Preparation method of high-rigidity lithium-ion battery separator and made separator

A lithium-ion battery, high-rigidity technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of lithium dendrite piercing and insufficient rigidity of the separator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

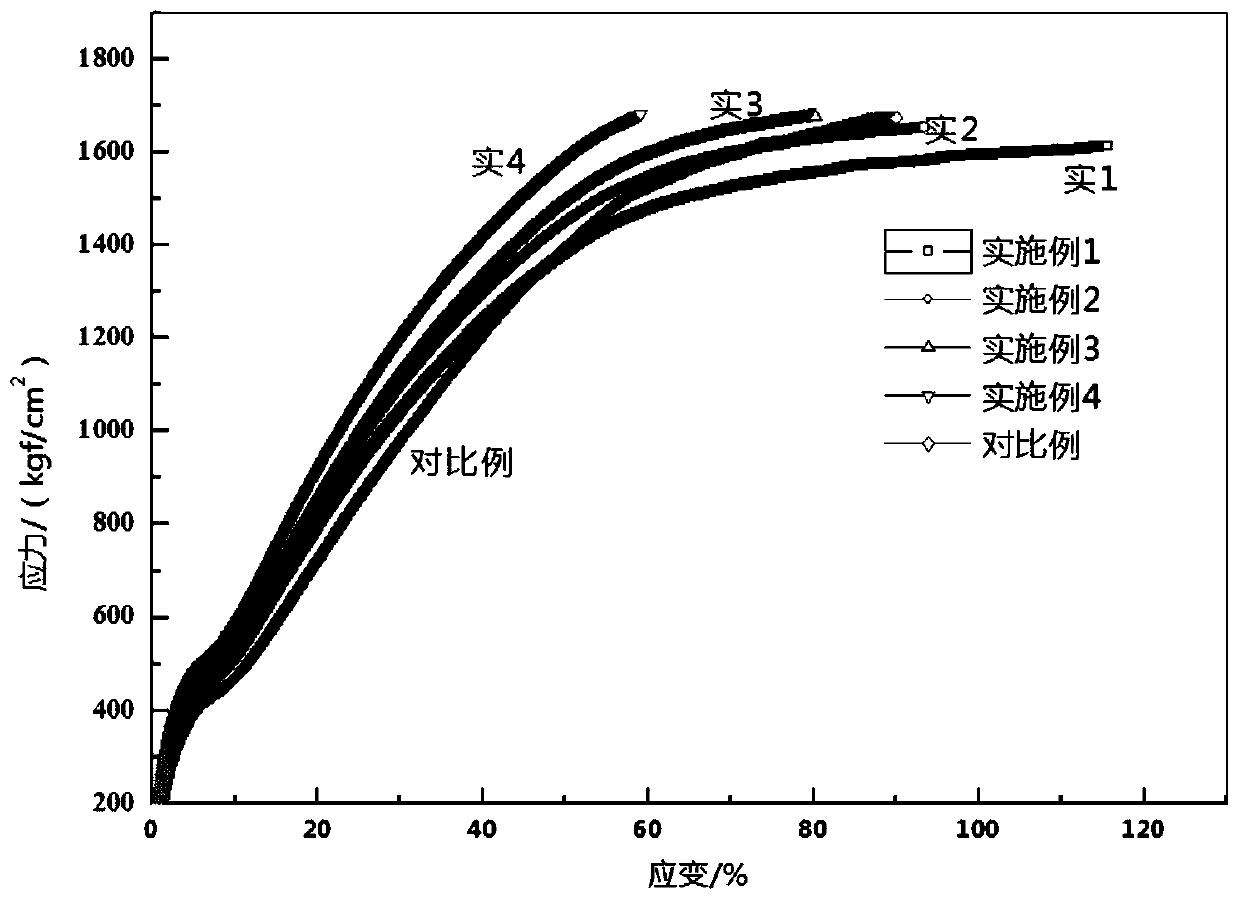

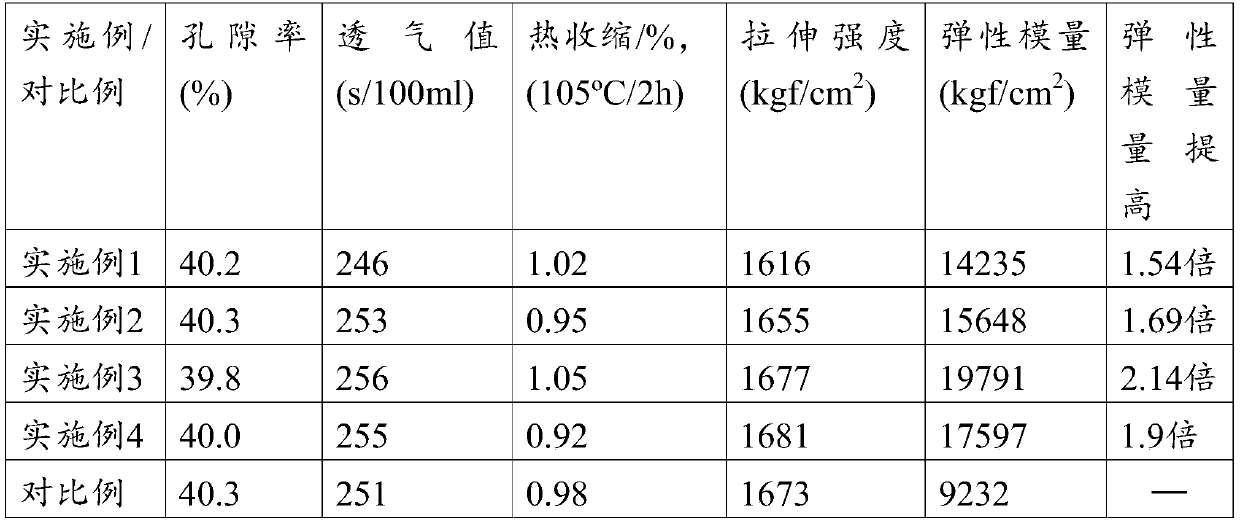

Embodiment 1

[0029] The isotacticity of material ① is 98, the melt index is 2.0g / 10min, the weight average molecular weight is 350000, and the molecular weight distribution is 5.2; the isotacticity of material ② is 93, the melt index is 1.8g / 10min, and the weight average molecular weight is 450000. The molecular weight distribution is 3.0; material ①: material ② is 9.5:0.5; mixing is 600rpm, 5h; ℃ annealing for 15 hours; then longitudinal stretching, the cold drawing temperature is 80 ℃, the ratio is 1.1; the hot drawing temperature is 150 ℃, the ratio is 2.0; the setting temperature is 160 ℃, and the setting time is 10min. A 16 μm thick, 40% porosity sample was prepared.

Embodiment 2

[0031] The isotacticity of material ① is 98, the melt index is 2.0g / 10min, the weight average molecular weight is 350000, and the molecular weight distribution is 5.2; the isotacticity of material ② is 89, the melt index is 1.6g / 10min, and the weight average molecular weight is 470000. The molecular weight distribution is 3.0; material ①:material ② is 9.5:0.5; the mixing is 600rpm, 5h; the extrusion temperature is 230°C, the die temperature is 205°C, the casting roll is 75°C, and a 16μm thick diaphragm is prepared by winding. 1500m, and then annealed at 140°C for 15 hours; then stretched longitudinally, the cold drawing temperature is 80°C, and the magnification is 1.1; the hot drawing temperature is 150°C, and the magnification is 2.0; the setting temperature is 160°C, and the setting time is 10min. A 16 μm thick, 40% porosity sample was prepared.

Embodiment 3

[0033] The isotacticity of material ① is 98, the melt index is 2.0g / 10min, the weight average molecular weight is 350000, and the molecular weight distribution is 5.2; the isotacticity of material ② is 89, the melt index is 1.6g / 10min, and the weight average molecular weight is 470000. The molecular weight distribution is 3.3; material ①:material ② is 8.5:1.5; the mixing is 800rpm, 6h; the extrusion temperature is 230°C, the die temperature is 205°C, the casting roll is 75°C, and a 16μm thick diaphragm is prepared by winding. 1500m, and then annealed at 140°C for 15 hours; then stretched longitudinally, the cold drawing temperature is 80°C, and the magnification is 1.1; the hot drawing temperature is 150°C, and the magnification is 2.0; the setting temperature is 160°C, and the setting time is 10min. A 16 μm thick, 40% porosity sample was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com