Cavity structure of reaction chamber used in solar cell dry method texturing technology

A solar cell and dry texturing technology, which is applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the difficulty of connecting reaction chambers with gate valves and other chambers, the difficulty of processing large reaction chambers, and the overall size of equipment Increase and other problems to achieve the effect of convenient disassembly and assembly, reduced processing difficulty, and reduced delivery costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

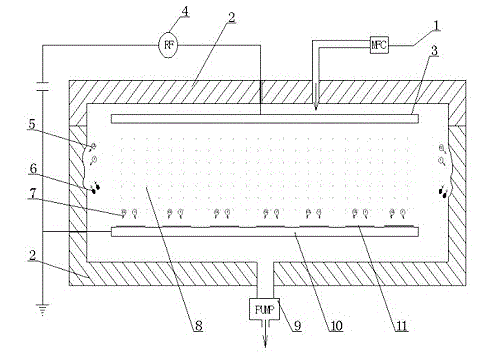

[0021] Such as figure 1 Shown is a schematic diagram of plasma etching (RIE) process reaction chamber corrosion. 1. Indicates the entrance of process chemical gas; 2. It is the process reaction chamber; 3. It is the upper parallel electrode plate; 4. It is RF radio frequency power supply; 6. Indicates the precipitation and pollution of metal ions due to the corrosion of the cavity; 7. Indicates the etching of silicon wafers by F and Cl free radicals produced by chemical gases; 8. is plasma; 9. is a vacuum pump; 10. is The lower parallel electrode plate; 11, is a wafer. The RF power supply 4 applies high-frequency voltage to the parallel electrode plates 3 and 10 to discharge the low-pressure chemical gas in the cavity to generate plasma. This chemically active plasma 8 is usually produced by the discharge of chlorine and fluorocarbon gases. It not only contains electrons and ions, but also a large number of active free radicals, such as Cl, F, Cl-, F-, etc. The F and Cl rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com