Pull rod connection structure in short-stress path rolling mill

A technology of short stress line and connection structure, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve problems such as connection difficulties, and achieve the effect of solving connection difficulties, saving time, and reliable and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

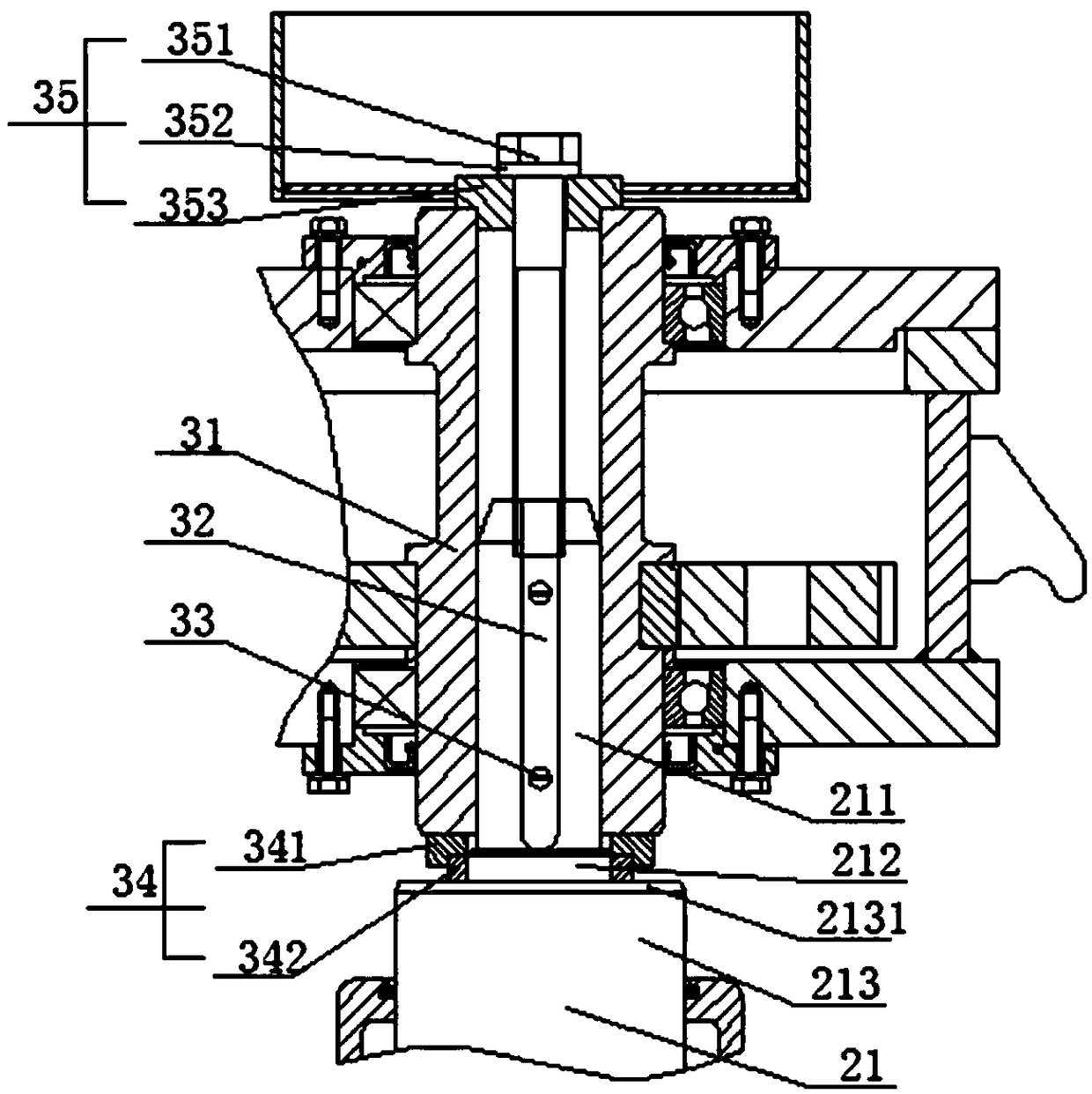

[0026] like figure 1 As shown, a tie rod connection structure 3 in a short stress line rolling mill includes a hollow shaft 31, the shaft head 211 of the tie rod 21 is located in the hollow shaft 31, and the shaft head 211 and the hollow shaft 31 are connected by a key 32, and the shaft head 211 The surface and the inner wall of the hollow shaft 31 are respectively provided with a keyway, and the key 32 is located in the keyway; the upper end of the shaft head 211 is detachably connected in the hollow shaft 31 through a connecting member 35, and the lower end surface of the hollow shaft 31 and the shaft body 213 of the pull rod 21 An adjustment member 34 is installed therebetween, and the adjustment member 34 can be used to adjust the distance between the lower end surface of the hollow shaft 31 and the end surface of the shaft shoulder 2131 of the shaft body 213 . At the same time, the key 32 is fixed in the keyway provided on the shaft head 211 with a screw 33, so that the k...

Embodiment 2

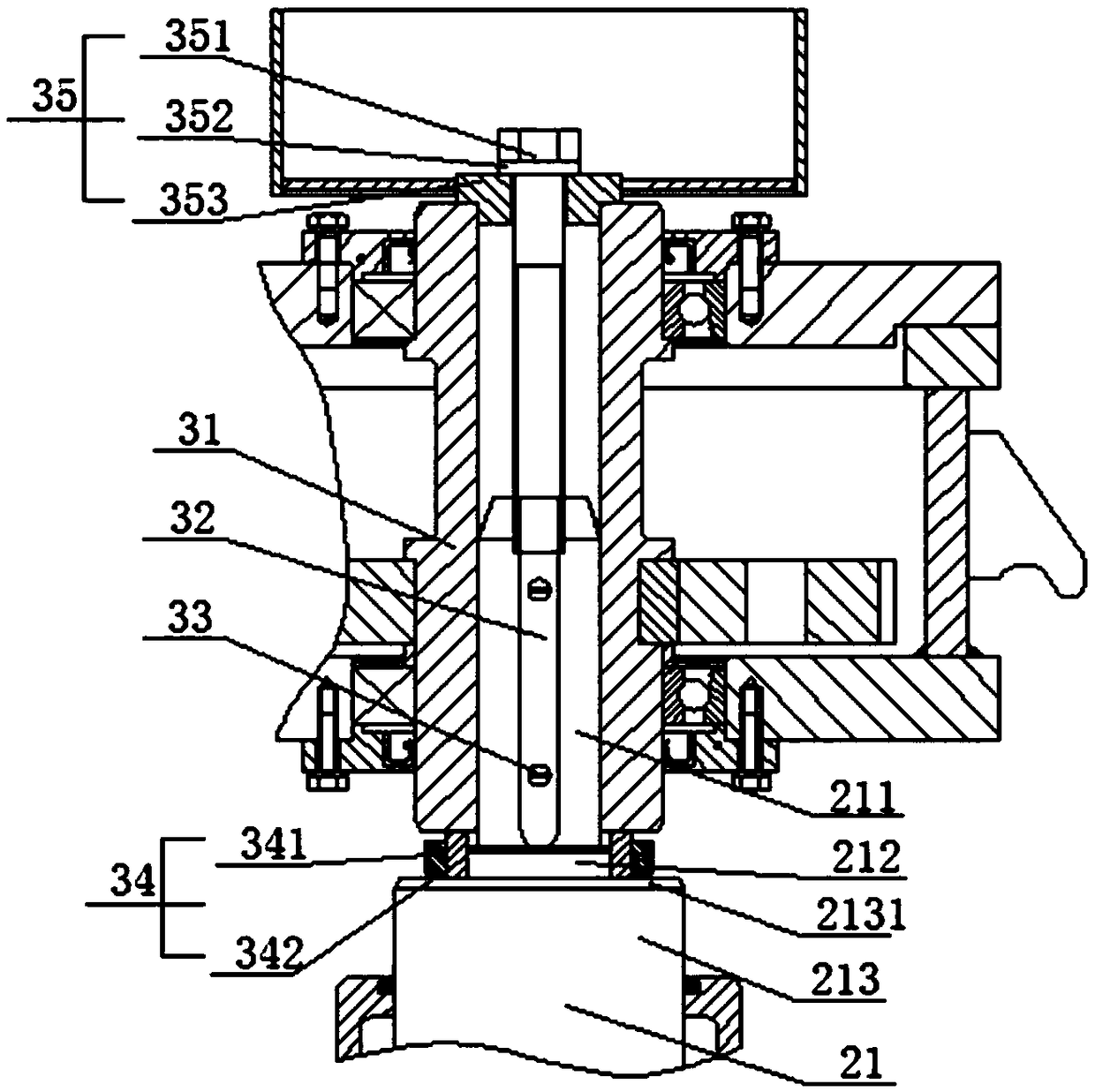

[0031] like figure 2 As shown, a tie rod connection structure 3 in a short stress line rolling mill includes a hollow shaft 31, the shaft head 211 of the tie rod 21 is located in the hollow shaft 31, and the shaft head 211 and the hollow shaft 31 are connected by a key 32, and the shaft head 211 The surface and the inner wall of the hollow shaft 31 are respectively provided with a keyway, and the key 32 is located in the keyway; the upper end of the shaft head 211 is detachably connected in the hollow shaft 31 through a connecting member 35, and the lower end surface of the hollow shaft 31 and the shaft body 213 of the pull rod 21 An adjustment member 34 is installed therebetween, and the adjustment member 34 can be used to adjust the distance between the lower end surface of the hollow shaft 31 and the end surface of the shaft shoulder 2131 of the shaft body 213 . At the same time, the key 32 is fixed in the keyway provided on the shaft head 211 with a screw 33, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com