Carbon fiber composite structural member with multilayer structure, and preparation method thereof

A multi-layer structure and composite structure technology, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of difficult connection, low bonding force, difficult aluminum alloy, etc., to avoid oxidation problems and avoid thermal oxidation. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

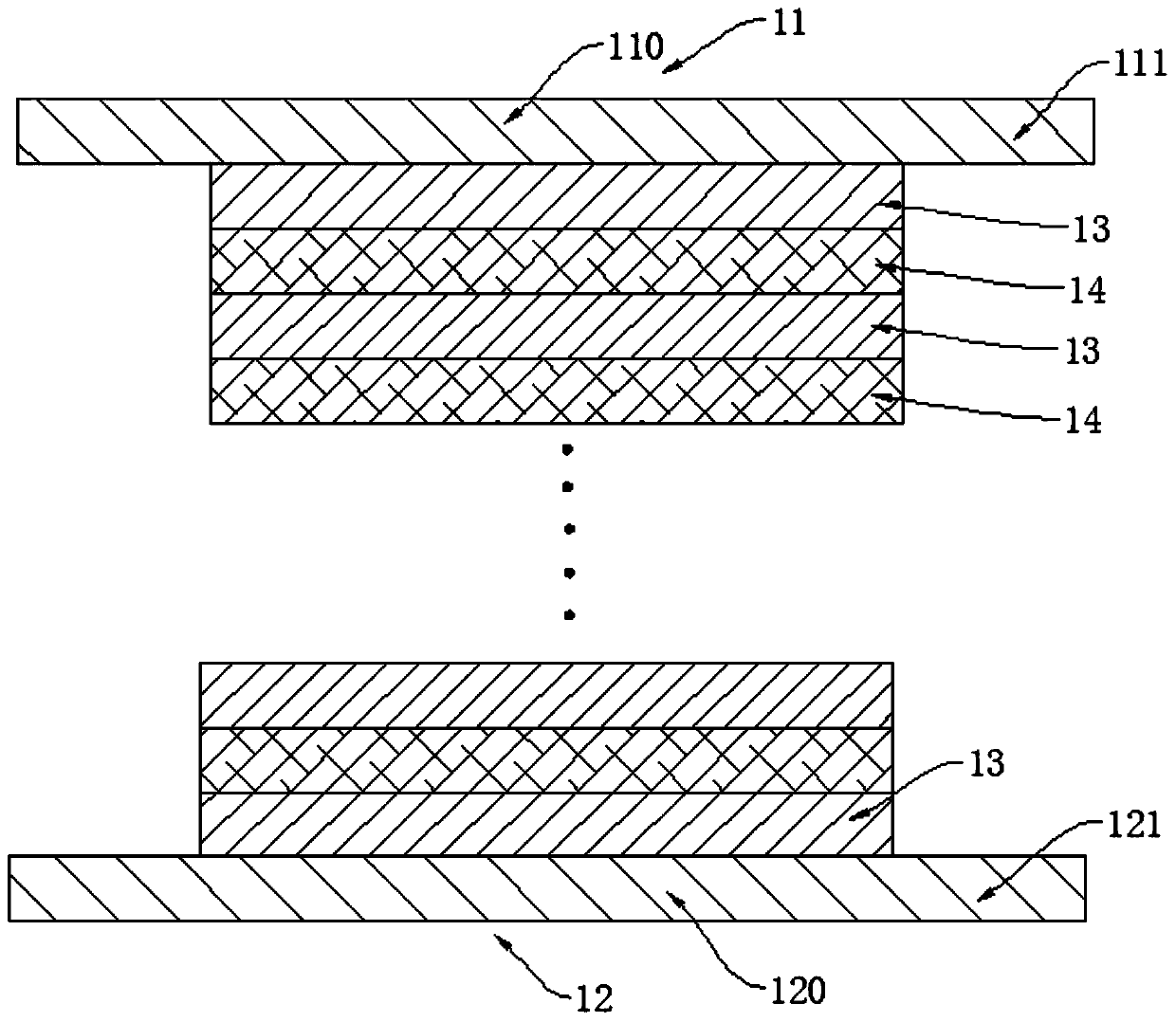

[0064] The present invention also includes a preparation method for preparing the above-mentioned carbon fiber composite structure with a multi-layer structure. The preparation method comprises the following steps:

[0065] Blanking the first metal layer 11, the second metal layer 12, the alloy layer 13 and the carbon fiber layer 14 respectively;

[0066] Arranging the first metal layer 11, the second metal layer 12, the alloy layer 13 and the carbon fiber layer 14 into a multi-layer structure as described above;

[0067] fixedly connecting the first extension part 111 and the second extension part 121, so that the multi-layer structure forms a connecting piece;

[0068] Stamping and then heating the connecting piece, or heating and then stamping, so that the connecting piece is formed into a formed part;

[0069] Cool the molded parts under pressure;

[0070] Trimming and punching are carried out on the formed part after pressure holding and cooling, so as to finally obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com