Low-inertia quick-response metal-ceramic composite turbine rotary shaft

A fast-response, metal-ceramic technology, applied in the direction of turbines, metal processing equipment, blade support components, etc., can solve problems such as performance attenuation, high melting point, structural evolution damage, etc., to achieve improved transient response, mature and reliable technology, The effect of solving connection difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] The low-inertia, fast-response metal-ceramic composite turbine shaft includes a composite material turbine 1 and a high-temperature-resistant steel shaft 2 welded together, such as figure 1 shown.

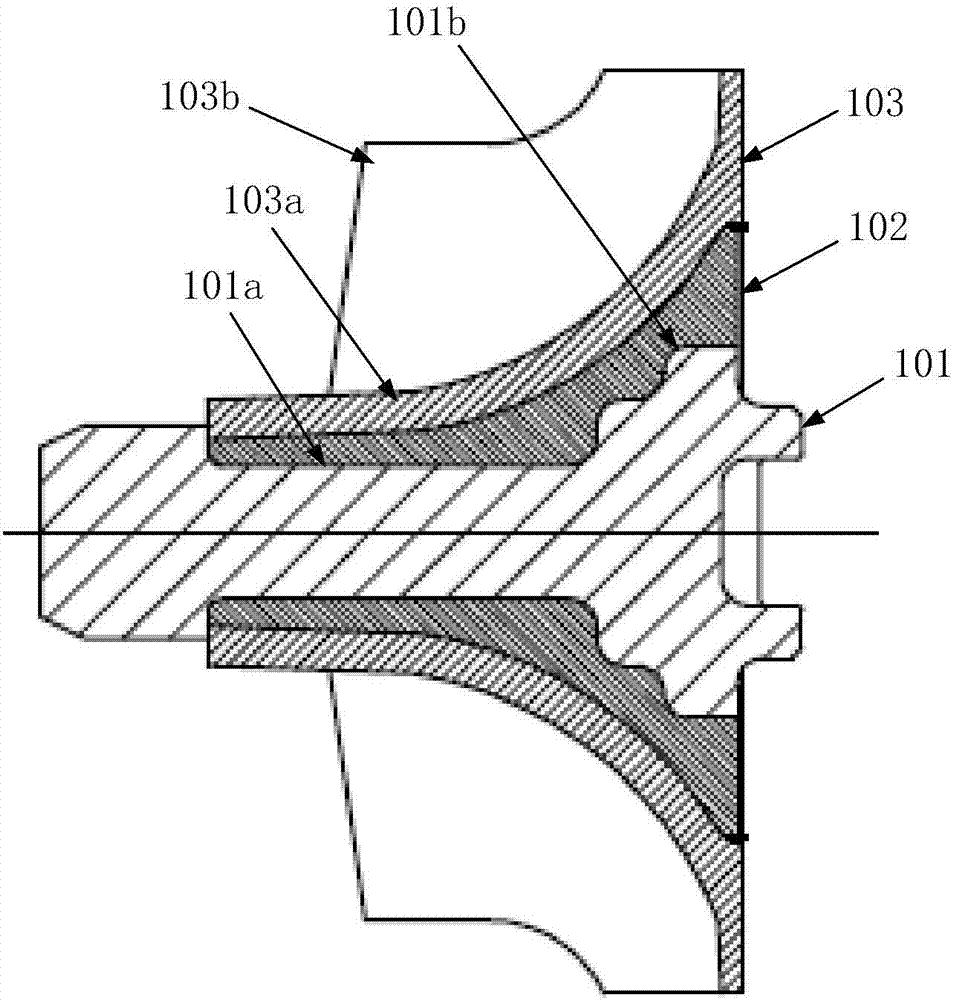

[0020] The composite material turbine 1 is divided into a three-layer structure from the inside to the outside, which are respectively the inner body 101, the transition layer 102 and the blade layer 103, as figure 2 shown. Wherein, the inner body 101 is made of traditional nickel-based alloy steel, which is a uniform rotator manufactured by casting. Specifically: the nickel-based alloy steel is nickel-based alloy steel K418, with a density of 8.0kg / cm^3, a linear expansion coefficient of 12.6e-6 / °C, a thermal conductivity of 10.15W / m.°C, and a heat resistance of 800°C.

[0021] The transition layer 102 is a superalloy powder sintered to the inner body....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com