Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "The physical and chemical properties remain unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultralow-expansion coefficient high transparent glass-ceramics and method for producing its product

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

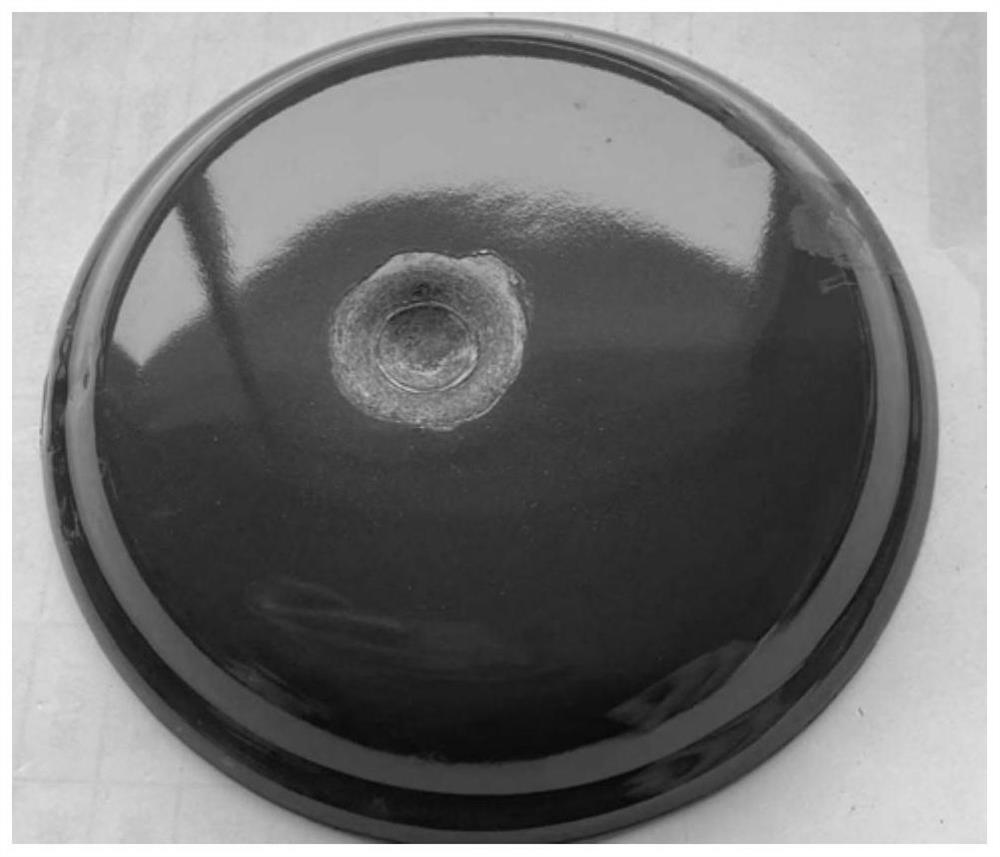

Method for producing black transparent microcrystal glass and its products

The invention provides a method for producing black transparent microcrystal glass and its products, wherein the base glass comprises Li2O, RO, Al2O3 and SiO2, the coloring agent comprises NiO, V2O5 and Fe2O3, the crystal nucleus agent comprises TiO2, Zr2O5 and P2O5, the weight percentage of each component being, Li2O: 2.5-4.7%, RO: 2-3%, Al2O3: 17-26%, SiO2: 62-72%, NiO: 0.05-0.1%, V2O5: 0.1-0.2%, Fe2O3: 0.05-0.1%, TiO2: 2-2.5%, ZrO2: 1.5-2.5%, P2O5: 1-2%. The formulation and related die arrangement can be used for making electromagnetic oven plate, disc, microwave oven disc, roasting and grilling plate, baking oven cloche, frying pan and various pots.

Owner:广东科迪微晶玻璃实业有限公司 +1

Nano particle modified binder, preparation method and using method

ActiveCN105419720AWide heat resistanceImprove heat resistanceNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentGas phaseHeat resistance

The invention relates to a nano particle modified binder which comprises a binder main body and nanofiller, wherein the binder main body comprises 45-55 wt% of organic silicon resin, 25-35 wt% of glass powder and 15-20 wt% of boron carbide powder; and the nanofiller comprises 5-10 wt% of nanometer aluminum powder, 5-10 wt% of nanometer silica powder and 1-2 wt% of alumina whisker. A method for preparing the nano particle modified binder comprises the steps of respectively preparing the binder main body and the nanofiller and then evenly dispersing and adding the nanofiller in the binder main body. A method for using the binder comprises the steps of evenly bonding the to-be-glued surface of an object with the binder, bonding the object, and achieving object bonding after heat treatment and chemical vapor deposition. The binder accord to the preparation method and the using method not only is extensive in use range, but also has good heat resistance and keeps physical and chemical properties basically unchanged in high temperature environment for a long time.

Owner:BEIHANG UNIV

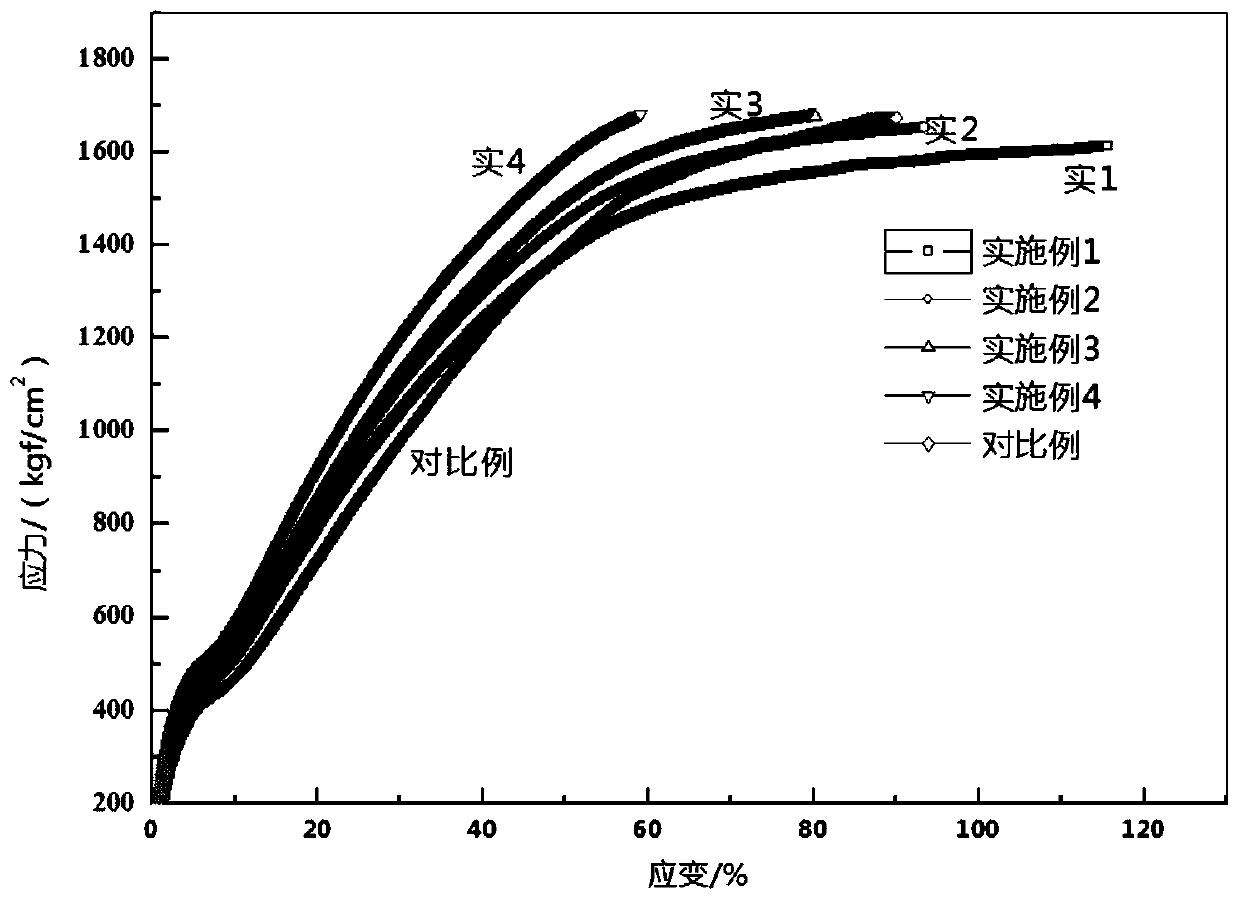

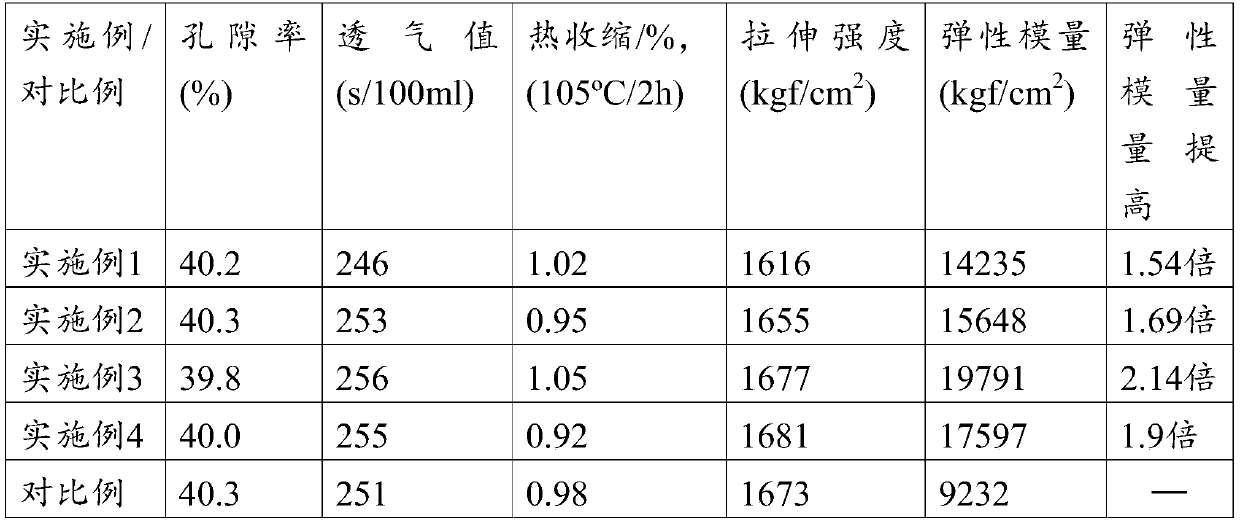

Preparation method of high-rigidity lithium-ion battery separator and made separator

ActiveCN110391384AHigh modulusHigh modulus of elasticityCell component detailsFlat articlesEngineeringPolypropylene

The application provides a preparation method of a high-rigidity lithium-ion battery separator. Two polypropylene materials with large difference in isotacticity and weight average molecular weight are adopted, the polypropylene materials with high isotacticity and weight average molecular weight account for a large proportion, and the elastic modulus of the prepared separator can be improved by 1.5-2 times compared with that of a common separator prepared from a single polypropylene material through the processes of material mixing, extrusion casting, annealing, stretching and heat setting, so that the high-rigidity separator is prepared, and the rest physical and chemical properties of the separator are basically kept unchanged. The high-rigidity separator is used as a lithium ion battery separator, can reduce the problems that the separator is easily pierced by lithium dendrites and folds of the separator in winding in the use process of the lithium ion battery, and improves the safety of the lithium ion battery in the use process.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

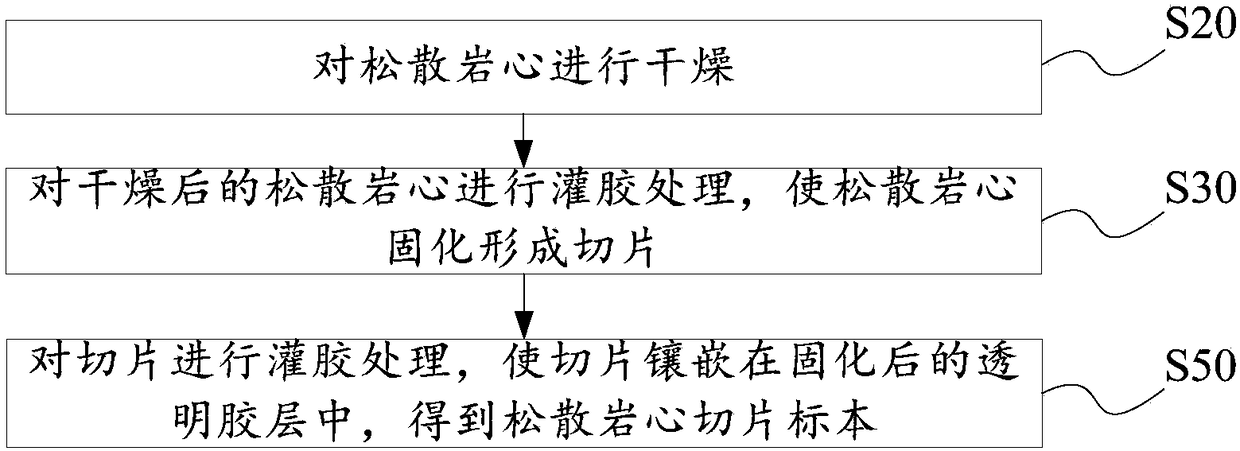

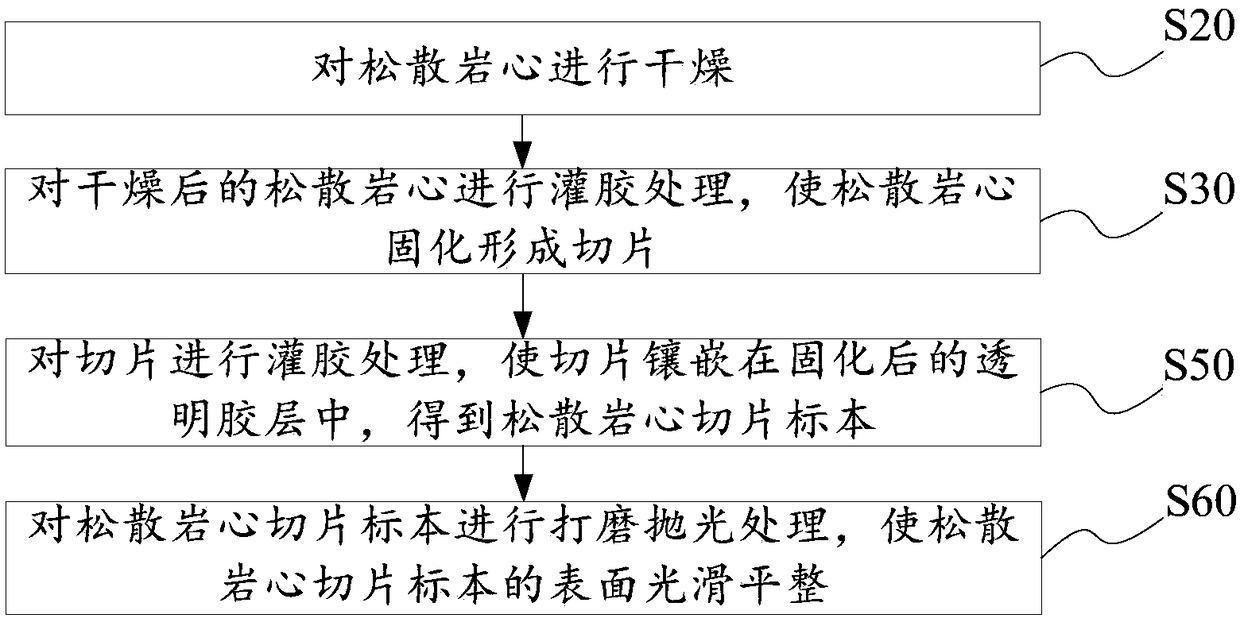

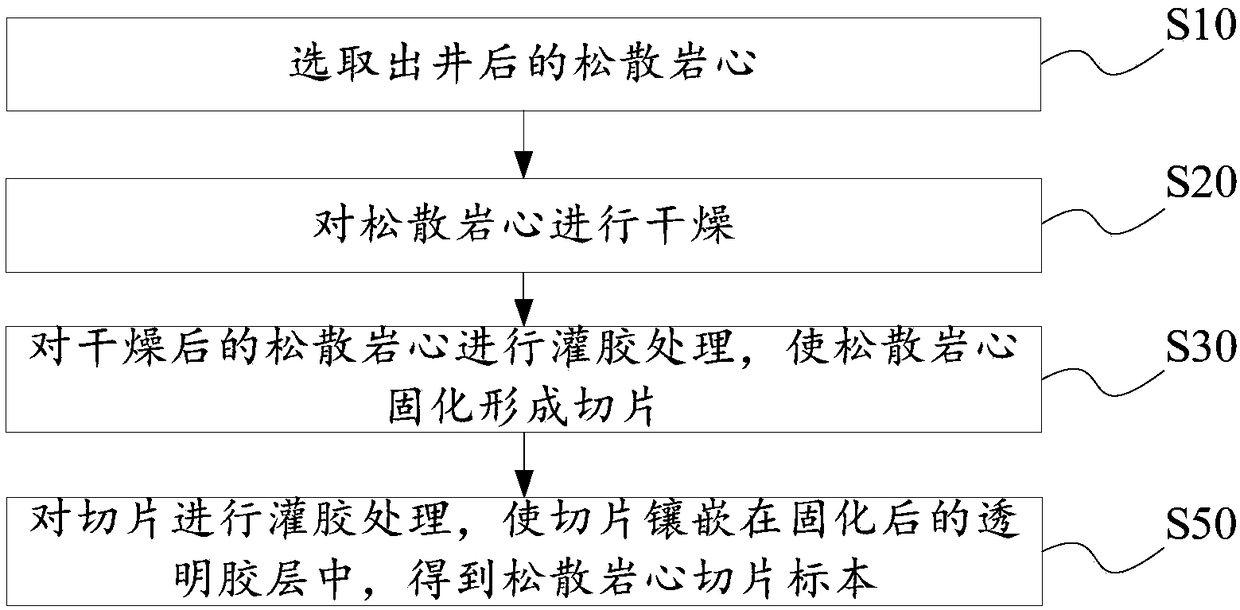

Loose rock core slice specimen and manufacture method thereof

InactiveCN108414314AStable physical and chemical propertiesGood lookingPreparing sample for investigationRock coreChemical property

The invention provides a loose rock core slice specimen and a manufacture method thereof. The manufacture method of the loose rock core slice specimen includes the steps: S20 drying a loose rock core;S30 filling the dried loose rock core with glue, and curing the loose rock core to form a slice; S50 filling the slice with glue, and embedding the slice into a cured transparent glue layer to obtainthe loose rock core slice specimen. The dried loose rock core and the slice are filled with transparent resin glue in the step S30 and the step S50. According to the method, the dried loose rock coreis repeatedly filled with the glue, so that the loose clay rock core forms the slice specimen, the loose rock core needing to be preserved is completely sealed into the transparent resin glue by theprepared slice specimen and cannot be affected by the temperature and the humidity of outside environments and human factors, physical and chemical properties are invariant, and long-term preservationis facilitated.

Owner:国土资源实物地质资料中心

Method for producing black transparent microcrystal glass and its products

ActiveCN1305796CWide crystallization temperature rangeThe physical and chemical properties remain unchangedMicrowave ovenEngineering

The invention provides a method for producing black transparent microcrystal glass and its products, wherein the base glass comprises Li2O, RO, Al2O3 and SiO2, the coloring agent comprises NiO, V2O5 and Fe2O3, the crystal nucleus agent comprises TiO2, Zr2O5 and P2O5, the weight percentage of each component being, Li2O: 2.5-4.7%, RO: 2-3%, Al2O3: 17-26%, SiO2: 62-72%, NiO: 0.05-0.1%, V2O5: 0.1-0.2%, Fe2O3: 0.05-0.1%, TiO2: 2-2.5%, ZrO2: 1.5-2.5%, P2O5: 1-2%. The formulation and related die arrangement can be used for making electromagnetic oven plate, disc, microwave oven disc, roasting and grilling plate, baking oven cloche, frying pan and various pots.

Owner:广东科迪微晶玻璃实业有限公司 +1

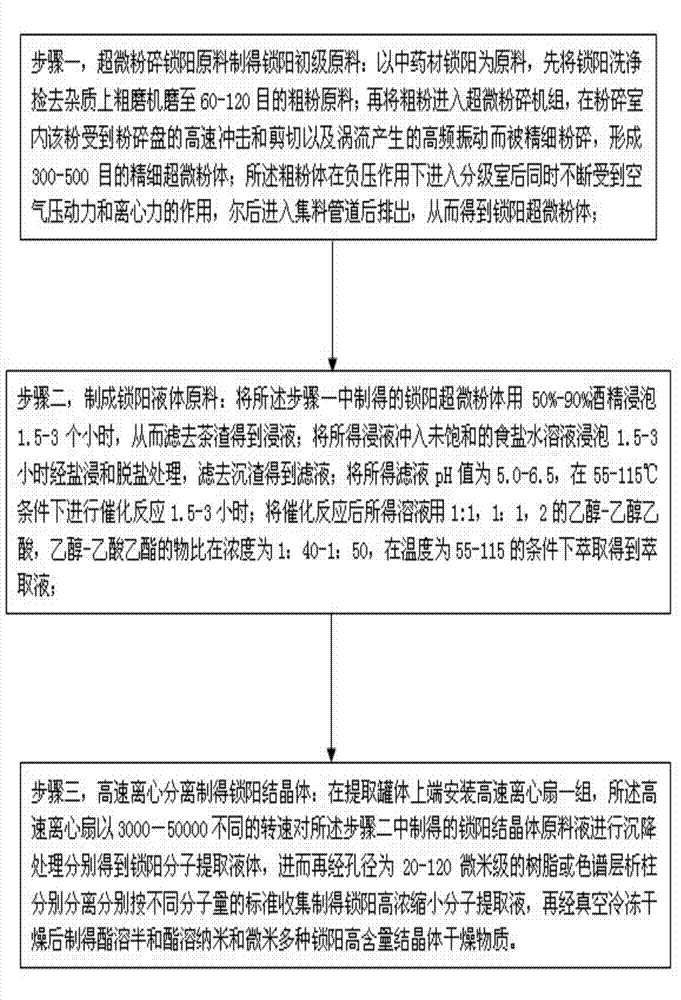

Extraction method for cynomorium songaricum extract product

InactiveCN103919821AThe physical and chemical properties remain unchangedEasy to crushCosmetic preparationsToilet preparationsFreeze-dryingVacuum drying

The invention discloses a producing method for selenium-rich cynomorium songaricum extract products. The producing method is characterized by including steps as follows: step one: pretreating cynomorium songaricum, coarsely grinding the cynomorium songaricum and crushing the cynomorium songaricum in an ultramicro manner with an addition of seleninic acid to obtain a selenium-rich cynomorium songaricum ultramicro powder raw material; step two: preparing a cynomorium songaricum ultramicro raw material liquid; and step three: producing various extract products of high-purity micromolecular ester-soluble or semi-ester soluble nanocrystals or micron-sized crystals through a high speed centrifugal separation process and a vacuum drying process. The beneficial effects of the above producing method for the cynomorium songaricum extract products are that: a cynomorium songaricum crude raw material is subjected to deep processing by an ultramicro crushing process so that the cynomorium songaricum raw material is crushed finely with a particle size distribution being uniform. Any heat is not generated during the crushing process and original physical and chemical performance and biological availability of the cynomorium songaricum are substantially improved. Ultrasound wave which is generated during the ultramicro crushing process has a certain sterilizing and fresh-keeping function. Because a cynomorium songaricum liquid extractive is extracted through an organic solvent and is separated by the high speed centrifugal separation process and crystals of the cynomorium songaricum are produced through the vacuum freeze drying process, effective components in the cynomorium songaricum crude raw material is prevented from losing and active components in the cynomorium songaricum are saved furthest. Time of the process flow is shortened. The producing method is energy-saving, can save medicinal raw materials and reduces product costs.

Owner:SHANGHAI PUDONG INTPROP PROTECTION ASSOC

Sealing frame for planar display device and production thereof

InactiveCN1780538AImprove consistencyHigh precisionHermetically-sealed casingsAdhesivesFritDisplay device

The seal frame in use for the flat panel display is made by means of following steps: mixes the un-crystallizing low melting point glass frit with organic bonding materials; pre-burns the mixed materials in a dedicated mold for making seal frame, and then makes mold stripping; the seal frame is a right angle endless frame; the length and the width of the outskirt of the seal frame equals the length and width of the flat panel display sealed; the width of the seal frame is 0.4-5 mm; the height of the seal frame equals the sum of the space between front board and rear board and 10-20 um.

Owner:ZHEJIANG UNIV

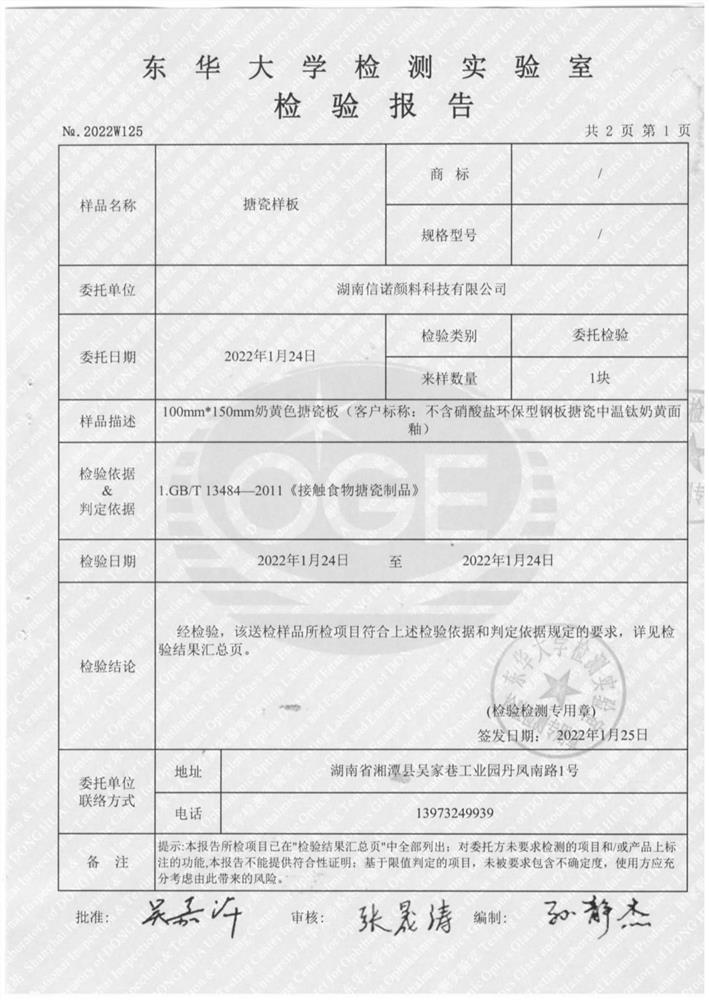

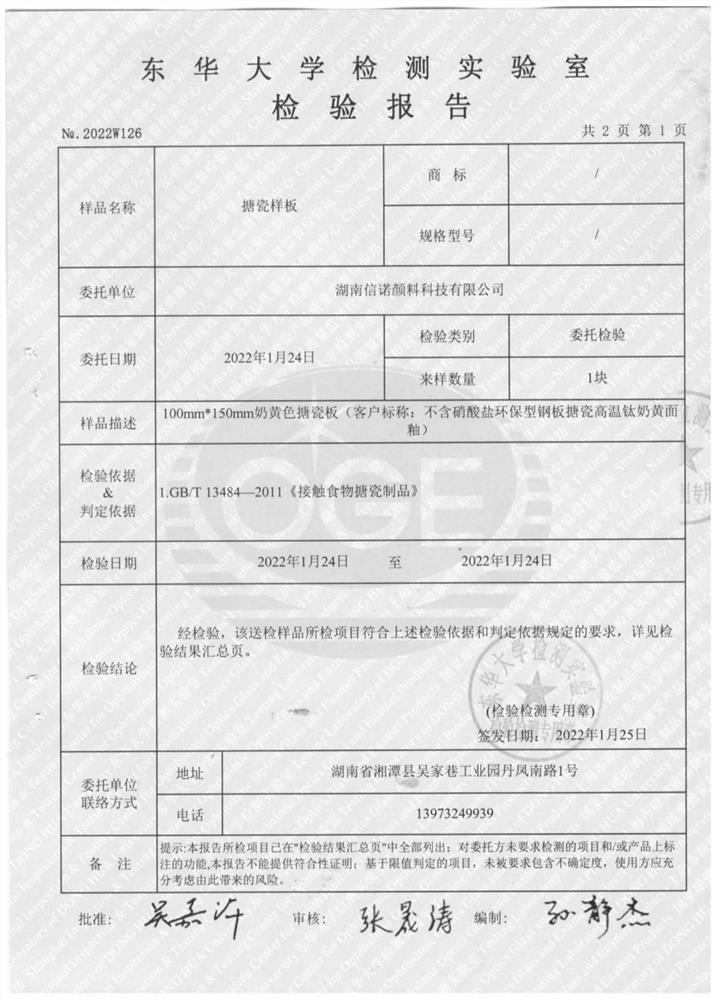

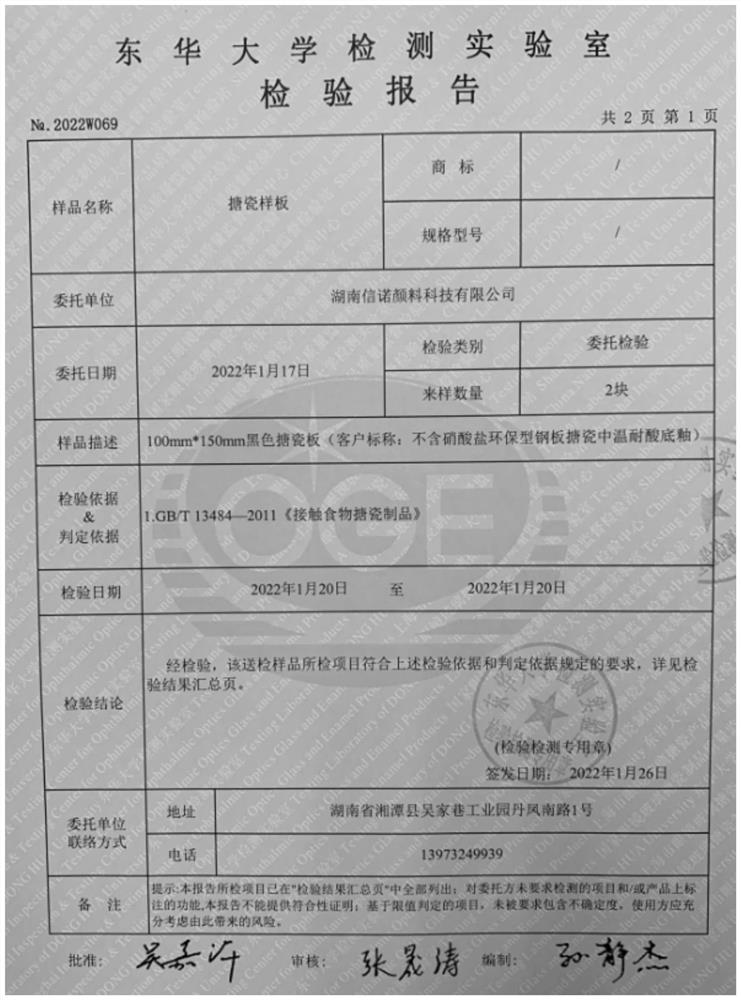

Nitrate-free environment-friendly steel plate enamel medium-temperature titanium creamy yellow cover glaze and preparation method thereof

PendingCN114409257AIncrease the oxidizing atmosphereSolve the pollution of the environmentPotassium feldsparSodium silicate

The invention discloses nitrate-free environment-friendly steel plate enamel medium-temperature titanium creamy yellow cover glaze and a preparation method thereof, and the nitrate-free environment-friendly steel plate enamel medium-temperature titanium creamy yellow cover glaze comprises the following components in parts by mass: 27-29 parts of quartz, 20-22 parts of anhydrous borax, 15-17 parts of rutile, 11-14 parts of potassium feldspar, 2-4 parts of magnesium carbonate, 2-4 parts of potassium carbonate and 9-11 parts of sodium fluosilicate. According to the invention, 1-2 parts by mass of calcium carbonate and 0.02-0.05 part by mass of potassium dichromate are melted at 1260 + / -10 DEG C under the condition of pure oxygen, and the firing temperature of the finished product is 800-830 DEG C. The medium-temperature titanium creamy glaze does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel medium-temperature titanium creamy glaze, nitrogen oxide gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:湖南信诺技术股份有限公司

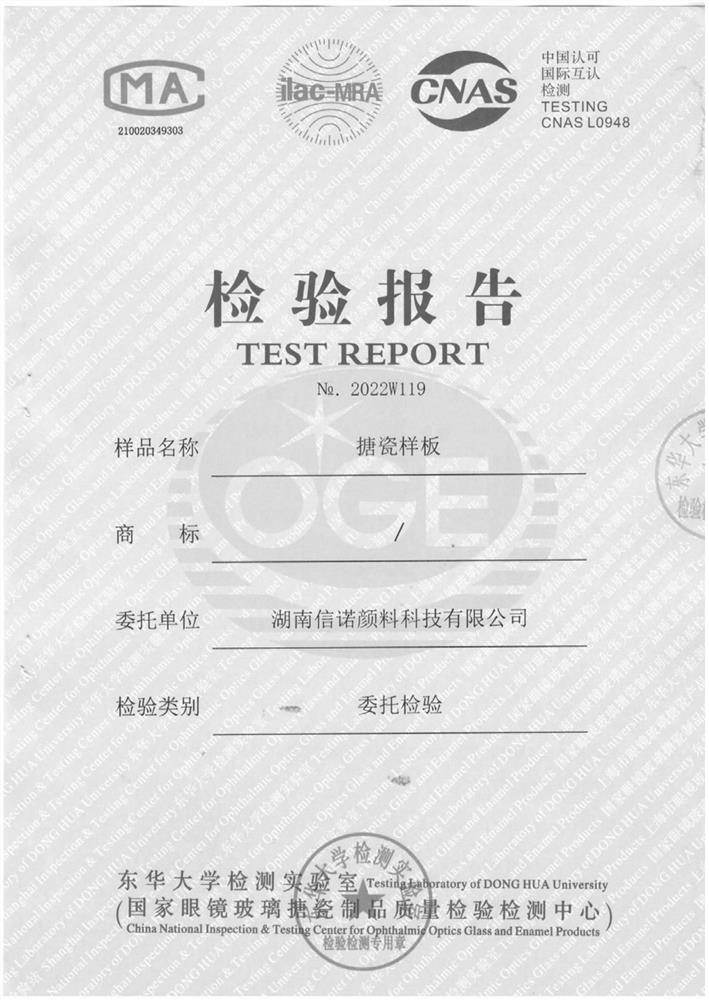

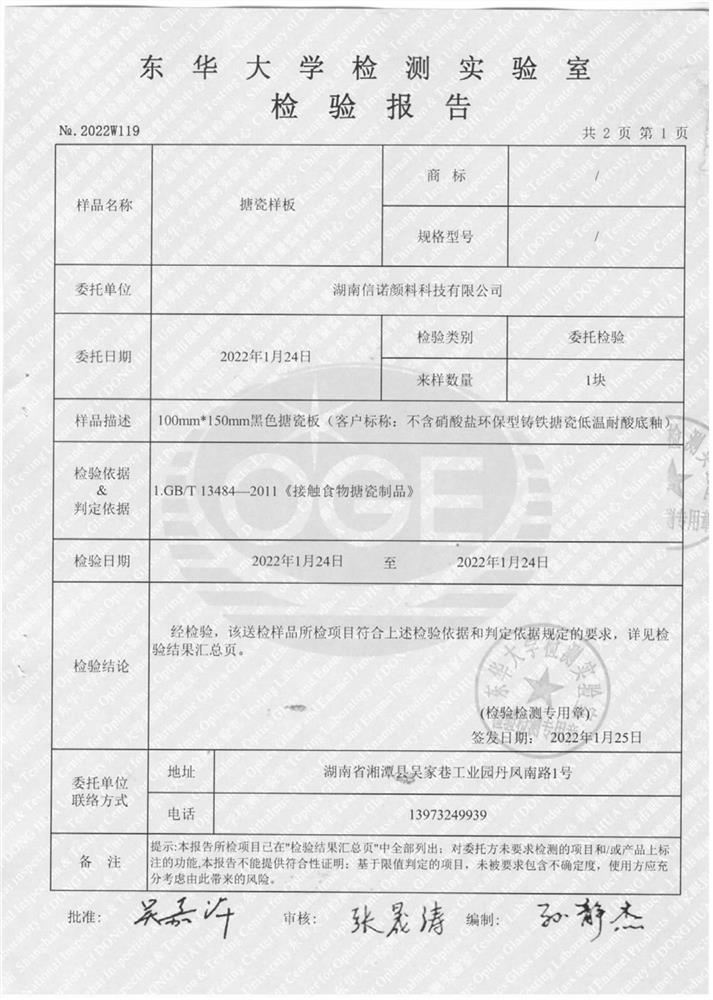

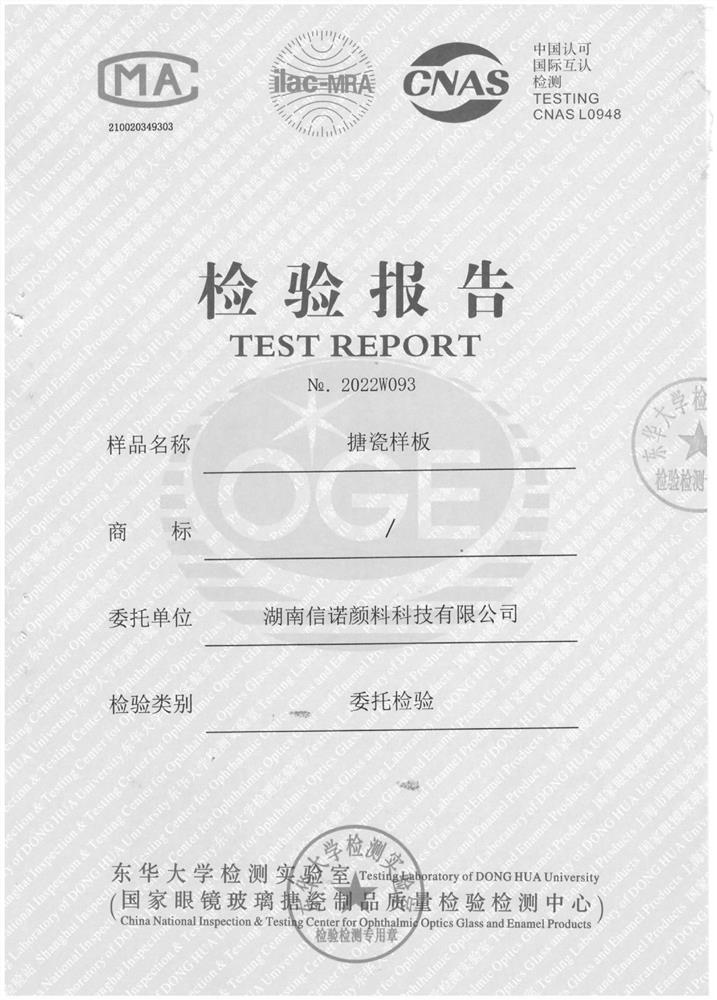

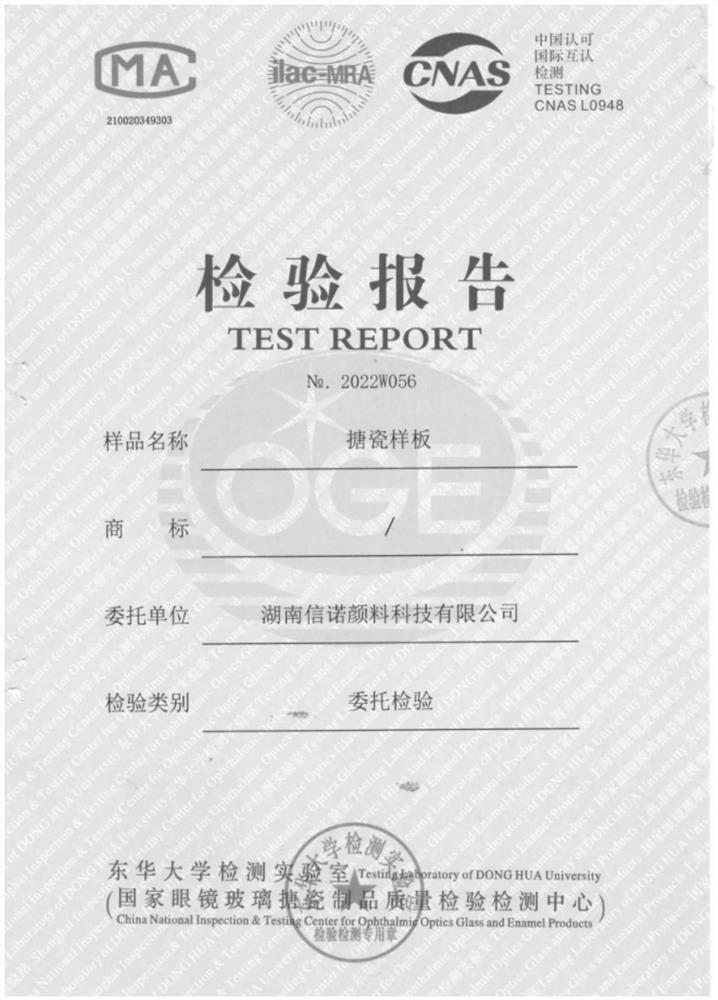

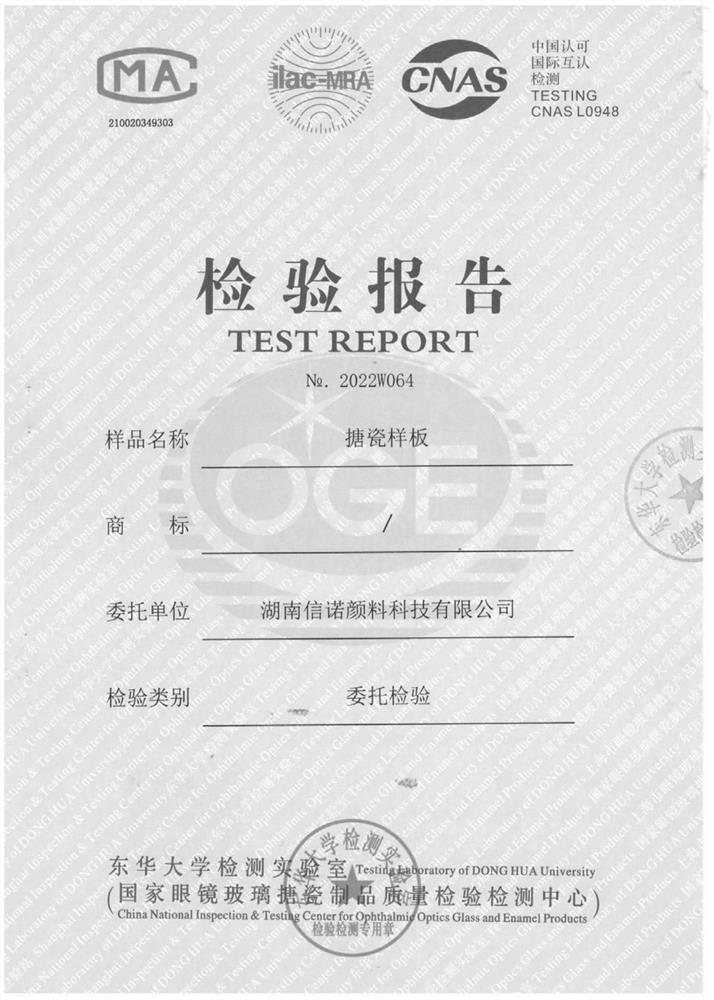

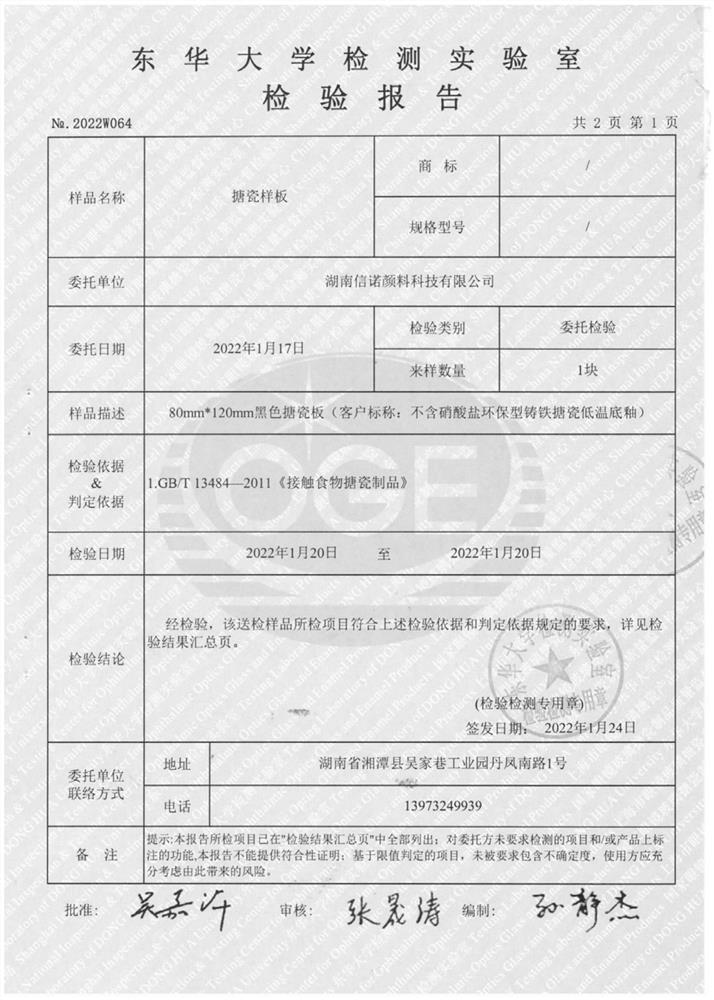

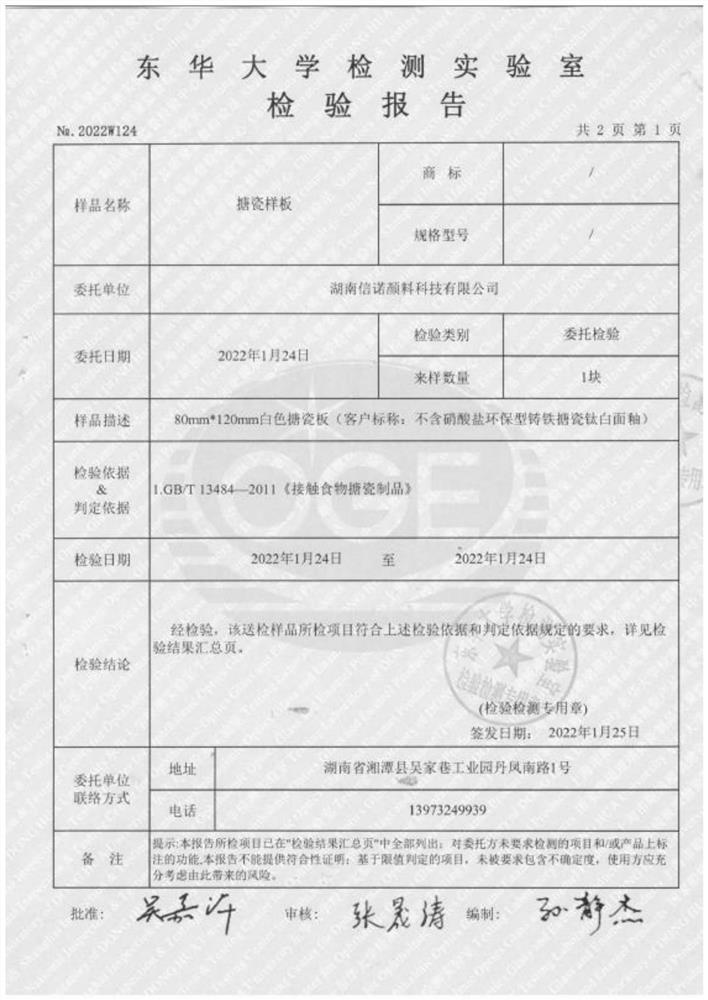

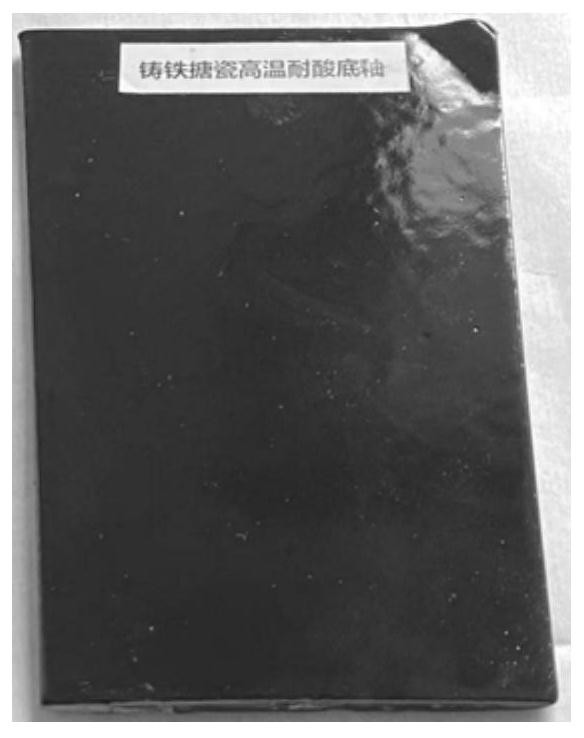

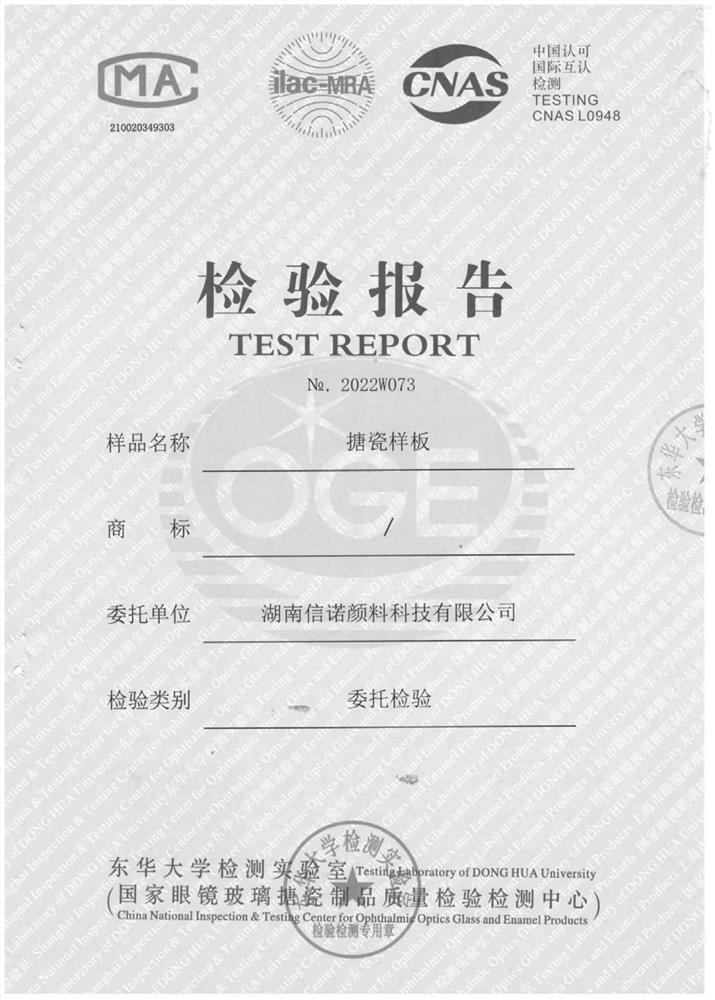

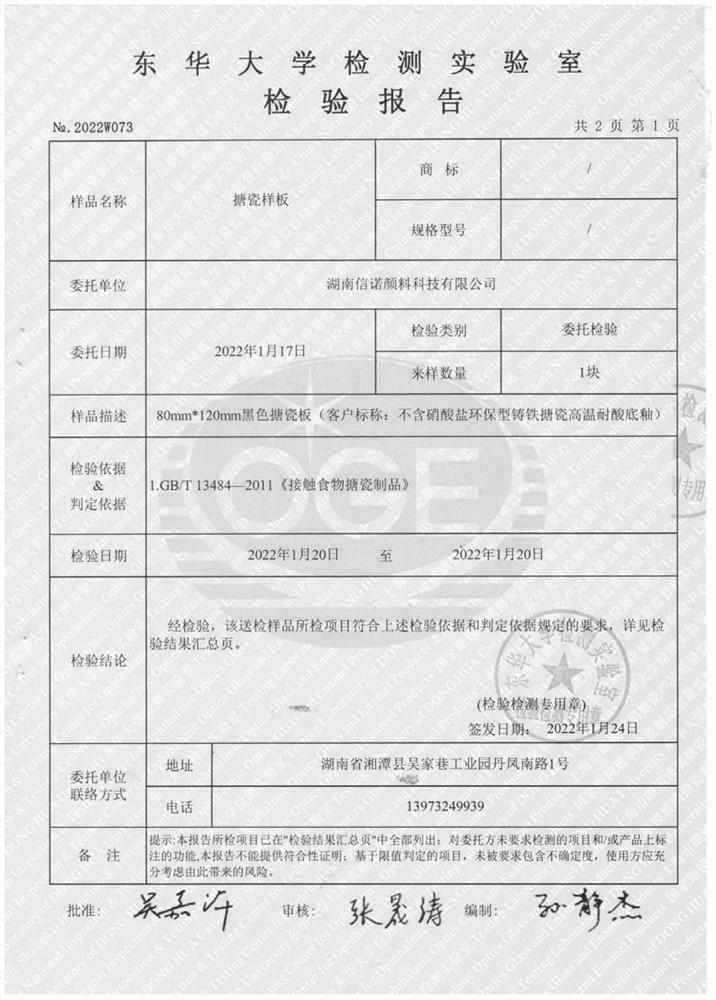

Nitrate-free environment-friendly cast iron enamel low-temperature acid-resistant ground coat and preparation method thereof

The invention discloses a nitrate-free environment-friendly cast iron enamel low-temperature acid-resistant ground coat and a preparation method thereof, and belongs to the technical field of enamel, the formula comprises the following components by mass: 46-50 parts of quartz, 24-27 parts of borax anhydrous, 5-7 parts of sodium carbonate, 1.2-1.4 parts of manganese oxide, 0.6-0.8 part of cobalt oxide, 4.5-5.5 parts of calcium carbonate, 3.5-4.5 parts of sodium fluosilicate, 3.0-4.0 parts of titanium dioxide, and 2.0-3.5 parts of potassium feldspar. And 3.5 to 4.5 parts of lithium carbonate. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 740-760 DEG C. The formula does not contain nitrate, and the major technical problem that in the production process of existing cast iron enamel low-temperature acid-resistant ground coat, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

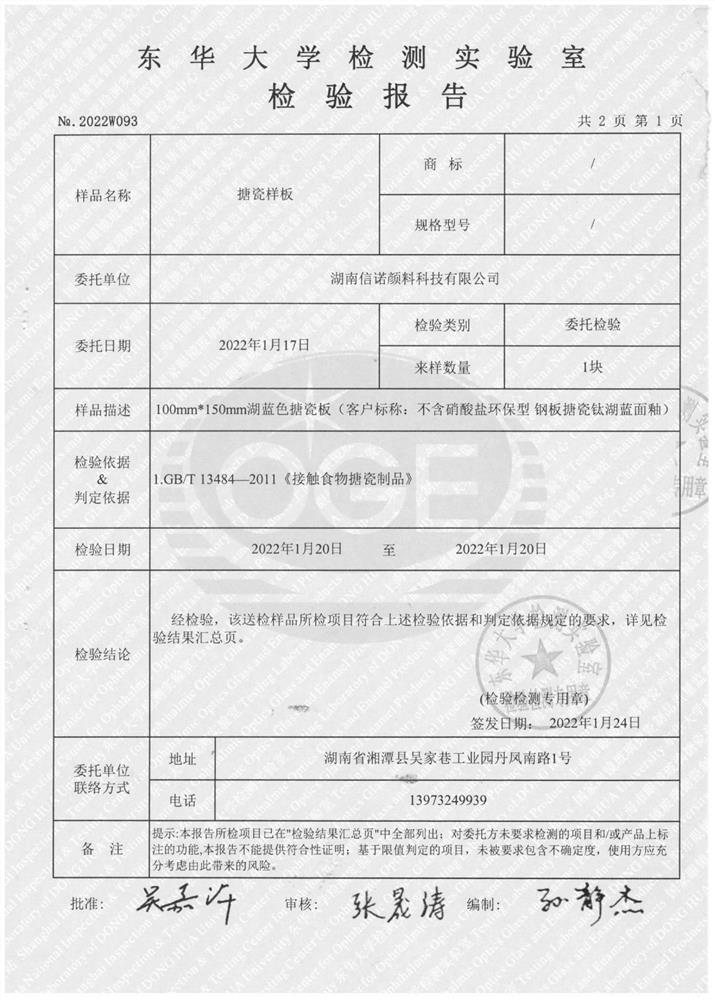

Nitrate-free environment-friendly steel plate enamel titanium lake blue cover glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly steel plate enamel titanium lake blue cover glaze and a preparation method thereof, and the nitrate-free environment-friendly steel plate enamel titanium lake blue cover glaze comprises the following components in parts by mass: 22-25 parts of quartz, 28-30 parts of borax anhydrous, 11-14 parts of titanium dioxide, 9-11 parts of potassium feldspar, 0.7-1 part of magnesium carbonate, 1-2 parts of sodium carbonate, 7-9 parts of sodium fluosilicate and 1-2 parts of calcium carbonate. And 1.5-2.5 parts by mass of copper oxide. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1260 + / -10 DEG C, and the firing temperature of the finished product is 800-830 DEG C. The titanium lake blue cover glaze does not contain nitrate, and the major technical problem that the environment is polluted due to emission of nitric oxide gas generated in the production process of existing steel plate enamel titanium lake blue cover glaze is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nanoparticle modified binder, preparation method and use method

ActiveCN105419720BWide heat resistanceImprove heat resistanceNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentGas phaseHeat resistance

Owner:BEIHANG UNIV

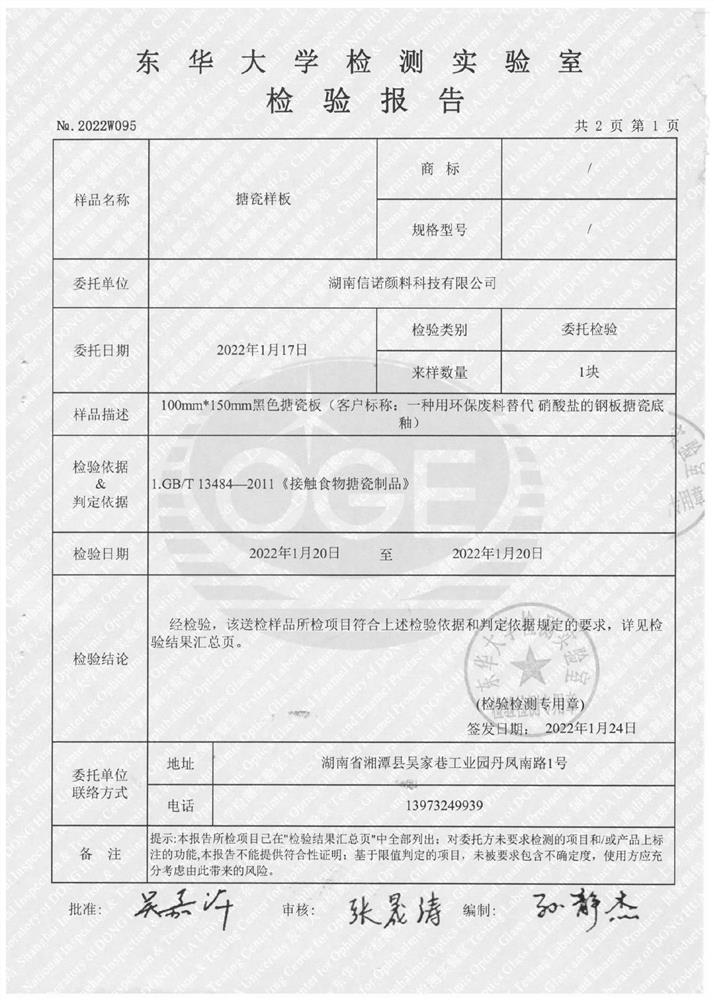

Steel plate enamel ground coat using environment-friendly waste material to replace nitrate and preparation method of steel plate enamel ground coat

PendingCN114315152AIncrease the oxidizing atmosphereFluxing GuaranteeAluminium hydroxideCopper oxide

The invention discloses a steel plate enamel ground coat using environment-friendly waste to replace nitrate and a preparation method thereof. The formula of the ground glaze comprises the following components in parts by mass: 8-10 parts of environment-friendly waste, 17-20 parts of quartz, 13-16 parts of anhydrous borax, 20-22 parts of sodium carbonate, 12-13 parts of potassium feldspar, 7-8 parts of calcium carbonate, 4-5 parts of barium carbonate, 0.4-0.6 part of magnesium carbonate, 2-2.5 parts of aluminum hydroxide, 3-4 parts of ferric oxide, 0.8-1.0 part of manganese oxide, 0.2-0.4 part of copper oxide, 0.8-1.0 part of nickel oxide and 4.5-5 parts of fluorite powder. The raw materials are uniformly mixed according to the proportion and are melted at 1250 + / -10 DEG C under the condition of pure oxygen, and the firing temperature of the finished product is 800-860 DEG C. The formula does not contain nitrate, and the major technical problem that nitrogen oxide (NOx) gas generated in the production process of the existing steel plate enamel ground glaze is discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

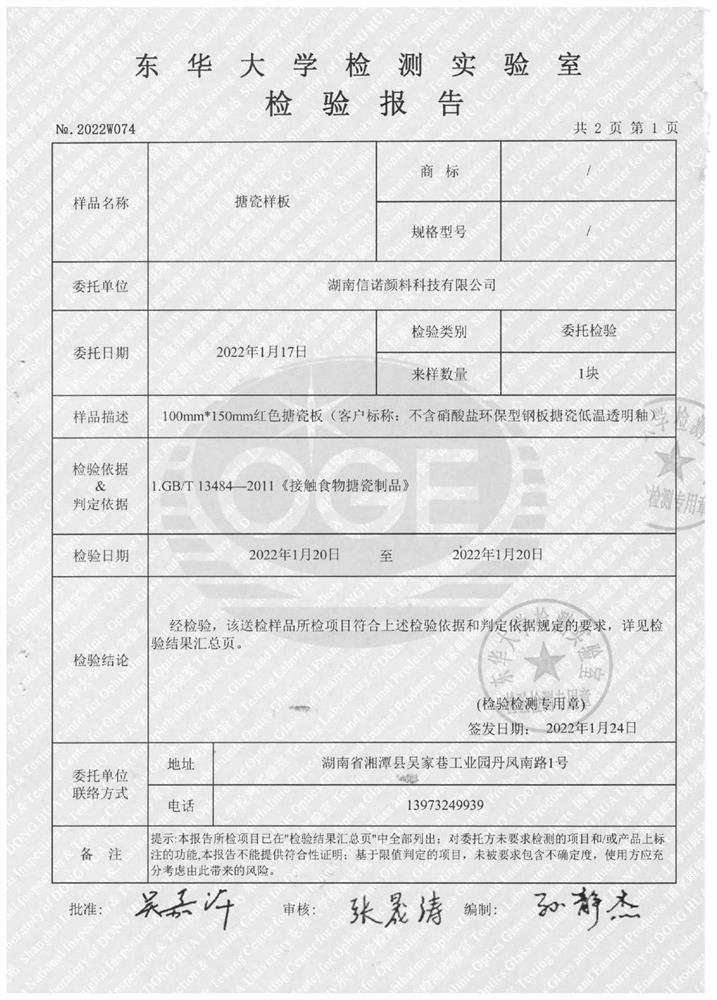

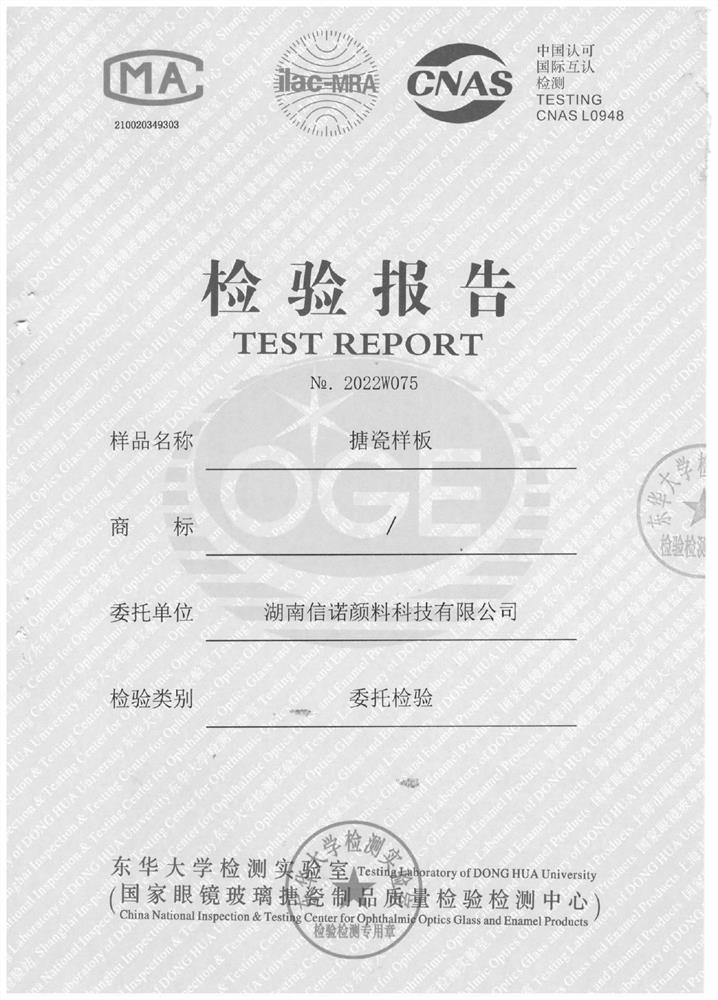

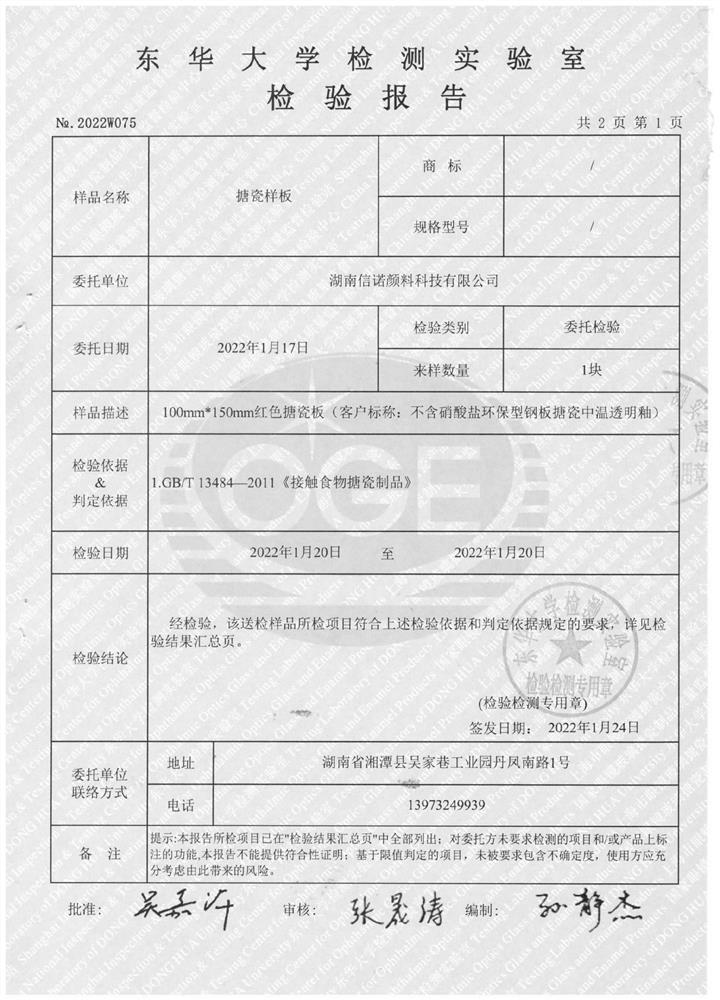

Nitrate-free environment-friendly steel plate enamel low-temperature transparent glaze and preparation method thereof

PendingCN114213016ASolve the pollution of the environmentIncrease the oxidizing atmospherePotassium feldsparSodium silicate

The invention discloses nitrate-free environment-friendly steel plate enamel low-temperature transparent glaze and a preparation method thereof, and belongs to the technical field of enamel, and the formula comprises the following components in parts by mass: 19-22 parts of borax anhydrous, 26-28 parts of potassium feldspar, 24-26 parts of quartz, 9-12 parts of sodium carbonate, 6-8 parts of sodium fluosilicate, 2-4 parts of titanium dioxide and 4-6 parts of fluorite. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 760-790 DEG C. The formula does not contain nitrate, and the major technical problem that the environment is polluted due to emission of nitrogen oxide (NOx) gas generated in the production process of the existing low-temperature transparent glaze for steel plate enamel is fundamentally solved.

Owner:湖南信诺技术股份有限公司

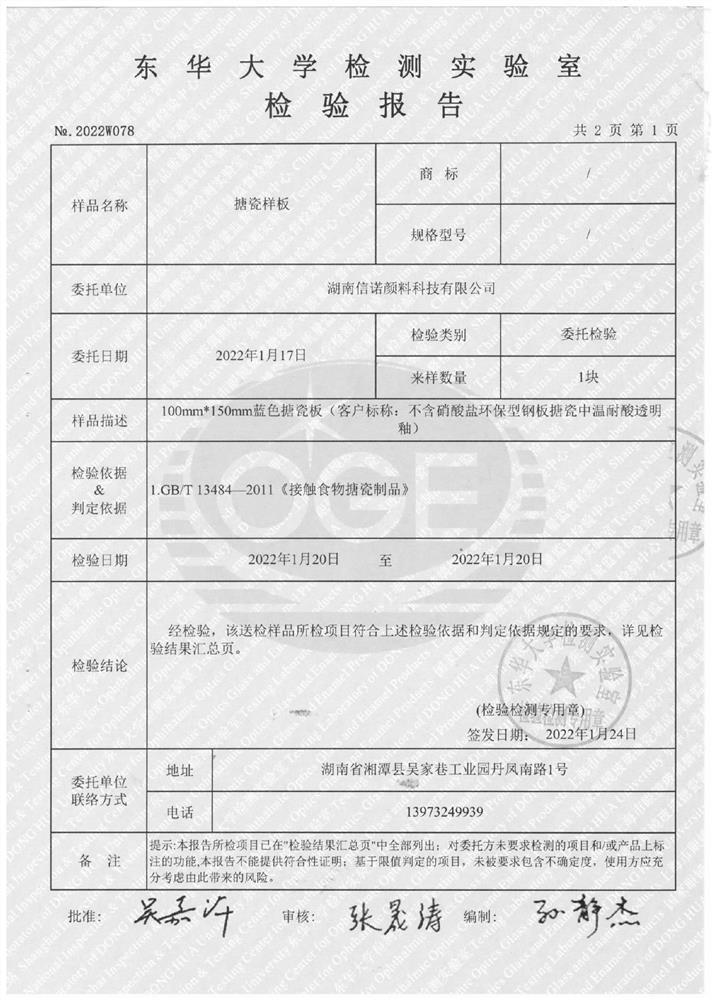

Nitrate-free environment-friendly steel plate enamel medium-temperature acid-resistant transparent glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly steel plate enamel medium-temperature acid-resistant transparent glaze and a preparation method thereof, and belongs to the technical field of enamel, and the formula comprises the following components in parts by mass: 23-26 parts of borax anhydrous, 39-41 parts of quartz, 10-13 parts of sodium carbonate, 4-6 parts of titanium dioxide, 6-8 parts of aluminum oxide, 5-7 parts of fluorite and 3-5 parts of barium carbonate. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1260 + / -10 DEG C, and the firing temperature of the finished product is 800-840 DEG C. The formula does not contain nitrate, and the major technical problem that nitrogen oxide (NOx) gas generated in the production process of the existing steel plate enamel medium-temperature acid-resistant transparent glaze is discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel low-temperature nickel ground glaze, preparation method and application

PendingCN114276020AReduce usageThe physical and chemical properties remain unchangedManganese oxidePotassium carbonate

The invention discloses nitrate-free environment-friendly steel plate enamel low-temperature nickel ground glaze, a preparation method and application, and the formula of the nickel ground glaze comprises the following components in parts by mass: 16-20 parts of quartz, 25-27 parts of anhydrous borax, 12-14 parts of sodium carbonate, 1.5-3.5 parts of potassium carbonate, 3.5-5.0 parts of calcium carbonate, 11-13 parts of fluorite, 21-23 parts of potassium feldspar, 1-2 parts of albite, 0.7-0.9 part of nickel oxide and 0.5-0.6 part of antimony oxide. And 2.4 to 3.0 parts of manganese oxide. The formula of the low-temperature nickel ground glaze does not contain nitrate, a pure oxygen combustion mode is adopted in the melting process, and the major technical problem that in the production process of existing steel plate enamel low-temperature nickel ground glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel low-temperature titanium dioxide cover glaze and preparation method thereof

The invention discloses a nitrate-free environment-friendly steel plate enamel low-temperature titanium dioxide cover glaze and a preparation method thereof. The invention belongs to the technical field of enamel. The formula comprises the following components in parts by mass: 38-40 parts of quartz, 33-35 parts of borax anhydrous, 0.01-0.02 part of cobalt oxide, 14-16 parts of titanium dioxide, 1.8-2.5 parts of magnesium carbonate, 2-4 parts of sodium tripolyphosphate, 6-8 parts of sodium fluosilicate, 4-6 parts of potassium carbonate and 1.5-2 parts of aluminum oxide. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 760-790 DEG C. The formula of the low-temperature titanium white cover glaze does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel low-temperature titanium white cover glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Ultralow-expansion coefficient high transparent microcrystalline glass and method for producing its product

ActiveCN101139171BTransparency unchangedThe physical and chemical properties remain unchangedThermal impactCelsius Degree

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

Medium-temperature cobalt-nickel ground coat for nitrate-free environment-friendly steel plate enamel, and preparation method and application thereof

PendingCN114315143AReduce usageThe physical and chemical properties remain unchangedGlazeCopper oxide

The invention discloses a nitrate-free environment-friendly steel plate enamel medium-temperature cobalt-nickel ground coat, a preparation method and application, and the formula of the nitrate-free environment-friendly steel plate enamel medium-temperature cobalt-nickel ground coat comprises the following components in parts by mass: 38-42 parts of quartz, 22-24 parts of borax anhydrous, 4-6 parts of sodium carbonate, 2-4 parts of potassium carbonate, 1.8-2.2 parts of calcium carbonate and 4-5 parts of fluorite. The invention relates to a high-strength ceramic material, which is prepared from the following components in parts by weight: 14.5 to 16 parts of potassium feldspar, 3 to 5 parts of albite, 1.4 to 1.6 parts of nickel oxide, 1.1 to 1.3 parts of copper oxide, 0.7 to 0.8 part of cobalt oxide, 2.0 to 2.2 parts of manganese oxide and 1.9 to 2.1 parts of iron oxide. The formula does not contain nitrate, a pure oxygen combustion mode is adopted in the melting process, and the major technical problem that in the production process of existing steel plate enamel medium-temperature cobalt-nickel ground glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Sealing frame for planar display device and production thereof

InactiveCN100379328CImprove consistencyHigh precisionHermetically-sealed casingsAdhesivesFritDisplay device

The seal frame in use for the flat panel display is made by means of following steps: mixes the un-crystallizing low melting point glass frit with organic bonding materials; pre-burns the mixed materials in a dedicated mold for making seal frame, and then makes mold stripping; the seal frame is a right angle endless frame; the length and the width of the outskirt of the seal frame equals the length and width of the flat panel display sealed; the width of the seal frame is 0.4-5 mm; the height of the seal frame equals the sum of the space between front board and rear board and 10-20 um.

Owner:ZHEJIANG UNIV

Nitrate-free environment-friendly cast iron enamel low-temperature ground coat and preparation method thereof

The invention discloses a nitrate-free environment-friendly cast iron enamel low-temperature ground coat and a preparation method thereof, and belongs to the technical field of enamel, and the formula comprises the following components in parts by mass: 10-14 parts of quartz, 29-31 parts of anhydrous borax, 6-8 parts of sodium carbonate, 3.5-6.0 parts of potassium carbonate, 8-9 parts of barium carbonate, 7-8 parts of fluorite, 24-26 parts of potassium feldspar, 1.2-1.6 parts of magnesium carbonate, 1.2-1.4 parts of nickel oxide and 0.5-0.6 part of copper oxide. 1.2 to 1.4 parts of manganese oxide, 0.5 to 0.6 part of cobalt oxide and 0.8 to 0.9 part of aluminum oxide. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 740-760 DEG C. The formula does not contain nitrate, and the major technical problem that in the production process of existing cast iron enamel low-temperature ground glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel medium-temperature transparent glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly steel plate enamel medium-temperature transparent glaze and a preparation method thereof, and belongs to the technical field of enamel, the nitrate-free environment-friendly steel plate enamel medium-temperature transparent glaze comprises the following components by mass: 20-22 parts of borax anhydrous, 14-16 parts of potassium feldspar, 35-37 parts of quartz, 8-10 parts of sodium carbonate, 7-9 parts of sodium fluosilicate, 4-6 parts of titanium dioxide, 0.2-0.8 part of zinc oxide, and 6-8 parts of alumina. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1260 + / -10 DEG C, and the firing temperature of the finished product is 800-840 DEG C. The formula does not contain nitrate, and the major technical problem that nitrogen oxide (NOx) gas generated in the production process of the existing steel plate enamel medium-temperature transparent glaze is discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel high-temperature titanium creamy yellow cover glaze and preparation method thereof

PendingCN114349347AIncrease the oxidizing atmosphereFluxing GuaranteeNitric oxide gasPotassium carbonate

The invention discloses nitrate-free environment-friendly steel plate enamel high-temperature titanium creamy yellow cover glaze and a preparation method thereof, and the nitrate-free environment-friendly steel plate enamel high-temperature titanium creamy yellow cover glaze comprises the following components in parts by mass: 18-21 parts of quartz, 15-17 parts of anhydrous borax, 12-14 parts of rutile, 20-23 parts of potassium feldspar, 8-10 parts of trisodium phosphate, 2-4 parts of potassium carbonate and 7-9 parts of sodium fluosilicate. The raw materials are melted at the temperature of 1290 + / -10 DEG C and under the condition of pure oxygen, and the firing temperature of a finished product is 850-880 DEG C. The high-temperature titanium creamy cover glaze does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel high-temperature titanium creamy cover glaze, nitric oxide gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

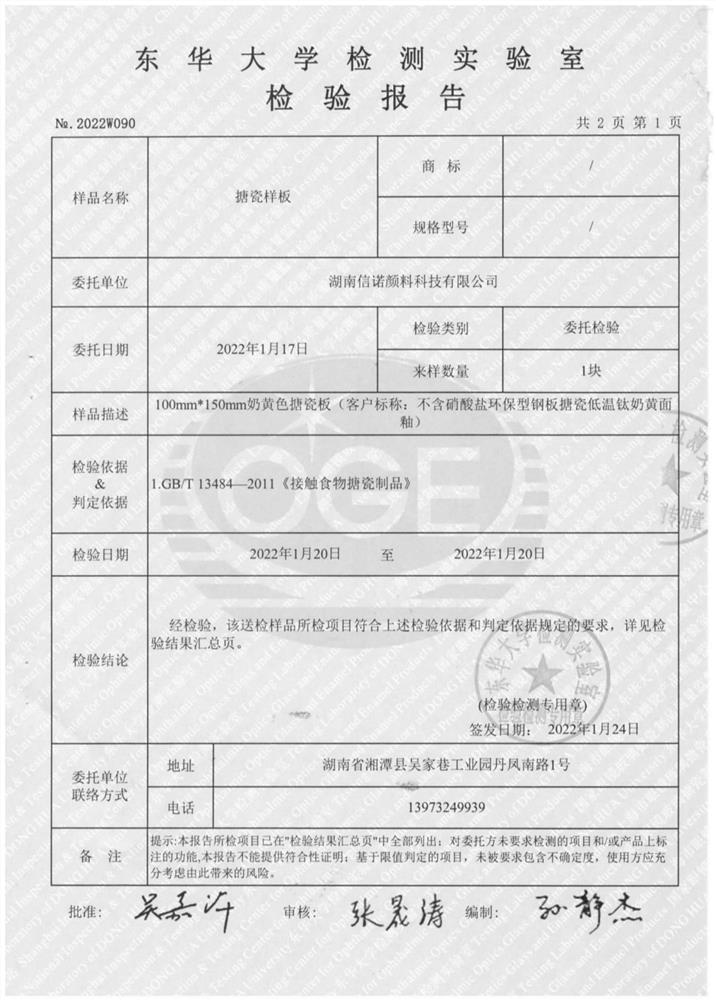

Nitrate-free environment-friendly steel plate enamel low-temperature titanium creamy yellow cover glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly steel plate enamel low-temperature titanium creamy yellow cover glaze and a preparation method thereof, and the nitrate-free environment-friendly steel plate enamel low-temperature titanium creamy yellow cover glaze comprises the following components in parts by mass: 23-25 parts of quartz, 27-30 parts of anhydrous borax, 3-5 parts of phosphate, 12-15 parts of titanium dioxide, 9-11 parts of potassium feldspar, 1-3 parts of magnesium carbonate and 1-3 parts of potassium carbonate. 6 to 8 parts by mass of sodium fluosilicate and 0.1 to 0.15 part by mass of potassium dichromate. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 760-790 DEG C. The low-temperature titanium creamy cover glaze does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel low-temperature titanium creamy cover glaze, nitric oxide gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Medium-temperature acid-resistant ground coat for nitrate-free environment-friendly steel plate enamel, and preparation method and application thereof

PendingCN114315147AReduce usageThe physical and chemical properties remain unchangedPotassium feldsparCobalt oxide

The invention discloses a nitrate-free environment-friendly steel plate enamel medium-temperature acid-resistant ground coat, a preparation method and application, and the formula of the nitrate-free environment-friendly steel plate enamel medium-temperature acid-resistant ground coat comprises the following components in parts by mass: 48-52 parts of quartz, 24-26 parts of anhydrous borax, 7-9 parts of sodium carbonate, 1.5-1.7 parts of manganese oxide, 0.8-1.0 part of nickel oxide and 1.0-1.1 parts of cobalt oxide. The formula comprises the following components in parts by weight: 2.8 to 3.6 parts of calcium carbonate, 1.2 to 1.8 parts of sodium fluosilicate, 2.0 to 3.0 parts of titanium dioxide, 1.2 to 1.5 parts of potassium feldspar, 5 to 6 parts of lithium carbonate and 0.4 to 0.8 part of fluorite. The formula provided by the invention does not contain nitrate, and a pure oxygen combustion mode is adopted in the melting process, so that the major technical problem that the environment is polluted due to emission of nitrogen oxide (NOx) gas generated in the production process of the existing steel plate enamel medium-temperature acid-resistant ground coat is fundamentally solved.

Owner:湖南信诺技术股份有限公司

Nitrate-free environment-friendly cast iron enamel titanium white cover glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly cast iron enamel titanium white cover glaze and a preparation method thereof. The invention belongs to the technical field of enamel. The formula comprises the following components in parts by mass: 30-33 parts of quartz, 18-21 parts of borax anhydrous, 14-16 parts of titanium dioxide, 1-2 parts of magnesium carbonate, 2-4 parts of sodium tripolyphosphate, 6-8 parts of sodium fluosilicate, 3-5 parts of potassium carbonate, 2-3 parts of lithium carbonate and 2-3 parts of potassium feldspar. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 740-780 DEG C. The formula does not contain nitrate, and the major technical problem that in the production process of existing cast iron enamel titanium white cover glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly cast iron enamel high-temperature acid-resistant ground coat and preparation method thereof

PendingCN114368903AIncrease the oxidizing atmosphereFluxing GuaranteeManganese oxideMaterials science

The invention discloses a nitrate-free environment-friendly cast iron enamel high-temperature acid-resistant ground coat and a preparation method thereof, and belongs to the technical field of enamel, the formula comprises the following components by mass: 50-54 parts of quartz, 24-27 parts of anhydrous borax, 5-7 parts of sodium carbonate, 1.5-1.7 parts of manganese oxide, 0.7-0.9 part of cobalt oxide, 4.5-5.5 parts of calcium carbonate, 4-5 parts of sodium fluosilicate, 3.0-4.0 parts of titanium dioxide, and 2.0-3.8 parts of potassium feldspar. And 3.5 to 4.5 parts of lithium carbonate. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1290 + / -10 DEG C, and the firing temperature of the finished product is 800-820 DEG C. The formula does not contain nitrate, and the major technical problem that in the production process of existing cast iron enamel high-temperature acid-resistant ground coat, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly medium-temperature pearlescent glaze for enameled steel plates and preparation method thereof

The invention discloses nitrate-free environment-friendly medium-temperature pearlescent glaze for an enameled steel plate and a preparation method, and belongs to the technical field of enamel, the nitrate-free environment-friendly medium-temperature pearlescent glaze comprises the following components in parts by mass: 38-44 parts of quartz, 12-14 parts of borax, 16-18 parts of potassium feldspar, 0.7-3 parts of potassium carbonate, 8-11 parts of titanium dioxide, 2-5 parts of calcium carbonate, 10-12 parts of sodium carbonate, 3-8 parts of sodium fluosilicate and 0.5-1 part of lithium carbonate. And 2-5 parts of talcum powder. The raw materials are uniformly mixed according to the proportion and are melted at 1260 + / -10 DEG C, and the firing temperature of the finished product is 800-840 DEG C. The formula does not contain nitrate, and the technical problem that the environment is polluted due to emission of nitrogen oxide (NOx) gas generated in the production and processing process of the existing medium-temperature pearlescent glaze for the enameled steel sheet is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel medium-temperature titanium white cover glaze and preparation method thereof

The invention discloses a nitrate-free environment-friendly steel plate enamel medium-temperature titanium white cover glaze and a preparation method thereof. The invention belongs to the technical field of enamel. The formula comprises the following components in parts by mass: 35-37 parts of quartz, 28-30 parts of borax anhydrous, 0.01-0.03 part of cobalt oxide, 16-18 parts of titanium dioxide, 2-4 parts of magnesium carbonate, 9-11 parts of trisodium phosphate, 5-7 parts of sodium fluosilicate, 3-5 parts of potassium carbonate and 1-3 parts of aluminum oxide. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1260 + / -10 DEG C, and the firing temperature of the finished product is 800-840 DEG C. According to the present invention, the formula does not contain nitrate, such that the major technical problem of environmental pollution caused by emission of nitrogen oxide (NOx) gas generated during the production process of the existing steel plate enamel intermediate temperature titanium dioxide cover glaze is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel high-temperature transparent glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly steel plate enamel high-temperature transparent glaze and a preparation method thereof, and belongs to the technical field of enamel, and the formula comprises the following components in parts by mass: 21-23 parts of borax anhydrous, 36-38 parts of potassium feldspar, 19-21 parts of quartz, 6-8 parts of sodium fluosilicate, 5-7 parts of fluorite, 4-6 parts of titanium dioxide, 6-8 parts of aluminum oxide and 2-4 parts of barium carbonate. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1290 + / -10 DEG C, and the firing temperature of the finished product is 850-880 DEG C. The formula does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel high-temperature transparent glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com