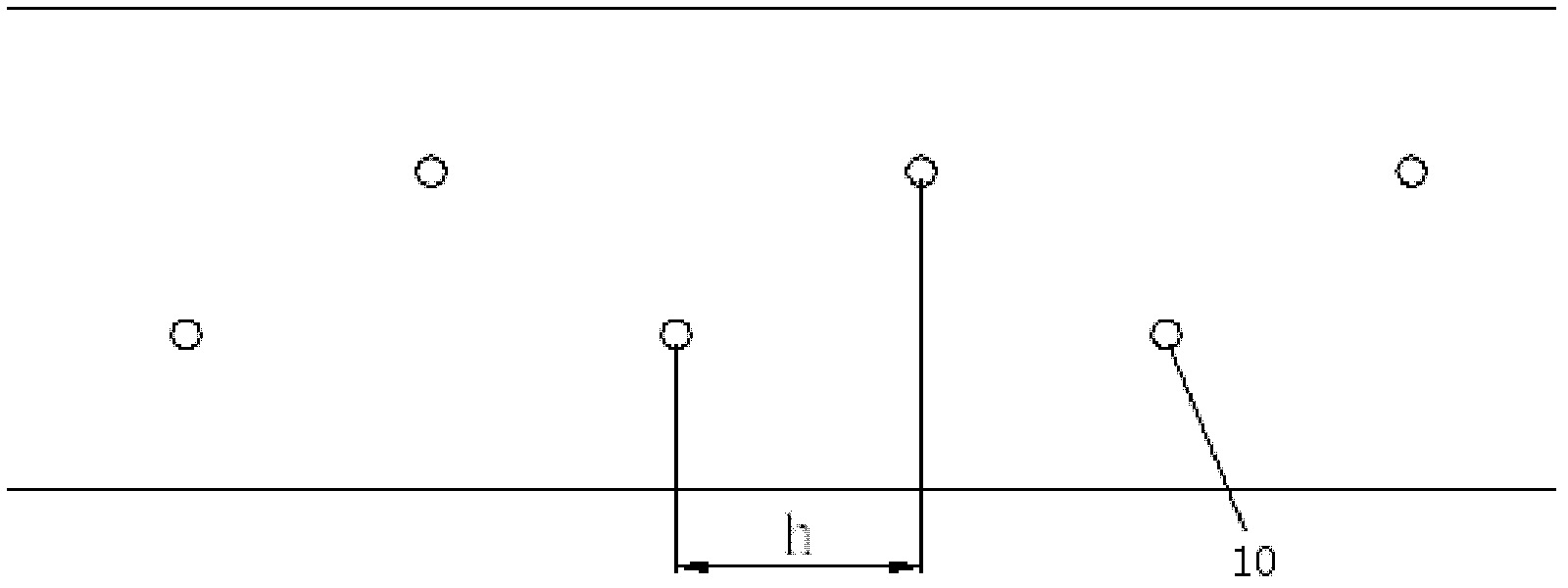

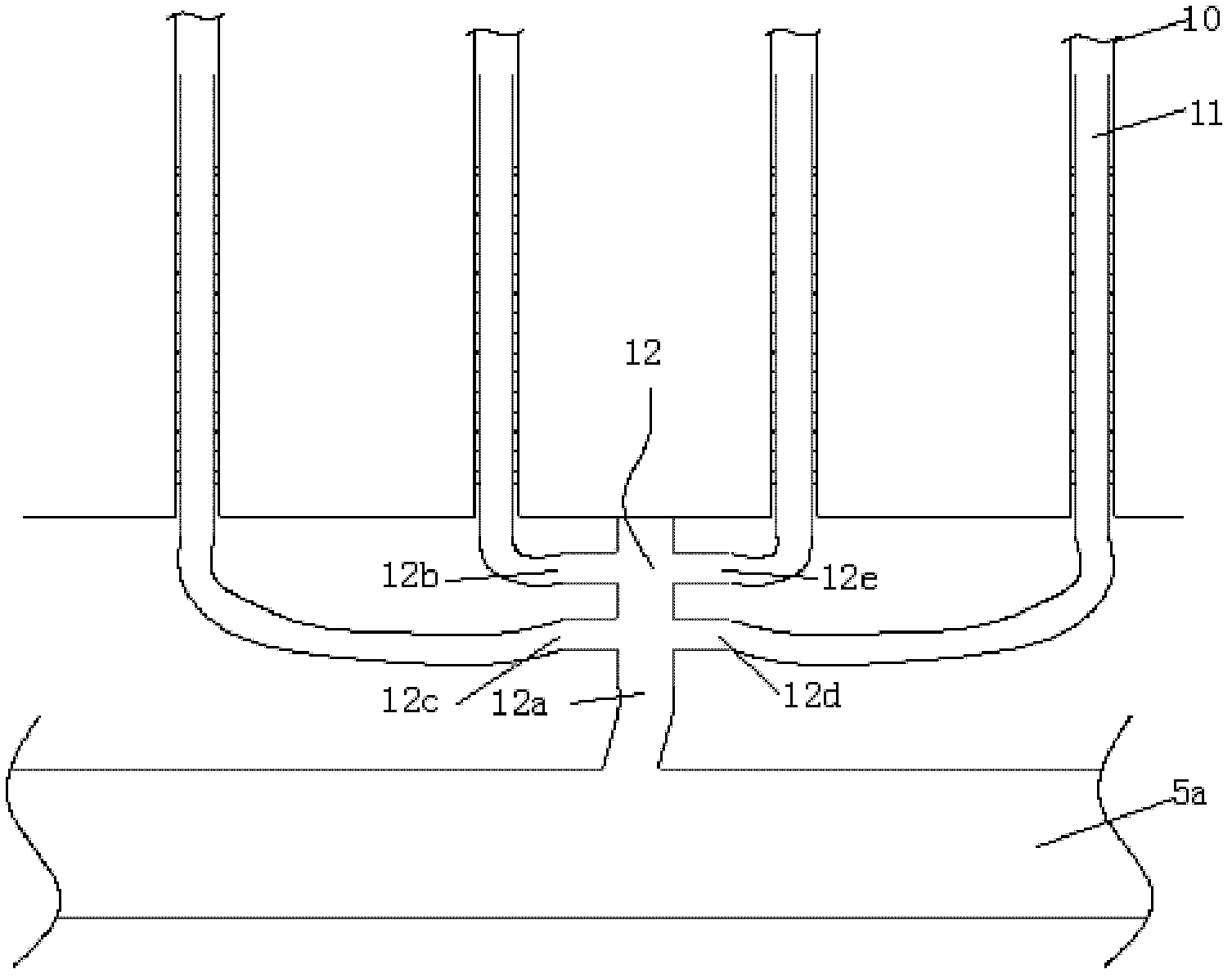

Low permeability coal seam gas pre-drainage method though intensive drilling holes and pipe pressure-up

InactiveCN103046946ASolve the problem of small effective extraction radiusAchieve large-scale anti-reflectionGas removalEngineeringCoal

The invention discloses a low permeability coal seam gas pre-drainage method though intensive drilling holes and pipe pressure-up. The method includes the following steps: a plurality of through drilling holes are arranged on a pre-drainage coal seam; a first drainage pipe is laid on one side of an air inlet roadway close to the pre-drainage coal seam, and one ends of the plurality of through drilling holes are connected with the first drainage pipe; a second drainage pipe is laid on one side of an air return roadway close to the pre-drainage coal seam, the other ends of the plurality of through drilling holes are connected with the second drainage pipe so as to enable the plurality of through drilling holes to be communicated with the first drainage pipe and the second drainage pipe respectively to form a gas pre-drainage system, and a first negative pressure boosting pipe system is laid in the air inlet roadway and communicated with the first drainage pipe so as to boost negative pressure of the first drainage pipe; and a second negative pressure boosting pipe system is laid in the air return roadway and communicated with the second drainage pipe so as to boot negative pressure of the second drainage pipe.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

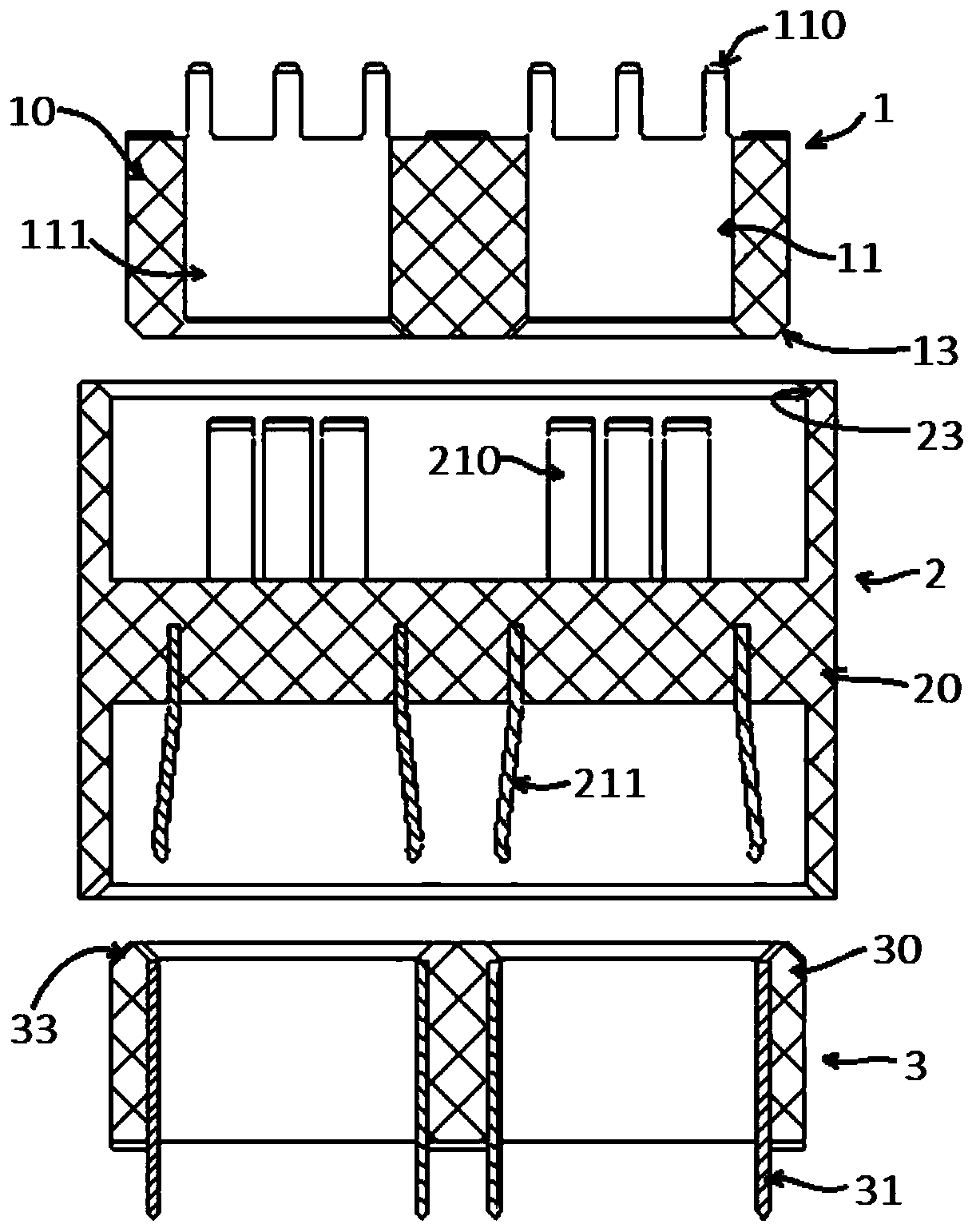

Energy consumption support and assembly type concrete framework dual energy consumption node and assembly method

The invention relates to an energy consumption support and assembly type concrete framework dual energy consumption node and an assembly method. The mode comprises a beam end embedding unit, a column end embedding unit, a connecting unit and a connecting assembly, wherein the connecting unit is connected with the beam end embedding unit and the column end embedding unit; and the connecting assembly is used for connecting the beam end embedding unit, the column end embedding unit and the connecting unit. During the assembly, firstly, a prefabricated concrete beam with the beam end embedding unit, a prefabricated concrete column with the column end embedding unit and the connecting unit are firstly prefabricated; then, the prefabricated concrete beam and the prefabricated concrete column are hoisted to designed positions; a beam end embedding metal plate and a beam end connecting plate of the connecting unit are oppositely attached together; a column end connecting plate and a column end embedding metal plate are oppositely attached; and the beam end embedding unit, the column end embedding unit and the connecting unit are connected into a whole. The mode and the assembly method have the advantages that the full assembly type connection is adopted, so that the connection is safe and reliable; the structure is reasonable; the construction difficulty is low; the field construction is convenient and fast; and the work intensity is low.

Owner:HEFEI UNIV OF TECH

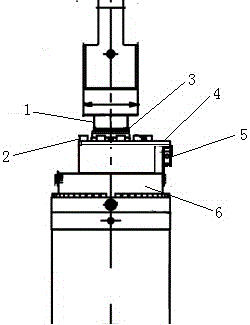

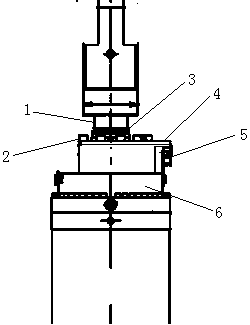

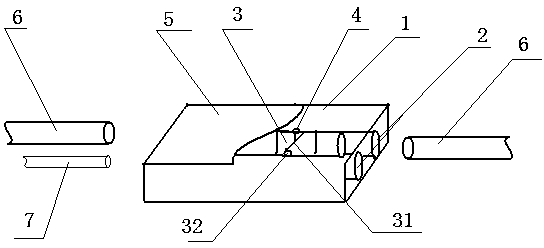

Rotary locking element

The invention discloses a rotary locking element. The rotary locking element is characterized by comprising a locking disc, U-shaped cylindrical steel and two bolts, wherein a location groove connected with a rotary body is arranged in the locking disc; a plurality of insertion-connection grooves are arranged around the location groove; the U-shaped cylindrical steel is formed through integrally moulding a parallel rod parallel to the locking disc and two vertical rods vertical to the locking disc; nuts of the bolts are connected to the U-shaped cylindrical steel; and the two vertical rods are inserted in the insertion-connection grooves of the locking disc. The locking disc is prevented from being liable to scrape with peripheral equipment during an action process with the rotary body through indirectly connecting the rotary locking disc with a servomotor body through the U-shaped cylindrical steel; and meanwhile, difficult connection between bolt holes in the locking disc and bolt holes of the servomotor body due to inconformity is avoided. The rotary locking element disclosed by the invention is simple in structure, convenient to operate, and suitable for industrialized production.

Owner:STATE GRID CORP OF CHINA +2

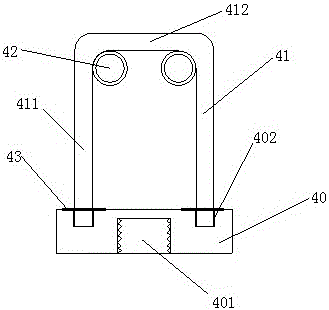

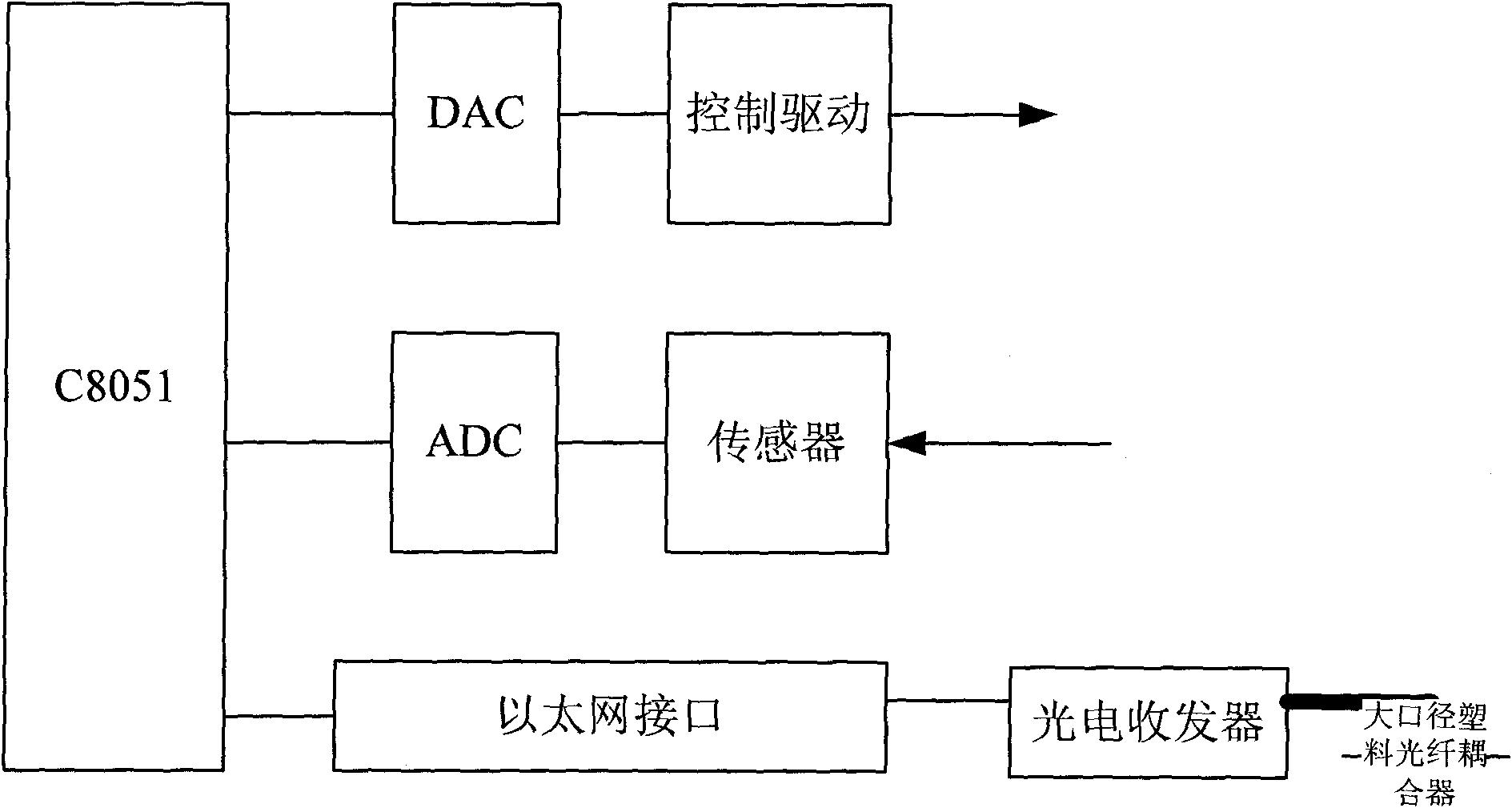

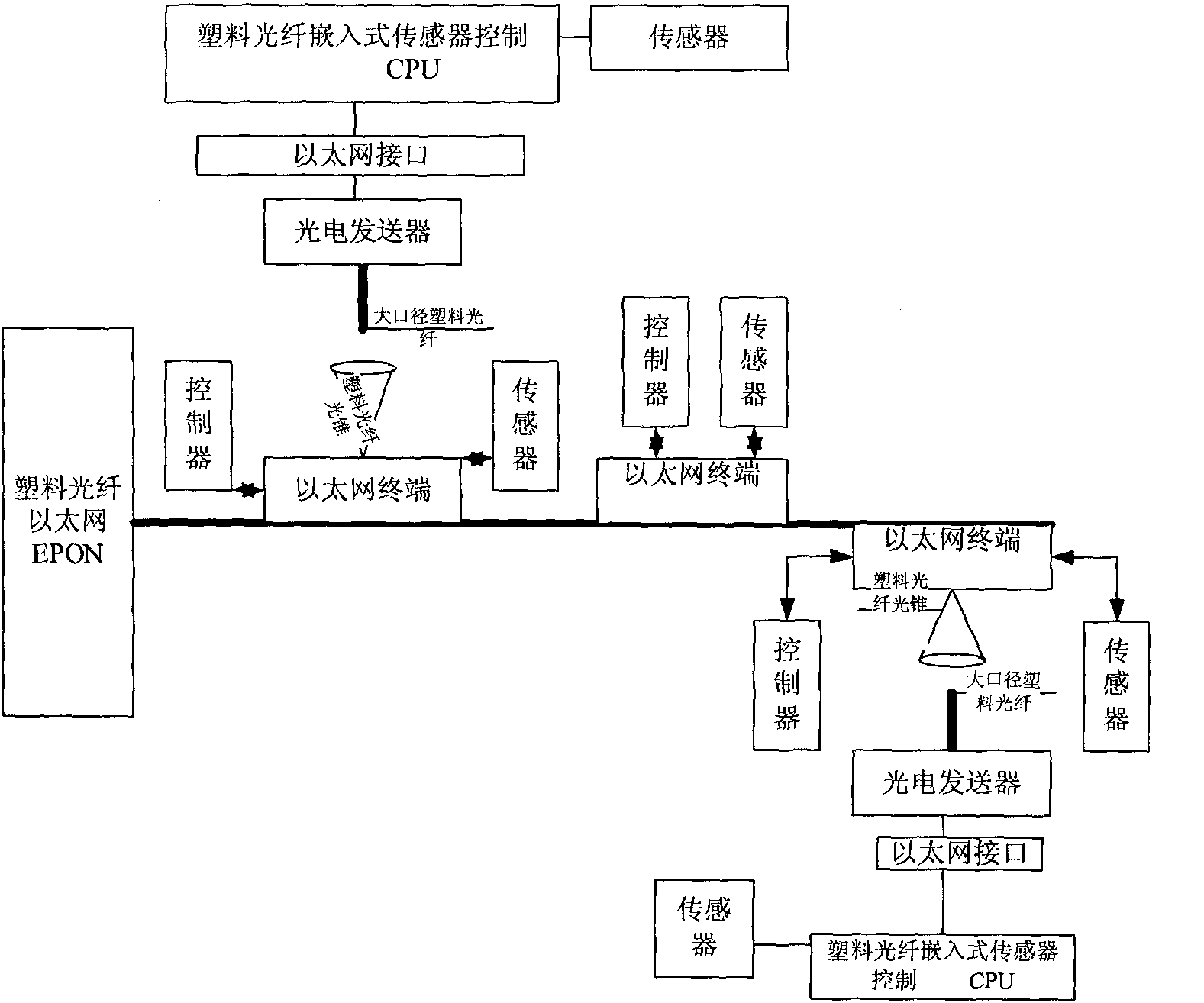

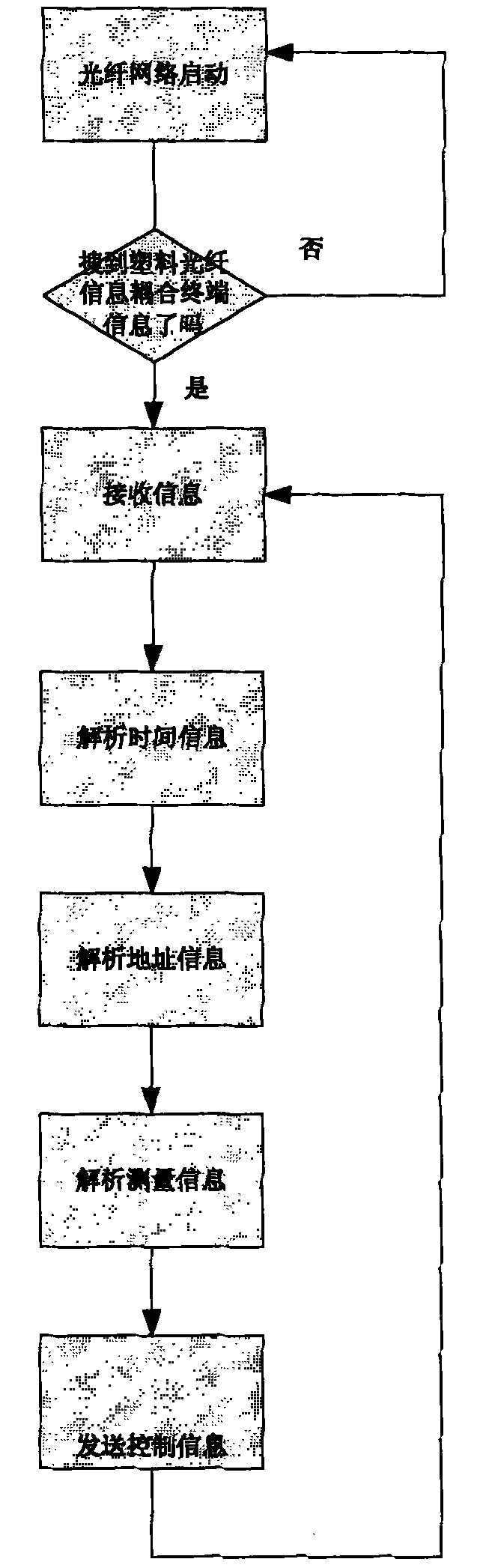

Plastic optical fiber bus optical information coupling device

InactiveCN101833313ATroubleshooting the connectionEasy accessFibre transmissionTotal factory controlWireless transceiverFrequency spectrum

The invention discloses a plastic optical fiber bus optical information coupling device, which is characterized in that: a terminal computer C8051 performs information collection through an ADC module; a wireless transceiver module and a laser transceiver module are used to perform communication through multi-spectrum wireless electrooptical signals and an optical network to send measurement information to a control center; the wireless transceiver module and the laser transceiver module are used to perform communication through multi-spectrum wireless electrooptical signals and the optical network to send the control information of the control center to the terminal computer C8051; and the terminal computer C8051 inputs the information through the DAC module into the controller to perform control. The device of the invention can overcome the drawbacks of information coupling singleness and immobility of the conventional terminal, increase network information exchange performance, enable a bus to measure and control through different kinds of media information, and form a mobile network measurement and control bus.

Owner:HARBIN ENG UNIV

Special die for concrete electric pole convenient to construct and production process

The invention relates to the technical field of concrete electric poles, and discloses a special die for a concrete electric pole convenient to construct and a production process. The die comprises anupper pole steel die and a lower pole steel die, wherein the upper pole steel die comprises an upper pole concave cavity and an upper pole protruding column, and the lower pole steel die comprises alower pole concave cavity and a lower pole protruding column. The production process comprises the following steps of: producing an upper pole through the upper pole steel die by using an upper pole production line, producing a lower pole with a hollow inner cavity through the lower pole steel die by using a lower pole production line, and placing the upper pole into the hollow inner cavity of thelower pole by utilizing an assembling production line to obtain a finished electric pole product. The special die can be used to reliably, conveniently and efficiently produce the concrete electric pole with the advantages of being flexible in height adjustment, convenient to construct and maintain and high in structural strength and saving transportation space.

Owner:安徽联众电力科技有限公司

Adapter connector and connector assembly

ActiveCN110391562ATroubleshooting the connectionCoupling contact membersCouplings bases/casesEngineeringElectrical and Electronics engineering

The invention relates to electric connection elements, and especially relates to an adapter connector and a connector assembly. The connector assembly includes a first connector, a second connector and the adapter connector in plugging connection with the first and second connectors during using; the plugging ends of the first and second connectors and the plugging end of the adapter connector have insertion gaps in a direction vertical to a plugging direction; the adapter connector is in plugging connection with the first and second connectors through chip contact members; and the plugging contact surface of an adaptor contact member with a first contact piece of the first connector is vertical to the plugging contact surface of the adaptor contact member with a second contact piece of the second connector. The plugging contact surfaces of the adaptor contact member in contact with the contact pieces of the two connectors are vertical to each other, so that the adapter connector and the two connectors can slide along the plugging contact surfaces, namely, the adapter connector and the two connectors can float in direction which are vertical to each other, and thus, large toleranceplugging can be realized, the reliable contact of the contact members can be guarantees.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

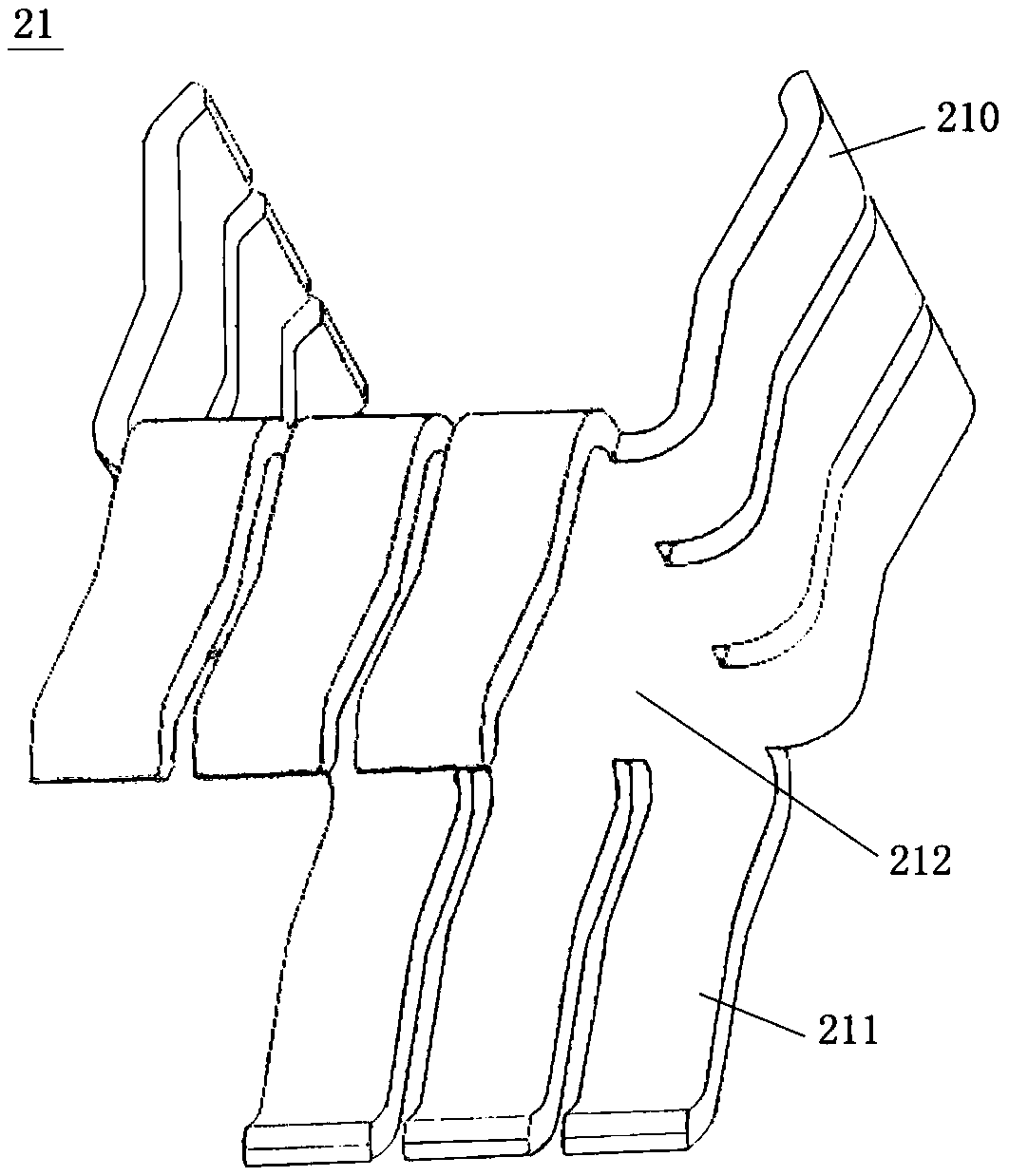

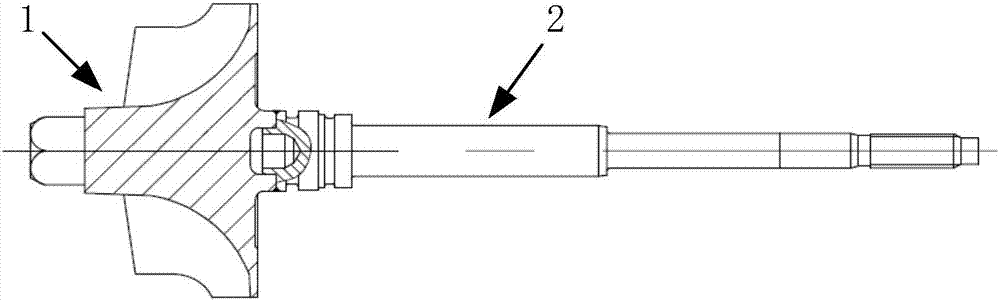

Low-inertia quick-response metal-ceramic composite turbine rotary shaft

ActiveCN107035412AImprove transient response performanceSmall inertiaTurbinesBlade accessoriesCeramic compositeEngineering

The invention discloses a low-inertia quick-response metal-ceramic composite turbine rotary shaft. The low-inertia quick-response metal-ceramic composite turbine rotary shaft comprises a turbine and a rotary shaft body. The turbine is divided into three structure layers from inside to outside and comprises an inner main body, a transition layer and blade layer. The inner main body is made from traditional nickel-based alloy steel is a uniform rotation body manufactured through a casting molding method. The transition layer adopts high-temperature alloy powder and is sintered onto the inner main body. The blade layer adopts a mixed ceramic material of silicon nitride and zirconium oxide and is provided with a hub surface layer and turbine blades peripherally arranged on the outer wall of an axle. The rotary shaft body is made from high-temperature-resistant steel, and one end of the rotary shaft body is coaxially connected with a composite wheel in a hollow friction welding mode. The turbine rotary shaft is formed by compositing the multiple materials of nickel-based alloy steel-high-temperature alloy powder-ceramic, the mass of the turbine is lowered, and thus the effect that the turbine can bear the 1050 DEG C high temperature working environment is achieved; and compared with high-temperature-resistant steel rotary shafts of the same material and traditional friction welding processes, connection is reliable, the manufacturing cost is low, and the purpose of improving the responsiveness of an engine is achieved.

Owner:北京领动国创科技有限公司

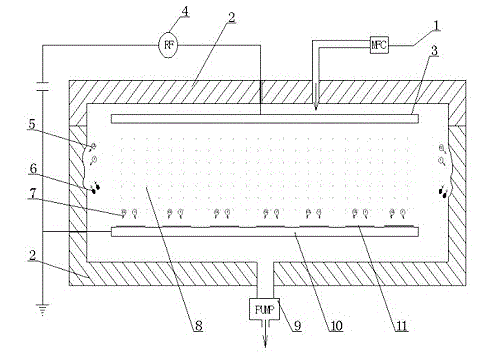

Cavity structure of reaction chamber used in solar cell dry method texturing technology

ActiveCN104934505AReduce processing difficultyReduce delivery costsFinal product manufactureSemiconductor devicesHigh energySolar cell

The invention relates to the solar cell manufacturing equipment, plasma etching, and vacuum reaction chamber technology fields and especially relates to a cavity structure of a reaction chamber used in a solar cell dry method texturing technology. A cavity main body is formed through assembling and welding a plurality of stainless steel sheet materials. Surfaces of the stainless steel sheet materials are sprayed and plated with a teflon coating. A teflon coating surface is inlaid with a detachable aluminum alloy liner armor plate. The teflon coating is a PTFE, PFA or FEP material. Sand blasting is performed on the stainless steel sheet material surfaces. The aluminum alloy liner armor plate is an aluminum plate or an aluminum liner armor plate whose surface is processed through deep anodic oxidation. By using the cavity structure of the invention, processing difficulty is decreased and commissioning cost is reduced; deformation is small under vacuum pressure of a large-scale cavity; dismounting is convenient and a problem that connections between the reaction chamber and a gate valve, and the reaction chamber and other cavities are difficult is effectively solved; the aluminum alloy liner armor plate possesses chemical corrosion resistance performance; bombardment of high-energy particles to the coating can be effectively blocked and there is no metal ion pollution to a silicon wafer.

Owner:CHANGZHOU BITAI TECH

Assembling method of plastic-wood house easy to assemble and disassemble

InactiveCN103216110ADoes not affect appearanceCompact structureBuilding material handlingPurlinEaves

The invention discloses an assembling method of a plastic-wood house easy to assemble and disassemble. The assembling method includes a first step of connecting stand columns with foundation beams and waist square-columns, a second step of connecting the stand columns with upper beams, wherein two connecting modes are included, one mode is that L-shaped connecting pieces are adopted to connect and fix at corners, and the other mode is that T-shaped connecting pieces are adopted to connect and fix at wide surface extending junctions, a third step of connecting and fixing eaves purlins and the upper beams, a fourth step of connecting short columns with the upper beams and ridge purlins, a fifth step of enabling slope purlins to be respectively connected and fixed with the eaves purlins and the ridge purlins, a sixth step of installing and fixing house shingle panels on the slope purlins of a roof, a seventh step of installing plastic-wood square strips on the foundation beams and the waist square-columns to make retention walls, an eighth step of installing external wall panels outside the retention walls, and arranging insulation boards on the inner sides of the external wall panels, a ninth step of fixing internal wall panels on keels of the external wall panels, and a tenth step of embedding lines, installing doors and windows and carrying out decoration processing. The assembling method of the plastic-wood house easy to assemble and disassemble enables a house to be tight in structure, high in firmness and accurate in sizes, and solves the problem of difficult connecting of plastic-wood technology. Moreover, the connecting pieces are hidden after connecting and do not influence appearance of the house.

Owner:湖南绿广景观新材料有限公司

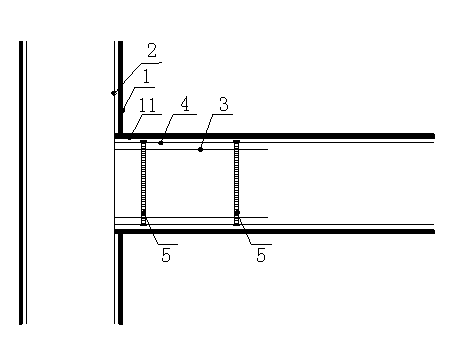

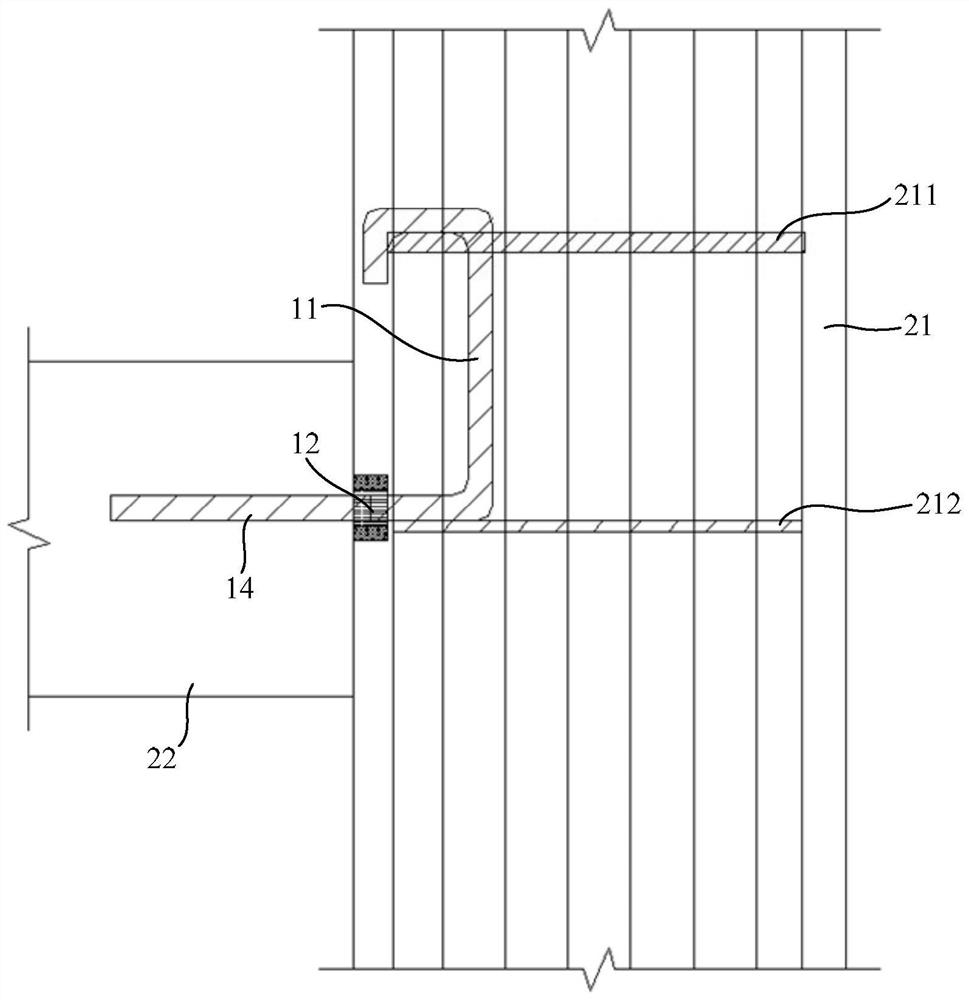

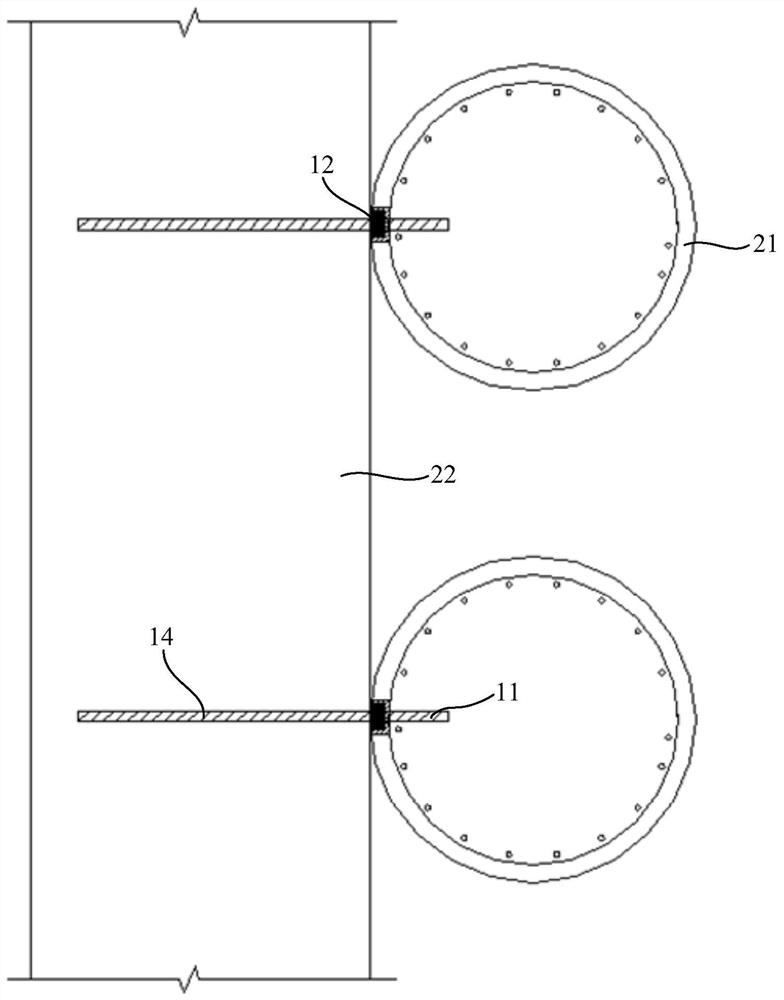

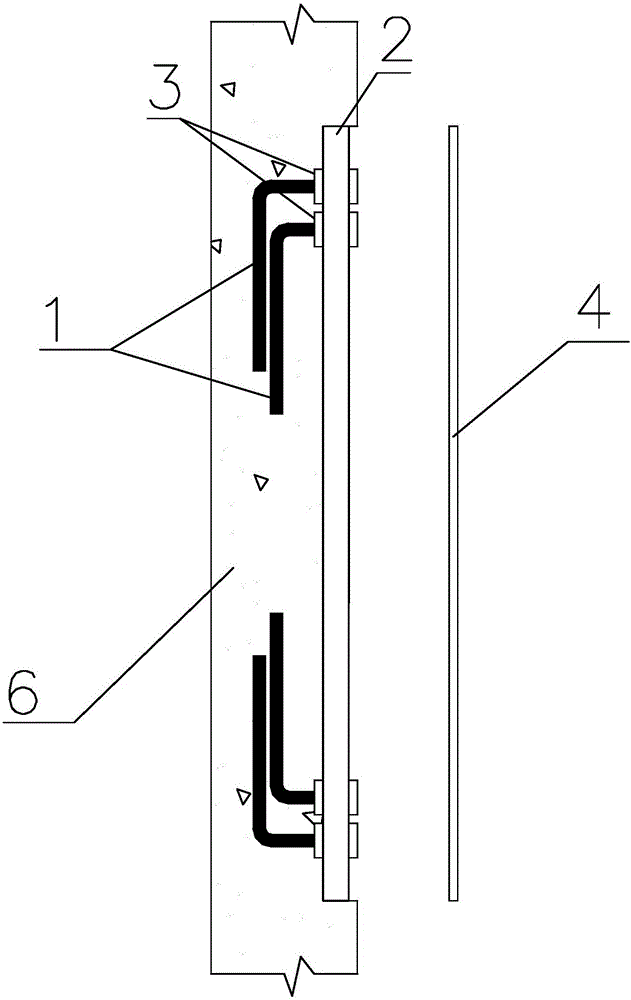

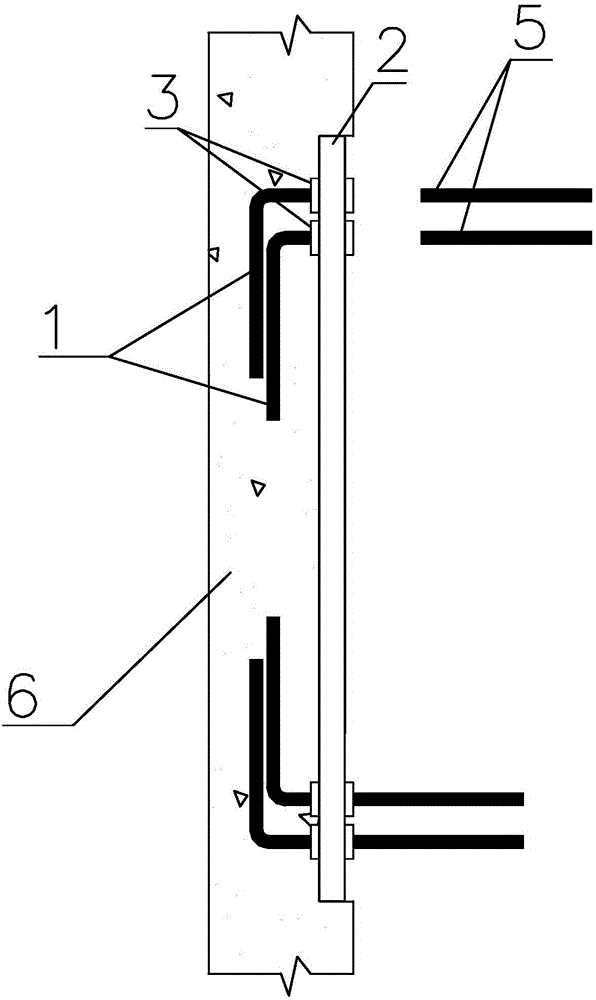

Connecting structure of waist beam and support pile and construction method of connecting structure

InactiveCN112281866AGuaranteed stabilityTroubleshooting the connectionExcavationsArchitectural engineeringRebar

The invention relates to a connecting structure of a waist beam and a support pile. The connecting structure comprises a pre-buried part, a protective sleeve and an additional rib, wherein the pre-buried part corresponds to the waist beam to be constructed, one end of the pre-buried part is buried in support piles, and the other end of the pre-buried part is exposed outwards and is flush with thesurface of the support piles; the protective sleeve is detachably arranged at the exposed end part of the pre-buried part in a sleeving manner; and the additional rib is matched with the pre-buried part and used for being fixedly connected with a beam steel rib of the waist beam to be constructed. The beam steel rib is fixedly connected with the pre-buried part by detaching the protective sleeve and fixedly connecting the additional rib with the pre-buried part, and therefore after the waist beam is formed through pouring, the waist beam is fixedly connected with the supporting piles. The problem that the waist beam and the supporting piles are difficult to connect is effectively solved, damage to pile bodies of the supporting piles is avoided, the overall stability of the supporting pilesis guaranteed, the connecting strength of the supporting piles and the waist beam is high, and the construction quality and the construction efficiency are improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Energy consumption support assembly type concrete framework structure splicing node and assembling method thereof

The invention relates to an energy consumption support assembly type concrete framework structure splicing node and an assembling method thereof. The splicing node comprises a beam end splicing unit embedded on a prefabricated concrete beam and a column end splicing unit embedded on a prefabricated concrete column, and also comprises a connecting component for connecting the beam end splicing unit and the column end splicing unit; the beam end splicing unit and the column end splicing unit are engaged and spliced. According to the method, firstly, the beam end splicing unit, the column end splicing unit, the prefabricated concrete column and the prefabricated concrete beam are prefabricated; then, the beam end splicing unit and the column end splicing unit are embedded in the designed positions; then, the position of the prefabricated concrete column is regulated, so that the beam end splicing unit and the column end splicing unit are engaged and spliced; the beam end splicing unit and the column end splicing unit are spliced to form a whole node support device. The splicing node and the assembling method have the advantages that the splicing performance is good; the connection is reliable; the structure is reasonable; the technical operation requirements are low; the site operation is convenient and fast; the work intensity is low.

Owner:HEFEI UNIV OF TECH

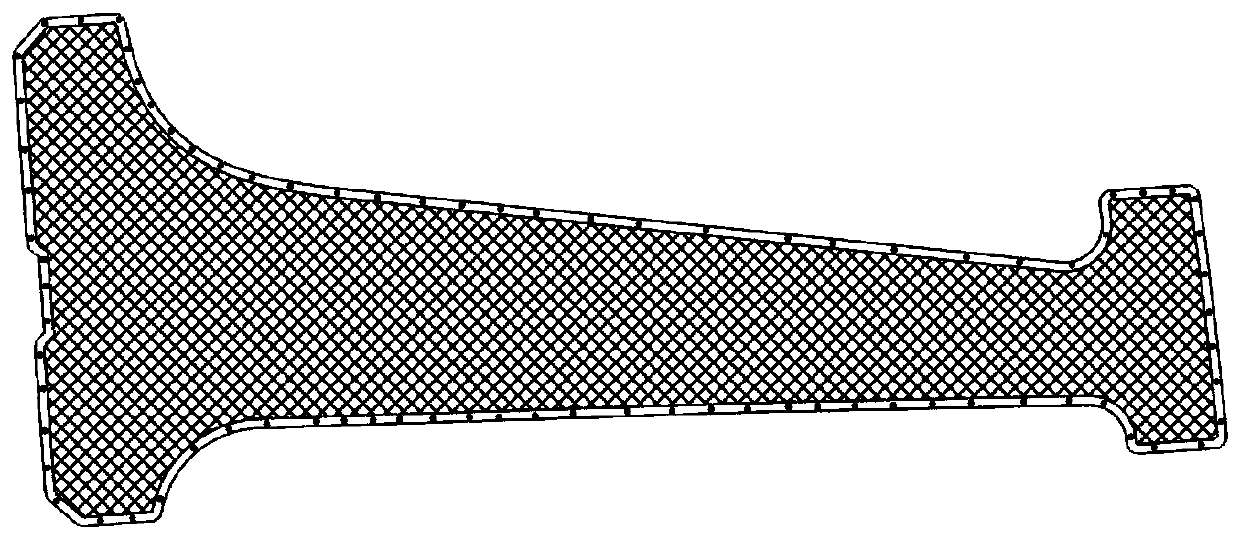

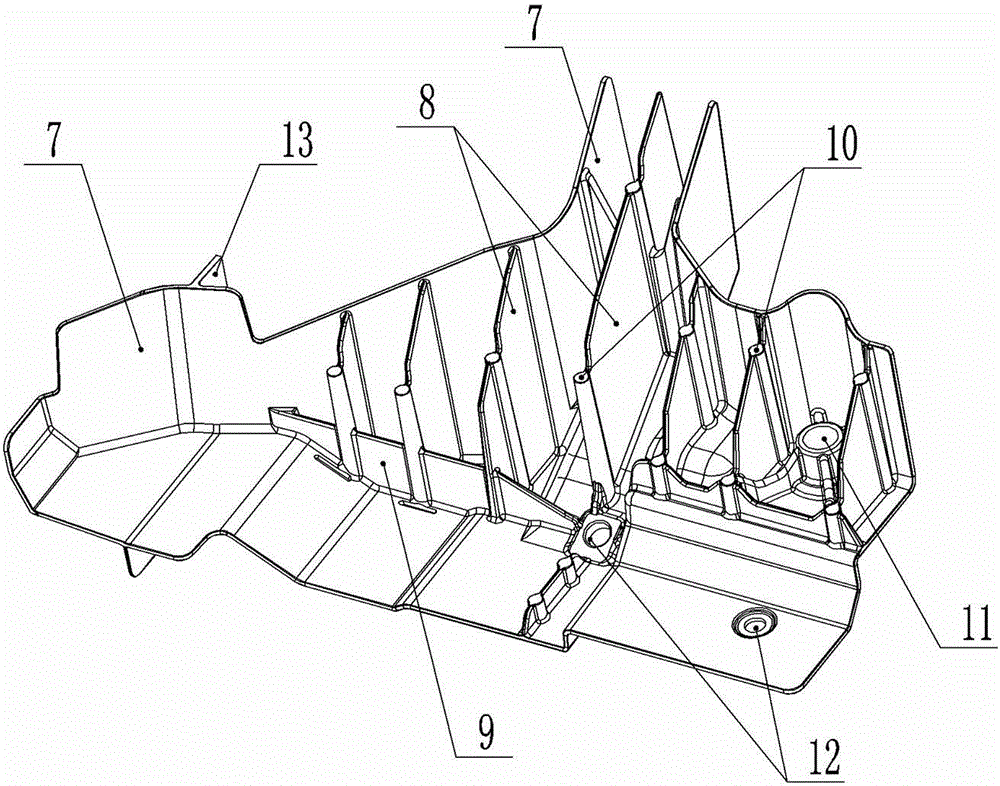

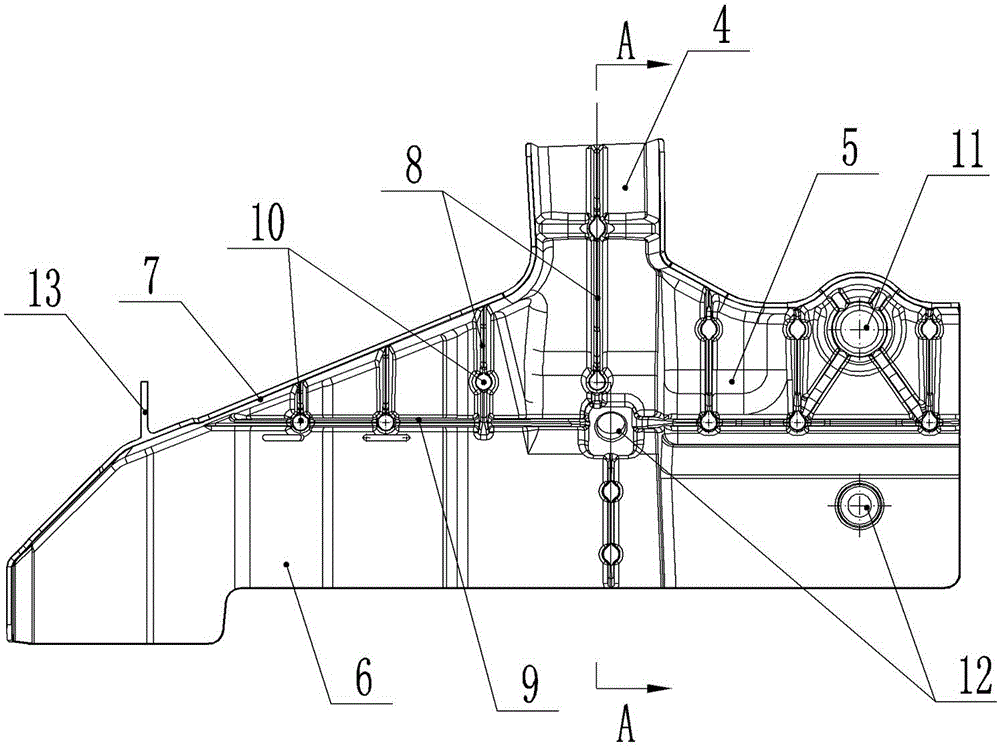

Front longitudinal beam back segment structure for electric automobile

ActiveCN104648476ATroubleshooting the connectionEasy to achieve lightweight designUnderstructuresCross connectionEnergy absorption

The invention relates to a pure electric automobile part, in particular to a front longitudinal beam back segment structure for an electric automobile. The front longitudinal beam back segment structure comprises a front fit connecting segment connected with a front longitudinal beam, a downward energy absorption middle segment positioned on the middle part, and a back fitting connecting segment connected with a doorsill longitudinal beam in sequence along an automobile body, wherein the whole front longitudinal beam back segment structure is flared with the front part being smaller and the back part being larger; both sides of the front longitudinal beam back segment structure are provided with upward flanges; a plurality of longitudinal reinforcing plates and at least one transverse reinforcing plate are arranged on the inner side of the downward energy absorption middle segment; reinforcing posts are arranged at intervals on the longitudinal reinforcing plates; the longitudinal reinforcing plates and the transverse reinforcing plate are connected crossly; reinforcing posts are arranged on the joints of intersections. By adopting the front longitudinal beam back segment structure, the problem of difficulty in connecting a front longitudinal beam sunken region with the doorsill longitudinal beam is solved, and all-aluminum light design of the longitudinal beams of an automobile body is realized conveniently.

Owner:ZHENGZHOU BIKE NEW ENERGY AUTOMOBILE

a rotary lock

ActiveCN106382279BEasy to scratchTroubleshooting the connectionSecuring devicesEngineeringServomotor

The invention discloses a rotary locking element. The rotary locking element is characterized by comprising a locking disc, U-shaped cylindrical steel and two bolts, wherein a location groove connected with a rotary body is arranged in the locking disc; a plurality of insertion-connection grooves are arranged around the location groove; the U-shaped cylindrical steel is formed through integrally moulding a parallel rod parallel to the locking disc and two vertical rods vertical to the locking disc; nuts of the bolts are connected to the U-shaped cylindrical steel; and the two vertical rods are inserted in the insertion-connection grooves of the locking disc. The locking disc is prevented from being liable to scrape with peripheral equipment during an action process with the rotary body through indirectly connecting the rotary locking disc with a servomotor body through the U-shaped cylindrical steel; and meanwhile, difficult connection between bolt holes in the locking disc and bolt holes of the servomotor body due to inconformity is avoided. The rotary locking element disclosed by the invention is simple in structure, convenient to operate, and suitable for industrialized production.

Owner:STATE GRID CORP OF CHINA +2

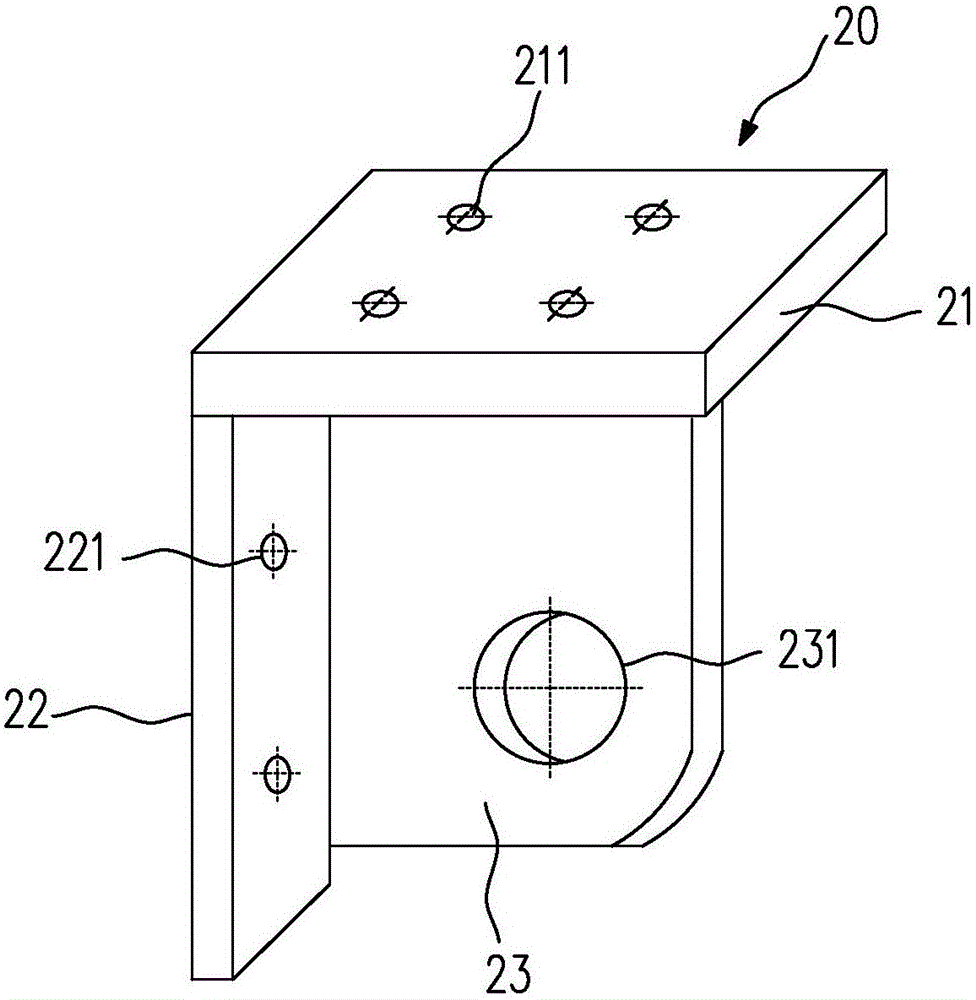

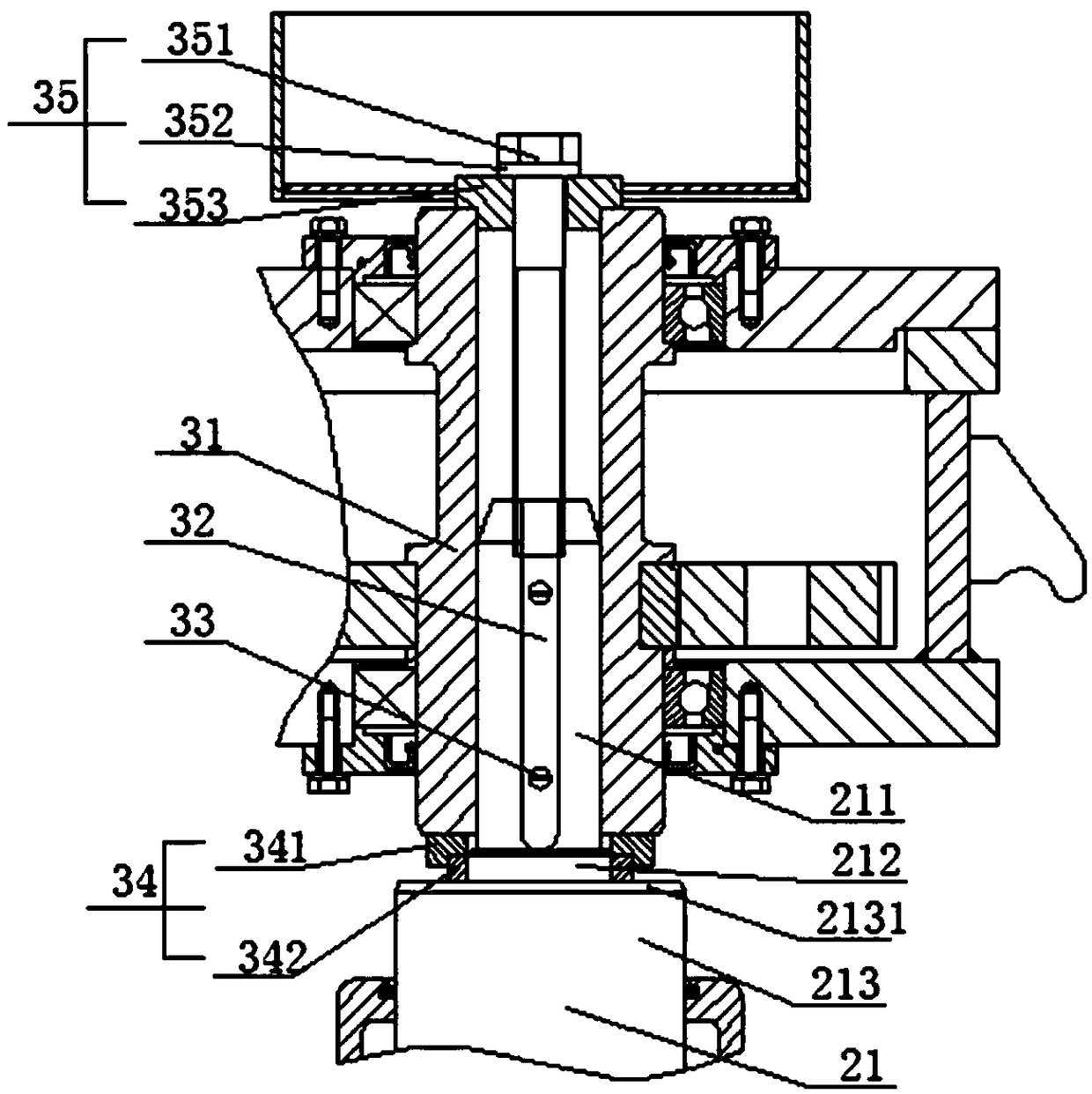

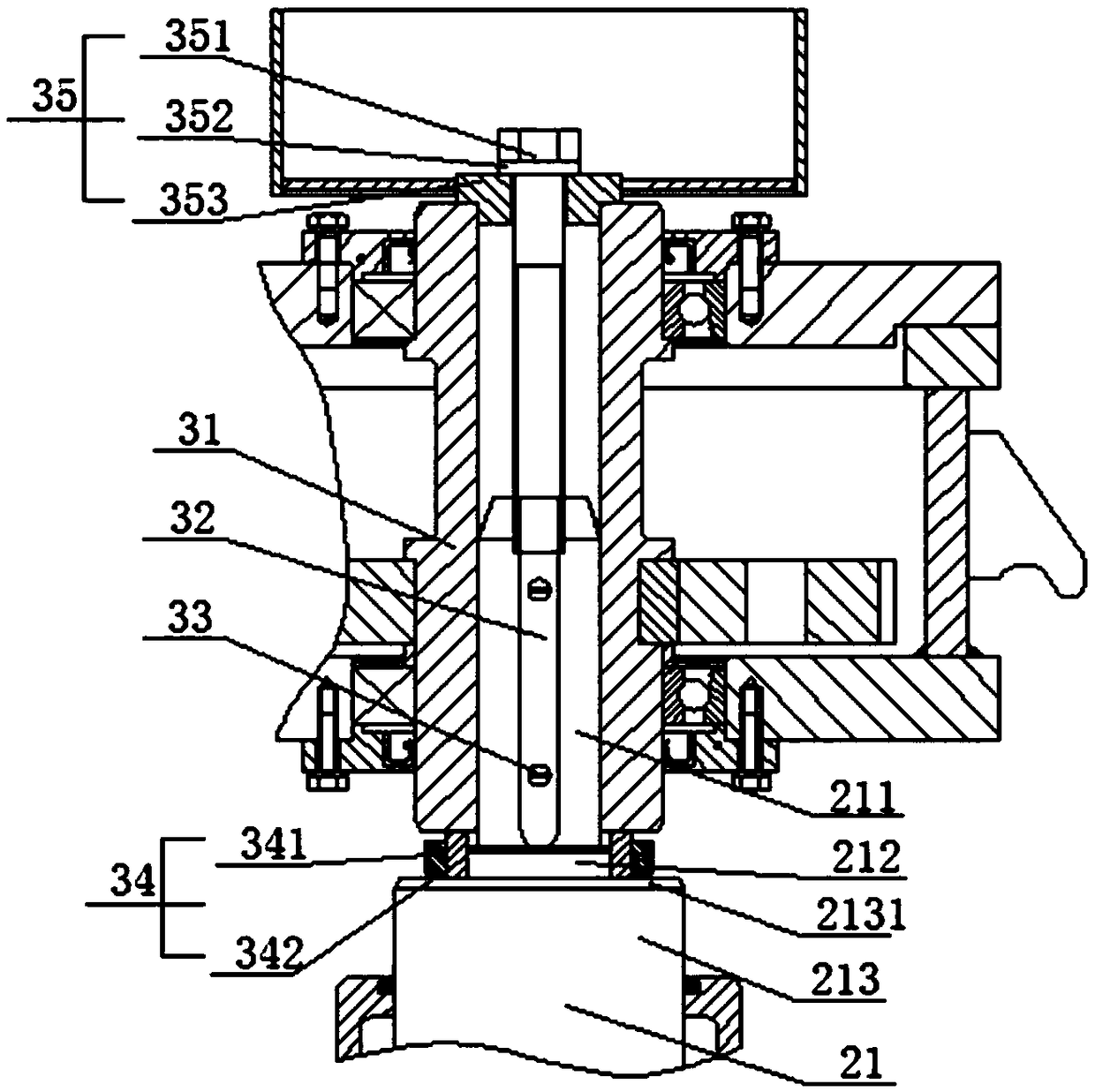

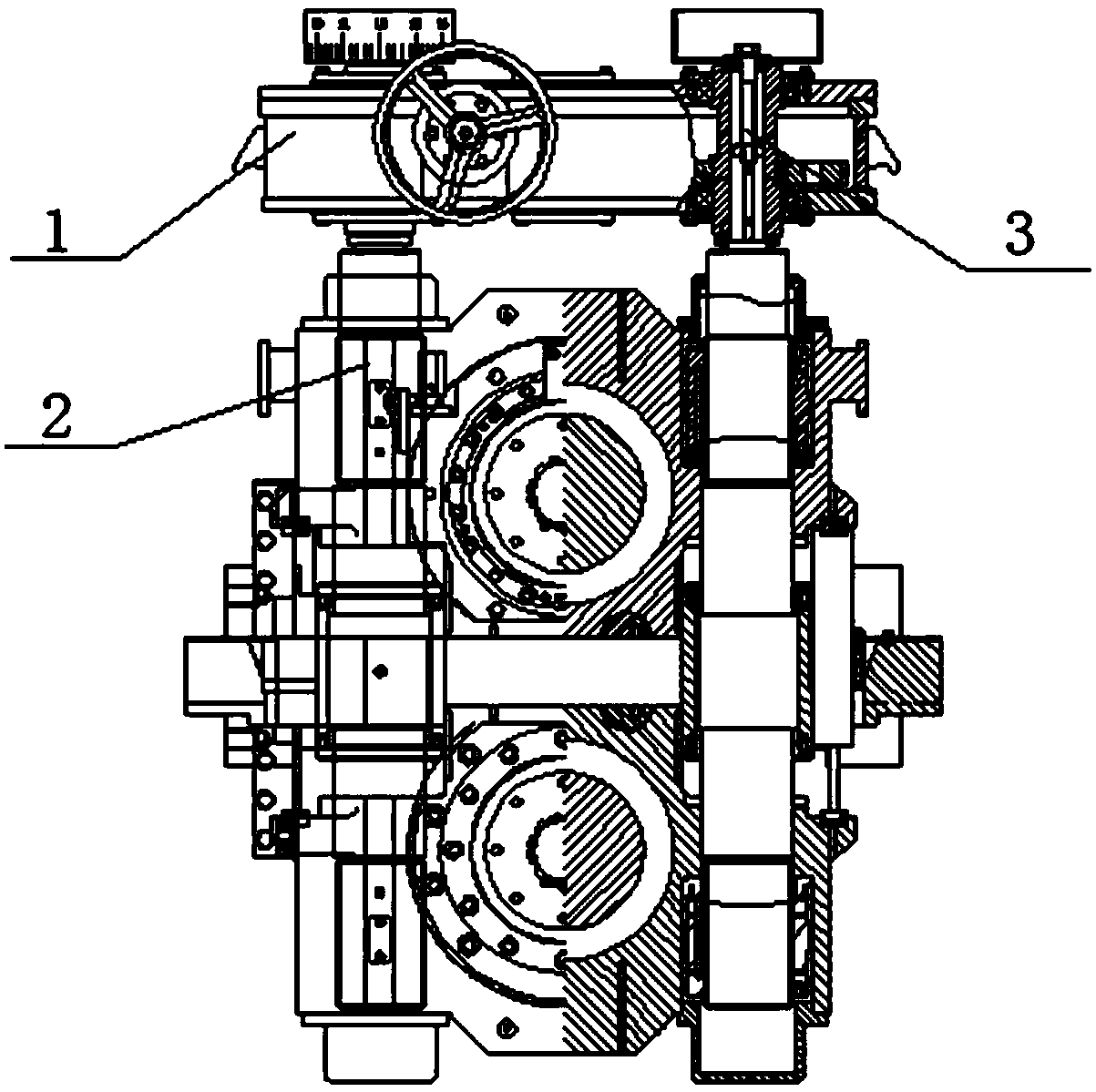

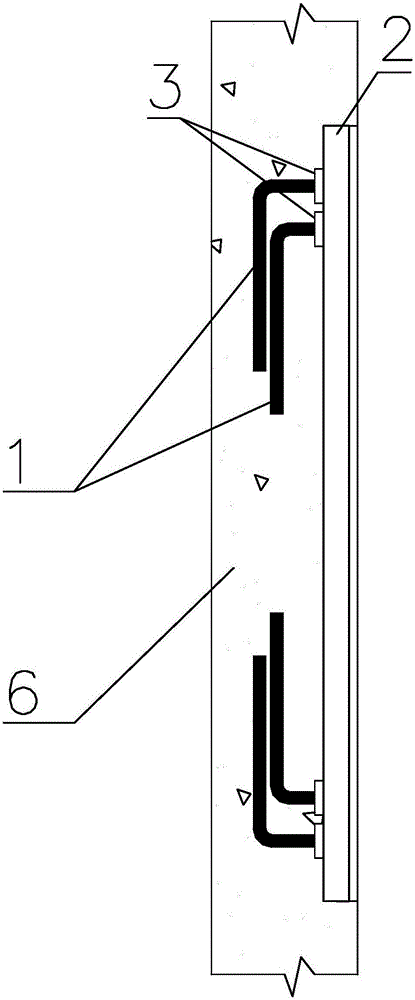

Pull rod connection structure in short-stress path rolling mill

PendingCN109013707AResolve connectionFirmly connectedMetal rolling stand detailsMetal rolling arrangementsStress pathEngineering

The invention provides a pull rod connection structure in a short-stress path rolling mill. The pull rod connection structure comprises a hollow shaft. A shaft head of a pull rod is located in the hollow shaft. The shaft head and the hollow shaft are connected through a key. Key grooves are formed in the surface of the shaft head and the inner wall of the hollow shaft correspondingly. The shaft islocated in the key grooves. The upper end of the shaft head is detachably connected in the hollow shaft through a connection component. A regulation component is installed between the lower end faceof the hollow shaft and a shaft body of the pull rod. The regulation component can be used for adjusting the distance between the lower end face of the hollow shaft and the end face of a shaft shoulder of the shaft body. The problem of the connection difficulty caused by installation and machining deviation can be well solved.

Owner:中重科技(天津)股份有限公司

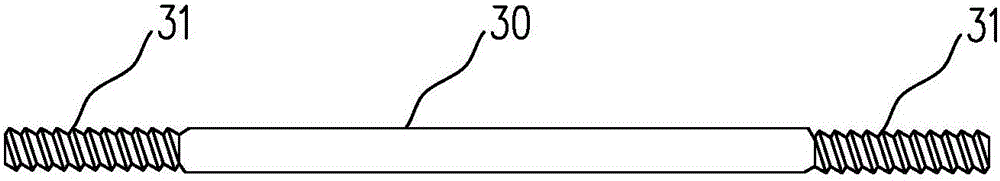

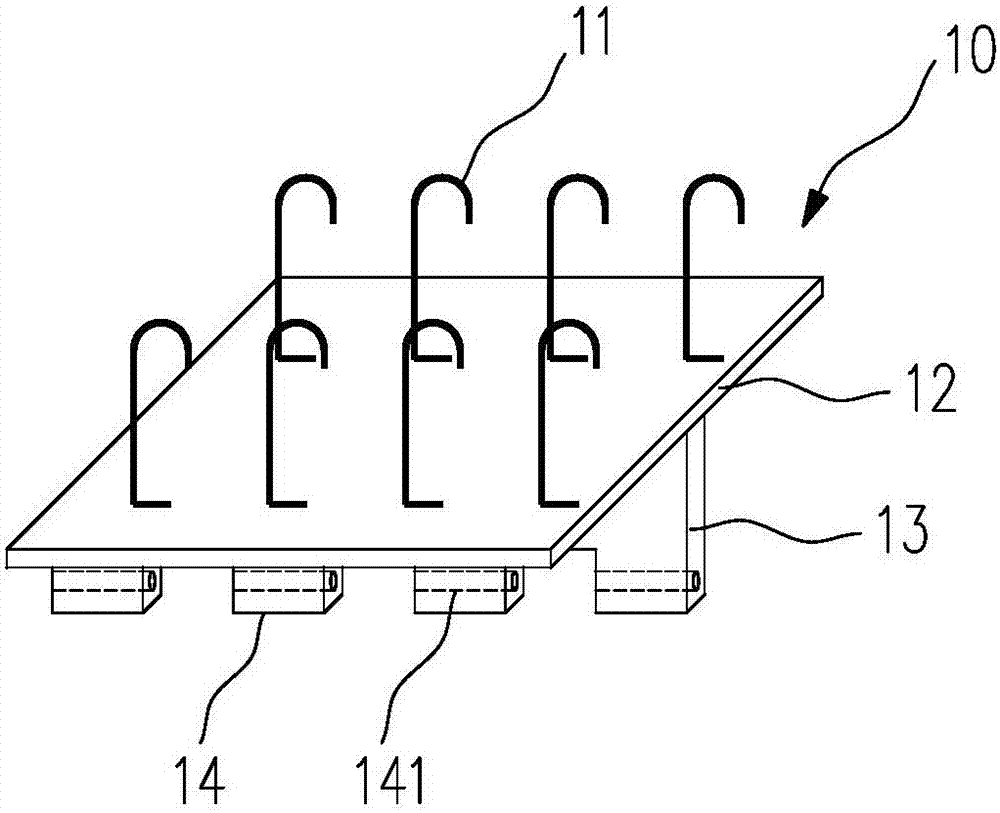

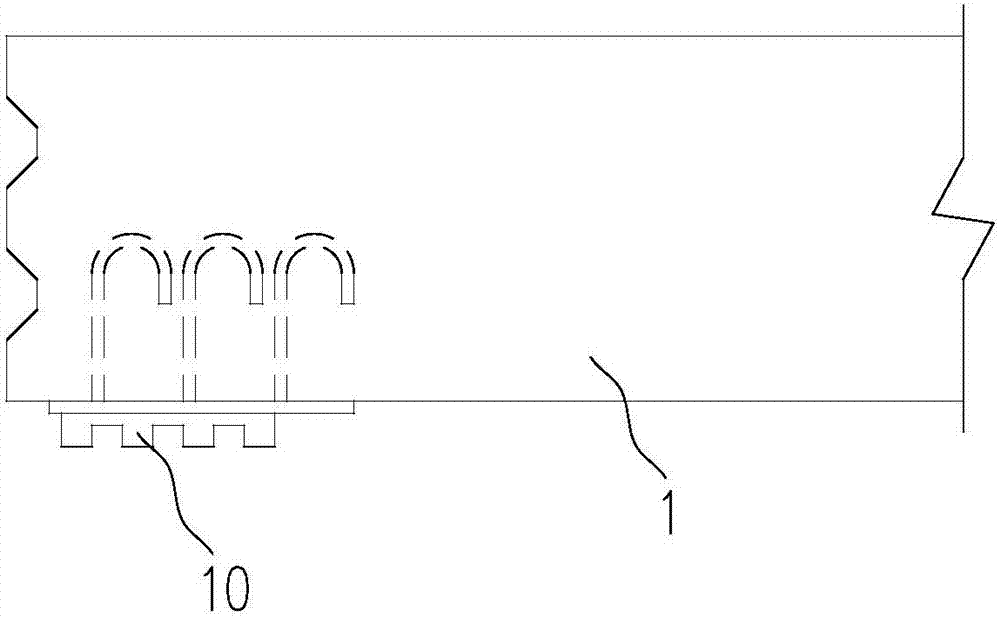

Embedded steel bar connecting piece and construction method thereof

PendingCN105672580AGuaranteed reliabilityDoes not affect flatnessBuilding reinforcementsContinuous beamRebar

The invention discloses an embedded steel bar connecting piece which is capable of ensuring reliability of section pouring of continuous beams and plates, convenient to construct, simple in structure and good in construction effect and a construction method of the embedded steel bar concrete layer is poured at one ends of the embedded screws, and an auxiliary fixing device is connected to the other ends of the embedded screws. A post screw is connected to one end of each embedded screw. The embedded steel bar connecting piece is composed of the embedded screws, the auxiliary fixing device and the post screws. By means of the design, the difficulty on steel bar connection of concrete beams and plates which need to be poured in a section mode is successfully overcome. Thus, a concrete structure poured in a section mode can be normally constructed, and the reliability of steel bar connection of beams and plates is ensured while the surface evenness of concrete is not influenced.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Energy-dissipating braced assembled concrete frame structure splicing joints and its assembly method

ActiveCN105821960BFast constructionReduce labor intensityShock proofingConcrete beamsUltimate tensile strength

The invention relates to an energy consumption support assembly type concrete framework structure splicing node and an assembling method thereof. The splicing node comprises a beam end splicing unit embedded on a prefabricated concrete beam and a column end splicing unit embedded on a prefabricated concrete column, and also comprises a connecting component for connecting the beam end splicing unit and the column end splicing unit; the beam end splicing unit and the column end splicing unit are engaged and spliced. According to the method, firstly, the beam end splicing unit, the column end splicing unit, the prefabricated concrete column and the prefabricated concrete beam are prefabricated; then, the beam end splicing unit and the column end splicing unit are embedded in the designed positions; then, the position of the prefabricated concrete column is regulated, so that the beam end splicing unit and the column end splicing unit are engaged and spliced; the beam end splicing unit and the column end splicing unit are spliced to form a whole node support device. The splicing node and the assembling method have the advantages that the splicing performance is good; the connection is reliable; the structure is reasonable; the technical operation requirements are low; the site operation is convenient and fast; the work intensity is low.

Owner:HEFEI UNIV OF TECH

Low permeability coal seam gas pre-drainage method though intensive drilling holes and pipe pressure-up

InactiveCN103046946BSolve the problem of small effective extraction radiusAchieve large-scale anti-reflectionGas removalEngineeringCoal

The invention discloses a low permeability coal seam gas pre-drainage method though intensive drilling holes and pipe pressure-up. The method includes the following steps: a plurality of through drilling holes are arranged on a pre-drainage coal seam; a first drainage pipe is laid on one side of an air inlet roadway close to the pre-drainage coal seam, and one ends of the plurality of through drilling holes are connected with the first drainage pipe; a second drainage pipe is laid on one side of an air return roadway close to the pre-drainage coal seam, the other ends of the plurality of through drilling holes are connected with the second drainage pipe so as to enable the plurality of through drilling holes to be communicated with the first drainage pipe and the second drainage pipe respectively to form a gas pre-drainage system, and a first negative pressure boosting pipe system is laid in the air inlet roadway and communicated with the first drainage pipe so as to boost negative pressure of the first drainage pipe; and a second negative pressure boosting pipe system is laid in the air return roadway and communicated with the second drainage pipe so as to boot negative pressure of the second drainage pipe.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

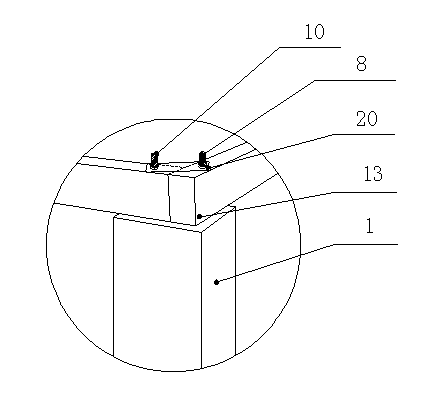

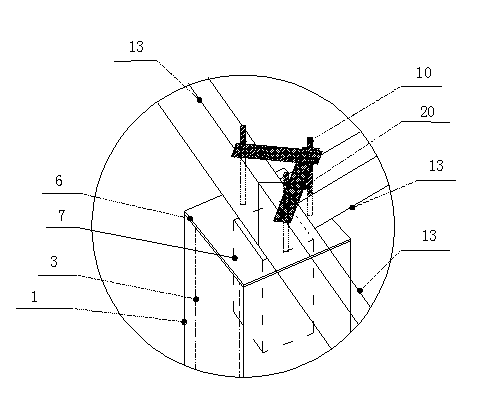

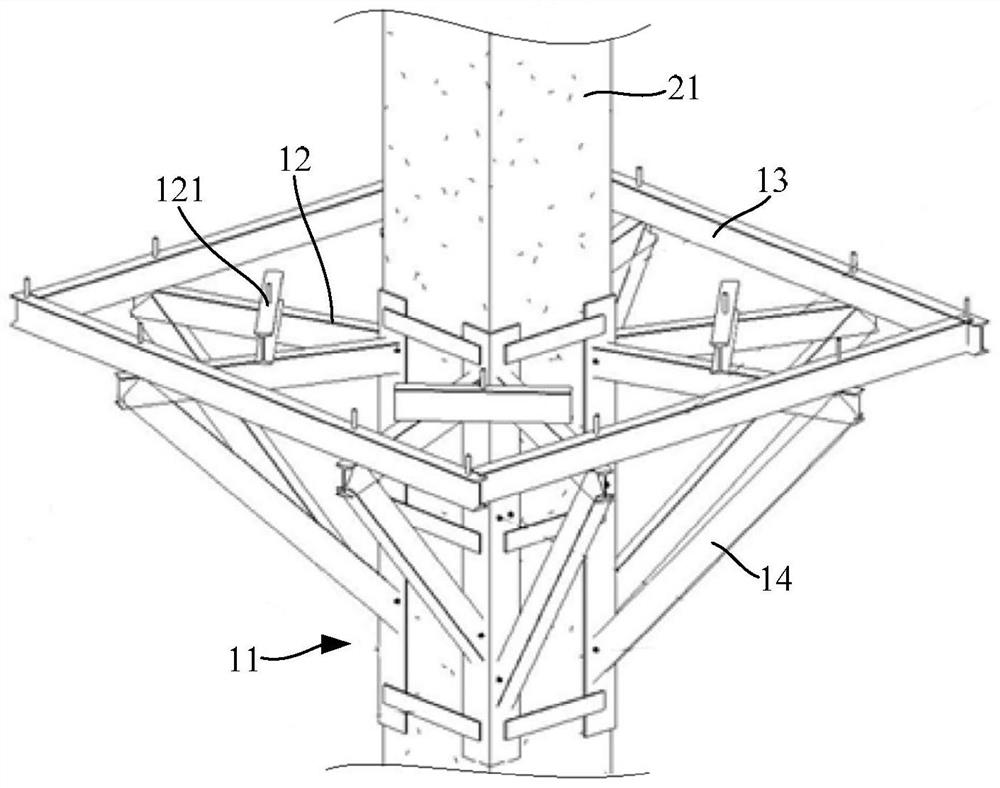

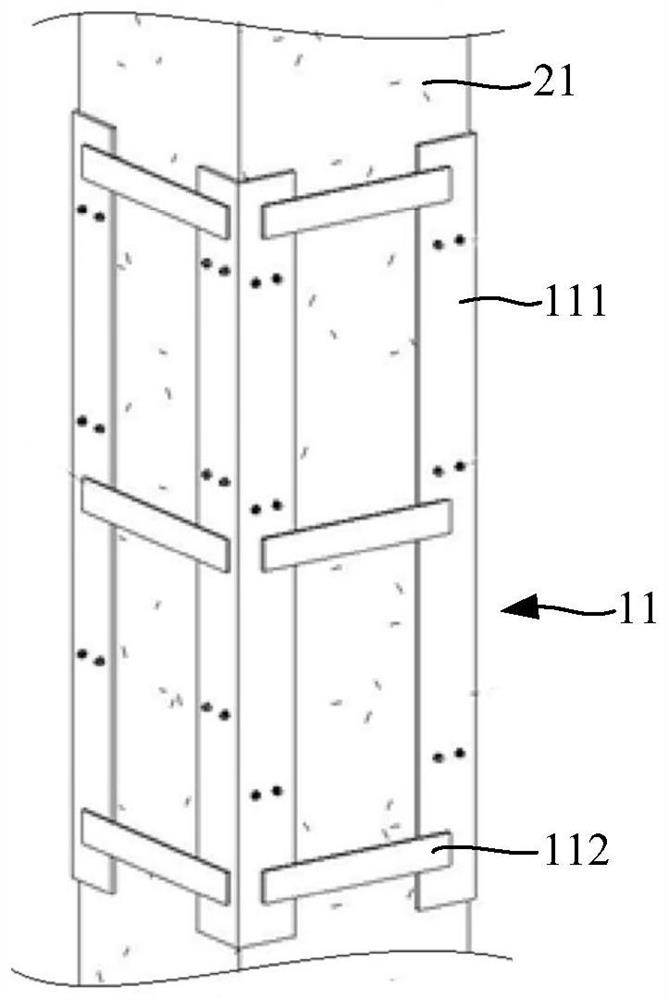

Connecting structure of handling frame and stand column and construction method of connecting structure

PendingCN113653309AEasy to installImprove stabilityScaffold accessoriesBuilding support scaffoldsStructural engineeringMechanical engineering

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A chamber structure of a reaction chamber for a solar cell dry texturing process

ActiveCN104934505BReduce processing difficultyReduce delivery costsFinal product manufactureSemiconductor devicesHigh energySolar cell

The invention relates to the solar cell manufacturing equipment, plasma etching, and vacuum reaction chamber technology fields and especially relates to a cavity structure of a reaction chamber used in a solar cell dry method texturing technology. A cavity main body is formed through assembling and welding a plurality of stainless steel sheet materials. Surfaces of the stainless steel sheet materials are sprayed and plated with a teflon coating. A teflon coating surface is inlaid with a detachable aluminum alloy liner armor plate. The teflon coating is a PTFE, PFA or FEP material. Sand blasting is performed on the stainless steel sheet material surfaces. The aluminum alloy liner armor plate is an aluminum plate or an aluminum liner armor plate whose surface is processed through deep anodic oxidation. By using the cavity structure of the invention, processing difficulty is decreased and commissioning cost is reduced; deformation is small under vacuum pressure of a large-scale cavity; dismounting is convenient and a problem that connections between the reaction chamber and a gate valve, and the reaction chamber and other cavities are difficult is effectively solved; the aluminum alloy liner armor plate possesses chemical corrosion resistance performance; bombardment of high-energy particles to the coating can be effectively blocked and there is no metal ion pollution to a silicon wafer.

Owner:CHANGZHOU BITAI TECH

A special mold and production process for concrete electric poles with convenient construction

The invention relates to the technical field of concrete electric poles, and discloses a special die for a concrete electric pole convenient to construct and a production process. The die comprises anupper pole steel die and a lower pole steel die, wherein the upper pole steel die comprises an upper pole concave cavity and an upper pole protruding column, and the lower pole steel die comprises alower pole concave cavity and a lower pole protruding column. The production process comprises the following steps of: producing an upper pole through the upper pole steel die by using an upper pole production line, producing a lower pole with a hollow inner cavity through the lower pole steel die by using a lower pole production line, and placing the upper pole into the hollow inner cavity of thelower pole by utilizing an assembling production line to obtain a finished electric pole product. The special die can be used to reliably, conveniently and efficiently produce the concrete electric pole with the advantages of being flexible in height adjustment, convenient to construct and maintain and high in structural strength and saving transportation space.

Owner:安徽联众电力科技有限公司

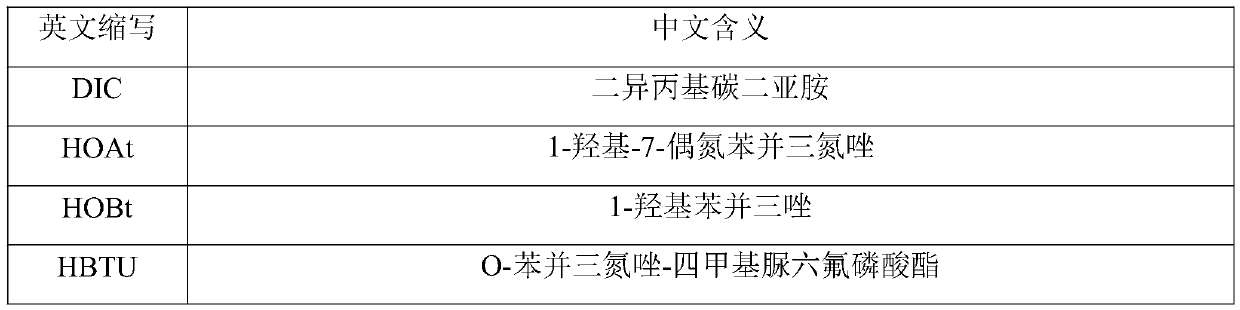

Preparation method of glucagon

PendingCN111018963ATroubleshooting the connectionExtended reaction timePeptide preparation methodsBulk chemical productionPancreatic glucagonTetrapeptide

The invention relates to a preparation method for glucagon by a solid-phase fragment method. The method comprises the following steps: connecting 5-29 fragments one by one by utilizing a solid-phase synthesis method according to a sequence; and then connecting the tetrapeptide fragment Fmoc-His(Trt)-Ser(tBu)-Gln(Trt)-Gly-OH to 5-29 fragment peptide resin, carrying out acidolysis to remove a protecting group and cut peptide to obtain a glucagon crude product, and carrying out purification and freeze-drying to obtain a glucagon pure product. The method has the advantages of easiness in synthesis, low impurity content and cost saving.

Owner:CHINESE PEPTIDE CO

Graphene wire and cable connecting device

InactiveCN104201482AHigh strengthLight in massElectric connection structural associationsClamped/spring connectionsEngineeringStructural engineering

A graphene wire and cable connecting device comprises a graphene wire and cable connector, graphene wire and cable jacks, a locking device, a reinforcing and fixing bolt, and a protective insulating layer. The body of the graphene wire and cable connecting device is the graphene wire and cable connector, two ends of the connector are provided with the graphene wire and cable jacks, the graphene wire and cable jacks are connected with the locking device, and graphene wires and cables pass through the jacks and are fixed on the locking device so that two branches of graphene wires and cables are tightly and firmly connected. Under an external force of the graphene wires and cables, the locking device further fastens to lower contract specific resistance and improve connection reliability. The reinforcing and fixing bolt is arranged on an outer side of the locking device in order to enable the locking device to further fasten and strengthen, and the protective insulating layer is arranged outside the whole graphene wire and cable connecting device.

Owner:魏颖

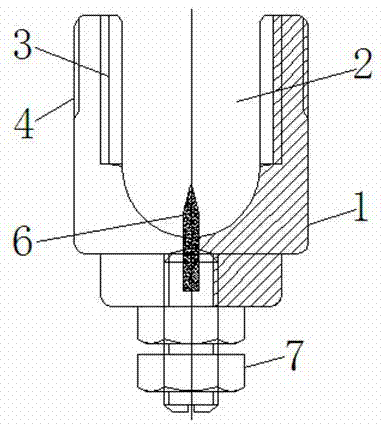

Lightning protection device connecting piece used in overhead insulated wires

PendingCN107240789AFirmly connectedEasy to installContact members penetrating/cutting insulation/cable strandsMultiple conductors connectorEngineeringScrew thread

The invention relates to a lightning protection device connector for overhead insulated wires. An external thread is provided on the outer side of the upper part of the seat, a screw is provided at the lower part of the clamping seat, a steel nail is provided on the upper end of the screw rod, a nut is provided on the screw rod, and the upper end of the steel nail is arranged in the installation groove. Bolts are provided on the internal thread of the installation groove, and round nuts are provided on the external thread of the clamping seat. The invention is convenient for installation and connection, and the crimping is firm.

Owner:JIANGSU AONENG ELECTRICITY CABLE ACCESSORIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com