Low permeability coal seam gas pre-drainage method though intensive drilling holes and pipe pressure-up

A coal seam gas and pre-drainage technology, which is applied in the field of coal mine gas extraction, can solve the problems of short pre-drainage time, increased gas extraction volume, poor coal seam permeability, etc., so as to alleviate the large amount of drilling works and increase gas extraction. volume, improve the effect of negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

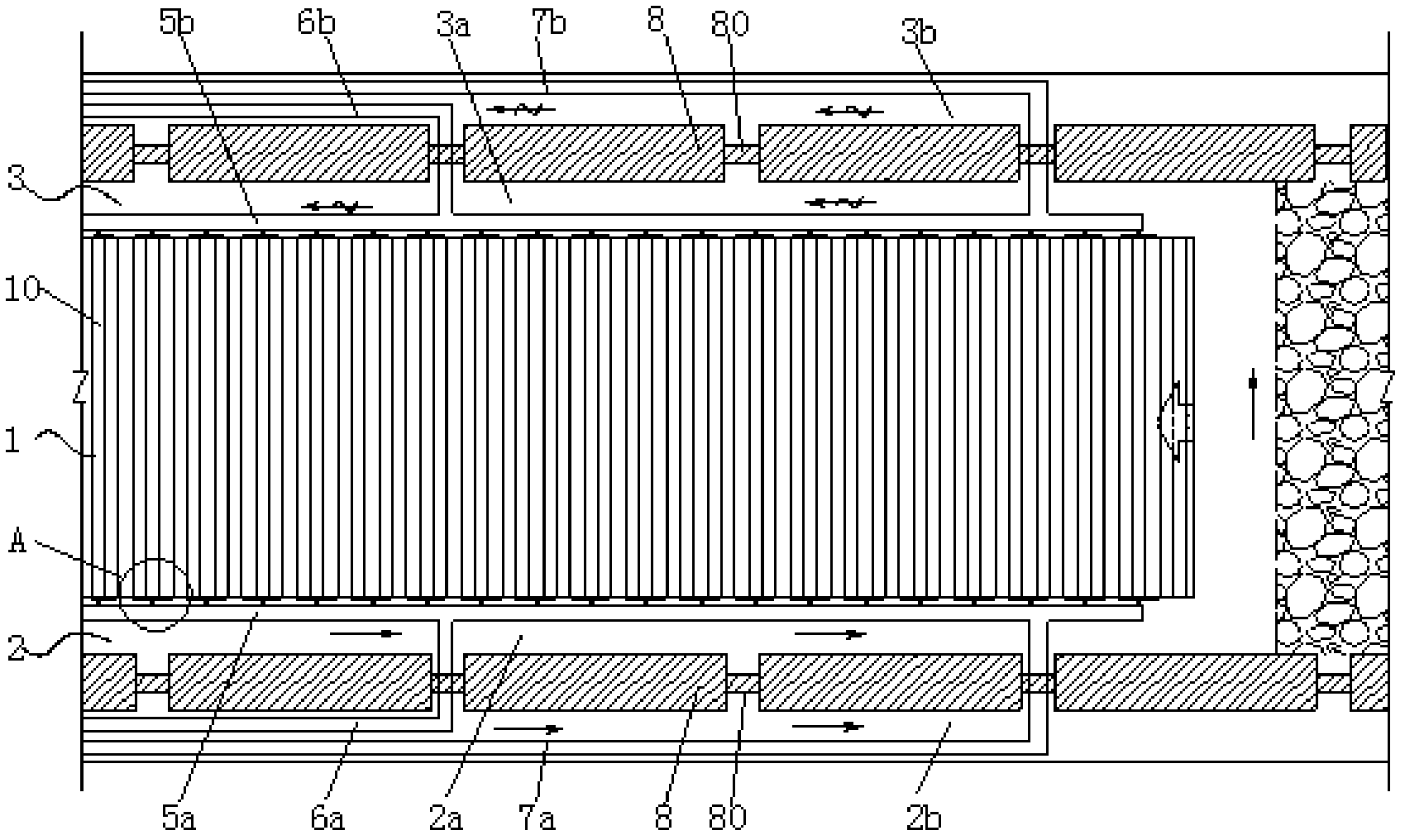

[0025] Such as figure 1 As shown in the structural diagram of the method for pre-pumping low-permeability coal seam gas by densely penetrating through boreholes and pipes to raise pressure in the present invention, the method for pre-pumping low-permeability coal seam gas by densely penetrating boreholes and pipes to raise pressure in the present invention includes the following steps:

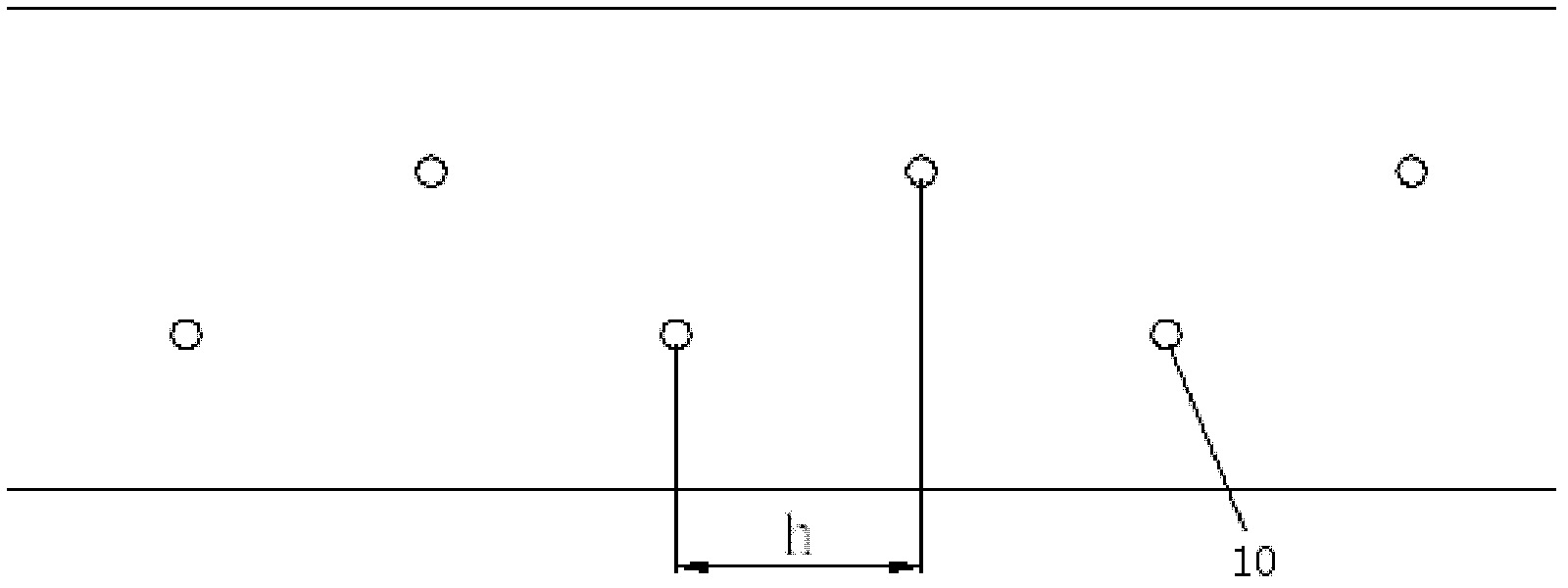

[0026] A plurality of through boreholes 10 are arranged on the pre-pumped coal seam 1, the through boreholes 10 penetrate from one side of the pre-pumped coal seam 1 to the other side, and the through boreholes 10 cover the entire mining area;

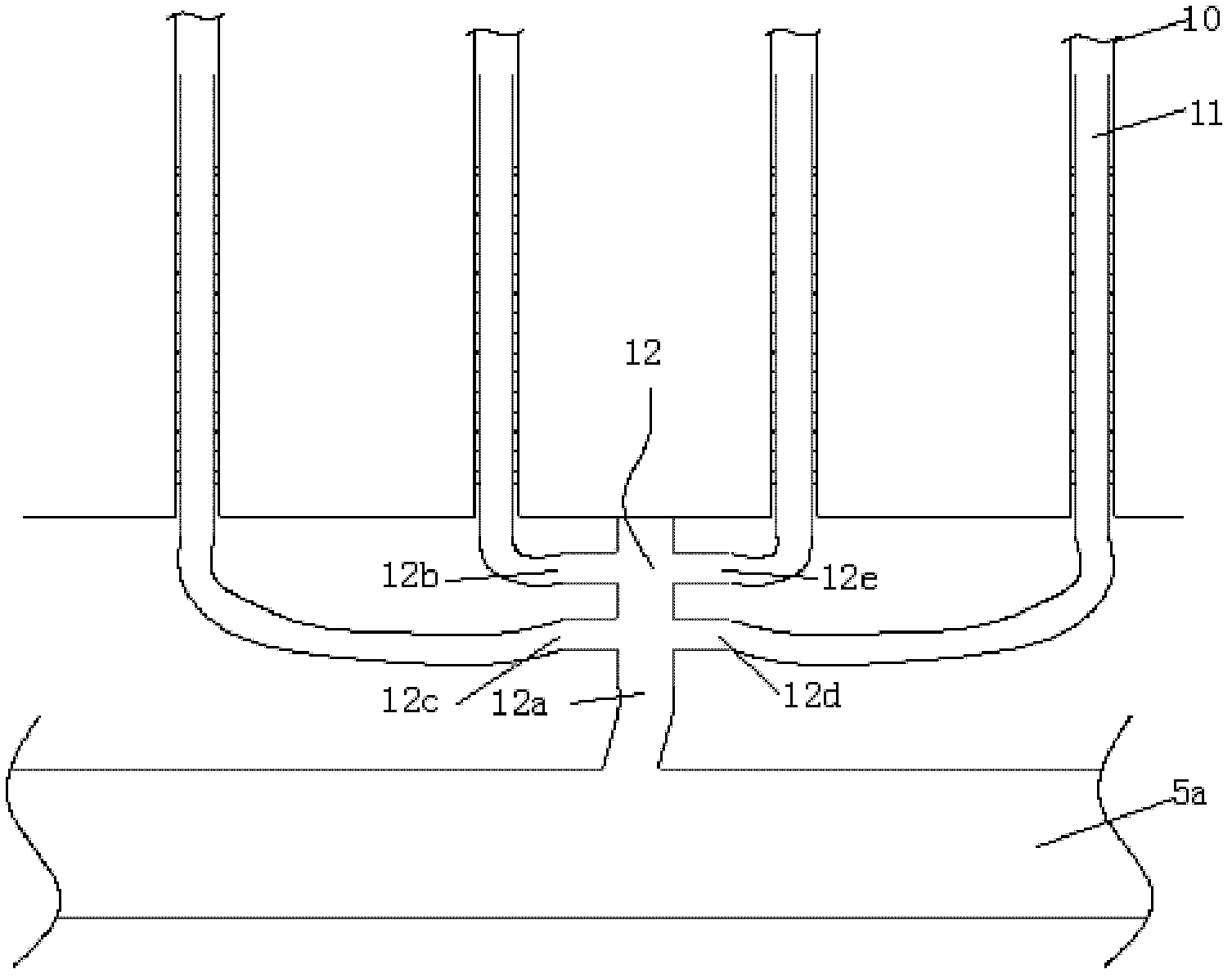

[0027] Lay the first extraction pipeline 5a on the side of the air inlet chute 2 close to the pre-drainage coal seam 1, and connect one end of a plurality of through boreholes 10 with the first extraction pipeline 5a;

[0028] The second extraction pipeline 5b is laid on the side of the return air channel 3 near the pre-extracted coal seam 1, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com